CN110235926B - Carousel formula shrimp peeling apparatus - Google Patents

Carousel formula shrimp peeling apparatus Download PDFInfo

- Publication number

- CN110235926B CN110235926B CN201910481701.4A CN201910481701A CN110235926B CN 110235926 B CN110235926 B CN 110235926B CN 201910481701 A CN201910481701 A CN 201910481701A CN 110235926 B CN110235926 B CN 110235926B

- Authority

- CN

- China

- Prior art keywords

- roller

- peeling

- wheel disc

- bevel gear

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A22—BUTCHERING; MEAT TREATMENT; PROCESSING POULTRY OR FISH

- A22C—PROCESSING MEAT, POULTRY, OR FISH

- A22C29/00—Processing shellfish or bivalves, e.g. oysters, lobsters; Devices therefor, e.g. claw locks, claw crushers, grading devices; Processing lines

- A22C29/02—Processing shrimps, lobsters or the like ; Methods or machines for the shelling of shellfish

- A22C29/024—Opening, shelling or peeling shellfish

- A22C29/026—Mechanically peeling and shelling shrimps, prawns or other soft-shelled crustaceans

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Mechanical Engineering (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Food Science & Technology (AREA)

- Meat, Egg Or Seafood Products (AREA)

Abstract

A rotary disc type prawn shelling device comprises a frame; the feeding mechanism is positioned at the top of the frame and comprises a feeding hopper, a material distribution roller and a material discharge pipe, the material distribution roller is positioned at the bottom of the feeding hopper, and the material discharge pipe is connected with the bottom of the material distribution roller; the peeling mechanism comprises a turntable mechanism and a peeling roller mechanism, the turntable mechanism comprises a large bevel gear, a wheel disc, a motor and a driving shaft, the driving shaft is vertically arranged on the rack and connected with the motor, and the wheel disc and the large bevel gear are arranged on the upper part of the driving shaft; the peeling roller mechanism comprises a small bevel gear, a peeling roller and a driven shaft, the driven shaft is horizontally arranged on the rack, the small bevel gear is arranged on the driven shaft and vertically meshed with the large bevel gear, and the peeling roller is arranged in the middle of the driven shaft; the separating mechanism is positioned on one side of the shelling roller and comprises a brush roller, a small motor, a shrimp meat collecting hopper and a shrimp meat discharging pipe, the small motor is installed on the rack, the brush roller is installed on the small motor and is axially vertical to the shelling roller, the shrimp meat collecting hopper is positioned right below the wheel disc, and the entrance of the shrimp meat discharging pipe is right opposite to the brush roller.

Description

Technical Field

The invention relates to an aquatic product machine, in particular to a rotary disc type prawn shelling device.

Background

The prawn shell is thin and fertile, has high meat content, delicious meat quality and rich nutrition, is a high-quality food material for cooking various delicacies and making various leisure and flavor foods, and is deeply loved by consumers at home and abroad. The prawn is one of the aquatic products with the largest global demand, the global total yield of the prawn is about 400 million tons in 2016 years, and the total yield of six countries of China, India, Thailand, Indonesia, Vietnam and Ecuador exceeds 75% of the global total yield of the prawn. China is the biggest prawn producing country in the world and is also one of the main trade countries of prawns. The shrimp meat of the prawns is an important product for rough processing after the prawns are harvested, and the total amount of the shrimp meat accounts for about half of the total amount of the penaeus products exported in China.

The currently and generally used method for shelling the prawns is to unfreeze the prawns after quick freezing and then manually shell the prawns, so that the manual shelling efficiency is low and the quality of the prawns is damaged. With the rapid development of the prawn processing industry and the rise of labor cost, the production mode mainly using manual peeling cannot meet the requirements of prawn peeling production. Therefore, the realization of mechanized automatic production instead of manual peeling is a necessary way for solving the current processing dilemma of prawns and improving the peeling level of prawns.

Disclosure of Invention

The invention aims to solve the technical problem in the prior art, and provides a rotary disc type prawn peeling device which can complete feeding, one-by-one peeling and shell and kernel separation of prawns and realize mechanical automatic peeling of prawns.

In order to achieve the purpose, the invention provides a rotating disc type prawn peeling device, which comprises:

a frame;

the feeding mechanism comprises a feeding hopper, a material distribution roller and a material discharge pipe, the feeding hopper is arranged at the top of the rack, the material distribution roller is positioned at the bottom of the feeding hopper, and an inlet of the material discharge pipe is connected with the bottom of the material distribution roller;

the peeling mechanism comprises a turntable mechanism and a peeling roller mechanism, the turntable mechanism comprises a large bevel gear, a wheel disc, a motor and a driving shaft, the driving shaft is vertically arranged on the rack and connected with the motor, and the wheel disc and the large bevel gear are respectively arranged on the upper part of the driving shaft; the peeling roller mechanism comprises a small bevel gear, a peeling roller and a driven shaft, the driven shaft is horizontally arranged on the rack, the small bevel gear is arranged at one end of the driven shaft and vertically meshed with the large bevel gear, and the peeling roller is arranged in the middle of the driven shaft; and

the separating mechanism is located on one side of the shelling roller and comprises a brush roller, a small motor, a shrimp meat collecting hopper and a shrimp meat discharging pipe, the small motor is installed on the rack, the brush roller is installed on a rotating shaft of the small motor, the axis of the brush roller is perpendicular to the axis of the shelling roller, the shrimp meat collecting hopper is installed on the rack and located under the wheel disc, the shrimp meat discharging pipe is installed on the rack and located on the outer side of the wheel disc, and the inlet of the shrimp meat discharging pipe is right opposite to the brush roller.

The rotary disc type prawn shelling device is characterized in that a cylindrical gear is mounted in the middle of the driving shaft, an output shaft of the motor is meshed with the cylindrical gear through a gear, and the driving shaft realizes rotation of the rotary disc and the large bevel gear through gear transmission.

The rotary disc type prawn shelling device is characterized in that the material distribution roller comprises a roller, a roller shaft, belt pulleys and a motor, the roller is installed in the middle of the roller shaft, bearings with seats are arranged at two ends of the roller shaft respectively, the bearings with the seats are installed on two sides of the feeding hopper, and the belt pulleys are installed at one end of the roller shaft and connected with the motor.

The rotary disc type prawn peeling device is characterized in that a plurality of rows of grooves are uniformly distributed on the side surface of the roller, each row of grooves comprise a plurality of crescent grooves which are sequentially arranged, each crescent groove is correspondingly provided with one discharge pipe respectively, and the discharge pipes are sequentially arranged at the bottom of the roller.

Foretell carousel formula shrimp peeling apparatus, wherein, every the degree of depth of crescent moon groove is 20mm, every the crooked face of crescent moon groove and the abdominal nature crookedness adaptation of shrimp, the crooked line of crooked face is radius 40mm and contained angle for 129 circular arc pitch arc that correspond.

Foretell carousel formula shrimp peeling apparatus, wherein, it is a plurality of peeling roller mechanism follows the horizontal evenly distributed of bull bevel gear circumference, peeling roller with the quotation of rim plate is at a distance of 2mm, the export of arranging the material pipe is located peeling roller the place ahead, it is in to arrange the litopenaeus vannamei that the material pipe discharged the rotation of rim plate and peeling roller gets into under the centre gripping clearance of rim plate and peeling roller is rubbed and is rubbed the shelling.

The rotating disc type prawn peeling device is characterized in that the rotating disc comprises a plurality of alternately distributed peeling areas and kernel discharging areas, the peeling areas are fan-shaped areas, and the fan-shaped opening angle theta of the peeling areas is as follows:

the sector opening angle α of the kernel-removing area is as follows:

α=90-θ;

wherein, a is the diameter of the peeling roller, b is the length of the peeling roller, l is the effective peeling stroke of the prawns, and r is the radius of the wheel disc.

The rotating disc type prawn peeling device is characterized in that the peeling roller and the wheel disc rotate in the same direction, the linear speeds of the center positions of the peeling roller and the wheel disc are consistent, and the transmission ratio n of the large bevel gear and the small bevel gear meets the following requirements:

wherein a is the diameter of the peeling roller, b is the length of the peeling roller, and r is the radius of the wheel disc.

The rotary disc type prawn peeling device is characterized in that the rotating angular speed of the material distribution roller is equal to the angular speed of the wheel disc, the initial phase of the material distribution roller is that the crescent groove is located at the bottom of the roller and is right opposite to the inlet of the material discharge pipe, and the peeling area of the wheel disc is right opposite to the outlet of the material discharge pipe.

The rotary disc type prawn shelling device is characterized in that the shelling roller and the rotary disc are respectively made of nylon materials, and the rotary drum is made of polyurethane materials.

The invention has the technical effects that:

1. the feeding mechanism of the invention can realize that four prawns are respectively distributed one by one each time. The roller made of polyurethane material can greatly reduce the damage of prawns in the separation process, and the crescent groove matched with the body bending degree of the prawns can accommodate a single prawn and prevent two prawns from entering the groove at the same time;

2. the shelling mechanism can realize efficient shelling of prawns through the rotating matching of the shelling roller and the wheel disc. The shells and the meat are separated by using the friction and the kneading of the roll surfaces and the disc surfaces for the shrimp shells, four shelling rollers can simultaneously shell four prawns, and the shelling area and the kernel discharging area of the wheel disc are alternately circulated to realize the integration of the shelling and the kernel discharging of the prawns, so that the shelling and the kernel separating efficiency is improved;

3. the invention has simple structure and high shelling efficiency, and can completely realize the mechanization of distribution, shelling, separation and collection of prawns.

The invention is described in detail below with reference to the drawings and specific examples, but the invention is not limited thereto.

Drawings

FIG. 1 is a schematic structural diagram of an embodiment of the present invention;

FIG. 2 is a schematic structural diagram of a husking mechanism according to an embodiment of the present invention;

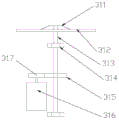

FIG. 3 is a schematic structural diagram of a turntable mechanism according to an embodiment of the present invention;

FIG. 4 is a schematic illustration of a wheel disc structure according to an embodiment of the present invention;

FIG. 5 is a schematic view of a roller structure according to an embodiment of the present invention;

fig. 6 is a schematic diagram of a wheel disc region segmentation according to an embodiment of the present invention.

Wherein, the figure is marked

1 machine frame

2 feeding mechanism

21 feeding hopper

22 material-separating roller

221 crescent groove

222 bend line

23 discharge pipe

3 husking mechanism

31 turntable mechanism

311 big bevel gear

312 wheel disc

313 drive shaft

314 bearing with seat

315 cylindrical gear

316 electric machine

317 gear

318 peeling region

319 zone for kernel removal

32 shucking roller mechanism

321 small bevel gear

322 bearing with seat

323 peeling roller

324 driven shaft

4 separating mechanism

41 Brush roller

42 small motor

43 shrimp meat collecting bucket

44 shrimp shell discharge pipe

Detailed Description

The invention will be described in detail with reference to the following drawings, which are provided for illustration purposes and the like:

referring to fig. 1, fig. 1 is a schematic structural diagram of an embodiment of the present invention. The invention relates to a rotary disc type prawn shelling device, which comprises: the device comprises a frame 1, a feeding mechanism 2, a husking mechanism 3 and a separating mechanism 4. Wherein, feeding mechanism 2 includes feeding hopper 21, branch material cylinder 22 and row's material pipe 23, feeding hopper 21 is fixed in the top of frame 1, divide the material cylinder 22 to be located the bottom of feeding hopper 21, arrange the entry of material pipe 23 with divide the bottom of material cylinder 22 to be connected. The husking mechanism 3 is composed of a turntable mechanism 31 and a husking roller mechanism 32. The operation principle of the peeling mechanism 3 is that the peeling roller 323 and the wheel disc 312 rotate in the same direction, and the shell and the meat are separated by the friction and the kneading of the roller surface and the disc surface against the shrimp shells. The separating mechanism 4 is located on one side of the peeling roller 323, the separating mechanism 4 comprises a brush roller 41, a small motor 42, a shrimp meat collecting hopper 43 and a shrimp meat discharging pipe 44, the small motor 42 is fixed on the rack 1, the brush roller 41 is installed on a rotating shaft of the small motor 42, the axis of the brush roller 41 is perpendicular to the axis of the peeling roller 323 and is arranged behind the peeling roller 323, the shrimp meat collecting hopper 43 is installed and fixed on the rack 1 and is located right below the wheel disc 312, the shrimp meat discharging pipe 44 is obliquely and fixedly installed on the rack 1 and is located on the outer side of the wheel disc 312, and the inlet of the shrimp meat discharging pipe 44 is right opposite to the brush roller 41. The number of the dried small shrimp discharging pipes 44 is four in the present embodiment, and the dried small shrimps are uniformly distributed around the wheel disc 312. The peeled shrimp directly falls into the shrimp meat collecting bucket 43 of the separating mechanism 4, the dried small shrimps are swept out of the wheel disc 312 and fall into the corresponding dried small shrimp discharging pipe 44, and then the dried small shrimps are discharged along the dried small shrimp discharging pipe 44.

Referring to fig. 2 and 3, fig. 2 is a schematic structural diagram of a husking mechanism according to an embodiment of the present invention, and fig. 3 is a schematic structural diagram of a turntable mechanism according to an embodiment of the present invention. The husking mechanism 3 comprises a turntable mechanism 31 and a husking roller mechanism 32, wherein the turntable mechanism 31 comprises a large bevel gear 311, a wheel disc 312, a motor 316 and a driving shaft 313, the driving shaft 313 is vertically arranged on the rack 1 and is connected with the motor 316, the driving shaft 313 can be vertically fixed on the rack 1 through two bearings 314 with seats, and the wheel disc 312 and the large bevel gear 311 are respectively arranged on the upper part of the driving shaft 313. In this embodiment, a cylindrical gear 315 is installed in the middle of the driving shaft 313, an output shaft of the motor 316 is meshed with the cylindrical gear 315 through a gear 317, and the driving shaft 313 realizes rotation of the wheel disc 312 and the large bevel gear 311 through gear transmission; the husking roller mechanism 32 comprises a small bevel gear 321, a husking roller 323 and a driven shaft 324, the driven shaft 324 is horizontally arranged on the rack 1 and can be horizontally fixed on the rack 1 through two bearings 322 with seats, the small bevel gear 321 is arranged at one end of the driven shaft 324 and vertically meshed with the large bevel gear 311, and the husking roller 323 is arranged in the middle of the driven shaft 324. The shelling roller 323 and the wheel disc 312 rotate in the same direction, the shell and the meat are separated by utilizing the friction and the kneading of the roller surface and the disc surface against the shrimp shells, the shrimp shells enter the gap between the shelling roller 323 and the wheel disc 312 along with the rotation of the shelling roller 323 and then move to the rear of the shelling roller 323, and the shrimp meat falls into the kernel discharge area 319 after the wheel disc 312 finishes the shelling stroke.

According to the invention, a plurality of the husking roller mechanisms 32 can be horizontally and uniformly distributed along the circumference of the large bevel gear 311, preferably 4 husking roller mechanisms 32 are adopted in the embodiment, 4 corresponding discharge pipes 23 are provided, and the four husking rollers 323 are driven to rotate by the rotation of the large bevel gear 311. The distance between the peeling roller 323 and the disc surface of the wheel disc 312 is preferably about 2mm, the outlet of the discharge pipe 23 is positioned in front of the peeling roller 323, so that prawns discharged from the discharge pipe 23 can enter the clamping gap between the wheel disc 312 and the peeling roller 323 under the rotation of the wheel disc 312 and the peeling roller 323 to be rubbed and peeled. The peeling roller 323 and the wheel disc 312 are preferably made of nylon materials respectively, the peeling roller 323 and the wheel disc 312 rotate in the same direction, and in order to ensure effective peeling, the linear speed of the central position where the peeling roller 323 and the wheel disc 312 are in contact needs to be kept consistent. To keep the linear speed consistent, the transmission ratio n of the large bevel gear 311 and the small bevel gear 321 needs to satisfy:

wherein a is the diameter of the peeling roller 323, b is the length of the peeling roller 323, and r is the radius of the wheel disc 312.

Referring to fig. 5, fig. 5 is a schematic view of a roller structure according to an embodiment of the present invention. The material distributing roller 22 may include a roller, a roller shaft, a belt pulley and a motor, the roller is preferably a polyurethane material, the roller is sleeved in the middle of the roller shaft, two ends of the roller shaft are respectively provided with a bearing with a seat, the two bearings with the seat are sleeved on the roller shaft and are respectively arranged on two sides of the roller, the two bearings with the seat are arranged on the front side and the rear side of the feeding hopper 21, so that the material distributing roller 22 is fixed, and the belt pulley is arranged at one end of the roller shaft and is connected with the motor through a belt to realize transmission. The structure, the connection relation and the functions of the roller shaft, the belt pulley and the motor are mature prior art, a plurality of rows of grooves are uniformly distributed on the side surface of the roller, the grooves are preferably 4 rows, each row of grooves comprise a plurality of crescent grooves 221 which are arranged in sequence, 4 crescent grooves 221 are preferably arranged in each row of grooves, and each crescent groove 221 is correspondingly provided with one discharging pipe 23, 4 discharging pipes 23 are arranged at the bottom of the roller in sequence. The depth of each crescent groove 221 is preferably about 20mm, the curved surface of each crescent groove 221 is adapted to the natural curvature of the abdomen of the prawn, and the curved line 222 of the curved surface is preferably an arc line with a radius of 40mm and an included angle of 129 degrees. Each crescent 221 is capable of receiving one prawn, so that each row of flutes separates four prawns during rotation of the drum. The four discharge pipes 23 at the bottom of the material separating roller 22 correspond to the four crescent grooves 221 respectively, and prawns in the crescent grooves 221 can fall into the corresponding discharge pipes 23. The rotating angular speed of the material distributing roller 22 is equal to the angular speed of the wheel disc 312, and meanwhile, when the crescent groove 221 is located at the bottom of the material distributing roller 22 and faces the inlet of the material discharging pipe 23, the shelling area 318 of the wheel disc 312 faces the outlet of the material discharging pipe 23, so that prawns can be guaranteed to smoothly fall from the roller to the shelling area 318 every time.

Referring to fig. 4 and 6, fig. 4 is a schematic diagram of a wheel disc structure according to an embodiment of the present invention, and fig. 6 is a schematic diagram of a wheel disc area segmentation according to an embodiment of the present invention. The wheel disc 312 of this embodiment includes a plurality of alternating shelling areas 318 and flight areas 319. the wheel disc 312 is preferably made of nylon material and the wheel disc 312 rotates counterclockwise. For example, four shelling areas 318 and four nut areas 319 may be distributed on the wheel disc 312, and the shelling areas 318 and the nut areas 319 are alternately distributed. The peeling area 318 is a sector area, and the sector angle of the peeling area 318 reflects the size of the peeling area 318. The fan angle θ of the peeling area 318 is:

as can be seen from equation (1), the angular sector of the peeling area 318 is related to the diameter of the peeling roller 323, the length of the peeling roller 323, and the radius of the wheel disc 312. the angular sector α of the kernel area 319 is:

α=90-θ; (2)

wherein a is the diameter of the peeling roller 323, b is the length of the peeling roller 323, l is the effective peeling stroke of the prawns, and r is the radius of the wheel disc 312. The effective shelling stroke of the prawns can be determined by the earlier stage prawn shelling test and is a fixed value.

When the prawn separating device works, a plurality of prawns are poured into the feeding hopper 21, and the prawn separating roller 22 enters the crescent groove 221 on the roller in the rotating process. The crescent groove 221 rotates towards the bottom, the rest prawns on the crescent groove 221 are blocked by the side wall of the feeding hopper 21, and only one prawn is left in each crescent groove 221. When the crescent grooves 221 rotate to the bottom of the material distributing roller 22, the prawns in the four crescent grooves 221 fall into the corresponding material discharging pipes 23 respectively. The prawns slide down the discharge pipe 23 to the shelling area 318 of the wheel disc 312. The peeling roller 323 and the wheel disc 312 rotate at the same linear speed in the same direction under the driving of the motor 316, and the wheel disc 312 rotates anticlockwise. The prawns in the peeling area 318 are simultaneously rubbed and kneaded by the peeling roller 323 and the wheel disc 312 against the shrimp shell, and the shrimp shell and the shrimp meat are gradually separated. In the process of shelling the prawns, the wheel disc 312 gradually rotates for a shelling stroke, namely the wheel disc 312 rotates for an angle of theta degrees, the shelled shrimps after shelling then fall into the kernel discharging area 319 under the rotation of the wheel disc 312, and then the shelled shrimps directly fall into the shelled shrimp collecting hopper 43. The dried small shrimps gradually enter the gap between the peeling roller 323 and the surface of the wheel disc 312 and gradually move to the rear of the peeling roller 323 along with the rotation of the wheel disc 312. The dried small shrimps are swept out of the wheel disc 312 by the rotating force of the brush roller 41 to the outside of the wheel disc 312 and fall into the corresponding dried small shrimp discharge pipe 44, and then discharged along the dried small shrimp discharge pipe 44. The four prawns in the previous round complete the husking process, and the material separating roller 22 continues to rotate to enter the next round of husking circulation.

The invention has simple structure and high shelling efficiency, and can realize the working procedures of distribution, shelling, separation and collection of prawns in a completely mechanized manner.

The present invention may be embodied in other specific forms without departing from the spirit or essential attributes thereof, and it should be understood that various changes and modifications can be effected therein by one skilled in the art without departing from the spirit and scope of the invention as defined in the appended claims.

Claims (10)

1. A rotary disc type prawn peeling device comprises a frame, a feeding mechanism, a peeling mechanism and a separating mechanism, and is characterized in that,

the feeding mechanism comprises a feeding hopper, a material distribution roller and a material discharge pipe, the feeding hopper is mounted at the top of the rack, the material distribution roller is positioned at the bottom of the feeding hopper, and an inlet of the material discharge pipe is connected with the bottom of the material distribution roller;

the peeling mechanism comprises a turntable mechanism and a peeling roller mechanism, the turntable mechanism comprises a large bevel gear, a wheel disc, a motor and a driving shaft, the driving shaft is vertically arranged on the rack and connected with the motor, and the wheel disc and the large bevel gear are respectively arranged on the upper part of the driving shaft; the peeling roller mechanism comprises a small bevel gear, a peeling roller and a driven shaft, the driven shaft is horizontally arranged on the rack, the small bevel gear is arranged at one end of the driven shaft and vertically meshed with the large bevel gear, and the peeling roller is arranged in the middle of the driven shaft; and

the separating mechanism is located on one side of the shelling roller and comprises a brush roller, a small motor, a shrimp meat collecting hopper and a shrimp meat discharging pipe, the small motor is installed on the rack, the brush roller is installed on a rotating shaft of the small motor, the axis of the brush roller is perpendicular to the axis of the shelling roller, the shrimp meat collecting hopper is installed on the rack and located under the wheel disc, the shrimp meat discharging pipe is installed on the rack and located on the outer side of the wheel disc, and the inlet of the shrimp meat discharging pipe is right opposite to the brush roller.

2. The rotary disc type prawn peeling device as claimed in claim 1, wherein a cylindrical gear is installed in the middle of the driving shaft, the output shaft of the motor is meshed with the cylindrical gear through a gear, and the driving shaft realizes the rotation of the rotary disc and the large bevel gear through gear transmission.

3. The rotary disc type prawn peeling device as claimed in claim 1 or 2, wherein the material separating roller comprises a roller, a roller shaft, belt pulleys and a motor, the roller is installed in the middle of the roller shaft, two ends of the roller shaft are respectively provided with a bearing with a seat, the bearing with the seat is installed on two sides of the feeding hopper, and the belt pulleys are installed at one end of the roller shaft and connected with the motor.

4. The rotary disc type prawn peeling device as claimed in claim 3, wherein a plurality of rows of grooves are uniformly distributed on the side surface of the roller, each row of grooves comprises a plurality of crescent grooves which are sequentially arranged, each crescent groove is correspondingly provided with one discharging pipe, and the plurality of discharging pipes are sequentially arranged at the bottom of the roller.

5. The rotary disc type prawn peeling device as claimed in claim 4, wherein the depth of each crescent groove is 20mm, the curved surface of each crescent groove is matched with the natural curvature of the prawn abdomen, and the curved line of the curved surface is a circular arc with the radius of 40mm and the included angle of 129 degrees.

6. The rotary disc type prawn peeling device as claimed in claim 4, wherein a plurality of peeling roller mechanisms are horizontally and evenly distributed along the circumference of the large bevel gear, the peeling rollers are 2mm away from the disc surface of the wheel disc, the outlet of the discharge pipe is positioned in front of the peeling rollers, and prawns discharged from the discharge pipe enter the clamping gap between the wheel disc and the peeling rollers under the rotation of the wheel disc and the peeling rollers to be rubbed and peeled.

7. The rotary disk type prawn peeling device as claimed in claim 4, wherein the rotary disk comprises a plurality of alternately distributed peeling areas and kernel removing areas, the peeling areas are sector areas, and the sector angle θ of the peeling areas is:

the sector opening angle α of the kernel-removing area is as follows:

α=90-θ;

wherein, a is the diameter of the peeling roller, b is the length of the peeling roller, l is the effective peeling stroke of the prawns, and r is the radius of the wheel disc.

8. The rotary disc type prawn peeling device as claimed in claim 7, wherein the peeling roller and the wheel disc rotate in the same direction, the linear speeds of the central positions of the peeling roller and the wheel disc are consistent, and the transmission ratio n of the large bevel gear and the small bevel gear satisfies the following conditions:

wherein a is the diameter of the peeling roller, b is the length of the peeling roller, and r is the radius of the wheel disc.

9. The rotary disc type prawn peeling device as claimed in claim 4, wherein the rotation angular speed of the material separating roller is equal to the angular speed of the wheel disc, and the initial phase of the material separating roller is that when the crescent groove is positioned at the bottom of the roller and is opposite to the inlet of the material discharging pipe, the peeling area of the wheel disc is opposite to the outlet of the material discharging pipe.

10. The rotary disc type prawn peeling device as claimed in claim 3, wherein the peeling roller and the rotary disc are respectively made of nylon material, and the roller is made of polyurethane material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910481701.4A CN110235926B (en) | 2019-06-04 | 2019-06-04 | Carousel formula shrimp peeling apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910481701.4A CN110235926B (en) | 2019-06-04 | 2019-06-04 | Carousel formula shrimp peeling apparatus |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110235926A CN110235926A (en) | 2019-09-17 |

| CN110235926B true CN110235926B (en) | 2020-05-22 |

Family

ID=67885970

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910481701.4A Active CN110235926B (en) | 2019-06-04 | 2019-06-04 | Carousel formula shrimp peeling apparatus |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110235926B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2971925T3 (en) * | 2020-02-07 | 2024-06-10 | Nova Tech Engineering Llc | Shrimp Processing Apparatus and Methods |

| CN114931159B (en) * | 2022-05-18 | 2023-01-03 | 中国农业机械化科学研究院集团有限公司 | Prawn self-adaptation peeling device |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3018510A (en) * | 1960-08-17 | 1962-01-30 | Peelers Company | Shrimp peeling machine |

| EP0743010A1 (en) * | 1995-04-28 | 1996-11-20 | Albert Kant | Method and apparatus for peeling shrimp |

| JPH0998712A (en) * | 1995-10-03 | 1997-04-15 | Nichirei Corp | Removing of back intestine of bare prawn and back intestine removing device |

| CN102699941A (en) * | 2012-06-27 | 2012-10-03 | 山东理工大学 | Cellular turntable driving type spherical fruit and vegetable breaking-cutting machine |

| CN203575511U (en) * | 2013-11-21 | 2014-05-07 | 河北农业大学 | Prawn shelling device |

| KR101640396B1 (en) * | 2016-03-29 | 2016-07-18 | (주)그랜드벨 | An Apparatus for Peeling the Prawn |

| CN108887366A (en) * | 2018-10-09 | 2018-11-27 | 黎杰 | A kind of spiral shell truncates machine |

-

2019

- 2019-06-04 CN CN201910481701.4A patent/CN110235926B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3018510A (en) * | 1960-08-17 | 1962-01-30 | Peelers Company | Shrimp peeling machine |

| EP0743010A1 (en) * | 1995-04-28 | 1996-11-20 | Albert Kant | Method and apparatus for peeling shrimp |

| JPH0998712A (en) * | 1995-10-03 | 1997-04-15 | Nichirei Corp | Removing of back intestine of bare prawn and back intestine removing device |

| CN102699941A (en) * | 2012-06-27 | 2012-10-03 | 山东理工大学 | Cellular turntable driving type spherical fruit and vegetable breaking-cutting machine |

| CN203575511U (en) * | 2013-11-21 | 2014-05-07 | 河北农业大学 | Prawn shelling device |

| KR101640396B1 (en) * | 2016-03-29 | 2016-07-18 | (주)그랜드벨 | An Apparatus for Peeling the Prawn |

| CN108887366A (en) * | 2018-10-09 | 2018-11-27 | 黎杰 | A kind of spiral shell truncates machine |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110235926A (en) | 2019-09-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20200138083A1 (en) | Automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation | |

| WO2021013074A1 (en) | Automatic holboellia latifolia peel and pulp separating machine | |

| CN110839686B (en) | Shrimp peeling device | |

| CN110235926B (en) | Carousel formula shrimp peeling apparatus | |

| CN101803790B (en) | Shucking machine of oil-tea camellia fruit | |

| CN206260774U (en) | Self-positioning pre-breaking shell spiral in the same direction is classified flexible walnut extruding shell-cracking kernel-taking device certainly | |

| CN110065796B (en) | Prawn sequencing and orienting device | |

| CN201403482Y (en) | Nut dehuller | |

| CN104206512B (en) | Full-automatic shrimp decorticator | |

| US4312099A (en) | Process for shucking a mollusk | |

| CN212545443U (en) | Shell and seed separator | |

| CN211482729U (en) | Shrimp peeling device | |

| CN208403141U (en) | Shell eggshell device | |

| CN214071698U (en) | Automatic peeling machine for garlic | |

| CN112090753B (en) | Rice quantitative packaging device | |

| CN209882996U (en) | Take off pu machine | |

| CN211802395U (en) | Abalone grading device | |

| CN211793034U (en) | Lotus seed peeling and coat removing machine | |

| CN110122541B (en) | Prawn separating and sequencing device | |

| CN113455666A (en) | Bitter almond shell breaking and peeling device and bitter almond peeling method | |

| CN206251884U (en) | A kind of fruit peeling separating and treating apparatus | |

| CN213695626U (en) | Vertical flexible walnut shell breaking machine | |

| CN214346658U (en) | Walnut sorter and contain its preceding processing apparatus for walnut shell breaking | |

| CN217065311U (en) | Continuous multistage equipment of shelling of sunflower seeds | |

| CN106856867A (en) | Fresh edible corn husker |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |