CN101919088A - 电池隔膜结构 - Google Patents

电池隔膜结构 Download PDFInfo

- Publication number

- CN101919088A CN101919088A CN2008801204668A CN200880120466A CN101919088A CN 101919088 A CN101919088 A CN 101919088A CN 2008801204668 A CN2008801204668 A CN 2008801204668A CN 200880120466 A CN200880120466 A CN 200880120466A CN 101919088 A CN101919088 A CN 101919088A

- Authority

- CN

- China

- Prior art keywords

- composite sheet

- layer

- basic unit

- multilayer composite

- glass mat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/46—Separators, membranes or diaphragms characterised by their combination with electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/06—Lead-acid accumulators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/14—Electrodes for lead-acid accumulators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/411—Organic material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/411—Organic material

- H01M50/414—Synthetic resins, e.g. thermoplastics or thermosetting resins

- H01M50/417—Polyolefins

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/411—Organic material

- H01M50/414—Synthetic resins, e.g. thermoplastics or thermosetting resins

- H01M50/423—Polyamide resins

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/411—Organic material

- H01M50/429—Natural polymers

- H01M50/4295—Natural cotton, cellulose or wood

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/431—Inorganic material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/431—Inorganic material

- H01M50/434—Ceramics

- H01M50/437—Glass

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/44—Fibrous material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/449—Separators, membranes or diaphragms characterised by the material having a layered structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/449—Separators, membranes or diaphragms characterised by the material having a layered structure

- H01M50/451—Separators, membranes or diaphragms characterised by the material having a layered structure comprising layers of only organic material and layers containing inorganic material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/449—Separators, membranes or diaphragms characterised by the material having a layered structure

- H01M50/457—Separators, membranes or diaphragms characterised by the material having a layered structure comprising three or more layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/489—Separators, membranes, diaphragms or spacing elements inside the cells, characterised by their physical properties, e.g. swelling degree, hydrophilicity or shut down properties

- H01M50/491—Porosity

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/155—Including a paper layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/159—Including a nonwoven fabric which is not a scrim

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/172—Coated or impregnated

- Y10T442/174—Including particulate material other than fiber in coating or impregnation

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/184—Nonwoven scrim

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/184—Nonwoven scrim

- Y10T442/197—Including a nonwoven fabric which is not a scrim

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Inorganic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Manufacturing & Machinery (AREA)

- Nanotechnology (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Composite Materials (AREA)

- Cell Separators (AREA)

- Secondary Cells (AREA)

- Laminated Bodies (AREA)

- Primary Cells (AREA)

Abstract

本申请公开了用于铅酸蓄电池中的多层复合片材,其包括a)包括纸或玻璃纤维毡的基层;b)用离散的粘合剂颗粒粘接到所述基层的第一表面的聚合物纳米纤维的层;以及c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述基层相对的表面的稀松布层。本申请还公开了用于铅酸蓄电池的板组件,其包括一个或多个相邻或部分地围封铅板放置的多层复合片材。

Description

相关申请的交叉引用

本申请要求2007年12月11日提交的美国临时专利申请No.61/007082的优先权,其全部内容援引并入本申请。

背景技术

铅酸蓄电池含有铅板,铅板可通过将铅氧化物(PbO)的含水糊剂涂布至铅栅并进而干燥所述铅栅而制备。在某些方法(例如连续铸造方法)中,在干燥所述板时,铅氧化物由电极吸水纸(pasting paper)保持在适当的位置。在其他方法(例如带状铸造(strip casting)方法)中,不需要电极吸水纸。

一旦干燥,所述铅板通过在它们被浸没在6摩尔的硫酸溶液中时向所述板施加电荷来“形成”,得到正极板和负极板。较新的生产方法包括向所述糊剂中加入膨胀剂材料(粉末状的硫酸盐)来生产负极板,因此不需要形成所述板。在任一情况下,在相反极性的板之间插入隔膜,物理地隔离它们。所述隔膜的主要目的是防止由于颗粒跨接在具有相反电荷的板之间导致短路。一旦施加隔膜,将相反的板对放置进电池室的单元(cell)中,加入电解液(稀硫酸),并且附上盖子。所述电极吸水纸(如果存在)通常由于与电解液接触而随时间劣化。

典型的隔膜是玻璃纤维毡。尽管从防止颗粒跨接在极板之间的意义上说,所述毡必须作为屏障,但是其不应过分妨碍极板在溶液中的离子迁移,否则将导致性能降低。后者的性质鼓励使用相对开放的、多孔毡,不过这可能要求所述毡较厚来阻止颗粒跨接。传统的隔膜的总厚度为4mm到6mm(0.157-0.236英寸)。这占据了电池中的另外的体积并排出电解液。由于用于离子交换的硫酸的量较小,这限制了电池在电容和放电速率方面的性能。而且,倾向较小的物理电池尺寸的趋势使得这些大体积的传统的隔膜不理想。

在某些电池中,所述玻璃毡隔膜可被称为“吸收性玻璃隔膜”,其基本上填充了板之间的全部空间,但是其吸收了硫酸电解液使得基本上没有自由流动的酸。这样的电池可被颠倒使用或在其侧面而不必担心酸溢出。吸收性玻璃毡遇到的很多问题与附加的隔膜的问题相同,即,希望使厚度最小化和防止颗粒跨接的目的不一致。

因而,解决铅酸蓄电池的这些或其他电流限制的隔离电池板的方法和装置在商业上是有益的。

发明内容

在一个方面,本发明提供了用于铅酸蓄电池中的多层复合片材。所述片材包括:

a)包括纸或玻璃纤维毡的基层;

b)用离散的粘合剂颗粒粘接到所述基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层与所述基层相背的表面的稀松布层(scrim layer)。

在另一个方面,本发明提供了用于铅酸蓄电池的板组件(plate assembly)。所述板组件包括具有第一和第二相背表面的铅板,所述第一和第二相背表面分别涂敷有包括铅氧化物的第一和第二层,所述第一和第二层分别与第一和第二多层复合片材接触,所述复合片材的每一个包括:

a)纸基层;

b)用离散的粘合剂颗粒粘接到所述纸基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述纸基层相背的表面的稀松布层;

其中所述板的第一和第二层中的每一个层分别在与所述第一和第二多层复合片材的纸基层的第一表面相背的第二表面上与所述第一和第二多层复合片材的纸基层相邻并粘接。

在又一个方面,本发明提供了用于铅酸蓄电池的板组件。所述板组件包括具有第一和第二相背表面的铅板,所述第一和第二相背表面分别涂敷有包括铅氧化物的第一和第二层,所述第一和第二层中至少一个层与多层复合片材接触,所述多层复合片材包括:

a)玻璃纤维毡基层;

b)用离散的粘合剂颗粒粘接到所述玻璃纤维毡基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述玻璃纤维毡基层相背的表面的稀松布层;

其中所述板的第一和第二层中的至少一个层在与所述多层复合片材的玻璃纤维毡基层的第一表面相背的第二表面上与所述多层复合片材的玻璃纤维毡基层相邻。

附图说明

图1a是适合于用作根据本发明的电池隔膜的多层复合片材的示意图;

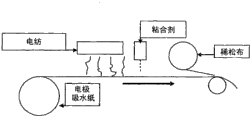

图1b是适合于制造根据本发明的多层复合片材的设备示意图;

图2是适合于制造根据本发明的多层复合片材的纸的显微照片;

图3是适合于制造根据本发明的多层复合片材的纳米纤维层网的显微照片;

图4是图3的纳米纤维层网在较高放大倍数下的显微照片;

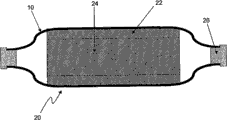

图5是采用根据本发明的多层复合片材的电池板的剖面示意图。

发明详述

现在参考附图描述本发明,其中同样的数字表示同样的特征。附图显示本发明的某些非限制性的实施方案。图1a、1b和5不按比例,并且不用做工程制图。

如图1a中示意性所示,本发明提供了适合于用作电池隔膜的多层复合片材。在某些实施方案中,正如现在将要讨论的,所述复合片材可用作组合的电池电极吸水纸/隔膜。所述复合片材,通常以10显示,包括纤维层12,在纤维层12上存在不导电的聚合物纳米纤维层14,而在层14上存在聚合物稀松布层16。在本实施方案的情况下,所述纤维层12是电极吸水纸。离散的粘合剂颗粒18将纳米纤维层粘合到所述纸层和稀松布层二者,从而将所述三层整合形成所述复合片材。在这个具体的实施方案中,所述粘合剂渗透纳米纤维层使得给定的粘合剂颗粒可同时直接地接触全部三层。然而,某些粘合剂颗粒将所述纸层和纳米纤维层粘合在一起,而其他粘合剂即将所述纳米纤维层粘合到所述稀松布层也是合适的。

纤维层12可以是普通的用于电池吸水目的的任意等级的纸。适合的纸的制造商包括Glatfelter、Crystex、MB Paperles和Purico。所述纸起到电极吸水纸的通常功能,即其使得在板制备期间铅氧化物浆与板良好粘合。

电解液容易渗透纳米纤维层14,但是可能存在于电池中的铅化合物的颗粒基本上不能透过纳米纤维层14。因而,纳米纤维层作为隔膜,防止这样的颗粒在板之间形成跨接并使电池短路。

所述纳米纤维的直径典型地至少为40nm以及更典型地至少为100nm。所述直径典型地至多1000nm,更典型地至多700nm,以及最典型地至多400nm。所述纳米纤维层通常至多5000nm厚,或至多3000nm厚。典型地至少为200nm厚,或至少500nm厚,或至少1000nm厚,以及最典型地平均约2000nm厚。所述层的平均孔直径典型地至多1000nm和更典型地至多500nm。所述孔的平均直径通常至少为100nm。合适的纳米纤维材料典型地是合成聚合物,并且包括耐电解液化学腐蚀的聚合物。这些包括尼龙、聚氯乙烯、聚苯乙烯、聚丙烯、聚乙烯和具有α烯烃的乙烯和/或丙烯的共聚物。

稀松布层16为纳米纤维网提供支持,并且由耐硫酸化学腐蚀的非导电材料制成。所述稀松布典型地具有相当开放的结构并通常具有0.5-2mm(0.02-0.08英寸)的网幅厚度,以提供具有足够长度和物理分隔的板。制成稀松布的材料类似于上述用于制造纳米纤维层的材料。稀松布的一个实例是商品名为Pureflow的轻质无纺聚丙烯。也可以使用例如由尼龙、聚丙烯以及聚乙烯制造的各种筛网。粘合剂颗粒18可由热熔性粘合剂制备,例如Loctite的Hysol SprayPac Polyshot。

使用根据本发明的多层复合片材作为组合的电池电极吸水纸/隔膜的多个优点可被认识到。通过用本发明的较薄的隔膜代替传统的厚的隔膜使电解液的体积增加,这将典型地增加电池容量,并且通过更好地润湿板和增加酸的传输,额外的体积还将典型地改进电池性能。由于纳米纤维网辐的基质较细,电阻将典型地降低,从而可以得到较高的放电速率。由于不再需要制造和安装独立的隔膜,材料和工艺费用将典型地显著地降低。

在另一个实施方案中,多层复合片材10的纤维层12是吸收性玻璃毡。这样的结构可以特别用作由带状铸造制备的板的隔膜,其不要求使用电极吸水纸。如上所述,当电池被侧着或颠倒使用时,所述吸收性玻璃毡吸收硫酸电解液以防止其溢出。但是所述毡可以比在传统应用中的更薄,因为其不需要用作隔膜,隔膜的功能由纳米纤维层14执行。这使得在保持良好性能的同时可以减小电池的物理尺寸。合适的吸收性玻璃毡描述在美国专利No.US5091275和US7144633中,二者均援引并入本申请中。

在某些实施方案中,所述吸收性玻璃毡包含硼硅酸盐玻璃纤维。在某些实施方案中,在电池装配期间,所述玻璃毡可以刚性、压缩状态处理,但是一旦浸入电池板之间的电解液中就膨胀。这样的毡可由玻璃微纤维形成并用包含胶体二氧化硅颗粒和硫酸盐的水性粘合剂混合物浸渍。干燥并压缩所述被浸渍的毡,使得所述盐在所述毡中凝结二氧化硅颗粒,从而防止了当干燥所述毡时二氧化硅颗粒向所述毡的表面迁移。在干燥所述毡时,所述粘合剂残留物仍均匀地分布在所述毡整体上,并将干燥的毡保持在刚性、压缩的状态以使其容易处理。

在某些实施方案中,所述毡被压缩和干燥至其厚度略微小于电极板之间指定的距离,还为纳米纤维层和稀松布层留下了空间。因此,单独的毡可以设置在电池中的每对电极板之间,在装配过程期间没有使用复杂设备用于在板之间压缩所述毡。可选地,如下参考图5的描述,在制备期间所述毡可被定形以使得它们可以被成对地放置在板的相背侧并且粘合在一起。

当电池电解液接触粘合剂时,所述盐溶解进电解液中,留下二氧化硅颗粒。这些具有高的表面积和合适的表面化学性质,便于氧在正极和负极之间的传输。当粘合剂盐溶解时,所述毡相对电极板表面膨胀来填充电极板间的空间。

多层复合片材的制造

所述复合片材可由多种方法制备,并且用于一种示例性方法的合适的设备示意性图示在图1b中,下面将参考使用纸作为纤维层12的方法描述该方法,但是如果代替使用吸收性玻璃毡,可以使用类似的方法。初始步骤涉及在电池电极吸水纸上电纺纳米纤维的聚合物层。随后,将离散的耐化学腐蚀的粘合剂(例如热溶性粘合剂,尽管可以使用其它的粘合剂)的小滴沉积在纳米纤维的表面上。这可由气力喷雾机完成,其导致沉积粘合剂的极小的离散小滴而不是均匀的膜。通过避免粘合剂的均匀膜,通过所述纳米纤维和附着的稀松布,保持了良好的渗透性。最后,将所述稀松布施用在沉积的粘合剂上。这类似于层叠成型,因为所述稀松布可通过直接地卷过移动的纸的网幅/纳米纤维组件而施用并将最终复合片材卷起。完成的卷(rolls)进而根据所需的尺寸切开。

使用多层复合片材的电池板

参考图5,其描绘了用20指代的电池板,其包括根据本发明的作为组合的电极吸水纸/隔膜的多层复合片材10。所述电极吸水纸/隔膜10首先施用到铅板(典型地栅)24的两侧,铅板先前已涂敷了含水铅氧化物糊22,纸侧接触所述铅氧化物。从而在板的整个制造过程中,将所述糊支持在栅24。在板的四个侧边中的三个上,所述电极吸水纸/隔膜复合片材膨胀越过栅的边缘,以使得它们能够密封在一起,来产生围绕板的三个侧边的统一的外壳。这可使用机械密封机、热密封机或热熔密封机使用另外的粘合剂26来接合两个复合片材的外边缘来完成。所述粘合剂可以是任意耐酸类型的,以及典型地为例如用来结合层的热熔性粘合剂。得到封闭的、物理上分离的在三个侧边上围绕着板的外壳,第四侧开口以使电连接器与板连接。在形成工艺之前,将所述板晒干(cure)(干燥)。形成之后,所述板(电极)交替具有相反电荷并被放置进电池壳。不需要传统的隔膜,因为所述板现在由稀松布和纳米纤维层组成的物理隔离复合体覆盖。然后加入稀硫酸并密封电池。在电解液中,所述电极吸水纸将随着时间劣化,但是耐化学腐蚀纳米纤维层和稀松布将保持不变并继续防止短路,同时仍然提供非常高的离子交换。类似地,在纤维层12是吸收性玻璃毡而不是纸的情况下,所述纳米纤维层14用作隔膜防止颗粒跨接。在这种情况下,通过将复合片材粘合在一起制备的结构可仅仅滑过已涂糊剂并干燥的板而制备,而不使用复合物作为电极吸水纸用于涂敷铅氧化物。

当用作组合的电池电极吸水纸/隔膜时,根据本发明的多层复合片材提供了多个优势。通过组合聚合物纳米纤维网和具有电极吸水纸的稀松布,在电池板的制造期间,可以加入能够物理分隔所述板来防止颗粒跨接的可渗透屏蔽(permeable shield)。这消除了在生产电池时在板之间安装隔膜的隔离步骤。所述电纺网具有密度低、相对于质量表面积大、孔隙体积高和孔隙尺寸小的优点。所述稀松布为复合片材提供了强度但相对较薄。由于不需要独立的隔膜,电池体积增加,因此提供了更多的电解液和相当的较高的容量和放电速率。这较大的体积还使电池整体尺寸减小,而不牺牲容量或蓄存势能。

尽管参考具体的实施方案在此描述了本发明,但本发明不限于所示的细节。相反,在不背离本发明的情况下,在权利要求的范围和相当的范围内可以进行多种改变。

Claims (15)

1.用于铅酸蓄电池中的多层复合片材,其包含:

a)包含纸或玻璃纤维毡的基层;

b)用离散的粘合剂颗粒粘接到所述基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述基层相背的表面的稀松布层。

2.根据权利要求1所述的复合片材,其中所述纳米纤维的直径在40nm到1000nm的范围内。

3.根据权利要求1或2所述的复合片材,其中所述纳米纤维的直径在100nm到400nm的范围内。

4.根据前述权利要求任一项所述的复合片材,其中所述聚合物纳米纤维的层的平均厚度在200nm到2000nm的范围内。

5.根据前述权利要求任一项所述的复合片材,其中所述聚合物纳米纤维的层的平均厚度在800nm到2000nm的范围内。

6.根据前述权利要求任一项所述的复合片材,其中所述聚合物纳米纤维的层的平均孔隙直径在100nm到500nm的范围内。

7.根据前述权利要求任一项所述的复合片材,其中所述基层包含纸。

8.根据前述权利要求任一项所述的复合片材,其中b)和c)中的每一种粘合剂颗粒是热熔性粘合剂颗粒。

9.根据权利要求1-6和8中任一项所述的复合片材,其中所述基层包含玻璃纤维毡。

10.根据权利要求9所述的复合片材,其中所述玻璃纤维毡包含硼硅酸盐玻璃纤维。

11.根据权利要求9或10所述的复合片材,其中所述玻璃纤维毡包含分散在其中的硫酸盐和胶体二氧化硅。

12.根据权利要求9-11任一项所述的复合片材,其中所述玻璃纤维毡是压缩的毡,在浸入电池电解液之后厚度能膨胀。

13.用于铅酸蓄电池中的板组件,其包含具有第一和第二相背表面的铅板,所述第一和第二相背表面分别涂敷有包含铅氧化物的第一和第二层,所述第一和第二层分别与第一和第二多层复合片材接触,所述复合片材的每一个包含:

a)纸基层;

b)用离散的粘合剂颗粒粘接到所述纸基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述纸基层相背的表面的稀松布层;

其中所述板的第一和第二层中的每一个层分别在与所述第一和第二多层复合片材的纸基层的第一表面相背的第二表面上与所述第一和第二多层复合片材的纸基层相邻并粘接,并且其中所述第一和第二多层复合片材粘合在一起从而在三侧上围封所述铅板。

14.用于铅酸蓄电池中的板组件,其包含具有第一和第二相背表面的铅板,所述第一和第二相背表面分别涂敷有包含铅氧化物的第一和第二层,所述第一和第二层中至少一个层与多层复合片材接触,所述多层复合片材包含:

a)玻璃纤维毡基层;

b)用离散的粘合剂颗粒粘接到所述玻璃纤维毡基层的第一表面的聚合物纳米纤维的层;以及

c)用离散的粘合剂颗粒粘接到所述纳米纤维的层的与所述玻璃纤维毡基层相背的表面的稀松布层;

其中所述板的第一和第二层中的至少一个层在与所述多层复合片材的玻璃纤维毡基层的第一表面相背的第二表面上与所述多层复合片材的玻璃纤维毡基层相邻。

15.根据权利要求14所述的板组件,其中所述第一和第二层分别接触第一和第二多层复合片材;

其中所述板的第一和第二层中的每一个层分别在与所述第一和第二多层复合片材的玻璃纤维毡基层的第一表面相背的第二表面上与所述第一和第二多层复合片材的玻璃纤维毡基层相邻,并且其中所述第一和第二多层复合片材粘合在一起从而在三侧上围封所述铅板。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US708207P | 2007-12-11 | 2007-12-11 | |

| US61/007,082 | 2007-12-11 | ||

| PCT/US2008/086159 WO2009076401A1 (en) | 2007-12-11 | 2008-12-10 | Batter separator structures |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101919088A true CN101919088A (zh) | 2010-12-15 |

| CN101919088B CN101919088B (zh) | 2013-06-12 |

Family

ID=40626542

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2008801204668A Expired - Fee Related CN101919088B (zh) | 2007-12-11 | 2008-12-10 | 电池隔膜结构 |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US7981818B2 (zh) |

| EP (1) | EP2235767B1 (zh) |

| JP (1) | JP5341911B2 (zh) |

| KR (1) | KR20100096232A (zh) |

| CN (1) | CN101919088B (zh) |

| AT (1) | ATE519240T1 (zh) |

| AU (1) | AU2008335203A1 (zh) |

| CA (1) | CA2709285A1 (zh) |

| EA (1) | EA016283B1 (zh) |

| ES (1) | ES2370608T3 (zh) |

| IL (1) | IL206231A0 (zh) |

| TN (1) | TN2010000259A1 (zh) |

| UA (1) | UA97720C2 (zh) |

| WO (1) | WO2009076401A1 (zh) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103534864A (zh) * | 2011-05-13 | 2014-01-22 | 新神户电机株式会社 | 铅蓄电池 |

| CN103563126A (zh) * | 2011-06-20 | 2014-02-05 | 格拉特菲尔特盖恩斯巴赫股份有限公司 | 用于铅酸电池的多功能网 |

| CN103806329A (zh) * | 2014-02-17 | 2014-05-21 | 中材科技股份有限公司 | 一种高性能涂板纸及其制备方法 |

| CN111370719A (zh) * | 2020-03-19 | 2020-07-03 | 辽宁科京新材料科技有限公司 | 一种液流电池用高导电双极板及其连续化加工装置和方法 |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7892993B2 (en) | 2003-06-19 | 2011-02-22 | Eastman Chemical Company | Water-dispersible and multicomponent fibers from sulfopolyesters |

| US20040260034A1 (en) | 2003-06-19 | 2004-12-23 | Haile William Alston | Water-dispersible fibers and fibrous articles |

| US8513147B2 (en) | 2003-06-19 | 2013-08-20 | Eastman Chemical Company | Nonwovens produced from multicomponent fibers |

| US9525177B2 (en) | 2008-11-18 | 2016-12-20 | Johnson Controls Technology Company | Electrical power storage devices |

| DE102008062765A1 (de) | 2008-12-18 | 2010-07-01 | Vb Autobatterie Gmbh & Co. Kgaa | Textiles flächiges Material für eine Batterieelektrode |

| CN105355863B (zh) | 2009-02-26 | 2019-04-02 | 约翰逊控制技术公司 | 电池电极及其制造方法 |

| US8512519B2 (en) | 2009-04-24 | 2013-08-20 | Eastman Chemical Company | Sulfopolyesters for paper strength and process |

| US9118065B2 (en) | 2010-05-27 | 2015-08-25 | Johns Manville | Lead-oxide battery plate with nonwoven glass mat |

| US20120183861A1 (en) | 2010-10-21 | 2012-07-19 | Eastman Chemical Company | Sulfopolyester binders |

| JP2012178320A (ja) * | 2011-02-28 | 2012-09-13 | Itm Co Ltd | 多孔質シート |

| US9666848B2 (en) | 2011-05-20 | 2017-05-30 | Dreamweaver International, Inc. | Single-layer lithium ion battery separator |

| US8906200B2 (en) | 2012-01-31 | 2014-12-09 | Eastman Chemical Company | Processes to produce short cut microfibers |

| WO2013158484A1 (en) | 2012-04-18 | 2013-10-24 | King Abdullah University Of Science And Technology | Electrode separator |

| JP2013245428A (ja) * | 2012-05-29 | 2013-12-09 | Shinshu Univ | セパレーター、セパレーター製造方法及びセパレーター製造装置 |

| WO2014039509A2 (en) | 2012-09-04 | 2014-03-13 | Ocv Intellectual Capital, Llc | Dispersion of carbon enhanced reinforcement fibers in aqueous or non-aqueous media |

| US10700326B2 (en) | 2012-11-14 | 2020-06-30 | Dreamweaver International, Inc. | Single-layer lithium ion battery separators exhibiting low shrinkage rates at high temperatures |

| CN104871343B (zh) | 2012-12-12 | 2018-06-15 | 日本电气株式会社 | 隔膜、电极元件、电能存储装置和用于制造隔膜的方法 |

| US20140248524A1 (en) * | 2013-03-01 | 2014-09-04 | Honeywell International Inc. | Batteries and methods of manufacturing batteries |

| WO2014138509A1 (en) * | 2013-03-07 | 2014-09-12 | Daramic, Llc | Laminated oxidation protected separator |

| US10607790B2 (en) | 2013-03-15 | 2020-03-31 | Dreamweaver International, Inc. | Direct electrolyte gelling via battery separator composition and structure |

| US20140299268A1 (en) * | 2013-04-09 | 2014-10-09 | The Boeing Company | Thermally Curable Bonding Film Adhesive with Uniform Thickness |

| US9303357B2 (en) | 2013-04-19 | 2016-04-05 | Eastman Chemical Company | Paper and nonwoven articles comprising synthetic microfiber binders |

| US9605126B2 (en) | 2013-12-17 | 2017-03-28 | Eastman Chemical Company | Ultrafiltration process for the recovery of concentrated sulfopolyester dispersion |

| US9598802B2 (en) | 2013-12-17 | 2017-03-21 | Eastman Chemical Company | Ultrafiltration process for producing a sulfopolyester concentrate |

| US9293748B1 (en) | 2014-09-15 | 2016-03-22 | Hollingsworth & Vose Company | Multi-region battery separators |

| EP3259790A4 (en) * | 2015-02-19 | 2019-01-16 | Hollingsworth & Vose Company | BATTERY SEPARATORS COMPRISING CHEMICAL ADDITIVES AND / OR OTHER CONSTITUENTS |

| US9786885B2 (en) | 2015-04-10 | 2017-10-10 | Hollingsworth & Vose Company | Battery separators comprising inorganic particles |

| WO2018147866A1 (en) * | 2017-02-10 | 2018-08-16 | Daramic, Llc | Improved separators with fibrous mat, lead acid batteries, and methods and systems associated therewith |

| KR20230156454A (ko) * | 2017-03-18 | 2023-11-14 | 다라믹 엘엘씨 | 납축 전지를 위한 개선된 복합재 층 또는 분리판 |

| KR102103307B1 (ko) * | 2018-10-22 | 2020-04-23 | 주식회사 한국아트라스비엑스 | 컨테이너 포메이션 공정에서의 콜로이다 실리카가 포함된 전해액을 적용한 agm 배터리 제조 방법 및 agm 배터리 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4137377A (en) * | 1977-10-19 | 1979-01-30 | The Gates Rubber Company | Maintenance-free lead-acid cell |

| CN1229527A (zh) * | 1995-09-20 | 1999-09-22 | 霍林斯沃及沃斯公司 | 用于电池的填充玻璃纤维的隔板及其制造方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5590055A (en) | 1978-12-28 | 1980-07-08 | Japan Storage Battery Co Ltd | Lead storage battery |

| US4606982A (en) | 1985-05-09 | 1986-08-19 | Gates Energy Products, Inc. | Sealed lead-acid cell and method |

| US5091275A (en) * | 1990-04-25 | 1992-02-25 | Evanite Fiber Corporation | Glass fiber separator and method of making |

| JPH06325745A (ja) * | 1993-05-14 | 1994-11-25 | Nippon Sheet Glass Co Ltd | 液式鉛蓄電池用セパレータ |

| JP2001035470A (ja) * | 1999-07-26 | 2001-02-09 | Nippon Muki Co Ltd | 蓄電池用セパレータ |

| JP2003036831A (ja) * | 2001-07-23 | 2003-02-07 | Furukawa Battery Co Ltd:The | ゲル状電解液をそなえたシール形鉛蓄電池 |

| US6703161B2 (en) * | 2001-09-20 | 2004-03-09 | Daramic, Inc. | Multilayer separator for lead-acid batteries |

| US7144633B2 (en) | 2002-07-29 | 2006-12-05 | Evanite Fiber Corporation | Glass compositions |

| JP4593566B2 (ja) * | 2003-06-17 | 2010-12-08 | ナノフィル カンパニー リミテッド | 電気化学素子用複合膜、その製造方法及びこれを備えた電気化学素子 |

| JP5032002B2 (ja) * | 2004-06-17 | 2012-09-26 | 株式会社クラレ | 電池用セパレータ及びアルカリ電池 |

| US20080014506A1 (en) * | 2006-04-19 | 2008-01-17 | Nippon Sheet Glass Company, Limited | Separator for lead-acid battery, pasting paper for lead-acid battery, plate for lead-acid battery and lead-acid battery |

| US20080070463A1 (en) * | 2006-09-20 | 2008-03-20 | Pankaj Arora | Nanowebs |

-

2008

- 2008-12-10 EP EP08859408A patent/EP2235767B1/en not_active Not-in-force

- 2008-12-10 ES ES08859408T patent/ES2370608T3/es active Active

- 2008-12-10 KR KR1020107015030A patent/KR20100096232A/ko not_active Application Discontinuation

- 2008-12-10 WO PCT/US2008/086159 patent/WO2009076401A1/en active Application Filing

- 2008-12-10 US US12/331,820 patent/US7981818B2/en not_active Expired - Fee Related

- 2008-12-10 JP JP2010538110A patent/JP5341911B2/ja not_active Expired - Fee Related

- 2008-12-10 CN CN2008801204668A patent/CN101919088B/zh not_active Expired - Fee Related

- 2008-12-10 AU AU2008335203A patent/AU2008335203A1/en not_active Abandoned

- 2008-12-10 EA EA201070727A patent/EA016283B1/ru not_active IP Right Cessation

- 2008-12-10 UA UAA201008632A patent/UA97720C2/ru unknown

- 2008-12-10 AT AT08859408T patent/ATE519240T1/de not_active IP Right Cessation

- 2008-12-10 CA CA2709285A patent/CA2709285A1/en not_active Abandoned

-

2010

- 2010-06-04 TN TN2010000259A patent/TN2010000259A1/fr unknown

- 2010-06-07 IL IL206231A patent/IL206231A0/en unknown

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4137377A (en) * | 1977-10-19 | 1979-01-30 | The Gates Rubber Company | Maintenance-free lead-acid cell |

| CN1229527A (zh) * | 1995-09-20 | 1999-09-22 | 霍林斯沃及沃斯公司 | 用于电池的填充玻璃纤维的隔板及其制造方法 |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103534864A (zh) * | 2011-05-13 | 2014-01-22 | 新神户电机株式会社 | 铅蓄电池 |

| US9735409B2 (en) | 2011-05-13 | 2017-08-15 | Hitachi Chemical Company, Ltd. | Lead acid battery |

| CN103563126A (zh) * | 2011-06-20 | 2014-02-05 | 格拉特菲尔特盖恩斯巴赫股份有限公司 | 用于铅酸电池的多功能网 |

| CN109742301A (zh) * | 2011-06-20 | 2019-05-10 | 格拉特菲尔特盖恩斯巴赫股份有限公司 | 用于铅酸电池的多功能网 |

| CN109742301B (zh) * | 2011-06-20 | 2021-12-21 | 格拉特菲尔特盖恩斯巴赫股份有限公司 | 用于铅酸电池的多功能网 |

| CN103806329A (zh) * | 2014-02-17 | 2014-05-21 | 中材科技股份有限公司 | 一种高性能涂板纸及其制备方法 |

| CN103806329B (zh) * | 2014-02-17 | 2016-03-02 | 中材科技股份有限公司 | 一种高性能涂板纸及其制备方法 |

| CN111370719A (zh) * | 2020-03-19 | 2020-07-03 | 辽宁科京新材料科技有限公司 | 一种液流电池用高导电双极板及其连续化加工装置和方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2008335203A1 (en) | 2009-06-18 |

| EA016283B1 (ru) | 2012-03-30 |

| JP5341911B2 (ja) | 2013-11-13 |

| EP2235767A1 (en) | 2010-10-06 |

| EP2235767B1 (en) | 2011-08-03 |

| ES2370608T3 (es) | 2011-12-20 |

| WO2009076401A1 (en) | 2009-06-18 |

| TN2010000259A1 (en) | 2011-11-11 |

| UA97720C2 (ru) | 2012-03-12 |

| KR20100096232A (ko) | 2010-09-01 |

| JP2011507191A (ja) | 2011-03-03 |

| EA201070727A1 (ru) | 2010-12-30 |

| US20090148760A1 (en) | 2009-06-11 |

| CN101919088B (zh) | 2013-06-12 |

| US7981818B2 (en) | 2011-07-19 |

| IL206231A0 (en) | 2010-12-30 |

| CA2709285A1 (en) | 2009-06-18 |

| ATE519240T1 (de) | 2011-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101919088B (zh) | 电池隔膜结构 | |

| EP2721664B1 (en) | Multifunctional web for use in a lead-acid battery | |

| PL183536B1 (pl) | Sposób wytwarzania przekładek warstwowych z włókien szklanych do baterii, zwłaszcza ołowiowo-kwasowych, oraz przekładka warstwowa z włókien szklanych do baterii, zwłaszcza ołowiowo-kwasowych | |

| US10283746B2 (en) | Small pore size nonwoven mat with hydrophilic/acid resistant filler used in lead acid batteries and applications therefor | |

| US20100203395A1 (en) | Non-woven gauntlets for batteries | |

| CN201122621Y (zh) | 用于锌镍碱性蓄电池的复合隔膜 | |

| JP2021163759A (ja) | 固体電池用シートの製造方法及びそれに使用される積層体の製造方法 | |

| CN102210044A (zh) | 用于电池电极的层状织物材料 | |

| KR20140055064A (ko) | 바인더 필름을 포함하는 전극조립체 및 그의 제조방법 | |

| EP3916879A1 (en) | Multilayer non-woven mat for lead acid batteries and applications therefor | |

| US6569560B1 (en) | Battery with encapsulated electrode plates | |

| JPS61281454A (ja) | 電池用セパレ−タ | |

| CN218039459U (zh) | 锂电池及车辆 | |

| KR20110023394A (ko) | 배터리 분리막 활물질 지지체용 중공형 부직포 및 그 제조 방법 | |

| JP4968983B2 (ja) | 密閉型鉛蓄電池用セパレータ | |

| CN220774651U (zh) | 一种吸液性能好的钠离子电池隔膜结构 | |

| CN112271407B (zh) | 一种高亲水性的锂电池隔膜及其制备方法 | |

| CN102560901B (zh) | 电池活性物质支架用纺粘无纺布及其制造方法 | |

| USRE16548E (en) | of bakewell | |

| KR100732801B1 (ko) | 기계적으로 안정적인 기공성 초박 부직포, 상기 부직포의제조 방법 및 용도 | |

| CN112259918A (zh) | 一种复合式隔板及电池 | |

| CN116565334A (zh) | 一种多层复合吸液材料及其制备方法和应用 | |

| JPS5821775B2 (ja) | デンチヨウフシヨクフセパレ−タ− | |

| JPH031457A (ja) | 蓄電池のセル要素複合体並びにニッケル・亜鉛密閉蓄電池 | |

| JP2001283815A (ja) | 二次電池用基材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20130612 Termination date: 20141210 |

|

| EXPY | Termination of patent right or utility model |