WO2024142830A1 - Aluminum alloy forging material, aluminum alloy forged product, and method for manufacturing same - Google Patents

Aluminum alloy forging material, aluminum alloy forged product, and method for manufacturing same Download PDFInfo

- Publication number

- WO2024142830A1 WO2024142830A1 PCT/JP2023/043832 JP2023043832W WO2024142830A1 WO 2024142830 A1 WO2024142830 A1 WO 2024142830A1 JP 2023043832 W JP2023043832 W JP 2023043832W WO 2024142830 A1 WO2024142830 A1 WO 2024142830A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mass

- less

- range

- aluminum alloy

- content

- Prior art date

Links

- 229910000838 Al alloy Inorganic materials 0.000 title claims abstract description 221

- 238000005242 forging Methods 0.000 title claims description 99

- 238000000034 method Methods 0.000 title claims description 41

- 239000000463 material Substances 0.000 title claims description 38

- 238000004519 manufacturing process Methods 0.000 title claims description 20

- 239000000047 product Substances 0.000 claims abstract description 65

- 239000013078 crystal Substances 0.000 claims abstract description 28

- 239000002244 precipitate Substances 0.000 claims abstract description 23

- 239000012535 impurity Substances 0.000 claims abstract description 19

- 238000005266 casting Methods 0.000 claims description 46

- 229910052751 metal Inorganic materials 0.000 claims description 35

- 239000002184 metal Substances 0.000 claims description 35

- 239000000956 alloy Substances 0.000 claims description 28

- 229910045601 alloy Inorganic materials 0.000 claims description 22

- 238000010438 heat treatment Methods 0.000 claims description 21

- 239000000203 mixture Substances 0.000 claims description 21

- 238000010791 quenching Methods 0.000 claims description 14

- 230000000171 quenching effect Effects 0.000 claims description 14

- 230000032683 aging Effects 0.000 claims description 12

- 238000000265 homogenisation Methods 0.000 claims description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 11

- 230000008018 melting Effects 0.000 claims description 9

- 238000002844 melting Methods 0.000 claims description 9

- 229910052802 copper Inorganic materials 0.000 claims description 7

- 239000002245 particle Substances 0.000 claims description 7

- 238000012545 processing Methods 0.000 claims description 5

- 239000004033 plastic Substances 0.000 claims description 4

- 239000000498 cooling water Substances 0.000 description 49

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 42

- 238000001816 cooling Methods 0.000 description 26

- 150000001875 compounds Chemical class 0.000 description 20

- 230000000694 effects Effects 0.000 description 19

- 238000009749 continuous casting Methods 0.000 description 15

- 239000010949 copper Substances 0.000 description 14

- 238000001953 recrystallisation Methods 0.000 description 14

- 229910052782 aluminium Inorganic materials 0.000 description 13

- 239000012530 fluid Substances 0.000 description 13

- 239000000243 solution Substances 0.000 description 13

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical group [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 11

- 238000011156 evaluation Methods 0.000 description 11

- 230000004907 flux Effects 0.000 description 11

- 238000012360 testing method Methods 0.000 description 11

- 230000001050 lubricating effect Effects 0.000 description 10

- 239000010687 lubricating oil Substances 0.000 description 10

- 230000002093 peripheral effect Effects 0.000 description 9

- 238000007670 refining Methods 0.000 description 9

- 229910052710 silicon Inorganic materials 0.000 description 9

- 239000000725 suspension Substances 0.000 description 9

- 230000007797 corrosion Effects 0.000 description 8

- 238000005260 corrosion Methods 0.000 description 8

- 230000007423 decrease Effects 0.000 description 8

- 229910052742 iron Inorganic materials 0.000 description 8

- 229910052804 chromium Inorganic materials 0.000 description 7

- 229910052748 manganese Inorganic materials 0.000 description 7

- 239000012071 phase Substances 0.000 description 6

- 239000006104 solid solution Substances 0.000 description 6

- 229910052725 zinc Inorganic materials 0.000 description 6

- 229910017082 Fe-Si Inorganic materials 0.000 description 5

- 229910017133 Fe—Si Inorganic materials 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 230000007547 defect Effects 0.000 description 5

- 239000007789 gas Substances 0.000 description 5

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 229910019018 Mg 2 Si Inorganic materials 0.000 description 4

- 229910019064 Mg-Si Inorganic materials 0.000 description 4

- 229910019406 Mg—Si Inorganic materials 0.000 description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 4

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 4

- 239000000314 lubricant Substances 0.000 description 4

- 239000002994 raw material Substances 0.000 description 4

- 239000007921 spray Substances 0.000 description 4

- 229910052726 zirconium Inorganic materials 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 239000012467 final product Substances 0.000 description 3

- 229910000765 intermetallic Inorganic materials 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 238000001556 precipitation Methods 0.000 description 3

- 238000005204 segregation Methods 0.000 description 3

- 238000007711 solidification Methods 0.000 description 3

- 230000008023 solidification Effects 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 238000005728 strengthening Methods 0.000 description 3

- 229910021365 Al-Mg-Si alloy Inorganic materials 0.000 description 2

- 229910018464 Al—Mg—Si Inorganic materials 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 229910018565 CuAl Inorganic materials 0.000 description 2

- 229910019752 Mg2Si Inorganic materials 0.000 description 2

- 238000007550 Rockwell hardness test Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000002425 crystallisation Methods 0.000 description 2

- 230000008025 crystallization Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000005868 electrolysis reaction Methods 0.000 description 2

- 238000001887 electron backscatter diffraction Methods 0.000 description 2

- 230000005496 eutectics Effects 0.000 description 2

- 238000000445 field-emission scanning electron microscopy Methods 0.000 description 2

- -1 for example Substances 0.000 description 2

- 229910002804 graphite Inorganic materials 0.000 description 2

- 239000010439 graphite Substances 0.000 description 2

- 238000009863 impact test Methods 0.000 description 2

- 229910052500 inorganic mineral Inorganic materials 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 150000001247 metal acetylides Chemical class 0.000 description 2

- 239000011707 mineral Substances 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 230000001376 precipitating effect Effects 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 230000001360 synchronised effect Effects 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 239000003981 vehicle Substances 0.000 description 2

- 229910018191 Al—Fe—Si Inorganic materials 0.000 description 1

- 229910000521 B alloy Inorganic materials 0.000 description 1

- 229910017827 Cu—Fe Inorganic materials 0.000 description 1

- 229910017060 Fe Cr Inorganic materials 0.000 description 1

- 229910002544 Fe-Cr Inorganic materials 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 240000008415 Lactuca sativa Species 0.000 description 1

- 229910017708 MgZn2 Inorganic materials 0.000 description 1

- 238000006124 Pilkington process Methods 0.000 description 1

- 235000019484 Rapeseed oil Nutrition 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 229910052790 beryllium Inorganic materials 0.000 description 1

- 238000009529 body temperature measurement Methods 0.000 description 1

- 239000000378 calcium silicate Substances 0.000 description 1

- 229910052918 calcium silicate Inorganic materials 0.000 description 1

- OYACROKNLOSFPA-UHFFFAOYSA-N calcium;dioxido(oxo)silane Chemical compound [Ca+2].[O-][Si]([O-])=O OYACROKNLOSFPA-UHFFFAOYSA-N 0.000 description 1

- 239000004359 castor oil Substances 0.000 description 1

- 235000019438 castor oil Nutrition 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000011362 coarse particle Substances 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- ZEMPKEQAKRGZGQ-XOQCFJPHSA-N glycerol triricinoleate Natural products CCCCCC[C@@H](O)CC=CCCCCCCCC(=O)OC[C@@H](COC(=O)CCCCCCCC=CC[C@@H](O)CCCCCC)OC(=O)CCCCCCCC=CC[C@H](O)CCCCCC ZEMPKEQAKRGZGQ-XOQCFJPHSA-N 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 235000019198 oils Nutrition 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000011819 refractory material Substances 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 235000012045 salad Nutrition 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 235000015112 vegetable and seed oil Nutrition 0.000 description 1

- 239000008158 vegetable oil Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/02—Alloys based on aluminium with silicon as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/06—Alloys based on aluminium with magnesium as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/04—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon

- C22F1/05—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon of alloys of the Al-Si-Mg type, i.e. containing silicon and magnesium in approximately equal proportions

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

Definitions

- the present invention relates to an aluminum alloy material for forging, an aluminum alloy forging, and a method for producing the same.

- iron-based materials were used exclusively for automobile parts, particularly suspension parts.

- aluminum or aluminum alloy materials primarily for the purpose of reducing weight.

- Zr is effective in preventing recrystallization, it has the following problems.

- Zr forms compounds with Al-Ti-B based alloys. These compounds accumulate at the bottom of the furnace in which the molten alloy is stored, contaminating the furnace. In addition, these compounds also crystallize out as coarse particles in the produced ingot, reducing its strength.

- Aspect 1 of the present invention is a composition in which Cu is in the range of 0.25 mass% or more and 0.55 mass% or less, Mg is in the range of 0.60 mass% or more and 1.25 mass% or less, Si is in the range of 0.90 mass% or more and 1.4 mass% or less, Mn is in the range of 0.35 mass% or more and 0.60 mass% or less, Fe is in the range of 0.15 mass% or more and 0.30 mass% or less, Zn is in the range of 0.25 mass% or less, Cr is in the range of 0.050 mass% or more and 0.30 mass% or less, Ti is in the range of 0.01 mass% or more and 0.1 mass% or less, and B is in the range of 0.0010 mass% or less.

- the aluminum alloy forging material is composed of an aluminum alloy having an alloy composition containing 0.030% by mass or more, 0.0010% by mass or more and 0.050% by mass or less of Zr, a ratio of the Fe content to the Mn content Fe/Mn of 0.3 to 1.2 by mass, and the balance being Al and unavoidable impurities, and has a post-cast electrical conductivity of 25% IACS to 35% IACS and a Rockwell hardness HRF of 62 to 82.

- Aspect 3 of the present invention is a steel sheet having a Cu content in the range of 0.25 mass% or more and 0.55 mass% or less, a Mg content in the range of 0.60 mass% or more and 1.25 mass% or less, a Si content in the range of 0.90 mass% or more and 1.4 mass% or less, a Mn content in the range of 0.35 mass% or more and 0.60 mass% or less, a Fe content in the range of 0.15 mass% or more and 0.30 mass% or less, a Zn content in the range of 0.25 mass% or less, a Cr content in the range of 0.050 mass% or more and 0.30 mass% or less, a Ti content in the range of 0.01 mass% or more and 0.1 % or less by mass, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less

- FIG. 1 is a perspective view showing an example of an aluminum alloy forging according to an embodiment of the present invention.

- FIG. FIG. 2 is a plan view showing another example of an aluminum alloy forged product according to an embodiment of the present invention.

- FIG. 2 is a perspective view showing yet another example of an aluminum alloy forged product according to an embodiment of the present invention.

- 1 is a cross-sectional view showing an example of the vicinity of a mold of a horizontal continuous casting apparatus for producing an aluminum alloy forging according to an embodiment of the present invention.

- 5 is an enlarged cross-sectional view of a main portion near a cooling water cavity of the horizontal continuous casting machine shown in FIG. 4.

- FIG. 2 is an explanatory diagram illustrating a heat flux in a cooling wall portion of a horizontal continuous casting apparatus.

- FIG. 2 is a plan view showing the position at which the central portion was sampled from the aluminum alloy forging obtained in this example for preparing a test piece for evaluating mechanical properties.

- FIG. 2 is a plan view showing a test

- an aluminum alloy forging material contains Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, Ti in the range of 0.01 mass% or more and 0.02 mass% or less, and Zn in the range of 0.03 mass% or more and 0.04 mass% or less.

- An aluminum alloy forging material has Cu in the range of 0.25% by mass or more and 0.55% by mass or less, Mg in the range of 0.60% by mass or more and 1.25% by mass or less, Si in the range of 0.90% by mass or more and 1.4% by mass or less, Mn in the range of 0.35% by mass or more and 0.60% by mass or less, Fe in the range of 0.15% by mass or more and 0.30% by mass or less, Zn in the range of 0.25% by mass or less, Cr in the range of 0.050% by mass or more and 0.30% by mass or less, Ti in the range of 0.01% by mass or more and 0.1% by mass or less, and the range below, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content Fe/Mn being 0.3 to 1.2 in mass ratio, with the balance

- the electrical conductivity of the aluminum alloy forging material of the above embodiment is 25% IACS or more and 35% IACS or less. This electrical conductivity is the electrical conductivity at room temperature, which is about 20°C ⁇ 15°C. If the electrical conductivity is less than 25% IACS, the material will be too hard and its workability will decrease, whereas if it exceeds 35% IACS, the material will be too soft, resulting in poor machinability (ability to break away chips), and the guaranteed strength of the final product may not be satisfied.

- the Rockwell hardness HRF of the aluminum alloy forging material of the above embodiment is 62 or more and 82 or less.

- the Rockwell hardness HRF is a value measured in accordance with JIS Z2245:2016 "Rockwell hardness test - Test method". This is because the workability is good if the Rockwell hardness HRF is within this range. That is, if the Rockwell hardness HRF is less than 62, the material is too soft, resulting in poor machinability (chip breakability) and inability to satisfy the guaranteed strength of the final product, while if it exceeds 82, the material is too hard, resulting in poor workability.

- the aluminum alloy forged product of this embodiment has an impact value of 10 J/cm 2 or more at room temperature.

- the size of precipitates containing Mn within 2.0 ⁇ m, including grain boundaries is 0.5 ⁇ m or less.

- the aluminum alloy forgings of this embodiment correspond to 6000 series aluminum alloy forgings in that they contain Mg and Si.

- Cu has the effect of finely dispersing Mg-Si compounds in the aluminum alloy and the effect of improving the tensile strength of the aluminum alloy by precipitating as Al-Cu-Mg-Si compounds including the Q phase.

- the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

- Mg has the effect of improving the tensile strength of the aluminum alloy.

- Mg contributes to strengthening the aluminum alloy by dissolving in the aluminum parent phase or precipitating as Mg-Si compounds (Mg 2 Si) such as the ⁇ ′′ phase, or Al-Cu-Mg-Si compounds (AlCuMgSi) such as the Q phase.

- Mg 2 Si also has the effect of suppressing the formation of CuAl 2 phase in the aluminum alloy. By suppressing the formation of CuAl 2 phase, the corrosion resistance of the aluminum alloy forging 1a is improved. By keeping the Mg content within the above range, it is possible to improve the corrosion resistance as well as the mechanical properties at room temperature of the aluminum alloy forging 1a.

- Si 0.90 mass% or more, 1.4 mass% or less

- Si has the effect of improving the mechanical properties and corrosion resistance of the aluminum alloy forging 1a at room temperature.

- coarse primary crystal Si grains may crystallize, which may reduce the tensile strength of the aluminum alloy.

- Mn 0.35 mass% or more, 0.60 mass% or less

- Mn has the effect of improving the tensile strength of the aluminum alloy by forming fine granular precipitates containing intermetallic compounds such as Al-Mn-Fe-Si and Al-Mn-Cr-Fe-Si in the aluminum alloy.

- the Mn content is within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

- FIG. 3 is a plan view of yet another example of an aluminum alloy forged product according to an embodiment of the present invention.

- the aluminum alloy forging 1c shown in Fig. 3 has three connecting portions 4f, 4g, and 4h.

- the connecting portions 4f and 4g are connected to each other by the long portion 2, and the connecting portions 4f and 4h are connected to each other by the long portion 2.

- a through hole is provided in the connecting portion 4f.

- This aluminum alloy forging 1b can be used as, for example, an A-type suspension arm.

- Cu is in the range of 0.25 mass% or more and 0.55 mass% or less

- Mg is in the range of 0.60 mass% or more and 1.25 mass% or less

- Si is in the range of 0.90 mass% or more and 1.4 mass% or less

- Mn is in the range of 0.35 mass% or more and 0.60 mass% or less

- Fe is in the range of 0.15 mass% or more and 0.30 mass% or less

- Zn is in the range of 0.25 mass% or less

- Cr is in the range of 0.050 mass% or more and 0.30 mass% or less

- Ti is 0.01 mass% and 0.1% by mass or less

- B in the range of 0.0010% by mass or more and 0.030% by mass or less

- Zr in the range of 0.0010% by mass or more and 0.050% by mass or less

- a ratio of the Fe content to the Mn content Fe/Mn is 0.3 to 1.2 in mass ratio

- the balance is Al and unavoidable impurities.

- the molten metal receiving section 11 is composed of a molten metal inlet section 11a that receives the molten aluminum alloy M obtained in the above-mentioned molten metal forming process, a molten metal holding section 11b, and an outlet section 11c into the hollow section 21 of the mold 12.

- the molten aluminum alloy M held in the molten metal holding portion 11b in the molten metal receiving portion 11 is poured into the hollow portion 21 of the mold 12 through the pouring passage 13a provided in the refractory plate body 13.

- the molten aluminum alloy M supplied into the hollow portion 21 is then cooled and solidified by the cooling device 23 described below, and is drawn out from the other end side 12b of the mold 12 as an aluminum alloy rod B, which is a solidified ingot.

- the elevation angle is less than 0°, when the aluminum alloy rod B is pulled out of the mold 12, it encounters resistance at the other end 12b, which is the mold outlet, and casting may become difficult.

- the elevation angle exceeds 3°, the contact of the inner peripheral surface 21a with the molten aluminum alloy M may become insufficient, and the effect of removing heat from the molten aluminum alloy M and its solidified shell to the mold 12 may decrease, resulting in insufficient solidification.

- a remelted skin may appear on the surface of the aluminum alloy rod B, or unsolidified molten aluminum alloy M may erupt from the end of the aluminum alloy rod B, which is not preferable, as this may lead to casting problems.

- the inner surface 21a of the mold 12 is cooled by the cooling water W contained in the cooling water cavity 24, which removes heat from the molten aluminum alloy M filling the hollow portion 21 of the mold 12 from the surface in contact with the inner surface 21a of the mold 12, forming a solidified shell on the surface of the molten aluminum alloy M.

- the mold 12 is formed so that the thickness t of the cooling wall 27 of the mold 12, i.e., the distance between the inner bottom surface 24a of the cooling water cavity 24 and the inner peripheral surface 21a of the hollow portion 21 of the mold 12, is within a range of, for example, 0.5 mm to 3.0 mm, and preferably 0.5 mm to 2.5 mm.

- the material for forming the mold 12 is selected so that the thermal conductivity of at least the cooling wall 27 of the mold 12 is within a range of 100 W/m ⁇ K to 400 W/m ⁇ K.

- the aluminum alloy rod B is pulled out at a constant speed by a pull-out drive device (not shown) installed near the other end 12b of the mold 12, so that it is cast continuously to form a long aluminum alloy rod B.

- the pulled aluminum alloy rod B is then cut to the desired length, for example, by a synchronous cut-off machine (not shown).

- composition ratio of the cast aluminum alloy rod B can be confirmed, for example, by a method using a photoelectric emission spectrophotometric analyzer (example: Shimadzu PDA-5500, manufactured by Japan) as described in "JIS H 1305.”

- the lubricating oil supply rate is preferably 0.05 mL/min to 5 mL/min (more preferably 0.1 mL/min to 1 mL/min). If the supply rate is too low, the molten aluminum alloy M of the aluminum alloy rod B may not solidify and may leak from the mold 12 due to insufficient lubrication. If the amount of supply is excessive, the excess may be mixed into the aluminum alloy bar B and cause internal defects.

- the casting speed which is the speed at which the aluminum alloy rod B is pulled out of the mold 12, is preferably 200 mm/min or more and 1500 mm/min or less (more preferably 400 mm/min or more and 1000 mm/min or less). This is because, at a casting speed within this range, the network structure of the crystals formed by casting becomes uniform and fine, which increases the resistance of the aluminum matrix to deformation at high temperatures and improves the high-temperature mechanical strength.

- the amount of cooling water sprayed from the shower opening 25a of the cooling water spray passage 25 is preferably 10 L/min or more and 50 L/min or less (more preferably 25 L/min or more and 40 L/min or less) per mold. If the amount of cooling water is less than this, the molten aluminum alloy M may not solidify and may leak from the mold 12. In addition, the surface of the cast aluminum alloy bar B may remelt, forming an uneven structure that may remain as an internal defect. On the other hand, if the amount of cooling water is more than this range, the mold 12 may lose too much heat, causing it to solidify midway.

- the average temperature of the molten aluminum alloy M flowing from the molten metal receiving portion 11 into the mold 12 is, for example, preferably 650°C or higher and 750°C or lower (more preferably 680°C or higher and 720°C or lower). If the temperature of the molten aluminum alloy M is too low, there is a risk that coarse crystals will form in the mold 12 or in front of it and will be incorporated into the aluminum alloy bar B as internal defects. On the other hand, if the temperature of the molten aluminum alloy M is too high, a large amount of hydrogen gas will be easily incorporated into the molten aluminum alloy M, which will be incorporated into the aluminum alloy bar B as porosity and may cause internal cavities.

- the cooling wall portion 27 of the mold 12 is configured so that the heat flux value per unit area is 10 ⁇ 10 5 W/m 2 or more, thereby making it possible to prevent seizure of the cast aluminum alloy bar B. In addition, it is preferable that the heat flux value per unit area is 50 ⁇ 10 5 W/m 2 or less.

- the aluminum alloy rod B thus obtained is cooled and solidified under conditions where the heat flux value per unit area in the cooling wall 27 is 10 ⁇ 10 5 W/m 2 or more, thereby suppressing adhesion of reaction products, such as carbides, caused by contact between the lubricating oil gas and the molten aluminum alloy M. This makes it unnecessary to cut and remove carbides, etc., on the surface of the aluminum alloy rod B, and allows the aluminum alloy rod B to be produced with a high yield.

- Molds are generally made of metal components with good thermal conductivity, and have a hollow structure to allow the introduction of a coolant inside.

- the mold used in this embodiment is appropriately selected from metals such as copper and aluminum, or graphite, from the viewpoint of heat transfer performance and durability at the contact point with the molten metal.

- the header is generally made of a refractory material and is installed on the upper side of the mold. There are no particular restrictions on the material and size of the header, and it can be appropriately selected depending on the composition range of the alloy to be cast and the dimensions of the cast product.

- the casting method described above makes it possible to obtain a uniform metal structure even in medium to large castings.

- the forging process is a process in which the aluminum alloy casting after casting is cut to a predetermined size, the obtained forging material is heated to a predetermined temperature, and then pressure is applied by a press machine to mold it into a die.

- the forging process is performed without performing the homogenization process that was conventionally performed after casting to remove segregation. Therefore, since it is necessary to perform the segregation removal performed by the homogenization process by heating the material during forging, it is necessary to perform the heating at a temperature of 500°C or higher and below the melting point. Then, the forging process is performed to obtain a forged product (for example, a suspension arm part of an automobile).

- the material heating temperature during forging is less than 500°C, compounds such as AlFeSi and Mg 2 Si in the alloy structure remain in a segregated state, the deformation resistance increases, making it impossible to perform sufficient processing, and cracks occur. Furthermore, if the temperature exceeds the melting point, defects such as eutectic melting are likely to occur.

- the forged product is subjected to solution treatment by holding it at a treatment temperature of 530°C or more and 560°C or less for 0.3 or more and 3 hours or less.

- the heating rate from room temperature to the above-mentioned treatment temperature is preferably 5.0°C/min or more. If the treatment temperature is less than 530°C, the solute elements may not be dissolved in solid solution. On the other hand, if the treatment temperature exceeds 560°C, the solute elements may be dissolved in solid solution more, but eutectic melting and recrystallization may occur easily. In addition, if the heating rate is less than 5.0°C/min, Mg 2 Si may precipitate coarsely. On the other hand, if the treatment temperature is less than 530°C, the solution treatment may not proceed, making it difficult to achieve high strength by aging precipitation.

- the quenching process is a process in which the forged product in the solid-solution state obtained in the solution treatment process is rapidly cooled to form a supersaturated solid solution.

- the forged product is placed in a water tank that stores water (quenching water) and quenched by submerging the forged product.

- the temperature of the water in the tank is preferably 20°C or higher and 60°C or lower.

- the forged product is preferably placed in the water tank for 5 seconds or higher and 60 seconds or lower after solution treatment so that all surfaces of the forged product are in contact with water.

- the submersion time of the forged product varies depending on the size of the casting, but is, for example, between more than 1 minute and 30 minutes.

- the aging treatment process is a process in which the forged product is heated and held at a relatively low temperature to precipitate the elements that are supersaturated in solid solution, thereby imparting an appropriate hardness.

- a method for producing an aluminum alloy forged product further includes, between the casting step and the forging step, a homogenization heat treatment step in which the aluminum alloy cast product is subjected to homogenization heat treatment by holding the aluminum alloy cast product at a temperature range of 370° C. or higher and 560° C. or lower for 2 hours or higher and 10 hours or lower.

- the method for producing an aluminum alloy forged product of this embodiment differs from the method for producing an aluminum alloy forged product of the above-described embodiment in that it includes a homogenization heat treatment step.

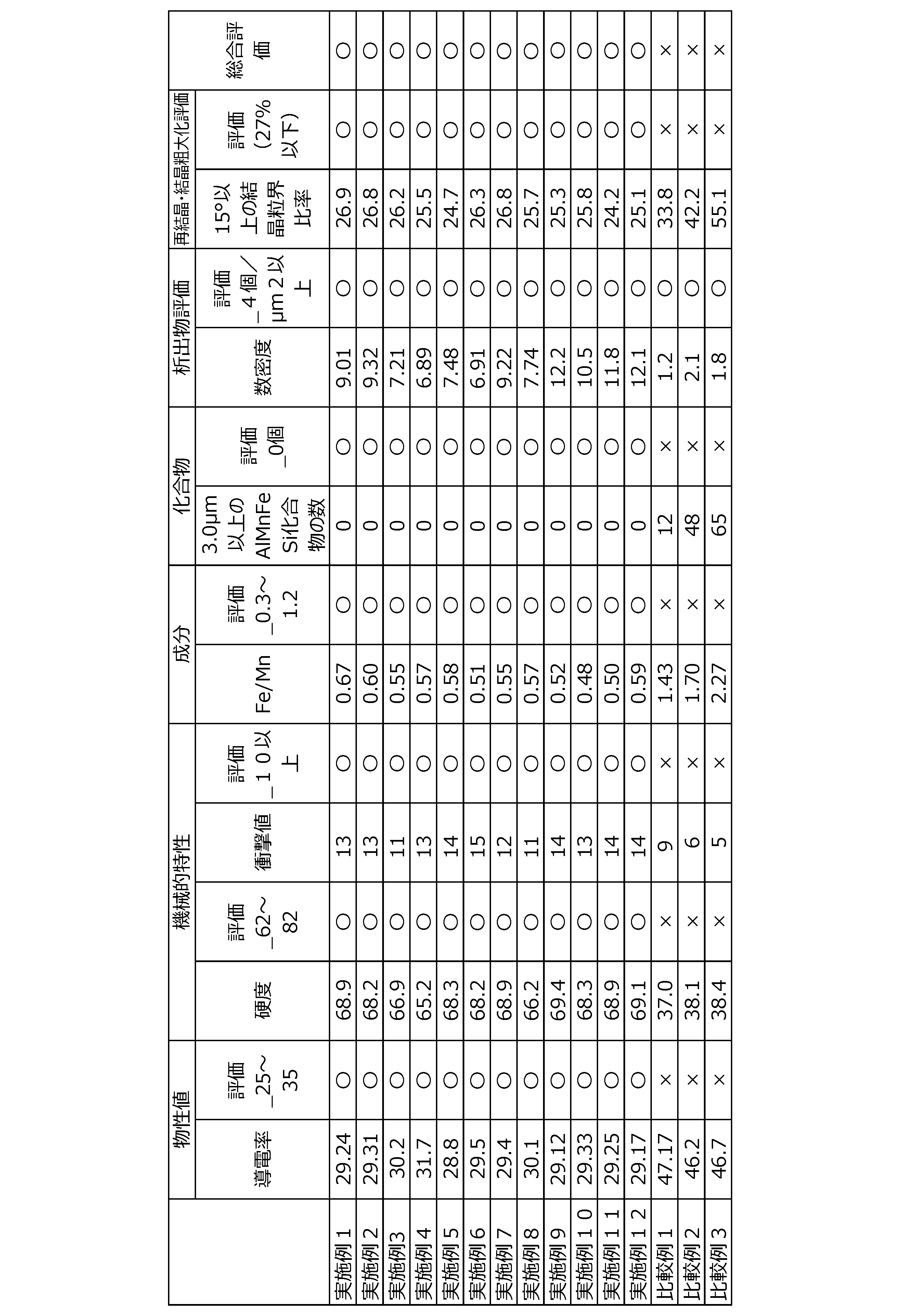

- Examples 1 to 8 and Comparative Examples 1 to 3 (Production of continuous cast products) First, an aluminum alloy having the alloy composition (the balance being aluminum) shown in the following Table 1 was prepared. A continuous cast product having a circular cross section and a diameter of 82 mm was produced from the prepared aluminum alloy.

- ⁇ Conductivity (%IACS)> The conductivity was measured at room temperature. (Judgment criteria) "Good”: 25% IACS or more and 35% IACS or less. “X”: Less than 25% IACS or more than 35% IACS.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Forging (AREA)

Abstract

Provided is an aluminum alloy forged product containing: 0.25-0.55 mass% of Cu; 0.60-1.25 mass% of Mg; 0.95-1.4 mass% of Si; 0.35-0.60 mass% of Mn; 0.15-0.30 mass% of Fe; at most 0.25 mass% of Zn; 0.050-0.30 mass% of Cr; 0.01-0.1 mass% of Ti; 0.0010-0.030 mass% of B; and 0.0010-0.050 mass% of Zr, wherein the Fe/Mn ratio is less than 1.4, the remainder consists of Al and unavoidable impurities, the number density of Mn-containing precipitates within 2.0 μm including grain boundaries is 4/μm2 or more, and when the fraction of high-angle grain boundaries having a crystal misorientation of 15° or more is 27% or less, the impact value at room temperature is 10 J/cm2 or more.

Description

本発明は、アルミニウム合金鍛造用素材、アルミニウム合金鍛造品及びその製造方法に関する。

本願は、2022年12月27日に、日本に出願された特願2022-210255号に基づき優先権を主張し、その内容をここに援用する。 The present invention relates to an aluminum alloy material for forging, an aluminum alloy forging, and a method for producing the same.

This application claims priority based on Japanese Patent Application No. 2022-210255, filed on December 27, 2022, the contents of which are incorporated herein by reference.

本願は、2022年12月27日に、日本に出願された特願2022-210255号に基づき優先権を主張し、その内容をここに援用する。 The present invention relates to an aluminum alloy material for forging, an aluminum alloy forging, and a method for producing the same.

This application claims priority based on Japanese Patent Application No. 2022-210255, filed on December 27, 2022, the contents of which are incorporated herein by reference.

近年、アルミニウム合金は、軽量性を生かして各種製品の構造部材としての用途が拡大しつつある。例えば、自動車の足廻りやバンパー部品では、今まで高張力鋼が用いられてきた。一方、近年は高強度アルミニウム合金材が用いられるようになっている。

In recent years, aluminum alloys have been increasingly used as structural components for various products, taking advantage of their light weight. For example, high-tensile steel has traditionally been used for automobile suspension and bumper parts. However, in recent years, high-strength aluminum alloy materials have come to be used.

また、自動車部品、その中でも、例えばサスペンション部品には、専ら鉄系材料が使用されていた。一方、近年は軽量化を主目的として、アルミニウム材料又はアルミニウム合金材料に置き換えられることが多くなってきた。

Furthermore, in the past, iron-based materials were used exclusively for automobile parts, particularly suspension parts. However, in recent years, they have increasingly been replaced with aluminum or aluminum alloy materials, primarily for the purpose of reducing weight.

これらの自動車部品では、優れた耐食性、高強度及び優れた加工性が要求されることから、アルミニウム合金材料としてAl-Mg-Si系合金、特にA6061が多用されている。そして、このような自動車部品は、強度の向上を図るため、アルミニウム合金材料を加工用素材として塑性加工の1つである鍛造加工を行って製造される。

Since these automotive parts require excellent corrosion resistance, high strength and excellent workability, Al-Mg-Si alloys, especially A6061, are often used as the aluminum alloy material. In order to improve the strength of these automotive parts, they are manufactured by forging, a type of plastic processing, using the aluminum alloy material as the processing material.

また、最近では、コストダウンを図る必要があるため、押出をせずに鋳造部材をそのまま素材として鍛造した後、溶体化処理と人工時効処理を行う処理(T6処理)して得たサスペンション部品が実用化され始めており、さらなる軽量化を目的として、従来のA6061に代わる高強度合金の開発が進められている(例えば、特許文献1~3を参照。)。

In addition, recently, due to the need to reduce costs, suspension parts have begun to be put to practical use in which the cast components are used as they are without extrusion, and then subjected to a solution treatment and artificial aging treatment (T6 treatment). In order to further reduce weight, development of high-strength alloys to replace the conventional A6061 is underway (see, for example, Patent Documents 1 to 3).

しかしながら、上述したAl-Mg-Si系の高強度合金は、鍛造及び熱処理工程において加工組織が再結晶し、粗大結晶粒が発生することにより、十分な高強度を得ることができないという問題があった。そのため、粗大再結晶粒生成防止のため、Zr(ジルコニウム)を添加して再結晶を防止しているものがある(例えば、上記特許文献1,2を参照。)。

However, the above-mentioned high-strength Al-Mg-Si alloys have the problem that the processed structure recrystallizes during the forging and heat treatment processes, resulting in the generation of coarse crystal grains, making it impossible to obtain sufficiently high strength. For this reason, some alloys have been designed to prevent recrystallization by adding Zr (zirconium) to prevent the generation of coarse recrystallized grains (see, for example, Patent Documents 1 and 2 above).

しかしながら、Zrを添加することは、再結晶防止に効果があるものの、次のような問題点があった。

(1)Zrの添加により、Al-Ti-B系合金の結晶粒微細化効果が弱められ、鋳塊自体の結晶粒が粗くなり、塑性加工後の加工品(鍛造品)の強度低下を招く。

(2)鋳塊自体の結晶粒微細化効果が弱められるため、鋳塊割れが発生し易くなり、内部欠陥が増加し、歩留まりが悪化する。

(3)Zrは、Al-Ti-B系合金と化合物を形成し、合金溶湯を貯留する炉の底に化合物が堆積し、炉を汚染すると共に、製造した鋳塊においてもこれら化合物が鋳塊中に粗大に晶出し、強度を低下させる。 Although the addition of Zr is effective in preventing recrystallization, it has the following problems.

(1) The addition of Zr weakens the effect of refining the crystal grains of the Al-Ti-B alloy, making the crystal grains of the ingot itself coarse, which leads to a decrease in the strength of the processed product (forged product) after plastic working.

(2) The effect of refining the crystal grains of the ingot itself is weakened, so that the ingot is more likely to crack, internal defects increase, and the yield decreases.

(3) Zr forms compounds with Al-Ti-B based alloys. These compounds accumulate at the bottom of the furnace in which the molten alloy is stored, contaminating the furnace. In addition, these compounds also crystallize out as coarse particles in the produced ingot, reducing its strength.

(1)Zrの添加により、Al-Ti-B系合金の結晶粒微細化効果が弱められ、鋳塊自体の結晶粒が粗くなり、塑性加工後の加工品(鍛造品)の強度低下を招く。

(2)鋳塊自体の結晶粒微細化効果が弱められるため、鋳塊割れが発生し易くなり、内部欠陥が増加し、歩留まりが悪化する。

(3)Zrは、Al-Ti-B系合金と化合物を形成し、合金溶湯を貯留する炉の底に化合物が堆積し、炉を汚染すると共に、製造した鋳塊においてもこれら化合物が鋳塊中に粗大に晶出し、強度を低下させる。 Although the addition of Zr is effective in preventing recrystallization, it has the following problems.

(1) The addition of Zr weakens the effect of refining the crystal grains of the Al-Ti-B alloy, making the crystal grains of the ingot itself coarse, which leads to a decrease in the strength of the processed product (forged product) after plastic working.

(2) The effect of refining the crystal grains of the ingot itself is weakened, so that the ingot is more likely to crack, internal defects increase, and the yield decreases.

(3) Zr forms compounds with Al-Ti-B based alloys. These compounds accumulate at the bottom of the furnace in which the molten alloy is stored, contaminating the furnace. In addition, these compounds also crystallize out as coarse particles in the produced ingot, reducing its strength.

このように、Zrの添加は、再結晶防止に効果があるものの、強度の安定性を維持するのが困難であった。

Thus, although the addition of Zr was effective in preventing recrystallization, it was difficult to maintain strength stability.

本発明は、かかる技術的背景に鑑みてなされたものであって、常温における機械的特性に優れたアルミニウム合金鍛造用素材、アルミニウム合金鍛造品及びその製造方法を提供することを目的とする。

The present invention was made in consideration of this technical background, and aims to provide an aluminum alloy forging material that has excellent mechanical properties at room temperature, an aluminum alloy forging product, and a manufacturing method thereof.

本発明は、上記課題を解決するため、以下の手段を提供する。

The present invention provides the following means to solve the above problems.

本発明の態様1は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で1.4未満であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造用素材であって、鋳造後の導電率が25%IACS以上35%IACS以下、かつ、ロックウェル硬さHRFが62以上82以下である、アルミニウム合金鍛造用素材である。

Aspect 1 of the present invention is a composition in which Cu is in the range of 0.25 mass% or more and 0.55 mass% or less, Mg is in the range of 0.60 mass% or more and 1.25 mass% or less, Si is in the range of 0.90 mass% or more and 1.4 mass% or less, Mn is in the range of 0.35 mass% or more and 0.60 mass% or less, Fe is in the range of 0.15 mass% or more and 0.30 mass% or less, Zn is in the range of 0.25 mass% or less, Cr is in the range of 0.050 mass% or more and 0.30 mass% or less, Ti is in the range of 0.01 mass% or more and 0.1 mass% or less, and B is in the range of 0.0010 mass% or less. This aluminum alloy forging material is composed of an aluminum alloy having an alloy composition containing 0.010% to 0.030% by mass, 0.0010% to 0.050% by mass of Zr, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 by mass, and the balance consisting of Al and unavoidable impurities, and has a post-cast electrical conductivity of 25% IACS to 35% IACS and a Rockwell hardness HRF of 62 to 82.

本発明の態様2は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で0.3以上1.2以下であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造用素材であって、鋳造後の導電率が25%IACS以上35%IACS以下、かつ、ロックウェル硬さHRFが62以上82以下である、アルミニウム合金鍛造用素材である。

Aspect 2 of the present invention is a composition comprising Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, Ti in the range of 0.01 mass% or more and 0.1 mass% or less, and B in the range of 0.0010 mass% or less. The aluminum alloy forging material is composed of an aluminum alloy having an alloy composition containing 0.030% by mass or more, 0.0010% by mass or more and 0.050% by mass or less of Zr, a ratio of the Fe content to the Mn content Fe/Mn of 0.3 to 1.2 by mass, and the balance being Al and unavoidable impurities, and has a post-cast electrical conductivity of 25% IACS to 35% IACS and a Rockwell hardness HRF of 62 to 82.

本発明の態様3は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で1.4未満であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造品であって、粒界を含む2.0μm以内にMnを含有する析出物の数密度が4個/μm2以上含まれており、結晶方位差15゜以上の大角粒界の比率が27%以下であり、かつ、常温における衝撃値が10J/cm2以上である、アルミニウム合金鍛造品である。

Aspect 3 of the present invention is a steel sheet having a Cu content in the range of 0.25 mass% or more and 0.55 mass% or less, a Mg content in the range of 0.60 mass% or more and 1.25 mass% or less, a Si content in the range of 0.90 mass% or more and 1.4 mass% or less, a Mn content in the range of 0.35 mass% or more and 0.60 mass% or less, a Fe content in the range of 0.15 mass% or more and 0.30 mass% or less, a Zn content in the range of 0.25 mass% or less, a Cr content in the range of 0.050 mass% or more and 0.30 mass% or less, a Ti content in the range of 0.01 mass% or more and 0.1 % or less by mass, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 in terms of mass ratio, and the balance being Al and unavoidable impurities, wherein the number density of precipitates containing Mn within 2.0 μm including grain boundaries is 4 precipitates/μm2 or more , the ratio of high-angle grain boundaries having a crystal orientation difference of 15° or more is 27% or less, and the impact value at room temperature is 10 J/ cm2 or more.

本発明の態様4は、態様3のアルミニウム合金鍛造品において、前記析出物のサイズが0.5μm以下である。

In aspect 4 of the present invention, in the aluminum alloy forged product of aspect 3, the size of the precipitates is 0.5 μm or less.

本発明の態様5は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で0.3以上1.2以下であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造品であって、粒界を含む2.0μm以内にMnを含有する析出物の数密度が4個/μm2以上含まれており、結晶方位差15゜以上の大角粒界の比率が27%以下であり、かつ、常温における衝撃値が10J/cm2以上である、アルミニウム合金鍛造品である。

Aspect 5 of the present invention is a steel sheet having a Cu content in the range of 0.25 mass% or more and 0.55 mass% or less, an Mg content in the range of 0.60 mass% or more and 1.25 mass% or less, an Si content in the range of 0.90 mass% or more and 1.4 mass% or less, an Mn content in the range of 0.35 mass% or more and 0.60 mass% or less, an Fe content in the range of 0.15 mass% or more and 0.30 mass% or less, an Zn content in the range of 0.25 mass% or less, an Cr content in the range of 0.050 mass% or more and 0.30 mass% or less, an Ti content in the range of 0.01 mass% or more and 0.1 mass% or less, and an Zn content in the range of 0.02 mass% or more and 0.05 mass% or less. % or less, B in the range of 0.0010 mass % or more and 0.030 mass % or less, Zr in the range of 0.0010 mass % or more and 0.050 mass % or less, a ratio of the Fe content to the Mn content Fe/Mn is 0.3 to 1.2 in mass ratio, and the balance is an alloy composition consisting of Al and unavoidable impurities, wherein the number density of precipitates containing Mn within 2.0 μm including grain boundaries is 4 precipitates/μm2 or more , the ratio of high-angle grain boundaries having a crystal orientation difference of 15° or more is 27% or less, and the aluminum alloy forging has an impact value of 10 J/cm2 or more at room temperature.

本発明の態様6は、態様5のアルミニウム合金鍛造品において、前記析出物のサイズが0.5μm以下である。

Aspect 6 of the present invention is an aluminum alloy forged product according to aspect 5, in which the size of the precipitates is 0.5 μm or less.

本発明の態様7は、態様3から態様6のいずれか一つのアルミニウム合金鍛造品の製造方法であって、前記アルミニウム合金の溶湯を得る溶湯形成工程と、前記得られた溶湯を鋳造加工することによって鋳造品を得る鋳造工程と、前記鋳造品を500℃~融点以下の温度で素材加熱し塑性加工を施して鍛造品を得る鍛造工程と、前記得られた鍛造品に20℃~500℃までの昇温速度が5.0℃/min以上で昇温し、530~560℃で0.3~3時間以内で保持する溶体化処理を行う溶体化処理工程と、前記溶体化処理後5~60秒以内に前記鍛造品の全ての表面が焼き入れ水に接触し、1分を超え、40分以内水槽内で焼き入れする焼き入れ工程と、前記焼き入れ処理工程を経た鍛造品に180℃~220℃の温度で0.5時間~8時間加熱して時効処理を行う時効処理工程と、を有する、アルミニウム合金鍛造品の製造方法である。

Aspect 7 of the present invention is a method for producing an aluminum alloy forging according to any one of aspects 3 to 6, comprising the steps of: forming a molten metal of the aluminum alloy; casting the molten metal to obtain a casting; heating the casting at a temperature between 500°C and the melting point and performing plastic processing to obtain a forging; solution treatment of the forging at a temperature of 20°C to 500°C at a heating rate of 5.0°C/min or more and maintaining the temperature at 530 to 560°C for 0.3 to 3 hours; quenching the entire surface of the forging in contact with quenching water within 5 to 60 seconds after the solution treatment and quenching in a water tank for more than 1 minute and not exceeding 40 minutes; and aging treatment of the forging after the quenching treatment at a temperature of 180°C to 220°C for 0.5 to 8 hours to perform aging treatment.

本発明の態様8は、態様4のアルミニウム合金鍛造品の製造方法において、前記鋳造工程と前記鍛造工程との間に、前記アルミニウム合金鋳造品を、370℃以上560℃以下の温度範囲で2時間以上10時間以下保持して均質化熱処理を行う均質化熱処理工程を更に有する。

Aspect 8 of the present invention is a method for manufacturing an aluminum alloy forged product according to aspect 4, which further includes a homogenization heat treatment step between the casting step and the forging step, in which the aluminum alloy casting product is held at a temperature range of 370°C to 560°C for 2 hours to 10 hours to perform homogenization heat treatment.

本発明によれば、常温における機械的特性に優れたアルミニウム合金鍛造用素材を提供できる。

本発明によれば、常温における機械的特性に優れたアルミニウム合金鍛造品を提供できる。

また、本発明によれば、これまでアルミ合金溶湯を鋳造したのちに、偏析除去するために施していた均質化処理工程を削減している為、低コスト・省エネなアルミニウム合金鍛造品の製造方法を提供できる。 According to the present invention, it is possible to provide an aluminum alloy material for forging that has excellent mechanical properties at room temperature.

According to the present invention, it is possible to provide an aluminum alloy forging having excellent mechanical properties at room temperature.

Furthermore, according to the present invention, the homogenization treatment step that has been conventionally performed after casting of the molten aluminum alloy to remove segregation is eliminated, thereby providing a low-cost, energy-saving method for producing aluminum alloy forged products.

本発明によれば、常温における機械的特性に優れたアルミニウム合金鍛造品を提供できる。

また、本発明によれば、これまでアルミ合金溶湯を鋳造したのちに、偏析除去するために施していた均質化処理工程を削減している為、低コスト・省エネなアルミニウム合金鍛造品の製造方法を提供できる。 According to the present invention, it is possible to provide an aluminum alloy material for forging that has excellent mechanical properties at room temperature.

According to the present invention, it is possible to provide an aluminum alloy forging having excellent mechanical properties at room temperature.

Furthermore, according to the present invention, the homogenization treatment step that has been conventionally performed after casting of the molten aluminum alloy to remove segregation is eliminated, thereby providing a low-cost, energy-saving method for producing aluminum alloy forged products.

以下、本発明の実施形態について、図面を参照して詳細に説明する。

なお、以下の説明で用いる図面は、特徴をわかりやすくするために、便宜上特徴となる部分を拡大して示している場合があり、各構成要素の寸法比率などが実際と同じであるとは限らない。また、以下の説明において例示される材料、寸法等は一例であって、本発明はそれらに必ずしも限定されるものではなく、その効果を変更しない範囲で適宜変更して実施することが可能である。 Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

In addition, the drawings used in the following description may show characteristic parts in an enlarged scale for the sake of convenience in order to make the characteristics easier to understand, and the dimensional ratios of each component may not necessarily be the same as in reality. Furthermore, the materials, dimensions, etc. exemplified in the following description are merely examples, and the present invention is not necessarily limited to them, and may be appropriately modified and implemented within a range that does not change the effects of the present invention.

なお、以下の説明で用いる図面は、特徴をわかりやすくするために、便宜上特徴となる部分を拡大して示している場合があり、各構成要素の寸法比率などが実際と同じであるとは限らない。また、以下の説明において例示される材料、寸法等は一例であって、本発明はそれらに必ずしも限定されるものではなく、その効果を変更しない範囲で適宜変更して実施することが可能である。 Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

In addition, the drawings used in the following description may show characteristic parts in an enlarged scale for the sake of convenience in order to make the characteristics easier to understand, and the dimensional ratios of each component may not necessarily be the same as in reality. Furthermore, the materials, dimensions, etc. exemplified in the following description are merely examples, and the present invention is not necessarily limited to them, and may be appropriately modified and implemented within a range that does not change the effects of the present invention.

[アルミニウム合金鍛造用素材]

先ず、本発明の一実施形態に係るアルミニウム合金鍛造用素材である。

本実施形態のアルミニウム合金鍛造用素材は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で1.4未満であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金鍛造用素材であって、鋳造後の導電率が25%IACS以上35%IACS以下、かつ、ロックウェル硬さHRFが62以上82以下である。 [Aluminum alloy forging materials]

First, an aluminum alloy forging material according to one embodiment of the present invention.

The aluminum alloy forging material of this embodiment contains Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, Ti in the range of 0.01 mass% or more and 0.02 mass% or less, and Zn in the range of 0.03 mass% or more and 0.04 mass% or less. 0.1% by mass or less, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 by mass, with the remainder being Al and unavoidable impurities, and the aluminum alloy forging material has an electrical conductivity after casting of 25% IACS or more and 35% IACS or less, and a Rockwell hardness HRF of 62 or more and 82 or less.

先ず、本発明の一実施形態に係るアルミニウム合金鍛造用素材である。

本実施形態のアルミニウム合金鍛造用素材は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で1.4未満であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金鍛造用素材であって、鋳造後の導電率が25%IACS以上35%IACS以下、かつ、ロックウェル硬さHRFが62以上82以下である。 [Aluminum alloy forging materials]

First, an aluminum alloy forging material according to one embodiment of the present invention.

The aluminum alloy forging material of this embodiment contains Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, Ti in the range of 0.01 mass% or more and 0.02 mass% or less, and Zn in the range of 0.03 mass% or more and 0.04 mass% or less. 0.1% by mass or less, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 by mass, with the remainder being Al and unavoidable impurities, and the aluminum alloy forging material has an electrical conductivity after casting of 25% IACS or more and 35% IACS or less, and a Rockwell hardness HRF of 62 or more and 82 or less.

本発明の別の実施形態に係るアルミニウム合金鍛造用素材は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で0.3以上1.2以下であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造用素材であって、鋳造後の導電率が25%IACS以上35%IACS以下、かつ、ロックウェル硬さHRFが62以上82以下である。

Fe/Mnは、質量比で0.3以上1.0以下とすることができ、また、0.4以上0.8以下とすることができ、また、0.4以上0.7以下とすることができる。 An aluminum alloy forging material according to another embodiment of the present invention has Cu in the range of 0.25% by mass or more and 0.55% by mass or less, Mg in the range of 0.60% by mass or more and 1.25% by mass or less, Si in the range of 0.90% by mass or more and 1.4% by mass or less, Mn in the range of 0.35% by mass or more and 0.60% by mass or less, Fe in the range of 0.15% by mass or more and 0.30% by mass or less, Zn in the range of 0.25% by mass or less, Cr in the range of 0.050% by mass or more and 0.30% by mass or less, Ti in the range of 0.01% by mass or more and 0.1% by mass or less, and the range below, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content Fe/Mn being 0.3 to 1.2 in mass ratio, with the balance being Al and unavoidable impurities, and the aluminum alloy forging material is composed of an aluminum alloy having an alloy composition, the electrical conductivity after casting being 25% IACS or more and 35% IACS or less, and a Rockwell hardness HRF of 62 or more and 82 or less.

The Fe/Mn mass ratio can be set to 0.3 or more and 1.0 or less, can be set to 0.4 or more and 0.8 or less, or can be set to 0.4 or more and 0.7 or less.

Fe/Mnは、質量比で0.3以上1.0以下とすることができ、また、0.4以上0.8以下とすることができ、また、0.4以上0.7以下とすることができる。 An aluminum alloy forging material according to another embodiment of the present invention has Cu in the range of 0.25% by mass or more and 0.55% by mass or less, Mg in the range of 0.60% by mass or more and 1.25% by mass or less, Si in the range of 0.90% by mass or more and 1.4% by mass or less, Mn in the range of 0.35% by mass or more and 0.60% by mass or less, Fe in the range of 0.15% by mass or more and 0.30% by mass or less, Zn in the range of 0.25% by mass or less, Cr in the range of 0.050% by mass or more and 0.30% by mass or less, Ti in the range of 0.01% by mass or more and 0.1% by mass or less, and the range below, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content Fe/Mn being 0.3 to 1.2 in mass ratio, with the balance being Al and unavoidable impurities, and the aluminum alloy forging material is composed of an aluminum alloy having an alloy composition, the electrical conductivity after casting being 25% IACS or more and 35% IACS or less, and a Rockwell hardness HRF of 62 or more and 82 or less.

The Fe/Mn mass ratio can be set to 0.3 or more and 1.0 or less, can be set to 0.4 or more and 0.8 or less, or can be set to 0.4 or more and 0.7 or less.

上記実施形態のアルミニウム合金鍛造用素材は、MgとSiを含む点で6000系アルミニウム合金に相当する。

The aluminum alloy forging material in the above embodiment corresponds to the 6000 series aluminum alloy in that it contains Mg and Si.

(導電率:25%IACS以上35%IACS以下)

上記実施形態のアルミニウム合金鍛造用素材の導電率は、25%IACS以上35%IACS以下である。この導電率は室温における導電率であるとし、この室温とは20℃±15℃程度とする。

導電率が25%IACS未満の場合は硬すぎて加工性が低下する、35%IACSを超える場合は柔らかいことで切削性(切粉分断性)の悪化、及び最終製品の保証強度を満足できないことがある。 (Conductivity: 25% IACS or more and 35% IACS or less)

The electrical conductivity of the aluminum alloy forging material of the above embodiment is 25% IACS or more and 35% IACS or less. This electrical conductivity is the electrical conductivity at room temperature, which is about 20°C ± 15°C.

If the electrical conductivity is less than 25% IACS, the material will be too hard and its workability will decrease, whereas if it exceeds 35% IACS, the material will be too soft, resulting in poor machinability (ability to break away chips), and the guaranteed strength of the final product may not be satisfied.

上記実施形態のアルミニウム合金鍛造用素材の導電率は、25%IACS以上35%IACS以下である。この導電率は室温における導電率であるとし、この室温とは20℃±15℃程度とする。

導電率が25%IACS未満の場合は硬すぎて加工性が低下する、35%IACSを超える場合は柔らかいことで切削性(切粉分断性)の悪化、及び最終製品の保証強度を満足できないことがある。 (Conductivity: 25% IACS or more and 35% IACS or less)

The electrical conductivity of the aluminum alloy forging material of the above embodiment is 25% IACS or more and 35% IACS or less. This electrical conductivity is the electrical conductivity at room temperature, which is about 20°C ± 15°C.

If the electrical conductivity is less than 25% IACS, the material will be too hard and its workability will decrease, whereas if it exceeds 35% IACS, the material will be too soft, resulting in poor machinability (ability to break away chips), and the guaranteed strength of the final product may not be satisfied.

(ロックウェル硬さHRF:62以上82以下)

上記実施形態のアルミニウム合金鍛造用素材のロックウェル硬さHRFは、62以上82以下である。ここで、ロックウェル硬さHRFはJISZ2245:2016の「ロックウェル硬さ試験-試験方法」に準拠して測定された値である。

ロックウェル硬さHRFがこの範囲であれば、加工性が良好だからである。すなわち、ロックウェル硬さHRFが62未満の場合は柔らかいことで切削性(切粉分断性)の悪化、及び最終製品の保証強度を満足できないことがあり、82を超える場合は硬すぎて加工性が低下する。 (Rockwell hardness HRF: 62 or more and 82 or less)

The Rockwell hardness HRF of the aluminum alloy forging material of the above embodiment is 62 or more and 82 or less. Here, the Rockwell hardness HRF is a value measured in accordance with JIS Z2245:2016 "Rockwell hardness test - Test method".

This is because the workability is good if the Rockwell hardness HRF is within this range. That is, if the Rockwell hardness HRF is less than 62, the material is too soft, resulting in poor machinability (chip breakability) and inability to satisfy the guaranteed strength of the final product, while if it exceeds 82, the material is too hard, resulting in poor workability.

上記実施形態のアルミニウム合金鍛造用素材のロックウェル硬さHRFは、62以上82以下である。ここで、ロックウェル硬さHRFはJISZ2245:2016の「ロックウェル硬さ試験-試験方法」に準拠して測定された値である。

ロックウェル硬さHRFがこの範囲であれば、加工性が良好だからである。すなわち、ロックウェル硬さHRFが62未満の場合は柔らかいことで切削性(切粉分断性)の悪化、及び最終製品の保証強度を満足できないことがあり、82を超える場合は硬すぎて加工性が低下する。 (Rockwell hardness HRF: 62 or more and 82 or less)

The Rockwell hardness HRF of the aluminum alloy forging material of the above embodiment is 62 or more and 82 or less. Here, the Rockwell hardness HRF is a value measured in accordance with JIS Z2245:2016 "Rockwell hardness test - Test method".

This is because the workability is good if the Rockwell hardness HRF is within this range. That is, if the Rockwell hardness HRF is less than 62, the material is too soft, resulting in poor machinability (chip breakability) and inability to satisfy the guaranteed strength of the final product, while if it exceeds 82, the material is too hard, resulting in poor workability.

[アルミニウム合金鍛造品]

本発明の一実施形態に係るアルミニウム合金鍛造品について説明する。

図1は、本発明の一実施形態に係るアルミニウム合金鍛造品の斜視図である。

図1に示すように、アルミニウム合金鍛造品1aは、長尺部2と、長尺部2の長手方向の両端にそれぞれ接続された連結部4a,4bとを有する。長尺部は断面が4角形とされている。これら2つの連結部4には、それぞれ貫通孔が設けられていればよい。この形状のアルミニウム合金鍛造品1aは、例えば、I型サスペンションアームとして用いることができる。 [Aluminum alloy forgings]

An aluminum alloy forging according to one embodiment of the present invention will be described.

FIG. 1 is a perspective view of an aluminum alloy forging according to one embodiment of the present invention.

As shown in Fig. 1, an aluminum alloy forging 1a has along portion 2 and connecting portions 4a, 4b connected to both ends of the long portion 2 in the longitudinal direction. The long portion has a rectangular cross section. Each of the two connecting portions 4 may have a through hole. The aluminum alloy forging 1a having this shape can be used as, for example, an I-type suspension arm.

本発明の一実施形態に係るアルミニウム合金鍛造品について説明する。

図1は、本発明の一実施形態に係るアルミニウム合金鍛造品の斜視図である。

図1に示すように、アルミニウム合金鍛造品1aは、長尺部2と、長尺部2の長手方向の両端にそれぞれ接続された連結部4a,4bとを有する。長尺部は断面が4角形とされている。これら2つの連結部4には、それぞれ貫通孔が設けられていればよい。この形状のアルミニウム合金鍛造品1aは、例えば、I型サスペンションアームとして用いることができる。 [Aluminum alloy forgings]

An aluminum alloy forging according to one embodiment of the present invention will be described.

FIG. 1 is a perspective view of an aluminum alloy forging according to one embodiment of the present invention.

As shown in Fig. 1, an aluminum alloy forging 1a has a

本実施形態のアルミニウム合金鍛造品は、Cuを0.25質量%以上0.55質量%以下の範囲内、Mgを0.60質量%以上1.25質量%以下の範囲内、Siを0.90質量%以上1.4質量%以下の範囲内、Mnを0.35質量%以上0.60質量%以下の範囲内、Feを0.15質量%以上0.30質量%以下の範囲内、Znを0.25質量%以下の範囲内、Crを0.050質量%以上0.30質量%以下の範囲内、Tiを0.01質量%以上0.1質量%以下の範囲内、Bを0.0010質量%以上0.030質量%以下の範囲内、Zrを0.0010質量%以上0.050質量%以下の範囲内で含有し、Mnの含有量に対するFeの含有量の比Fe/Mnが質量比で1.4未満であり、残部がAl及び不可避不純物からなる合金組成を有するアルミニウム合金から構成されるアルミニウム合金鍛造品であって、粒界を含む2.0μm以内にMnを含有する析出物の数密度が4個/μm2以上含まれており、結晶方位差15゜以上の大角粒界の比率が27%以下である。

また、本実施形態のアルミニウム合金鍛造品は、常温における衝撃値において、10J/cm2以上とされている。 The aluminum alloy forging of this embodiment contains Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, and Ti in the range of 0.01 mass% or less. and 0.1% by mass or less, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 in terms of mass ratio, and the balance being Al and unavoidable impurities.

Moreover, the aluminum alloy forged product of this embodiment has an impact value of 10 J/cm 2 or more at room temperature.

また、本実施形態のアルミニウム合金鍛造品は、常温における衝撃値において、10J/cm2以上とされている。 The aluminum alloy forging of this embodiment contains Cu in the range of 0.25 mass% or more and 0.55 mass% or less, Mg in the range of 0.60 mass% or more and 1.25 mass% or less, Si in the range of 0.90 mass% or more and 1.4 mass% or less, Mn in the range of 0.35 mass% or more and 0.60 mass% or less, Fe in the range of 0.15 mass% or more and 0.30 mass% or less, Zn in the range of 0.25 mass% or less, Cr in the range of 0.050 mass% or more and 0.30 mass% or less, and Ti in the range of 0.01 mass% or less. and 0.1% by mass or less, B in the range of 0.0010% by mass or more and 0.030% by mass or less, Zr in the range of 0.0010% by mass or more and 0.050% by mass or less, a ratio of the Fe content to the Mn content (Fe/Mn) of less than 1.4 in terms of mass ratio, and the balance being Al and unavoidable impurities.

Moreover, the aluminum alloy forged product of this embodiment has an impact value of 10 J/cm 2 or more at room temperature.

粒界を含む2.0μm以内に含まれるMnを含む析出物のサイズを例示すると、0.5μm以下である。

For example, the size of precipitates containing Mn within 2.0 μm, including grain boundaries, is 0.5 μm or less.

本実施形態のアルミニウム合金鍛造品は、MgとSiを含む点で6000系アルミニウム合金の鍛造品に相当する。

The aluminum alloy forgings of this embodiment correspond to 6000 series aluminum alloy forgings in that they contain Mg and Si.

(Cu:0.25質量%以上、0.55質量%以下)

Cuは、アルミニウム合金中でMg-Si系化合物を微細に分散させる作用や、Q相を始めとするAl-Cu-Mg-Si系化合物として析出することでアルミニウム合金の引張強さを向上させる作用を有する。Cuの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Cu: 0.25% by mass or more, 0.55% by mass or less)

Cu has the effect of finely dispersing Mg-Si compounds in the aluminum alloy and the effect of improving the tensile strength of the aluminum alloy by precipitating as Al-Cu-Mg-Si compounds including the Q phase. By keeping the Cu content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

Cuは、アルミニウム合金中でMg-Si系化合物を微細に分散させる作用や、Q相を始めとするAl-Cu-Mg-Si系化合物として析出することでアルミニウム合金の引張強さを向上させる作用を有する。Cuの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Cu: 0.25% by mass or more, 0.55% by mass or less)

Cu has the effect of finely dispersing Mg-Si compounds in the aluminum alloy and the effect of improving the tensile strength of the aluminum alloy by precipitating as Al-Cu-Mg-Si compounds including the Q phase. By keeping the Cu content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

(Mg:0.60質量%以上、1.25質量%以下)

Mgは、アルミニウム合金の引張強さを向上させる作用を有する。アルミニウム母相へMgが固溶する、あるいは、β”相などのMg-Si系化合物(Mg2Si)、またはQ相を始めとするAl-Cu-Mg-Si系化合物(AlCuMgSi)として析出することで、アルミニウム合金の強化に寄与する。また、Mg2Siは、アルミニウム合金中でのCuAl2相の生成を抑制する作用がある。CuAl2相の生成が抑制されることによって、アルミニウム合金鍛造品1aの耐食性が向上する。Mgの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性とともに耐食性を向上させることができる。 (Mg: 0.60% by mass or more, 1.25% by mass or less)

Mg has the effect of improving the tensile strength of the aluminum alloy. Mg contributes to strengthening the aluminum alloy by dissolving in the aluminum parent phase or precipitating as Mg-Si compounds (Mg 2 Si) such as the β″ phase, or Al-Cu-Mg-Si compounds (AlCuMgSi) such as the Q phase. Mg 2 Si also has the effect of suppressing the formation of CuAl 2 phase in the aluminum alloy. By suppressing the formation of CuAl 2 phase, the corrosion resistance of the aluminum alloy forging 1a is improved. By keeping the Mg content within the above range, it is possible to improve the corrosion resistance as well as the mechanical properties at room temperature of the aluminum alloy forging 1a.

Mgは、アルミニウム合金の引張強さを向上させる作用を有する。アルミニウム母相へMgが固溶する、あるいは、β”相などのMg-Si系化合物(Mg2Si)、またはQ相を始めとするAl-Cu-Mg-Si系化合物(AlCuMgSi)として析出することで、アルミニウム合金の強化に寄与する。また、Mg2Siは、アルミニウム合金中でのCuAl2相の生成を抑制する作用がある。CuAl2相の生成が抑制されることによって、アルミニウム合金鍛造品1aの耐食性が向上する。Mgの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性とともに耐食性を向上させることができる。 (Mg: 0.60% by mass or more, 1.25% by mass or less)

Mg has the effect of improving the tensile strength of the aluminum alloy. Mg contributes to strengthening the aluminum alloy by dissolving in the aluminum parent phase or precipitating as Mg-Si compounds (Mg 2 Si) such as the β″ phase, or Al-Cu-Mg-Si compounds (AlCuMgSi) such as the Q phase. Mg 2 Si also has the effect of suppressing the formation of CuAl 2 phase in the aluminum alloy. By suppressing the formation of CuAl 2 phase, the corrosion resistance of the aluminum alloy forging 1a is improved. By keeping the Mg content within the above range, it is possible to improve the corrosion resistance as well as the mechanical properties at room temperature of the aluminum alloy forging 1a.

(Si:0.90質量%以上、1.4質量%以下)

Siは、Mgと同様にアルミニウム合金鍛造品1aの常温における機械的特性と共に耐食性を向上させる作用を有する。但し、アルミニウム合金にSiを過剰に添加すると、粗大な初晶Si粒が晶出することにより、アルミニウム合金の引張強さが低下するおそれがある。Siの含有率が上記の範囲内にあることによって、初晶Siの晶出を抑えつつ、アルミニウム合金鍛造品1aの常温における機械的特性と共に耐食性を向上させることができる。 (Si: 0.90 mass% or more, 1.4 mass% or less)

Like Mg, Si has the effect of improving the mechanical properties and corrosion resistance of the aluminum alloy forging 1a at room temperature. However, if excessive Si is added to the aluminum alloy, coarse primary crystal Si grains may crystallize, which may reduce the tensile strength of the aluminum alloy. By keeping the Si content within the above range, it is possible to improve the mechanical properties and corrosion resistance of the aluminum alloy forging 1a at room temperature while suppressing the crystallization of primary crystal Si.

Siは、Mgと同様にアルミニウム合金鍛造品1aの常温における機械的特性と共に耐食性を向上させる作用を有する。但し、アルミニウム合金にSiを過剰に添加すると、粗大な初晶Si粒が晶出することにより、アルミニウム合金の引張強さが低下するおそれがある。Siの含有率が上記の範囲内にあることによって、初晶Siの晶出を抑えつつ、アルミニウム合金鍛造品1aの常温における機械的特性と共に耐食性を向上させることができる。 (Si: 0.90 mass% or more, 1.4 mass% or less)

Like Mg, Si has the effect of improving the mechanical properties and corrosion resistance of the aluminum alloy forging 1a at room temperature. However, if excessive Si is added to the aluminum alloy, coarse primary crystal Si grains may crystallize, which may reduce the tensile strength of the aluminum alloy. By keeping the Si content within the above range, it is possible to improve the mechanical properties and corrosion resistance of the aluminum alloy forging 1a at room temperature while suppressing the crystallization of primary crystal Si.

(Mn:0.35質量%以上、0.60質量%以下)

Mnは、アルミニウム合金中でAl-Mn-Fe-SiやAl-Mn-Cr-Fe-Siなどの金属間化合物を含む微細な粒状の晶出物を形成することで、アルミニウム合金の引張強さを向上させる作用を有する。Mnの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Mn: 0.35 mass% or more, 0.60 mass% or less)

Mn has the effect of improving the tensile strength of the aluminum alloy by forming fine granular precipitates containing intermetallic compounds such as Al-Mn-Fe-Si and Al-Mn-Cr-Fe-Si in the aluminum alloy. When the Mn content is within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

Mnは、アルミニウム合金中でAl-Mn-Fe-SiやAl-Mn-Cr-Fe-Siなどの金属間化合物を含む微細な粒状の晶出物を形成することで、アルミニウム合金の引張強さを向上させる作用を有する。Mnの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Mn: 0.35 mass% or more, 0.60 mass% or less)

Mn has the effect of improving the tensile strength of the aluminum alloy by forming fine granular precipitates containing intermetallic compounds such as Al-Mn-Fe-Si and Al-Mn-Cr-Fe-Si in the aluminum alloy. When the Mn content is within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

(Fe:0.15質量%以上、0.30質量%以下)

Feは、アルミニウム合金中でAl-Mn-Fe-Si、Al-Mn-Cr-Fe-Si、Al-Fe-Si、Al-Cu-Fe、Al-Mn-Feなどの金属間化合物を含む微細な晶出物として晶出することで、アルミニウム合金の引張強さを向上させる作用がある。Feの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。

なお、Fe/Mnの関係は1.4未満である。Fe/Mnの関係が1.4未満であることによって、3.0μm以上のAlFeSi系化合物の晶出を抑制することができ、且つ結晶粒内にAlMn系化合物の数密度を向上させることができる。 (Fe: 0.15 mass% or more, 0.30 mass% or less)

Fe has the effect of improving the tensile strength of the aluminum alloy by crystallizing in the aluminum alloy as fine crystallized products including intermetallic compounds such as Al-Mn-Fe-Si, Al-Mn-Cr-Fe-Si, Al-Fe-Si, Al-Cu-Fe, Al-Mn-Fe, etc. By keeping the Fe content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

The Fe/Mn relationship is less than 1.4. By making the Fe/Mn relationship less than 1.4, it is possible to suppress crystallization of AlFeSi-based compounds having a size of 3.0 μm or more, and to improve the number density of AlMn-based compounds in crystal grains.

Feは、アルミニウム合金中でAl-Mn-Fe-Si、Al-Mn-Cr-Fe-Si、Al-Fe-Si、Al-Cu-Fe、Al-Mn-Feなどの金属間化合物を含む微細な晶出物として晶出することで、アルミニウム合金の引張強さを向上させる作用がある。Feの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。

なお、Fe/Mnの関係は1.4未満である。Fe/Mnの関係が1.4未満であることによって、3.0μm以上のAlFeSi系化合物の晶出を抑制することができ、且つ結晶粒内にAlMn系化合物の数密度を向上させることができる。 (Fe: 0.15 mass% or more, 0.30 mass% or less)

Fe has the effect of improving the tensile strength of the aluminum alloy by crystallizing in the aluminum alloy as fine crystallized products including intermetallic compounds such as Al-Mn-Fe-Si, Al-Mn-Cr-Fe-Si, Al-Fe-Si, Al-Cu-Fe, Al-Mn-Fe, etc. By keeping the Fe content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

The Fe/Mn relationship is less than 1.4. By making the Fe/Mn relationship less than 1.4, it is possible to suppress crystallization of AlFeSi-based compounds having a size of 3.0 μm or more, and to improve the number density of AlMn-based compounds in crystal grains.

(Cr:0.050質量%以上、0.30質量%以下)

Crは、アルミニウム合金中でAl-Mn-Cr-Fe-SiやAl-Fe-Crなどの金属間化合物を含む微細な粒状の晶出物を形成することで、アルミニウム合金の引張強さを向上させる作用を有する。Crの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Cr: 0.050 mass% or more, 0.30 mass% or less)

Cr has the effect of improving the tensile strength of the aluminum alloy by forming fine granular crystallized products including intermetallic compounds such as Al-Mn-Cr-Fe-Si and Al-Fe-Cr in the aluminum alloy. By having the Cr content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

Crは、アルミニウム合金中でAl-Mn-Cr-Fe-SiやAl-Fe-Crなどの金属間化合物を含む微細な粒状の晶出物を形成することで、アルミニウム合金の引張強さを向上させる作用を有する。Crの含有率が上記の範囲内にあることによって、アルミニウム合金鍛造品1aの常温における機械的特性を向上させることができる。 (Cr: 0.050 mass% or more, 0.30 mass% or less)

Cr has the effect of improving the tensile strength of the aluminum alloy by forming fine granular crystallized products including intermetallic compounds such as Al-Mn-Cr-Fe-Si and Al-Fe-Cr in the aluminum alloy. By having the Cr content within the above range, the mechanical properties of the aluminum alloy forging 1a at room temperature can be improved.

(Ti:0.01質量%以上、0.1質量%以下)

Tiは、アルミニウム合金の結晶粒を微細化し、展伸加工性を向上させる作用を有する。Ti含有率が0.01質量%未満の場合、結晶粒の微細化効果が十分に得られないおそれがある。一方、Ti含有率が0.1質量%を超えると、粗大な晶出物を形成し、展伸加工性が低下するおそれがある。また、アルミニウム合金鍛造品1aにTiを含む粗大な晶出物が多量に混入すると靭性が低下する場合がある。したがって、Tiの含有率は0.012質量%以上、0.035質量%以下とする。Tiの含有率は、好ましくは0.015質量%以上、0.050質量%以下である。 (Ti: 0.01 mass% or more, 0.1 mass% or less)