soft drink

soft drink, any of a class of nonalcoholic beverages, usually but not necessarily carbonated, normally containing a natural or artificial sweetening agent, edible acids, natural or artificial flavours, and sometimes juice. Natural flavours are derived from fruits, nuts, berries, roots, herbs, and other plant sources. Coffee, tea, milk, cocoa, and undiluted fruit and vegetable juices are not considered soft drinks.

The term soft drink was originated to distinguish the flavoured drinks from hard liquor, or distilled spirits. Soft drinks were recommended as a substitute in the effort to change the hard-drinking habits of early Americans. Indeed, health concerns of modern consumers led to new categories of soft drinks emphasizing low calorie count, low sodium content, no caffeine, and “all natural” ingredients.

There are many specialty soft drinks. Mineral waters are very popular in Europe and Latin America. Kava, made from roots of a bushy shrub, Piper methysticum, is consumed by the people of Fiji and other Pacific islands. In Cuba people enjoy a carbonated cane juice; its flavour comes from unrefined syrup. In tropical areas, where diets frequently lack sufficient protein, soft drinks containing soybean flour have been marketed. In Egypt carob (locust bean) extract is used. In Brazil a soft drink is made using maté as a base. The whey obtained from making buffalo cheese is carbonated and consumed as a soft drink in North Africa. Some eastern Europeans enjoy a drink prepared from fermented stale bread. Honey and orange juice go into a popular drink of Israel.

History of soft drinks

The first marketed soft drinks appeared in the 17th century as a mixture of water and lemon juice sweetened with honey. In 1676 the Compagnie de Limonadiers was formed in Paris and granted a monopoly for the sale of its products. Vendors carried tanks on their backs from which they dispensed cups of lemonade.

Carbonated beverages and waters were developed from European attempts in the 17th century to imitate the popular and naturally effervescent waters of famous springs, with primary interest in their reputed therapeutic values. The effervescent feature of the waters was recognized early as most important. Flemish scientist Jan Baptista van Helmont first used the term gas in his reference to the carbon dioxide content. French physician Gabriel Venel referred to aerated water, confusing the gas with ordinary air. British scientist Joseph Black named the gaseous constituent fixed air.

Robert Boyle, an Anglo-Irish philosopher and scientist who helped found modern chemistry, published his Short Memoirs for the Natural Experimental History of Mineral Waters in 1685. It included sections on examining mineral springs, on the properties of the water, on its effects upon the human body, and, lastly, “of the imitation of natural medicinal waters by chymical and other artificial wayes.”

Numerous reports of experiments and investigations were included in the Philosophical Transactions of the Royal Society of London in the late 1700s, including the studies of Stephen Hales, Joseph Black, David Macbride, William Brownrigg, Henry Cavendish, and Thomas Lane.

English clergyman and scientist Joseph Priestley is nicknamed “the father of the soft drinks industry” for his experiments on gas obtained from the fermenting vats of a brewery. In 1772 he demonstrated a small carbonating apparatus to the College of Physicians in London, suggesting that, with the aid of a pump, water might be more highly impregnated with fixed air. French chemist Antoine-Laurent Lavoisier made the same suggestion in 1773.

To Thomas Henry, an apothecary in Manchester, England, is attributed the first production of carbonated water, which he made in 12-gallon barrels using an apparatus based on Priestley’s design. Swiss jeweler Jacob Schweppe read the papers of Priestley and Lavoisier and determined to make a similar device. By 1794 he was selling his highly carbonated artificial mineral waters to his friends in Geneva; later he started a business in London.

At first, bottled waters were used medicinally, as evidenced in a letter written by English industrialist Matthew Boulton to philosopher Erasmus Darwin in 1794:

J. Schweppe prepares his mineral waters of three sorts. No. 1 is for common drinking with your dinner. No. 2 is for nephritick patients and No. 3 contains the most alkali given only in more violent cases.

By about 1820, improvements in manufacturing processes allowed a much greater output, and bottled water became popular. Mineral salts and flavours were added—ginger about 1820, lemon in the 1830s, tonic in 1858. In 1886 John Pemberton, a pharmacist in Atlanta, Georgia, invented Coca-Cola, the first cola drink.

Production

All ingredients used in soft drinks must be of high purity and food grade to obtain a quality beverage. These include the water, carbon dioxide, sugar, acids, juices, and flavours.

Water

Although water is most often taken from a safe municipal supply, it usually is processed further to ensure uniformity of the finished product; the amount of impurities in the municipal supply may vary from time to time. In some bottling plants the water-treatment equipment may simply consist of a sand filter to remove minute solid matter and activated carbon purifier to remove colour, chlorine, and other tastes or odours. In most plants, however, water is treated by a process known as superchlorination and coagulation. There the water is exposed for two hours to a high concentration of chlorine and to a flocculant, which removes organisms such as algae and bacteria; it then passes through a sand filter and activated carbon.

Carbon dioxide and carbonation

Carbon dioxide gas gives the beverage its sparkle and tangy taste and prevents spoilage. It is supplied to the soft drink manufacturer in either solid form (dry ice) or liquid form maintained under approximately 1,200 pounds per square inch (84 kilograms per square centimetre) pressure in heavy steel containers. Lightweight steel containers are used when the liquid carbon dioxide is held under refrigeration. In that case, the internal pressure is about 325 pounds per square inch.

Carbonation (of either the water or the finished beverage mixture) is effected by chilling the liquid and cascading it in thin layers over a series of plates in an enclosure containing carbon dioxide gas under pressure. The amount of gas the water will absorb increases as the pressure is increased and the temperature is decreased.

Flavouring syrup

Flavouring syrup is normally a concentrated solution of a sweetener (sugar or artificial), an acidulant for tartness, flavouring, and a preservative when necessary. The flavouring syrup is made in two steps. First, a “simple syrup” is prepared by making a solution of water and sugar. This simple sugar solution can be treated with carbon and filtered if the sugar quality is poor. All of the other ingredients are then added in a precise order to make up what is called a “finished syrup.”

Finishing

There are two methods for producing a finished product from the flavouring syrup. In the first, the syrup is diluted with water and the product then cooled, carbonated, and bottled. In the second, the maker measures a precise amount of syrup into each bottle, then fills it with carbonated water. In either case, the sugar content (51–60 percent in the syrup) is reduced to 8–13 percent in the finished beverage. Thus, a 12-ounce soft drink may contain more than 40 grams of sugar.

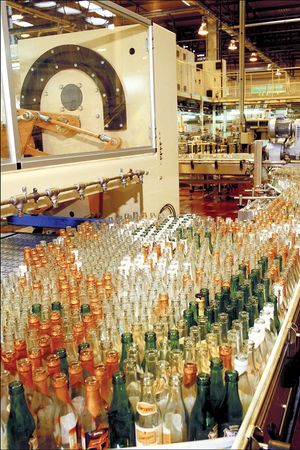

The blending of syrups and mixing with plain or carbonated water, the container washing, and container filling are all done almost entirely by automatic machinery. Returnable bottles are washed in hot alkali solutions for a minimum of five minutes, then rinsed thoroughly. Single-service or “one-trip” containers are generally air-rinsed or rinsed with potable water before filling. Automatic fillers can service hundreds of containers per minute.

Pasteurizing noncarbonated beverages

Noncarbonated beverages require ingredients and techniques similar to those for carbonated beverages. However, since they lack the protection against spoilage afforded by carbonation, these are usually pasteurized, either in bulk, by continuous flash pasteurization prior to filling, or in the bottle.

Powdered soft drinks

These are made by blending the flavouring material with dry acids, gums, artificial colour, etc. If the sweetener has been included, the consumer need only add the proper amount of plain or carbonated water.

Iced soft drinks

The first iced soft drink consisted of a cup of ice covered with a flavoured syrup. Sophisticated dispensing machines now blend measured quantities of syrup with carbonated or plain water to make the finished beverage. To obtain the soft ice, or slush, the machine reduces the beverage temperature to between −5 and −2 °C (22 and 28 °F).

Packaging and vending

Soft drinks are packaged in glass or plastic bottles, tin-free steel, aluminum, or plastic cans, treated cardboard cartons, foil pouches, or in large stainless steel containers.

Vending of soft drinks had its modest beginning with the use of ice coolers in the early 20th century. Nowadays, most drinks are cooled by electric refrigeration for consumption on the premises. Vending machines dispense soft drinks in cups, cans, or bottles, and restaurants, bars, and hotels use dispensing guns to handle large volume. There are two methods of vending soft drinks in cups. In the “pre-mix” system, the finished beverage is prepared by the soft drink manufacturer and filled into five- or 10-gallon stainless steel tanks. The tanks of beverage are attached to the vending machine where the beverage is cooled and dispensed. In the “post-mix” system the vending machine has its own water and carbon dioxide supply. The water is carbonated as required and is mixed with flavoured syrup as it is dispensed into the cup.