WO2024219896A1 - Non-aqueous electrolyte and lithium secondary battery comprising same - Google Patents

Non-aqueous electrolyte and lithium secondary battery comprising same Download PDFInfo

- Publication number

- WO2024219896A1 WO2024219896A1 PCT/KR2024/005354 KR2024005354W WO2024219896A1 WO 2024219896 A1 WO2024219896 A1 WO 2024219896A1 KR 2024005354 W KR2024005354 W KR 2024005354W WO 2024219896 A1 WO2024219896 A1 WO 2024219896A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- chemical formula

- aqueous electrolyte

- carbon atoms

- organic solvent

- Prior art date

Links

- 239000011255 nonaqueous electrolyte Substances 0.000 title claims abstract description 63

- 229910052744 lithium Inorganic materials 0.000 title claims description 43

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 title claims description 39

- 239000000126 substance Substances 0.000 claims abstract description 122

- 239000003960 organic solvent Substances 0.000 claims abstract description 48

- -1 cyclic siloxane compound Chemical class 0.000 claims abstract description 30

- 239000000654 additive Substances 0.000 claims abstract description 20

- 230000000996 additive effect Effects 0.000 claims abstract description 19

- 229910003002 lithium salt Inorganic materials 0.000 claims abstract description 16

- 159000000002 lithium salts Chemical class 0.000 claims abstract description 16

- 125000004432 carbon atom Chemical group C* 0.000 claims description 60

- 150000001875 compounds Chemical class 0.000 claims description 40

- 239000007773 negative electrode material Substances 0.000 claims description 26

- 125000001424 substituent group Chemical group 0.000 claims description 21

- 125000003545 alkoxy group Chemical group 0.000 claims description 18

- 239000002409 silicon-based active material Substances 0.000 claims description 18

- 125000001174 sulfone group Chemical group 0.000 claims description 12

- 125000000217 alkyl group Chemical group 0.000 claims description 11

- 125000004185 ester group Chemical group 0.000 claims description 11

- 229910052731 fluorine Inorganic materials 0.000 claims description 11

- QAOWNCQODCNURD-UHFFFAOYSA-L sulfate group Chemical group S(=O)(=O)([O-])[O-] QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 claims description 11

- 125000001273 sulfonato group Chemical group [O-]S(*)(=O)=O 0.000 claims description 11

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 claims description 10

- 125000002947 alkylene group Chemical group 0.000 claims description 8

- 150000005676 cyclic carbonates Chemical class 0.000 claims description 8

- 125000003342 alkenyl group Chemical group 0.000 claims description 6

- 125000000304 alkynyl group Chemical group 0.000 claims description 6

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical group [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 5

- 229910013870 LiPF 6 Inorganic materials 0.000 claims description 5

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical group OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 claims description 5

- 229910052794 bromium Inorganic materials 0.000 claims description 5

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 claims description 5

- 229910052801 chlorine Inorganic materials 0.000 claims description 5

- 150000002148 esters Chemical class 0.000 claims description 5

- 125000001033 ether group Chemical group 0.000 claims description 5

- 229910052740 iodine Inorganic materials 0.000 claims description 5

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 claims description 5

- ZBKFYXZXZJPWNQ-UHFFFAOYSA-N isothiocyanate group Chemical group [N-]=C=S ZBKFYXZXZJPWNQ-UHFFFAOYSA-N 0.000 claims description 5

- 125000000468 ketone group Chemical group 0.000 claims description 5

- 125000002560 nitrile group Chemical group 0.000 claims description 5

- 125000005373 siloxane group Chemical group [SiH2](O*)* 0.000 claims description 5

- 125000003808 silyl group Chemical group [H][Si]([H])([H])[*] 0.000 claims description 5

- AMXOYNBUYSYVKV-UHFFFAOYSA-M lithium bromide Chemical compound [Li+].[Br-] AMXOYNBUYSYVKV-UHFFFAOYSA-M 0.000 claims description 4

- KWGKDLIKAYFUFQ-UHFFFAOYSA-M lithium chloride Chemical compound [Li+].[Cl-] KWGKDLIKAYFUFQ-UHFFFAOYSA-M 0.000 claims description 4

- 229910013063 LiBF 4 Inorganic materials 0.000 claims description 3

- 229910013684 LiClO 4 Inorganic materials 0.000 claims description 3

- 229910010941 LiFSI Inorganic materials 0.000 claims description 3

- 229910013398 LiN(SO2CF2CF3)2 Inorganic materials 0.000 claims description 3

- ACFSQHQYDZIPRL-UHFFFAOYSA-N lithium;bis(1,1,2,2,2-pentafluoroethylsulfonyl)azanide Chemical compound [Li+].FC(F)(F)C(F)(F)S(=O)(=O)[N-]S(=O)(=O)C(F)(F)C(F)(F)F ACFSQHQYDZIPRL-UHFFFAOYSA-N 0.000 claims description 3

- VDVLPSWVDYJFRW-UHFFFAOYSA-N lithium;bis(fluorosulfonyl)azanide Chemical compound [Li+].FS(=O)(=O)[N-]S(F)(=O)=O VDVLPSWVDYJFRW-UHFFFAOYSA-N 0.000 claims description 3

- 229910010238 LiAlCl 4 Inorganic materials 0.000 claims description 2

- 229910010090 LiAlO 4 Inorganic materials 0.000 claims description 2

- 229910015015 LiAsF 6 Inorganic materials 0.000 claims description 2

- 229910015044 LiB Inorganic materials 0.000 claims description 2

- 229910012513 LiSbF 6 Inorganic materials 0.000 claims description 2

- HSZCZNFXUDYRKD-UHFFFAOYSA-M lithium iodide Inorganic materials [Li+].[I-] HSZCZNFXUDYRKD-UHFFFAOYSA-M 0.000 claims description 2

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 claims 1

- 229910013188 LiBOB Inorganic materials 0.000 claims 1

- 239000011737 fluorine Substances 0.000 claims 1

- 239000006259 organic additive Substances 0.000 claims 1

- 239000010408 film Substances 0.000 description 26

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 23

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 23

- 239000010410 layer Substances 0.000 description 22

- 239000007774 positive electrode material Substances 0.000 description 17

- 229910052723 transition metal Inorganic materials 0.000 description 16

- 239000011230 binding agent Substances 0.000 description 13

- 239000004020 conductor Substances 0.000 description 12

- 238000003860 storage Methods 0.000 description 11

- 239000002905 metal composite material Substances 0.000 description 10

- 239000002904 solvent Substances 0.000 description 10

- SBLRHMKNNHXPHG-UHFFFAOYSA-N 4-fluoro-1,3-dioxolan-2-one Chemical compound FC1COC(=O)O1 SBLRHMKNNHXPHG-UHFFFAOYSA-N 0.000 description 9

- 239000000203 mixture Substances 0.000 description 9

- OIFBSDVPJOWBCH-UHFFFAOYSA-N Diethyl carbonate Chemical compound CCOC(=O)OCC OIFBSDVPJOWBCH-UHFFFAOYSA-N 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 8

- 239000011572 manganese Substances 0.000 description 8

- 229910052759 nickel Inorganic materials 0.000 description 8

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 7

- 229910052782 aluminium Inorganic materials 0.000 description 7

- IGILRSKEFZLPKG-UHFFFAOYSA-M lithium;difluorophosphinate Chemical compound [Li+].[O-]P(F)(F)=O IGILRSKEFZLPKG-UHFFFAOYSA-M 0.000 description 7

- 239000002388 carbon-based active material Substances 0.000 description 6

- 239000003792 electrolyte Substances 0.000 description 6

- 238000005755 formation reaction Methods 0.000 description 6

- 229910002804 graphite Inorganic materials 0.000 description 6

- 239000010439 graphite Substances 0.000 description 6

- 239000002002 slurry Substances 0.000 description 6

- XTHFKEDIFFGKHM-UHFFFAOYSA-N Dimethoxyethane Chemical compound COCCOC XTHFKEDIFFGKHM-UHFFFAOYSA-N 0.000 description 5

- 239000006182 cathode active material Substances 0.000 description 5

- 230000008602 contraction Effects 0.000 description 5

- 239000011267 electrode slurry Substances 0.000 description 5

- 239000000835 fiber Substances 0.000 description 5

- 125000001153 fluoro group Chemical group F* 0.000 description 5

- 230000014759 maintenance of location Effects 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 150000003624 transition metals Chemical class 0.000 description 5

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 4

- 239000005977 Ethylene Substances 0.000 description 4

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 4

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 4

- 239000004372 Polyvinyl alcohol Substances 0.000 description 4

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 239000006229 carbon black Substances 0.000 description 4

- 239000002041 carbon nanotube Substances 0.000 description 4

- 229910021393 carbon nanotube Inorganic materials 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- KPUWHANPEXNPJT-UHFFFAOYSA-N disiloxane Chemical class [SiH3]O[SiH3] KPUWHANPEXNPJT-UHFFFAOYSA-N 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- JBTWLSYIZRCDFO-UHFFFAOYSA-N ethyl methyl carbonate Chemical compound CCOC(=O)OC JBTWLSYIZRCDFO-UHFFFAOYSA-N 0.000 description 4

- 239000004745 nonwoven fabric Substances 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 229920002451 polyvinyl alcohol Polymers 0.000 description 4

- 230000009467 reduction Effects 0.000 description 4

- 239000010936 titanium Substances 0.000 description 4

- 229910052719 titanium Inorganic materials 0.000 description 4

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 3

- 229910014689 LiMnO Inorganic materials 0.000 description 3

- 229910013290 LiNiO 2 Inorganic materials 0.000 description 3

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 229920000459 Nitrile rubber Polymers 0.000 description 3

- 239000002033 PVDF binder Substances 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 229910021383 artificial graphite Inorganic materials 0.000 description 3

- 125000003118 aryl group Chemical group 0.000 description 3

- 229910017052 cobalt Inorganic materials 0.000 description 3

- 239000010941 cobalt Substances 0.000 description 3

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 3

- 239000006258 conductive agent Substances 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000012153 distilled water Substances 0.000 description 3

- 230000006872 improvement Effects 0.000 description 3

- 229910001416 lithium ion Inorganic materials 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910021382 natural graphite Inorganic materials 0.000 description 3

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 3

- 230000009257 reactivity Effects 0.000 description 3

- 238000007086 side reaction Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- DHKHKXVYLBGOIT-UHFFFAOYSA-N 1,1-Diethoxyethane Chemical compound CCOC(C)OCC DHKHKXVYLBGOIT-UHFFFAOYSA-N 0.000 description 2

- VAYTZRYEBVHVLE-UHFFFAOYSA-N 1,3-dioxol-2-one Chemical compound O=C1OC=CO1 VAYTZRYEBVHVLE-UHFFFAOYSA-N 0.000 description 2

- GVNVAWHJIKLAGL-UHFFFAOYSA-N 2-(cyclohexen-1-yl)cyclohexan-1-one Chemical compound O=C1CCCCC1C1=CCCCC1 GVNVAWHJIKLAGL-UHFFFAOYSA-N 0.000 description 2

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 2

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 2

- 101150065749 Churc1 gene Proteins 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- LCGLNKUTAGEVQW-UHFFFAOYSA-N Dimethyl ether Chemical compound COC LCGLNKUTAGEVQW-UHFFFAOYSA-N 0.000 description 2

- 229920002943 EPDM rubber Polymers 0.000 description 2

- 229920002153 Hydroxypropyl cellulose Polymers 0.000 description 2

- 229910003936 Li(Ni0.5Mn0.3Co0.2)O2 Inorganic materials 0.000 description 2

- 229910004406 Li(Ni0.6Mn0.2CO0.2)O2 Inorganic materials 0.000 description 2

- 229910004427 Li(Ni0.7Mn0.15Co0.15)O2 Inorganic materials 0.000 description 2

- 229910004437 Li(Ni0.8Mn0.1Co0.1)O2 Inorganic materials 0.000 description 2

- 229910012851 LiCoO 2 Inorganic materials 0.000 description 2

- 229910015643 LiMn 2 O 4 Inorganic materials 0.000 description 2

- 229910013716 LiNi Inorganic materials 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000002202 Polyethylene glycol Substances 0.000 description 2

- 229920000265 Polyparaphenylene Polymers 0.000 description 2

- 102100038239 Protein Churchill Human genes 0.000 description 2

- 229920002472 Starch Polymers 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 239000006230 acetylene black Substances 0.000 description 2

- 230000004913 activation Effects 0.000 description 2

- 239000011149 active material Substances 0.000 description 2

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical compound [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000004917 carbon fiber Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000006231 channel black Substances 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- 125000000753 cycloalkyl group Chemical group 0.000 description 2

- 238000000354 decomposition reaction Methods 0.000 description 2

- NJLLQSBAHIKGKF-UHFFFAOYSA-N dipotassium dioxido(oxo)titanium Chemical compound [K+].[K+].[O-][Ti]([O-])=O NJLLQSBAHIKGKF-UHFFFAOYSA-N 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- FKRCODPIKNYEAC-UHFFFAOYSA-N ethyl propionate Chemical compound CCOC(=O)CC FKRCODPIKNYEAC-UHFFFAOYSA-N 0.000 description 2

- 125000000816 ethylene group Chemical group [H]C([H])([*:1])C([H])([H])[*:2] 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 229920001973 fluoroelastomer Polymers 0.000 description 2

- 239000006260 foam Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 125000000524 functional group Chemical group 0.000 description 2

- JBFHTYHTHYHCDJ-UHFFFAOYSA-N gamma-caprolactone Chemical compound CCC1CCC(=O)O1 JBFHTYHTHYHCDJ-UHFFFAOYSA-N 0.000 description 2

- GAEKPEKOJKCEMS-UHFFFAOYSA-N gamma-valerolactone Chemical compound CC1CCC(=O)O1 GAEKPEKOJKCEMS-UHFFFAOYSA-N 0.000 description 2

- 125000005843 halogen group Chemical group 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 2

- 239000001863 hydroxypropyl cellulose Substances 0.000 description 2

- 235000010977 hydroxypropyl cellulose Nutrition 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 239000003273 ketjen black Substances 0.000 description 2

- 239000006233 lamp black Substances 0.000 description 2

- VGYDTVNNDKLMHX-UHFFFAOYSA-N lithium;manganese;nickel;oxocobalt Chemical class [Li].[Mn].[Ni].[Co]=O VGYDTVNNDKLMHX-UHFFFAOYSA-N 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- WPBNNNQJVZRUHP-UHFFFAOYSA-L manganese(2+);methyl n-[[2-(methoxycarbonylcarbamothioylamino)phenyl]carbamothioyl]carbamate;n-[2-(sulfidocarbothioylamino)ethyl]carbamodithioate Chemical compound [Mn+2].[S-]C(=S)NCCNC([S-])=S.COC(=O)NC(=S)NC1=CC=CC=C1NC(=S)NC(=O)OC WPBNNNQJVZRUHP-UHFFFAOYSA-L 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 150000002825 nitriles Chemical class 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- SUSQOBVLVYHIEX-UHFFFAOYSA-N phenylacetonitrile Chemical compound N#CCC1=CC=CC=C1 SUSQOBVLVYHIEX-UHFFFAOYSA-N 0.000 description 2

- 229920002401 polyacrylamide Polymers 0.000 description 2

- 229920002239 polyacrylonitrile Polymers 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920001223 polyethylene glycol Polymers 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 229920006254 polymer film Polymers 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 2

- 239000004627 regenerated cellulose Substances 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 239000008107 starch Substances 0.000 description 2

- 235000019698 starch Nutrition 0.000 description 2

- 229920003048 styrene butadiene rubber Polymers 0.000 description 2

- 239000006234 thermal black Substances 0.000 description 2

- 239000010409 thin film Substances 0.000 description 2

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 2

- 229910000314 transition metal oxide Inorganic materials 0.000 description 2

- 229910052720 vanadium Inorganic materials 0.000 description 2

- 239000011787 zinc oxide Substances 0.000 description 2

- ZZXUZKXVROWEIF-UHFFFAOYSA-N 1,2-butylene carbonate Chemical compound CCC1COC(=O)O1 ZZXUZKXVROWEIF-UHFFFAOYSA-N 0.000 description 1

- ZPFAVCIQZKRBGF-UHFFFAOYSA-N 1,3,2-dioxathiolane 2,2-dioxide Chemical compound O=S1(=O)OCCO1 ZPFAVCIQZKRBGF-UHFFFAOYSA-N 0.000 description 1

- FSSPGSAQUIYDCN-UHFFFAOYSA-N 1,3-Propane sultone Chemical compound O=S1(=O)CCCO1 FSSPGSAQUIYDCN-UHFFFAOYSA-N 0.000 description 1

- WNXJIVFYUVYPPR-UHFFFAOYSA-N 1,3-dioxolane Chemical compound C1COCO1 WNXJIVFYUVYPPR-UHFFFAOYSA-N 0.000 description 1

- NVJUHMXYKCUMQA-UHFFFAOYSA-N 1-ethoxypropane Chemical compound CCCOCC NVJUHMXYKCUMQA-UHFFFAOYSA-N 0.000 description 1

- HFZLSTDPRQSZCQ-UHFFFAOYSA-N 1-pyrrolidin-3-ylpyrrolidine Chemical compound C1CCCN1C1CNCC1 HFZLSTDPRQSZCQ-UHFFFAOYSA-N 0.000 description 1

- PQNNUQKDERZMPQ-UHFFFAOYSA-N 2,2-bis(trifluoromethyl)-1,3-dioxolane Chemical compound FC(F)(F)C1(C(F)(F)F)OCCO1 PQNNUQKDERZMPQ-UHFFFAOYSA-N 0.000 description 1

- KTPHYLJFAZNALV-UHFFFAOYSA-N 2,3,4-trifluorobenzonitrile Chemical compound FC1=CC=C(C#N)C(F)=C1F KTPHYLJFAZNALV-UHFFFAOYSA-N 0.000 description 1

- GKPHNZYMLJPYJJ-UHFFFAOYSA-N 2,3-difluorobenzonitrile Chemical compound FC1=CC=CC(C#N)=C1F GKPHNZYMLJPYJJ-UHFFFAOYSA-N 0.000 description 1

- DAVJMKMVLKOQQC-UHFFFAOYSA-N 2-(2-fluorophenyl)acetonitrile Chemical compound FC1=CC=CC=C1CC#N DAVJMKMVLKOQQC-UHFFFAOYSA-N 0.000 description 1

- UHOPWFKONJYLCF-UHFFFAOYSA-N 2-(2-sulfanylethyl)isoindole-1,3-dione Chemical compound C1=CC=C2C(=O)N(CCS)C(=O)C2=C1 UHOPWFKONJYLCF-UHFFFAOYSA-N 0.000 description 1

- JHQBLYITVCBGTO-UHFFFAOYSA-N 2-(4-fluorophenyl)acetonitrile Chemical compound FC1=CC=C(CC#N)C=C1 JHQBLYITVCBGTO-UHFFFAOYSA-N 0.000 description 1

- GDHXJNRAJRCGMX-UHFFFAOYSA-N 2-fluorobenzonitrile Chemical compound FC1=CC=CC=C1C#N GDHXJNRAJRCGMX-UHFFFAOYSA-N 0.000 description 1

- LWLOKSXSAUHTJO-UHFFFAOYSA-N 4,5-dimethyl-1,3-dioxolan-2-one Chemical compound CC1OC(=O)OC1C LWLOKSXSAUHTJO-UHFFFAOYSA-N 0.000 description 1

- BJWMSGRKJIOCNR-UHFFFAOYSA-N 4-ethenyl-1,3-dioxolan-2-one Chemical compound C=CC1COC(=O)O1 BJWMSGRKJIOCNR-UHFFFAOYSA-N 0.000 description 1

- LSUWCXHZPFTZSF-UHFFFAOYSA-N 4-ethyl-5-methyl-1,3-dioxolan-2-one Chemical compound CCC1OC(=O)OC1C LSUWCXHZPFTZSF-UHFFFAOYSA-N 0.000 description 1

- AEKVBBNGWBBYLL-UHFFFAOYSA-N 4-fluorobenzonitrile Chemical compound FC1=CC=C(C#N)C=C1 AEKVBBNGWBBYLL-UHFFFAOYSA-N 0.000 description 1

- AUXJVUDWWLIGRU-UHFFFAOYSA-N 4-propyl-1,3-dioxolan-2-one Chemical compound CCCC1COC(=O)O1 AUXJVUDWWLIGRU-UHFFFAOYSA-N 0.000 description 1

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 description 1

- 229910000925 Cd alloy Inorganic materials 0.000 description 1

- 229910052684 Cerium Inorganic materials 0.000 description 1

- 229910052688 Gadolinium Inorganic materials 0.000 description 1

- 229910004424 Li(Ni0.8Co0.15Al0.05)O2 Inorganic materials 0.000 description 1

- 229910013733 LiCo Inorganic materials 0.000 description 1

- 229910015645 LiMn Inorganic materials 0.000 description 1

- 229910015644 LiMn 2 - z Ni Inorganic materials 0.000 description 1

- 229910013528 LiN(SO2 CF3)2 Inorganic materials 0.000 description 1

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- XOBKSJJDNFUZPF-UHFFFAOYSA-N Methoxyethane Chemical compound CCOC XOBKSJJDNFUZPF-UHFFFAOYSA-N 0.000 description 1

- RJUFJBKOKNCXHH-UHFFFAOYSA-N Methyl propionate Chemical compound CCC(=O)OC RJUFJBKOKNCXHH-UHFFFAOYSA-N 0.000 description 1

- RFFFKMOABOFIDF-UHFFFAOYSA-N Pentanenitrile Chemical compound CCCCC#N RFFFKMOABOFIDF-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- XBDQKXXYIPTUBI-UHFFFAOYSA-M Propionate Chemical compound CCC([O-])=O XBDQKXXYIPTUBI-UHFFFAOYSA-M 0.000 description 1

- 229910052772 Samarium Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- VIEVWNYBKMKQIH-UHFFFAOYSA-N [Co]=O.[Mn].[Li] Chemical class [Co]=O.[Mn].[Li] VIEVWNYBKMKQIH-UHFFFAOYSA-N 0.000 description 1

- QTHKJEYUQSLYTH-UHFFFAOYSA-N [Co]=O.[Ni].[Li] Chemical class [Co]=O.[Ni].[Li] QTHKJEYUQSLYTH-UHFFFAOYSA-N 0.000 description 1

- SOXUFMZTHZXOGC-UHFFFAOYSA-N [Li].[Mn].[Co].[Ni] Chemical compound [Li].[Mn].[Co].[Ni] SOXUFMZTHZXOGC-UHFFFAOYSA-N 0.000 description 1

- IDSMHEZTLOUMLM-UHFFFAOYSA-N [Li].[O].[Co] Chemical class [Li].[O].[Co] IDSMHEZTLOUMLM-UHFFFAOYSA-N 0.000 description 1

- KXKVLQRXCPHEJC-UHFFFAOYSA-N acetic acid trimethyl ester Natural products COC(C)=O KXKVLQRXCPHEJC-UHFFFAOYSA-N 0.000 description 1

- 229920000800 acrylic rubber Polymers 0.000 description 1

- BTGRAWJCKBQKAO-UHFFFAOYSA-N adiponitrile Chemical compound N#CCCCCC#N BTGRAWJCKBQKAO-UHFFFAOYSA-N 0.000 description 1

- NDPGDHBNXZOBJS-UHFFFAOYSA-N aluminum lithium cobalt(2+) nickel(2+) oxygen(2-) Chemical compound [Li+].[O--].[O--].[O--].[O--].[Al+3].[Co++].[Ni++] NDPGDHBNXZOBJS-UHFFFAOYSA-N 0.000 description 1

- 239000003125 aqueous solvent Substances 0.000 description 1

- 125000004104 aryloxy group Chemical group 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- IAQRGUVFOMOMEM-UHFFFAOYSA-N butene Natural products CC=CC IAQRGUVFOMOMEM-UHFFFAOYSA-N 0.000 description 1

- 229920005549 butyl rubber Polymers 0.000 description 1

- KVNRLNFWIYMESJ-UHFFFAOYSA-N butyronitrile Chemical compound CCCC#N KVNRLNFWIYMESJ-UHFFFAOYSA-N 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910000428 cobalt oxide Inorganic materials 0.000 description 1

- IVMYJDGYRUAWML-UHFFFAOYSA-N cobalt(ii) oxide Chemical compound [Co]=O IVMYJDGYRUAWML-UHFFFAOYSA-N 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 125000000392 cycloalkenyl group Chemical group 0.000 description 1

- VBWIZSYFQSOUFQ-UHFFFAOYSA-N cyclohexanecarbonitrile Chemical compound N#CC1CCCCC1 VBWIZSYFQSOUFQ-UHFFFAOYSA-N 0.000 description 1

- SVPZJHKVRMRREG-UHFFFAOYSA-N cyclopentanecarbonitrile Chemical compound N#CC1CCCC1 SVPZJHKVRMRREG-UHFFFAOYSA-N 0.000 description 1

- 238000009831 deintercalation Methods 0.000 description 1

- SBZXBUIDTXKZTM-UHFFFAOYSA-N diglyme Chemical compound COCCOCCOC SBZXBUIDTXKZTM-UHFFFAOYSA-N 0.000 description 1

- IEJIGPNLZYLLBP-UHFFFAOYSA-N dimethyl carbonate Chemical compound COC(=O)OC IEJIGPNLZYLLBP-UHFFFAOYSA-N 0.000 description 1

- VUPKGFBOKBGHFZ-UHFFFAOYSA-N dipropyl carbonate Chemical compound CCCOC(=O)OCCC VUPKGFBOKBGHFZ-UHFFFAOYSA-N 0.000 description 1

- POLCUAVZOMRGSN-UHFFFAOYSA-N dipropyl ether Chemical compound CCCOCCC POLCUAVZOMRGSN-UHFFFAOYSA-N 0.000 description 1

- 238000010494 dissociation reaction Methods 0.000 description 1

- 230000005593 dissociations Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000011883 electrode binding agent Substances 0.000 description 1

- 229940093499 ethyl acetate Drugs 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- QKBJDEGZZJWPJA-UHFFFAOYSA-N ethyl propyl carbonate Chemical compound [CH2]COC(=O)OCCC QKBJDEGZZJWPJA-UHFFFAOYSA-N 0.000 description 1

- 125000003709 fluoroalkyl group Chemical group 0.000 description 1

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 229910021389 graphene Inorganic materials 0.000 description 1

- 125000003106 haloaryl group Chemical group 0.000 description 1

- 229910021385 hard carbon Inorganic materials 0.000 description 1

- SDAXRHHPNYTELL-UHFFFAOYSA-N heptanenitrile Chemical compound CCCCCCC#N SDAXRHHPNYTELL-UHFFFAOYSA-N 0.000 description 1

- 125000001072 heteroaryl group Chemical group 0.000 description 1

- 125000004366 heterocycloalkenyl group Chemical group 0.000 description 1

- 125000000592 heterocycloalkyl group Chemical group 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000009830 intercalation Methods 0.000 description 1

- 230000002687 intercalation Effects 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- 229910003473 lithium bis(trifluoromethanesulfonyl)imide Inorganic materials 0.000 description 1

- 229910000625 lithium cobalt oxide Inorganic materials 0.000 description 1

- 229910002102 lithium manganese oxide Inorganic materials 0.000 description 1

- FRMOHNDAXZZWQI-UHFFFAOYSA-N lithium manganese(2+) nickel(2+) oxygen(2-) Chemical class [O-2].[Mn+2].[Ni+2].[Li+] FRMOHNDAXZZWQI-UHFFFAOYSA-N 0.000 description 1

- QEXMICRJPVUPSN-UHFFFAOYSA-N lithium manganese(2+) oxygen(2-) Chemical class [O-2].[Mn+2].[Li+] QEXMICRJPVUPSN-UHFFFAOYSA-N 0.000 description 1

- QSZMZKBZAYQGRS-UHFFFAOYSA-N lithium;bis(trifluoromethylsulfonyl)azanide Chemical compound [Li+].FC(F)(F)S(=O)(=O)[N-]S(=O)(=O)C(F)(F)F QSZMZKBZAYQGRS-UHFFFAOYSA-N 0.000 description 1

- URIIGZKXFBNRAU-UHFFFAOYSA-N lithium;oxonickel Chemical class [Li].[Ni]=O URIIGZKXFBNRAU-UHFFFAOYSA-N 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- VNKYTQGIUYNRMY-UHFFFAOYSA-N methoxypropane Chemical compound CCCOC VNKYTQGIUYNRMY-UHFFFAOYSA-N 0.000 description 1

- 229940017219 methyl propionate Drugs 0.000 description 1

- KKQAVHGECIBFRQ-UHFFFAOYSA-N methyl propyl carbonate Chemical compound CCCOC(=O)OC KKQAVHGECIBFRQ-UHFFFAOYSA-N 0.000 description 1

- 125000001570 methylene group Chemical group [H]C([H])([*:1])[*:2] 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- YKYONYBAUNKHLG-UHFFFAOYSA-N n-Propyl acetate Natural products CCCOC(C)=O YKYONYBAUNKHLG-UHFFFAOYSA-N 0.000 description 1

- 229910000480 nickel oxide Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 125000000449 nitro group Chemical group [O-][N+](*)=O 0.000 description 1

- YSIMAPNUZAVQER-UHFFFAOYSA-N octanenitrile Chemical compound CCCCCCCC#N YSIMAPNUZAVQER-UHFFFAOYSA-N 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- GNRSAWUEBMWBQH-UHFFFAOYSA-N oxonickel Chemical compound [Ni]=O GNRSAWUEBMWBQH-UHFFFAOYSA-N 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 239000004810 polytetrafluoroethylene Substances 0.000 description 1

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- FVSKHRXBFJPNKK-UHFFFAOYSA-N propionitrile Chemical compound CCC#N FVSKHRXBFJPNKK-UHFFFAOYSA-N 0.000 description 1

- 229940090181 propyl acetate Drugs 0.000 description 1

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 1

- 229920001384 propylene homopolymer Polymers 0.000 description 1

- 230000001603 reducing effect Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 239000005060 rubber Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 229910021384 soft carbon Inorganic materials 0.000 description 1

- 239000007784 solid electrolyte Substances 0.000 description 1

- 229910052596 spinel Inorganic materials 0.000 description 1

- 239000011029 spinel Substances 0.000 description 1

- 229910052712 strontium Inorganic materials 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- IAHFWCOBPZCAEA-UHFFFAOYSA-N succinonitrile Chemical compound N#CCCC#N IAHFWCOBPZCAEA-UHFFFAOYSA-N 0.000 description 1

- 229920005608 sulfonated EPDM Polymers 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- ZUHZGEOKBKGPSW-UHFFFAOYSA-N tetraglyme Chemical compound COCCOCCOCCOCCOC ZUHZGEOKBKGPSW-UHFFFAOYSA-N 0.000 description 1

- YFNKIDBQEZZDLK-UHFFFAOYSA-N triglyme Chemical compound COCCOCCOCCOC YFNKIDBQEZZDLK-UHFFFAOYSA-N 0.000 description 1

- QJMMCGKXBZVAEI-UHFFFAOYSA-N tris(trimethylsilyl) phosphate Chemical compound C[Si](C)(C)OP(=O)(O[Si](C)(C)C)O[Si](C)(C)C QJMMCGKXBZVAEI-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- NQPDZGIKBAWPEJ-UHFFFAOYSA-N valeric acid Chemical compound CCCCC(O)=O NQPDZGIKBAWPEJ-UHFFFAOYSA-N 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

- PAPBSGBWRJIAAV-UHFFFAOYSA-N ε-Caprolactone Chemical compound O=C1CCCCCO1 PAPBSGBWRJIAAV-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the present invention relates to a non-aqueous electrolyte and a lithium secondary battery including the same.

- secondary batteries are the most suitable for various applications, and among these secondary batteries, lithium secondary batteries are attracting attention as they can be miniaturized to the point where they can be applied to personal IT devices and have the highest energy density.

- lithium secondary batteries are manufactured by injecting or impregnating a non-aqueous electrolyte into an electrode assembly consisting of a cathode, an anode, and a porous separator.

- the positive active materials of these lithium secondary batteries are being considered to include lithium-containing cobalt oxide, LiMnO 2 with a layered crystal structure, LiMn 2 O 4 with a spinel crystal structure, lithium-containing nickel oxide (LiNiO 2 ), and lithium nickel-cobalt-manganese transition metal oxides.

- silicon-based active materials such as graphite have been used as negative active materials, but recently, silicon-based active materials are also being considered because they have higher capacity than carbon-based active materials.

- the silicon-based active material has the advantage of having a high capacity, but has the problem of very large volume expansion/contraction during the charge/discharge process. This large volume expansion/contraction greatly reduces the conductivity of the negative electrode, which causes a decrease in life performance.

- a solid electrolyte interface layer hereinafter referred to as SEI film

- SEI film solid electrolyte interface layer

- silicon-based active materials have a large volume expansion, which causes problems such as SEI film breakage and continuous generation of new negative electrode surfaces. Accordingly, SEI film formation reactions continuously occur, which accelerates electrolyte side reactions, and the thickness of the SEI film increases, which increases resistance.

- One object of the present invention is to solve the above problems, and to provide a non-aqueous electrolyte capable of forming an SEI film having excellent resilience and improved durability on a negative electrode, thereby implementing a lithium secondary battery having improved life performance and storage performance.

- the present invention provides a non-aqueous electrolyte comprising a lithium salt, an organic solvent and an additive, wherein the additive comprises a compound represented by the following chemical formula 1.

- R 1 and R 2 independently represent F, Br, Cl, I, a nitrile group, an ester group, an ether group, a ketone group, a carboxyl group, a substituted or unsubstituted alkyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkenyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkynyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkoxy group having 1 to 10 carbon atoms, a boron group, a borate group, an isocyanate group, an isothiocyanate group, a silyl group, a siloxane group, a sulfone group, a sulfonate group, a sulfate group, a substituent represented by the following chemical formula 2, or a combination of two or more thereof, at least one of the R 1 and R 2 comprises

- L 1 is an alkylene group, an ester group, a sulfone group, a sulfonate group, a sulfate group, or a combination of two or more thereof having 1 to 10 carbon atoms

- R 3 is an alkoxy group having 1 to 10 carbon atoms substituted with at least one fluorine atom

- * is a bonding site.

- the present invention provides a lithium secondary battery including a cathode; a cathode opposite to the cathode; a separator interposed between the cathode and the cathode; and the non-aqueous electrolyte described above.

- the non-aqueous electrolyte of the present invention is characterized by including a cyclic siloxane compound having a specific structure including an alkoxy group in which at least one F is substituted as an additive.

- the compound is capable of forming a polymer-type siloxane SEI film upon reduction at an anode, and such a polymer-type siloxane SEI film has a high shear modulus and can contribute to the formation of an SEI film having excellent thermal stability and chemical and electrochemical safety.

- the alkoxy group in which at least one F is substituted included in the cyclic siloxane compound enables the formation of an inorganic SEI film such as LiF upon reduction at an anode, thereby improving the durability of the SEI film, and in particular, since the alkoxy group is a good leaving group, it can strongly induce an SEI film formation reaction. Accordingly, a lithium secondary battery including the non-aqueous electrolyte according to the present invention can have improved cycle performance and storage performance, particularly improved cycle performance and storage performance at high temperatures.

- an alkyl group having 1 to 5 carbon atoms means an alkyl group including 1 to 5 carbon atoms, that is, CH 3 -, CH 3 CH 2 -, CH 3 CH 2 CH 2 -, (CH 3 ) 2 CH-, CH 3 CH 2 CH 2 CH 2 -, (CH 3 ) 2 CHCH 2 -, CH 3 CH 2 CH 2 CH 2 -, (CH 3 ) 2 CHCH 2 CH 2 -, etc.

- both the alkyl group and the aryl group may be substituted or unsubstituted.

- substitution means, unless otherwise defined, that at least one hydrogen bonded to carbon is replaced with an element other than hydrogen, for example, an alkyl group having 1 to 20 carbon atoms, an alkenyl group having 2 to 20 carbon atoms, an alkynyl group having 2 to 20 carbon atoms, an alkoxy group having 1 to 20 carbon atoms, a cycloalkyl group having 3 to 12 carbon atoms, a cycloalkenyl group having 3 to 12 carbon atoms, a cycloalkynyl group having 3 to 12 carbon atoms, a heterocycloalkyl group having 3 to 12 carbon atoms, a heterocycloalkenyl group having 3 to 12 carbon atoms, a heterocycloalkynyl group having 2 to 12 carbon atoms, an aryloxy group having 6 to 12 carbon atoms, a

- the present invention relates to a non-aqueous electrolyte.

- the non-aqueous electrolyte according to the present invention comprises a lithium salt, an organic solvent and an additive, and is characterized in that the additive comprises a compound represented by the following chemical formula 1.

- R 1 and R 2 independently represent F, Br, Cl, I, a nitrile group, an ester group, an ether group, a ketone group, a carboxyl group, a substituted or unsubstituted alkyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkenyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkynyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkoxy group having 1 to 10 carbon atoms, a boron group, a borate group, an isocyanate group, an isothiocyanate group, a silyl group, a siloxane group, a sulfone group, a sulfonate group, a sulfate group, a substituent represented by the following chemical formula 2, or a combination of two or more thereof, at least one of the R 1 and R 2 comprises

- L 1 is an alkylene group, an ester group, a sulfone group, a sulfonate group, a sulfate group, or a combination of two or more thereof having 1 to 10 carbon atoms

- R 3 is an alkoxy group having 1 to 10 carbon atoms substituted with at least one fluorine atom

- * is a bonding site.

- the lithium salt used in the present invention various lithium salts commonly used in non-aqueous electrolytes for lithium secondary batteries can be used without limitation.

- the lithium salt contains Li + as a cation and F- , Cl- , Br- , I- , NO3- , N(CN) 2- , BF4- , ClO4- , AlO4- , AlCl4- , PF6- , SbF6- , AsF6-, B10Cl10-, BF2C2O4- , BC4O8- , PF4C2O4- , PF2C4O8- , ( CF3 ) 2PF4- , ( CF3 ) 3PF3- , ( CF3 ) 4PF2- , ( CF3 ) 5PF- , ( CF3 ) 6P- , CF3SO3- , C It may include at least one selected from the group consisting of 4 F 9 SO 3 - ,

- the lithium salt may include at least one selected from the group consisting of LiCl, LiBr, LiI, LiBF 4 , LiClO 4 , LiAlO 4 , LiAlCl 4 , LiPF 6 , LiSbF 6 , LiAsF 6 , LiB 10 Cl 10 , LiBOB (LiB(C 2 O 4 ) 2 ), LiCF 3 SO 3 , LiFSI (LiN(SO 2 F) 2 ), LiCH 3 SO 3 , LiCF 3 CO 2 , LiCH 3 CO 2 and LiBETI (LiN(SO 2 CF 2 CF 3 ) 2 ).

- the lithium salt may include at least one selected from the group consisting of LiBF 4 , LiClO 4 , LiPF 6 , LiBOB (LiB(C 2 O 4 ) 2 ), LiCF 3 SO 3 , LiTFSI (LiN(SO 2 CF 3 ) 2 ), LiFSI ((LiN(SO 2 F) 2 ) and LiBETI (LiN(SO 2 CF 2 CF 3 ) 2 ).

- the above lithium salt may be included in the non-aqueous electrolyte at a concentration of 0.5 M to 5 M, specifically at a concentration of 0.8 M to 4 M, and more specifically at a concentration of 0.8 M to 2.0 M.

- concentration of the lithium salt satisfies the above range, the lithium ion yield (Li + transference number) and the degree of dissociation of lithium ions may be improved, thereby improving the output characteristics of the battery.

- the above organic solvent is a non-aqueous solvent commonly used in lithium secondary batteries, and is not particularly limited as long as decomposition due to oxidation reactions, etc. during the charge/discharge process of the secondary battery can be minimized.

- the organic solvent may include at least one selected from the group consisting of a cyclic carbonate-based organic solvent, a linear carbonate-based organic solvent, a linear ester-based organic solvent, and a cyclic ester-based organic solvent.

- the organic solvent may include a cyclic carbonate-based organic solvent, a linear carbonate-based organic solvent, or a mixture thereof.

- the above cyclic carbonate-based organic solvent is a high-viscosity organic solvent having a high dielectric constant and capable of dissociating a lithium salt in the electrolyte well, and specifically, may include at least one organic solvent selected from the group consisting of ethylene carbonate (EC), fluoroethylene carbonate (FEC), propylene carbonate (PC), 1,2-butylene carbonate, 2,3-butylene carbonate, 1,2-pentylene carbonate, 2,3-pentylene carbonate, and vinylene carbonate, more specifically, may include at least one selected from the group consisting of ethylene carbonate (EC) and fluoroethylene carbonate (FEC), and even more specifically, may include fluoroethylene carbonate (FEC) in terms of contributing to the formation of an inorganic (LiF)-containing SEI film.

- EC ethylene carbonate

- FEC fluoroethylene carbonate

- PC propylene carbonate

- 1,2-butylene carbonate 2,3-butylene carbonate

- the linear carbonate-based organic solvent is an organic solvent having low viscosity and low dielectric constant, and specifically may include at least one selected from the group consisting of dimethyl carbonate (DMC), diethyl carbonate (DEC), dipropyl carbonate, ethylmethyl carbonate (EMC), methylpropyl carbonate, and ethylpropyl carbonate, and more specifically may include at least one selected from the group consisting of ethylmethyl carbonate (EMC) and diethyl carbonate (DEC), and more specifically may include diethyl carbonate (DEC) in that it can further improve the oxidation stability of the non-aqueous electrolyte.

- DMC dimethyl carbonate

- DEC diethyl carbonate

- EMC ethylmethyl carbonate

- EMC ethylmethyl carbonate

- DEC diethyl carbonate

- DEC diethyl carbonate

- DEC diethyl carbonate

- DEC diethyl carbonate

- the above organic solvent may be a mixture of a cyclic carbonate-based organic solvent and a linear carbonate-based organic solvent.

- the cyclic carbonate-based organic solvent and the linear carbonate-based organic solvent may be mixed in a volume ratio of 5:95 to 40:60, specifically, a volume ratio of 7:93 to 25:75.

- the organic solvent may further include at least one carbonate organic solvent selected from the group consisting of the cyclic carbonate organic solvent and the linear carbonate organic solvent, and at least one ester organic solvent selected from the group consisting of the linear ester organic solvent and the cyclic ester organic solvent, in order to produce an electrolyte having high ionic conductivity.

- the above linear ester organic solvent may specifically include at least one selected from the group consisting of methyl acetate, ethyl acetate, propyl acetate, methyl propionate, ethyl propionate, propyl propionate, and butyl propionate.

- the cyclic ester organic solvent may specifically include at least one selected from the group consisting of ⁇ -butyrolactone, ⁇ -valerolactone, ⁇ -caprolactone, ⁇ -valerolactone, and ⁇ -caprolactone.

- the organic solvent may be used without limitation by adding an organic solvent commonly used in a non-aqueous electrolyte as needed.

- an organic solvent commonly used in a non-aqueous electrolyte

- at least one organic solvent from among an ether-based organic solvent, a glyme-based solvent, and a nitrile-based organic solvent may be additionally included.

- any one selected from the group consisting of dimethyl ether, diethyl ether, dipropyl ether, methyl ethyl ether, methyl propyl ether, ethyl propyl ether, 1,3-dioxolane (DOL), and 2,2-bis(trifluoromethyl)-1,3-dioxolane (TFDOL) or a mixture of two or more thereof may be used, but is not limited thereto.

- the above-mentioned glyme solvent has a high dielectric constant and low surface tension compared to linear carbonate-based organic solvents, and is a solvent with low reactivity with metals, and may include at least one selected from the group consisting of dimethoxyethane (glyme, DME), diethoxyethane, diglyme, tri-glyme, and tetra-glyme (TEGDME), but is not limited thereto.

- the above nitrile solvent may be at least one selected from the group consisting of acetonitrile, propionitrile, butyronitrile, valeronitrile, caprylonitrile, heptanenitrile, cyclopentane carbonitrile, cyclohexane carbonitrile, 2-fluorobenzonitrile, 4-fluorobenzonitrile, difluorobenzonitrile, trifluorobenzonitrile, phenylacetonitrile, 2-fluorophenylacetonitrile, and 4-fluorophenylacetonitrile, but is not limited thereto.

- the above non-aqueous electrolyte contains an additive.

- the above additive comprises a compound represented by the following chemical formula 1.

- R 1 and R 2 independently represent F, Br, Cl, I, a nitrile group, an ester group, an ether group, a ketone group, a carboxyl group, a substituted or unsubstituted alkyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkenyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkynyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkoxy group having 1 to 10 carbon atoms, a boron group, a borate group, an isocyanate group, an isothiocyanate group, a silyl group, a siloxane group, a sulfone group, a sulfonate group, a sulfate group, a substituent represented by the following chemical formula 2, or a combination of two or more thereof, at least one of the R 1 and R 2 comprises

- L 1 is an alkylene group, an ester group, a sulfone group, a sulfonate group, a sulfate group, or a combination of two or more thereof having 1 to 10 carbon atoms

- R 3 is an alkoxy group having 1 to 10 carbon atoms substituted with at least one fluorine atom

- * is a bonding site.

- R 1 and/or R 2 substituted on Si is an alkoxy group having 1 to 10 carbon atoms substituted with at least one F, specifically a cyclic siloxane compound including a substituent represented by the above chemical formula 2.

- the cyclic siloxane structure is opened upon reduction at the cathode to form a polymer-type siloxane SEI film.

- This polymer-type siloxane SEI film not only has excellent flexibility and resilience, but also has a high shear modulus and excellent thermal stability, chemical stability, and electrochemical stability.

- the compound represented by the chemical formula 1 includes a substituent represented by the chemical formula 2, and the substituent is reduced at the cathode to form an inorganic SEI film containing an inorganic substance such as LiF.

- This inorganic SEI film can significantly improve the durability of the SEI film.

- the compound of the chemical formula 1 according to the present invention forms the above-described polymer type/inorganic composite SEI film, the durability, flexibility, and stability of the SEI film can be improved simultaneously.

- the substituent (R 1 and/or R 2 ) included in the compound represented by the above chemical formula 1 is characterized by including a fluorine-substituted alkoxy group, specifically a substituent represented by the above chemical formula 2, and the fluorine-substituted alkoxy group is a rather weak electron withdrawn group and functions as a good leaving group. This can induce and promote the formation of an inorganic SEI film such as LiF.

- the non-aqueous electrolyte according to the present invention enables improvement of the life performance and storage performance of a lithium secondary battery, particularly improvement of the life performance and storage performance at high temperatures.

- the compound represented by the chemical formula 1 can be more preferably applied to an anode using a silicon-based active material. Since Li of lithiated Si formed by activation of an anode including a silicon-based active material and F derived from the compound represented by the chemical formula 1 can have a strong interaction with each other (Glue effect), it can be more advantageous in forming a durable and resilient SEI film on a silicon-based active material which is extremely subject to volume expansion during charge and discharge.

- R 1 and R 2 may independently include F, Br, Cl, I, a nitrile group, an ester group, an ether group, a ketone group, a carboxyl group, a substituted or unsubstituted alkyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkenyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkynyl group having 1 to 10 carbon atoms, a substituted or unsubstituted alkoxy group having 1 to 10 carbon atoms, a boron group, a borate group, an isocyanate group, an isothiocyanate group, a silyl group, a siloxane group, a sulfone group, a sulfonate group, a sulfate group, a substituent represented by the following chemical formula 2, or a combination of two or more thereof.

- at least one of the R 1 and R 2 may independently

- L 1 is an alkylene group, an ester group, a sulfone group, a sulfonate group, a sulfate group, or a combination of two or more thereof having 1 to 10 carbon atoms

- R 3 is an alkoxy group having 1 to 10 carbon atoms substituted with at least one fluorine atom

- * is a bonding site.

- either one of R 1 and R 2 may include a substituent represented by the chemical formula 2.

- R 1 It includes a substituent represented by the above chemical formula 2, and the above R 2 may not include a substituent represented by the above chemical formula 2.

- R 2 may be an alkyl group having 1 to 5 carbon atoms, more specifically an ethyl group or a methyl group, and even more specifically a methyl group.

- L 1 is an alkylene group, an ester group, a sulfone group, a sulfonate group, a sulfate group, or a combination of two or more thereof having 1 to 10 carbon atoms

- R 3 is an alkoxy group having 1 to 10 carbon atoms substituted with at least one fluorine atom

- * is a bonding site.

- L 1 can be specifically an alkylene group having 1 to 10 carbon atoms, a sulfone group or a combination thereof, more specifically an alkylene group having 1 to 5 carbon atoms, and even more specifically a methylene group or an ethylene group in terms of easily accepting electrons during cathodic reduction, thereby further improving the reducing property, and even more specifically an ethylene group.

- R 3 may be an alkoxy group having 1 to 10 carbon atoms substituted with at least one F, specifically an alkoxy group having 1 to 5 carbon atoms substituted with at least one F, more specifically one selected from the group consisting of -OCF 3 , -OCF 2 CF 3 and -OCF 2 CF 2 CF 3 , and even more specifically -OCF 3 in terms of preventing a decrease in reactivity due to steric hindrance.

- n may be an integer of 3 to 8, specifically 3 or 4, and more specifically 3.

- R 1 and/or R 2 in each repeating unit may be the same or different.

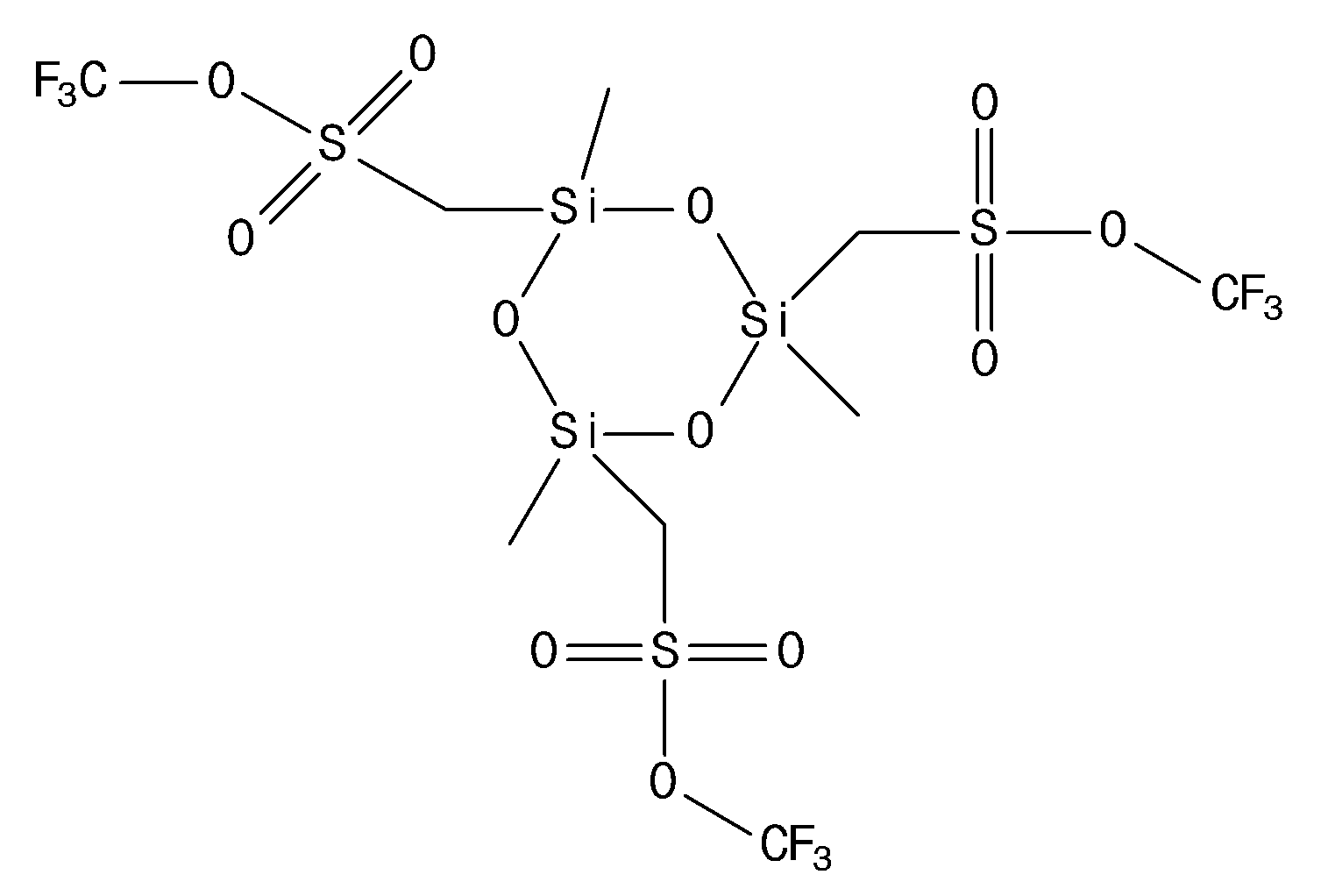

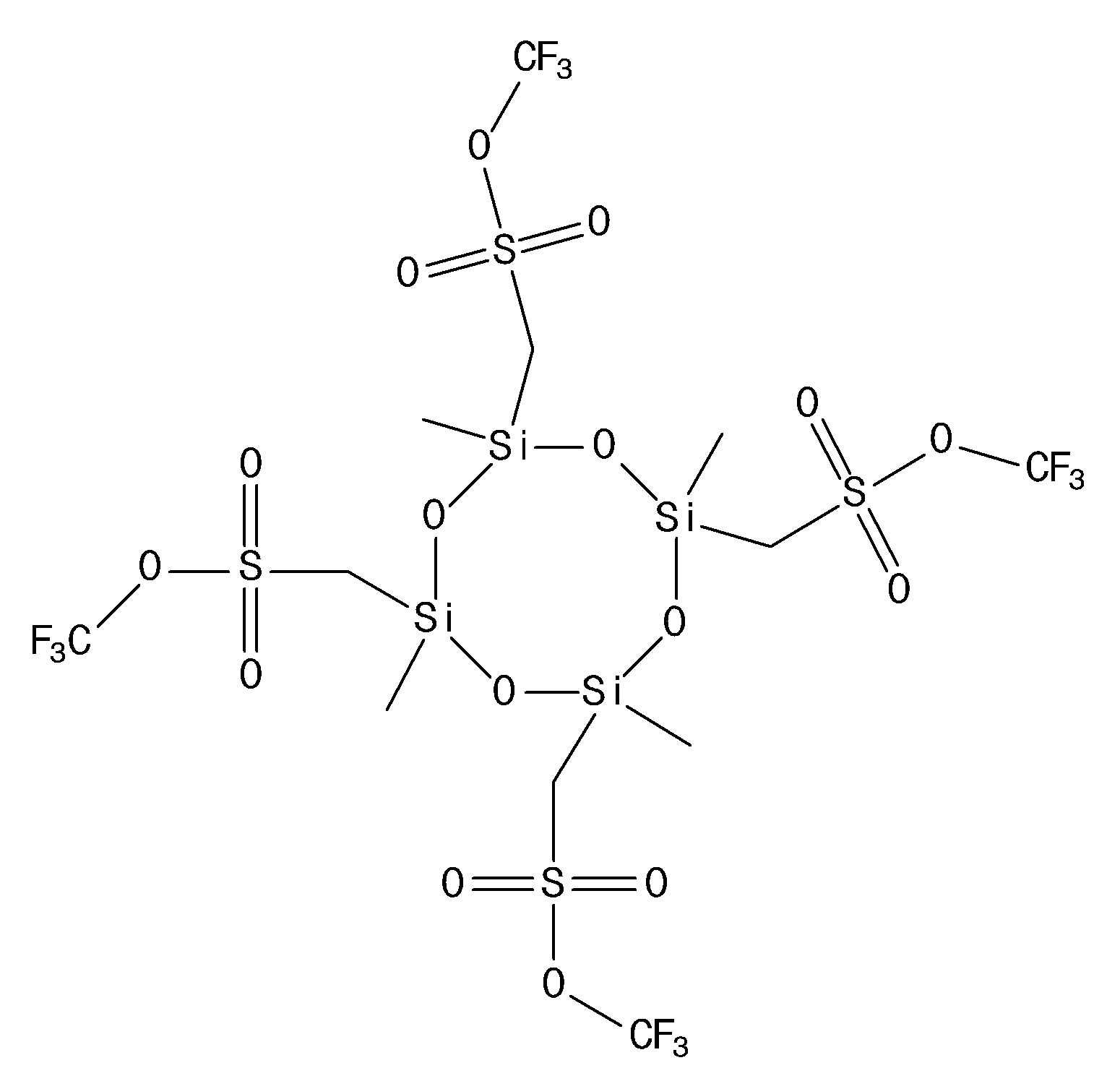

- the compound represented by the chemical formula 1 may include at least one compound selected from the group consisting of chemical formulas 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7, 1-8, 1-9, 1-10, 1-11, and 1-12, more specifically, may include at least one compound selected from the group consisting of chemical formulas 1-1, 1-3, 1-9, and 1-10, and even more specifically, may include at least one compound selected from the group consisting of chemical formulas 1-1 and 1-3, and even more specifically, may include a compound represented by chemical formula 1-1.

- the compound represented by the above chemical formula 1 may be included in an amount of 0.01 wt% to 10 wt%, specifically 0.3 wt% to 7 wt%, more specifically 0.5 wt% to 5 wt%, and even more specifically 1 wt% to 3 wt%, based on the weight of the non-aqueous electrolyte.

- a flexible and durable SEI film can be formed on the negative electrode, while preventing an increase in resistance when added in excessive amounts.

- the above additive may further include an additional additive together with the compound represented by Chemical Formula 1.

- the above additional additive may be included in the non-aqueous electrolyte to prevent decomposition of the non-aqueous electrolyte in a high-power environment, causing cathode collapse, or to provide low-temperature high-rate discharge characteristics, high-temperature stability, overcharge prevention, and suppression of battery expansion at high temperatures.

- the additional additive may include at least one selected from the group consisting of lithium difluorophosphate (LiDFP), vinylene carbonate, vinyl ethylene carbonate, fluoroethylene carbonate, propane sultone, propene sultone, succinonitrile, adiponitrile, ethylene sulfate, lithium bis-(oxalato)borate (LiBOB), 3-trimethoxysilanyl-propyl-N-aniline (TMSPa), and tris(trimethylsilyl) phosphate (TMSPi), and specifically, lithium difluorophosphate (LiDFP).

- LiDFP lithium difluorophosphate

- vinylene carbonate vinyl ethylene carbonate

- fluoroethylene carbonate propane sultone, propene sultone

- succinonitrile propane sultone

- adiponitrile ethylene sulfate

- LiBOB lithium bis-(oxalato)borate

- TMSPa 3-tri

- the above additional additive may be included in the non-aqueous electrolyte in an amount of 0.1 wt% to 15 wt%, more specifically 0.3 wt% to 3 wt%.

- the weight ratio of the compound represented by the chemical formula 1 and the additional additive may be 45:55 to 99:1, specifically 50:50 to 95:5, and more specifically 70:30 to 85:15, and when within the above range, the life performance and high-temperature storage performance may be improved to a more desirable level.

- the present invention provides a lithium secondary battery including the above-described non-aqueous electrolyte.

- a lithium secondary battery according to the present invention includes a negative electrode; a positive electrode opposite to the negative electrode; a separator interposed between the negative electrode and the positive electrode; and the non-aqueous electrolyte described above.

- the above lithium secondary battery can be manufactured by housing an electrode assembly including the negative electrode; a positive electrode opposing the negative electrode; and a separator interposed between the negative electrode and the positive electrode in a battery case, and then injecting the above-described non-aqueous electrolyte.

- the above negative electrode includes a negative electrode active material.

- the above negative active material may be any material used as a negative active material in the relevant field without limitation.

- the above negative active material may specifically include at least one selected from a silicon-based active material and a carbon-based active material, and more specifically may include a silicon-based active material.

- the above silicon-based active material exhibits higher capacity than the carbon-based active material, but has a problem in that the degree of volume expansion/contraction due to charge/discharge is large.

- a flexible, resilient, and durable SEI film can be formed on the negative electrode, thereby preventing electrolyte side reactions and enabling the implementation of a lithium secondary battery having high life performance and storage performance.

- the above silicon-based active material may include a compound represented by the following chemical formula A.

- the silicon-based active material may be Si.

- the average particle diameter (D 50 ) of the above silicon-based active material may be 1 ⁇ m to 20 ⁇ m.

- the above carbon-based active material may include at least one selected from the group consisting of graphite, hard carbon, soft carbon, carbon black, graphene, and fibrous carbon, and preferably may include graphite.

- the graphite may include at least one selected from the group consisting of artificial graphite and natural graphite.

- the average particle diameter (D 50 ) of the above carbon-based active material may be 10 ⁇ m to 30 ⁇ m, preferably 15 ⁇ m to 25 ⁇ m, in order to ensure structural stability during charge and discharge and reduce side reactions with the electrolyte.

- the above negative electrode may include a negative electrode current collector; and a negative electrode active material layer disposed on at least one surface of the negative electrode current collector.

- the negative electrode active material may be included in the negative electrode active material layer.

- the above negative electrode current collector is not particularly limited as long as it has high conductivity without causing chemical changes in the battery.

- the negative electrode current collector may be made of copper, stainless steel, aluminum, nickel, titanium, calcined carbon, copper or stainless steel surface-treated with carbon, nickel, titanium, silver, etc., an aluminum-cadmium alloy, etc.

- the above negative electrode collector may typically have a thickness of 3 to 500 ⁇ m.

- the above negative electrode current collector may form fine irregularities on the surface to strengthen the bonding strength of the negative electrode active material.

- the above negative electrode current collector may be used in various forms such as a film, a sheet, a foil, a net, a porous body, a foam, a non-woven fabric, etc.

- the negative electrode active material layer is disposed on at least one surface of the negative electrode current collector. Specifically, the negative electrode active material layer may be disposed on one surface or both surfaces of the negative electrode current collector.

- the above negative active material may be included in the negative active material layer at 60 wt% to 99 wt% in order to sufficiently express the capacity in the secondary battery while minimizing the effect of volume expansion/contraction on the battery.

- the above negative active material layer may further include a conductive material and/or a binder together with the silicon-based active material.

- the above binder can be used to improve the adhesion between the negative electrode active material layer and the negative electrode current collector described later, or to improve the bonding strength between silicon-based active materials.

- the binder comprises at least one selected from the group consisting of styrene butadiene rubber (SBR), nitrile butadiene rubber (NBR), acrylonitrile butadiene rubber, acrylic rubber, butyl rubber, fluoro rubber, polyvinyl alcohol, carboxymethyl cellulose (CMC), starch, hydroxypropyl cellulose, regenerated cellulose, polyvinyl alcohol (PVA), polyacrylic acid (PAA), polyethylene glycol (PEG), polyacrylonitrile (PAN), and polyacryl amide (PAM), in that it can further improve electrode adhesion and provide sufficient resistance to volume expansion/contraction of the silicon-based active material. Can be.

- SBR styrene butadiene rubber

- NBR nitrile butadiene rubber

- acrylonitrile butadiene rubber acrylic rubber

- butyl rubber fluoro rubber

- polyvinyl alcohol carboxymethyl cellulose (CMC), starch, hydroxypropyl cellulose, regenerated

- the above binder may be included in the negative electrode active material layer at 1 wt% to 30 wt%, and when present in the above range, the negative electrode active material may be better bound, thereby minimizing the problem of volume expansion of the active material, while at the same time facilitating dispersion of the binder during the preparation of a slurry for forming the negative electrode active material layer, thereby improving the coatability and phase stability of the slurry.

- the conductive material may be used to assist and improve conductivity in a secondary battery, and is not particularly limited as long as it has conductivity without causing a chemical change.

- the conductive material may include at least one selected from the group consisting of graphite such as natural graphite or artificial graphite; carbon black such as carbon black, acetylene black, Ketjen black, channel black, paneth black, lamp black, and thermal black; conductive fibers such as carbon fibers or metal fibers; conductive tubes such as carbon nanotubes; metal powders such as fluorocarbon, aluminum, and nickel powder; conductive whiskers such as zinc oxide and potassium titanate; conductive metal oxides such as titanium oxide; and polyphenylene derivatives.

- graphite such as natural graphite or artificial graphite

- carbon black such as carbon black, acetylene black, Ketjen black, channel black, paneth black, lamp black, and thermal black

- conductive fibers such as carbon fibers or metal fibers

- conductive tubes such as carbon nano

- the above-mentioned conductive agent may be included in the negative electrode active material layer at 1 wt% to 20 wt%, and when within the above range, it is preferable in that it can form an excellent conductive network while alleviating the increase in resistance due to the binder.

- the thickness of the above negative active material layer may be 5 ⁇ m to 500 ⁇ m, preferably 5 ⁇ m to 100 ⁇ m.

- the above negative electrode can be manufactured by coating a negative electrode slurry including a negative electrode active material and optionally a binder, a conductive material, and a solvent for forming a negative electrode slurry on the negative electrode current collector, and then drying and rolling.

- the solvent for forming the negative electrode slurry may include at least one selected from the group consisting of distilled water, ethanol, methanol and isopropyl alcohol, preferably distilled water, in order to facilitate dispersion of the negative electrode active material, binder and/or conductive agent.

- the above positive electrode contains a positive electrode active material.

- the above positive electrode active material is a compound capable of reversible intercalation and deintercalation of lithium, and specifically, may include a lithium-transition metal composite oxide including lithium and at least one transition metal selected from nickel, cobalt, manganese, and aluminum, preferably a lithium-transition metal composite oxide including lithium and a transition metal selected from nickel, cobalt, and manganese.

- the lithium transition metal composite oxides include lithium-manganese oxides (e.g., LiMnO 2 , LiMn 2 O 4 , etc.), lithium-cobalt oxides (e.g., LiCoO 2 , etc.), lithium-nickel oxides (e.g., LiNiO 2 , etc.), lithium-nickel-manganese oxides (e.g., LiNi 1-Y Mn Y O 2 (wherein, 0 ⁇ Y ⁇ 1), LiMn 2-z Ni z O 4 (wherein, 0 ⁇ Z ⁇ 2)), lithium-nickel-cobalt oxides (e.g., LiNi 1-Y1 Co Y1 O 2 (wherein, 0 ⁇ Y1 ⁇ 1)), lithium-manganese-cobalt oxides (e.g., LiCo 1-Y2 Mn Y2 O 2 (wherein, 0 ⁇ Y2 ⁇ 1), LiMn 2-z1 Co z1 O 4 (wherein, (0 ⁇ Z1 ⁇ 2) etc

- the lithium transition metal composite oxide may be LiCoO 2 , LiMnO 2 , LiNiO 2 , lithium nickel-manganese-cobalt oxide (for example, Li(Ni 0.6 Mn 0.2 Co 0.2 )O 2 , Li(Ni 0.5 Mn 0.3 Co 0.2 )O 2 , Li(Ni 0.7 Mn 0.15 Co 0.15 )O 2 or Li(Ni 0.8 Mn 0.1 Co 0.1 )O 2 , or lithium nickel cobalt aluminum oxide (for example, Li(Ni 0.8 Co 0.15 Al 0.05 )O 2 , etc.), and considering the prominence of the improvement effect according to the control of the type and content ratio of the constituent elements forming the lithium transition metal composite oxide, the lithium transition metal composite oxide may be The oxide may be Li ( Ni0.6Mn0.2Co0.2 ) O2 , Li(Ni0.5Mn0.3Co0.2)O2, Li(Ni0.7Mn0.15Co0.15)O2 or Li(Ni0.8Mn0.1Co0.1 )

- the cathode active material may be a lithium-transition metal composite oxide, and may contain nickel in an amount of 60 mol% or more based on the total mole number of transition metals included in the lithium-transition metal composite oxide.

- the cathode active material may be a lithium-transition metal composite oxide, wherein the transition metal includes nickel; and at least one selected from manganese, cobalt, and aluminum, and may contain nickel in an amount of 60 mol% or more, specifically 60 to 90 mol%, based on the total mole number of transition metals.

- the positive electrode active material may include a lithium composite transition metal oxide represented by the following chemical formula B.

- a, b, c and d may be 0.70 ⁇ a ⁇ 0.95, 0.025 ⁇ b ⁇ 0.20, 0.025 ⁇ c ⁇ 0.20, 0 ⁇ d ⁇ 0.05, respectively.

- a, b, c, and d may be 0.80 ⁇ a ⁇ 0.95, 0.025 ⁇ b ⁇ 0.15, 0.025 ⁇ c ⁇ 0.15, and 0 ⁇ d ⁇ 0.05, respectively.

- a, b, c, and d may be 0.85 ⁇ a ⁇ 0.90, 0.05 ⁇ b ⁇ 0.10, 0.05 ⁇ c ⁇ 0.10, and 0 ⁇ d ⁇ 0.03, respectively.

- the above positive electrode may include a positive electrode current collector; and a positive electrode active material layer disposed on at least one surface of the positive electrode current collector.

- the positive electrode active material layer may include the above-described positive electrode active material.

- the thickness of the above positive electrode collector can typically be 3 to 500 ⁇ m.

- the above-mentioned positive electrode current collector may form fine irregularities on the surface to strengthen the bonding strength of the negative electrode active material.

- the above-mentioned positive electrode current collector may be used in various forms such as a film, a sheet, a foil, a net, a porous body, a foam, a non-woven fabric, etc.

- the positive electrode active material layer is disposed on at least one surface of the positive electrode current collector. Specifically, the positive electrode active material layer may be disposed on one surface or both surfaces of the positive electrode current collector.

- the above cathode active material may be included in the cathode active material layer at 80 to 99 wt%, taking into account sufficient capacity of the cathode active material.

- the above-described positive electrode active material layer may further include a binder and/or a conductive material together with the above-described positive electrode active material.

- the above binder is a component that assists in the binding of the active material and the conductive material and the binding to the current collector, and specifically, may include at least one selected from the group consisting of polyvinylidene fluoride, polyvinyl alcohol, carboxymethyl cellulose (CMC), starch, hydroxypropyl cellulose, regenerated cellulose, polyvinyl pyrrolidone, polytetrafluoroethylene, polyethylene, polypropylene, ethylene-propylene-diene terpolymer (EPDM), sulfonated EPDM, styrene-butadiene rubber, and fluororubber, preferably polyvinylidene fluoride.

- CMC carboxymethyl cellulose

- EPDM ethylene-propylene-diene terpolymer

- EPDM ethylene-propylene-diene terpolymer

- EPDM ethylene-propylene-diene terpolymer

- EPDM ethylene-propylene-diene terpoly

- the above binder may be included in the positive electrode active material layer at 1 to 20 wt%, preferably 1.2 to 10 wt%, in order to sufficiently secure binding force between components such as the positive electrode active material.

- the conductive material may be used to assist and improve conductivity in a secondary battery, and is not particularly limited as long as it has conductivity without causing a chemical change.

- the positive electrode conductive material may include at least one selected from the group consisting of graphite such as natural graphite or artificial graphite; carbon black such as carbon black, acetylene black, Ketjen black, channel black, paneth black, lamp black, thermal black, etc.; conductive fibers such as carbon fibers or metal fibers; conductive tubes such as carbon nanotubes; fluorocarbons; metal powders such as aluminum or nickel powder; conductive whiskers such as zinc oxide or potassium titanate; conductive metal oxides such as titanium oxide; and polyphenylene derivatives, and preferably, the positive electrode conductive material may include carbon nanotubes in terms of improving conductivity.

- the above-mentioned conductive material may be included in the positive electrode active material layer at 1 wt% to 20 wt%, preferably 1.2 wt% to 10 wt%, in order to sufficiently secure electrical conductivity.

- the thickness of the above positive electrode active material layer may be 5 ⁇ m to 500 ⁇ m, preferably 20 ⁇ m to 200 ⁇ m.

- the above positive electrode can be manufactured by coating a positive electrode slurry including a positive electrode active material and optionally a binder, a conductive material, and a solvent for forming a positive electrode slurry on the positive electrode current collector, and then drying and rolling.

- the above separator may be interposed between the anode and the cathode.

- a conventional porous polymer film used as a conventional separator for example, a porous polymer film made of a polyolefin polymer such as an ethylene homopolymer, a propylene homopolymer, an ethylene/butene copolymer, an ethylene/hexene copolymer, and an ethylene/methacrylate copolymer, can be used alone or in a laminated manner, or a conventional porous nonwoven fabric, for example, a nonwoven fabric made of high-melting-point glass fiber, polyethylene terephthalate fiber, etc., can be used, but is not limited thereto.

- a coated separator containing a ceramic component or a polymer material to secure heat resistance or mechanical strength can be used, and can optionally be used in a single-layer or multi-layer structure.

- the external shape of the lithium secondary battery of the present invention may be in the shape of a cylinder, a square, a pouch, or a coin using a can.

- FEC fluoroethylene carbonate

- DEC diethyl carbonate

- a non-aqueous electrolyte was prepared by adding LiPF 6 as a lithium salt, a compound represented by the chemical formula 1-1 as an additive, and lithium difluorophosphate (LiDFP) to the organic solvent.

- LiPF 6 lithium difluorophosphate

- the above LiPF 6 was included in the non-aqueous electrolyte at a molar concentration of 1.5 M.

- the compound represented by the following chemical formula 1-1 was included in the non-aqueous electrolyte at 2 wt%, and lithium difluorophosphate was included in the non-aqueous electrolyte at 0.5 wt%.

- a positive electrode mixture slurry (solid content 75.5 wt%) was prepared by adding positive electrode active material (Li[Ni 0.85 Co 0.05 Mn 0.07 Al 0.03 ]O 2 ): conductive material (carbon nanotube): binder (polyvinylidene fluoride) in a weight ratio of 97.74:0.70:1.56 to N-methyl-2-pyrrolidone (NMP) as a solvent.

- the positive electrode mixture slurry was applied to one surface of a positive electrode current collector (Al thin film) having a thickness of 12 ⁇ m, and drying and roll pressing were performed to prepare a positive electrode.

- a negative electrode mixture slurry (solid content 26 wt%) was prepared by adding negative active material (silicon-based active material, Si): conductive agent (carbon black): binder (styrene-stadiene rubber) to distilled water as a solvent in a weight ratio of 70.0:20.3:9.7.

- the negative electrode mixture slurry was applied to one surface of a 15 ⁇ m thick negative electrode current collector (Cu thin film), and drying and roll pressing were performed to prepare a negative electrode.

- a polyethylene porous film separator was interposed between the positive and negative electrodes manufactured above in a dry room, and then the non-aqueous electrolyte manufactured above was injected to manufacture a secondary battery.

- a non-aqueous electrolyte and a lithium secondary battery were manufactured in the same manner as in Example 1, except that the compound represented by the chemical formula 1-1 was added to the non-aqueous electrolyte in an amount of 0.5 wt% instead of 2 wt%.

- a non-aqueous electrolyte and a lithium secondary battery were manufactured in the same manner as in Example 1, except that the compound represented by the chemical formula 1-1 was added to the non-aqueous electrolyte in an amount of 5 wt% instead of 2 wt%.

- a non-aqueous electrolyte and a lithium secondary battery were manufactured in the same manner as in Example 1, except that a compound represented by the chemical formula 1-9 was added to the non-aqueous electrolyte in an amount of 2 wt% instead of the compound represented by the chemical formula 1-1.

- a non-aqueous electrolyte and a lithium secondary battery were manufactured in the same manner as in Example 1, except that the compound represented by the chemical formula 1-1 was not added.

- a non-aqueous electrolyte and a lithium secondary battery were manufactured in the same manner as in Example 1, except that a compound represented by the chemical formula X was added to the non-aqueous electrolyte in an amount of 2 wt% instead of the compound represented by the chemical formula 1-1.