CN108978115B - Control method and system of washing machine, washing machine and computer equipment - Google Patents

Control method and system of washing machine, washing machine and computer equipment Download PDFInfo

- Publication number

- CN108978115B CN108978115B CN201710411715.XA CN201710411715A CN108978115B CN 108978115 B CN108978115 B CN 108978115B CN 201710411715 A CN201710411715 A CN 201710411715A CN 108978115 B CN108978115 B CN 108978115B

- Authority

- CN

- China

- Prior art keywords

- washing machine

- dehydration

- time length

- time

- washing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005406 washing Methods 0.000 title claims abstract description 229

- 238000000034 method Methods 0.000 title claims abstract description 103

- 230000018044 dehydration Effects 0.000 claims abstract description 173

- 238000006297 dehydration reaction Methods 0.000 claims abstract description 173

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 74

- 230000008569 process Effects 0.000 claims abstract description 52

- 239000013589 supplement Substances 0.000 claims abstract description 19

- 230000006870 function Effects 0.000 claims description 62

- 238000004590 computer program Methods 0.000 claims description 23

- 238000005303 weighing Methods 0.000 claims description 12

- 238000001514 detection method Methods 0.000 claims description 6

- 238000010412 laundry washing Methods 0.000 claims 1

- 230000000694 effects Effects 0.000 abstract description 40

- 238000010586 diagram Methods 0.000 description 14

- 230000003111 delayed effect Effects 0.000 description 5

- 230000002035 prolonged effect Effects 0.000 description 5

- 230000009286 beneficial effect Effects 0.000 description 3

- 230000001934 delay Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000001502 supplementing effect Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F33/00—Control of operations performed in washing machines or washer-dryers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F34/00—Details of control systems for washing machines, washer-dryers or laundry dryers

- D06F34/14—Arrangements for detecting or measuring specific parameters

- D06F34/18—Condition of the laundry, e.g. nature or weight

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B40/00—Technologies aiming at improving the efficiency of home appliances, e.g. induction cooking or efficient technologies for refrigerators, freezers or dish washers

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Control Of Washing Machine And Dryer (AREA)

Abstract

The invention provides a control method and system of a washing machine, the washing machine, a computer device and a computer readable storage medium. The control method of the washing machine comprises the following steps: receiving a main washing function or rinsing function completion instruction, and starting dewatering; detecting whether the article has an eccentric condition in the dehydration process; when the eccentric condition exists, rinsing in the next stage is carried out; and when the eccentricity still exists in the last dehydration process, giving an alarm after at least one water supplement is finished. The control method of the washing machine provided by the invention has the advantages that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

Description

Technical Field

The invention relates to the technical field of washing machine control, in particular to a washing machine control method and system, a washing machine, computer equipment and a computer readable storage medium.

Background

At present, the normal standard program washing of the washing machine is performed in the order of main washing, first time dehydration, first time rinsing, second time dehydration, second time rinsing, and last time dehydration, and thus the washing machine needs to perform dehydration during the washing of laundry. However, when the main washing process of the washing machine is finished, the clothes are wound in the drum, so that the inner drum is unbalanced, and if the eccentricity of the articles in the dehydration process is large, the inner drum cannot shake at a high speed in the dehydration process, and the articles seriously impact the box body to cause the complete machine to shift.

In the related technology, when the articles are eccentric in the dehydration process of the pulsator washing machine, so that the dehydration cannot be carried out at a high speed, the dehydration is stopped, then the clothes are washed and dispersed, the dehydration step is restarted, and if the 3 rd water inlet or the eccentric condition causes the dehydration to be carried out at a high speed, an alarm is sent to allow a user to carry out manual treatment. The control method of the existing washing machine has the following defects:

if the clothes are unbalanced, water may need to be re-fed to wash and scatter in the processes of the 1 st dehydration, the 2 nd dehydration and the last dehydration, so that water is fed into a washing process of the washing machine for 1 to 9 times, and human intervention is needed for 3 times in an extreme case, the washing machine can complete a complete washing program, the washing completion time of the clothes is prolonged, water resources are seriously wasted, and the use experience of a user is greatly reduced.

Disclosure of Invention

The present invention is directed to solving at least one of the problems of the prior art or the related art.

To this end, a first object of the present invention is to provide a control method of a washing machine.

A second object of the present invention is to provide a control system of a washing machine.

A third object of the present invention is to provide a washing machine.

A fourth object of the present invention is to provide a computer device.

A fifth object of the present invention is to provide a computer-readable storage medium.

In view of the above, according to a first object of the present invention, there is provided a control method of a washing machine, including: receiving a main washing function or rinsing function completion instruction, and starting dewatering; detecting whether the article has an eccentric condition in the dehydration process; when the eccentric condition exists, rinsing in the next stage is carried out; and when the eccentricity still exists in the last dehydration process, giving an alarm after at least one water supplement is finished.

The control method of the washing machine provided by the invention comprises the steps of receiving a main washing function or rinsing function completion instruction, starting dewatering by the washing machine, detecting whether the article has an eccentric condition in the dewatering process, specifically, directly rinsing the next stage by the washing machine when the article has the eccentric condition, and giving an alarm after finishing at least one water supplement when the article still has the eccentric condition in the last dewatering process. Compared with the control method provided by the prior art, the control method of the washing machine provided by the invention has the advantages that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

The control method of the washing machine according to the present invention may further have the following technical features:

in the above technical solution, preferably, the control method of a washing machine further includes: presetting total dehydration time; timing and recording the time length for completing dehydration each time; calculating the time length of not dehydrating; and the time length for not performing the dehydration is equal to the preset total dehydration time length-sigma time length for completing the dehydration each time.

According to the technical scheme, the time length of the previous times of dehydration is calculated, and the time length of the previous times of dehydration is increased to the last time of dehydration, so that the last time of dehydration is increased, and the rinsing effect is guaranteed.

In any of the above technical solutions, preferably, the control method of the washing machine further includes: the last time of dehydration is delayed for the time of non-dehydration.

In the technical scheme, the last time of dehydration is delayed for a long time without the time of dehydration, so that the last time of dehydration is prolonged, the rinsing effect of the washing machine on clothes is improved, and the use experience of a user on the washing machine is further improved.

In any of the above technical solutions, preferably, before the step of receiving the main wash function instruction, the method further includes: and carrying out fuzzy bearing on the articles to be washed, and recording the first weight.

In the technical scheme, before receiving the main washing function instruction, the washing machine is controlled to add appropriate water quantity by carrying out fuzzy bearing on the articles to be washed and recording the first weight, so that the washing machine is controlled to add appropriate water quantity according to the first weight, the clothes can be rinsed cleanly, water is saved, and the use experience of a user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

In any of the above technical solutions, preferably, the control method of the washing machine further includes: after the final dewatering is completed, the item is again fuzzy loaded and the second weight is recorded.

According to the technical scheme, after the last dehydration is finished, the fuzzy load bearing is carried out on the articles again, the second weight is recorded, the last dehydration degree is determined according to the second weight and the first weight, and the rinsing and dehydration effects of the clothes are further guaranteed.

According to a second object of the present invention, there is provided a control system of a washing machine, comprising: the first control unit is used for receiving a main washing function or rinsing function completion instruction and starting dewatering; the detection unit is used for detecting whether the articles have the eccentric condition in the dehydration process; a second control unit for entering a rinsing function of a next stage when there is an eccentricity; and the alarm unit is used for giving an alarm after finishing at least one water supplement when the last dehydration process still has an eccentric condition.

The control system of the washing machine provided by the invention receives a main washing function or rinsing function completion instruction through the first control unit, the washing machine starts to dewater, and then detects whether the articles have an eccentric condition in the dewatering process through the detection unit. Compared with the control system provided by the prior art, the control system of the washing machine provided by the invention has the advantages that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

According to the control system of the washing machine provided by the invention, the following technical characteristics can be provided:

in the above technical solution, preferably, the control system of the washing machine further includes: the setting unit is used for presetting the total dehydration time; the timing unit is used for timing and recording the time length for finishing the dehydration each time; the calculating unit is used for calculating the time length of non-dehydration; and the time length for not performing the dehydration is equal to the preset total dehydration time length-sigma time length for completing the dehydration each time.

According to the technical scheme, the total dehydration time length is preset through the setting unit, the time used for completing the dehydration each time is timed and recorded through the timing unit, the time length for not performing the dehydration in the previous times of dehydration is calculated through the calculating unit, the time length for not performing the dehydration in the previous times of dehydration is increased to the last time of dehydration, the last time of dehydration is further increased, and the rinsing effect is guaranteed.

In any of the above technical solutions, preferably, the control system of the washing machine further includes: and the time delay unit is used for delaying the last dehydration time length by the time length without dehydration.

In the technical scheme, the time delay unit delays the time of last dehydration for the time of not dehydrating, so that the time of last dehydration is prolonged, the rinsing effect of the washing machine on clothes is improved, and the use experience of a user on the washing machine is further improved.

In any of the above technical solutions, preferably, before the step of receiving the main wash function instruction, the method further includes: and the weighing unit is used for carrying out fuzzy bearing on the articles to be washed and recording the first weight.

In the technical scheme, before receiving a main washing function instruction, the weighing unit is used for carrying out fuzzy bearing on articles to be washed, recording the first weight, controlling the washing machine to add proper water quantity according to the first weight, ensuring that the clothes can be rinsed cleanly, saving water and further improving the use experience of a user on the washing machine. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

In any of the above technical solutions, preferably, the weighing unit is further configured to, after the last dehydration is completed, perform fuzzy load bearing on the article again, and record the second weight.

According to the technical scheme, after the last dehydration is finished, the weighing unit is used for carrying out fuzzy bearing on the articles again, the second weight is recorded, the last dehydration degree is determined according to the second weight and the first weight, and the rinsing and dehydration effects of the clothes are further guaranteed.

According to a third object of the present invention, there is provided a washing machine including the control system of the washing machine of any one of the above technical solutions.

The washing machine provided by the invention adopts the control system of the washing machine in any technical scheme, so that the washing machine has all the beneficial effects of the control system of the washing machine, and the detailed description is omitted.

According to a fourth object of the present invention, there is provided a computer device comprising a memory, a processor and a computer program stored in the memory and executable on the processor, wherein the processor implements the steps of the control method of the washing machine according to any one of the above-mentioned technical solutions when executing the computer program.

A fourth object of the present invention is to provide a computer device, which includes a memory, a processor and a computer program stored in the memory and capable of running on the processor, wherein the processor implements the steps of the control method of the washing machine according to any of the above technical solutions when executing the computer program. Therefore, the processor of the computer device according to the fourth aspect of the present invention implements the steps of the control method of the washing machine according to any one of the above-mentioned technical solutions when executing the computer program, so that the method has all the beneficial technical effects of the control method of the washing machine according to any one of the above-mentioned technical solutions, and is not described herein again.

According to a fifth object of the present invention, there is provided a computer readable storage medium having stored thereon a computer program which, when executed by a processor, implements the steps of the control method of a washing machine according to any one of the above-mentioned aspects.

A fifth object of the present invention is to provide a computer readable storage medium having a computer program stored thereon, the computer program, when executed by a processor, implementing the steps of the control method of a washing machine according to any of the above-mentioned aspects. Since the step of implementing the control method of the washing machine according to any one of the above technical solutions is executed by the processor in the computer program of the computer-readable storage medium according to the fifth object of the present invention, all the advantageous technical effects of the control method of the washing machine according to any one of the above technical solutions are achieved, and are not described herein again.

Additional aspects and advantages of the invention will be set forth in part in the description which follows, and in part will be obvious from the description, or may be learned by practice of the invention.

Drawings

The above and/or additional aspects and advantages of the present invention will become apparent and readily appreciated from the following description of the embodiments, taken in conjunction with the accompanying drawings of which:

fig. 1 illustrates a schematic flowchart of a control method of a washing machine according to a first embodiment of the present invention;

fig. 2 is a schematic flowchart illustrating a control method of a washing machine according to a second embodiment of the present invention;

fig. 3 is a schematic flowchart illustrating a control method of a washing machine according to a third embodiment of the present invention;

fig. 4 is a schematic block diagram illustrating a control system of a washing machine according to a fourth embodiment of the present invention;

fig. 5 is a schematic block diagram illustrating a control system of a washing machine according to a fifth embodiment of the present invention;

fig. 6 is a schematic block diagram illustrating a control system of a washing machine according to a first embodiment of the present invention;

fig. 7 is a schematic block diagram illustrating a control system of a washing machine according to a second embodiment of the present invention;

fig. 8 is a schematic block diagram illustrating a control system of a washing machine according to a third embodiment of the present invention;

fig. 9 is a schematic block diagram illustrating a control system of a washing machine according to a fourth embodiment of the present invention;

fig. 10 shows a schematic block diagram of a washing machine according to a first embodiment of the present invention;

fig. 11 shows a schematic configuration diagram of a computer apparatus according to a first embodiment of the present invention.

Detailed Description

In order that the above objects, features and advantages of the present invention can be more clearly understood, a more particular description of the invention will be rendered by reference to the appended drawings. It should be noted that the embodiments and features of the embodiments of the present application may be combined with each other without conflict.

In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention, however, the present invention may be practiced in other ways than those specifically described herein, and therefore the scope of the present invention is not limited to the specific embodiments disclosed below.

As shown in fig. 1, a schematic flowchart of a control method of a washing machine according to a first embodiment of the present invention. The control method comprises the following steps:

102, receiving a main washing function or rinsing function completion instruction, and starting dewatering;

104, detecting whether the articles have eccentricity in the dehydration process;

and step 108, when the eccentricity still exists in the last dehydration process, alarming after at least one water supplement is finished.

The control method of the washing machine provided by the invention comprises the steps of receiving a main washing function or rinsing function completion instruction, starting dewatering by the washing machine, detecting whether the article has an eccentric condition in the dewatering process, specifically, directly rinsing the next stage by the washing machine when the article has the eccentric condition, and giving an alarm after finishing at least one water supplement when the article still has the eccentric condition in the last dewatering process. Compared with the control method provided by the prior art, the control method of the washing machine provided by the invention has the advantages that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

As shown in fig. 2, a schematic flowchart of a control method of a washing machine according to a second embodiment of the present invention. Wherein, the time length of not carrying out dehydration is equal to the total time length of presetting dehydration-sigma the time length used for completing dehydration each time, the control method comprises:

and 214, when the eccentricity condition still exists in the last dehydration process, giving an alarm after at least one water supplement is finished.

In the embodiment, the time length of the previous times of dehydration is calculated, and the time length of the previous times of dehydration is increased to the last time of dehydration, so that the last time of dehydration is increased, and the rinsing effect is ensured.

As shown in fig. 3, a schematic flowchart of a control method of a washing machine according to a third embodiment of the present invention. Wherein the time length for not performing dehydration is equal to the preset total dehydration time length-the time length for completing dehydration each time; the control method comprises the following steps:

and step 316, when the eccentricity still exists in the last dehydration process, alarming after at least one water supplement is finished.

In the embodiment, the last time of dewatering is delayed for the time that the dewatering is not carried out, so that the last time of dewatering is prolonged, the rinsing effect of the washing machine on clothes is improved, and the use experience of a user on the washing machine is further improved.

As shown in fig. 4, a schematic flowchart of a control method of a washing machine according to a fourth embodiment of the present invention. The control method comprises the following steps:

and step 410, when the eccentricity condition still exists in the last dehydration process, alarming after at least one water supplement is finished.

In the embodiment, before receiving the main washing function instruction, the fuzzy load bearing is carried out on the articles to be washed, and the first weight is recorded, so that the washing machine is controlled to add a proper amount of water according to the first weight, the clothes can be rinsed cleanly, water is saved, and the use experience of a user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

As shown in fig. 5, a schematic flowchart of a control method of a washing machine according to a fifth embodiment of the present invention. The control method comprises the following steps:

502, carrying out fuzzy bearing on the articles to be washed, and recording a first weight;

and step 512, after the last dehydration is finished, the fuzzy load bearing is carried out on the article again, and the second weight is recorded.

In the embodiment, the fuzzy bearing is carried out on the articles again after the last dehydration is finished, and the second weight is recorded, so that the final dehydration degree is determined according to the second weight and the first weight, and the rinsing and dehydration effects of the clothes are further ensured.

As shown in fig. 6, a schematic block diagram of a control system of a washing machine according to a first embodiment of the present invention. Wherein, the control system 600 of the washing machine includes:

a first control unit 602 for receiving a main washing function or rinsing function completion instruction and starting dehydration;

a detecting unit 604 for detecting whether the article is eccentric during the dehydration process;

a second control unit 606 for entering a rinsing function of a next stage when there is an eccentricity;

and the alarm unit 608 is used for giving an alarm after at least one water supplement is finished when the eccentricity condition still exists in the last dehydration process.

According to the control system 600 of the washing machine, provided by the invention, the first control unit 602 receives a main washing function or rinsing function completion instruction, the washing machine starts to dehydrate, the detection unit 604 detects whether the articles have an eccentric condition in the dehydration process, specifically, the second control unit 606 detects whether the articles have the eccentric condition, the washing machine directly performs rinsing in the next stage when the eccentric condition exists, and the alarm unit 608 sends out an alarm after finishing at least one water supplement when the articles still have the eccentric condition in the last dehydration process. Compared with the control system provided by the prior art, the control system 600 of the washing machine provided by the invention has the advantages that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

As shown in fig. 7, a schematic block diagram of a control system of a washing machine according to a second embodiment of the present invention. Wherein, the control system 700 of the washing machine includes:

a first control unit 702 for receiving a main washing function or rinsing function completion instruction to start dehydration;

a detecting unit 704 for detecting whether the article is eccentric during the dehydration process;

a second control unit 706 for entering a rinsing function of a next stage when there is an eccentricity;

the alarm unit 708 is used for giving an alarm after at least one water supplement is finished when the eccentricity condition still exists in the last dehydration process;

a setting unit 710 for presetting a total dehydration time;

a timing unit 712 for timing and recording the time length for completing the dehydration each time;

a calculating unit 714 for calculating the time length for which dehydration is not performed;

and the time length for not performing the dehydration is equal to the preset total dehydration time length-sigma time length for completing the dehydration each time.

In this embodiment, the total time of the dewatering is preset by the setting unit 710, the time used for each dewatering is timed and recorded by the timing unit 712, and finally the time length for which the previous times of dewatering are not performed is calculated by the calculating unit 714, and the time length for which the previous times of dewatering are not performed is increased to the last time of dewatering, so that the last time of dewatering is increased, and the rinsing effect is ensured.

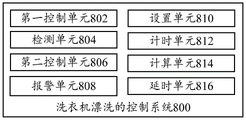

As shown in fig. 8, a schematic block diagram of a control system of a washing machine according to a third embodiment of the present invention. Wherein, the control system 800 of the washing machine includes:

a first control unit 802 for receiving a main washing function or rinsing function completion instruction and starting dehydration;

the detection unit 804 is used for detecting whether the articles have eccentricity in the dehydration process;

a second control unit 806 for entering a rinsing function of a next stage when there is an eccentricity;

the alarm unit 808 is used for giving an alarm after at least one water supplement is finished when the eccentricity condition still exists in the last dehydration process;

a setting unit 810 for presetting a total dehydration time;

a timing unit 812 for timing and recording a time length used for completing dehydration each time;

a calculating unit 814, configured to calculate a non-dehydration duration;

a delay unit 816, configured to delay the last dehydration duration by the non-dehydration duration;

and the time length for not performing the dehydration is equal to the preset total dehydration time length-sigma time length for completing the dehydration each time.

In this embodiment, the time delay unit 816 delays the last time of dehydration for the time length of not performing dehydration, so that the last time of dehydration is prolonged, the rinsing effect of the washing machine on the clothes is improved, and the use experience of the user on the washing machine is further improved.

In one embodiment of the present invention, preferably, before the step of receiving the main washing function command, the control system of the washing machine further includes: and the weighing unit is used for carrying out fuzzy bearing on the articles to be washed and recording the first weight.

In the embodiment, before receiving the main washing function instruction, the weighing unit is used for carrying out fuzzy load bearing on the articles to be washed, and recording the first weight, so that the washing machine is controlled to add proper water quantity according to the first weight, the clothes can be rinsed cleanly, water is saved, and the use experience of a user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

As shown in fig. 9, a schematic block diagram of a control system of a washing machine according to a fourth embodiment of the present invention. Wherein, the control system 900 of the washing machine includes:

the weighing unit 902 is used for carrying out fuzzy load bearing on the articles to be washed and recording a first weight;

a first control unit 904 for receiving a main washing function or rinsing function completion instruction to start dehydration;

a detection unit 906 for detecting whether the article has eccentricity during the dehydration process;

a second control unit 908 for entering a rinsing function of a next stage when there is an eccentricity;

and the alarm unit 910 is used for giving an alarm after at least one water supplement is finished when the eccentricity condition still exists in the last dehydration process.

In this embodiment, before receiving the main washing function instruction, the weighing unit 902 is used to perform fuzzy load bearing on the articles to be washed, and record the first weight, so that the washing machine is controlled to add an appropriate amount of water according to the first weight, the laundry can be rinsed clean, water is saved, and the use experience of the user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

In one embodiment of the present invention, the weighing unit 902 is preferably also used to blur the load bearing of the article again after the last dehydration is completed and record the second weight.

In this embodiment, after the last dehydration is completed, the weighing unit 902 is used to perform fuzzy weight bearing on the articles again, and record the second weight, so as to determine the last dehydration degree according to the second weight and the first weight, and further ensure the rinsing and dehydration effects of the clothes.

As shown in fig. 10, a schematic block diagram of a washing machine according to a first embodiment of the present invention. Wherein, the washing machine 1000 includes: a control system 1002 for a washing machine according to any of the preceding claims.

The washing machine 1000 provided by the invention adopts the control system 1002 of the washing machine in any technical scheme, so that the washing machine 1000 has all the beneficial effects of the control system 1002 of the washing machine, and is not described herein again.

Fig. 11 is a schematic structural diagram of a computer device according to an embodiment of the present invention. Wherein, this computer equipment 1 includes: a memory 12, a processor 14 and a computer program stored on the memory 12 and executable on the processor 14, the processor 14 when executing the computer program implementing the steps of:

receiving a main washing function or rinsing function completion instruction, and starting dewatering;

detecting whether the article has an eccentric condition in the dehydration process;

when the eccentric condition exists, the rinsing function of the next stage is started;

and when the eccentricity still exists in the last dehydration process, giving an alarm after at least one water supplement is finished.

The computer device 1 provided by the invention is a server for supporting the operation of a control system of a washing machine, and executes a computer program stored in a memory 12 through a processor 14, so that the water supplementing times of the washing machine in a washing process are greatly reduced, the washing completion time of clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of a user on the washing machine is improved.

In one embodiment of the present invention, preferably, the processor, when executing the computer program, further implements the steps of: presetting total dehydration time; timing and recording the time length for completing dehydration each time; calculating the time length of not dehydrating; wherein the time length for not performing dehydration is equal to the preset total dehydration time length-the time length for completing dehydration each time; the last time of dehydration is delayed for the time of non-dehydration.

In the embodiment, the time length used for completing the dewatering each time is counted and recorded by presetting the total dewatering time length, and the time length used for not performing the dewatering is calculated, wherein the time length used for not performing the dewatering each time is the preset total dewatering time length-sigma, so that the calculated time length used for not performing the dewatering is accurate, and the reliability of the subsequent last dewatering delay control of the washing machine is ensured. Further, through not carrying out the dehydration duration with the time delay of last dehydration duration for the time of last dehydration can prolong, promotes washing machine to the rinsing effect of clothing, further promotes the user and experiences washing machine's use.

In an embodiment of the present invention, preferably, before the step of receiving the main wash function instruction, the method further includes: and carrying out fuzzy bearing on the articles to be washed, and recording the first weight.

In the embodiment, before receiving the main washing function instruction, the fuzzy load bearing is carried out on the articles to be washed, and the first weight is recorded, so that the washing machine is controlled to add a proper amount of water according to the first weight, the clothes can be rinsed cleanly, water is saved, and the use experience of a user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

In one embodiment of the present invention, preferably, the processor, when executing the computer program, further implements the steps of: after the final dewatering is completed, the item is again fuzzy loaded and the second weight is recorded.

In the embodiment, the fuzzy bearing is carried out on the articles again after the last dehydration is finished, and the second weight is recorded, so that the final dehydration degree is determined according to the second weight and the first weight, and the rinsing and dehydration effects of the clothes are further ensured.

An embodiment of the invention provides a computer-readable storage medium having stored thereon a computer program which, when executed by a processor, performs the steps of: receiving a main washing function or rinsing function completion instruction, and starting dewatering; detecting whether the article has an eccentric condition in the dehydration process; when the eccentric condition exists, the rinsing function of the next stage is started; and when the eccentricity still exists in the last dehydration process, giving an alarm after at least one water supplement is finished.

The present invention provides a computer-readable storage medium installed in a server supporting operation of a control system of a washing machine, the computer-readable storage medium has stored thereon a computer program which, by executing the computer program, the following steps can be realized, specifically, the washing machine starts to dewater by receiving a main washing function or rinsing function finishing instruction, then detects whether the article has an eccentric condition in the dewatering process, when the eccentric condition exists, the washing machine directly carries out the rinsing of the next stage, when the eccentric condition still exists in the articles in the last dewatering process, after at least one time of water replenishing, the alarm is sent out, so that the water replenishing times in one washing process of the washing machine are greatly reduced, the washing finishing time of the clothes is shortened, the water is saved, meanwhile, the rinsing effect of the clothes is not weakened at all, and the use experience of the user on the washing machine is improved.

In one embodiment of the invention, the computer program, when executed by the processor, preferably further implements the steps of: presetting total dehydration time; timing and recording the time length for completing dehydration each time; calculating the time length of not dehydrating; wherein the time length for not performing dehydration is equal to the preset total dehydration time length-the time length for completing dehydration each time; the last time of dehydration is delayed for the time of non-dehydration.

In the embodiment, the time length of the previous times of dehydration is calculated, and the time length of the previous times of dehydration is increased to the last time of dehydration, so that the last time of dehydration is increased, and the rinsing effect is ensured. Further, through not carrying out the dehydration duration with the time delay of last dehydration duration for the time of last dehydration can prolong, promotes washing machine to the rinsing effect of clothing, further promotes the user and experiences washing machine's use.

In an embodiment of the present invention, preferably, before the step of receiving the main wash function instruction, the method further includes: and carrying out fuzzy bearing on the articles to be washed, and recording the first weight.

In the embodiment, before receiving the main washing function instruction, the fuzzy load bearing is carried out on the articles to be washed, and the first weight is recorded, so that the washing machine is controlled to add a proper amount of water according to the first weight, the clothes can be rinsed cleanly, water is saved, and the use experience of a user on the washing machine is further improved. Namely, in the concrete implementation process, the water inflow of different gears is preset on the washing machine, the water inflow of different gears is matched with the weight of the articles to be washed, when a user puts clothes into a washing barrel, the weight of the clothes to be washed is obtained through fuzzy bearing, and then the proper washing gears are matched, the water inlet main washing is carried out, the washing effect of the clothes is guaranteed, and the energy-saving and environment-friendly effects are achieved.

In one embodiment of the present invention, preferably, the processor, when executing the computer program, further implements the steps of: after the final dewatering is completed, the item is again fuzzy loaded and the second weight is recorded.

In the embodiment, the fuzzy bearing is carried out on the articles again after the last dehydration is finished, and the second weight is recorded, so that the final dehydration degree is determined according to the second weight and the first weight, and the rinsing and dehydration effects of the clothes are further ensured.

In the description herein, the description of the terms "one embodiment," "some embodiments," "specific embodiments," etc., means that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one embodiment or example of the invention. In this specification, the schematic representations of the terms used above do not necessarily refer to the same embodiment or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments or examples.

The above description is only a preferred embodiment of the present invention and is not intended to limit the present invention, and various modifications and changes may be made by those skilled in the art. Any modification, equivalent replacement, or improvement made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (11)

1. A control method of a washing machine, characterized by comprising:

receiving a main washing function or rinsing function completion instruction, and starting dewatering;

detecting whether the article has an eccentric condition in the dehydration process;

when the eccentricity condition exists, rinsing in the next stage is carried out;

when the eccentricity condition still exists in the last dehydration process, an alarm is given out after at least one water supplement is finished;

presetting total dehydration time;

timing and recording the time length for completing dehydration each time;

calculating the time length of not dehydrating;

and delaying the last dehydration time length by the non-dehydration time length.

2. The control method of a washing machine according to claim 1,

and the time length for not dehydrating is equal to the preset total dehydrating time length-sigma, and the time length for completing dehydrating each time is used.

3. The control method of a washing machine as claimed in claim 1 or 2, further comprising, before the step of receiving the main wash function command:

and carrying out fuzzy bearing on the articles to be washed, and recording the first weight.

4. The control method of a washing machine according to claim 3, further comprising:

after the final dewatering is completed, the item is again fuzzy loaded and a second weight is recorded.

5. A control system of a washing machine, comprising:

the first control unit is used for receiving a main washing function or rinsing function completion instruction and starting dewatering;

the detection unit is used for detecting whether the articles have the eccentric condition in the dehydration process;

a second control unit for entering the rinsing function of a next stage when the eccentricity condition exists;

the alarm unit is used for giving an alarm after at least one water supplement is finished when the eccentricity condition still exists in the last dehydration process;

the setting unit is used for presetting the total dehydration time;

the timing unit is used for timing and recording the time length for finishing the dehydration each time;

the calculating unit is used for calculating the time length of non-dehydration;

and the time delay unit is used for delaying the last dehydration time length by the non-dehydration time length.

6. The control system of a washing machine according to claim 5,

and the time length for not dehydrating is equal to the preset total dehydrating time length-sigma, and the time length for completing dehydrating each time is used.

7. The control system of a washing machine as claimed in claim 5 or 6, further comprising, before the step of receiving the main wash function command:

and the weighing unit is used for carrying out fuzzy bearing on the articles to be washed and recording the first weight.

8. The control system of a washing machine according to claim 7,

and the weighing unit is also used for carrying out fuzzy bearing on the object again after the last dehydration is finished, and recording a second weight.

9. A washing machine characterized by comprising a control system of a washing machine as claimed in any one of claims 5 to 8.

10. Computer device comprising a memory, a processor and a computer program stored on said memory and executable on said processor, characterized in that said processor, when executing said computer program, carries out the steps of a control method of a laundry washing machine according to any one of claims 1 to 4.

11. A computer-readable storage medium, on which a computer program is stored, characterized in that the computer program, when being executed by a processor, implements the steps of the control method of a laundry machine according to any one of claims 1 to 4.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710411715.XA CN108978115B (en) | 2017-06-05 | 2017-06-05 | Control method and system of washing machine, washing machine and computer equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710411715.XA CN108978115B (en) | 2017-06-05 | 2017-06-05 | Control method and system of washing machine, washing machine and computer equipment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108978115A CN108978115A (en) | 2018-12-11 |

| CN108978115B true CN108978115B (en) | 2020-12-08 |

Family

ID=64502558

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201710411715.XA Active CN108978115B (en) | 2017-06-05 | 2017-06-05 | Control method and system of washing machine, washing machine and computer equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108978115B (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111123854B (en) * | 2019-12-02 | 2021-10-22 | 联想(北京)有限公司 | Processing method and processing system |

| CN113668180B (en) * | 2020-05-15 | 2024-06-14 | 青岛海尔洗衣机有限公司 | Control method of washing machine |

| CN113944033B (en) * | 2020-07-17 | 2023-11-10 | 天津海尔洗涤电器有限公司 | Dehydration control method, device and equipment |

| CN113981654B (en) * | 2020-07-27 | 2024-03-26 | 天津海尔洗涤电器有限公司 | Washing machine control method and device, washing machine and storage medium |

| CN114481548B (en) * | 2020-11-13 | 2023-11-03 | 无锡小天鹅电器有限公司 | Laundry treating apparatus, control method and device thereof, and storage medium |

| CN112941819B (en) * | 2021-01-27 | 2023-03-17 | 珠海格力电器股份有限公司 | Washing machine control method, device, equipment and storage medium |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN86105570A (en) * | 1985-06-20 | 1987-02-25 | 三洋电机株式会社 | Washing machine |

| KR100315813B1 (en) * | 1999-07-16 | 2001-12-12 | 구자홍 | A method for sensing of unbalance in the case of washing/rinsing |

| JP2006288603A (en) * | 2005-04-08 | 2006-10-26 | Sharp Corp | Automatic washing machine |

| CN101187125A (en) * | 2007-02-15 | 2008-05-28 | 南京乐金熊猫电器有限公司 | Control method for business washing machine |

| CN103820974A (en) * | 2012-11-16 | 2014-05-28 | 海尔集团公司 | Automatic cleaning washer |

| CN104919106A (en) * | 2012-12-21 | 2015-09-16 | 伊莱克斯家用产品股份有限公司 | Method for controlling a laundry washing machine and laundry washing machine |

| CN105986399A (en) * | 2015-03-05 | 2016-10-05 | 无锡小天鹅股份有限公司 | Washing machine and method for judging washing machine load eccentricity |

| CN106319837A (en) * | 2015-06-24 | 2017-01-11 | 青岛海尔滚筒洗衣机有限公司 | Method for setting washing programs based on preset electric energy and washing machine |

-

2017

- 2017-06-05 CN CN201710411715.XA patent/CN108978115B/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN86105570A (en) * | 1985-06-20 | 1987-02-25 | 三洋电机株式会社 | Washing machine |

| KR100315813B1 (en) * | 1999-07-16 | 2001-12-12 | 구자홍 | A method for sensing of unbalance in the case of washing/rinsing |

| JP2006288603A (en) * | 2005-04-08 | 2006-10-26 | Sharp Corp | Automatic washing machine |

| CN101187125A (en) * | 2007-02-15 | 2008-05-28 | 南京乐金熊猫电器有限公司 | Control method for business washing machine |

| CN103820974A (en) * | 2012-11-16 | 2014-05-28 | 海尔集团公司 | Automatic cleaning washer |

| CN104919106A (en) * | 2012-12-21 | 2015-09-16 | 伊莱克斯家用产品股份有限公司 | Method for controlling a laundry washing machine and laundry washing machine |

| CN105986399A (en) * | 2015-03-05 | 2016-10-05 | 无锡小天鹅股份有限公司 | Washing machine and method for judging washing machine load eccentricity |

| CN106319837A (en) * | 2015-06-24 | 2017-01-11 | 青岛海尔滚筒洗衣机有限公司 | Method for setting washing programs based on preset electric energy and washing machine |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108978115A (en) | 2018-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108978115B (en) | Control method and system of washing machine, washing machine and computer equipment | |

| CN107488977B (en) | Washing machine control method | |

| CN113737459B (en) | Control method and control device for power failure recovery of washing machine and washing machine | |

| WO2018082581A1 (en) | Method for controlling water removal in washing machine and control apparatus | |

| CN111118819A (en) | Rinsing treatment method, rinsing treatment device and clothes treatment device | |

| CN109267307A (en) | Dry method for confirming remaining time, equipment and device for clothing processing | |

| CN114016246A (en) | Washing machine and dewatering control method and device thereof | |

| CN112575519B (en) | Multi-drum washing machine drainage control method and device, storage medium and washing machine | |

| CN113914061B (en) | Dehydration control method and device, clothes treatment equipment and storage medium | |

| CN110359219B (en) | Washing machine control method and washing machine | |

| CN113265837B (en) | Laundry treating apparatus, control method and device thereof, and storage medium | |

| CN110016784A (en) | The control method and device of washing machine | |

| CN112941812B (en) | Control method and device of washing machine, storage medium and processor | |

| CN111945373B (en) | Dehydration control method and device, clothes treatment equipment and storage medium | |

| CN108930129B (en) | Washing machine rinsing control method and system and washing machine | |

| CN112411123A (en) | Rinsing control method and device and washing equipment | |

| CN112760913A (en) | Control method and device for drainage pump, washing machine, storage medium and processor | |

| CN115058857B (en) | Washing control method and device of washing machine, electronic equipment and storage medium | |

| CN113981654B (en) | Washing machine control method and device, washing machine and storage medium | |

| CN113832649B (en) | Dehydration control method, device, clothes treatment equipment and storage medium | |

| CN113789636B (en) | Control method and device of multi-tub washing machine and washing machine | |

| CN116837589A (en) | Dehydration control method for optimizing deviation correcting action of roller | |

| CN114016269B (en) | Clothes drying processing method and device, washing and drying integrated machine and storage medium | |

| CN112877988B (en) | Washing equipment, control method and device thereof, storage medium and processor | |

| WO2024088203A1 (en) | Method for increasing spin-drying achievement rate of washing machine, and storage medium and electronic apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20190710 Address after: No. 18 Changjiang South Road, National High-tech Development Zone, Xinwu District, Wuxi City, Jiangsu Province, 214000 Applicant after: Wuxi Swan Electrical Appliances Co., Ltd. Address before: 214028 No. 18 Changjiang South Road, Wuxi National High-tech Development Zone, Jiangsu Province Applicant before: Wuxi Xiaotianer Co., Ltd. |

|

| GR01 | Patent grant | ||

| GR01 | Patent grant |