CN102928207A - Onboard LED automatic testing method - Google Patents

Onboard LED automatic testing method Download PDFInfo

- Publication number

- CN102928207A CN102928207A CN2012104840983A CN201210484098A CN102928207A CN 102928207 A CN102928207 A CN 102928207A CN 2012104840983 A CN2012104840983 A CN 2012104840983A CN 201210484098 A CN201210484098 A CN 201210484098A CN 102928207 A CN102928207 A CN 102928207A

- Authority

- CN

- China

- Prior art keywords

- led

- plate

- carries

- automatic test

- pick

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Testing Of Optical Devices Or Fibers (AREA)

- Testing Of Individual Semiconductor Devices (AREA)

- Led Devices (AREA)

Abstract

The invention relates to an onboard LED automatic testing method, and belongs to the technical field of quality control for electronic products. In the method, detecting equipment controls a camera to only photograph within the maximum boundary of a board where the LED is located, further the color and luminance of the picture can be tested to obtain the testing result of the LED, so that the influence of light rays of the ambient environment on the testing is avoided as far as possible, the testing requirement can be met without adopting a testing accommodating chamber, the testing procedure is greatly simplified, the testing efficiency is improved, further, the shutter time of the camera can be shortened through improving the luminance of the LED, the luminance of the LED and the luminance of the background can be distinguished better, and the testing accuracy is improved. The onboard LED automatic testing method provided by the invention is low in cost and has a wider application range.

Description

Technical field

The present invention relates to Quality of electronic products monitoring technique field, particularly LED detection technique field refers to that specifically a kind of plate carries the automatic test approach of LED.

Background technology

In commercial production, electron trade especially, the LED quantity of product is usually more.After LED being installed on circuit board or the panel, need test LED whether normally to install.Method of testing commonly used is to rely on eye recognition, and this is so that test result makes a mistake easily and testing efficiency is low.Therefore, only have and adopt effective automatic test to replace traditional manual testing, the needs that the increasing electronic product of ability adaptation scale is produced.

In the prior art, usually adopt common camera to cooperate image recognition apparatus to realize that the extensive of LED detects automatically.The light-emitting diode (LED) car lamp testing apparatus that provides such as practical new patent 200820133993.Its advantage is, first-class detection the cheap of equipment of making a video recording, and detecting effect can satisfy the demands substantially.But problem is that this testing apparatus must use one to detect room, is not subjected to the impact of external light source to guarantee testing process, just can reach the detection effect of expection.But, in order to realize the detection for LED equipment quality, detection must be carried out after finishing the LED assembly work, the sheet materials such as circuit board that LED fixed together is placed on one detects complexity and the difficulty that has obviously improved testing in the room, has reduced the efficient that detects.On the other hand, corresponding to the LED that is installed on the different plates, need to adopt different detection rooms could guarantee the effect that detects in the applicable situation of assurance, this has obviously improved again the cost that LED detects.

Summary of the invention

The objective of the invention is to have overcome above-mentioned shortcoming of the prior art, providing a kind of does not need to adopt the detection room can carry out the LED test, and the test effect can reach the identical even better level of the prior art that adopts the darkroom, thereby simplified the flow process of test, improved the efficient of test, and with low cost, range of application comparatively widely plate is carried the automatic test approach of LED.

In order to realize above-mentioned purpose, the automatic test approach that plate of the present invention carries LED may further comprise the steps:

(1) carry the LED power supply to described plate, described plate carries LED and is arranged on a circuit board or the panel;

(2) pick-up unit control camera is taken take the photo of described plate as the maximum boundary scope;

(3) described pick-up unit detects color and the brightness of described photo;

(4) described pick-up unit judges according to color and the brightness of described photo whether LED is normal, and obtains testing result.

This plate carries in the automatic test approach of LED, describedly carries LED power supply to plate, and be specially: carry the LED power supply to plate, carry the LED power supply to plate, making background luminance is 20~30 o'clock, and the brightness range of LED to be detected is 90~100.

This plate carries in the automatic test approach of LED, and the shooting time shutter scope that described camera is taken take described plate as the photo of maximum boundary scope is 1/1500 second~1/800 second.Be preferably 1/1000 second.

This plate carries in the automatic test approach of LED, and described step (3) specifically may further comprise the steps:

(31) described pick-up unit detects the rgb value of described each pixel of photo;

(32) described pick-up unit is analyzed color and the brightness of pixel set according to described rgb value.

This plate carries in the automatic test approach of LED, and described pick-up unit also is connected with a mechanical arm, and described method is further comprising the steps of before in described step (1):

(0) described pick-up unit is controlled described mechanical arm the plate at LED place to be detected is moved to predetermined camera site before the described camera.

This plate carries in the automatic test approach of LED, and described method is further comprising the steps of afterwards in described step (4):

(5) described pick-up unit is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, and returns step (0).

This plate carries in the automatic test approach of LED, described deposit position comprises certified products deposit position and unacceptable product deposit position, described pick-up unit is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, be specially: described pick-up unit is according to described testing result, control described mechanical arm, the plate of finishing the LED place of detection is moved to corresponding certified products deposit position or unacceptable product deposit position.

Having adopted plate of the present invention to carry the automatic test approach of LED, is the photo of maximum boundary scope because it only takes LED place plate; And then by detecting color and the brightness of described photo, obtain the LED testing result, thereby avoided as much as possible the impact of surrounding environment light on test generation, thus do not needing to adopt the requirement that can satisfy detection in the situation that detects room, significantly simplified the flow process of test, improved the efficient of test, further, by improving LED brightness, shorten the camera aperture time, can distinguish better the brightness of LED and background, improve the accuracy that detects.It is with low cost that plate of the present invention carries the automatic test approach of LED, and range of application is comparatively extensive.

Description of drawings

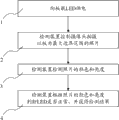

Fig. 1 is the flow chart of steps that plate of the present invention carries the automatic test approach of LED.

Fig. 2 is the testing apparatus synoptic diagram that method of the present invention is utilized.

Embodiment

In order more clearly to understand technology contents of the present invention, describe in detail especially exemplified by following examples.

See also shown in Figure 1, the flow chart of steps of carrying the automatic test approach of LED for plate of the present invention.

In one embodiment, the method may further comprise the steps:

(1) carry the LED power supply to described plate, described plate carries LED and is arranged on a circuit board or the panel;

(2) pick-up unit control camera is taken take the photo of described plate as the maximum boundary scope;

(3) described pick-up unit detects color and the brightness of described photo;

(4) described pick-up unit judges according to color and the brightness of described photo whether LED is normal, and obtains testing result.

A kind of preferred embodiment in, step (1) is described carries the LED power supply to plate, be specially to plate and carry the LED power supply, making background luminance is lower time of situation of 20~30, LED to be detected reaches 90~100 brightness range (brightness RGB three looks of LED are respectively 0~255, and the corresponding brightness scope is 0~100).And the shooting time shutter that described camera is taken take described plate as the photo of maximum boundary scope is the shortest in 1/1500 second, no longer than 1/800 second, take 1/1000 second as the preferred time shutter.Thereby obvious luminance difference is arranged between LED and background, and can on the photo of taking, obviously distinguish.

In a kind of further preferred embodiment, described step (3) specifically may further comprise the steps:

(31) described pick-up unit detects the rgb value of described each pixel of photo;

(32) described pick-up unit is analyzed color and the brightness of pixel set according to described rgb value.

A kind of further preferred embodiment in, described pick-up unit also is connected with a mechanical arm, described method is further comprising the steps of before in described step (1):

(0) described pick-up unit is controlled described mechanical arm the plate at LED place to be detected is moved to predetermined camera site before the described camera.

And further comprising the steps of afterwards in described step (4):

(5) described pick-up unit is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, and returns step (0).

In a kind of preferred embodiment, described deposit position comprises certified products deposit position and unacceptable product deposit position, pick-up unit described in the step (5) is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, be specially: described pick-up unit is according to described testing result, control described mechanical arm, the plate of finishing the LED place of detection is moved to corresponding certified products deposit position or unacceptable product deposit position, thereby finish the automatic sorting of the rear product of test.

In an application of the invention, the plate of the present invention automatic test approach that carries LED can be finished by checkout equipment shown in Figure 2.PC 1 control camera 2 is taken the picture of LED 3, and resolves the rgb value of picture pixel, analyzes color and the brightness of pixel set, thereby judges whether LED is normal.The pcb board 4 that is equipped with LED 3 is placed into position before the camera 2 by workman or mechanical arm (not shown) etc., guarantees that the border that coverage does not exceed pcb board 4 gets final product.

Aforesaid, finish at PC cooperative mechanical arm in the situation of automatic capturing pcb board to be detected and automatic sorting, whole testing process can be finished in unattended situation automatically, this just means, equipment operating environment can need not to consider whether to satisfy the needs of manual observation, and in the extremely low situation of ambient brightness, move, thereby further promote the accuracy that detects.

Having adopted plate of the present invention to carry the automatic test approach of LED, is the photo of maximum boundary scope because it only takes LED place plate; And then by detecting color and the brightness of described photo, obtain the LED testing result, thereby avoided as much as possible the impact of surrounding environment light on test generation, thus do not needing to adopt the requirement that can satisfy detection in the situation that detects room, significantly simplified the flow process of test, improved the efficient of test, further, by improving LED brightness, shorten the camera aperture time, can distinguish better the brightness of LED and background, improve the accuracy that detects.It is with low cost that plate of the present invention carries the automatic test approach of LED, and range of application is comparatively extensive.

In this instructions, the present invention is described with reference to its specific embodiment.But, still can make various modifications and conversion obviously and not deviate from the spirit and scope of the present invention.Therefore, instructions and accompanying drawing are regarded in an illustrative, rather than a restrictive.

Claims (9)

1. a plate carries the automatic test approach of LED, and described plate carries LED and is arranged on the plate, it is characterized in that, described method may further comprise the steps:

(1) carries the LED power supply to described plate;

(2) one pick-up units are controlled a camera and are taken take the photo of described plate as the maximum boundary scope;

(3) described pick-up unit detects color and the brightness of described photo;

(4) described pick-up unit judges according to color and the brightness of described photo whether LED is normal, and obtains testing result.

2. plate according to claim 1 carries the automatic test approach of LED, it is characterized in that, described plate is circuit board or panel.

3. plate according to claim 1 carries the automatic test approach of LED, it is characterized in that, describedly carries LED power supply to plate, is specially:

Carry the LED power supply to plate, making background luminance is 20~30 o'clock, and the brightness range of LED to be detected is 90~100.

4. plate according to claim 1 carries the automatic test approach of LED, it is characterized in that, the shooting time shutter that described camera is taken take described plate as the photo of maximum boundary scope is 1/1500 second~1/800 second.

5. plate according to claim 4 carries the automatic test approach of LED, it is characterized in that, the described time shutter is 1/1000 second.

6. plate according to claim 1 carries the automatic test approach of LED, it is characterized in that, described step (3) specifically may further comprise the steps:

(31) described pick-up unit detects the rgb value of described each pixel of photo;

(32) described pick-up unit is analyzed color and the brightness of pixel set according to described rgb value.

According to claim 1 in 6 each described plate carry the automatic test approach of LED, it is characterized in that described pick-up unit also is connected with a mechanical arm, described method is further comprising the steps of before in described step (1):

(0) described pick-up unit is controlled described mechanical arm the plate at LED place to be detected is moved to predetermined camera site before the described camera.

8. plate according to claim 7 carries the automatic test approach of LED, it is characterized in that, described method is further comprising the steps of afterwards in described step (4):

(5) described pick-up unit is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, and returns step (0).

9. plate according to claim 8 carries the automatic test approach of LED, it is characterized in that, described deposit position comprises certified products deposit position and unacceptable product deposit position, described pick-up unit is controlled described mechanical arm and will be finished the plate at the LED place of detection and move to deposit position, is specially:

Described pick-up unit is controlled described mechanical arm according to described testing result, and the plate of finishing the LED place of detection is moved to corresponding certified products deposit position or unacceptable product deposit position.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012104840983A CN102928207A (en) | 2012-11-23 | 2012-11-23 | Onboard LED automatic testing method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012104840983A CN102928207A (en) | 2012-11-23 | 2012-11-23 | Onboard LED automatic testing method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102928207A true CN102928207A (en) | 2013-02-13 |

Family

ID=47643060

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012104840983A Pending CN102928207A (en) | 2012-11-23 | 2012-11-23 | Onboard LED automatic testing method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102928207A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104076296A (en) * | 2013-03-29 | 2014-10-01 | 深圳市海洋王照明工程有限公司 | Testing method and device for LED signal lamp light-emitting board |

| CN104111160A (en) * | 2013-04-22 | 2014-10-22 | 展晶科技(深圳)有限公司 | Light emitting diode detection system and light emitting diode detection method |

| CN108226816A (en) * | 2017-11-30 | 2018-06-29 | 群光电子(苏州)有限公司 | A kind of equipment of proved keyboard LED light function |

| CN109916441A (en) * | 2017-12-13 | 2019-06-21 | 佛山市顺德区美的电热电器制造有限公司 | Test method and test macro for household electrical appliance |

| CN110488515A (en) * | 2019-08-06 | 2019-11-22 | 深圳市利航电子有限公司 | The LED light bar detection device and method of backlight |

| CN110531240A (en) * | 2019-08-16 | 2019-12-03 | 珠海易发照明器材有限公司 | A kind of LED light source characteristic verifying attachment and method |

| CN111429442A (en) * | 2020-03-31 | 2020-07-17 | 华南师范大学 | Circuit board L ED module detection method, device, equipment and storage medium |

| CN113495818A (en) * | 2020-03-20 | 2021-10-12 | 微盟电子(昆山)有限公司 | Keyboard light detection system and method, computer readable storage medium and electronic device |

| US11451714B2 (en) | 2019-12-13 | 2022-09-20 | Mpi Corporation | Light emitting element detecting method and equipment |

| TWI788002B (en) * | 2021-09-09 | 2022-12-21 | 英業達股份有限公司 | Inspection system applied to light emitting diode on circuit board |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005191387A (en) * | 2003-12-26 | 2005-07-14 | Fujitsu Ltd | Method and device for testing image pickup element |

| CN1982857A (en) * | 2005-12-14 | 2007-06-20 | 深圳迈瑞生物医疗电子股份有限公司 | Method, apparatus and system for automatically measuring luminescent device |

| WO2011037481A1 (en) * | 2009-09-22 | 2011-03-31 | Eternity Manufacturing Limited | Diamond sorting system |

| KR20110110730A (en) * | 2010-04-01 | 2011-10-07 | 샤프 가부시키가이샤 | Apparatus and method for measuring light emission, and readable recording medium |

| CN102540038A (en) * | 2010-12-27 | 2012-07-04 | 苏州晶能科技有限公司 | Sorting and testing equipment for full-automatic Light-Emitting Diode (LED) light source modules, and sorting and testing method thereof |

-

2012

- 2012-11-23 CN CN2012104840983A patent/CN102928207A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005191387A (en) * | 2003-12-26 | 2005-07-14 | Fujitsu Ltd | Method and device for testing image pickup element |

| CN1982857A (en) * | 2005-12-14 | 2007-06-20 | 深圳迈瑞生物医疗电子股份有限公司 | Method, apparatus and system for automatically measuring luminescent device |

| WO2011037481A1 (en) * | 2009-09-22 | 2011-03-31 | Eternity Manufacturing Limited | Diamond sorting system |

| KR20110110730A (en) * | 2010-04-01 | 2011-10-07 | 샤프 가부시키가이샤 | Apparatus and method for measuring light emission, and readable recording medium |

| CN102540038A (en) * | 2010-12-27 | 2012-07-04 | 苏州晶能科技有限公司 | Sorting and testing equipment for full-automatic Light-Emitting Diode (LED) light source modules, and sorting and testing method thereof |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104076296A (en) * | 2013-03-29 | 2014-10-01 | 深圳市海洋王照明工程有限公司 | Testing method and device for LED signal lamp light-emitting board |

| CN104111160A (en) * | 2013-04-22 | 2014-10-22 | 展晶科技(深圳)有限公司 | Light emitting diode detection system and light emitting diode detection method |

| CN108226816A (en) * | 2017-11-30 | 2018-06-29 | 群光电子(苏州)有限公司 | A kind of equipment of proved keyboard LED light function |

| CN109916441B (en) * | 2017-12-13 | 2022-02-25 | 佛山市顺德区美的电热电器制造有限公司 | Testing method and testing system for household appliances |

| CN109916441A (en) * | 2017-12-13 | 2019-06-21 | 佛山市顺德区美的电热电器制造有限公司 | Test method and test macro for household electrical appliance |

| CN110488515A (en) * | 2019-08-06 | 2019-11-22 | 深圳市利航电子有限公司 | The LED light bar detection device and method of backlight |

| CN110488515B (en) * | 2019-08-06 | 2020-07-07 | 深圳市利航电子有限公司 | LED light bar detection device and method of backlight source |

| CN110531240A (en) * | 2019-08-16 | 2019-12-03 | 珠海易发照明器材有限公司 | A kind of LED light source characteristic verifying attachment and method |

| US11451714B2 (en) | 2019-12-13 | 2022-09-20 | Mpi Corporation | Light emitting element detecting method and equipment |

| CN113495818A (en) * | 2020-03-20 | 2021-10-12 | 微盟电子(昆山)有限公司 | Keyboard light detection system and method, computer readable storage medium and electronic device |

| CN113495818B (en) * | 2020-03-20 | 2024-03-15 | 微盟电子(昆山)有限公司 | Keyboard lamp detection system and method, computer readable storage medium and electronic device |

| CN111429442A (en) * | 2020-03-31 | 2020-07-17 | 华南师范大学 | Circuit board L ED module detection method, device, equipment and storage medium |

| TWI788002B (en) * | 2021-09-09 | 2022-12-21 | 英業達股份有限公司 | Inspection system applied to light emitting diode on circuit board |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102928207A (en) | Onboard LED automatic testing method | |

| US7166856B2 (en) | Apparatus and method to inspect display panels | |

| CN107796825B (en) | Device detection method | |

| CN201707304U (en) | Device for automated optical inspection of surface of product | |

| KR101669862B1 (en) | vision inspection device for a terminal type harness | |

| CN204330609U (en) | Six axis robot AOI detection system | |

| CN109788281A (en) | A kind of light leak test method and device of camera module | |

| CN109870463B (en) | Electronic chip fault detection device | |

| CN109668832A (en) | Cellular li-ion battery surface bulge detection device and its method based on subregion light source | |

| CN116797528A (en) | Method, system and device for creating an enclosed space for inspecting a coated surface | |

| CN106770361A (en) | A kind of full-automatic screen optical detection apparatus and detection method | |

| CN204241186U (en) | Detection device and detection system for detecting light-emitting component | |

| CN106303509A (en) | Camera sub-assemblies dust and defect detecting system and method | |

| KR100902636B1 (en) | Test apparatus for infrared rays camera module | |

| CN202670946U (en) | Elevator car lamp detection system | |

| US20100246365A1 (en) | Method of adjusting brightness of illumination device and bio disk drive using the method | |

| JP2012149946A (en) | Inspection device, inspection method and program | |

| CN105717119A (en) | Double-row wire-harness color detecting device | |

| CN102156106A (en) | Rapid solar wafer detection system | |

| US9756230B2 (en) | Mounting and inspection data creation device and mounting and inspection data creation method | |

| TWI448606B (en) | Method and device for inspecting surface | |

| CN205157919U (en) | Automatic optical detector | |

| CN204258992U (en) | A kind of vehicle-mounted camera automatic detection device | |

| JP2012225716A (en) | Visual appearance inspection device and visual appearance inspection method for substrate | |

| US20160102967A1 (en) | Differential lighting |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20130213 |