WO2024190050A1 - Secondary battery electrolyte and secondary battery - Google Patents

Secondary battery electrolyte and secondary battery Download PDFInfo

- Publication number

- WO2024190050A1 WO2024190050A1 PCT/JP2024/000259 JP2024000259W WO2024190050A1 WO 2024190050 A1 WO2024190050 A1 WO 2024190050A1 JP 2024000259 W JP2024000259 W JP 2024000259W WO 2024190050 A1 WO2024190050 A1 WO 2024190050A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- electrolyte

- secondary battery

- lithium

- imide

- Prior art date

Links

- 239000003792 electrolyte Substances 0.000 title claims abstract description 233

- -1 imide anions Chemical class 0.000 claims abstract description 180

- 150000003839 salts Chemical class 0.000 claims abstract description 105

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 claims abstract description 52

- 239000008151 electrolyte solution Substances 0.000 claims description 69

- 229910001416 lithium ion Inorganic materials 0.000 claims description 37

- 150000001768 cations Chemical class 0.000 claims description 36

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 claims description 35

- 125000002915 carbonyl group Chemical group [*:2]C([*:1])=O 0.000 claims description 32

- 125000002947 alkylene group Chemical group 0.000 claims description 30

- 229910052744 lithium Inorganic materials 0.000 claims description 30

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 claims description 29

- 125000000475 sulfinyl group Chemical group [*:2]S([*:1])=O 0.000 claims description 28

- 125000000472 sulfonyl group Chemical group *S(*)(=O)=O 0.000 claims description 28

- 125000000217 alkyl group Chemical group 0.000 claims description 25

- 125000001153 fluoro group Chemical group F* 0.000 claims description 23

- 150000005676 cyclic carbonates Chemical class 0.000 claims description 22

- 125000000843 phenylene group Chemical group C1(=C(C=CC=C1)*)* 0.000 claims description 17

- VDVLPSWVDYJFRW-UHFFFAOYSA-N lithium;bis(fluorosulfonyl)azanide Chemical compound [Li+].FS(=O)(=O)[N-]S(F)(=O)=O VDVLPSWVDYJFRW-UHFFFAOYSA-N 0.000 claims description 16

- 229910021645 metal ion Inorganic materials 0.000 claims description 12

- 239000012948 isocyanate Substances 0.000 claims description 8

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 claims description 7

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 6

- 229910001496 lithium tetrafluoroborate Inorganic materials 0.000 claims description 6

- IGILRSKEFZLPKG-UHFFFAOYSA-M lithium;difluorophosphinate Chemical compound [Li+].[O-]P(F)(F)=O IGILRSKEFZLPKG-UHFFFAOYSA-M 0.000 claims description 6

- 150000008065 acid anhydrides Chemical class 0.000 claims description 5

- 150000003459 sulfonic acid esters Chemical class 0.000 claims description 5

- QAOWNCQODCNURD-UHFFFAOYSA-N sulfuric acid Substances OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 claims description 3

- 239000000460 chlorine Substances 0.000 abstract description 4

- 229910052801 chlorine Inorganic materials 0.000 abstract description 3

- 239000010410 layer Substances 0.000 description 57

- 230000014759 maintenance of location Effects 0.000 description 45

- 239000002904 solvent Substances 0.000 description 39

- 238000003860 storage Methods 0.000 description 28

- 150000001875 compounds Chemical class 0.000 description 26

- 230000000694 effects Effects 0.000 description 25

- 239000000203 mixture Substances 0.000 description 22

- 238000000034 method Methods 0.000 description 20

- 230000005012 migration Effects 0.000 description 18

- 238000013508 migration Methods 0.000 description 18

- 239000007774 positive electrode material Substances 0.000 description 18

- 238000007789 sealing Methods 0.000 description 17

- 238000005516 engineering process Methods 0.000 description 16

- 239000007773 negative electrode material Substances 0.000 description 16

- 229920000642 polymer Polymers 0.000 description 16

- 150000001450 anions Chemical class 0.000 description 14

- 239000004020 conductor Substances 0.000 description 13

- 238000000354 decomposition reaction Methods 0.000 description 13

- 229910052751 metal Inorganic materials 0.000 description 12

- 238000001514 detection method Methods 0.000 description 11

- 238000000576 coating method Methods 0.000 description 10

- 239000007769 metal material Substances 0.000 description 10

- 239000002002 slurry Substances 0.000 description 10

- 230000006641 stabilisation Effects 0.000 description 10

- 238000011105 stabilization Methods 0.000 description 10

- 229910052782 aluminium Inorganic materials 0.000 description 9

- 239000011883 electrode binding agent Substances 0.000 description 9

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 8

- 238000007599 discharging Methods 0.000 description 8

- 239000011808 electrode reactant Substances 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 8

- 239000002184 metal Substances 0.000 description 8

- 230000004048 modification Effects 0.000 description 8

- 238000012986 modification Methods 0.000 description 8

- 150000002148 esters Chemical group 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 239000003960 organic solvent Substances 0.000 description 7

- 238000002360 preparation method Methods 0.000 description 7

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 6

- 239000002033 PVDF binder Substances 0.000 description 6

- 239000000470 constituent Substances 0.000 description 6

- 125000004122 cyclic group Chemical group 0.000 description 6

- 230000004927 fusion Effects 0.000 description 6

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- 239000004743 Polypropylene Substances 0.000 description 5

- 239000012790 adhesive layer Substances 0.000 description 5

- 239000003575 carbonaceous material Substances 0.000 description 5

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 5

- 150000002500 ions Chemical class 0.000 description 5

- 239000005001 laminate film Substances 0.000 description 5

- 229920001155 polypropylene Polymers 0.000 description 5

- 239000002243 precursor Substances 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- ZPFAVCIQZKRBGF-UHFFFAOYSA-N 1,3,2-dioxathiolane 2,2-dioxide Chemical group O=S1(=O)OCCO1 ZPFAVCIQZKRBGF-UHFFFAOYSA-N 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- 229910013872 LiPF Inorganic materials 0.000 description 4

- 229910013870 LiPF 6 Inorganic materials 0.000 description 4

- 101150058243 Lipf gene Proteins 0.000 description 4

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 4

- 230000009471 action Effects 0.000 description 4

- 239000003125 aqueous solvent Substances 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 239000006258 conductive agent Substances 0.000 description 4

- 125000000524 functional group Chemical group 0.000 description 4

- 239000012528 membrane Substances 0.000 description 4

- 125000004433 nitrogen atom Chemical group N* 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- FSSPGSAQUIYDCN-UHFFFAOYSA-N 1,3-Propane sultone Chemical compound O=S1(=O)CCCO1 FSSPGSAQUIYDCN-UHFFFAOYSA-N 0.000 description 3

- VAYTZRYEBVHVLE-UHFFFAOYSA-N 1,3-dioxol-2-one Chemical compound O=C1OC=CO1 VAYTZRYEBVHVLE-UHFFFAOYSA-N 0.000 description 3

- RYIRMSRYCSMGJA-UHFFFAOYSA-N 1,5,2,4-dioxadithiepane 2,2,4,4-tetraoxide Chemical compound O=S1(=O)CS(=O)(=O)OCCO1 RYIRMSRYCSMGJA-UHFFFAOYSA-N 0.000 description 3

- FALRKNHUBBKYCC-UHFFFAOYSA-N 2-(chloromethyl)pyridine-3-carbonitrile Chemical compound ClCC1=NC=CC=C1C#N FALRKNHUBBKYCC-UHFFFAOYSA-N 0.000 description 3

- DSMUTQTWFHVVGQ-UHFFFAOYSA-N 4,5-difluoro-1,3-dioxolan-2-one Chemical compound FC1OC(=O)OC1F DSMUTQTWFHVVGQ-UHFFFAOYSA-N 0.000 description 3

- BJWMSGRKJIOCNR-UHFFFAOYSA-N 4-ethenyl-1,3-dioxolan-2-one Chemical compound C=CC1COC(=O)O1 BJWMSGRKJIOCNR-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 3

- 239000005057 Hexamethylene diisocyanate Substances 0.000 description 3

- 238000010521 absorption reaction Methods 0.000 description 3

- 229910052783 alkali metal Inorganic materials 0.000 description 3

- 150000001340 alkali metals Chemical class 0.000 description 3

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 3

- 150000001342 alkaline earth metals Chemical class 0.000 description 3

- 150000008064 anhydrides Chemical class 0.000 description 3

- JFDZBHWFFUWGJE-UHFFFAOYSA-N benzonitrile Chemical compound N#CC1=CC=CC=C1 JFDZBHWFFUWGJE-UHFFFAOYSA-N 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 125000004432 carbon atom Chemical group C* 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- 229910002804 graphite Inorganic materials 0.000 description 3

- 239000010439 graphite Substances 0.000 description 3

- RRAMGCGOFNQTLD-UHFFFAOYSA-N hexamethylene diisocyanate Chemical compound O=C=NCCCCCCN=C=O RRAMGCGOFNQTLD-UHFFFAOYSA-N 0.000 description 3

- 150000002596 lactones Chemical class 0.000 description 3

- 229910003002 lithium salt Inorganic materials 0.000 description 3

- 159000000002 lithium salts Chemical class 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 229940014800 succinic anhydride Drugs 0.000 description 3

- IAHFWCOBPZCAEA-UHFFFAOYSA-N succinonitrile Chemical compound N#CCCC#N IAHFWCOBPZCAEA-UHFFFAOYSA-N 0.000 description 3

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 3

- 238000004804 winding Methods 0.000 description 3

- AVPYLKIIPLFMHQ-UHFFFAOYSA-N 1,2,6-oxadithiane 2,2,6,6-tetraoxide Chemical compound O=S1(=O)CCCS(=O)(=O)O1 AVPYLKIIPLFMHQ-UHFFFAOYSA-N 0.000 description 2

- SBLRHMKNNHXPHG-UHFFFAOYSA-N 4-fluoro-1,3-dioxolan-2-one Chemical compound FC1COC(=O)O1 SBLRHMKNNHXPHG-UHFFFAOYSA-N 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 2

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 2

- XTHFKEDIFFGKHM-UHFFFAOYSA-N Dimethoxyethane Chemical compound COCCOC XTHFKEDIFFGKHM-UHFFFAOYSA-N 0.000 description 2

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 2

- 229910013063 LiBF 4 Inorganic materials 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- 238000005481 NMR spectroscopy Methods 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 229910001413 alkali metal ion Inorganic materials 0.000 description 2

- 229910001420 alkaline earth metal ion Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 229910021383 artificial graphite Inorganic materials 0.000 description 2

- 238000001636 atomic emission spectroscopy Methods 0.000 description 2

- 229910052790 beryllium Inorganic materials 0.000 description 2

- ATBAMAFKBVZNFJ-UHFFFAOYSA-N beryllium atom Chemical compound [Be] ATBAMAFKBVZNFJ-UHFFFAOYSA-N 0.000 description 2

- 238000009529 body temperature measurement Methods 0.000 description 2

- 229910052791 calcium Inorganic materials 0.000 description 2

- 239000011575 calcium Substances 0.000 description 2

- 150000007942 carboxylates Chemical class 0.000 description 2

- 150000005678 chain carbonates Chemical class 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 239000011889 copper foil Substances 0.000 description 2

- 125000004093 cyano group Chemical group *C#N 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- FKRCODPIKNYEAC-UHFFFAOYSA-N ethyl propionate Chemical compound CCOC(=O)CC FKRCODPIKNYEAC-UHFFFAOYSA-N 0.000 description 2

- 229910052731 fluorine Inorganic materials 0.000 description 2

- GAEKPEKOJKCEMS-UHFFFAOYSA-N gamma-valerolactone Chemical compound CC1CCC(=O)O1 GAEKPEKOJKCEMS-UHFFFAOYSA-N 0.000 description 2

- 238000009616 inductively coupled plasma Methods 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 239000011147 inorganic material Substances 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 239000011244 liquid electrolyte Substances 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 239000012071 phase Substances 0.000 description 2

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920000098 polyolefin Polymers 0.000 description 2

- 229910052700 potassium Inorganic materials 0.000 description 2

- 239000011591 potassium Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- 229910052708 sodium Inorganic materials 0.000 description 2

- 239000011734 sodium Substances 0.000 description 2

- 150000003871 sulfonates Chemical class 0.000 description 2

- 230000008961 swelling Effects 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- 229920003051 synthetic elastomer Polymers 0.000 description 2

- 239000005061 synthetic rubber Substances 0.000 description 2

- 229910052723 transition metal Inorganic materials 0.000 description 2

- YFHICDDUDORKJB-UHFFFAOYSA-N trimethylene carbonate Chemical compound O=C1OCCCO1 YFHICDDUDORKJB-UHFFFAOYSA-N 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- KYPOHTVBFVELTG-OWOJBTEDSA-N (e)-but-2-enedinitrile Chemical compound N#C\C=C\C#N KYPOHTVBFVELTG-OWOJBTEDSA-N 0.000 description 1

- OQHXCCQBSGTCGM-UHFFFAOYSA-N 1,2,5-oxadithiolane 2,2,5,5-tetraoxide Chemical compound O=S1(=O)CCS(=O)(=O)O1 OQHXCCQBSGTCGM-UHFFFAOYSA-N 0.000 description 1

- WNXJIVFYUVYPPR-UHFFFAOYSA-N 1,3-dioxolane Chemical compound C1COCO1 WNXJIVFYUVYPPR-UHFFFAOYSA-N 0.000 description 1

- RYHBNJHYFVUHQT-UHFFFAOYSA-N 1,4-Dioxane Chemical compound C1COCCO1 RYHBNJHYFVUHQT-UHFFFAOYSA-N 0.000 description 1

- HNAGHMKIPMKKBB-UHFFFAOYSA-N 1-benzylpyrrolidine-3-carboxamide Chemical compound C1C(C(=O)N)CCN1CC1=CC=CC=C1 HNAGHMKIPMKKBB-UHFFFAOYSA-N 0.000 description 1

- UHOPWFKONJYLCF-UHFFFAOYSA-N 2-(2-sulfanylethyl)isoindole-1,3-dione Chemical compound C1=CC=C2C(=O)N(CCS)C(=O)C2=C1 UHOPWFKONJYLCF-UHFFFAOYSA-N 0.000 description 1

- HBZYYOYCJQHAEL-UHFFFAOYSA-N 2-[3-(dicyanomethylidene)inden-1-ylidene]propanedinitrile Chemical compound C1=CC=C2C(=C(C#N)C#N)CC(=C(C#N)C#N)C2=C1 HBZYYOYCJQHAEL-UHFFFAOYSA-N 0.000 description 1

- BCGCCTGNWPKXJL-UHFFFAOYSA-N 3-(2-cyanoethoxy)propanenitrile Chemical compound N#CCCOCCC#N BCGCCTGNWPKXJL-UHFFFAOYSA-N 0.000 description 1

- AWVNJBFNHGQUQU-UHFFFAOYSA-N 3-butoxypropanenitrile Chemical compound CCCCOCCC#N AWVNJBFNHGQUQU-UHFFFAOYSA-N 0.000 description 1

- VWEYDBUEGDKEHC-UHFFFAOYSA-N 3-methyloxathiolane 2,2-dioxide Chemical compound CC1CCOS1(=O)=O VWEYDBUEGDKEHC-UHFFFAOYSA-N 0.000 description 1

- KLLQVNFCMHPYGL-UHFFFAOYSA-N 5h-oxathiole 2,2-dioxide Chemical compound O=S1(=O)OCC=C1 KLLQVNFCMHPYGL-UHFFFAOYSA-N 0.000 description 1

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- BHPQYMZQTOCNFJ-UHFFFAOYSA-N Calcium cation Chemical compound [Ca+2] BHPQYMZQTOCNFJ-UHFFFAOYSA-N 0.000 description 1

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 1

- OIFBSDVPJOWBCH-UHFFFAOYSA-N Diethyl carbonate Chemical compound CCOC(=O)OCC OIFBSDVPJOWBCH-UHFFFAOYSA-N 0.000 description 1

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- JGFBQFKZKSSODQ-UHFFFAOYSA-N Isothiocyanatocyclopropane Chemical compound S=C=NC1CC1 JGFBQFKZKSSODQ-UHFFFAOYSA-N 0.000 description 1

- 229910004190 Li1.15(Mn0.65Ni0.22Co0.13)O2 Inorganic materials 0.000 description 1

- 229910008744 Li1.2Mn0.52Co0.175Ni0.1O2 Inorganic materials 0.000 description 1

- 229910013075 LiBF Inorganic materials 0.000 description 1

- 229910012278 LiCo0.98Al0.01Mg0.01O2 Inorganic materials 0.000 description 1

- 229910032387 LiCoO2 Inorganic materials 0.000 description 1

- 229910011857 LiFe0.3Mn0.7PO4 Inorganic materials 0.000 description 1

- 229910011990 LiFe0.5Mn0.5PO4 Inorganic materials 0.000 description 1

- 229910052493 LiFePO4 Inorganic materials 0.000 description 1

- 229910000668 LiMnPO4 Inorganic materials 0.000 description 1

- 229910013716 LiNi Inorganic materials 0.000 description 1

- 229910013825 LiNi0.33Co0.33Mn0.33O2 Inorganic materials 0.000 description 1

- 229910002991 LiNi0.5Co0.2Mn0.3O2 Inorganic materials 0.000 description 1

- 229910002995 LiNi0.8Co0.15Al0.05O2 Inorganic materials 0.000 description 1

- 229910003005 LiNiO2 Inorganic materials 0.000 description 1

- 229910002097 Lithium manganese(III,IV) oxide Inorganic materials 0.000 description 1

- JLVVSXFLKOJNIY-UHFFFAOYSA-N Magnesium ion Chemical compound [Mg+2] JLVVSXFLKOJNIY-UHFFFAOYSA-N 0.000 description 1

- RJUFJBKOKNCXHH-UHFFFAOYSA-N Methyl propionate Chemical compound CCC(=O)OC RJUFJBKOKNCXHH-UHFFFAOYSA-N 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- XBDQKXXYIPTUBI-UHFFFAOYSA-M Propionate Chemical compound CCC([O-])=O XBDQKXXYIPTUBI-UHFFFAOYSA-M 0.000 description 1

- 229910008479 TiSi2 Inorganic materials 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- 230000002159 abnormal effect Effects 0.000 description 1

- KXKVLQRXCPHEJC-UHFFFAOYSA-N acetic acid trimethyl ester Natural products COC(C)=O KXKVLQRXCPHEJC-UHFFFAOYSA-N 0.000 description 1

- 239000006230 acetylene black Substances 0.000 description 1

- BTGRAWJCKBQKAO-UHFFFAOYSA-N adiponitrile Chemical compound N#CCCCCC#N BTGRAWJCKBQKAO-UHFFFAOYSA-N 0.000 description 1

- 229910001423 beryllium ion Inorganic materials 0.000 description 1

- DFJQEGUNXWZVAH-UHFFFAOYSA-N bis($l^{2}-silanylidene)titanium Chemical compound [Si]=[Ti]=[Si] DFJQEGUNXWZVAH-UHFFFAOYSA-N 0.000 description 1

- 229910001593 boehmite Inorganic materials 0.000 description 1

- 150000001642 boronic acid derivatives Chemical class 0.000 description 1

- OBNCKNCVKJNDBV-UHFFFAOYSA-N butanoic acid ethyl ester Natural products CCCC(=O)OCC OBNCKNCVKJNDBV-UHFFFAOYSA-N 0.000 description 1

- PWLNAUNEAKQYLH-UHFFFAOYSA-N butyric acid octyl ester Natural products CCCCCCCCOC(=O)CCC PWLNAUNEAKQYLH-UHFFFAOYSA-N 0.000 description 1

- 229910001424 calcium ion Inorganic materials 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 1

- 150000004649 carbonic acid derivatives Chemical class 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 1

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000000748 compression moulding Methods 0.000 description 1

- 238000006482 condensation reaction Methods 0.000 description 1

- 229920001940 conductive polymer Polymers 0.000 description 1

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- VMUOSHREZKXCIV-UHFFFAOYSA-N cyclohexane-1,3,5-tricarbonitrile Chemical compound N#CC1CC(C#N)CC(C#N)C1 VMUOSHREZKXCIV-UHFFFAOYSA-N 0.000 description 1

- SVPZJHKVRMRREG-UHFFFAOYSA-N cyclopentanecarbonitrile Chemical compound N#CC1CCCC1 SVPZJHKVRMRREG-UHFFFAOYSA-N 0.000 description 1

- DFJYZCUIKPGCSG-UHFFFAOYSA-N decanedinitrile Chemical compound N#CCCCCCCCCC#N DFJYZCUIKPGCSG-UHFFFAOYSA-N 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000018044 dehydration Effects 0.000 description 1

- 238000006297 dehydration reaction Methods 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- SXWUDUINABFBMK-UHFFFAOYSA-L dilithium;fluoro-dioxido-oxo-$l^{5}-phosphane Chemical compound [Li+].[Li+].[O-]P([O-])(F)=O SXWUDUINABFBMK-UHFFFAOYSA-L 0.000 description 1

- IEJIGPNLZYLLBP-UHFFFAOYSA-N dimethyl carbonate Chemical compound COC(=O)OC IEJIGPNLZYLLBP-UHFFFAOYSA-N 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- PYMZYVXDCJXPAM-UHFFFAOYSA-N ethane-1,2-diol;propanenitrile Chemical compound CCC#N.CCC#N.OCCO PYMZYVXDCJXPAM-UHFFFAOYSA-N 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- HHEIMYAXCOIQCJ-UHFFFAOYSA-N ethyl 2,2-dimethylpropanoate Chemical compound CCOC(=O)C(C)(C)C HHEIMYAXCOIQCJ-UHFFFAOYSA-N 0.000 description 1

- JBTWLSYIZRCDFO-UHFFFAOYSA-N ethyl methyl carbonate Chemical compound CCOC(=O)OC JBTWLSYIZRCDFO-UHFFFAOYSA-N 0.000 description 1

- 125000000816 ethylene group Chemical group [H]C([H])([*:1])C([H])([H])[*:2] 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000005669 field effect Effects 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 229920001973 fluoroelastomer Polymers 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000002290 gas chromatography-mass spectrometry Methods 0.000 description 1

- 239000011245 gel electrolyte Substances 0.000 description 1

- VANNPISTIUFMLH-UHFFFAOYSA-N glutaric anhydride Chemical compound O=C1CCCC(=O)O1 VANNPISTIUFMLH-UHFFFAOYSA-N 0.000 description 1

- ZTOMUSMDRMJOTH-UHFFFAOYSA-N glutaronitrile Chemical compound N#CCCCC#N ZTOMUSMDRMJOTH-UHFFFAOYSA-N 0.000 description 1

- 229910021469 graphitizable carbon Inorganic materials 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- LNLFLMCWDHZINJ-UHFFFAOYSA-N hexane-1,3,6-tricarbonitrile Chemical compound N#CCCCC(C#N)CCC#N LNLFLMCWDHZINJ-UHFFFAOYSA-N 0.000 description 1

- FAHBNUUHRFUEAI-UHFFFAOYSA-M hydroxidooxidoaluminium Chemical compound O[Al]=O FAHBNUUHRFUEAI-UHFFFAOYSA-M 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000004255 ion exchange chromatography Methods 0.000 description 1

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 1

- 239000003273 ketjen black Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 150000002641 lithium Chemical class 0.000 description 1

- 229910003473 lithium bis(trifluoromethanesulfonyl)imide Inorganic materials 0.000 description 1

- QSZMZKBZAYQGRS-UHFFFAOYSA-N lithium;bis(trifluoromethylsulfonyl)azanide Chemical compound [Li+].FC(F)(F)S(=O)(=O)[N-]S(=O)(=O)C(F)(F)F QSZMZKBZAYQGRS-UHFFFAOYSA-N 0.000 description 1

- QVXQYMZVJNYDNG-UHFFFAOYSA-N lithium;bis(trifluoromethylsulfonyl)methylsulfonyl-trifluoromethane Chemical compound [Li+].FC(F)(F)S(=O)(=O)[C-](S(=O)(=O)C(F)(F)F)S(=O)(=O)C(F)(F)F QVXQYMZVJNYDNG-UHFFFAOYSA-N 0.000 description 1

- MCVFFRWZNYZUIJ-UHFFFAOYSA-M lithium;trifluoromethanesulfonate Chemical compound [Li+].[O-]S(=O)(=O)C(F)(F)F MCVFFRWZNYZUIJ-UHFFFAOYSA-M 0.000 description 1

- 229910001425 magnesium ion Inorganic materials 0.000 description 1

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 1

- 239000000395 magnesium oxide Substances 0.000 description 1

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 229940017219 methyl propionate Drugs 0.000 description 1

- 125000001570 methylene group Chemical group [H]C([H])([*:1])[*:2] 0.000 description 1

- UUIQMZJEGPQKFD-UHFFFAOYSA-N n-butyric acid methyl ester Natural products CCCC(=O)OC UUIQMZJEGPQKFD-UHFFFAOYSA-N 0.000 description 1

- KTQDYGVEEFGIIL-UHFFFAOYSA-N n-fluorosulfonylsulfamoyl fluoride Chemical compound FS(=O)(=O)NS(F)(=O)=O KTQDYGVEEFGIIL-UHFFFAOYSA-N 0.000 description 1

- 229910021382 natural graphite Inorganic materials 0.000 description 1

- 229910021470 non-graphitizable carbon Inorganic materials 0.000 description 1

- 239000011255 nonaqueous electrolyte Substances 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 229920006284 nylon film Polymers 0.000 description 1

- YSIMAPNUZAVQER-UHFFFAOYSA-N octanenitrile Chemical compound CCCCCCCC#N YSIMAPNUZAVQER-UHFFFAOYSA-N 0.000 description 1

- 125000001979 organolithium group Chemical group 0.000 description 1

- 230000001151 other effect Effects 0.000 description 1

- 238000007500 overflow downdraw method Methods 0.000 description 1

- MHYFEEDKONKGEB-UHFFFAOYSA-N oxathiane 2,2-dioxide Chemical compound O=S1(=O)CCCCO1 MHYFEEDKONKGEB-UHFFFAOYSA-N 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 125000005004 perfluoroethyl group Chemical group FC(F)(F)C(F)(F)* 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- XQZYPMVTSDWCCE-UHFFFAOYSA-N phthalonitrile Chemical compound N#CC1=CC=CC=C1C#N XQZYPMVTSDWCCE-UHFFFAOYSA-N 0.000 description 1

- 229920006391 phthalonitrile polymer Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229910001414 potassium ion Inorganic materials 0.000 description 1

- 230000003389 potentiating effect Effects 0.000 description 1

- OWAHJGWVERXJMI-UHFFFAOYSA-N prop-2-ynyl methanesulfonate Chemical compound CS(=O)(=O)OCC#C OWAHJGWVERXJMI-UHFFFAOYSA-N 0.000 description 1

- RAFBXJGDOLMWDJ-UHFFFAOYSA-N propane-1,2,2,3-tetracarbonitrile Chemical compound N#CCC(C#N)(C#N)CC#N RAFBXJGDOLMWDJ-UHFFFAOYSA-N 0.000 description 1

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 1

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 1

- 125000004805 propylene group Chemical group [H]C([H])([H])C([H])([*:1])C([H])([H])[*:2] 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 238000001953 recrystallisation Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 229910001415 sodium ion Inorganic materials 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 229920003048 styrene butadiene rubber Polymers 0.000 description 1

- 229920001059 synthetic polymer Polymers 0.000 description 1

- PCCVSPMFGIFTHU-UHFFFAOYSA-N tetracyanoquinodimethane Chemical compound N#CC(C#N)=C1C=CC(=C(C#N)C#N)C=C1 PCCVSPMFGIFTHU-UHFFFAOYSA-N 0.000 description 1

- BFKJFAAPBSQJPD-UHFFFAOYSA-N tetrafluoroethene Chemical group FC(F)=C(F)F BFKJFAAPBSQJPD-UHFFFAOYSA-N 0.000 description 1

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 1

- 238000007751 thermal spraying Methods 0.000 description 1

- FYSNRJHAOHDILO-UHFFFAOYSA-N thionyl chloride Chemical compound ClS(Cl)=O FYSNRJHAOHDILO-UHFFFAOYSA-N 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- 125000002023 trifluoromethyl group Chemical group FC(F)(F)* 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/056—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes

- H01M10/0564—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes the electrolyte being constituted of organic materials only

- H01M10/0566—Liquid materials

- H01M10/0567—Liquid materials characterised by the additives

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/056—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes

- H01M10/0564—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes the electrolyte being constituted of organic materials only

- H01M10/0566—Liquid materials

- H01M10/0568—Liquid materials characterised by the solutes

Definitions

- This technology relates to electrolytes for secondary batteries and secondary batteries.

- secondary batteries are being developed as a power source that is small, lightweight, and has a high energy density.

- These secondary batteries contain a positive electrode, a negative electrode, and an electrolyte (secondary battery electrolyte), and various studies are being conducted on the configuration of these secondary batteries.

- Faiz Ahmed et al. “Novel divalent organo-lithium salts with high electrochemical and thermal stability for aqueous rechargeable Li-Ion batteries”, Electrochimica Acta, 298, 2019, 709-716 Faiz Ahmed et al., “Highly conductive divalent fluorosulfonyl imide based electrolytes improving Li-ion battery performance: Additive potentiating”, Journal of Power Sources, 455, 2020, 227980

- the electrolyte for a secondary battery contains an electrolyte salt and chloride ions.

- the electrolyte salt contains imide anions, and the imide anions include at least one of a first imide anion represented by formula (1), a second imide anion represented by formula (2), a third imide anion represented by formula (3), and a fourth imide anion represented by formula (4).

- the chloride ion content is 5,000 ppm by weight or less.

- Each of R1 and R2 is either a fluorine group or a fluorinated alkyl group.

- Each of R3 and R4 is either a fluorine group or a fluorinated alkyl group.

- Each of X1, X2, X3 and X4 is either a carbonyl group, a sulfinyl group or a sulfonyl group.

- R5 is a fluorinated alkylene group.

- Each of Y1, Y2, and Y3 is any one of a carbonyl group, a sulfinyl group, and a sulfonyl group.

- Each of R6 and R7 is either a fluorine group or a fluorinated alkyl group.

- R8 is either an alkylene group, a phenylene group, a fluorinated alkylene group, or a fluorinated phenylene group.

- Each of Z1, Z2, Z3, and Z4 is either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- the secondary battery of one embodiment of the present technology includes a positive electrode, a negative electrode, and an electrolyte, and the electrolyte has a configuration similar to that of the electrolyte for a secondary battery of one embodiment of the present technology described above.

- the secondary battery electrolyte contains an electrolyte salt and chloride ions

- the electrolyte salt contains imide anions

- the imide anions contain one or more of the first imide anion, the second imide anion, the third imide anion, and the fourth imide anion

- the chloride ion content is 5,000 ppm by weight or less, so that excellent battery characteristics can be obtained.

- FIG. 1 is a perspective view illustrating a configuration of a secondary battery according to an embodiment of the present technology.

- FIG. 2 is a cross-sectional view showing the configuration of the battery element shown in FIG.

- FIG. 3 is a block diagram showing a configuration of an application example of a secondary battery.

- Electrolyte for secondary batteries First, an electrolyte for a secondary battery (hereinafter simply referred to as an "electrolyte”) according to an embodiment of the present technology will be described.

- the electrolytic solution is a liquid electrolyte used in a secondary battery, which is an electrochemical device.

- the electrolytic solution may be used in other electrochemical devices.

- the type of the other electrochemical device is not particularly limited, but specifically, it is a capacitor or the like.

- the electrolyte contains an electrolyte salt and chloride ions (Cl ⁇ ). More specifically, the electrolyte further contains a solvent that disperses (ionizes) the electrolyte salt.

- the electrolyte salt is a compound that ionizes in a solvent and contains an anion and a cation.

- the anion includes an imide anion.

- the imide anion includes one or more of a first imide anion represented by formula (1), a second imide anion represented by formula (2), a third imide anion represented by formula (3), and a fourth imide anion represented by formula (4). That is, the electrolyte salt includes one imide anion as an anion.

- the type of the first imide anion may be one type or two or more types. The same applies to each of the second imide anion, the third imide anion, and the fourth imide anion.

- Each of R1 and R2 is either a fluorine group or a fluorinated alkyl group.

- Each of W1, W2, and W3 is either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- Each of R3 and R4 is either a fluorine group or a fluorinated alkyl group.

- Each of X1, X2, X3 and X4 is either a carbonyl group, a sulfinyl group or a sulfonyl group.

- R5 is a fluorinated alkylene group.

- Each of Y1, Y2, and Y3 is any one of a carbonyl group, a sulfinyl group, and a sulfonyl group.

- Each of R6 and R7 is either a fluorine group or a fluorinated alkyl group.

- R8 is either an alkylene group, a phenylene group, a fluorinated alkylene group, or a fluorinated phenylene group.

- Each of Z1, Z2, Z3, and Z4 is either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- the anion contains an imide anion is as follows. First, when a secondary battery using an electrolyte is charged and discharged, a good quality coating derived from the electrolyte salt is formed on the surface of each of the positive and negative electrodes, suppressing the decomposition reaction of the electrolyte on the surface of each of the positive and negative electrodes. In this case, the decomposition reaction of the solvent is particularly suppressed. Second, the above-mentioned coating is used to improve the migration speed of cations near the surfaces of each of the positive and negative electrodes. Third, the migration speed of cations is improved even in the electrolyte liquid.

- the first imide anion is a chain anion (divalent negative ion) containing two nitrogen atoms (N) and three functional groups (W1 to W3).

- R1 and R2 are not particularly limited as long as they are either a fluorine group (-F) or a fluorinated alkyl group. Thus, R1 and R2 are not, for example, a hydrogen group (-H) or an alkyl group. R1 and R2 may be the same group or different groups.

- a fluorinated alkyl group is an alkyl group in which one or more hydrogen groups (-H) have been replaced with a fluorine group.

- the fluorinated alkyl group may be linear or branched with one or more side chains.

- the number of carbon atoms in the fluorinated alkyl group is not particularly limited, but is specifically 1 to 10. This is because the solubility and ionization properties of the electrolyte salt containing the first imide anion are improved.

- fluorinated alkyl groups include a perfluoromethyl group (--CF 3 ) and a perfluoroethyl group (--C 2 F 5 ).

- W1 to W3 are not particularly limited as long as they are either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- W1 to W3 may be the same group or different groups.

- any two of W1 to W3 may be the same group.

- the second imide anion is a chain anion (trivalent negative ion) containing three nitrogen atoms and four functional groups (X1 to X4).

- R3 and R4 are similar to those for R1 and R2.

- X1 to X4 are not particularly limited as long as they are either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- X1 to X4 may be the same group or different groups.

- any two of X1 to X4 may be the same group, or any three of X1 to X4 may be the same group.

- the third imide anion is a cyclic anion (divalent negative ion) containing two nitrogen atoms, three functional groups (Y1 to Y3), and one connecting group (R5).

- the fluorinated alkylene group R5 is an alkylene group in which one or more hydrogen groups have been replaced with fluorine groups.

- the fluorinated alkylene group may be linear or branched with one or more side chains.

- the number of carbon atoms in the fluorinated alkylene group is not particularly limited, but is specifically 1 to 10. This is because it improves the solubility and ionization properties of the electrolyte salt containing the third imide anion.

- fluorinated alkylene groups include a perfluoromethylene group (--CF 2 --) and a perfluoroethylene group (--C 2 F 4 --).

- Y1 to Y3 are not particularly limited as long as they are either a carbonyl group, a sulfinyl group, or a sulfonyl group.

- Y1 to Y3 may be the same group or different groups.

- any two of Y1 to Y3 may be the same group.

- the quaternary imide anion is a chain anion (divalent negative ion) containing two nitrogen atoms, four functional groups (Z1 to Z4), and one connecting group (R8).

- R6 and R7 are similar to those for R1 and R2.

- R8 is not particularly limited as long as it is any one of an alkylene group, a phenylene group, a fluorinated alkylene group, and a fluorinated phenylene group.

- the alkylene group may be linear or branched having one or more side chains.

- the number of carbon atoms in the alkylene group is not particularly limited, but specifically, it is 1 to 10. This is because the solubility and ionization property of the electrolyte salt containing the quaternary imide anion are improved.

- Specific examples of the alkylene group include a methylene group ( -CH2- ), an ethylene group (-C2H4- ) , and a propylene group ( -C3H6- ).

- fluorinated alkylene group R8 Details regarding the fluorinated alkylene group R8 are the same as those regarding the fluorinated alkylene group R5.

- a fluorinated phenylene group is a phenylene group in which one or more hydrogen groups have been substituted with fluorine groups.

- a specific example of a fluorinated phenylene group is a monofluorophenylene group (-C 6 H 3 F-).

- Z1 to Z4 are not particularly limited as long as they are either a carbonyl group, a sulfinyl group, or a sulfonyl group. In other words, Z1 to Z4 may be the same group or different groups. Of course, any two of Z1 to Z4 may be the same group, or any three of Z1 to Z4 may be the same group.

- Specific examples of the first imide anion include anions represented by each of formulas (1-1) to (1-30).

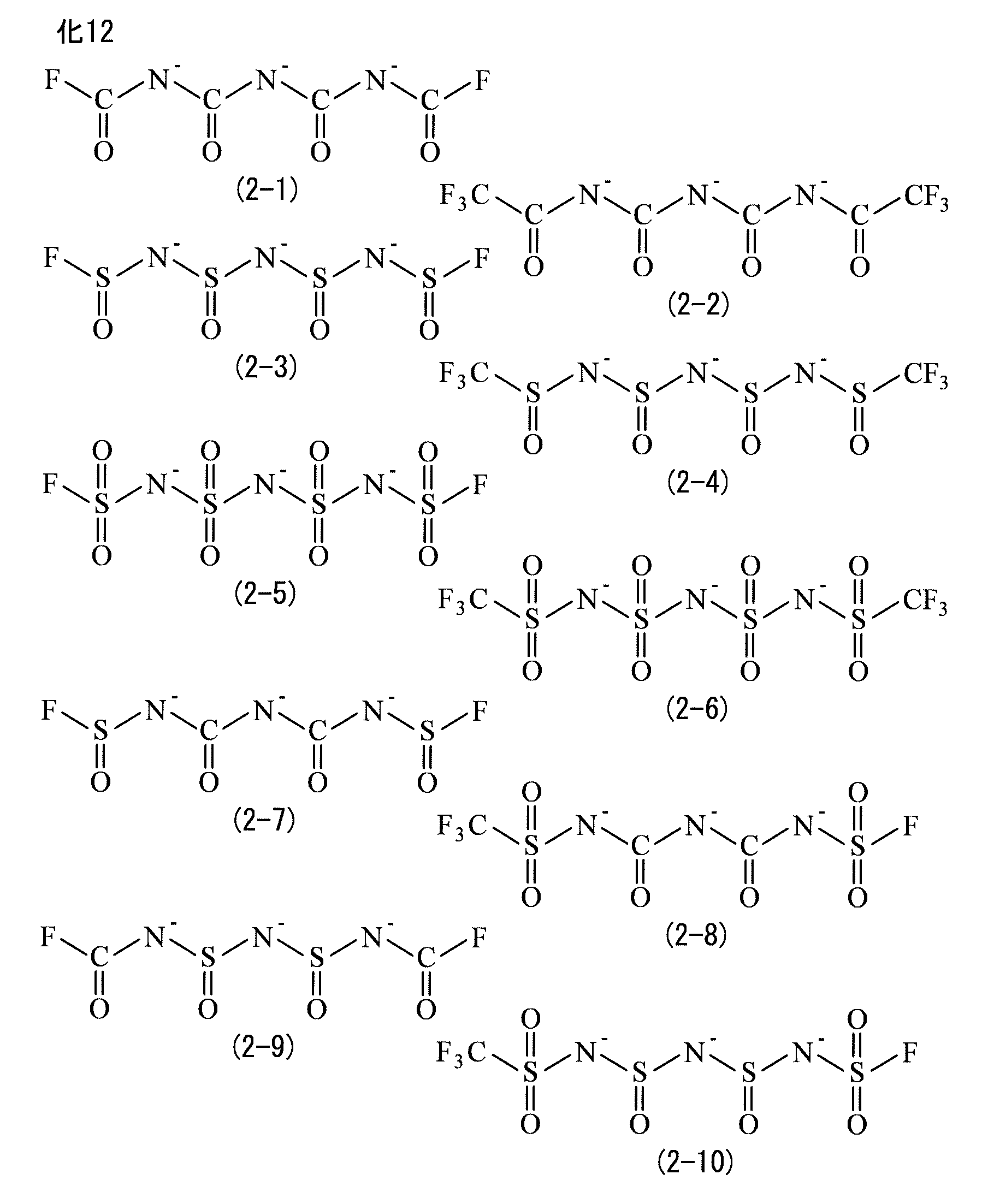

- second imide anion examples include the anions represented by formulas (2-1) to (2-22).

- third imide anion examples include the anions represented by formulas (3-1) to (3-15).

- fourth imide anion examples include the anions represented by formulas (4-1) to (4-65).

- the type of cation is not particularly limited. Specifically, the cation contains one or more types of light metal ions. That is, the electrolyte salt contains light metal ions as cations. This is because a high voltage can be obtained.

- the type of light metal ion is not particularly limited, but specific examples include alkali metal ions and alkaline earth metal ions. Specific examples of alkali metal ions include lithium ions, sodium ions, and potassium ions. Specific examples of alkaline earth metal ions include beryllium ions, magnesium ions, and calcium ions. In addition, the light metal ion may be an aluminum ion, etc.

- the light metal ions contain lithium ions, because this allows a sufficiently high voltage to be obtained.

- the content of the electrolyte salt in the electrolytic solution is not particularly limited and can be set arbitrarily.

- the content of the electrolyte salt in the electrolytic solution is preferably 0.2 mol/kg to 2 mol/kg. This is because high ionic conductivity can be obtained.

- the "content of the electrolyte salt” described here refers to the content of the electrolyte salt relative to the solvent.

- the electrolyte is analyzed using one or more of the following analytical methods: inductively coupled plasma (ICP) atomic emission spectroscopy, nuclear magnetic resonance spectroscopy (NMR), and gas chromatography-mass spectrometry (GC-MS).

- ICP inductively coupled plasma

- NMR nuclear magnetic resonance spectroscopy

- GC-MS gas chromatography-mass spectrometry

- Chloride ion Chloride ions are included in the electrolyte primarily for reasons that will be explained below.

- chloride ions are generated during the synthesis of electrolyte salts containing imide anions, and the chloride ions are mixed into the electrolyte solution.

- chloride ions derived from thionyl chloride (SOCl 2 ) are generated.

- electrolyte salts containing imide anions originally contain chloride ions, and these chloride ions are mixed into the electrolyte solution.

- chloride ions are generated because electrolyte salts containing imide anions contain chlorine as a constituent element.

- electrolyte salts containing imide anions contain chlorine as a constituent element, so chloride ions are generated, and chloride ions are also generated because they are mixed into the electrolyte.

- chloride ions may be present in the electrolyte for reasons other than those mentioned above.

- the content of chloride ions in the electrolyte is 5,000 ppm by weight or less, more specifically, 0 ppm by weight to 5,000 ppm by weight. This is because the chemical stability of the electrolyte is improved, and the decomposition reaction of the electrolyte is suppressed.

- chloride ions affect the chemical stability of the electrolyte.

- the chloride ion content is more than 5,000 ppm by weight, the chemical stability of the electrolyte decreases, making the electrolyte more susceptible to decomposition when a secondary battery using that electrolyte is charged and discharged.

- the chloride ion content is 5,000 ppm by weight or less, the chemical stability of the electrolyte improves, making the electrolyte less susceptible to decomposition when a secondary battery using that electrolyte is charged and discharged.

- the content of chloride ions in the electrolyte is 100 ppm by weight or less, more specifically 0 ppm by weight to 100 ppm by weight, even more preferably 50 ppm by weight or less, more specifically 0 ppm by weight to 50 ppm by weight, and particularly preferably 30 ppm by weight or less, more specifically 0 ppm by weight to 30 ppm by weight. This is because the chemical stability of the electrolyte is further improved.

- the electrolyte is analyzed using an analytical method such as ion chromatography. This separates the chloride ions and measures their amount.

- the solvent contains one or more of non-aqueous solvents (organic solvents), and the electrolyte solution containing the non-aqueous solvent is a so-called non-aqueous electrolyte solution.

- the non-aqueous solvent is an ester, an ether, or the like, more specifically, a carbonate ester compound, a carboxylate ester compound, a lactone compound, or the like.

- Carbonate compounds include cyclic carbonates and chain carbonates.

- cyclic carbonates are ethylene carbonate and propylene carbonate.

- chain carbonates are dimethyl carbonate, diethyl carbonate, and ethyl methyl carbonate.

- Carboxylic acid ester compounds include chain carboxylates.

- chain carboxylates include methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, propyl propionate, ethyl trimethylacetate, methyl butyrate, and ethyl butyrate.

- Lactone compounds include lactones. Specific examples of lactones include gamma-butyrolactone and gamma-valerolactone.

- the ethers may be 1,2-dimethoxyethane, tetrahydrofuran, 1,3-dioxolane, 1,4-dioxane, etc.

- the electrolyte may further contain one or more of the other electrolyte salts. This is because the cation migration speed is improved in the vicinity of the surfaces of the positive electrode and the negative electrode, and the cation migration speed is also improved in the electrolyte.

- the content of the other electrolyte salt in the electrolyte is not particularly limited and can be set arbitrarily.

- the type of other electrolyte salt is not particularly limited, but specifically, it is a light metal salt such as a lithium salt. However, the above electrolyte salts are excluded from the lithium salts described here.

- lithium salts include lithium hexafluorophosphate (LiPF 6 ), lithium tetrafluoroborate (LiBF 4 ), lithium trifluoromethanesulfonate (LiCF 3 SO 3 ), lithium bis(fluorosulfonyl)imide (LiN(FSO 2 ) 2 ), lithium bis(trifluoromethanesulfonyl)imide (LiN(CF 3 SO 2 ) 2 ), lithium tris(trifluoromethanesulfonyl)methide (LiC(CF 3 SO 2 ) 3 ), lithium bis(oxalato)borate (LiB(C 2 O 4 ) 2 ), lithium difluorooxalatoborate (LiBF 2 (C 2 O 4 )), and lithium difluorodi(oxalato)borate (LiPF 2 (C 2 O 4 ) 2 ) . ), lithium tetrafluorooxalatophosphate (Li

- the other electrolyte salt contains one or more of lithium hexafluorophosphate, lithium tetrafluoroborate, lithium bis(fluorosulfonyl)imide, lithium bis(oxalato)borate, and lithium difluorophosphate.

- the cation migration speed is sufficiently improved near the surfaces of the positive electrode and negative electrode, and the cation migration speed is also sufficiently improved in the electrolyte solution.

- the electrolyte may further contain one or more of the other solvents.

- a coating derived from the other solvent is formed on the surface of each of the positive and negative electrodes, so that the decomposition reaction of the electrolyte is suppressed.

- the content of the other solvent in the electrolyte is not particularly limited and can be set arbitrarily.

- the types of other solvents are not particularly limited, but specific examples include unsaturated cyclic carbonates, fluorinated cyclic carbonates, sulfonic acid esters, dicarboxylic acid anhydrides, disulfonic acid anhydrides, sulfates, nitrile compounds, and isocyanate compounds.

- the unsaturated cyclic carbonate is a cyclic carbonate containing an unsaturated carbon bond (carbon-carbon double bond).

- the number of unsaturated carbon bonds is not particularly limited, and may be one or more.

- Specific examples of the unsaturated cyclic carbonate include vinylene carbonate, vinylethylene carbonate, and methyleneethylene carbonate.

- a fluorinated cyclic carbonate is a cyclic carbonate containing fluorine as a constituent element. That is, a fluorinated cyclic carbonate is a compound in which one or more hydrogen groups of a cyclic carbonate are substituted with fluorine groups. Specific examples of the fluorinated cyclic carbonate include monofluoroethylene carbonate and difluoroethylene carbonate.

- the sulfonate esters include cyclic monosulfonate esters, cyclic disulfonate esters, chain monosulfonate esters, chain disulfonate esters, etc.

- cyclic monosulfonate esters include 1,3-propane sultone, 1-propene-1,3-sultone, 1,4-butane sultone, 2,4-butane sultone, methanesulfonic acid propargyl ester, etc.

- Specific examples of cyclic disulfonate esters include cyclodisone, etc.

- dicarboxylic acid anhydride Specific examples of dicarboxylic acid anhydrides include succinic anhydride, glutaric anhydride, and maleic anhydride.

- disulfonic anhydride Specific examples of disulfonic anhydrides include ethanedisulfonic anhydride and propanedisulfonic anhydride.

- sulfate ester is ethylene sulfate (1,3,2-dioxathiolane 2,2-dioxide).

- the nitrile compound is a compound having one or more cyano groups (-CN).

- Specific examples of the nitrile compound include octanenitrile, benzonitrile, phthalonitrile, succinonitrile, glutaronitrile, adiponitrile, sebaconitrile, 1,3,6-hexanetricarbonitrile, 3,3'-oxydipropionitrile, 3-butoxypropionitrile, ethylene glycol bispropionitrile ether, 1,2,2,3-tetracyanopropane, tetracyanopropane, fumaronitrile, 7,7,8,8-tetracyanoquinodimethane, cyclopentanecarbonitrile, 1,3,5-cyclohexanetricarbonitrile, and 1,3-bis(dicyanomethylidene)indane.

- the isocyanate compound is a compound having one or more isocyanate groups (-NCO).

- a specific example of the isocyanate compound is hexamethylene diisocyanate.

- an electrolyte salt is added to a solvent.

- another electrolyte salt may be added to the solvent, or an additive may be added to the solvent.

- the electrolyte salt and the like are dispersed or dissolved in the solvent by the above-mentioned process, and thus an electrolyte solution is prepared.

- This electrolyte solution contains chloride ions for the above-mentioned reasons.

- the electrolyte contains an electrolyte salt and chloride ions

- the electrolyte salt contains imide anions

- the content of chloride ions in the electrolyte is 5000 ppm by weight or less.

- the electrolyte salt contains imide anions, as described above, when a secondary battery using an electrolyte is charged and discharged, the decomposition reaction of the electrolyte is suppressed by utilizing the high-quality coating derived from the electrolyte salt, and the migration rate of cations is improved.

- the content of chloride ions in the electrolyte is 5,000 ppm by weight or less, the chemical stability of the electrolyte is improved, as described above. This further suppresses the decomposition reaction of the electrolyte when a secondary battery using the electrolyte is charged and discharged.

- the electrolyte salt contains light metal ions as cations, a higher voltage can be obtained, and therefore a greater effect can be achieved.

- the light metal ions contain lithium ions, a higher voltage can be obtained, and therefore an even greater effect can be achieved.

- the content of electrolyte salt in the electrolyte solution is 0.2 mol/kg to 2 mol/kg, high ionic conductivity can be obtained, resulting in even greater effects.

- the electrolyte further contains one or more of the following electrolyte salts as other electrolyte salts: lithium hexafluorophosphate, lithium tetrafluoroborate, lithium bis(fluorosulfonyl)imide, lithium bis(oxalato)borate, and lithium difluorophosphate, the cation migration rate is further improved, and thus a greater effect can be obtained.

- the electrolyte further contains one or more of the following solvents as other solvents: unsaturated cyclic carbonates, fluorinated cyclic carbonates, sulfonic acid esters, dicarboxylic acid anhydrides, disulfonic acid anhydrides, sulfate esters, nitrile compounds, and isocyanate compounds, the decomposition reaction of the electrolyte is suppressed, and thus a greater effect can be obtained.

- the secondary battery described here is a secondary battery that obtains battery capacity by utilizing the absorption and release of electrode reactants, and is equipped with a positive electrode, a negative electrode, and an electrolyte.

- the charge capacity of the negative electrode is preferably greater than the discharge capacity of the positive electrode.

- the electrochemical capacity per unit area of the negative electrode is preferably greater than the electrochemical capacity per unit area of the positive electrode. This is to prevent electrode reactants from depositing on the surface of the negative electrode during charging.

- the type of electrode reactant is not particularly limited, but specifically includes light metals such as alkali metals and alkaline earth metals.

- alkali metals include lithium, sodium, and potassium

- alkaline earth metals include beryllium, magnesium, and calcium.

- the electrode reactant is lithium.

- a secondary battery that obtains battery capacity by utilizing the absorption and release of lithium is known as a lithium-ion secondary battery.

- lithium-ion secondary battery lithium is absorbed and released in an ionic state.

- Fig. 1 shows a perspective view of a secondary battery

- Fig. 2 shows a cross-sectional view of a battery element 20 shown in Fig. 1.

- FIG. 1 the exterior film 10 and the battery element 20 are shown in a state where they are separated from each other, and a cross section of the battery element 20 along the XZ plane is shown by a dashed line. In FIG. 2, only a part of the battery element 20 is shown.

- this secondary battery includes an exterior film 10, a battery element 20, a positive electrode lead 31, a negative electrode lead 32, and sealing films 41 and 42.

- the secondary battery described here uses a flexible or pliable exterior film 10 as an exterior member for housing the battery element 20 inside. Therefore, the secondary battery shown in Figures 1 and 2 is a so-called laminate film type secondary battery.

- the exterior film 10 has a bag-like structure that is sealed with the battery element 20 housed therein. As a result, the exterior film 10 houses a positive electrode 21, a negative electrode 22, and a separator 23, which will be described later.

- the exterior film 10 is a single film-like member that is folded in the folding direction F.

- This exterior film 10 is provided with a recessed portion 10U (a so-called deep drawn portion) for accommodating the battery element 20.

- the exterior film 10 is a three-layer laminate film in which a fusion layer, a metal layer, and a surface protection layer are laminated in this order from the inside, and when the exterior film 10 is folded, the outer peripheral edges of the opposing fusion layers are fused to each other.

- the fusion layer contains a polymer compound such as polypropylene.

- the metal layer contains a metallic material such as aluminum.

- the surface protection layer contains a polymer compound such as nylon.

- the configuration (number of layers) of the exterior film 10 is not particularly limited, so it may be one or two layers, or four or more layers.

- the battery element 20 is housed inside the exterior film 10.

- the battery element 20 is a so-called power generating element, and includes a positive electrode 21, a negative electrode 22, a separator 23, and an electrolyte (not shown), as shown in Figures 1 and 2 .

- the battery element 20 is a so-called wound electrode body, so that the positive electrode 21 and the negative electrode 22 are wound around the winding axis P while facing each other via the separator 23.

- This winding axis P is a virtual axis extending in the Y-axis direction, as shown in FIG. 1.

- the three-dimensional shape of the battery element 20 is not particularly limited.

- the battery element 20 has a flat three-dimensional shape, so that the shape of the cross section (cross section along the XZ plane) of the battery element 20 intersecting the winding axis P is a flat shape defined by the major axis J1 and the minor axis J2.

- the long axis J1 is an imaginary axis extending in the X-axis direction and has a length greater than that of the short axis J2.

- the short axis J2 is an imaginary axis extending in the Z-axis direction intersecting the X-axis direction and has a length less than that of the long axis J1.

- the three-dimensional shape of the battery element 20 is a flattened cylinder, and therefore the cross-sectional shape of the battery element 20 is a flattened, approximately elliptical shape.

- the positive electrode 21 includes a positive electrode current collector 21A and a positive electrode active material layer 21B.

- the positive electrode collector 21A has a pair of surfaces on which the positive electrode active material layer 21B is provided.

- This positive electrode collector 21A contains a conductive material such as a metal material, and a specific example of the conductive material is aluminum.

- the positive electrode active material layer 21B contains one or more types of positive electrode active materials that absorb and release lithium. However, the positive electrode active material layer 21B may further contain one or more types of other materials such as a positive electrode binder and a positive electrode conductor.

- the method of forming the positive electrode active material layer 21B is not particularly limited, but specifically includes a coating method.

- the positive electrode active material layer 21B is provided on both sides of the positive electrode collector 21A.

- the positive electrode active material layer 21B may be provided on only one side of the positive electrode collector 21A on the side where the positive electrode 21 faces the negative electrode 22.

- the type of positive electrode active material is not particularly limited, but specifically includes lithium-containing compounds.

- This lithium-containing compound is a compound that contains one or more transition metal elements as constituent elements along with lithium, and may further contain one or more other elements as constituent elements.

- the type of other element is not particularly limited, so long as it is an element other than lithium and transition metal elements, but specifically includes elements belonging to groups 2 to 15 of the long period periodic table.

- the type of lithium-containing compound is not particularly limited, but specifically includes oxides, phosphate compounds, silicate compounds, and borate compounds.

- oxides include LiNiO2 , LiCoO2 , LiCo0.98Al0.01Mg0.01O2 , LiNi0.5Co0.2Mn0.3O2 , LiNi0.8Co0.15Al0.05O2 , LiNi0.33Co0.33Mn0.33O2 , Li1.2Mn0.52Co0.175Ni0.1O2 , Li1.15 ( Mn0.65Ni0.22Co0.13 ) O2 , and LiMn2O4 .

- phosphate compounds include LiFePO4 , LiMnPO4 , LiFe0.5Mn0.5PO4 , and LiFe0.3Mn0.7PO4 .

- the positive electrode binder contains one or more of the following materials: synthetic rubber and polymeric compounds.

- synthetic rubber include styrene-butadiene rubber, fluororubber, and ethylene-propylene-diene.

- polymeric compounds include polyvinylidene fluoride, polyimide, and carboxymethyl cellulose.

- the positive electrode conductive agent contains one or more conductive materials such as carbon materials, metal materials, and conductive polymer compounds.

- conductive materials such as carbon materials, metal materials, and conductive polymer compounds.

- Specific examples of carbon materials include graphite, carbon black, acetylene black, and ketjen black.

- the negative electrode 22 includes a negative electrode current collector 22A and a negative electrode active material layer 22B.

- the negative electrode current collector 22A has a pair of surfaces on which the negative electrode active material layer 22B is provided.

- This negative electrode current collector 22A contains a conductive material such as a metal material, and a specific example of the conductive material is copper.

- the negative electrode active material layer 22B contains one or more types of negative electrode active materials that absorb and release lithium. However, the negative electrode active material layer 22B may further contain one or more types of other materials such as a negative electrode binder and a negative electrode conductor.

- the method of forming the negative electrode active material layer 22B is not particularly limited, but specifically includes one or more types of a coating method, a gas phase method, a liquid phase method, a thermal spraying method, and a baking method (sintering method).

- the negative electrode active material layer 22B is provided on both sides of the negative electrode collector 22A.

- the negative electrode active material layer 22B may be provided on only one side of the negative electrode collector 22A on the side where the negative electrode 22 faces the positive electrode 21.

- the type of negative electrode active material is not particularly limited, but specific examples include carbon materials and metal-based materials, because they provide high energy density.

- carbon materials include graphitizable carbon, non-graphitizable carbon, and graphite.

- the graphite may be natural graphite or artificial graphite.

- Metallic materials are a general term for materials that contain one or more of metallic elements and semi-metallic elements that can form an alloy with lithium as constituent elements, and specific examples of the metallic elements and semi-metallic elements include silicon and tin.

- the metallic materials may be a single element, an alloy, a compound, a mixture of two or more of these, or a material that contains two or more of these phases.

- Specific examples of metallic materials include TiSi2 and SiOx (0 ⁇ x ⁇ 2 or 0.2 ⁇ x ⁇ 1.4).

- the separator 23 is an insulating porous film interposed between the positive electrode 21 and the negative electrode 22, and allows lithium to pass through in an ion state while preventing the occurrence of a short circuit due to contact between the positive electrode 21 and the negative electrode 22.

- This separator 23 contains a polymer compound such as polyethylene.

- the electrolyte is impregnated into each of the positive electrode 21, the negative electrode 22, and the separator 23, and has the above-mentioned configuration. That is, the electrolyte contains an electrolyte salt and chloride ions, the electrolyte salt contains imide anions, and the content of chloride ions in the electrolyte is within the above-mentioned range.

- the positive electrode lead 31 is a positive electrode wiring connected to the positive electrode current collector 21A of the positive electrode 21, and is led out of the exterior film 10.

- the positive electrode lead 31 contains a conductive material such as a metal material, and a specific example of the conductive material is aluminum.

- the shape of the positive electrode lead 31 is either a thin plate shape or a mesh shape.

- the negative electrode lead 32 is a negative electrode wiring connected to the negative electrode current collector 22A of the negative electrode 22, and is led out of the exterior film 10.

- the lead-out direction of the negative electrode lead 32 is the same as the lead-out direction of the positive electrode lead 31.

- This negative electrode lead 32 contains a conductive material such as a metal material, and a specific example of the conductive material is copper.

- the details of the shape of the negative electrode lead 32 are the same as the details of the shape of the positive electrode lead 31.

- the sealing film 41 is inserted between the exterior film 10 and the positive electrode lead 31, and the sealing film 42 is inserted between the exterior film 10 and the negative electrode lead 32.

- the sealing films 41 and 42 may be omitted.

- the sealing film 41 is a sealing member that prevents outside air and the like from entering the inside of the exterior film 10.

- This sealing film 41 contains a polymer compound such as polyolefin that has adhesion to the positive electrode lead 31, and a specific example of the polymer compound is polypropylene.

- the configuration of the sealing film 42 is the same as that of the sealing film 41, except that the sealing film 42 is a sealing member that has adhesion to the negative electrode lead 32.

- the sealing film 42 contains a polymer compound such as polyolefin that has adhesion to the negative electrode lead 32.

- This secondary battery operates in the battery element 20 as follows.

- lithium When charging, lithium is released from the positive electrode 21 and is absorbed into the negative electrode 22 via the electrolyte.

- discharging lithium is released from the negative electrode 22 and is absorbed into the positive electrode 21 via the electrolyte.

- discharging and charging lithium is absorbed and released in an ionic state.

- the positive electrode 21 and the negative electrode 22 are each produced and an electrolyte solution is prepared according to the procedure described below. Then, the positive electrode 21, the negative electrode 22, and the electrolyte solution are used to manufacture the secondary battery. A secondary battery is assembled and a stabilization process is performed on the secondary battery after assembly.

- a positive electrode active material, a positive electrode binder, and a positive electrode conductive agent are mixed together to prepare a positive electrode mixture. Then, the positive electrode mixture is poured into a solvent to prepare a paste-like positive electrode mixture slurry.

- the solvent may be an aqueous solvent or an organic solvent.

- the positive electrode active material layer 21B is formed by applying the positive electrode mixture slurry to both sides of the positive electrode current collector 21A.

- the positive electrode active material layer 21B is compression molded using a roll press or the like. In this case, the positive electrode active material layer 21B may be heated, or the compression molding of the positive electrode active material layer 21B may be repeated multiple times. In this way, the positive electrode active material layer 21B is formed on both sides of the positive electrode current collector 21A, and the positive electrode 21 is produced.

- the negative electrode 22 is formed by the same procedure as the procedure for producing the positive electrode 21 described above. Specifically, first, a mixture (negative electrode mixture) in which the negative electrode active material, the negative electrode binder, and the negative electrode conductive agent are mixed together is put into a solvent to prepare a paste-like negative electrode mixture slurry. Details regarding the solvent are as described above. Next, the negative electrode mixture slurry is applied to both sides of the negative electrode current collector 22A to form the negative electrode active material layer 22B. Finally, the negative electrode active material layer 22B is compression molded. As a result, the negative electrode active material layer 22B is formed on both sides of the negative electrode current collector 22A, and the negative electrode 22 is produced.

- the positive electrode lead 31 is connected to the positive electrode collector 21A of the positive electrode 21 using a joining method such as welding, and the negative electrode lead 32 is connected to the negative electrode collector 22A of the negative electrode 22 using a joining method such as welding.

- the positive electrode 21 and the negative electrode 22 are stacked on top of each other with the separator 23 interposed therebetween to form a laminate (not shown).

- the laminate is then wound to produce a wound body (not shown), which is then pressed using a press or the like to form the wound body into a flat shape.

- the wound body after this formation has a configuration similar to that of the battery element 20, except that it is not impregnated with the electrolyte.

- the exterior film 10 adheresive layer/metal layer/surface protection layer

- the exterior film 10 is folded so that the exterior films 10 face each other.

- the outer edges of two of the opposing adhesive layers are joined to each other using an adhesive method such as heat fusion, thereby placing the roll inside the bag-shaped exterior film 10.

- the outer peripheral edges of the remaining sides of the opposing fusion layers are joined to each other by using an adhesive method such as a heat fusion method.

- a sealing film 41 is inserted between the exterior film 10 and the positive electrode lead 31, and a sealing film 42 is inserted between the exterior film 10 and the negative electrode lead 32.

- the wound body is impregnated with the electrolyte, producing the battery element 20.

- the battery element 20 is then enclosed inside the bag-shaped exterior film 10, and a secondary battery is assembled.

- Stabilization treatment of secondary battery after assembly The assembled secondary battery is charged and discharged. Stabilization conditions such as the environmental temperature, the number of charge/discharge cycles (number of cycles), and charge/discharge conditions can be set arbitrarily. As a result, a coating is formed on the surface of each of the positive electrode 21 and the negative electrode 22, and the state of the battery element 20 is electrochemically stabilized. Thus, the secondary battery is completed.

- the secondary battery includes an electrolyte, and the electrolyte has the above-mentioned configuration, and therefore, for the above-mentioned reasons, the decomposition reaction of the electrolyte is significantly suppressed while the lithium ion migration speed is guaranteed, and therefore excellent battery characteristics can be obtained.

- the secondary battery is a lithium-ion secondary battery

- sufficient battery capacity can be stably obtained by utilizing the absorption and release of lithium, resulting in even greater effects.

- the electrolyte solution may contain other electrolyte salts in addition to the electrolyte salt containing the imide anion.

- the electrolyte solution contains lithium hexafluorophosphate as another electrolyte salt, and that the content of the electrolyte salt in the electrolyte solution is optimized in relation to the content of the other electrolyte salt in the electrolyte solution.

- the electrolyte salt contains a cation and an imide anion.

- the hexafluorophosphate ion contains a lithium ion and a hexafluorophosphate ion.

- the sum T (mol/kg) of the cation content C1 in the electrolyte and the lithium ion content C2 in the electrolyte is preferably 0.7 mol/kg to 2.2 mol/kg.

- the ratio R (mol%) of the number of moles M2 of hexafluorophosphate ions in the electrolyte to the number of moles M1 of imide anions in the electrolyte is preferably 13 mol% to 6000 mol%. This is because the migration speeds of the cations and lithium ions in the vicinity of the surfaces of the positive electrode 21 and the negative electrode 22 are sufficiently improved, and the migration speeds of the cations and lithium ions in the electrolyte are also sufficiently improved.

- the “content of cations in the electrolyte” described here is the content of electrolyte salt of cations relative to the solvent, and the “content of lithium ions in the electrolyte” is the content of lithium ions relative to the solvent.

- the secondary battery When calculating the sum T and the ratio R, the secondary battery is disassembled to recover the electrolyte, and the electrolyte is then analyzed using ICP atomic emission spectrometry. This allows the contents C1, C2 and the mole numbers M1, M2 to be determined, and the sum T and the ratio R to be calculated.

- the electrolyte solution contains electrolyte salt, and therefore the same effect can be obtained.

- the electrolyte salt is used in combination with another electrolyte salt (lithium hexafluorophosphate)

- the total amount of both (sum T) is optimized, and the mixing ratio (ratio R) of both is also optimized. This further improves the migration speed of cations and lithium ions near the surfaces of the positive electrode 21 and the negative electrode 22, and also further improves the migration speed of cations and lithium ions in the electrolyte solution. Therefore, a greater effect can be obtained.

- the electrolyte solution contains lithium hexafluorophosphate as another electrolyte salt.

- the electrolyte solution may contain lithium bis(fluorosulfonyl)imide as another electrolyte salt instead of lithium hexafluorophosphate. Even in this case, it is preferable that the content of the electrolyte salt in the electrolyte solution is optimized in relation to the content of the other electrolyte salt in the electrolyte solution.

- the bis(fluorosulfonyl)imide lithium contains lithium ions and bis(fluorosulfonyl)imide ions.

- the sum T (mol/kg) of the cation content C1 in the electrolyte and the lithium ion content C2 in the electrolyte is preferably 0.7 mol/kg to 2.2 mol/kg.