CN102329602A - Ultralow-concentration fracturing fluid and preparation method thereof - Google Patents

Ultralow-concentration fracturing fluid and preparation method thereof Download PDFInfo

- Publication number

- CN102329602A CN102329602A CN 201110221055 CN201110221055A CN102329602A CN 102329602 A CN102329602 A CN 102329602A CN 201110221055 CN201110221055 CN 201110221055 CN 201110221055 A CN201110221055 A CN 201110221055A CN 102329602 A CN102329602 A CN 102329602A

- Authority

- CN

- China

- Prior art keywords

- solution

- fracturing liquid

- adopts

- ultralow density

- liquid according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Detergent Compositions (AREA)

Abstract

The invention relates to an ultralow-concentration fracturing fluid and a preparation method thereof. Currently, a reservoir is reconstructed by adopting a hydraulic fracturing method with the following shortcomings: (1) the rubber crushing residue content in the fracturing fluid is high and is generally 500-600 mg/L; and (2) the using amount of the rubber crushing agent is larger during reconstructing the reservoir and the average using amount is up to about 0.03%. The ultralow-concentration fracturing fluid provided by the invention comprises 93.35-97.4 parts of water, 0.25-0.35 part of hydroxypropyl guar, 1.0-2.0 parts of cross-linking agent, 0.40-2.0 parts of surfactant, 0.20-1.0 part of clay stabilizer, 0.05-0.5 part of bacteriacide and 0.2-0.8 part of temperature resistant reinforcing agent; and the preparation method comprises the following steps of: preparing a solution A in a container; and mixing the solution A and the cross-linking agent according to a volume ratio of 100:1-100:2 so as to form the fracturing fluid. In the fracturing fluid provided by the invention, the concentration of the hydroxypropyl guar as a thickening agent is up to 0.25-0.35%.

Description

Technical field

The present invention relates to a kind of employed ultralow density fracturing liquid of yield-increasing technique that is used for hyposmosis and the transformation of ultra-low penetration gas field reservoir fracturing and preparation method thereof, is that a kind of viscosifying agent hydroxypropyl guar gum concentration that is used for the gas field pressing crack construction is 0.30%~0.35% fracturing liquid system specifically.

Technical background

At present; Long celebrating gas field depth of reservoirs is higher than 3000m, and reservoir temperature reaches more than 90 ℃, mostly adopts the waterfrac treatment mode to carry out reservoir reconstruction; For guaranteeing carrying out smoothly of pressing crack construction; The concentration of viscosifying agent hydroxypropylguar gum is 0.50%~0.55% in the employed water-based fracturing liquid system, have to make seam preferably and take the sand function, but this system is not enough below existing:

1. the broken glue residue content of fracturing liquid system is high, generally at 500~600mg/L.

2. gel breaker large usage quantity during reservoir reconstruction, average dosage reaches about 0.03%.

Above-mentioned factor has influenced the fracturing reform effect to a certain extent.

Summary of the invention

It is ultralow density fracturing liquid of 0.30%~0.35% and preparation method thereof that the technical problem that the present invention solved provides a kind of viscosifying agent concentration that is used for the gas field reservoir reconstruction.

For solving above-mentioned technical problem, the technical scheme that the present invention takes:

A kind of ultralow density fracturing liquid, its special character is: be made up of according to weight part following material:

93.35~97.4 parts in water

0.25~0.35 part of hydroxypropylguar gum

1.0~2.0 parts of linking agents

0.40~2.0 part in tensio-active agent

0.20~1.0 part of clay stabilizer

0.05~0.5 part in sterilant

0. 2~0.8 part of heatproof toughener.

Above-mentioned linking agent adopts inorganic borate crosslinker.

Above-mentioned tensio-active agent is for being used for reducing hydro carbons emulsifying agent, alkyl sulfonates emulsifying agent, the alkylsurfuric acid salt emulsifying agent of the water and the IT of oil in water.

Above-mentioned clay stabilizer adopts the quaternary ammonium salt type.

The clay stabilizer of above-mentioned quaternary ammonium salt type adopts with trimethylammonium tertiary amine and hydrochloride and the synthetic trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer that generates of epichlorohydrin reaction.

Above-mentioned sterilant adopts dodecyl benzyl dimethyl ammonium chloride or RH-893.

Above-mentioned heatproof toughener adopts organic bases.

Above-mentioned heatproof toughener adopts 1% pH value of water solution greater than 13 organic bases.

Above-mentioned heatproof toughener adopts Monoethanolamine MEA BASF, trolamine, quadrol.

The of the fracturing fluid preparation method of a kind of ultralow density, its special character is: described preparation method realizes through following steps:

(1), the preparation of solution A: in container, add entry; Under with pump circulation or whisking appliance condition of stirring; Slowly add hydroxypropylguar gum, add tensio-active agent, clay stabilizer, sterilant, heatproof toughener then respectively, continue to circulate or stirred 30 minutes; Make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and linking agent, mix the formation fracturing liquid according to the volume ratio of solution A: linking agent=100:1 ~ 100:2.

Compared with prior art, beneficial effect of the present invention:

1, viscosifying agent hydroxypropyl guar gum concentration is reduced to 0.25~0.35% in the fracturing liquid system.

2,, make the viscosifying agent solution of ultralow density can be used for the pressing crack construction in long celebrating gas field through adopting high performance linking agent.

Description of drawings

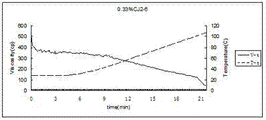

Fig. 1 is a heat resistance graphic representation of the present invention.

Embodiment

Below in conjunction with accompanying drawing and embodiment the present invention is elaborated.

The present invention is made up of according to weight part following material:

93.35~97.4 parts in water

0.25~0.35 part of hydroxypropylguar gum

1.0~2.0 parts of linking agents

0.40~2.0 part in tensio-active agent

0.20~1.0 part of clay stabilizer

0.05~0.5 part in sterilant

0. 2~0.8 part of heatproof toughener

Above-mentioned linking agent adopts inorganic borate crosslinker.

Above-mentioned tensio-active agent is for being used for reducing hydro carbons emulsifying agent, alkyl sulfonates emulsifying agent, the alkylsurfuric acid salt emulsifying agent of the water and the IT of oil in water.

Above-mentioned clay stabilizer adopts the quaternary ammonium salt type,

The clay stabilizer of above-mentioned quaternary ammonium salt type adopts with trimethylammonium tertiary amine and hydrochloride and the synthetic trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer that generates of epichlorohydrin reaction.

Above-mentioned sterilant adopts dodecyl benzyl dimethyl ammonium chloride or RH-893.

Above-mentioned heatproof toughener adopts organic bases.

Above-mentioned heatproof toughener adopts 1% pH value of water solution greater than 13 organic bases.

Above-mentioned heatproof toughener adopts Monoethanolamine MEA BASF, trolamine, quadrol.

Preparing method of the present invention realizes through following steps:

(1), the preparation of solution A: in container, add entry; Add entry, under with pump circulation or whisking appliance condition of stirring, slowly add hydroxypropylguar gum; Add tensio-active agent, clay stabilizer, sterilant, heatproof toughener then respectively; Continue to circulate or stirred 30 minutes, make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and linking agent, mix the formation fracturing liquid according to the volume ratio of solution A: linking agent=100:1 ~ 100:2.

Embodiment 1: join by following consumption and get each material:

93.35 parts in water

0.25 part of hydroxypropylguar gum

1.0 parts of inorganic borate crosslinkers

0.4 part of hydro carbons emulsifying agent

0.2 part of trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer

0.05 part of dodecyl benzyl dimethyl ammonium chloride

0. 2 parts of Monoethanolamine MEA BASFs

The material of above-mentioned batching is prepared through following steps:

(1), the preparation of solution A: in container, add entry; Add entry, under with pump circulation or whisking appliance condition of stirring, slowly add hydroxypropylguar gum; Add hydro carbons emulsifying agent, trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer, dodecyl benzyl dimethyl ammonium chloride, Monoethanolamine MEA BASF then respectively; Continue to circulate or stirred 30 minutes, make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and inorganic borate crosslinker, according to solution A: the volume ratio of inorganic borate crosslinker=100:1 is mixed the formation fracturing liquid.

Embodiment 2: join by following consumption and get each material:

95.375 parts in water

0.3 part of hydroxypropylguar gum

1.5 parts of inorganic borate crosslinkers

1.2 parts of alkyl sulfonates emulsifying agents

0.6 part of trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer

0.275 part of RH-893

0.5 part of trolamine

The material of above-mentioned batching is prepared through following steps:

(1), the preparation of solution A: in container, add entry; Add entry, under with pump circulation or whisking appliance condition of stirring, slowly add hydroxypropylguar gum; Add alkyl sulfonates emulsifying agent, trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer, RH-893, trolamine then respectively; Continue to circulate or stirred 30 minutes, make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and inorganic borate crosslinker, according to solution A: the volume ratio of inorganic borate crosslinker=100:1.5 is mixed the formation fracturing liquid.

Embodiment 3: join by following consumption and get each material:

97.4 parts in water

0.35 part of hydroxypropylguar gum

2.0 parts of inorganic borate crosslinkers

2.0 parts of alkylsurfuric acid salt emulsifying agents

1.0 parts of trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizers

0.5 part of dodecyl benzyl dimethyl ammonium chloride

0.8 part of quadrol

The material of above-mentioned batching is prepared through following steps:

(1), the preparation of solution A: in container, add entry; Add entry, under with pump circulation or whisking appliance condition of stirring, slowly add hydroxypropylguar gum; Add alkylsurfuric acid salt emulsifying agent, trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer, alkylsurfuric acid salt emulsifying agent, quadrol then respectively; Continue to circulate or stirred 30 minutes, make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and inorganic borate crosslinker, according to solution A: the volume ratio of inorganic borate crosslinker=100:2 is mixed the formation fracturing liquid.

Experimental data:

Following test item detects according to SY-T 5107-2005 " aqueous fracturing fluid method of evaluating performance " examination criteria.

One, base fluid:

According to each material of embodiment 2 proportionings.

Two, TP

Base fluid and linking agent JL-9 carry out the heatproof test according to the crosslinked rear section of 100:1.5, get a part of crosslinked gel and ammonium persulphate again and break its breaking glue solution performance of glue after-filtration survey.

Three, performance

1, heat resistance is referring to Fig. 1.

2, breaking glue solution performance evaluation.

| Project | Surface tension (mN/m) | Anti-swollen ability |

| Breaking glue solution behind the frozen glue | 27.94 | 85.6% |

3, residue content: 155mg/L.

Four, conclusion

Through above test contrast, can find out that the ultralow density fracturing liquid need not to add tensio-active agent etc. and itself possesses the function that reduces surface tension, prevents clay swelling, and is better than conventional guanidine glue temperature tolerance simultaneously.

Claims (10)

1. ultralow density fracturing liquid is characterized in that: be made up of according to weight part following material:

93.35~97.4 parts in water

0.25~0.35 part of hydroxypropylguar gum

1.0~2.0 parts of linking agents

0.40~2.0 part in tensio-active agent

0.20~1.0 part of clay stabilizer

0.05~0.5 part in sterilant

0. 2~0.8 part of heatproof toughener.

2. a kind of ultralow density fracturing liquid according to claim 1, it is characterized in that: described linking agent adopts inorganic borate crosslinker.

3. a kind of ultralow density fracturing liquid according to claim 1 and 2 is characterized in that: described tensio-active agent is for being used for reducing hydro carbons emulsifying agent, alkyl sulfonates emulsifying agent, the alkylsurfuric acid salt emulsifying agent of the water and the IT of oil in water.

4. a kind of ultralow density fracturing liquid according to claim 3 is characterized in that: described clay stabilizer adopts the quaternary ammonium salt type.

5. a kind of ultralow density fracturing liquid according to claim 4 is characterized in that: the clay stabilizer of described quaternary ammonium salt type adopts with trimethylammonium tertiary amine and hydrochloride and the synthetic trimethylammonium hydroxypropyl quaternary ammonium salt clay stabilizer that generates of epichlorohydrin reaction.

6. a kind of ultralow density fracturing liquid according to claim 5 is characterized in that: described sterilant adopts dodecyl benzyl dimethyl ammonium chloride or RH-893.

7. a kind of ultralow density fracturing liquid according to claim 6 is characterized in that: described heatproof toughener adopts organic bases.

8. a kind of ultralow density fracturing liquid according to claim 7 is characterized in that: described heatproof toughener adopts 1% pH value of water solution greater than 13 organic bases.

9. a kind of ultralow density fracturing liquid according to claim 8 is characterized in that: described heatproof toughener adopts Monoethanolamine MEA BASF, trolamine, quadrol.

10. any of the fracturing fluid preparation method of described a kind of ultralow density who requires according to aforesaid right is characterized in that: described preparation method realizes through following steps:

(1), the preparation of solution A: in container, add entry; Under with pump circulation or whisking appliance condition of stirring; Slowly add hydroxypropylguar gum, add tensio-active agent, clay stabilizer, sterilant, heatproof toughener then respectively, continue to circulate or stirred 30 minutes; Make liquid mixing abundant, form solution A;

(2), when pump is annotated solution A, with solution A and linking agent, mix the formation fracturing liquid according to the volume ratio of solution A: linking agent=100:1 ~ 100:2.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110221055 CN102329602A (en) | 2011-08-03 | 2011-08-03 | Ultralow-concentration fracturing fluid and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110221055 CN102329602A (en) | 2011-08-03 | 2011-08-03 | Ultralow-concentration fracturing fluid and preparation method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102329602A true CN102329602A (en) | 2012-01-25 |

Family

ID=45481573

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201110221055 Pending CN102329602A (en) | 2011-08-03 | 2011-08-03 | Ultralow-concentration fracturing fluid and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102329602A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102676148A (en) * | 2012-05-25 | 2012-09-19 | 西南石油大学 | High-density low-friction fracturing fluid |

| CN102757777A (en) * | 2012-06-21 | 2012-10-31 | 中国石油天然气股份有限公司 | Inhibition water-locking type high-temperature-resistant fracturing fluid for fracturing of dense gas reservoir |

| CN104893705A (en) * | 2015-04-09 | 2015-09-09 | 西南石油大学 | Boron cross-linking agent and boron crosslinking fracturing fluid used for high temperature deep well |

| CN105198757A (en) * | 2015-10-15 | 2015-12-30 | 中国石油集团川庆钻探工程有限公司长庆井下技术作业公司 | Small cationic bisquaternary ammonium salt clay stabilizer and preparation method thereof |

| CN105384845A (en) * | 2014-09-05 | 2016-03-09 | 中国石油化工股份有限公司 | Etherification modified sodium alginate and preparation method thereof, water-based jelly fracturing fluid containing etherification modified sodium alginate, and applications of water-based jelly fracturing fluid containing etherification modified sodium alginate |

| CN104046347B (en) * | 2013-03-12 | 2017-03-01 | 中国石油化工股份有限公司 | A kind of hydroxypropyl guar fracturing fluid synergist, preparation method and application |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102102013A (en) * | 2009-12-18 | 2011-06-22 | 中国石油天然气股份有限公司 | Inorganic boron high-temperature time-delay fracturing fluid |

-

2011

- 2011-08-03 CN CN 201110221055 patent/CN102329602A/en active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102102013A (en) * | 2009-12-18 | 2011-06-22 | 中国石油天然气股份有限公司 | Inorganic boron high-temperature time-delay fracturing fluid |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102676148A (en) * | 2012-05-25 | 2012-09-19 | 西南石油大学 | High-density low-friction fracturing fluid |

| CN102757777A (en) * | 2012-06-21 | 2012-10-31 | 中国石油天然气股份有限公司 | Inhibition water-locking type high-temperature-resistant fracturing fluid for fracturing of dense gas reservoir |

| CN102757777B (en) * | 2012-06-21 | 2014-04-02 | 中国石油天然气股份有限公司 | Inhibition water-locking type high-temperature-resistant fracturing fluid for fracturing of dense gas reservoir |

| CN104046347B (en) * | 2013-03-12 | 2017-03-01 | 中国石油化工股份有限公司 | A kind of hydroxypropyl guar fracturing fluid synergist, preparation method and application |

| CN105384845A (en) * | 2014-09-05 | 2016-03-09 | 中国石油化工股份有限公司 | Etherification modified sodium alginate and preparation method thereof, water-based jelly fracturing fluid containing etherification modified sodium alginate, and applications of water-based jelly fracturing fluid containing etherification modified sodium alginate |

| CN104893705A (en) * | 2015-04-09 | 2015-09-09 | 西南石油大学 | Boron cross-linking agent and boron crosslinking fracturing fluid used for high temperature deep well |

| CN104893705B (en) * | 2015-04-09 | 2018-02-16 | 西南石油大学 | A kind of borate crosslinker and the boron crosslinked fracturing fluid for being applied to high temperature deep well for preparing |

| CN105198757A (en) * | 2015-10-15 | 2015-12-30 | 中国石油集团川庆钻探工程有限公司长庆井下技术作业公司 | Small cationic bisquaternary ammonium salt clay stabilizer and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102329602A (en) | Ultralow-concentration fracturing fluid and preparation method thereof | |

| CN109337663A (en) | Low permeability reservoir continuous mixed displacement of reservoir oil type fracturing fluid and its preparation method and application | |

| CN103422840B (en) | Use the flooding method of anions and canons complexed surfactant | |

| CN101812290A (en) | Acid clean fracturing fluid and preparation method thereof | |

| CN103897686B (en) | Clean steering acid liquid system for acidification and preparation method thereof | |

| CN104099077A (en) | High mineralization oil reservoir composite oil displacement agent | |

| CN101362943A (en) | Preparation of novel thermal resistant and shearing resistant clean fracturing fluid thickener by long chain quaternary ammonium salt containing 18-40 carbon number | |

| CN105441058A (en) | High-temperature-resistant low-concentration guar gum weighted fracturing fluid and application thereof | |

| CN105086982B (en) | Multi-component slickwater drag reducer and preparation method thereof | |

| CN104650845A (en) | High-temperature non-crosslinked clean fracturing fluid and preparation method thereof | |

| CN106566521B (en) | Preparation and application of anion clean fracturing fluid and gel breaker thereof | |

| CN106318365A (en) | Reversible physical crosslinking polymer fracturing fluid and preparation method thereof | |

| CN103409123A (en) | Application of glycine betaine surface active agent system in chemical oil displacement | |

| CN102329603B (en) | Low-concentration carboxymethyl fracturing fluid and preparation method thereof | |

| CN107686723A (en) | CO (carbon monoxide)2Response in-situ gel channeling sealing sol and preparation method and application thereof | |

| CN105331348A (en) | Homogeneous-phase microemulsion oil-displacing agent applied to low-permeation oil field and preparation method of homogeneous-phase microemulsion oil-displacing agent | |

| CN108102633A (en) | Viscoelastic acid-based fracturing fluid and preparation method thereof | |

| CN104277818B (en) | Friction-reducing agent of fracturing fluid and its application | |

| CN103436245A (en) | Synthetic polymer fracturing fluid for fracturing | |

| CN108997994B (en) | Foaming agent for oil displacement and channeling prevention in oil field and preparation method thereof | |

| CN106244131A (en) | A kind of fracturing high-temperature microemulsion cleanup additive and preparation method thereof | |

| CN103740355A (en) | High-salinity water-based modified xanthan gum fracturing fluid and preparation method thereof | |

| CN113652222B (en) | Temperature-resistant salt-tolerant anionic surfactant clean fracturing fluid and preparation method thereof | |

| CN108690598A (en) | A kind of shale gas water blanket base fracturing fluid and preparation method thereof | |

| CN104277819B (en) | Shale gas reservoir friction-reducing agent of fracturing fluid and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20120125 |