WO2017092104A1 - 用于冲压成形的钢材及其成形构件与热处理方法 - Google Patents

用于冲压成形的钢材及其成形构件与热处理方法 Download PDFInfo

- Publication number

- WO2017092104A1 WO2017092104A1 PCT/CN2015/098890 CN2015098890W WO2017092104A1 WO 2017092104 A1 WO2017092104 A1 WO 2017092104A1 CN 2015098890 W CN2015098890 W CN 2015098890W WO 2017092104 A1 WO2017092104 A1 WO 2017092104A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- steel

- steel material

- austenite

- material according

- strength

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/005—Modifying the physical properties by deformation combined with, or followed by, heat treatment of ferrous alloys

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0294—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips involving a localised treatment

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/08—Ferrous alloys, e.g. steel alloys containing nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/16—Ferrous alloys, e.g. steel alloys containing copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/32—Ferrous alloys, e.g. steel alloys containing chromium with boron

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/001—Austenite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/004—Dispersions; Precipitations

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/005—Ferrite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/008—Martensite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2221/00—Treating localised areas of an article

- C21D2221/10—Differential treatment of inner with respect to outer regions, e.g. core and periphery, respectively

Definitions

- the present invention relates to a steel material for press forming, and a press forming member and a heat treatment method based on the above steel material.

- first-generation advanced high-strength steels such as dual-phase (DP) steel, multi-phase (CP) steel, phase change induced plasticity (TRIP) steel, martensitic steel (the strong plastic product, ie tensile strength ⁇ total elongation) It has been widely used in the automotive field and has played an important role in reducing the weight of automobiles.

- DP dual-phase

- CP multi-phase

- TRIP phase change induced plasticity

- martensitic steel the strong plastic product, ie tensile strength ⁇ total elongation

- the second-generation advanced high-strength steel represented by twin-induced plasticity (TWIP) can reach 60GPa% and has been industrialized.

- TWIP twin-induced plasticity

- the main purpose of developing the third generation of advanced high-strength steel is to strike a balance between the cost of materials and the performance of materials.

- the strong plastic product is generally above 25GPa%.

- Mn content is 4-8 wt%, generally low carbon content, and its structure is double of retained austenite and ferrite.

- the strengthening mechanism is generally TRIP effect, the phase transformation of retained austenite during deformation, resulting in high work hardening rate and elongation of about 30%; Mn content is 12-22% by weight, such steel the initial structure of austenite, typically stacking fault energy 20mJ / m 2, since it is a strengthening mechanism of TWIP (twinning induced plasticity), such steel has excellent work hardening rate and is generally about 60% elongation;

- the Mn content is 22-30% by weight, and the strengthening mechanism is MBIP (Microband-induced plasticity).

- the steel has high carbon content and aluminum content, and the stacking fault energy is 80 mJ/m 2 .

- the formation of a microshear band during the deformation results in a high work hardening rate and a generally 60% elongation.

- medium-manganese steel with manganese content of 3-10% has been widely concerned.

- the hot-rolled microstructure of medium-manganese steel is generally martensite structure, and then the appropriate annealing temperature is selected, and the two-phase region is kept for a sufficient time to obtain a two-phase structure of austenite and ferrite, and is completed in the process.

- the diffusion of carbon and manganese into austenite stabilizes the austenite to room temperature and gives more austenite structure. Higher strength and elongation are obtained by utilizing the deformation of retained austenite and hindering crack propagation.

- the design of medium manganese TRIP steel has a low carbon content, generally below 0.2%, and its tensile strength is generally about 1000 MPa, the yield strength is below 600 MPa, and the elongation is below 30%.

- the control of retained austenite has an important influence on the strong plasticity of steel. There are many factors affecting the mechanism of residual austenite plastic deformation, including mechanical stability and austenite stacking fault energy. Among them, carbon is an inexpensive solid solution strengthening element and austenite stabilizing element, and carbon element has an influence on the stacking fault energy and changes the grain size of the steel by influencing the heat treatment process.

- the stacking fault energy has an important influence on the deformation mechanism of austenite. With the decrease of stacking fault energy, the plastic deformation mechanism is followed by dislocation slip mechanism, deformation twinning and martensite transformation.

- the factors affecting the stacking fault energy are mainly the composition and grain size of austenite. Carbon, manganese and aluminum will increase the austenite stacking fault energy. A small amount of silicon can increase the austenite stacking fault energy and can act as a solid solution strengthening to increase the steel yield strength and tensile strength, while the chromium decreases. Austenitic stacking fault energy.

- the austenite grain transformation provides more nucleation sites and shear band interactions, but at the same time causes the elastic strain energy of the lattice trimming and the strain energy of the shear deformation to decrease.

- the phase transformation of the body Austenite grains or slabs are small in size, which increases the stacking fault energy and affects the plastic deformation mechanism.

- An object of the present invention is to provide a steel material for press forming having high toughness and high energy absorbing property, and a press forming member and a heat treatment method based on such a steel material.

- the heat treatment of the steel of the invention is heat-treated in the two-phase region, which is advantageous for achieving precise temperature control, high carbon and manganese content, good hardenability and low requirement for cooling rate.

- the mechanical properties of the heat-treated steel sheet are as follows: yield strength 0.5 to 1.2 GPa, tensile strength 1.0 to 1.5 GPa, and strong plastic product (tensile strength ⁇ elongation) of 25 GPa% or more. It is stamped and formed into a member on a mold, and is mainly used for, but not limited to, an automobile structural member.

- a steel material for press forming comprising 0.22 to 0.48% of C, 5 to 9.5% of Mn, 0.5 to 3.0% of Si+Al and the balance by weight percent a quantity of Fe and unavoidable impurities, wherein the steel is one of a hot rolled coil (plate), a hot rolled pickled coil (plate), a cold rolled annealed coil (plate), a cold rolled coated coil (plate), Heat treatment before heating to 650-780 ° C (including 680, 700, 720, 750 ° C, etc.) for 0.5 to 60 minutes (5, 10, 20, 30, 40, 50, etc.) And get.

- the diffusion rate of carbon and manganese in austenite is higher than that of austenite. It is several orders of magnitude slower in martensite, which causes a localized region of austenite to be enriched with more carbon and manganese.

- the final measured residual austenite has a carbon content of 0.5% or more and a manganese content of more than 7%.

- the grain of austenite is less than 1 ⁇ m.

- the steel material of the present invention is designed based on the composition of manganese in high carbon, having a carbon content of between 0.22 and 0.48%, preferably between 0.25 and 0.45%, and a manganese content of between 5 and 9.5%, preferably between 6 and 8%.

- Both carbon and manganese are austenite stabilizing elements, which can strongly reduce the austenitizing temperature of steel and the phase transition temperature of martensite. During the annealing heat treatment, the austenite/ferrite slab alternates.

- the structure, and the carbon and manganese are distributed into the austenite to stabilize the austenite to below room temperature, and the TRIP effect gradually changes to martensite during the deformation process, thereby improving the strength and ductility of the steel; in particular, the steel of the present invention Optimized composition design and annealing process steel, the retained austenite has higher carbon and manganese, some austenite has higher stacking fault energy, and deformation twinning is formed during deformation, which can further improve the work hardening rate and at the same time Improve material strength and ductility.

- the annealing temperature is preferably increased, resulting in coarser austenite grains, resulting in poor austenite stability during deformation.

- the toughness of steel is reduced.

- the carbon content is high, the eutectoid structure may be formed, and more coarse carbides are formed to deteriorate the mechanical properties of the steel.

- the steel material further comprises at least one of the following components: Cr: 0.001% to 5%; Mo: 0.001% to 2.0%; W: 0.001% to 2.0%; Ti: 0.0001% ⁇ 0.4%; Nb: 0.0001% to 0.4%; Zr: 0.0001% to 0.4%; V: 0.0001% to 0.4%; Cu: 0.0005% to 2%; Ni: 0.0005% to 3.0%; B: 0.0001% to 0.005 %.

- the ultra-high strength and toughness matching of the stamping member can be further ensured, so that the mechanical properties thereof are: yield strength of 0.5 to 1.2 GPa, tensile strength of 1.0 to 1.5 GPa, and strong plastic product. (Tensile strength ⁇ elongation) 25 GPa% or more.

- the steel material comprises a hot rolled steel sheet, a cold rolled steel sheet, or a steel sheet with a coated layer.

- the steel plate with a coating layer may be a zinc-coated steel sheet which is a hot-rolled steel sheet or a cold-rolled steel sheet on which a metal zinc layer is formed.

- the zinc-coated steel sheet includes one selected from the group consisting of hot dip galvanizing (GI), galvannealing (GA), zinc plating, or zinc-iron plating (GE).

- the steel sheet with a coating layer is a hot-rolled steel sheet or a cold-rolled steel sheet on which an aluminum-silicon layer is formed, or a steel sheet of an organic plating layer or a steel sheet with another alloy-plated layer.

- a press forming process comprising providing a steel material having the above-described composition, which is subjected to a heat treatment process after being heated to 650 to 780 ° C for 0.5 to 60 minutes, and then subjected to press forming.

- the steel material is directly subjected to cold stamping or hot stamping, and is subjected to a heat treatment process heated to 650 to 780 ° C for 0.5 to 60 minutes to obtain a desired stamping.

- the hardenability of steel will be greatly improved, so that the whole martensite structure can be obtained under air-cooling conditions after hot rolling, so it has high strength and causes cold rolling difficulties.

- the steel has a carbide formation temperature of 630 to 750 ° C, which is consistent with the softening annealing process conventionally used in industrial hood furnaces to precipitate carbides and reverse phase transformation of austenite in the steel, which reduces the strength of the steel. It also increases the elongation of steel for cold rolling.

- a press-formed member which is produced by the press-forming steel material of the present invention by the press forming process of the present invention.

- the microstructure of the steel material of the present invention or its press-formed member by volume includes: 30% or more of retained austenite, 70% or less of martensite (ferrite) structure, or 3% or less of carbides, thereby The mechanical properties are obtained: yield strength of 0.5 to 1.2 GPa, tensile strength of 1.0 to 1.5 GPa, and strong plastic product (tensile strength x elongation) of 25 GPa% or more.

- this The microstructure of the invented steel or its stamped and formed member after heat treatment to 650 to 780 ° C for 0.5 to 60 minutes, the microstructure in terms of area includes: 30% to 60% of retained austenite, 40% to 70% The body-centered cubic crystal structure of martensite or ferrite, less than 3% of carbides.

- the retained austenite and martensite or ferrite may be in the form of lath-like phases or have a slab thickness of between 10 and 300 nm.

- the austenite may include Mn of 7% or more and C of 0.5% or more in weight percentage.

- the retained austenite induces plasticity by phase transformation during the deformation process, or simultaneously assists the twinning induced plastic effect, thereby improving the matching of strength and ductility, so that the mechanical properties are achieved.

- the yield strength is 0.5 to 1.2 GPa

- the tensile strength is 1.0 to 1.5 GPa

- the strong plastic product is ⁇ 25 GPa%.

- the stamped forming member can be used for at least one of an automotive safety structural member, a reinforcing structural member, and a high strength automotive structural member. More specifically, the forming member may be used for at least one of a B-pillar reinforcement, a bumper, and a door impact beam, a wheel spoke. Of course, the forming member can also be used in any other land vehicle where a lightweight high strength and high ductility member is required.

- the partially stabilized austenite undergoes the TWIP effect during the deformation process, assisting the deformation, and is more conducive to improving the strong plasticity of the steel;

- Patent Document CN102021472B which refer to the process of FIG. 7

- the higher the present invention because the addition of Si and Al, increase the material temperature Ac 1, cold-rolled to make a softening annealing temperature is increased to 630-750 prepared °C (different from the softening annealing temperature of 450-630 °C according to the claims), its elongation and rolling deformation ability are improved compared with the comparative patent, which is consistent with the softening annealing process conventionally used in industrial hood furnaces, which is beneficial to the production organization.

- the present invention can obtain the desired performance by directly annealing at 650-780 ° C for 0.5-60 min using a hot rolled sheet.

- the invention adopts optimized C and Mn alloy design and optimizes the heat treatment design to make the high-volume fraction retained austenite (30%-60%) with reasonable stability, and therefore has a tensile strength of 1000 MPa or more, and is strong.

- Plastic product is more than 25GPa%.

- the desired properties can be obtained after 650-780 ° C for 0.5-60 min.

- the optimized design of the present invention allows the final microstructure to be obtained by annealing at 650-780 ° C for more than one time of Ac 1 or more for 0.5 to 60 minutes (the subsequent process path is required to further 100 ° C below Ac 1 ).

- the complex process of holding to 1 to 10 hours at Ac 1 temperature is different), the steel of the present invention can directly obtain the desired structure and properties after heat treatment in an industrial continuous annealing furnace.

- CN101638749B austenite is at a reverse transformation temperature 100 °C to the Ac 1 1 Ac 1-10 hours.

- the alloying element treatment of the hot rolled sheet is the same as the austenite reverse phase transformation treatment.

- the steel material is subjected to one-step treatment, that is, annealing at 650-780 ° C for 0.5 to 60 minutes, and the austenite content formed is much higher than the comparative patent technology, achieving a residual of 30% to 60%.

- Cylinder so it has better strength and ductility matching, strong plastic product of more than 25GPa%; its stamped and formed components are annealed at 650-780 °C for 0.5 to 60 minutes, the heat treatment process and microstructure are different from the contrast

- the patented technology has higher ductility, the elongation is higher than 18%, and the strong plastic product is above 25GPa%.

- the initial hot-rolled structure of the steel of the present invention is a lath-like martensite structure, which is characterized by the use of martensite laths. Annealing in the two-phase region completes the partitioning of carbon and manganese, so that the reverse phase transformation of austenite preserves the morphology of the martensite lath, and has sufficient carbon content and manganese content to enable it at room temperature. Stable existence, using the coordinated deformation of retained austenite and annealed martensite to increase the elongation of steel.

- the enrichment of a large amount of carbon in the austenite and austenite with fine grain or lath size caused by the reverse phase causes the austenite to increase the stacking fault energy, causing the austenite to undergo TWIP/ during the deformation process.

- the TRIP effect increases the work hardening rate of steel, suppresses the yielding platform, and improves the ductility of steel.

- the present invention obtains a hot rolled structure into a martensite structure by increasing the carbon content in the steel and controlling the content of manganese. Then in the two-phase zone, the two-phase structure of austenite and ferrite is obtained, and during this period, the carbon and manganese in the steel are enriched on the austenite, based on the design of appropriate carbon and manganese, at room temperature. Retained austenite having a higher carbon content and a manganese content is obtained.

- HR represents hot rolling

- CR represents cold rolling

- FIG. 3 is a microstructure of a parallel section of a No. 1 steel after being stretched and deformed by softening annealing at 650 ° C for 10 h according to an embodiment of the present invention

- Figure 4 is the engineering stress-strain curve of the No. 5 steel cold-rolled sheet No. C treatment process at normal temperature

- Figure 5 is the microstructure of the No. 5 steel cold-rolled sheet No. C treatment process

- Figure 6 is an X-ray diffraction pattern before and after deformation of the No. 5 steel cold-rolled sheet after the treatment process of the label C;

- Figure 7 is a heat treatment process diagram of the comparative patent document CN102021472B;

- Figure 8 is a comparison diagram of the process of the present invention and the comparative patent CN102021472B.

- Carbon is the cheapest strengthening element and can strongly increase the strength of steel through gap solid solution.

- an increase in the carbon content strongly reduces Ac 3 , thereby lowering the heating temperature and saving energy.

- excessively high carbon content may result in poor weldability of the steel, and may cause excessive strength of the sheet, damage the mold during the hot forming process, and reduce the life of the mold.

- the upper limit of carbon is set to 0.48%.

- the lower limit of the carbon content is 0.2%, preferably 0.25 to 0.45%.

- Manganese is an important element for improving the stability of austenite.

- Manganese austenite region can be enlarged, reduced temperature Ac 3.

- Manganese has an excellent effect of suppressing the transformation of austenite to ferrite and improving the hardenability of steel.

- the lower limit of manganese is limited to 5%.

- the increase in manganese reduces the corrosion resistance of the steel and reduces the weldability, and it is easy to form a twinned martensite to reduce the ductility of the material during quenching and cooling. Therefore, the upper limit of manganese is set to 9.5%.

- Si+Al 0.5% to 3.0%

- Both silicon and aluminum can inhibit the formation of carbides. Silicon and aluminum can increase the temperature of Ac 1 and increase the temperature of softening treatment of steel sheets before cold rolling. This is consistent with the softening annealing process conventionally used in industrial hood furnaces, and can suppress large sizes. Cementite is produced. During the cooling of the steel to room temperature, silicon and aluminum can inhibit the precipitation of cementite. And silicon can play the role of solid solution strengthening, improve the yield strength of steel, aluminum can significantly expand the temperature range of the two-phase region, and expand the process window, so the lower limit of Si + Al is 0.5%. In industrial production, too much Al will block the nozzle during continuous casting, increasing the difficulty of continuous casting. High silicon content can cause more impurities in the steel. Therefore, the upper limit of Si+Al is set to 3.0%.

- Cr, Mo, and W improve the hardenability of steel and can effectively increase the strength of steel.

- Cr can make the structure uniform and increase the tempering stability.

- the alloy cementite formed by Cr and C can hinder the austenite grain growth and improve the toughness of the steel.

- Mo can prevent temper brittleness, increase remanence and coercivity, and corrosion resistance in certain media.

- Mo can reduce the tendency of carbides to be distributed at grain boundaries.

- W has a similar effect to Mo, which can reduce the heat sensitivity of steel, increase hardenability and increase hardness. When the concentration is less than 0.001%, sufficient hardenability cannot be obtained, and even if it is more than 2.0%, no additional effect can be obtained, but the cost is increased.

- Ti, Nb, Zr, and V refine the grain of the steel, increase the strength, and obtain good heat treatment characteristics. Too low a concentration of Ti, Nb, Zr, and V does not work, and more than 0.4% increases unnecessary cost.

- Cu improves strength and toughness, especially atmospheric corrosion.

- content of Cu is more than 2.0%, workability may be deteriorated.

- Ni improves the strength of steel while maintaining good ductility and toughness.

- the content of Ni is less than 0.0005%, the desired effect is not obtained, and when the concentration of Ni is more than 2.0%, the cost is increased.

- B segregates at the austenite grain boundary, prevents the nucleation of the ferrite, and can strongly improve the hardenability of the steel, and can significantly increase the strength of the steel after the heat treatment.

- content of B is less than 0.0001%, it does not function.

- a B content higher than 0.005% does not significantly improve the function.

- One object of the present invention is to produce a yield strength of 500 to 1200 MPa, tensile strength 980 ⁇ 1480MPa, its strong plastic product (tensile strength ⁇ elongation) ⁇ 25GPa% of the steel plate.

- the steel sheet includes a hot rolled steel sheet, a cold rolled steel sheet, and a galvanized steel sheet or other plated steel sheet.

- the microstructure by volume after heat treatment includes: 30% to 70% of retained austenite, and 30% to 70% of body-centered cubic structure (martensite or ferrite). Its austenite has Mn ⁇ 7% by weight percentage, and C ⁇ 0.5%.

- the experiment conducted with the steel sheet of the present invention is described below.

- the steel materials of the components specified in Table 1 were homogenized at 1200 to 1500 ° C for 5 to 20 hours, and then held at 1000 ° C to 1200 ° C for 0.5 to 2 hours, followed by hot rolling to form a hot rolled sheet.

- the hot rolled sheet is treated by heating the hot rolled sheet to an annealing temperature for 0.5 to 60 minutes.

- the hot rolled sheet is subjected to softening annealing treatment before cold rolling, and the annealed hot rolled sheet is pickled, cold rolled to 1.5 mm, and kept at an annealing temperature for 0.5 to 60 minutes.

- the hot-rolled sheet and the cold-rolled sheet of No. 1 steel in Table 1 were subjected to one-step annealing treatment after being subjected to flat-plate stamping and forming after austenitizing treatment at 780 °C.

- the hot rolled sheet or the cold rolled sheet or other plated steel sheet is heated to 650 to 780 ° C for heat preservation before stamping.

- the cooling method can be air cooling or cooling to room temperature by other cooling methods.

- the steel sheet is transferred into a mold for press forming to obtain a shaped member of a desired shape.

- the obtained steel sheet may be directly subjected to cold stamping or hot stamping, and then kept at 650 to 780 ° C, and cooled to room temperature by air cooling or other cooling.

- the steel sheet is heated to 650 to 780 ° C to maintain the structure of the face-centered cubic structure and the body-centered cubic structure, and the carbon and manganese in the martensite (ferrite) are diffused to the austenite. Increase the stability of austenite and store it at room temperature.

- the sufficiently stable austenite undergoes phase change induced plasticity (TRIP, in particular, in some cases, partial austenite undergoes twinning induced plasticity (TWIP), thereby increasing the plasticity of the material.

- TRIP phase change induced plasticity

- TWIP twinning induced plasticity

- the microstructure of the stamped and formed member of the present invention by volume includes: 30% to 60% of retained austenite, 40% to 70% of body-centered cubic crystal structure of martensite or ferrite. Mn ⁇ 7% by weight percentage in austenite, C ⁇ 0.5%.

- Heating and holding experiments were performed on hot rolled or cold rolled sheets in a resistive box furnace with nitrogen protection.

- the specific experimental process is shown in Table 2.

- YS represents the yield strength, the stress value of 0.2% residual deformation is its yield limit; TS is the tensile strength; TE is the total elongation.

- the tensile specimens in Table 3 were ASTM standard specimens with a gauge length of 50 mm; the strain rate for the tensile mechanical properties test was 6.67 ⁇ 10 -4 s -1 .

- the steel sheet having the composition of the present invention can obtain a molded member excellent in strength and elongation comprehensive performance by the heat treatment process of the present invention. Specifically, a steel sheet having a yield strength of 500 to 1200 MPa, a tensile strength of 980 to 1480 MPa, and a strong plastic product (tensile strength ⁇ elongation) of ⁇ 30 GPa% can be realized.

- the tensile curves and microstructures of the steel sheet of the present invention after softening treatment are shown in Figures 2 and 3.

- Microstructure analysis of the uniform deformation zone of the invention steel a small amount of carbides exist in the steel, the structure is distributed in a strip shape, the austenitic slab is around 200 nm, and there is a strip structure in the austenite, which may be ⁇ - Martensite or austenite twins, which are mechanically twinned during deformation by calibration of the austenite.

- Figure 4 shows the tensile curve of the No. 5 steel cold-rolled sheet held at 670 ° C for 10 minutes.

- the yield strength, tensile strength and elongation meet the requirements of the invention, and the steel of the present invention remains consistent.

- the microstructure after cold rolling annealing still maintains the slab state distribution, and the grain size is below 1 micrometer, which not only improves the yield strength of the steel, but also improves the austenite layer.

- the wrong energy is beneficial to the mechanical twinning during the deformation process, thereby increasing the elongation of the steel and the work hardening rate.

- the volume fractions before and after deformation of the austenite were calculated to be 40% and 6%, respectively.

- the retained austenite undergoes a TWIP or TRIP effect, thereby ensuring the required strength and ductility of the steel of the present invention.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat Treatment Of Articles (AREA)

- Heat Treatment Of Sheet Steel (AREA)

Abstract

一种用于冲压成形的钢材,所述钢材以重量百分比计包括0.22~0.48%的C、5~9.5%的Mn、0.5~3.0%的Si+Al以及余量的Fe和不可避免的杂质,其中所述钢材为热轧、热轧酸洗、热轧酸洗镀层钢卷或钢板,或者冷轧退火、冷轧镀层钢卷或钢板。基于上述钢材的冲压成形工艺和冲压成形构件,主要用于但不限用于汽车结构件。所述钢卷或钢板或成形构件经加热至650~780℃保温0.5~60分钟而获得,含有超过30%(以体积分数计)的残余奥氏体,其力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积(抗拉强度×延伸率)25GPa%以上。一种成形构件和一种热处理方法。

Description

本发明涉及一种用于冲压成形的钢材,以及基于上述钢材的冲压成形构件和热处理方法。

节能减排已经成为汽车的重要指标,实现这些目标的重要手段是汽车的轻量化。降低车重能够提高燃油利用率并减少废气排放。在减重的同时保障安全性,高强度钢的使用就成为必然趋势。目前,比如双相(DP)钢、多相(CP)钢、相变诱发塑性(TRIP)钢、马氏体钢等第一代先进高强钢(其强塑积即抗拉强度×总延伸率为15~20GPa%)已在汽车领域广泛应用,并对汽车轻量化起到了重要作用。然而,第一代先进高强钢的成型性能及强度仍然有待提高,以满足日益提升的汽车设计需求。以孪晶诱导塑性(TWIP)为代表的第二代先进高强钢的强塑积可达60GPa%,并已经实现了产业化,但是由于合金元素的大量添加,导致其制造成本高,生产难度大,并且大量添加的合金元素恶化了钢的焊接性能,从而未得到广泛的应用。开发第三代先进高强钢的主要目的就是为了在材料的成本和材料的性能之间取得平衡,其强塑积一般在25GPa%以上。

根据最近的研究进展,含锰量在5wt%至30wt%的先进高强钢以其出色的力学性能将有可能成为下一代强度超过1GPa以上的先进汽车用钢。钢中含锰量的高低和钢的塑性变形机制,把锰钢分为三类:Mn含量在4~8wt%,一般含碳量较低,其组织为残余奥氏体和铁素体的双相组织,其强化机制一般为TRIP效应,在变形过程中残余奥氏体发生相变,导致高的加工硬化率和一般在30%左右的延伸率;Mn含量在12~22wt%,此类钢的初始组织为奥氏体组织,层错能一般为20mJ/m2,由于其强化机制为TWIP(孪晶诱导塑性),此类钢具有出色的加工硬化率和一般60%左右的延伸率;Mn含量在22~30wt%,其强化机制为MBIP(Microband-induced plasticity,微带诱导塑性),此类钢具有较高的碳含量和铝含量,其层错能在80mJ/m2。在变形过程中形成微剪切带导致高的加工硬化率和一般60%的延伸率。

综合目前节能减排和第三代先进高强钢的要求,锰含量在3~10%的中锰钢广受关注。中锰钢的热轧态组织一般为马氏体组织,而后选择合适的退火温度,在两相区保温足够的时间,得到奥氏体和铁素体的双相组织,并且在此过程中完成碳和锰向奥氏体中扩散的过程,使奥氏体体稳定至室温,得到较多的奥氏体组织。利用残余奥氏体的形变和阻碍裂纹扩展,获得较高的强度和延伸率。一般为了扩大两相区的温度区间会加入较高的铝,较多铝的加入会引起退火温度升高,晶粒粗大,导致屈服强度降低。一般中锰TRIP钢的设计,其碳含量较低,一般在0.2%以下,其抗拉强度一般在1000MPa左右,屈服强度在600MPa以下,延伸率在30%以下。

残余奥氏体的控制对于钢的强塑性有重要影响。影响残余奥氏体塑性变形机制的因素很多,其中包括机械稳定性和奥氏体的层错能。其中碳元素是便宜的固溶强化元素和奥氏体稳定元素,并且碳元素对层错能有影响和通过影响热处理工艺改变钢的晶粒尺寸。

层错能是奥氏体的变形机制有重要影响。随着层错能的降低,塑性变形机制依次为位错滑移机制、形变孪晶和发生马氏体相变。影响层错能的因素主要是奥氏体的成分和晶粒大小。碳、锰和铝将提高奥氏体的层错能,少量的硅能提高奥氏体的层错能并能起到固溶强化的作用而提高钢的屈服强度和抗拉强度,而铬降低奥氏体的层错能。奥氏体的晶粒变大会提供更多的层错的形核位置和剪切带的交互作用,但是同时会引起晶格切边的弹性应变能和剪切变形的应变能的降低而引起马氏体相变。奥氏体的晶粒或板条尺寸细小会提高其层错能,而影响其塑性变形机制。

发明内容

本发明的一个目的在于提供一种高强韧性和高吸能性的冲压成形用钢材,以及基于这种钢材的冲压成形构件和热处理方法。本发明的钢材热处理是在两相区保温处理,利于实现温度的精确控制,其碳锰含量高,淬透性好,对冷却速度要求低。将热处理后的钢板,其机械力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积(抗拉强度×延伸率)25GPa%以上。经在模具上冲压成形为构件,主要用于但不限于汽车结构件。

根据发明的第一方面,提供了一种用于冲压成形的钢材,所述钢材以重量百分比计包括0.22~0.48%的C、5~9.5%的Mn、0.5~3.0%的Si+Al以及余量的Fe和不可避免的杂质,其中所述钢材为热轧卷(板)、热轧酸洗卷(板)、冷轧退火卷(板)、冷轧镀层卷(板)之一,其在冲压成形之前经加热至650~780℃保温(其中可选择680、700、720、750℃等温度)0.5~60分钟(其中可选择5、10、20、30、40、50等时间)的热处理而获得。利用热力学软计算出两相区退火平衡时奥氏体中锰、碳及其它合金元素的变化。然后根据平衡时钢中奥氏体的比例和基于马氏体相变K-M公式,fM=1-exp(-0.011(Ms-QT)(其中QT=室温,Ms根据奥氏体中元素的变化求出),计算出得到最大残余奥氏体的对应的退火温度,根据不同合金成分和制造工艺,在此温度保温0.5分钟~1小时。结合成分设计和工艺选择,得到残余奥氏体的体积分数在30%~60%,体积分数40%~70%的马氏体(铁素体)组织,和0~3%的碳化物。由于碳元素和锰元素在奥氏体中扩散速度要比在马氏体中慢几个数量级,一次会造成奥氏体的局部区域富集较多的碳元素和锰元素,最终实测残余奥氏体中的碳含量在0.5%以上,锰含量大于7%,奥氏体的晶粒小于1μm。钢板在变形过程中,在奥氏体内部产生马氏体相变和形变孪晶,有利于提高钢板的吸能性和延伸率。

本发明的钢材基于高碳中锰的成分设计,碳含量在0.22~0.48%之间,优选0.25~0.45%,锰含量在5~9.5%之间,优选为6~8%。碳和锰都是奥氏体稳定元素,均能强烈的降低钢的奥氏体化温度和马氏体开始相变温度,在退火热处理过程中,形成奥氏体/铁素体的板条交替组织,且碳和锰配分至奥氏体中,使奥氏体稳定至室温以下,变形过程中发生TRIP效应逐渐相变为马氏体,提高钢材的强度和延性;特别地,本发明钢中优化的成分设计及退火工艺的钢材,其残余奥氏体具有较高的碳和锰,部分奥氏体的层错能较高,变形过程中形成形变孪晶,可进一步提高加工硬化率以及同时提高材料强度和延性。当碳和锰含量较低时,为得到较多的奥氏体,伴随其优选退火温度需提高,导致奥氏体的晶粒较粗大,而造成奥氏体稳定性较差,在变形过程中钢的强韧性降低。碳含量较高时,可能会形成过共析的组织,而形成较多的粗糙的碳化物而恶化钢的力学性能。申请人发现把Mn含量控制在5~9.5%,碳含量控制在0.22~0.48%之间,能取得较好的强塑性。

根据本发明的一个优选实施例,所述钢材进一步包含以下成分中的至少一种:Cr:0.001%~5%;Mo:0.001%~2.0%;W:0.001%~2.0%;Ti:0.0001%~0.4%;Nb:0.0001%~0.4%;Zr:0.0001%~0.4%;V:0.0001%~0.4%;Cu:0.0005%~2%;Ni:0.0005%~3.0%;B:0.0001%~0.005%。通过这些成分中至少一种与上述基本成分的组合,能进一步确保冲压构件的超高强韧性匹配,使得其机械力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积(抗拉强度×延伸率)25GPa%以上。

根据本发明的一个优选实施例,所述钢材包括热轧钢板、冷轧钢板、或带有涂镀层的钢板。所述带有涂镀层的钢板可为锌涂镀钢板,它是在其上形成金属锌层的热轧钢板或冷轧钢板。所述锌涂镀钢板包括选自热浸镀锌(GI)、镀锌退火(GA)、锌电镀或锌-铁电镀(GE)中的一种。所述带有涂镀层的钢板为在其上形成铝硅层的热轧钢板或冷轧钢板,或者有机镀层的钢板、或者带有其它合金化镀层的钢板。

根据本发明的一个方面,提供了一种冲压成形工艺,其包括提供具有上述成分的钢材,经过加热至650~780℃保温0.5~60分钟的热处理工艺处理后进行冲压成形。或者,所述钢材直接进行冷冲压或者热冲压成形后,经加热至650~780℃保温0.5~60分钟的热处理工艺处理后得到所需冲压件。随着碳元素和锰元素含量的提高,钢的淬透性会大幅提高,以至于在热轧后空冷条件下均能得到全马氏体组织,因此具有较高的强度,而造成冷轧困难。为解决冷轧困难的问题,申请人结合生产工艺,提出解决方案。在钢的碳化物生成温度630~750℃之间,与工业罩式炉常规采用的软化退火工艺一致,使钢中析出碳化物和产生逆相变的奥氏体,即降低了钢的强度,又提高了钢的延伸率便于冷轧。

根据本发明的另一方面,提供了一种冲压成形构件,所述冲压成形构件由本发明的冲压成形用钢材经过本发明的冲压成形工艺制备而成。

本发明的钢材或其冲压成形构件以体积计的微观组织包括:30%以上的残余奥氏体,70%以下的马氏体(铁素体)组织,或包括3%以下的碳化物,从而获得力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积(抗拉强度×延伸率)25GPa%以上。优选地,本

发明的钢材或其冲压成形构件在经过加热至650~780℃保温0.5~60分钟的热处理工艺后,以面积计的微观组织包括:30%至60%的残余奥氏体,40%至70%的体心立方晶体结构的马氏体或铁素体,低于3%的碳化物。优选地,所述残余奥氏体和马氏体或铁素体可呈板条状相间分布或,其板条厚度在10~300nm之间。优选地,奥氏体中以重量百分比计可包括大于等于7%的Mn以及大于等于0.5%的C。优选地,本发明的钢材或其冲压成形构件在受力变形过程中,残余奥氏体通过相变诱导塑性,或同时辅助孪晶诱导塑性效应,提高其强度和延性的匹配,使得力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积≥25GPa%。

根据本发明的一个优选实施例,所述冲压成形构件可以用于汽车安全结构件、增强结构件、和高强韧汽车结构件中的至少一种。更具体而言,所述成形构件可以用于B柱增强件、保险杠、和车门防撞梁、车轮轮辐中的至少一种。当然,所述成形构件也可以用于其它所有陆用车辆中要求轻质的高强度加高延性的构件的场合。

根据本发明的技术方案,能获得以下优点:

1.通过提高碳含量和合理锰含量的控制,使钢中存在大量的稳定性较高的残余奥氏体,奥氏体含量体积分数在30%以上,在变形过程中发生TRIP效应,提高钢的强塑性;

2.在优选的情况下,部分稳定的奥氏体在变形过程中发生TWIP效应,辅助变形,更有利于提高钢的强塑性;

3.与中Mn-TRIP钢相比,屈服强度明显提高,抗拉强度与延伸率的匹配亦明显提高;

4.生产工艺简单,对冷速要求较低,利于实现钢的微观组织的控制和保证力学性能的稳定性。

特别而言,与专利文献CN102021472B(其工艺图可参考图7)对比,本发明因为加入较高的Si和Al,提高材料Ac1温度,为冷轧做准备的软化退火温度提高至630-750℃(与其权利要求的450~630℃的软化退火温度不同),其延伸率及轧制变形能力较对比专利中有所提高,与工业罩式炉常规采用的软化退火工艺一致,有利于生产组织。并且本发明可以使用热轧板直接在650-780℃进行退火保温0.5-60min后可以获得理想的性能。且本发明通过优化的C和Mn合金设计,及优化

热处理设计,使其具有稳定性合理的高体积分数残余奥氏体(30%~60%),因此具有1000MPa以上的抗拉强度,并强塑积25GPa%以上。对于经过直接冲压成形或者热冲压成形的构件,经过650-780℃保温0.5-60min后亦可以获得理想的性能。

与专利文献CN101638749B对比,本发明优化的设计,使其最终仅一次Ac1以上的650-780℃退火0.5~60分钟即可获得所需组织性能(与其工艺路径的后续需进一步Ac1以下100℃至Ac1温度下1~10小时保温的复杂工艺不同),本发明的钢材可经工业连续退火炉热处理后直接获得所需的组织和性能。本发明与对比专利的工艺对比图可参考图8。

CN101638749B中奥氏体的逆相变是在Ac1以下100℃至Ac1温度下1-10小时。热轧板的合金元素配分处理与奥氏体逆相变处理工艺相同。

与专利文献CN104846274A对比,本发明中其钢材仅经过一步处理,即650-780℃退火0.5~60分钟,形成的奥氏体含量远高于该对比专利技术,达到30%~60%的残余奥氏体,因此其具有更好的强度与延性的匹配,强塑积达到25GPa%以上;其冲压成形的构件经650-780℃退火0.5~60分钟处理,其热处理工艺和微观组织均不同于对比专利技术,并具有更高的延性,延伸率均高于18%,强塑积达到25GPa%以上。

本发明钢的初始热轧组织为板条状的马氏体组织,利用马氏体板条比较细的特点。在两相区退火,完成碳和锰的配分,使得到的逆相变的奥氏体保存了马氏体板条的形态,并且其中有足够的碳含量和锰含量,使之能够在室温下稳定存在,利用残余奥氏体和退火马氏体的协调变形提高钢的延伸率。

逆相变得到的晶粒或板条尺寸细小的奥氏体和奥氏体中大量碳含量的富集,致使奥氏体的层错能升高,使奥氏体在形变过程中发生TWIP/TRIP效应,提高钢的加工硬化率,抑制屈服平台,提高钢的强塑性。

本发明通过提高钢中的碳含量和控制锰的含量,得到的热轧组织为马氏体组织。然后在两相区保温,得到奥氏体和铁素体的双相组织,并在此期间使钢中的碳和锰富集到奥氏体上,基于适当碳和锰的设计,在室温下得到较高碳含量和锰含量的残余奥氏体。

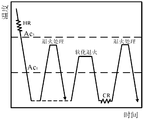

图1为本发明实施例的热处理工艺图,其HR表示表示热轧;CR表示冷轧;

图2为本发明实施例的1号钢在软化退火650℃保温10h后的工程应力应变曲线;

图3为本发明实施例的1号钢在软化退火650℃保温10h后拉伸变形后平行段的微观组织;

图4为5号钢冷轧板标号C处理工艺在常温下的工程应力应变曲线;

图5为5号钢冷轧板标号C处理工艺的微观组织;

图6为5号钢冷轧板标号C处理工艺后变形前和变形后的X射线衍射图谱;

图7为对比用专利文献CN102021472B的热处理工艺图;

图8为本发明与对比专利CN102021472B的工艺对比图。

下面将参考实施例更详细地描述本发明。实施例旨在解释本发明的示例性的实施方式,并且本发明不限于这些实施例。

本发明的钢材的化学成分(以重量百分比计)限定的原因如下:

C:0.22至0.48%

碳是最便宜的强化元素,可以通过间隙固溶强烈提高钢的强度。此外,碳含量的升高会强烈降低Ac3,从而降低加热温度节约能源。但是过高的碳含量会导致钢的焊接性能不好,而且可能会引起板材强度过高,在热成形过程中损坏模具,降低模具的寿命。为此碳的上限设为0.48%。为保证奥氏体中富集足够的碳,碳含量的下限为0.2%,优选为0.25~0.45%。

Mn:5%至9.5%

锰是提高奥氏体稳定性的重要元素。锰可以扩大奥氏体区域,降低Ac3温度。锰具有优良的抑制奥氏体向铁素体转变而提高钢的淬透性的作用。为了保证足够的奥氏体在室温稳定存在,把锰的下限定为5%。锰增高会减弱钢的抗腐蚀能力和降低焊接性能,并且容易在淬火冷却

过程中会形成孪晶马氏体降低材料的强塑性。所以锰的上限设为9.5%。

Si+Al:0.5%至3.0%

硅和铝都能抑制碳化物的形成,硅和铝能提高Ac1温度,提高冷轧前钢板软化处理的温度,与工业罩式炉常规采用的软化退火工艺一致,并且能够抑制尺寸较大的渗碳体产生。在钢冷却至室温的过程中,硅和铝能够抑制渗碳体的析出。并且硅能起到固溶强化的作用,提高钢的屈服强度,铝能够明显扩大两相区的温度范围,扩大工艺窗口,所以Si+Al的下限是0.5%。工业生产时,过多的Al会在连铸时阻塞喷嘴,增加连铸的难度。硅含量高会造成钢中的杂质较多。因此Si+Al的上限设定为3.0%。

Cr、Mo、W:0.001%至2.0%

Cr、Mo、W提高钢的淬透性,可有效提高钢的强度。Cr能使组织均匀,增加回火稳定性,Cr与C形成的合金渗碳体能阻碍奥氏体晶粒长大,提高钢的韧性。此外,Mo能防止回火脆性,增加剩磁和矫顽力以及在某些介质中的抗蚀性。Mo能降低碳化物在晶界分布的倾向。W与Mo有类似的作用,W可以降低钢的过热敏感性、增加淬透性和提高硬度。浓度低于0.001%时,则不能获得足够的淬透性,即使大于2.0%的情况下,也不能获得额外的效果,反而会增加成本。

Ti、Nb、Zr、V:0.0001%至0.4%

Ti、Nb、Zr和V使钢的晶粒细化、强度升高并且获得良好的热处理特性。Ti、Nb、Zr和V的浓度过低则起不到作用,而大于0.4%则会增加不必要的成本。

Cu、Ni:0.0005%至2.0%

Cu能提高强度和韧性,特别是大气腐蚀性能。Cu的含量大于2.0%,则加工性可能劣化。Ni能提高钢的强度,而又保持良好的塑性和韧性。Ni的含量低于0.0005%则得不到应有的作用,Ni的浓度大于2.0%,则会增加成本。

B:0.0001%至0.005%

B在奥氏体晶界偏析,阻止了铁素体的形核,可强烈提高钢的淬透性,热处理后可显著提高钢的强度。B的含量低于0.0001%,则起不到作用。B含量高于0.005%也不能明显提高起作用。

本发明的一个目的生产屈服强度500~1200MPa,抗拉强度

980~1480MPa,其强塑积(抗拉强度×延伸率)≥25GPa%的钢板。该钢板包括热轧钢板、冷轧钢板和镀锌钢板或其它镀层钢板。其热处理后以体积计的微观组织包括:30%至70%的残余奥氏体,30%至70%的体心立方结构的组织(马氏体或铁素体)。其奥氏体中以重量百分比计的Mn≥7%,C≥0.5%。

下面描述以本发明的钢板进行的实验。对如表1所确定的成分的钢材在1200~1500℃保温5~20h均质处理,然后在1000℃~1200℃之间保温0.5~2h后进行热轧以形成热轧板。参考图1,热轧板处理工艺为将热轧板在加热到退火温度保温0.5~60分钟。为易于冷轧在冷轧前将热轧板进行软化退火处理,将退火后的热轧板经酸洗后冷轧至1.5mm,并在退火温度保温0.5~60min。其中表1中1号钢的热轧板和冷轧板先在780℃奥氏体化处理后进行平板模冲压成形之后,在进行一步退火处理。

下面将描述成形构件的制造方法。在冲压之前将热轧板或者冷轧板或其它镀层状态下的钢板加热到650~780℃保温。其冷却方式可以是空冷或者以其它冷却方式冷却至室温。冷却后将钢板转移到模具中进行冲压成形,以获得所需形状的成形构件。或者将所得钢板直接进行冷冲压或热冲压成形,之后在650~780℃保温,以空冷或者其它冷却方式冷至室温。在上述制造方法中,将钢板加热到650~780℃保温,可获得面心立方结构和体心立方结构的组织,并且使马氏体(铁素体)中的碳和锰扩散到奥氏体,提高奥氏体稳定性,使之保存至室温。在成形构件变形过程中,足够稳定的奥氏体会发生相变诱导塑性(TRIP,特别地,在优选的情况下部分奥氏体会发生孪晶诱导塑性(TWIP),从而提高材料的塑性和吸能性。本发明的冲压成形构件以体积计的微观组织包括:30%至60%的残余奥氏体,40%至70%的体心立方晶体结构的马氏体或铁素体。其中奥氏体中以重量百分比计的Mn≥7%,C≥0.5%。

表1钢的化学成分

| C | Mn | P | S | 其它 | |

| 1 | 0.3 | 6.66 | 0.012 | 0.008 | 1.05Si 0.04Ti 0.005B |

| 2 | 0.28 | 5.75 | 0.009 | 0.002 | 1.05Si |

| 3 | 0.4 | 4 | 0.006 | 0.008 | 1Al 1.5Si 0.5Mo |

| 4 | 0.2 | 9.5 | 0.009 | 0.002 | 2Al 1Si |

| 5 | 0.28 | 6.3 | 0.009 | 0.008 | 1.5Si |

钢板的加热和热处理实验

将热轧板或者冷轧板在带有氮气保护的电阻式箱式炉中完成加热和保温实验。具体的实验工艺见表2。

表2不同的热处理工艺

不同热处理工艺得到的钢板的力学性能如表3所示。

表3钢板的拉伸力学性能

注:

YS表示屈服强度,取0.2%残余变形的应力值为其屈服极限;TS表示抗拉强度;TE表示总延伸率。

表3中拉伸试样为标距50mm的ASTM标准试样;拉伸力学性能测试的应变速率为6.67×10-4s-1。

通过表3的力学性能数据可以看出,具有本发明成分的钢板,通过本发明的热处理工艺,能获得强度和延伸率综合性能特别优异的成形构件。具体而言,能实现屈服强度500~1200MPa,抗拉强度980~1480MPa,其强塑积(抗拉强度×延伸率)≥30GPa%的钢板。

本发明钢板软化处理后的拉伸曲线和微观组织如图2和3所示。对发明钢均匀变形区进行微观组织分析,钢中存在少量的碳化物,组织呈带状分布,其奥氏体板条在200nm左右,并且奥氏体中存在条状组织,此组织可能是ε-马氏体或者奥氏体孪晶,经过衍射斑标定奥氏体在变形过程中发生了机械孪晶。

图4给出了5号钢冷轧板在670℃保温10分钟的拉伸曲线,其屈服强度、抗拉强度及延伸率满足发明要求,并且本发明钢一致保持较

高的加工硬化率,不存在屈服平台和吕德斯带。根据图5的微观组织表征可以看出,冷轧退火后的组织仍然基本保持板条状态分布,其晶粒尺寸在1微米以下,不仅提高了钢的屈服强度,而且提高了奥氏体的层错能,有利于其在变形过程中发生机械孪晶,从而提高钢的延伸率和加工硬化率。图6是此工艺下变形前后的X射线衍射图谱,经计算奥氏体变形前后的体积分数分别为40%和6%。在变形过程中,残余奥氏体发生了TWIP或者TRIP效应,从而保证了本发明钢的所要求的强度和塑性。

Claims (14)

- 一种用于冲压成形的钢材,其特征在于,所述钢材以重量百分比计包括0.22~0.48%的C、5~9.5%的Mn、0.5~3.0%的Si+Al以及余量的Fe和不可避免的杂质。

- 如权利要求1所述的钢材,其特征在于,还可包括以下成分中的至少一种:Cr:0.001%至2%;Mo:0.001%至2.0%;W:0.001%至2.0%;Ti:0.0001%至0.4%;Nb:0.0001%至0.4%;Zr:0.0001%至0.4%;V:0.0001%至0.4%;Cu:0.0005%至2%;Ni:0.0005%至3.0%;B:0.0001%至0.005%。

- 如权利要求1所述的钢材,其特征在于,所述钢材为热轧、热轧酸洗、热轧酸洗镀层钢卷或钢板,或者冷轧退火、冷轧镀层钢卷或钢板,其中镀层钢卷或钢板包括锌涂镀钢卷或钢板或其它涂层的钢卷或钢板。

- 如权利要求3所述的钢材,其特征在于,所述锌涂镀钢板为在其上形成金属锌层的热轧钢板或冷轧钢板。

- 如权利要求4所述的钢材,其特征在于,所述锌涂镀钢板包括选自热浸镀锌、镀锌退火、锌电镀或锌-铁电镀钢板中的一种。

- 如权利要求3所述的钢材,其特征在于,所述其它涂层的钢板为在其上形成铝硅层的热轧钢板或冷轧钢板,或者为在其上形成其它合金化镀层、有机镀层的钢板。

- 如权利要求1~6中任一项所述的钢材,所述钢材受到加热至650~780℃保温0.5~60分钟的热处理。

- 如权利要求7所述的钢材,其特征在于,在所述热处理后,所述钢材以面积计的微观组织包括:30%至60%的残余奥氏体,40%至 70%的体心立方晶体结构的马氏体或铁素体,低于3%的碳化物。

- 如权利要求8所述的钢材,其特征在于,所述残余奥氏体中以重量百分比计包括大于等于7%的Mn以及大于等于0.5%的C。

- 如权利要求9所述的钢材,其特征在于,在受力变形过程中,所述残余奥氏体通过相变诱导塑性,或同时辅助孪晶诱导塑性效应,提高其强度和延性的匹配,使得力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积≥25GPa%。

- 一种成形构件,其特征在于,所述成形构件由权利要求7-10项中任一项所述的钢材通过冲压成形工艺形成,所述成形构件包括汽车结构件。

- 一种成形构件,其特征在于,所述成形构件由权利要求1-6中任一项所述的钢材经直接冲压成形工艺或热冲压成形工艺形成,所述成形构件包括汽车结构件。

- 如权利要求12所述的成形构件,其特征在于,所述成形构件经加热至650~780℃保温0.5~60分钟,所述构件以面积计的微观组织包括:30%至60%的残余奥氏体,40%至70%的体心立方晶体结构的马氏体或铁素体,低于3%的碳化物,所述残余奥氏体中以重量百分比计包括大于等于7%的Mn以及大于等于0.5%的C,在受力变形过程中,所述奥氏体通过相变诱导塑性,并可辅助孪晶诱导塑性效应,提高其强度和延性的匹配,使得力学性能达到:屈服强度0.5~1.2GPa,抗拉强度1.0~1.5GPa,强塑积≥25GPa%。

- 一种热处理方法,其特征在于,包括以下步骤:(A)提供如权利要求1~6中任一项所述的钢材或者由所述钢材通过直接冲压或热冲压形成的成形构件;(B)将所述钢材或所述成形构件加热至650~780℃保温0.5~60分钟。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201580085081.2A CN108474081B (zh) | 2015-12-04 | 2015-12-25 | 用于冲压成形的钢材及其成形构件与热处理方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201510878323.5 | 2015-12-04 | ||

| CN201510878323.5A CN105483531A (zh) | 2015-12-04 | 2015-12-04 | 用于冲压成形的钢材及其成形构件与热处理方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017092104A1 true WO2017092104A1 (zh) | 2017-06-08 |

Family

ID=55670798

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2015/098890 WO2017092104A1 (zh) | 2015-12-04 | 2015-12-25 | 用于冲压成形的钢材及其成形构件与热处理方法 |

| PCT/CN2016/090629 WO2017219427A1 (zh) | 2015-12-04 | 2016-07-20 | 用于获得梯度化性能的处理工艺及其构件 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2016/090629 WO2017219427A1 (zh) | 2015-12-04 | 2016-07-20 | 用于获得梯度化性能的处理工艺及其构件 |

Country Status (3)

| Country | Link |

|---|---|

| CN (3) | CN105483531A (zh) |

| ES (1) | ES2971678T3 (zh) |

| WO (2) | WO2017092104A1 (zh) |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019020169A1 (de) * | 2017-07-25 | 2019-01-31 | Thyssenkrupp Steel Europe Ag | Blechbauteil, hergestellt durch warmumformen eines stahlflachprodukts und verfahren zu dessen herstellung |

| WO2019155014A1 (en) * | 2018-02-08 | 2019-08-15 | Tata Steel Ijmuiden B.V. | Method of shaping an article from a zinc or zinc alloy coated steel blank |

| CN112233735A (zh) * | 2020-09-07 | 2021-01-15 | 包头钢铁(集团)有限责任公司 | 一种珠光体钢轨钢化学成分的设计方法 |

| CN113416893A (zh) * | 2021-05-24 | 2021-09-21 | 鞍钢股份有限公司 | 汽车用高强高塑性铁素体奥氏体双相冷轧钢板及生产方法 |

| CN113462956A (zh) * | 2021-05-25 | 2021-10-01 | 上海大学 | 一种大截面高淬透性高强度中锰锻钢及其制备方法 |

| CN114032475A (zh) * | 2021-10-15 | 2022-02-11 | 首钢集团有限公司 | 一种高强度冷轧热镀锌中锰钢及其制备方法与热成形零部件 |

| CN114126796A (zh) * | 2019-06-17 | 2022-03-01 | 日本制铁株式会社 | 接合接头以及汽车用部件 |

| CN114450423A (zh) * | 2019-09-30 | 2022-05-06 | 蒂森克虏伯钢铁欧洲股份公司 | 用于生产至少部分调质的钢板部件的方法和至少部分调质的钢板部件 |

| CN114836688A (zh) * | 2022-04-20 | 2022-08-02 | 攀钢集团攀枝花钢铁研究院有限公司 | 一种逆相变铌微合金化轻质高强钢及其生产方法 |

| CN115161549A (zh) * | 2022-05-27 | 2022-10-11 | 郑州轻研合金科技有限公司 | 一种高抗拉强度合金钢板及其制备方法 |

| CN115323135A (zh) * | 2022-08-12 | 2022-11-11 | 华北理工大学 | 一种强塑积不低于45GPa%的超高强塑积中锰钢的制备方法 |

| CN115491583A (zh) * | 2021-06-18 | 2022-12-20 | 上海梅山钢铁股份有限公司 | 一种超深冲冷轧热镀铝锌钢板及其制造方法 |

| CN116516252A (zh) * | 2023-04-28 | 2023-08-01 | 鞍钢股份有限公司 | 1200MPa超高强塑热轧Mn-TRIP钢及其制备方法 |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10619223B2 (en) | 2016-04-28 | 2020-04-14 | GM Global Technology Operations LLC | Zinc-coated hot formed steel component with tailored property |

| WO2018055425A1 (en) * | 2016-09-22 | 2018-03-29 | Arcelormittal | High strength and high formability steel sheet and manufacturing method |

| CN107287401B (zh) * | 2017-06-10 | 2020-10-09 | 山东建筑大学 | 一种通过碳-锰综合配分提高传统q&p钢性能的方法 |

| CN107815612A (zh) * | 2017-11-02 | 2018-03-20 | 重庆哈工易成形钢铁科技有限公司 | 热冲压成形用钢材、热冲压成形工艺及成形构件 |

| CN111542635B (zh) * | 2017-12-28 | 2022-07-01 | 通用汽车环球科技运作有限责任公司 | 具有增强的抗氧化性的用于热冲压的钢 |

| JP7214973B2 (ja) * | 2018-03-30 | 2023-01-31 | マツダ株式会社 | 熱間プレス加工方法及び加工装置 |

| WO2019222950A1 (en) | 2018-05-24 | 2019-11-28 | GM Global Technology Operations LLC | A method for improving both strength and ductility of a press-hardening steel |

| CN108754103B (zh) * | 2018-06-07 | 2019-08-30 | 浙江大学 | 一种超细晶纯铁梯度材料制备方法 |

| CN112534078A (zh) | 2018-06-19 | 2021-03-19 | 通用汽车环球科技运作有限责任公司 | 具有增强的机械性质的低密度压制硬化钢 |

| US11530469B2 (en) | 2019-07-02 | 2022-12-20 | GM Global Technology Operations LLC | Press hardened steel with surface layered homogenous oxide after hot forming |

| CN110735022A (zh) * | 2019-11-20 | 2020-01-31 | 安徽工业大学 | 兼具冷、热成形柔性化应用的高强塑积超高强度汽车用钢 |

| CN113136529B (zh) * | 2021-03-10 | 2022-05-20 | 首钢集团有限公司 | 一种中锰钎杆及制备方法 |

| CN113106339B (zh) * | 2021-03-22 | 2022-02-11 | 北京科技大学 | 一种超高强高塑性抗高温氧化热冲压成形钢的制备方法 |

| CN115261742B (zh) * | 2021-04-30 | 2023-06-13 | 宝山钢铁股份有限公司 | 一种抗拉强度1000MPa热冲压部件及其制造方法 |

| CN113802065B (zh) * | 2021-11-18 | 2022-03-29 | 育材堂(苏州)材料科技有限公司 | 热冲压成形构件、热冲压成形用钢板以及热冲压工艺 |

| CN114318161B (zh) * | 2021-12-15 | 2022-06-03 | 常州大学 | 一种低温高应变速率超塑性中锰钢及其制备方法 |

| CN114293103B (zh) * | 2021-12-31 | 2022-07-29 | 台州绿创包装容器股份有限公司 | 一种金属气雾剂罐 |

| CN114686774B (zh) * | 2022-03-08 | 2022-12-02 | 四川大学 | 一种高强高韧纳米析出强化超细晶马氏体奥氏体双相钢及其制备方法 |

| CN114643309A (zh) * | 2022-03-25 | 2022-06-21 | 本钢板材股份有限公司 | 一种变强度热成形钢零件的加工方法 |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5983744A (ja) * | 1982-11-04 | 1984-05-15 | Sumitomo Metal Ind Ltd | 形状記憶合金 |

| JPH04333526A (ja) * | 1991-05-08 | 1992-11-20 | Sumitomo Metal Ind Ltd | 高延性熱延高張力鋼板およびその製造方法 |

| US20040234409A1 (en) * | 2003-02-27 | 2004-11-25 | Francois Ropital | Use of low alloy anticoking steels with an increased silicon and manganese content in refining and petrochemicals applications, and novel steel compositions |

| CN102884218A (zh) * | 2010-03-09 | 2013-01-16 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN104204266A (zh) * | 2012-03-19 | 2014-12-10 | 杰富意钢铁株式会社 | 高强度热镀锌钢板的制造方法以及高强度热镀锌钢板 |

| CN104220628A (zh) * | 2012-03-19 | 2014-12-17 | 杰富意钢铁株式会社 | 高强度热镀锌钢板的制造方法以及高强度热镀锌钢板 |

| CN104508156A (zh) * | 2012-07-23 | 2015-04-08 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN104508155A (zh) * | 2012-07-23 | 2015-04-08 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN105026600A (zh) * | 2013-03-04 | 2015-11-04 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法以及高强度热镀锌钢板及其制造方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0768583B2 (ja) * | 1984-03-07 | 1995-07-26 | 住友金属工業株式会社 | 高張力冷延鋼板の製造法 |

| SE528130C2 (sv) | 2004-10-04 | 2006-09-12 | Gestamp Hardtech Ab | Sätt att varmforma och härda ett plåtämne |

| CN101238233B (zh) * | 2005-08-03 | 2012-11-28 | 住友金属工业株式会社 | 热轧钢板及冷轧钢板及它们的制造方法 |

| SE531499C2 (sv) | 2007-11-15 | 2009-04-28 | Gestamp Hardtech Ab | B-stolpe till fordon |

| JP5637342B2 (ja) * | 2008-09-18 | 2014-12-10 | 国立大学法人 岡山大学 | ホットプレス加工を施した鋼板部材及びその製造方法 |

| SE1000236A1 (sv) | 2010-03-16 | 2011-02-22 | Gestamp Hardtech Ab | Presshärdningsanläggning och sätt att presshärda |

| CN102212742B (zh) | 2011-05-16 | 2013-08-28 | 马鸣图 | 一种强度柔性分布的热冲压成形汽车零件及其控制方法 |

| FI20115832L (fi) * | 2011-08-26 | 2013-02-27 | Rautaruukki Oyj | Menetelmä erinomaisilla mekaanisilla ominaisuuksilla varustetun terästuotteen valmistamiseksi, menetelmällä valmistettu terästuote ja muokkauslujitetun teräksen käyttö |

| CN103409613B (zh) | 2013-08-30 | 2014-09-10 | 上海交通大学 | 实现热冲压制件梯度性能分布的方法 |

| CN103521581B (zh) | 2013-10-23 | 2015-12-02 | 武汉理工大学 | 获得力学性能梯度热冲压零件的方法及模具 |

| CN103878237B (zh) | 2014-03-24 | 2015-04-15 | 华中科技大学 | 一种高强钢热冲压成形零件加工的方法 |

| CN104726677B (zh) * | 2015-03-30 | 2017-03-15 | 盐城科奥机械有限公司 | 固定衬板式厢式加热炉及其热成形分段强化工艺 |

| CN104729278B (zh) * | 2015-03-30 | 2016-09-28 | 盐城科奥机械有限公司 | 运动托辊式厢式加热炉及热成形分段强化工艺 |

| CN104831020A (zh) | 2015-04-03 | 2015-08-12 | 燕山大学 | 一种非均匀温度场下冲压淬火成形方法 |

-

2015

- 2015-12-04 CN CN201510878323.5A patent/CN105483531A/zh active Pending

- 2015-12-25 WO PCT/CN2015/098890 patent/WO2017092104A1/zh active Application Filing

- 2015-12-25 CN CN201580085081.2A patent/CN108474081B/zh active Active

-

2016

- 2016-06-20 CN CN201610440901.1A patent/CN106011418B/zh active Active

- 2016-07-20 WO PCT/CN2016/090629 patent/WO2017219427A1/zh unknown

- 2016-07-20 ES ES16905967T patent/ES2971678T3/es active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5983744A (ja) * | 1982-11-04 | 1984-05-15 | Sumitomo Metal Ind Ltd | 形状記憶合金 |

| JPH04333526A (ja) * | 1991-05-08 | 1992-11-20 | Sumitomo Metal Ind Ltd | 高延性熱延高張力鋼板およびその製造方法 |

| US20040234409A1 (en) * | 2003-02-27 | 2004-11-25 | Francois Ropital | Use of low alloy anticoking steels with an increased silicon and manganese content in refining and petrochemicals applications, and novel steel compositions |

| CN102884218A (zh) * | 2010-03-09 | 2013-01-16 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN104204266A (zh) * | 2012-03-19 | 2014-12-10 | 杰富意钢铁株式会社 | 高强度热镀锌钢板的制造方法以及高强度热镀锌钢板 |

| CN104220628A (zh) * | 2012-03-19 | 2014-12-17 | 杰富意钢铁株式会社 | 高强度热镀锌钢板的制造方法以及高强度热镀锌钢板 |

| CN104508156A (zh) * | 2012-07-23 | 2015-04-08 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN104508155A (zh) * | 2012-07-23 | 2015-04-08 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法 |

| CN105026600A (zh) * | 2013-03-04 | 2015-11-04 | 杰富意钢铁株式会社 | 高强度钢板及其制造方法以及高强度热镀锌钢板及其制造方法 |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110944765B (zh) * | 2017-07-25 | 2022-02-25 | 蒂森克虏伯钢铁欧洲股份公司 | 通过热成型扁钢产品生产的金属板构件及其生产方法 |

| CN110944765A (zh) * | 2017-07-25 | 2020-03-31 | 蒂森克虏伯钢铁欧洲股份公司 | 通过热成型扁钢产品生产的金属板构件及其生产方法 |

| WO2019020169A1 (de) * | 2017-07-25 | 2019-01-31 | Thyssenkrupp Steel Europe Ag | Blechbauteil, hergestellt durch warmumformen eines stahlflachprodukts und verfahren zu dessen herstellung |

| WO2019155014A1 (en) * | 2018-02-08 | 2019-08-15 | Tata Steel Ijmuiden B.V. | Method of shaping an article from a zinc or zinc alloy coated steel blank |

| US11519044B2 (en) | 2018-02-08 | 2022-12-06 | Tata Steel Ijmuiden B.V. | Method of shaping an article from a zinc or zinc alloy coated steel blank |

| CN114126796A (zh) * | 2019-06-17 | 2022-03-01 | 日本制铁株式会社 | 接合接头以及汽车用部件 |

| CN114126796B (zh) * | 2019-06-17 | 2023-09-26 | 日本制铁株式会社 | 接合接头以及汽车用部件 |

| CN114450423A (zh) * | 2019-09-30 | 2022-05-06 | 蒂森克虏伯钢铁欧洲股份公司 | 用于生产至少部分调质的钢板部件的方法和至少部分调质的钢板部件 |

| CN114450423B (zh) * | 2019-09-30 | 2023-12-05 | 蒂森克虏伯钢铁欧洲股份公司 | 用于生产至少部分调质的钢板部件的方法和至少部分调质的钢板部件 |

| CN112233735B (zh) * | 2020-09-07 | 2022-04-19 | 包头钢铁(集团)有限责任公司 | 一种珠光体钢轨钢化学成分的设计方法 |

| CN112233735A (zh) * | 2020-09-07 | 2021-01-15 | 包头钢铁(集团)有限责任公司 | 一种珠光体钢轨钢化学成分的设计方法 |

| CN113416893A (zh) * | 2021-05-24 | 2021-09-21 | 鞍钢股份有限公司 | 汽车用高强高塑性铁素体奥氏体双相冷轧钢板及生产方法 |

| CN113462956A (zh) * | 2021-05-25 | 2021-10-01 | 上海大学 | 一种大截面高淬透性高强度中锰锻钢及其制备方法 |

| CN113462956B (zh) * | 2021-05-25 | 2022-06-14 | 上海大学 | 一种大截面高淬透性高强度中锰锻钢及其制备方法 |

| CN115491583B (zh) * | 2021-06-18 | 2023-09-05 | 上海梅山钢铁股份有限公司 | 一种超深冲冷轧热镀铝锌钢板及其制造方法 |

| CN115491583A (zh) * | 2021-06-18 | 2022-12-20 | 上海梅山钢铁股份有限公司 | 一种超深冲冷轧热镀铝锌钢板及其制造方法 |

| CN114032475A (zh) * | 2021-10-15 | 2022-02-11 | 首钢集团有限公司 | 一种高强度冷轧热镀锌中锰钢及其制备方法与热成形零部件 |

| CN114032475B (zh) * | 2021-10-15 | 2022-12-16 | 首钢集团有限公司 | 一种高强度冷轧热镀锌中锰钢及其制备方法与热成形零部件 |

| CN114836688A (zh) * | 2022-04-20 | 2022-08-02 | 攀钢集团攀枝花钢铁研究院有限公司 | 一种逆相变铌微合金化轻质高强钢及其生产方法 |

| CN114836688B (zh) * | 2022-04-20 | 2023-10-27 | 攀钢集团攀枝花钢铁研究院有限公司 | 一种逆相变铌微合金化轻质高强钢及其生产方法 |

| CN115161549A (zh) * | 2022-05-27 | 2022-10-11 | 郑州轻研合金科技有限公司 | 一种高抗拉强度合金钢板及其制备方法 |

| CN115323135A (zh) * | 2022-08-12 | 2022-11-11 | 华北理工大学 | 一种强塑积不低于45GPa%的超高强塑积中锰钢的制备方法 |

| CN116516252A (zh) * | 2023-04-28 | 2023-08-01 | 鞍钢股份有限公司 | 1200MPa超高强塑热轧Mn-TRIP钢及其制备方法 |

| CN116516252B (zh) * | 2023-04-28 | 2024-03-19 | 鞍钢股份有限公司 | 1200MPa超高强塑热轧Mn-TRIP钢及其制备方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2971678T3 (es) | 2024-06-06 |

| CN106011418A (zh) | 2016-10-12 |

| CN108474081B (zh) | 2021-09-17 |

| WO2017219427A1 (zh) | 2017-12-28 |

| CN106011418B (zh) | 2018-05-22 |

| CN105483531A (zh) | 2016-04-13 |

| CN108474081A (zh) | 2018-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017092104A1 (zh) | 用于冲压成形的钢材及其成形构件与热处理方法 | |

| JP6893560B2 (ja) | 降伏比が低く均一伸びに優れた焼戻しマルテンサイト鋼及びその製造方法 | |

| US11279984B2 (en) | High-strength cold rolled steel sheet having high formability and a method of manufacturing thereof | |

| JP6043801B2 (ja) | 温間プレス成形用鋼板、温間プレス成形部材、及びこれらの製造方法 | |

| JP4575799B2 (ja) | 成形性に優れたホットプレス高強度鋼製部材の製造方法 | |

| KR101758522B1 (ko) | 항복강도 및 구멍확장성이 우수한 초고강도 고연성 강판 및 그 제조방법 | |

| EP3395993B1 (en) | High yield ratio type high-strength cold-rolled steel sheet and manufacturing method thereof | |

| WO2018076965A1 (zh) | 一种抗拉强度在1500MPa以上且成形性优良的冷轧高强钢及其制造方法 | |

| KR20080038753A (ko) | 성형성이 우수한 고장력 강판 및 그 제조 방법 | |

| US20230272511A1 (en) | Ultra-high-strength steel having excellent plasticity and method for manufacturing same | |

| KR101677398B1 (ko) | 열간성형용 강재 및 이를 이용한 부재 제조방법 | |

| CN115244200B (zh) | 高强度钢板及其制造方法 | |

| KR102020407B1 (ko) | 고항복비형 고강도 강판 및 이의 제조방법 | |

| EP3561121B1 (en) | Cold-rolled steel sheet having excellent bendability and hole expandability and method for manufacturing same | |

| CN112689684B (zh) | 经冷轧和涂覆的钢板及其制造方法 | |

| CN111448329A (zh) | 经冷轧和涂覆的钢板及其制造方法 | |

| KR20190107585A (ko) | 마르텐사이트계 석출 경화형 경량철강 및 그 제조방법 | |

| CN111465710B (zh) | 高屈强比型高强度钢板及其制造方法 | |

| KR20230056822A (ko) | 연성이 우수한 초고강도 강판 및 그 제조방법 | |

| CN111315909B (zh) | 冷成型性优异的超高强度高延展性钢板及其制造方法 | |

| KR20100047001A (ko) | 초고강도 열연강판 및 그 제조방법 | |

| CN108359897B (zh) | 一种屈服强度为1000MPa级的沉淀强化型铁素体钢及生产方法 | |

| KR20230087773A (ko) | 강도 및 연성이 우수한 강판 및 그 제조방법 | |

| JP2023539520A (ja) | 穴拡げ性に優れた高強度鋼板及びその製造方法 | |

| JP2023534825A (ja) | 成形性及び加工硬化率に優れた鋼板 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15909618 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15909618 Country of ref document: EP Kind code of ref document: A1 |