How to find defects in SMT electronics manufacturing

- 1. www.creativeelectron.com LED, BGA, and QFN Assembly and Inspection Defect Inspection Examples Copyright © 2014 Creative Electron NOT FOR DISTRIBUTION

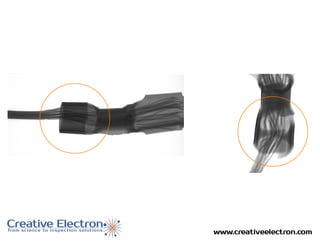

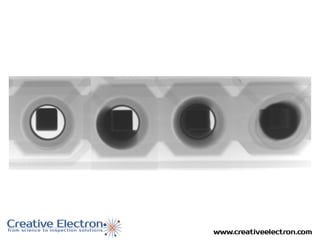

- 2. www.creativeelectron.com Where Are Defects Introduced? Counterfeit* Components

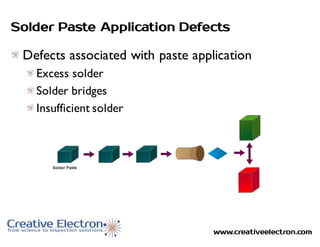

- 3. www.creativeelectron.com Defects associated with paste application Excess solder Solder bridges Insufficient solder Solder Paste Application Defects

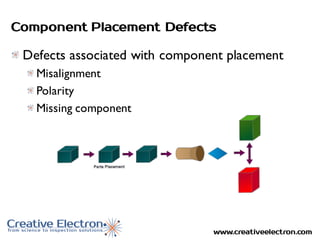

- 4. www.creativeelectron.com Component Placement Defects Defects associated with component placement Misalignment Polarity Missing component

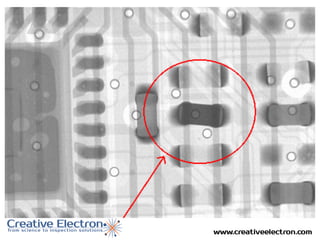

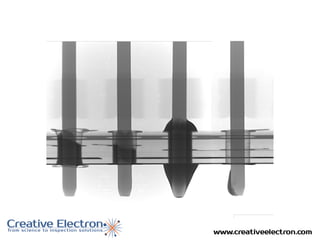

- 5. www.creativeelectron.com Reflow Oven Defects Defects associated with the reflow profile Voiding Bridging Solder balls Excess solder Insufficient solder

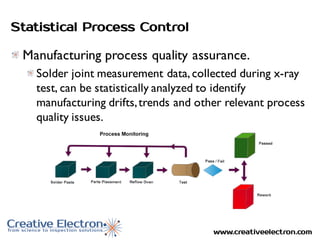

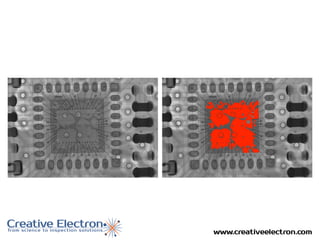

- 6. www.creativeelectron.com Statistical Process Control Manufacturing process quality assurance. Solder joint measurement data,collected during x-ray test, can be statistically analyzed to identify manufacturing drifts,trends and other relevant process quality issues.

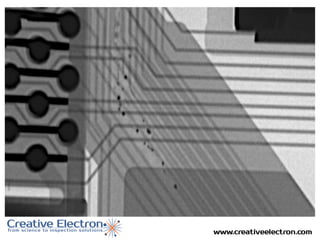

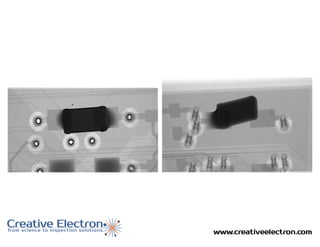

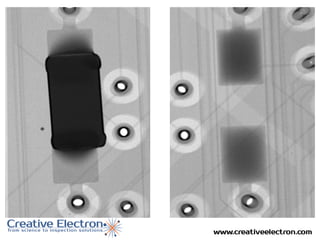

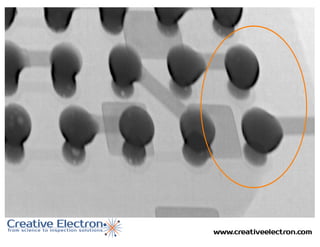

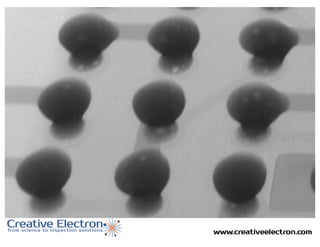

- 18. www.creativeelectron.com BGA Head In Pillow Visual Inspection

- 24. www.creativeelectron.com Thanks for your time!