WO2017207945A1 - Copolymère épaississant et suspensif - Google Patents

Copolymère épaississant et suspensif Download PDFInfo

- Publication number

- WO2017207945A1 WO2017207945A1 PCT/FR2017/051396 FR2017051396W WO2017207945A1 WO 2017207945 A1 WO2017207945 A1 WO 2017207945A1 FR 2017051396 W FR2017051396 W FR 2017051396W WO 2017207945 A1 WO2017207945 A1 WO 2017207945A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- monomer

- copolymer

- diisocyanate

- mol

- polyalkoxylated

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F265/00—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00

- C08F265/04—Macromolecular compounds obtained by polymerising monomers on to polymers of unsaturated monocarboxylic acids or derivatives thereof as defined in group C08F20/00 on to polymers of esters

- C08F265/06—Polymerisation of acrylate or methacrylate esters on to polymers thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/81—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- A61K8/8141—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- A61K8/8152—Homopolymers or copolymers of esters, e.g. (meth)acrylic acid esters; Compositions of derivatives of such polymers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

- A61Q19/10—Washing or bathing preparations

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q5/00—Preparations for care of the hair

- A61Q5/02—Preparations for cleaning the hair

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C69/00—Esters of carboxylic acids; Esters of carbonic or haloformic acids

- C07C69/96—Esters of carbonic or haloformic acids

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F212/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring

- C08F212/02—Monomers containing only one unsaturated aliphatic radical

- C08F212/04—Monomers containing only one unsaturated aliphatic radical containing one ring

- C08F212/06—Hydrocarbons

- C08F212/08—Styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F212/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring

- C08F212/02—Monomers containing only one unsaturated aliphatic radical

- C08F212/04—Monomers containing only one unsaturated aliphatic radical containing one ring

- C08F212/14—Monomers containing only one unsaturated aliphatic radical containing one ring substituted by heteroatoms or groups containing heteroatoms

- C08F212/22—Oxygen

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/04—Acids; Metal salts or ammonium salts thereof

- C08F220/06—Acrylic acid; Methacrylic acid; Metal salts or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/12—Esters of monohydric alcohols or phenols

- C08F220/14—Methyl esters, e.g. methyl (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/12—Esters of monohydric alcohols or phenols

- C08F220/16—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms

- C08F220/18—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms with acrylic or methacrylic acids

- C08F220/1804—C4-(meth)acrylate, e.g. butyl (meth)acrylate, isobutyl (meth)acrylate or tert-butyl (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/12—Esters of monohydric alcohols or phenols

- C08F220/16—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms

- C08F220/18—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms with acrylic or methacrylic acids

- C08F220/1808—C8-(meth)acrylate, e.g. isooctyl (meth)acrylate or 2-ethylhexyl (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/26—Esters containing oxygen in addition to the carboxy oxygen

- C08F220/28—Esters containing oxygen in addition to the carboxy oxygen containing no aromatic rings in the alcohol moiety

- C08F220/285—Esters containing oxygen in addition to the carboxy oxygen containing no aromatic rings in the alcohol moiety and containing a polyether chain in the alcohol moiety

- C08F220/286—Esters containing oxygen in addition to the carboxy oxygen containing no aromatic rings in the alcohol moiety and containing a polyether chain in the alcohol moiety and containing polyethylene oxide in the alcohol moiety, e.g. methoxy polyethylene glycol (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/52—Amides or imides

- C08F220/54—Amides, e.g. N,N-dimethylacrylamide or N-isopropylacrylamide

- C08F220/56—Acrylamide; Methacrylamide

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F222/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a carboxyl radical and containing at least one other carboxyl radical in the molecule; Salts, anhydrides, esters, amides, imides, or nitriles thereof

- C08F222/02—Acids; Metal salts or ammonium salts thereof, e.g. maleic acid or itaconic acid

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/40—Chemical, physico-chemical or functional or structural properties of particular ingredients

- A61K2800/48—Thickener, Thickening system

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C2601/00—Systems containing only non-condensed rings

- C07C2601/12—Systems containing only non-condensed rings with a six-membered ring

- C07C2601/16—Systems containing only non-condensed rings with a six-membered ring the ring being unsaturated

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/12—Esters of monohydric alcohols or phenols

- C08F220/16—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms

- C08F220/18—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms with acrylic or methacrylic acids

- C08F220/1802—C2-(meth)acrylate, e.g. ethyl (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

- C08F220/12—Esters of monohydric alcohols or phenols

- C08F220/16—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms

- C08F220/18—Esters of monohydric alcohols or phenols of phenols or of alcohols containing two or more carbon atoms with acrylic or methacrylic acids

- C08F220/1811—C10or C11-(Meth)acrylate, e.g. isodecyl (meth)acrylate, isobornyl (meth)acrylate or 2-naphthyl (meth)acrylate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2800/00—Copolymer characterised by the proportions of the comonomers expressed

- C08F2800/20—Copolymer characterised by the proportions of the comonomers expressed as weight or mass percentages

Definitions

- the invention relates to the field of the preparation of aqueous compositions comprising rheology modifying agents, especially the preparation of cosmetic or detergent aqueous compositions having improved thickening and clarity properties as well as good snpsensitive properties.

- the invention relates to a rheology modifier which is a copolymer obtained by polymerization of at least one crosslinking monomer with at least one anionic monomer comprising at least one polymerizable ethylenic unsaturation and at least one hydrophobic nonionic monomer comprising at least one polymerizable ethylenic unsaturation.

- Rheology modifying agents also known as thickening agents or viscosity agents

- they are present in the cleaning compositions, for example in personal care or hygiene compositions, in particular cosmetic compositions, or in maintenance compositions, in particular in detergent products.

- these compositions are rich in surfactant compounds.

- agents influence the rheological properties of the formulation, in particular the viscosity as well as the optical or aesthetic properties such as clarity. These agents also influence the ability to suspend and stabilize particles within the formulation.

- soliable or swellable copolymers in an alkaline medium ASE polymers for Alkali-Soluble Emulsions or Aikali-Swellable Emulsions. Mention may also be made of soluble or swellable copolymers in an aqueous medium. alkaline and hydrophobically modified (HASE polymers for Hydrophobicaliy modified Alkali-Soluble Emulsions or Hydrophobicaliy modified Alkali-Swellahle Emulsions).

- Aqueous compositions comprising ASE copolymers or HASE copolymers as rheology modifying agents are also known.

- aqueous compositions For these aqueous compositions, one seeks in particular to improve their properties and their performances for a wide range of plies. In particular, it is sought to obtain aqueous compositions having high clarity, good properties in terms of thickening effect as well as good properties. suspensivantes.

- the control of the viscosity and the production of aqueous compositions in the form of a continuous and clear phase are particularly sought after, in particular for a wide pH range.

- the properties and performance of the aqueous compositions must be able to be implemented both at acidic pH values and at neutral or basic pH values.

- An aqueous composition has good suspensive properties or a good suspending power when it is capable of keeping particles in suspension in its continuous phase. This capacity must be able to deviate over time in order to obtain stable aqueous compositions, for example when they are stored,

- the suspensive properties are evaluated by application of a suspension application test which makes it possible to determine the value of the modulus of elasticity G 'and the value of Tan ( ⁇ ) of the aqueous composition comprising a rheology modifying agent.

- the particles to be suspended in the continuous phase of the aqueous composition are solid bodies, solid or hollow. These particles to be suspended can also be liquid entities which are immiscible with the continuous phase of the aqueous composition or else encapsulated bodies or gaseous bodies which can be characterized by shapes, textures, structures, compositions, colors and different final properties,

- exfoliating particles for example polyethylene particles, crushed fruit shells, pumice stones. It is also possible to mention nourishing particles, for example eolagen spheres, as well as nacreous particles, for example titanium mica, distearate glycoSs, or even aesthetic particles, for example air bubbles, flakes or pigments. possibly colored.

- the particles to be suspended can be quite variable in size.

- the air bubbles can be 1 mm, 2 mm or 3 mm in size.

- the clarity or clarity of the aqueous compositions can be evaluated by measuring their transmittance, usually expressed as a percentage.

- a composition is considered clear or limpid if it has a transmittance, for a wavelength of 500 nm, of at least 60%, preferably at least 70% and more preferably at least 80%.

- Document FR 3000085 discloses the preparation of an aqueous shower gel composition comprising particles in suspension in a clear continuous phase.

- the crosslinking compound used is ethylene glycol dimethacrylate (EDMA) or triethylolpropane trimethacrylate (TMP-TMA).

- Documents FR 1363955 and FR 1329008 describe the preparation of aliphatic carboxylic acid aliphatic esters of ⁇ , ⁇ -ethyl and homo Southernllic alcohol.

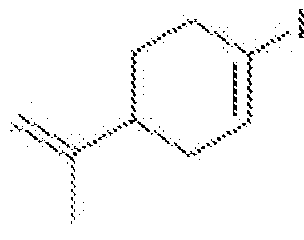

- the article by Ferret et al entitled Acryloxy and meih cryioxy palladium aikenes discloses a method of preparation from acrylates or methacrylates with achenes including a perillyl derivative.

- the invention makes it possible to provide a solution to all or some of the problems encountered with rheological modifying agents of the state of the art.

- the invention provides a copolymer (PI) obtained by polymerization reaction:

- L represents CH 2 , C3 ⁇ 4 monoalkoxylated or 3 ⁇ 4 polyalkoxylated

- L 5 represents a direct bond or C (O)

- Q represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisoeyanate (TDI) and isophorone-diisocyanate ⁇ Q 4 represents 3 ⁇ 4, CH2-CH2, CH2 mono-alkoxylated, CH2-CH2 monoalkoxylated, C3 ⁇ 4 polyalkoxylated or CH2-CH2 polyalkylated.

- TDI tolyl-1,3-diisoeyanate

- Q 4 represents 3 ⁇ 4, CH2-CH2, CH2 mono-alkoxylated, CH2-CH2 monoalkoxylated, C3 ⁇ 4 polyalkoxylated or CH2-CH2 polyalkylated.

- a monoalkoxylated or polyalkoxylated group comprises im or more alkoxy groups, in particular oxyethylene or oxypropylene groups or combinations thereof.

- alkoxy groups in particular oxyethylene or oxypropylene groups or combinations thereof.

- Such a number can range from 1 to 50, preferably from 1 to 10, oxyethylene or oxypropylene groups or combinations thereof.

- the monomers can be introduced separately or in the form of one or more mixtures of these monomers.

- the monomers are introduced in the form of a mixture.

- the anionic monomer (a) is an anionic monomer comprising a polymerizable vinyl function and at least one carboxylic acid function. More preferably, it is a monomer selected from acrylic acid, methacrylic acid, maleic acid, itaconic acid, crotonic acid, a salt of acrylic acid, a salt of methacrylic acid, a maleic acid salt, an itaconic acid salt, a crotonic acid salt, an acid salt thereof and mixtures thereof. More preferably according to the invention, the anionic monomer (a) is selected from acrylic acid, methacrylic acid, an acrylic acid salt, a methacrylic acid salt and mixtures thereof. Even more preferably according to the invention, the anionic monomer (a) is chosen from acrylic acid, methacrylic acid and mixtures thereof. The monomer (a) more particularly preferred is methacrylic acid.

- the anionic monomer (a) is implemented in an amount of at least 20 mole% 5 preferably 25 to 60 mol%, especially from 30 to 55 mol%, relative to the total molar amount of monomers.

- the hydrophobic nonionic monomer (b) is a hydrophobic nonionic monomer comprising a polymerizable vinyl function.

- the hydrophobic nonionic monomer (b) is chosen from acrylic acid esters, methacrylic acid esters, acrylic acid amides, niethaeryl acid amides, acrylic acid nitriies, nitriles of methacrylic acid or of acrylonitrile, styrene, methylstyrene and diisobutylene.

- the hydrophobic nonionic monomer (b) is selected from C1-C8alkyl acrylates, C1-C8alkyl methacrylates, C1-C8alkylmediates, C1-C8alkyl itaconates, C1-C8-alkyl erotonates, C1-C8 alkyl cinnamates and mixtures thereof, preferably methyl acrylate, ethyl acrylate, butyl, 2-ethylhexyl acrylate, methyl methacrylate, ethyl methacrylate, butyl methacrylate and mixtures thereof.

- the hydrophobic nonionic monomer (b) is selected from methyl acrylate, ethyl acrylate, butyl acrylate, methyl methacrylate, ethyl methacrylate, and mixtures thereof.

- the hydrophobic nonionic monomer (b) more particularly preferred is ethyl acrylate.

- the hydrophobic nonionic monomer (b) is used in an amount of 30 to 80 mol%, preferably 35 to 75 mol%, more preferably 45 to 70 mol%, relative to the total molar amount of monomers,

- the copolymer (PI) may be prepared from anionic monomer (a) chosen from acrylic acid, methacrylic acid and their mixtures, preferably methacrylic acid, and hydrophobic nonionic monomer (b) chosen from Methyl acrylate, ethyl acrylate, butyl acrylate, methyl methacrylate, ethyl methacrylate and mixtures thereof, preferably ethyl acrylate.

- the preparation of the copolymer (PI) according to the invention implements at least one monomer of formula (I).

- This monomer of formula (I) comprises at least two polymerizable ethylenic unsaturations which are of different natures.

- the monomer of formula (I) is advantageously a crosslinking monomer.

- the monomer of formula (I) is a crosslinking monomer whose two polymerizable ethylenic unsaturations have different properties which confer specific crosslinking properties to the monomer of formula (I).

- the monomer (c) is a compound of formula (I-A);

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisocyanate (TDI) and isophorone diisocyanate (IPDI) and

- Q 4 represents C3 ⁇ 4 CH2 ⁇ CH C3 ⁇ 4> monoaîkoxyîé, CH2-CH2 monoaîkoxyîé, polyalkoxylated CH 2 or CH 2 -CH 2 polyalkoxylated.

- the monomer (c) is a compound of formula (I-A) in which:

- L represents CH2

- the monomer (c) is a compound of formula (I-A) in which:

- L represents C3 ⁇ 4 monoalkoxy or CH 2 polyalkoxylated.

- R represents Q 3 OO OC (O) C (CH 3 ) -CH 2 or Q 3 OQ OC (O) C (H) -CH 2s

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from poly-1,3-diisocyanate (TDI) and isophorone diisocyanate (IPDI) and

- Q 4 represents C3 ⁇ 4, CBb-CHa, C3 ⁇ 4 monoalkoxy, CH2-CH2 monoalkoxy, polyalkoxylated CH 2 or polyalkoxylated CH 2 -CH 2.

- the invention provides a copolymer (PI) obtained by polymerization reaction:

- the monomer (c) is a compound chosen from: a compound (c1) of formula (I-A) in which L represents C3 ⁇ 4 and R represents -C (H3 ⁇ 4 and

- the monomer (c) is a compound of Ile (I-B):

- ⁇ L represents CH3 ⁇ 4 CEb monoalkoxylé or C3 ⁇ 4 polyalkoxylé

- Q 3 represents an unsymmetrical diisocyanate im compound diisocyanate residue, preferably selected from tolyl-1,3-diisocyanate (TDI) and isophorone diisocyanate (IPDi) and

- - Q 4 represents CH 2; CH2-CH2. C3 ⁇ 4 monoalkoxylated, CH2-CH2 monoalkoxylated, CH2 polyalkoxylated or CH2-CH2 polyalkoxylated.

- the monomer (c) is a compound of formula (I-B) in which;

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably chosen from among you 1-l, 3 -diisocyanate (TDI) and isophorone-diisocyanate (IPDI) and

- - Q 4 represents CH2-CH2-CH2, C3 ⁇ 4 monoalkoxylated, CH2-CH2 monoalkoxylated, CH2 polyalkoxylated or C13 ⁇ 4-CH2 polyalkoxylated.

- the monomer (c) is a compound of formula (I-B) in which:

- L is CH 2 or CH 2 monoalkoxylé polyalkoxylated

- - R represents -C (H) -CH 2> -C (C3 ⁇ 4) -C3 ⁇ 4 -C (H) - (H) C (O) O3 ⁇ 4 -C (H) -C (H) C3 ⁇ 4 ⁇ 2 € 3 ⁇ 4) 0 (0) ⁇ ? Q 3 OQ OC (0) C (CH) -CH 2 or Q I OQ OC (0) C (H) -CH 2S

- Q 3 represents a residue of an asymmetric diisoeyanate compound, preferably selected from 1,3-diisoeyanate (TDI) and isophorone diisoeyanate (IPDI) and

- Q 4 represents C3 ⁇ 4C3 ⁇ 4-CH 2 , C3 ⁇ 4 monoalkoxyté, CH2-CH2 monoalkoxylé, C3 ⁇ 4 polyalkoxyié CH2-CH2 polyalkoxyié.

- the monomer (e) is used in an amount of less than 5 mol%, preferably 0.01 to 5 mol% and more preferably 0.02 to 4 mol%, or 0.02 to 2 mol% or 0.04 to 0.5 mol%, based on the total molar amount of monomers.

- These compounds of formulas (I), (II-A) or (IB) according to the invention can be prepared according to a process comprising the reaction according to Scheme 1 during which the temperature is generally between 50 ° C. and 250 ° C. and may employ a radical inhibiting agent.

- the copolymer (PI) is pre-treated by a polymerization reaction comprising the use of monomers (a) and (b) and of monomer (c) of formulas (I). (I-A) or (I-B).

- the copolymer (PI) can therefore be prepared from these monomers (a), (b) and (c) of formulas (I), (I-A) or (I-B) alone.

- the copolymer (F1) can also be prepared from these three types of monomers associated with other monomers.

- Polymerization reaction to prepare the copolymer (PI) may employ one or more other monomers.

- the copolymer (P1) may be prepared by a polymerization reaction also implementing at least one nonionic monomer (d), different from the monomer (b), comprising a polymerizable vinyl function and a hydrocarbon base. comprising at least 10 carbon atoms.

- the nonionic monomer (d) is preferably chosen from: a monomer (d1) comprising a polymerizable vinyl function and a Cn-Cae hydrocarbon chain and

- a monomer (d2) comprising a polymerizable vinyl function, a C12-C30 hydrocarbon-based chain and from 1 to 150, preferably from 15 to 50 and more preferably from 20 to 30, alkylene-oxy groups.

- the preferred oxyalkylene groups are its ethoxy (EO), propoxy (PO) and butoxy (BO) groups, in particular the ethoxy (EO) group, a preferred nonionic monomer (d2). is a compound of formula (II):

- R * independently represents a polymerizable vinyl function

- R 2 represents independently:

- hydrocarbon chain comprising at least 10 carbon atoms, preferably a Cia-Cse hydrocarbon chain or

- hydrocarbon chain comprising at least 10 carbon atoms, preferably Ci2 hydrocarbon chain -C 3 6 and at least one heteroatom selected from O, S, M and P and

- n, p and q which may be identical or different, independently represent an integer or decimal number ranging from 0 to 150, the sum of m, p and q being non-zero.

- R 1 represents a polymerizable vinyl functional group chosen from a vinyl group, a methylvinyl group, an acrylate group, a methacrylate group, an allyl group and a methallyl group.

- the polymerization reaction may use from 0.01 to 10 mol% of monomer (d), based on the total molar amount of monomers.

- the polymerization reaction may use 0.02 to 5 mol% or 0.02 to 2 mol% of monomer (d), relative to the total molar amount of monomers.

- the copolymer (PI) may be prepared by a polymerization reaction also implementing at least one ionic monomer or not ionic (e), different from monomer (a) and monomer (b).

- the ionic or nonionic monomer (e) is chosen from:

- the tereomers preferably the dimers, the trimers or the unsaturated enamers of acrylic acid,

- R 3 , R 4 and R 5 which may be identical or different, independently represent H or C3 ⁇ 4 and

- ⁇ r is independently 1, 2 or 3 and

- R 6 , R 7 and R 8 which may be identical or different, independently represent H or b,

- R 9 represents H or CHs

- L 3 independently represents a direct bond or from 1 to 150, preferably from 15 to 100 and more preferably from 25 to 75 alkyleneoxy groups.

- the preferred oxyalkylene groups are the ethoxy (EO), propoxy (PO) and butoxy (BO) groups, in particular the group and oxy (EO).

- an ethoxy group is a residue -CH2-CH2-O

- a propoxy group is an ethoxy group substituted by a methyl group on one of the carbon atoms to replace an atom of hydrogen

- a butoxy group is an ethoxy group substituted by an ethyl radical on one of the carbon atoms to replace a hydrogen atom.

- HEMA or hydroxyethyl methacrylate which is a compound of formula (IV) in which RR 7 and R 9 represent H, R 8 represents C3 ⁇ 4, O represents C (O) O and L 3 represents an ethylene-oxy group,

- HPMA hydroxypropyl methacrylate which is a compound of formula (IV) wherein R * and R 7 -R 9 are H, S * represents C3 ⁇ 4 L 2 is C (0) 0 and L 3 represents a propylene group - oxy and

- the polymerization reaction may use from 0.01 to 25 mol% of monomer (e), relative to the total molar amount of monomers.

- the polymerization reaction may use from 0.02 to 15 mol% or from 0.02 to 10 mol% of monomer (e), relative to the total molar amount of monomers.

- the copolymer (PI) can be prepared by a polymerization reaction also using at least one other monomer (i).

- the monomer (f) is advantageously a rétieulant monomer, hydrophilic, hydrophobic one amphiphiie and is generally a compound comprising several unsaturations éthylém 'c. It is distinct from the monomer of formula (I) according to the invention.

- the monomer (f) can be a compound (V):

- R 30 is independently H or C3 ⁇ 4,

- L 4 independently represents a linear or branched C 1 -C 20 -alkylene group

- the monomer (f) may also be chosen from di (meth) acrylates such as polyalkylene glycol di (meth) acrylate, especially polypropylene glycol di (meth) acrylate, ethylene glycol di (meth) acrylate, polyethylene glycol di (meth) acrylate, methylene glycol di (meth) acrylate, 1,3-butylene glycol di (meth) acrylate, 1,6-butylene glycol di (meth) acrylate, 1,6-hexanediol di (meth) acrylate, neopentyl glycol di (meth) acrylate, 1,9-nonanediol di (meth) acrylate, but also 2,2-hexanediol ; (4- (acryloxypropyloxy) -phenyl) propane, 2,2'-bis (4- (acryloxypropyloxy) -phenyl) propane, 2,2'-bis (4- (acryloxypropyloxy)

- the monomer (i) may also be prepared by an esterification reaction of a polyol with an unsaturated anhydride such as acrylic anhydride, methacrylic anhydride, maleic anhydride or itaconic anhydride.

- an unsaturated anhydride such as acrylic anhydride, methacrylic anhydride, maleic anhydride or itaconic anhydride.

- compounds chosen from polyhaloalkanols such as 1,3-dichloropropanol and 1,3-dibromoisoproparsol; haloepoxyalkanes such as rehiorohydrin, epibromohydrin, 2-methyl epichlorohydrin and repiiodohydrme; polyglycidyl ethers such as 1,4-buianediol diglycidyl ether, glycerin-1,3-diglycidyl ether, ethylene glycol diglycidyl ether, propylene glycol diglycidyl ether

- the monomer ( ⁇ ) may also be selected from the hydrophilic materials. It may be in particular trinithiolpropane iri (meth) acrylate (TMPTA) or ethoxylated trimethylolpropane tri (meih) acrylate (such as, for example, TMPT ⁇ 30E).

- TMPTA trinithiolpropane iri (meth) acrylate

- ethoxylated trimethylolpropane tri (meih) acrylate such as, for example, TMPT ⁇ 30E.

- the monomer (i) may also have been selected from trimethylolpropane tri (meth) acrylate, ethoxylated iriethiothipropane (meth) acrylate, ethylene glycol di (meth) acrylate, ethylenebisacrylamide, diallylphthalate, dialylmaleate, and mixtures thereof.

- the monomer (f) may also be a separate mixture of two monomers, for example EGDCFEA (ethylene glycol dicyelopentenyl ether ether) and TMPTA still EGDCPEA and TMPTA 30E.

- EGDCFEA ethylene glycol dicyelopentenyl ether ether

- TMPTA still EGDCPEA and TMPTA 30E.

- the monomer (f) is preferably chosen from a compound of formula (Y), trimethylolpropane trimethacrylate, trimethylolpropane triacryate, ethoxylated trimethylolpropane trimethylolpropane, ethoxylated trimethylolpropane triacrylate, dimethaeryl d ethylene glycol.

- the polymerization reaction may employ less than 5 mol%, preferably 0.01 to 4 mol%, in particular 0.02 to 2 mol%, especially 0.04 to 1 mol%.

- monomer (f) based on the total molar amount of monomers.

- the ce-polymer (Pi) can be prepared by a polymerization reaction also implementing at least one monomer (g).

- the monomer (g) is advantageously a hydrophilic, hydrophobic or amphoteric reactive monomer and is generally a compound comprising a number of ethylenic unsaturations. 0 is distinct from the monomer of formula (I) according to the invention.

- the monomer (g) can be a compound of formula (VI):

- R n is independently H or CI-fe

- V independently represents an ethylene, propylene or butylene

- the monomer (g) is a compound of formula (VI) in which u represents an integer or decimal number ranging from 1 to 18, from 1 to 15 or from 2 to 16 or from 2 to 12.

- the polymerization reaction may employ less than 5 mol%, preferably 0.01 to 4 mol%, in particular 0.02 to 2 mol%, especially 0.04 to 1 mol%. monomer (g), based on the total molar amount of monomers.

- the preparation of the polymer (PI) also employs at least one chain transfer agent, preferably chosen from mercaptan compounds, in particular mercaptan compounds comprising at least four carbon atoms, such as butyl mercaptan, n-octyl mercaptan, n-dodecyl mercaptan, tef-dodecyl mercaptan.

- chain transfer agent preferably chosen from mercaptan compounds, in particular mercaptan compounds comprising at least four carbon atoms, such as butyl mercaptan, n-octyl mercaptan, n-dodecyl mercaptan, tef-dodecyl mercaptan.

- the eopolymer (PI) prepared according to the invention is thus obtained by a polymerization reaction.

- This reaction can be a radical polymerization reaction, for example an emulsion, dispersion or solution polymerization reaction.

- the polymerization may be conducted in a solvent, in the presence of at least one initiator compound.

- initiator compounds are the persimitate salts, especially ammonium persulfate.

- the reaction is a radical emulsion polymerization reaction.

- Radical emulsion polymerization can be carried out in the presence of at least one an isiotactic compound and optionally at least one chain transfer agent that generally regulates the molecular weight of the chains produced during the polymerization.

- chain transfer agent that generally regulates the molecular weight of the chains produced during the polymerization.

- ⁇ onic surfactants for example a fatty acid salt, an alkyl sulphate salt such as sodium lauryl sulphate, an alkyl ether sulphate salt such as iaury! sodium sulphate, an alkylbensenesulfonate salt such as sodium dodecylbenzenesulfonate, an alkyl phosphate salt or a diesyl sulfosuccinate salt, a cocoamphoacetate salt such as cocoamphoacetate sodium, a cocoamphodiacetate salt such as sodium, cocoamphodiacetate, a sodium salt, lauroyl glutamate such as sodium lauroyl glutamate, a cocoyi salt isethionate such as sodium cocoyl isethionate, a lauroyl methyl isethionate salt such as sodium laaroyl methyl isethionate, a methyl cocoyl taurate salt such as sodium methyi cocoyi taurate, a methyl oley

- nonionic surfactants for example a polyoxyethylene alkyl ether or a polyoxyethylene fatty acid ester,

- Cationic surfactants for example quaternary alkylammonium halides and quaternary arylammonium halides,

- zwitterionic or amphoteric surfactants for example surfactants comprising a betaine group and

- Q * represents n residue divaleni of unsymmetrical diisocyanate compound "preferably selected from i iyl- ⁇ , 3-diisocyaaate (TDI) and IsoplKsrone-diisoeysna e (IPDI) and

- - Q 4 is CH 3 ⁇ 4 C3 ⁇ 4 monoaikoxylé, CH2-CH2 monoaikoxylé, CH; polyalkoxylated or CH2-CH2 polyalkoxylated.

- the invention also relates to the use, for the preparation of a copolymer, of less than 5 mol%, relative to the total molar amount of monomers used, of at least one monomer of formula ( ⁇ -)). or of formula (I-B) according to the invention.

- the invention relates to the use, for the transfer of a polymer or a monomer mixture, of less than 5 mol%, relative to the total molar quantity of monomers used, from less than a monomer of formula (I);

- L represents CH2, monacoalkylated or polyalkoxylated C ⁇ b

- L J represents a direct bond or C (O)

- TDI teyl-1-diisocyanate

- 3 ⁇ 4 represents CH2, CH 2 -CH 2> C3 ⁇ 4 monoalkoxylated, CH2-CB2 monoalkoxylated, C3 ⁇ 4 polyoxyalkyl CH2-CH2 polyalkoxy.

- the invention relates to the use, for the cross-linking of a polymer or a mixture of monomers, of less than 5 mol%, with respect to the total molar quantity of monomers used, of at least one monomer of formula (I-A) or of formula (I-B) according to the invention.

- These uses according to the invention can also be defined according to the preparation characteristics of the copolymer (P1) according to the invention.

- the invention also relates to a process for preparing this copolymer according to the invention.

- the invention provides a process (1) for preparing a copolymer (PI) obtained by polymerization reaction:

- At least one anionic monomer comprising at least one polymerizable ethylenic unsaturation, preferably an anionic monomer comprising a polymerizable vinyl function and at least one carboxylic acid function,

- L represents CH 2, C3 ⁇ 4 monoalkoxylated or b polyalkoxylated

- ⁇ L 1 represents a direct connection or C (Q) S

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably chosen from tolyl-1,3-diisocyanate (TDI) and isophorone-diisocyanate (IPDI), and

- Q 4 represents 3 ⁇ 4, CH 2 -CH 2, monoalkoxylated CH 2, monoalkoxylated CH 2 -CH 2, polyalkoxylated CH 2 or polyalkoxylated CH 2 -CH 2 .

- the invention also provides a process (1) for preparing a copolymer (PI) obtained by polymerization reaction:

- At least one anionic monomer comprising at least one polymerizable ethylenic unsaturation preferably an anionic monomer comprising a polymerizable vinyl function and at least one carboxylic acid function.

- at least one hydrophobic nonionic monomer comprising at least one pegable ethylenic unsaturation preferably a hydrophobic nonionic monomer comprising a polymerizable vinyl function and

- the method (1) according to Pinventiort is also defined by the monomers and by the conditions used for the preparation of the copolymer (PI) according to the invention.

- the invention also relates to a process (2) for preparing a copolymer (P2) obtained by polymerization reaction also comprising the implementation during the polymerization reaction of a copolymer (PI), obtained beforehand during the reaction method of polymerization (1) according to the invention.

- the process (2) according to the invention comprises the polymerization reaction of a copolymer (PI) prepared beforehand according to the invention with:

- At least one amonic monomer comprising at least one polymerizable ethylenic unsaturation, preferably an anionic monomer comprising a polymerizable vinyl functional group and at least one carboxylic acid functional group,

- L represents CH3 ⁇ 4 CI3 ⁇ 4 monoalkoxy or C3 ⁇ 4 polyalkoxy

- ⁇ L 1 represents a direct bond or C (0)

- - Q J represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from 1,3-diylisocyanate (TDI) and isophorone-diisocyanate

- IPD ⁇ is CH2, CH2-CH2, CH2 monoalkoxy, CH2-CH2 monoalkoxy, CH2 polyalkoxy or CH2-CH2 polyalkoxylated.

- the process (2) according to the invention may also comprise the polymerization reaction of a copolymer (PI) prepared beforehand according to the invention with:

- At least one anionic monomer comprising at least one polymerizable ethylenic unsaturation, preferably an anionic monomer comprising a polymerizable vinyl functional group and at least one carboxylic acid functional group,

- the process (2) according to the invention is also defined by the monomers and by the conditions used for the preparation of the copolymer (PI) according to the invention.

- the multiphase copolymer (P2) according to the invention can be prepared sequentially, by radical polymerization in emulsion, in dispersion or in solution. Preferably, at least two consecutive steps are implemented, a first step for obtaining a first copolymer (PI), while a second polymerization step uses a copolymer (PI).

- the first step is to contact the monomers for preparing the copolymer (PI) with a polymerization initiator compound.

- This contacting can be performed in batch mode, in batch mode, still in semi-bateh mode or in semi-continuous mode. This contacting can be carried out in a duration ranging from several minutes to several hours.

- the second step of preparing the copolymer (P2) can comprise:

- This step then allows the formation of a copolymer (P2) according to the invention.

- the invention therefore also relates to the copolymer (P2) obtainable by the process (2) according to the invention.

- the copolymer (P2) according to the invention is multiphasic.

- the copolymer (P2) according to the invention comprises a core comprising a first copolymer (PI), totally partially covered by a second copolymer (PI), identical to or different from the first copolymer (PI).

- the copolymer (P2) comprises a core comprising a first copolymer (PI), totally or partially covered by a second copolymer (PI) for which the weight ratio 1 ° copolymer (P1) / 2 ° copolymer (Pi) is between 45/55 and 95/5, in particular between 60/40 and 90/10,

- the copolymers according to the invention are particularly effective as rheology modifiers in a wide range of aqueous compositions or as thickeners and suspensives.

- aqueous compositions in many industrial fields including drilling fracking fluids, formulations for ceramics, paper coating coatings.

- washing compositions containing surfactants such as care compositions or maintenance compositions ("personal care” and "home care” in English) comprising, for example, cosmetic, personal hygiene compositions, are mentioned.

- the copolymers (PI) and (P2) according to the invention have advantageous properties. They can therefore be incorporated in aqueous compositions.

- the invention also provides an aqueous composition comprising at least one copolymer (PI) according to the invention.

- the invention also provides an aqueous composition comprising at least one copolymer (P2) according to the invention.

- the invention also provides an aqueous composition comprising at least one copolymer (PI) according to the invention and at least one copolymer (P2) according to the invention.

- the aqueous composition according to the invention is a cosmetic composition and may comprise:

- the copolymers (PI) and (P2) according to the invention may be present in amounts ranging from 0.1 to 20% by weight, in particular from 0.5 to 12% by weight. weight, relative to the total weight of the composition.

- the composition according to the invention may comprise a clear continuous phase and particles in suspension distributed in the continuous phase.

- the copolymer according to the invention can then confer on the composition, clarity and suspension of the particles present.

- such a composition according to the invention does not generally require any mixing step, even if the composition has been stored for several weeks or even several months.

- composition according to the invention may also comprise one or more surfactant compounds, in particular chosen from anionic, zwitterionic or amphoteric, cationic or nonionic surfactants and mixtures thereof. It may also comprise one or more active ingredients.

- surfactant compounds in particular chosen from anionic, zwitterionic or amphoteric, cationic or nonionic surfactants and mixtures thereof. It may also comprise one or more active ingredients.

- the cosmetic composition according to the invention has a pH ranging from 3 to 9. Even more preferably, its pH is from 3 to 7. Even more preferentially, its pH is from 4 to 7.

- the invention therefore relates to the use for the preparation of an aqueous composition according to the invention or for the preparation of a cosmetic composition according to the invention.

- the invention also relates to a compound of formula (I):

- L represents CE, CEfe monoalkoxylated or C3 ⁇ 4 polyalkoxylated

- L 1 represents a direct bond or C (O)

- Q 3 GQ 4 OC (G) C (CH 3 ) CH 2 or Q 3 GQ 4 OC (O) C (H) -CH 2 , - Q 3 represents a divalent residue of a diisocyanate dissometrical compound, preferably selected from iolyl ⁇ l, 3 ⁇ diisocyanate (TDI) and isophorone-diisocyanate (1PDI) and

- Q 4 represents C3 ⁇ 4 s CH 2 -CH 2, monoalkoxylated CH 2, monoalkoxylated CH 2 -CH 2 , CH 2 polyalkoxylated or polyalkoxylated CH2-CH2,

- L represents C3 ⁇ 4, CH2 monoalkoxylated or C3 ⁇ 4 polyalkoxylated

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisocyanate (TDI) and isophorone diisocyanate (IPDI) and

- - Q 4 represents C3 ⁇ 4, CH 2 -CH 2 , CH 2 monoalkoxylated. Monoalkoxylated CH 2 -CH 2, polyalkoxylated CH 2 or polyalkoxylated CH 2 -CH 2,

- L represents CH 2 monoalkoxylated or CH 2 polyalkoxylated

- R represents Q 3 OQ OC (O) C (CH 3 ) -CH 2 or Q 3 OQ 4 OC (O) C (H) -CH 2s - Q 3 represents a divaleni residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisocyanate (TDI) and isopfaorone-diisocyarsate (IPDI) and

- - Q 4 represents 3 ⁇ 4, C b-CH 1, C3 ⁇ 4 monoalkoxylated, CH 2 -CH 2 monoalkoxylated, C3 ⁇ 4 polyalkoxylated or CH 2 -CH 2 polyalkoxylated.

- the invention also relates to a compound of formula (IB); (IB)

- L represents CH 2 , CH 2 monoalkoxylated or CH 2 polyalkoxylated

- ⁇ Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisocyanate (TDI) and isophorone-diisocyanate (IPDI) and

- Q 4 represents CH 2 , CH 2 -CH 2 , CH 2 monoalkoxylated, CH 2 -CH 2 monoalkoxylated, CH 2 polyalkoxylated or CH 2 -CH 2 polyalkoxylated.

- Preferred compounds according to the invention are compounds of formula (I-B) in which:

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisocyanate (TDI) and isophorone-diisocyanate

- Q 4 represents C3 ⁇ 4, CKb-Ctb., C3 ⁇ 4 monoalkoxylated, CH 2 -C3 ⁇ 4 monoalkoxylated, C3 ⁇ 4 polyalkoxylated or CH2-CH2 polyalkoxylated,

- L represents C3 ⁇ 4 monoalkoxylated or CH2 polyalkoxylated

- Q 3 represents a divalent residue of an asymmetric diisocyanate compound, preferably selected from tolyl-1,3-diisoeyanate (TDI) and isophorone-diisoeyanate

- Q 4 represents 3 ⁇ 4, CH 2 -CH 2 , monoalkoxylated CH, CH 2 -CH 2 monoalkoxy, polyalkoxylated CH 2 or polyalkoxylated CH 2 -CH 2 .

- SR 351 from Sartomer trimethylolpropane triacrylate (TMPTA),

- compound (d) solution comprising 45% by weight of methacrylic acid, 5% by weight of water and 50% by weight of compound (d2 ⁇ 1) of formula (II) in which R 1 represents a grouping -OC (0) C (C3 ⁇ 4) -CH 2, R 2 represents a branched hydrocarbon-based chain containing 16 carbon atoms (2-hexyldecanyl), m represents 25 and p and q represent 0.

- R 1 represents a grouping -OC (0) C (C3 ⁇ 4) -CH 2

- R 2 represents a branched hydrocarbon-based chain containing 16 carbon atoms (2-hexyldecanyl)

- m represents 25 and p and q represent 0.

- the mixture is heated to 78 ° C. with stirring and then 101.19 g of methacrylic anhydride are added. The mixture is stirred for 2 hours at 80 ° C. ⁇ 2 ° C.

- a mixture comprising 72% by weight of crosslinking monomer (c 2) and 28% by weight of methacrylic acid is obtained.

- the mixture 1 is prepared by introducing deionized water and a solution containing 28% by weight of sodium lauryl ether sulfate (SLES) or sodium lauryl sulphate (SDS), and optionally ethylene oxide-propylene oxide monohutyl ether.

- SLES sodium lauryl ether sulfate

- SDS sodium lauryl sulphate

- SLES sodium lauryl ether sulphate

- SDS sodium lauryl sulphate

- This premix is stirred to form a monomeric mixture.

- An initiator solution 1 comprising homogeneous persulfate and deionized water is prepared.

- An initiator solution 2 also comprising ammonium persuliate and deionized water is prepared.

- the initiator solution 1 and the premix of monomers are injected in parallel for 2 hours. Then for 1 hour, the initiator solution 2 was injected into the reactor heated to 85 ° C +/- 1 ° C.

- Water is optionally added and the mixture is baked for 30 minutes at a temperature of 85 ° C. ⁇ 1 ° C. The whole is then cooled to room temperature.

- the polymers according to the invention and the comparative polymers were prepared under these conditions by varying the monomer compositions of the monomer premixes.

- the aqueous formulation used comprises 2.4% by weight or 3% by weight of polymer (see Table 1), 9% by weight of a first surfactant compound (SLE8 or lauryi-enamel sodium sulphate), 3% by weight. a second surfactant compound (CAPB or Gocamidopropyl betaine) and water (qs 100% by weight).

- the pH of the formulation is adjusted to a value of 5, 6 or 7 by addition of lactic acid or sodium hydoxide.

- the formulations are evaluated for their properties of viscosity, clarity and suspensive performance, viscosity

- the viscosity of the formulations is measured using a Brookfield viscometer, model LVT. Before measuring the viscosity, each of the formulations is allowed to stand for 24 hours at 25 ° C. The mobile of the viscometer must be centered with respect to the opening of the formulation bottle. The viscosity is measured at 6 rpm using the appropriate module. The viscometer is allowed to rotate until the viscosity value is stabilized.

- the rheology modifying agent copolymer must bring sufficient viscosity to the formulation in which it is used.

- the desired viscosity for the thickened formulations should be greater than 4,000 mPa.s, especially greater than 6,000 mPa, s and more particularly greater than 8,000 mPa.s.

- each formulation is evaluated by measurement of ixansmittance using a UV Genesys UV UV spectrometer (Cole Parmer), equipped with otilabo-Einmal uvetien PS tanks, 4.5 mL, the device is preheated for 10 minutes before use then a first measurement is made by means of a tank filled with 3.8 ml of bipermuted water. A measurement is then made with a vessel filled with 3.8 ml of cosmetic formulation to be tested. The transmittance is measured at the wavelength of 500 nm. The higher the transrnittance value, expressed as a percentage, is higher the more the cosmetic composition is clear. For a transmittance value at 500 nm of at least 60%, the formulation is. clear. Suspensive performance

- Measurements of targetoeativity are carried out on the formulations using a Haake-Mars III Rheometer.

- the variations of Tan ( ⁇ ) and G 5 as a function of the stress t are measured at 25 ° C using a cone / plane geometry 1.

- the values of Tan (8) and of G 'to 10 d) are deduced from this measurement.

- the formulations have good suspending properties for combined values of G '> 20 Pa and Tan () ⁇ 0.55,

- the copolymer according to the invention makes it possible to advantageously combine performance in terms of thickening effect, clarity and suspensive properties.

- it makes it possible to obtain an aqueous formulation having the desired viscosity and comprising a clear continuous phase and particles in suspension distributed homogeneously in the continuous phase.

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Epidemiology (AREA)

- Birds (AREA)

- Dermatology (AREA)

- Emergency Medicine (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

- Macromonomer-Based Addition Polymer (AREA)

- Detergent Compositions (AREA)

- Cosmetics (AREA)

- Polyurethanes Or Polyureas (AREA)

Abstract

Description

Claims

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201780028749.9A CN109071726B (zh) | 2016-06-03 | 2017-06-02 | 具有增稠和悬浮性质的共聚物 |

| US16/096,512 US10835475B2 (en) | 2016-06-03 | 2017-06-02 | Copolymer having thickening and suspension properties |

| MX2018013624A MX2018013624A (es) | 2016-06-03 | 2017-06-02 | Copolimero que tiene propiedades de espesamiento y suspension. |

| BR112018071488-7A BR112018071488B1 (pt) | 2016-06-03 | 2017-06-02 | Copolímeros (p1) e (p2), processos de produção de copolímeros (p1) e (p2), composição aquosa e composição cosmética |

| KR1020187033959A KR102388928B1 (ko) | 2016-06-03 | 2017-06-02 | 점증 및 현탁 특성을 갖는 공중합체 |

| JP2018554026A JP7274864B2 (ja) | 2016-06-03 | 2017-06-02 | 増粘特性及び懸濁特性を有するコポリマー |

| CA3023388A CA3023388A1 (fr) | 2016-06-03 | 2017-06-02 | Copolymere epaississant et suspensif |

| EP17735186.3A EP3464397A1 (fr) | 2016-06-03 | 2017-06-02 | Copolymère épaississant et suspensif |

| ZA2018/06818A ZA201806818B (en) | 2016-06-03 | 2018-10-12 | Copolymer having thickening and suspension properties |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1655077A FR3052166B1 (fr) | 2016-06-03 | 2016-06-03 | Copolymere epaississant et suspensif |

| FR1655077 | 2016-06-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017207945A1 true WO2017207945A1 (fr) | 2017-12-07 |

Family

ID=56943676

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/FR2017/051396 WO2017207945A1 (fr) | 2016-06-03 | 2017-06-02 | Copolymère épaississant et suspensif |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US10835475B2 (fr) |

| EP (1) | EP3464397A1 (fr) |

| JP (1) | JP7274864B2 (fr) |

| KR (1) | KR102388928B1 (fr) |

| CN (1) | CN109071726B (fr) |

| BR (1) | BR112018071488B1 (fr) |

| CA (1) | CA3023388A1 (fr) |

| FR (1) | FR3052166B1 (fr) |

| MX (1) | MX2018013624A (fr) |

| WO (1) | WO2017207945A1 (fr) |

| ZA (1) | ZA201806818B (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT201900003841A1 (it) | 2019-03-15 | 2020-09-15 | Lamberti Spa | Composizioni per la cura della persona |

| EP3914224A1 (fr) * | 2019-01-23 | 2021-12-01 | Coatex | Composition cosmetique nettoyante comprenant un copolymère de type ase ou hase |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3092657A (en) * | 1961-05-17 | 1963-06-04 | Pfizer & Co C | Vitamin a ester |

| FR1329008A (fr) | 1962-04-25 | 1963-06-07 | Rhone Poulenc Sa | Nouveaux esters d'alcool périllique |

| FR1363955A (fr) | 1963-04-03 | 1964-06-19 | Rhone Poulenc Sa | Alcène-2 oates d'homopérillyle |

| US20060052564A1 (en) | 2003-09-12 | 2006-03-09 | Roehm Gmbh & Co. Kg | Mixture for the production of transparent plastic materials, transparent plastic materials, and method for the production and use thereof |

| FR3000085A1 (fr) | 2012-12-20 | 2014-06-27 | Coatex Sas | Agent polymerique pour obtenir une composition aqueuse stable comprenant des particules en suspension |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1000522A (en) | 1962-04-25 | 1965-08-04 | Rhone Poulenc Sa | Novel esters and their use as perfumery components |

| DE3689606T2 (de) * | 1985-10-22 | 1994-05-19 | Kuraray Co | Herstellungsverfahren für Phasengitter vom zusammengesetzten Muster-Refraktionstyp. |

| JPH0315070A (ja) * | 1989-03-08 | 1991-01-23 | Kuraray Co Ltd | 感光性樹脂組成物、それを用いたパターンおよびパターン作製法 |

| JPH031145A (ja) * | 1989-05-29 | 1991-01-07 | Kuraray Co Ltd | 感光性樹脂組成物、それを用いたパターンおよびパターン作製法 |

| JPH03164783A (ja) * | 1989-11-24 | 1991-07-16 | Kuraray Co Ltd | ホログラムおよびその製造方法 |

| JPH03164784A (ja) * | 1989-11-24 | 1991-07-16 | Kuraray Co Ltd | ホログラムおよびその製造方法 |

| JP2721572B2 (ja) * | 1990-02-28 | 1998-03-04 | 株式会社クラレ | 感光性樹脂組成物、それを用いたパターンおよびパターン作製法 |

| FR2872815B1 (fr) * | 2004-07-08 | 2008-06-27 | Coatex Soc Par Actions Simplif | Utilisation de copolymeres acryliques hydrosolubles dans des formations aqueuses eventuellement pigmentees et formulations obtenues |

-

2016

- 2016-06-03 FR FR1655077A patent/FR3052166B1/fr active Active

-

2017

- 2017-06-02 KR KR1020187033959A patent/KR102388928B1/ko active IP Right Grant

- 2017-06-02 BR BR112018071488-7A patent/BR112018071488B1/pt active IP Right Grant

- 2017-06-02 MX MX2018013624A patent/MX2018013624A/es unknown

- 2017-06-02 WO PCT/FR2017/051396 patent/WO2017207945A1/fr unknown

- 2017-06-02 CA CA3023388A patent/CA3023388A1/fr active Pending

- 2017-06-02 CN CN201780028749.9A patent/CN109071726B/zh active Active

- 2017-06-02 EP EP17735186.3A patent/EP3464397A1/fr active Pending

- 2017-06-02 JP JP2018554026A patent/JP7274864B2/ja active Active

- 2017-06-02 US US16/096,512 patent/US10835475B2/en active Active

-

2018

- 2018-10-12 ZA ZA2018/06818A patent/ZA201806818B/en unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3092657A (en) * | 1961-05-17 | 1963-06-04 | Pfizer & Co C | Vitamin a ester |

| FR1329008A (fr) | 1962-04-25 | 1963-06-07 | Rhone Poulenc Sa | Nouveaux esters d'alcool périllique |

| FR1363955A (fr) | 1963-04-03 | 1964-06-19 | Rhone Poulenc Sa | Alcène-2 oates d'homopérillyle |

| US20060052564A1 (en) | 2003-09-12 | 2006-03-09 | Roehm Gmbh & Co. Kg | Mixture for the production of transparent plastic materials, transparent plastic materials, and method for the production and use thereof |

| FR3000085A1 (fr) | 2012-12-20 | 2014-06-27 | Coatex Sas | Agent polymerique pour obtenir une composition aqueuse stable comprenant des particules en suspension |

Non-Patent Citations (2)

| Title |

|---|

| FERRET N ET AL: "Acryloxy and methacryloxy palladation of alkenes", JOURNAL OF THE CHEMICAL SOCIETY, CHEMICAL COMMUNICATIONS, CHEMICAL SOCIETY. LETCHWORTH, GB, no. 22, 1 January 1994 (1994-01-01), pages 2589 - 2590, XP003021091, ISSN: 0022-4936, DOI: 10.1039/C39940002589 * |

| ROBERT P. ADAMS ET AL: "Synthesis and GC-MS analysis of angelates and tiglates as an aid to identification of these components in essential oils", FLAVOUR AND FRAGRANCE JOURNAL, vol. 25, no. 2, 1 March 2010 (2010-03-01), pages 71 - 74, XP055077757, ISSN: 0882-5734, DOI: 10.1002/ffj.1968 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3914224A1 (fr) * | 2019-01-23 | 2021-12-01 | Coatex | Composition cosmetique nettoyante comprenant un copolymère de type ase ou hase |

| IT201900003841A1 (it) | 2019-03-15 | 2020-09-15 | Lamberti Spa | Composizioni per la cura della persona |

| WO2020187791A1 (fr) | 2019-03-15 | 2020-09-24 | Lamberti Spa | Compositions de soins personnels |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190133914A1 (en) | 2019-05-09 |

| US10835475B2 (en) | 2020-11-17 |

| BR112018071488A2 (pt) | 2019-02-19 |

| FR3052166B1 (fr) | 2020-05-22 |

| KR102388928B1 (ko) | 2022-04-21 |

| EP3464397A1 (fr) | 2019-04-10 |

| CN109071726B (zh) | 2021-07-16 |

| FR3052166A1 (fr) | 2017-12-08 |

| JP7274864B2 (ja) | 2023-05-17 |

| MX2018013624A (es) | 2019-03-14 |

| ZA201806818B (en) | 2020-01-29 |

| BR112018071488B1 (pt) | 2023-09-26 |

| CA3023388A1 (fr) | 2017-12-07 |

| JP2019517598A (ja) | 2019-06-24 |

| KR20190015244A (ko) | 2019-02-13 |

| CN109071726A (zh) | 2018-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1465932B1 (fr) | Polymeres associatifs gonflant aux alcalis, procedes et composition | |

| CN107001536B (zh) | 作为增稠剂和悬浮剂的多相聚合物 | |

| EP3464396B1 (fr) | Copolymère épaississant et suspensif | |

| JP2021073339A (ja) | 増粘剤および懸濁化剤としてのポリマー | |

| WO2017207945A1 (fr) | Copolymère épaississant et suspensif | |

| WO2023047023A1 (fr) | Préparation d'une composition sans tensio-actif sulfaté | |

| EP1812482A1 (fr) | Cumyl phenols substitues, leur utilisation dans un procede de copolymerisation, copolymeres obtenus et leur utilisation comme epaississants |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2018554026 Country of ref document: JP Kind code of ref document: A |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112018071488 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 3023388 Country of ref document: CA |

|

| ENP | Entry into the national phase |

Ref document number: 20187033959 Country of ref document: KR Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17735186 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2017735186 Country of ref document: EP Effective date: 20190103 |

|

| ENP | Entry into the national phase |

Ref document number: 112018071488 Country of ref document: BR Kind code of ref document: A2 Effective date: 20181018 |