WO2014167654A1 - Slide fastener and method for use thereof - Google Patents

Slide fastener and method for use thereof Download PDFInfo

- Publication number

- WO2014167654A1 WO2014167654A1 PCT/JP2013/060752 JP2013060752W WO2014167654A1 WO 2014167654 A1 WO2014167654 A1 WO 2014167654A1 JP 2013060752 W JP2013060752 W JP 2013060752W WO 2014167654 A1 WO2014167654 A1 WO 2014167654A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fastener

- front stop

- flange portion

- slider

- slide fastener

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B19/00—Slide fasteners

- A44B19/24—Details

- A44B19/36—Means for permanently uniting the stringers at the end; Means for stopping movement of slider at the end

Definitions

- the present invention relates to a slide fastener and a method for using the same.

- the opening and closing of the slide fastener can be controlled by moving the fastener slider back and forth, but the fastener slider slides unintentionally downward by an external force other than an operation by a human hand, etc., and the slide fastener in the closed state becomes the half-open state. It becomes a problem to become.

- Patent Document 1 As shown in FIG. 2 of the same document, a part of an element e is melted together with a sewing thread to form a flat shape, and a reinforcing piece P (V-shaped as shown in FIG. 2) is integrally formed therewith.

- the top stopper 2 provided in the above.

- the purpose is to “strongly and reliably prevent natural separation after closing the fastener” on the 21st line on the first page of the same document.

- the top stop 2 of the element row E is interposed between the inner wall 7 and the side wall 9 of the element guide column 8 as shown in FIG.

- the one side of the top stopper 2 is integrally in contact with the inner wall 7 and the other side is in contact with the side wall 9 of the element guide column 8 ".

- the handle of the fastener slider of the slide fastener In the outer jacket for mountain climbing or rock climbing, which is an example of the use of the slide fastener, the handle of the fastener slider of the slide fastener, the string attached to the puller, or the string attached to the puller attachment column, etc. It is assumed that it is not desired to grip the part directly with a human hand and slide the fastener slider downward. For example, in a harsh situation where the rock climber does not have the freedom of one hand and the other hand cannot move significantly, it is not easy to pay enough attention to moving the ⁇ gripped part '' of the fastener slider. The effort spent is not negligible.

- the inventor of the present application is aware of the releasability of the slide fastener that does not involve fixing the position of the fastener slider at the front stop and direct operation of the fastener slider by a human hand or the like. It was newly found that there is a sufficient significance to satisfy the seemingly contradictory purpose of securing.

- a slide fastener includes a set of fastener stringers (50) in which a fastener element (60) is provided on an opposite side edge (52) of a fastener tape (51) having a set of main surfaces (151). ), And a fastener slider (80) through which each fastener element (60) of the set of fastener stringers (50) is inserted, the upper blade plate (81) and the lower blade plate facing the upper blade plate (81). Connected to at least one of a blade plate (82), a connecting column (83) for connecting the upper blade plate (81) and the lower blade plate (82), and the upper blade plate (81) and the lower blade plate (82).

- a fastener slider (80) comprising a flange portion (85), wherein a passage of the fastener element (60) is defined by the connecting column (83) and the flange portion (85). It is a set of front stoppers (70) provided individually on the set of fastener stringers (50), and each front stopper (70) corresponds to the opposite side edge (52 of the fastener tape (51). And a set of front stoppers (70) that are integrally molded to be fixed to the slide fastener (100), wherein the fastener slider (80) includes at least one of the front stoppers.

- the fastener slider (80) When the fastener slider (80) is in the locked state, the fastener slider (80) is released from the locked state by displacement of at least one of the fastener tapes (51) in the vicinity of the front stop (70). It should be in an unlocked state.

- the at least one front stop (70) has an inner contact portion (P1) that contacts the side surface of the connecting column (83), and an outer contact portion (P2) that contacts the inner surface of the flange portion (85). ), And the fastener element (60) of at least one of the fastener stringers (50) can contact the side surface of the connecting column (83), and the flange portion (85). It includes an outer portion (Q2) that can contact an inner surface, is orthogonal to the main surface (151) of the fastener tape (51), and is parallel to the opposite side edge (52) of the fastener tape (51).

- a distance (W p1-p2 ) between the inner abutting portion (P1) and the outer abutting portion (P2) defined from the plane spacing between the planes is the inner portion defined by the plane spacing between the planes ( Q1) and the outside It is good that it is larger than the interval (W q1-q2 ) of the part (Q2).

- the flange portion (85) includes a first flange portion (85m) and a second flange portion (85n), and the pair of front stop portions (70) is a first front stop portion (70m) and a second front stop portion. (70n) may be included.

- the front stop portion (70) is injection-molded, and the inner contact portion (P1) is preferably a portion provided with a parting line (L10).

- the first front stop (70m) is press-fitted between the connecting column (83) and the first flange portion (85m), and between the connecting column (83) and the second flange portion (85n).

- a force that pulls the fastener slider (80) required for the fastener slider (80) to release the locked state is 15 N or less. There is good.

- the rear end (83R) of the connecting column (83) is the flange front end (85m5) of the first flange portion (85m) and the second flange. It is good to be located in the rear end (80R) side of the fastener slider (80) from the flange front end (85n5) of the portion (85n).

- Inclined surfaces (74j, 74k) that are inclined in the thickness direction of the front stop portion (70) are provided on the side surface of the front stop portion (70) on the side of the connecting column (83) or projecting in a convex shape.

- a ridge portion (78) is preferably provided.

- connection pillar (70) On each side surface of the first front stop (70m) and the second front stop (70n) on the side of the connection pillar (83), the connection pillar (70) toward the thickness center of the front stop (70). 83) It is preferable that at least one inclined surface (74j, 74k) inclined to the side is provided.

- a gate mark (M70) is formed in the concave depression (R70).

- the first front stop (70m) and the second front stop (70n) may be configured to be able to overlap when lined up side by side.

- One of the first front stop portion (70m) and the second front stop portion (70n) is a stepped portion that can face the upper wing plate (81) and the connecting column (83) of the slide fastener (80).

- (R14m, R14n) and the other of the first front stop (70m) and the second front stop (70n) is the lower wing plate (82) of the slide fastener (80) and the connecting column. It is good to have the level

- the first flange portion (85m) includes a first lower flange portion (85m2) connected to the lower wing plate (82) and a first upper flange portion (85m1) connected to the upper wing plate (81),

- the second flange portion (85n) includes a second lower flange portion (85n2) connected to the lower wing plate (82) and a second upper flange portion (85n1) connected to the upper wing plate (81),

- the first front stop (70m) has a first fin portion (107m) that can be disposed between the first lower flange portion (85m2) and the first upper flange portion (85m1), or the first 2 It is preferable that the front stop portion (70n) has a second fin portion (107n) that can be disposed between the second lower flange portion (85n2) and the second upper flange portion (85n1).

- the second front stop portion (70n) is provided with a claw portion (79) that can contact the second flange portion (85n), or the first front stop portion (70m) has the first flange.

- claw part (79) which can contact a part (85m) is good.

- fastener slider (80) is a free slider.

- fastener element (60) and the front stop (70) are integrally fixed to the opposite side edge (52) of the fastener tape (51) by injection molding.

- the method of using a slide fastener is a set of fastener elements (60) provided on opposite side edges (52) of a fastener tape (51) having a set of main surfaces (151).

- a fastener slider (80) through which a fastener stringer (50) and each fastener element (60) of the pair of fastener stringers (50) are inserted, the upper wing plate (81), the upper wing plate (81) Of the lower wing plate (82) opposed to the upper wing plate (81), the connecting column (83) connecting the lower wing plate (82), and the upper wing plate (81) and the lower wing plate (82).

- a fastener slider comprising a flange portion (85) connected to at least one of which a passage of the fastener element (60) is defined by the connecting column (83) and the flange portion (85). 80) and a set of front stoppers (70) individually provided on the set of fastener stringers (50), each front stopper (70) being opposed to the fastener tape (51).

- a method of using a slide fastener (100) comprising a set of front stop portions (70) integrally fixed to a side edge (52), wherein the fastener slider (80) is connected to the front stop portion (70).

- the fastener slider (80) is moved to the front side to press-fit at least one front stop (70) between the connecting column (83) and the flange (85) of the fastener slider (80).

- both the seemingly contradictory effects of fixing the position of the fastener slider at the front stop portion and ensuring the detachability of the slide fastener without direct operation by a human hand or the like on the fastener slider are achieved. be able to.

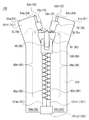

- FIG. 1 It is a schematic front view of the slide fastener which concerns on 1st Embodiment of this invention, and shows the state before the press-fit of the front stop part in a fastener slider.

- FIG. 1 It is a schematic explanatory drawing which shows the structure of the fastener slider of the slide fastener which concerns on 1st Embodiment of this invention, is a plane located in the thickness direction center of a fastener slider, and parallel with respect to an upper blade board and a lower blade board The plane structure by the side of the lower wing board when a fastener slider is divided into two up and down is shown.

- FIG. 1 It is the schematic side view and top view of a fastener element of a slide fastener concerning a 1st embodiment of the present invention, and shows the left side fastener element as an example.

- FIG. 1 It is a schematic perspective view of the left front stop part of the slide fastener which concerns on 1st Embodiment of this invention.

- FIG. 2 is a schematic side view of the left front stop portion of the slide fastener according to the first embodiment of the present invention, and is a view of the left front stop portion viewed from the dotted line DL70m in FIG.

- FIG. It is a schematic perspective view of the right front stop part of the slide fastener which concerns on 1st Embodiment of this invention. It is a schematic top view of the right front stop part of the slide fastener which concerns on 1st Embodiment of this invention. It is a schematic side view of the right front stop part of the slide fastener which concerns on 1st Embodiment of this invention.

- FIG. 2 is a schematic side view of the right front stop portion of the slide fastener according to the first embodiment of the present invention, and is a view of the right front stop portion viewed from the dotted line DL70n in FIG. FIG.

- It is a schematic diagram of the upper end part of the slide fastener which concerns on 1st Embodiment of this invention, Although a front stop part is pinched

- FIG. 14 is a schematic cross-sectional view showing a state after the left front stop portion of the slide fastener according to the first embodiment of the present invention is press-fitted into the fastener slider, and shows a cross-sectional configuration taken along a dotted line SL70m in FIG. FIG.

- FIG. 14 is a schematic cross-sectional view showing a state after the right front stop portion of the slide fastener according to the first embodiment of the present invention is press-fitted into the fastener slider, and shows a cross-sectional configuration taken along dotted line SL70n in FIG. It is a schematic diagram which shows the state which the left side fastener element of the slide fastener which concerns on 1st Embodiment of this invention moves within the fastener slider. It is a schematic diagram which shows the state which the right side fastener element of the slide fastener which concerns on 1st Embodiment of this invention moves within the fastener slider. It is a schematic cross-sectional schematic diagram of the left front stop portion of the slide fastener according to the second embodiment of the present invention.

- FIG. 1 It is a schematic cross-sectional view which shows the state by which the left front stop part of the slide fastener which concerns on 2nd Embodiment of this invention was press-fitted in the fastener slider.

- FIG. 1 It is a schematic side surface schematic diagram of the left side front stop part and right side front stop part of the slide fastener which concerns on 3rd Embodiment of this invention, and shows a tape in cross section.

- FIG. 1 It is a schematic cross-sectional schematic diagram which shows the state by which the left side front stop part of the slide fastener which concerns on 3rd Embodiment of this invention was press-fit in the fastener slider.

- FIG. 1 It is a schematic schematic diagram of the upper end part of the slide fastener which concerns on 4th Embodiment of this invention, and shows the state after pressing-in a front stop part in a fastener slider,

- a left front stop part is a connection pillar and The right front stop portion is deformed along with the press-fitting between the connecting column and the right lower flange portion.

- FIG. 1 It is a schematic cross-sectional schematic diagram which shows the state by which the right front stop part of the slide fastener which concerns on 4th Embodiment of this invention was press-fit in the fastener slider, and shows the cross section which follows the dotted line SL23 of FIG.

- the “front-rear direction” described in this application is, in principle, grasped based on the moving direction of the front and rear fastener sliders.

- the “front-rear direction” corresponds to the up-down direction when FIG. 1 is viewed from the front, and it can be seen that the fastener slider can move in the same direction.

- the “front-rear direction” can be additionally defined in various ways.

- the front-rear direction coincides with the extending direction of the opposite side edge of the fastener tape, coincides with the extending direction of the core string, coincides with the arrangement direction of the fastener elements, and coincides with the longitudinal direction of the fastener element row.

- the “left-right direction” basically corresponds to the left-right direction when FIG.

- “Left-right direction” corresponds to the side-by-side direction of a set of fastener tapes, matches the side-by-side direction of each fastener element of a set of fastener tapes, and is for inserting fastener elements on both sides of the connecting pillars of the fastener slider. This coincides with the horizontal direction of the openings.

- the “vertical direction” is a direction orthogonal to the “front / rear direction” and the “left / right direction”, and the upper and lower wing plates of the fastener slider and the upper and lower surfaces of various parts are named based on this. .

- “Thickness direction” corresponds to “vertical direction”.

- the “thickness direction” is typically a direction perpendicular to the upper and lower surfaces of the front stop and the fastener element, and coincides with the upper and lower arrangement directions of the upper and lower wing plates of the fastener slider.

- FIG. 1 is a schematic front view of a slide fastener, and shows a state before press-fitting of a front stop portion into a fastener slider.

- FIG. 2 is a schematic explanatory view showing the structure of the fastener slider of the slide fastener.

- the fastener slider is positioned on the plane parallel to the upper blade plate and the lower blade plate at the center of the fastener slider in the thickness direction.

- the plane structure by the side of the lower wing board when it divides into two up and down is shown.

- FIG. 3 is a schematic side view and top view of a fastener element of a slide fastener, showing the left fastener element as an example.

- FIG. 1 is a schematic front view of a slide fastener, and shows a state before press-fitting of a front stop portion into a fastener slider.

- FIG. 2 is a schematic explanatory view showing the structure of the fastener slider of the slide fastener.

- the fastener slider is

- FIG. 4 is a schematic perspective view of a left front stop portion of the slide fastener.

- FIG. 5 is a schematic top view of the left front stop portion of the slide fastener.

- FIG. 6 is a schematic side view of the left front stop portion of the slide fastener.

- FIG. 7 is a schematic side view of the left front stop portion of the slide fastener, and is a view of the left front stop portion seen from the dotted line DL70m in FIG.

- FIG. 8 is a schematic perspective view of the right front stop portion of the slide fastener.

- FIG. 9 is a schematic top view of the right front stop portion of the slide fastener.

- FIG. 10 is a schematic side view of the right front stop portion of the slide fastener.

- FIG. 11 is a schematic side view of the right front stop portion of the slide fastener, which is a view of the side of the right front stop portion in the direction of the arrow from the dotted line DL70n of FIG.

- FIG. 12 is a schematic diagram of the upper end portion of the slide fastener. Before the front stop portion is press-fitted between the connection column and the flange portion, the front stop portion is sandwiched between the connection column and the flange portion. Indicates an unlocked state.

- FIG. 13 is a schematic diagram of the upper end portion of the slide fastener, and shows a locked state after the front stop portion is press-fitted between the connecting column and the flange portion.

- FIG. 14 is a schematic cross-sectional schematic view showing a state after the left front stop portion of the slide fastener is press-fitted into the fastener slider, and shows a cross-sectional configuration taken along the dotted line SL70m in FIG.

- FIG. 15 is a schematic cross-sectional schematic view showing a state after the right front stop portion of the slide fastener is press-fitted into the fastener slider, and shows a cross-sectional configuration taken along a dotted line SL70n in FIG.

- FIG. 16 is a schematic diagram showing a state in which the left fastener element of the slide fastener moves in the fastener slider.

- FIG. 17 is a schematic diagram showing a state in which the right fastener element of the slide fastener moves in the fastener slider.

- the slide fastener 100 includes a set of fastener stringers 50.

- the slide fastener 100 includes a left fastener stringer 50m and a right fastener stringer 50n. It should be noted that “first” may be called instead of “left” and “second” may be called instead of “right”, and this is the same for other components.

- Each fastener stringer 50 includes a configuration in which a large number of fastener elements 60 are fixed to a core string 54 on the opposite side edge 52 of the fastener tape 51 by injection molding at regular intervals. Furthermore, each fastener stringer 50 includes a configuration in which a front stopper 70 is provided at the upper end of a fastener element row 68 that is an array of a plurality of fastener elements 60, and the front stopper 70 is formed by injection molding on the core string 54. It is stuck.

- the front stop portion 70 is a resin molding portion molded by a molding method typified by injection molding, and is typically configured in a block shape, and this also applies to the fastener element 60. .

- the fastener element 60 is not limited to an individual block-shaped resin molded portion of injection molding, and may be a coil element. In the case of a coil element, it will be sewn along the opposing side edge 52 of the fastener tape 51 with a sewing thread.

- the left-side fastener stringer 50m is long in the “front-rear direction” coinciding with the vertical direction of the front view of FIG. 1 and includes left-side fastener tape 51m having a predetermined width on the left and right.

- the left fastener tape 51m is a flexible base material that includes an upper surface 151f and a lower surface 151r as a set of main surfaces 151.

- the left fastener tape 51m is formed by weaving or knitting synthetic resin yarn, but is not necessarily limited to this, and in some cases, a resin layer for ensuring waterproofness is applied to the upper surface.

- the left side fastener element 60m is fixed to the opposite side edge 52m of the left side fastener tape 51m by injection molding at regular intervals.

- the left side core of the left side fastener tape 51m is enormous in the sectional view of the opposite side edge 52m.

- the left fastener element 60m is fixed to the string 54m.

- the left core string 54m is not an essential component, but by providing the left core string 54m, sufficient attachment strength of the left fastener element 60m to the left fastener tape 51m can be secured.

- a left front stop 70m is provided adjacent to the front end of the fastener element row 68m in which the left fastener elements 60m are arranged at regular intervals in the front-rear direction.

- the left front stop 70m is fixed to the left core 54m by injection molding.

- a butterfly stick 101m which is a component of the back stop 101, is provided, and the butterfly stick 101m is fixed to the left core string 54m by injection molding.

- the left front stop 70m is made of resin instead of metal and has a certain degree of elasticity. Thereby, the operation described later with reference to FIGS. 12 and 13 can be suitably secured.

- the left fastener stringer 50m applies to the right fastener stringer 50n in the same manner.

- the left fastener tape 51m is read as the right fastener tape 51n

- the left fastener element 60m is read as the right fastener element 60n

- the opposite side edge 52m is read as the opposite side edge 52n

- the left core cord 54m is read as the right core cord 54n.

- the left fastener element row 68m is read as the right fastener element row 68n

- the left front stop portion 70m is read as the right front stop portion 70n

- the butterfly stick 101m is read as the box rod 101n1.

- the code indicating the left element includes “m”

- the code indicating the right element includes “n”.

- the opposing side edge 52m of the left fastener tape 51m becomes the opposing side edge 52n of the right fastener tape 51n.

- the side edge facing the other fastener tape 51 is referred to as “opposing side edge”.

- the opposing side edge is not necessarily a side edge along the longitudinal direction of the fastener tape, and may be a side edge along the short side direction of the fastener tape.

- the right side fastener stringer 50n is provided with a box part 101n2 connected to a box bar 101n1. It is well understood by those skilled in the art that the rear stop portion 101 is configured by the box rod 101n1, the box portion 101n2, and the above-mentioned butterfly rod 101m, and detailed description thereof will be omitted. Note that the back stop portion 101 may be of a type in which the set of fastener stringers 50 is “unopenable / closable” at the lower end position. The back stop portion 101 is not limited to resin and may be made of metal.

- the fastener slider 80 is attached to the right fastener stringer 50n in this example.

- the fastener slider 80 is positioned at the rear end of the right fastener element row 68n, the butterfly stick 101m of the left fastener stringer 50m is inserted into the continuous space between the fastener slider 80 and the box portion 101n2, and the fastener slider 80 is slid forward. Thereby, the left and right fastener stringers 50 separated from each other can be united, that is, the slide fastener 100 can be closed.

- the specific configuration of the fastener slider 80 is arbitrary.

- the configuration of the fastener slider 80 can be understood from, for example, the disclosure of FIGS. 1, 2, 14, and 15.

- the fastener slider 80 according to this example is a “free slider” that does not have a claw portion that can be locked to the fastener element. By employing the free slider, the fastener slider 80 can be more freely moved, and the operation described later with reference to FIGS. 12 and 13 can be preferably ensured. Needless to say, the fastener slider 80 may have a claw portion.

- the fastener slider 80 is inserted through the left fastener element row 68m including the left fastener element 60m and the right fastener element row 68n including the right fastener element 60n, and the left fastener element row by the sliding movement of the fastener slider 80 in the front-rear direction.

- the left fastener element 60m and the right fastener element 60n are engaged and disengaged between 68m and the right fastener element row 68n.

- the fastener slider 80 has an upper wing plate 81, a lower wing plate 82 that faces and is parallel to the upper wing plate 81, an upper wing plate 81, and a lower wing plate.

- the right upper flange portion 85n1 connected to the right edge, the right lower flange portion 85n2 connected to the right edge of the lower blade 82, the pull attachment portion 88 provided on the upper surface of the upper blade 81, and the pull attachment portion 88 are attached.

- the left upper flange portion 85m1 and the left lower flange portion 85m2 are collectively referred to as “left flange portion 85m”, and the right upper flange portion 85n1 and right lower flange portion 85n2 are collectively referred to as “right flange portion 85n”.

- the left flange portion 85m and the right flange portion 85n are collectively referred to as a “flange portion 85”.

- the fastener slider 80 has a front end 80F and a rear end 80R according to the moving direction. Assuming that the fastener slider 80 is moved upward as described with reference to FIG. 1, the front end 80 ⁇ / b> F of the fastener slider 80 is on the side where the left and right fastener elements 60 in the unengaged state enter the fastener slider 80. is there.

- the rear side 80F of the fastener slider 80 is the side from which the left and right fastener elements 60 that have passed through the fastener slider 80 and are engaged are brought out.

- the rear end 80R of the fastener slider 80 is the side where the engaged right and left fastener elements 60 enter the fastener slider 80.

- the front end 80 ⁇ / b> F of the fastener slider 80 is a side from which the left and right fastener elements 60 that have passed through the fastener slider 80 and have become unengaged come out.

- the upper wing plate 81 and the lower wing plate 82 may be flat plate portions arranged to face each other. As can be understood from FIG. 2, the upper blade 81 and the lower blade 82 may define the element passage 84 of the fastener element 60 from the thickness direction of the fastener element 60. As shown in FIG. 2, a left lower flange portion 85 m 2 is provided on the left edge of the lower wing plate 82, and a right lower flange portion 85 n 2 is provided on the right edge of the lower wing plate 82. Although not shown directly, as is apparent from the additional consideration of FIGS.

- a left upper flange portion 85 m 1 is provided on the left side edge of the upper wing plate 81, and the right side edge of the upper wing plate 81 is on the right side.

- An upper flange portion 85n1 is provided.

- the element passage 84 of the fastener element 60 is closed from the left by the left lower flange portion 85m2 and the left upper flange portion 85m1, and the element passage 84 of the fastener element 60 is closed from the right by the right lower flange portion 85n2 and the right upper flange portion 85n1. It is done.

- the connecting pillar 83 is provided on the front end 80F side of the fastener slider 80, whereby a left opening OP10m for the left fastener element 60m and a right opening OP10n for the right fastener element 60n are formed between the upper blade 81 and the lower blade 82. Between.

- the connecting pillar 83 separates the element passage 84m of the left fastener element 60m from the element passage 84n of the right fastener element 60n on the front end 80F side of the fastener slider 80.

- the connecting column 83 includes a front column portion 83p having a constant width W83 on the front end 80F side of the fastener slider 80, and a rear column portion 83q that gradually decreases in width from the left and right sides from the front end 80F side to the rear end 80R side of the fastener slider 80.

- the connecting column 83 has a predetermined length between the upper wing plate 81 and the lower wing plate 82, has a predetermined front-rear length in the front-rear direction corresponding to the moving direction of the fastener slider 80, and the left flange portion. It has a left-right width along the horizontal arrangement direction of 85 m and the right flange portion 85 n.

- the left side surface 83m and the right side surface 83n of the rear side column portion 83q of the connecting column 83 extend so as to be close to each other from the front end 80F side to the rear end 80R side of the fastener slider 80, Then match.

- the left side surface 83m and the right side surface 83n are connected to each other on the front end 83F side of the connecting column 83 via an arcuate front end surface, and the left side surface 83m and the right side surface 83n of the connecting column 83 are connected to the connecting column 83. It is connected via an arcuate rear end surface on the rear end 83R side.

- the passage width W84m of the left fastener element passage 84m is defined by the inner side surface 89m of the left lower flange portion 85m2 and the connecting column 83, and finally the left side surface 83m of the rear column portion 83q.

- the passage width W84m of the left fastener element passage 84m is defined by the inner side surface 89m of the left upper flange portion 85m1 and the connecting column 83, and finally the left side surface 83m of the rear column portion 83q.

- the passage width W84n of the right fastener element passage 84n is defined by the inner side surface 89n of the right lower flange portion 85n2 and the connecting column 83, and finally the right side surface 83n of the rear column portion 83q.

- the passage width W84n of the right fastener element passage 84n is defined by the inner side surface 89m of the right upper flange portion 85n1 and the connecting column 83, and finally the right side surface 83n of the rear column portion 83q.

- the inner side surface 89m and the inner side surface 89n may be collectively referred to as an inner side surface 89.

- the fastener slider 80 has a mirror image symmetry relationship with respect to a plane in which the configuration on the upper wing plate 81 side and the configuration on the lower wing plate 82 side intersect perpendicularly to the connecting column 83. Accordingly, the passage width W84m of the fastener element passage 84m between the connection column 83 and the left lower flange portion 85m2 and the passage width W84m of the fastener element passage 84m between the connection column 83 and the left upper flange portion 85m1 are equal or change equally. It can be said that. Further, the passage widths W84m and W84n are equal, and these may be collectively referred to as “passage width W84”.

- the interval between the left flange portion 85m and the right flange portion 85n gradually decreases from the front end 80F side to the rear end 80R side of the fastener slider 80, and then converges to a certain width.

- the interval between the left flange portion 85m and the right flange portion 85n has a maximum interval W80F on the front end 80F side of the fastener slider 80 and a minimum interval W80R on the rear end 80R side of the fastener slider 80.

- the left flange portion 85m extends along the front-rear direction that coincides with the moving direction of the fastener slider 80 and the direction that coincides with the up-down direction described with reference to FIG. 1, and the left flange front end on the front end 80F side of the fastener slider 80 85m5 and a left flange rear end 85m6 on the rear end 80R side of the fastener slider 80.

- the right flange portion 85n extends along the front-rear direction that coincides with the moving direction of the fastener slider 80 and the direction that coincides with the up-down direction described with reference to FIG. 1, and the right flange front end 85n5 and the right flange rear end 85n6.

- the passage width W84m between the left flange front end 85m5 and the connecting pillar 83 is wider than the passage width W84m shown in FIG.

- the left side surface 83m of the front column portion 83p is parallel to the moving direction of the fastener slider 80 corresponding to the vertical direction when FIG. 2 is viewed from the front, and the left side surface of the rear column portion 83q configured as an inclined surface. This is because it is not flush with 83m. The same applies to the distance between the right flange front end 85n5 and the connecting column 83.

- the left flange front end 85m5 and the right flange front end 85n5 are positioned on an axis Lx85 orthogonal to the front-rear direction that coincides with the moving direction of the fastener slider 80 and parallel to the upper blade 81 and the lower blade 82.

- the rear end 83 ⁇ / b> R of the connecting column 83 is positioned on an axis Lx ⁇ b> 83 that is orthogonal to the front-rear direction that coincides with the moving direction of the fastener slider 80 and that is parallel to the upper blade 81 and the lower blade 82.

- a space D10 is provided between the axis Lx83 and the axis Lx85.

- the specific configuration of the fastener element 60 is arbitrary. For illustrative purposes, the configuration of the fastener element 60 will be described with particular attention to the left fastener element 60m with reference to FIG.

- the right-side fastener element 60n is configured to be mirror-image symmetrical with the left-side fastener element 60m, and redundant description thereof is omitted.

- FIG. 3 shows a side view configuration of the fastener element 60 in the upper part and FIG. 3 shows a top view configuration of the fastener element 60 in the lower part.

- the fastener element 60 has a body portion 61 fixed to the core string 54 of the fastener tape 51, and a head portion 62 connected to the body portion 61 via a narrow neck portion 63 in the front-rear direction.

- a concave portion R61 is formed at the center of the head portion 61 in the thickness direction

- a pair of convex portions 64 is formed at the center of the body portion 61 in the thickness direction so as to sandwich the head portion 62. Is done.

- the convex portion 64 of the left fastener element 60 is received in the concave portion R61 of the right fastener element 60, and this continuously occurs according to the engagement of the left and right fastener elements 60.

- the meshing of the left and right fastener elements 60 is effectively suppressed from becoming non-meshing by an external force in the thickness (front and back) direction of FIG.

- the left front stop 70m has an exemplary configuration shown in FIGS. 6A is a side view of the inner front surface 71c2 of the left front stop 70m as viewed from the front, and FIG. 6B is a side view of the outer front surface 71c1 of the left front stop 70m as viewed from the front. is there.

- the “inner side surface” here is a side surface that should face the connecting column 83

- the “outer side surface” is a side surface that should face the flange portion 85.

- the left front stop 70m has a flat upper surface 71a, a flat lower surface 71b, and a side surface 71c connecting the outer periphery of the upper surface 71a and the outer periphery of the lower surface 71b.

- the upper surface 71 a is a surface that should face the upper blade 81 of the fastener slider 80.

- the lower surface 71 b is a surface that should face the lower blade 82 of the fastener slider 80.

- the side surface 71 c includes an outer side surface 71 c 1 that should face the left flange portion 85 m of the fastener slider 80 and an inner side surface 71 c 2 that should face the connecting column 83.

- a recess R70 extending in the thickness direction of the left front stop 70m is formed on the inner side surface 71c2 of the left front stop 70m. Accordingly, dust due to wear or the like of the left front stop 70 that may be generated when the left front stop 70 is press-fitted between the connecting column 83 and the left flange 85m is received by the recess R70 and immediately to the outside of the fastener slider 80. Release can be suppressed.

- the left front stop 70m is located on the left front side 72p1 on the "front side” that matches the upper side when viewed from the front of the recess R70, and matches the lower side when viewed from the front of the recess R70 in FIG.

- the lateral width W72p of the left front side portion 72p1 shown in FIG. 5 is equal to the lateral width W72q of the left rear side portion 72q1 shown in FIG.

- a pair of convex surfaces convex toward the connecting column 83 is formed on the inner side surface 71c2 of the left front stop portion 70m so as to correspond to the left front side portion 72p1 and the left rear side portion 72q1.

- the left front stop 70 is preferably a resin molded part manufactured by a molding technique such as injection molding of a resin material, and is fixed to the opposite side edge 52m of the left fastener tape 51m.

- a gate mark M70 is formed on the bottom surface of the recess R70 as exemplarily shown in FIG. Since the gate mark M70 is formed in the depression R70, it is possible to effectively suppress burrs or the like that may occur in the gate mark M70 from coming into contact with the connecting pillar 83. It is particularly advantageous in the present embodiment that the front stopper 70 is made of resin and has a certain degree of elasticity.

- a parting line L10 is formed on the side surface 71c of the left front stop portion 70m over the entire circumference of the side surface 71c.

- the parting line L10 is located at the center in the thickness direction of the left front stop 70m.

- the side surface 71c is configured to be inclined from the upper surface 71a side or the lower surface 71b side toward the parting line L10.

- the inner side surface 71c2 of the left front stop 70 is an inclined surface that inclines from the upper surface 71a and the lower surface 71b to the mold dividing line L10, in other words, toward the connecting column 83 side. 74j and 74k are formed.

- the area where the left front stopper 70m contacts the connecting column 83 can be appropriately reduced.

- the area where the inner side surface 71c2 of the left front stopper 70 contacts the connecting column 83 may be reduced.

- the inner side surface 71c2 of the left front stop portion 70m is provided with an inner side contact portion P1 that should come into contact with the connecting column 83. It is provided at the position of the aforementioned parting line L10.

- the outer side surface 71c1 of the left front stop portion 70m is provided with an outer upper contact portion P2 that should contact the left upper flange portion 85m1, and further, an outer lower contact portion P2 that should contact the left lower flange portion 85m2. It is done.

- the outer upper abutting portion and the outer lower abutting portion are denoted by a common reference symbol P2, and are collectively referred to simply as an outer abutting portion.

- FIG. 7 the positions of the inner contact portion P ⁇ b> 1 and the outer contact portion P ⁇ b> 2 are exemplarily shown by circles. It can vary depending on.

- the circles in FIG. 7 showing the positions of the inner contact portion P1 and the outer contact portion P2 are shown for convenience in order to facilitate the understanding of the reader. This also applies to FIG. 11, FIG. 14 to FIG. 18, FIG. 21, and FIG.

- the right front stop 70n has an exemplary configuration shown in FIGS.

- FIG. 10A is a side view of the inner front surface 71c2 of the right front stop 70n as viewed from the front

- FIG. 10B is a side view of the outer front surface 71c1 of the right front stop 70n as viewed from the front. is there.

- the right front stop portion 70n has an upper surface 71a, a lower surface 71b, and a side surface 71c, and the side surface 71c includes an outer side surface 71c1 and an inner side surface 71c2, similarly to the left front stop portion 70m. Further, similarly, the right front stop portion 70n includes a right front side portion 72p2, a right rear side portion 72q2, and a right intermediate portion 72r2, similarly to the left front stop portion 70m.

- the right front stop portion 70n includes a configuration in which a claw portion 79 is provided on a main body portion 72k including a right front side portion 72p2, a right rear side portion 72q2, and a right intermediate portion 72r2.

- the claw portion 79 is a portion that should come into contact with the right flange portion 85n, and is provided in a convex shape on the outer surface 71c1 of the right front side portion 72p2 of the right front stop portion 70n.

- the amount by which the claw portion 79 protrudes from the outer side surface 71c1 of the right front stop portion 70n is arbitrary.

- the inner side surface 71c2 of the right front stop portion 70n is provided with an inner side contact portion P1 that should come into contact with the connecting column 83. It is provided at the position of the parting line L10.

- the outer side surface 71c1 of the right front stop 70n is provided with an outer upper abutting portion P2 to be in contact with the right upper flange portion 85n1, and further provided with an outer lower abutting portion P2 to be in contact with the right lower flange portion 85n2. It is done.

- the outer upper abutting portion and the outer lower abutting portion are denoted by a common reference symbol P2, and are collectively referred to simply as an outer abutting portion.

- FIG. 12 shows an unlocked state before the right front stop 70 n is sandwiched between the connecting column 83 and the flange portion 85 but before being press-fitted between the connecting column 83 and the flange portion 85.

- FIG. 13 shows a locked state after each front stopper 70 is press-fitted between the connecting column 83 and the flange 85.

- the fastener slider 80 has the front stop portion 70 sandwiched between the connection column 83 and the flange portion 85, and the front stop portion 70 is connected to the connection column 83.

- the locked state in which the front locking part 70 is press-fitted between the connecting column 83 and the flange part 85 can be taken.

- the free slider cannot take such a change of state, and is simply detached from the fastener stringer by the front stop. Is only suppressed.

- the interval W p1-p2 between the inner abutting portion P1 and the outer abutting portion P2 of the front stop portion 70 is set to the outer side of the inner portion Q1 of the fastener element 60. It is preferable to make it larger than the interval Wq1-q2 between the portions Q2.

- the left front stop 70m is also “press-fitted” between the connecting column 83 and the left flange 85m, and the flange 85 collides with the claw 79 or Contact.

- the first force is applied between the connecting column 83 and the flange portion 85. It is possible to push the front stop 70 with a large second force, that is, to “press-fit”, and to enter the “locked state”. A position where the flange portion 85 does not collide with the claw portion 79 may be set to the “locked state”. When the “locked state” is set to the “unlocked state”, the fastener slider 80 moves away from the claw portion 79.

- the left rear side portion 72q1 of the left front stop portion 70m is sandwiched and compressed between the left lower flange portion 85m2 and the rear column portion 83q of the connecting column 83. , Have been transformed between the two. Similarly, the left rear side portion 72q1 of the left front stop portion 70m is sandwiched and compressed between the left upper flange portion 85m1 and the rear column portion 83q of the connecting column 83, and is deformed between the two. Yes.

- the right rear side portion 72q2 of the right front stop portion 70n is sandwiched and pressed between the right flange portion 85 and the rear column portion 83q of the connecting column 83, and is deformed between the two.

- the right front stop 70n is inserted from the rear end 83R of the connecting column 83 toward the rear end 80R of the fastener slider 80 so as to be larger than the left front stop 70m.

- the right front side portion 72p2 of the right front stop portion 70n is sandwiched and pressed between the right flange portion 85n and the rear column portion 83q of the connecting column 83, and is slightly deformed between the two.

- the left front side portion 72p1 of the left front stop portion 70m is not sandwiched between the right flange portion 85n and the rear side column portion 83q of the connecting column 83, and is arranged adjacent to the front side column portion 83p of the connecting column 83. Is done.

- the above-mentioned inner contact portion P1 in other words, the portion where the parting line L10 of the inner side surface 71c2 of the left front stop portion 70m is located is connected.

- the left side surface 83m of the column 83 abuts on the left side surface 83m and is pressed outward by the left side surface 83m of the connecting column 83 when viewed from the front in FIG.

- the above-described outer contact portion P2 is in contact with the inner side surface 89m of the left flange portion 85m and is pressed inward on the right side when viewed in front from FIG. 14 by the inner side surface 89m of the left flange portion 85m.

- the plane PL86 including the lower end surface 86 of the left upper flange portion 85m1 and the upper end surface of the left lower flange portion 85m2 A plane PL87 including 87 is set.

- the left front stop 70m is divided into three parts by the plane PL86 and the plane PL87, it can be divided into an upper part 75m1, a lower part 75m2, and an intermediate part 76m.

- the upper part 75m1 is a part on the upper blade 81 side

- the lower part 75m2 is a part on the lower blade 82 side

- the intermediate part 76m is a part between the upper part 75m1 and the lower part 75m2.

- the inner contact portion P1 is provided in the intermediate portion 76m.

- the outer contact part P2 is provided in the upper part 75m1 and the lower part 75m2.

- the inner contact part P1 may be additionally or alternatively provided on at least one of the upper part 75m1 and the lower part 75m2.

- the outer contact portion P2 may be provided only on one of the upper portion 75m1 and the lower portion 75m2.

- the left front stop 70m with reference to FIG. 14 on the condition that the symbols are appropriately read applies similarly to the right front stop 70n shown in FIG.

- the left flange portion 85m is replaced with the right flange portion 85n

- the left side surface 83m of the connecting column 83 is replaced with the right side surface 83n of the connecting column 83

- the upper portion 75m1 is replaced with the upper portion 75n1

- the lower portion 75m2 is replaced with the lower portion 75n2.

- the intermediate part 76m is replaced by the intermediate part 76n.

- the left fastener element 60m when the left fastener element 60m is disposed between the connecting column 83 and the left flange portion 85m, the left fastener element 60m is not press-fitted between the two. It can be slightly displaced left and right between the flange portions 85m. As shown in FIG. 17, the right side fastener element 60n can be similarly described.

- a portion that can contact the left side surface 83m of the connecting column 83 is an inner portion Q1

- a portion that can contact the inner side surface 89m of the left flange portion 85m is an outer portion Q2.

- a portion that can contact the right side surface 83n of the connecting column 83 is referred to as an inner portion Q1

- a portion that can contact the inner side surface 89n of the right flange portion 85n is referred to as an outer portion Q2.

- the inner portion Q1 is a surface facing the connecting column 83 of the fastener element 60.

- the outer portion Q ⁇ b> 2 is a surface facing the flange portion 85 of the fastener element 60.

- FIG. 7 FIG. 11, FIG. 16, and FIG. 17, the size relationship between the left and right front stop portions 70 and the left and right fastener elements 60 will be described.

- the left and right front stop portions 70 are in a state before being press-fitted between the connecting column 83 and the flange portion 85, and FIGS. 7 and 11 show this state.

- a plane PL1 corresponding to the inner contact portion P1, a plane PL2 corresponding to the outer contact portion P2, and a plane PL3 corresponding to the outermost portion of the outer surface 71c1 are set.

- the inner side contact part P1 is equal to the part located in the outermost side, ie, the connection pillar 83 side, among the inner surface 71c2.

- the planes PL1 to PL3 are orthogonal to the main surface 151 of the fastener tape 51 and are parallel to the opposite side edge 52 of the fastener tape 51.

- the plane PL1 includes an inner contact portion P1 in the plane.

- the plane PL2 includes an outer contact portion P2 in the plane.

- the plane PL3 includes a portion located on the outermost side of the outer surface 71c1 in the plane.

- W70m> Wp1 -p2 is satisfied.

- the thickness of the left front stop portion 70m H70m, and satisfies W70m> H70m.

- the inner contact portion P1 and the outer contact portion P2 may be in different positions in the front-rear direction (depth direction perpendicular to the paper surface of FIG. 7). This also applies to FIG. 11, FIG. 16, and FIG.

- a plane PL1 corresponding to the inner contact portion P1 As shown in FIG. 11, a plane PL1 corresponding to the inner contact portion P1, a plane PL2 corresponding to the outer contact portion P2, and a plane PL3 corresponding to the outermost portion of the outer surface 71c1 of the main body portion 72k.

- the inner contact portion P1 is equal to the innermost portion of the inner side surface 71c2.

- the maximum lateral width W72k of the main body portion 72k of the right front stop 70n is equal to the surface interval between the planes PL1 and PL3.

- the interval between the inner contact portion P1 and the outer contact portion P2 W p1 ⁇ p2 is equal to the surface interval between the planes PL1 and PL2.

- W72k> Wp1 -p2 is satisfied.

- the thickness of the main body 72k of the left front stop 70m is H72k, and satisfies W72k> H72k.

- the thickness of the claw portion 79 is H79, and H72k ⁇ H79 is satisfied, whereby the strength of the claw portion 79 can be increased.

- a plane QL1 corresponding to the inner part Q1 and a plane QL2 corresponding to the outer part Q2 are set.

- the planes QL1 and QL2 are planes orthogonal to the fastener tape 51 and extending along the opposite side edge 52 of the fastener tape 51.

- the plane QL1 includes an inner portion Q1 in the plane, and the plane QL2 includes an outer portion Q2 in the plane.

- the maximum lateral width W65m of the left fastener element 60m is equal to the surface interval between the plane QL1 and the plane QL2.

- the distance between the inner part Q1 and the outer part Q2 W q1-q2 is equal to the distance between the planes QL1 and QL2.

- W65m Wq1 -q2 .

- a plane QL1 corresponding to the inner part Q1 and a plane QL2 corresponding to the outer part Q2 are set.

- the planes QL1 and QL2 are planes orthogonal to the fastener tape 51 and extending along the opposite side edge 52 of the fastener tape 51.

- the maximum width of the right fastener element 60n W65n is equal to the space between the planes QL1 and QL2.

- the distance between the inner part Q1 and the outer part Q2 W q1-q2 is equal to the distance between the planes QL1 and QL2.

- W65n Wq1 -q2 .

- the interval Wp1-p2 is between the inner part Q1 of the left fastener element 60m that can contact the left side surface 83m of the connecting column 83 and the outer part Q2 of the left fastener element 60m that can contact the inner side surface 89m of the left flange part 85m. Is larger than the interval Wq1-q2 .

- the front right side that abuts the inner abutment portion P1 of the right front stop portion 70n that abuts the right side surface 83n of the connecting column 83 and the inner side surface 89n of the right flange portion 85n can contact the inner portion Q1 of the right fastener element 60n that can contact the right side surface 83n of the connecting column 83 and the inner side surface 89n of the right flange portion 85n. It is larger than the interval W q1-q2 between the outer portions Q2 of the right fastener element 60n.

- the interval W q1-q2 ⁇ W84 is satisfied, and the interval W p1-p2 > W84 is satisfied.

- Patent Document 1 When a part of the element is melted together with the sewing thread as in Patent Document 1, it is practically difficult to finely adjust the melt width, and the effect cannot be exhibited as in the present application. Furthermore, in the case of Patent Document 1, it is necessary to add a V-shaped reinforcing piece P, which may lead to a complicated configuration and a reduction in manufacturing efficiency.

- the left side fastener tape 51m is pulled in the direction of the arrow LD51m.

- the right side fastener tape 51n is pulled in the direction of the arrow RD51n. Falls downward, and the slide fastener 100 can be opened.

- the pressure received by the front stop 70 between the connecting column 83 and the flange 85 by appropriately increasing the above-mentioned distance W p1-p2 related to the front stop 70 than the above-mentioned distance W q1-q2 related to the fastener element 60. Can be made appropriate.

- the direction in which the fastener tape 51m or 51n is pulled is not particularly limited, and may be a front-rear direction, a left-right direction, a vertical direction, or any vector determined from the sum of these directions.

- the fastener slider 80 may be lowered downward only by pulling the left fastener tape 51m in the direction of the arrow LD51m.

- the fastener slider 80 may be lowered downward only by pulling the right fastener tape 51n in the direction of the arrow RD51n.

- the directions indicated by the arrows LD51m and RD51n are parallel to the main surface 151 of the fastener tape 51 and orthogonal to the opposing side edge 52 of the fastener tape 51.

- the right front stop portion 70m is press-fitted between the connection column 83 and the right flange portion 85m

- the left front stop portion 70n is press-fitted between the connection column 83 and the left flange portion 85n.

- the pulling force of the fastener slider 80 required for releasing the locked state of the fastener slider 80 at the front stop 70 is preferably 20N or less, more preferably 15N or less, Further, it is preferably 1N or more, and more preferably 2N or more.

- the force test method may be a method defined in a standard such as JIS. It is desirable to test the slide fastener 100 in a state in which the slide fastener 100 is stretched in the vertical direction equal to the longitudinal direction and fixed in position.

- each pulling force in each direction is What is necessary is just a force required in order to satisfy the conditions of the force which pulls the fastener slider 80 required in order to escape from a state.

- the position of the rear end 83R of the connecting column 83 is located closer to the rear end 80R of the fastener slider 80 than the position of the flange front end 85m5 of the flange portion 85.

- FIG. 18 is a schematic cross-sectional schematic view of the left front stop portion of the slide fastener.

- FIG. 19 is a schematic cross-sectional view showing a state in which the left front stop portion of the slide fastener is press-fitted into the fastener slider.

- a ridge portion 78m is provided on the inner side surface 71c2 of the front stop portion 70. Even in such a case, the same effect as that of the above-described embodiment can be obtained.

- the ridge portion 78m may be provided in one or both of the upper portion 75m1 and the lower portion 75m2 instead of the intermediate portion 76m.

- a ridge portion 78m is provided on the inner side surface 71c2 of the left front stop 70m at the center of the thickness of the left front stop 70m.

- the ridge portion 78 m is a portion that abuts on the connecting column 83.

- a similar ridge 78n may be provided on the inner side surface 71c2 of the right front stop 70n.

- FIG. 20 is a schematic side view of the left front stop and the right front stop of the slide fastener, showing the tape in cross-section.

- FIG. 21 is a schematic cross-sectional view showing a state in which the left front stop portion of the slide fastener is press-fitted into the fastener slider.

- the left front stop portion 70m and the right front stop portion 70n are configured to overlap each other when they are lined up side by side. Even in such a case, the same effect as that of the above-described embodiment can be obtained.

- existing manufacturing equipment can be used effectively regardless of an increase in the total width when the left and right front stop portions 70 are lined up side by side.

- the total width when the right front stop portion 70m and the left front stop portion 70n are arranged side by side is large, and it is necessary to adjust the width of the alignment jig, etc. In the case of this embodiment, the necessity is reduced at least.

- a stepped portion R14m is provided in the inner portion of the left front stop portion 70m, and a stepped portion R14n is provided in the inner portion of the right front stop portion 70n.

- the step portion R14m is a portion that should face the upper wing plate 81 and the connecting column 83 of the fastener slider 80.

- the step portion R14n is a portion that should face the lower wing plate 81 and the connecting column 83 of the fastener slider 80.

- the horizontal plane S14n1 of the step R14n is arranged on the horizontal plane S14m1 of the step R14m, and the total when the right front stop 70m and the left front stop 70n are arranged side by side. The width is reduced.

- FIG. 22 is a schematic diagram of the front end portion of the slide fastener, showing a state after the front stop portion is press-fitted into the fastener slider, where the left front stop portion is connected to the connecting column and the left lower flange portion. The right front stop portion is deformed along with the press-fitting between the connecting column and the right lower flange portion.

- FIG. 23 is a schematic cross-sectional view showing a state in which the right front stop portion of the slide fastener is press-fitted into the fastener slider, and shows a cross section taken along the dotted line SL23 of FIG.

- the front stopper 70 has a fin portion 107 that can be disposed between the lower flange portion and the upper flange portion. Even in such a case, the same effect as that of the above-described embodiment can be obtained. By adding the fin portion 107, the front stopper 70 can be more firmly fixed to the fastener tape 51.

- the right front stop 70n includes a right fin portion 107n that can be disposed between the right lower flange portion 85n2 and the right upper flange portion 85n1.

- the left front stop portion 70m has a left fin portion 107m that can be disposed between the left lower flange portion 85m2 and the left upper flange portion 85m1.

- the fin portion 107 is sufficiently thinner than the front stop portion 70 and can be disposed in the gap between the upper flange portion and the lower flange portion.

- the left fastener element 60m has a left fin portion 108m that can be disposed between the left lower flange portion 85m2 and the left upper flange portion 85m1.

- the right fastener element 60n has a right fin portion 108n that can be disposed between the right lower flange portion 85n2 and the right upper flange portion 85n1.

- the fin portion 108 is sufficiently thinner than the fastener element 60 and can be disposed in the gap between the upper flange portion and the lower flange portion.

- the fastener slider (80) is slid to the front side which is the front stop portion (70) side by a first force, and the front stop portion (70) is partially inserted into the fastener slider (80), The fastener slider (80) is moved to the front side by a second force larger than the first force, and at least between the connecting column (83) and the flange portion (85) of the fastener slider (80).

- the use method of a slide fastener which press-fits one said front stop part (70).

- Release of the locked state of the fastener slider is not achieved only by directly displacing the fastener tape.

- the fastener tape may be displaced by pulling the garment on which the fastener tape is sewn, thereby releasing the locked state of the fastener slider.

- the fastener slider may be of a claw type.

Landscapes

- Slide Fasteners (AREA)

Abstract

A slide fastener (100) is configured so that a fastener slider (80) can take: an unlocked state in which at least one front stop section (70) is sandwiched between a connection column (83) and a flange section (85) and the at least one front stop section (70) is not press-fitted between the connection column (83) and the flange section (85); and a locked state in which the at least one front stop section (70) is press-fitted between the connection column (83) and the flange section (85). Preferably, when the fastener slider (80) is in the locked state, the displacement of at least one fastener tape (51) occurring near the front stop section (70) can release the fastener slider (80) from the locked state.

Description

本発明は、スライドファスナー及びその使用方法に関する。

The present invention relates to a slide fastener and a method for using the same.

スライドファスナーの開閉はファスナースライダーの前後移動により制御可能であるが、ヒトの手等による操作以外の外力によりファスナースライダーが下方向に意図せずにスライド移動し、閉状態のスライドファスナーが半開状態になってしまうことが問題になる。

The opening and closing of the slide fastener can be controlled by moving the fastener slider back and forth, but the fastener slider slides unintentionally downward by an external force other than an operation by a human hand, etc., and the slide fastener in the closed state becomes the half-open state. It becomes a problem to become.

特許文献1は、同文献の図2に示すように、エレメントeの一部を縫糸と共に溶融して扁平に形成し、これに(図2に示す如くV字状の)補強片Pを一体的に設けた上止部2を開示する。同文献には、同文献の1ページ目右項21行目に「ファスナー閉鎖後の自然開離を強力かつ確実に防止し得る」ことを目的とする、と記載されている。なお、同文献の2ページ目の左欄の2行目以降には、「第2図図示の如く前記の内壁部7とエレメント案内柱8の側壁部9間にエレメント列Eの上止部2を嵌合し、その上止部2の一側が内壁部7と、また他側がエレメント案内柱8の側壁部9とそれぞれ一体に接触するようになっている」と記載されている。

In Patent Document 1, as shown in FIG. 2 of the same document, a part of an element e is melted together with a sewing thread to form a flat shape, and a reinforcing piece P (V-shaped as shown in FIG. 2) is integrally formed therewith. Disclosed is the top stopper 2 provided in the above. In the same document, it is described that the purpose is to “strongly and reliably prevent natural separation after closing the fastener” on the 21st line on the first page of the same document. In the second column of the left column of the second page of the same document, “the top stop 2 of the element row E is interposed between the inner wall 7 and the side wall 9 of the element guide column 8 as shown in FIG. The one side of the top stopper 2 is integrally in contact with the inner wall 7 and the other side is in contact with the side wall 9 of the element guide column 8 ".

スライドファスナーの用途の一例である登山若しくはロッククライミング用アウタージャケットにおいては、スライドファスナーのファスナースライダーの引手、若しくは引手に取付けられた紐類、若しくは引手取付柱に取付けられた紐類等の「被把持部」をヒトの手で直接的に把持してファスナースライダーを下方向にスライド移動させることが望まれない状況が想定される。例えば、ロッククライマーの片手の自由がなく、他方の片手も大きくは動かせない過酷な状況においては、ファスナースライダーの「被把持部」を動かすことに十分な注意を払うことが容易ではなく、これに費やされる労力が無視できない。

In the outer jacket for mountain climbing or rock climbing, which is an example of the use of the slide fastener, the handle of the fastener slider of the slide fastener, the string attached to the puller, or the string attached to the puller attachment column, etc. It is assumed that it is not desired to grip the part directly with a human hand and slide the fastener slider downward. For example, in a harsh situation where the rock climber does not have the freedom of one hand and the other hand cannot move significantly, it is not easy to pay enough attention to moving the `` gripped part '' of the fastener slider. The effort spent is not negligible.

上述の例示的な説明から明らかなように、本願発明者は、ファスナースライダーの前止部での位置固定とファスナースライダーに対するヒトの手等による直接的な操作を伴わないスライドファスナーの開離性の確保という一見して相反する目的を両立することに十分な意義があることを新たに見出した。

As is clear from the above-described exemplary description, the inventor of the present application is aware of the releasability of the slide fastener that does not involve fixing the position of the fastener slider at the front stop and direct operation of the fastener slider by a human hand or the like. It was newly found that there is a sufficient significance to satisfy the seemingly contradictory purpose of securing.

本発明のある側面に係るスライドファスナーは、一組の主面(151)を有するファスナーテープ(51)の対向側縁(52)にファスナーエレメント(60)が設けられた一組のファスナーストリンガー(50)と、前記一組のファスナーストリンガー(50)の各ファスナーエレメント(60)が挿通されるファスナースライダー(80)であって、上翼板(81)、当該上翼板(81)に対向する下翼板(82)、前記上翼板(81)と前記下翼板(82)を連結する連結柱(83)、及び前記上翼板(81)及び下翼板(82)の少なくとも一方に連結したフランジ部(85)を備え、前記連結柱(83)と前記フランジ部(85)により前記ファスナーエレメント(60)の通路が規定される、ファスナースライダー(80)と、前記一組のファスナーストリンガー(50)に個別に設けられた一組の前止部(70)であって、各前止部(70)が、前記ファスナーテープ(51)の前記対向側縁(52)に一体的に固着する樹脂成形部分である、一組の前止部(70)と、を備えるスライドファスナー(100)であって、前記ファスナースライダー(80)は、少なくとも1つの前記前止部(70)が前記連結柱(83)と前記フランジ部(85)の間で挟まれ、かつ当該少なくとも1つの前止部(70)が前記連結柱(83)と前記フランジ部(85)の間に圧入されていない未ロック状態と、前記少なくとも1つの前止部(70)が前記連結柱(83)と前記フランジ部(85)の間に圧入されたロック状態とを取り得る。

A slide fastener according to an aspect of the present invention includes a set of fastener stringers (50) in which a fastener element (60) is provided on an opposite side edge (52) of a fastener tape (51) having a set of main surfaces (151). ), And a fastener slider (80) through which each fastener element (60) of the set of fastener stringers (50) is inserted, the upper blade plate (81) and the lower blade plate facing the upper blade plate (81). Connected to at least one of a blade plate (82), a connecting column (83) for connecting the upper blade plate (81) and the lower blade plate (82), and the upper blade plate (81) and the lower blade plate (82). A fastener slider (80) comprising a flange portion (85), wherein a passage of the fastener element (60) is defined by the connecting column (83) and the flange portion (85). It is a set of front stoppers (70) provided individually on the set of fastener stringers (50), and each front stopper (70) corresponds to the opposite side edge (52 of the fastener tape (51). And a set of front stoppers (70) that are integrally molded to be fixed to the slide fastener (100), wherein the fastener slider (80) includes at least one of the front stoppers. (70) is sandwiched between the connecting column (83) and the flange portion (85), and the at least one front stop (70) is between the connecting column (83) and the flange portion (85). An unlocked state in which the at least one front stop portion (70) is not press-fitted into the locking state and a locked state in which the at least one front stop portion (70) is press-fitted between the connecting column (83) and the flange portion (85) can be taken.

前記ファスナースライダー(80)が前記ロック状態にあるとき、前記前止部(70)付近での少なくとも一方の前記ファスナーテープ(51)の変位により前記ファスナースライダー(80)の前記ロック状態が解除され前記未ロック状態になる、と良い。

When the fastener slider (80) is in the locked state, the fastener slider (80) is released from the locked state by displacement of at least one of the fastener tapes (51) in the vicinity of the front stop (70). It should be in an unlocked state.

前記少なくとも1つの前止部(70)が、前記連結柱(83)の側面に当接する内側当接部(P1)、及び前記フランジ部(85)の内側面に当接する外側当接部(P2)を含み、少なくとも一方の前記ファスナーストリンガー(50)の前記ファスナーエレメント(60)が、前記連結柱(83)の前記側面に接触可能な内側部分(Q1)、及び前記フランジ部(85)の前記内側面に接触可能な外側部分(Q2)を含み、前記ファスナーテープ(51)の前記主面(151)に直交し、かつ前記ファスナーテープ(51)の前記対向側縁(52)に平行である平面同士の面間隔から規定される前記内側当接部(P1)と前記外側当接部(P2)の間隔(Wp1-p2)が、前記平面同士の面間隔から規定される前記内側部分(Q1)と前記外側部分(Q2)の間隔(Wq1-q2)よりも大きい、と良い。

The at least one front stop (70) has an inner contact portion (P1) that contacts the side surface of the connecting column (83), and an outer contact portion (P2) that contacts the inner surface of the flange portion (85). ), And the fastener element (60) of at least one of the fastener stringers (50) can contact the side surface of the connecting column (83), and the flange portion (85). It includes an outer portion (Q2) that can contact an inner surface, is orthogonal to the main surface (151) of the fastener tape (51), and is parallel to the opposite side edge (52) of the fastener tape (51). A distance (W p1-p2 ) between the inner abutting portion (P1) and the outer abutting portion (P2) defined from the plane spacing between the planes is the inner portion defined by the plane spacing between the planes ( Q1) and the outside It is good that it is larger than the interval (W q1-q2 ) of the part (Q2).

前記フランジ部(85)が第1フランジ部(85m)及び第2フランジ部(85n)を含み、前記一組の前止部(70)が第1前止部(70m)と第2前止部(70n)を含むと良い。

The flange portion (85) includes a first flange portion (85m) and a second flange portion (85n), and the pair of front stop portions (70) is a first front stop portion (70m) and a second front stop portion. (70n) may be included.

前記連結柱(83)と前記第1フランジ部(85m)の間への前記第1前止部(70m)の圧入及び前記連結柱(83)と前記第2フランジ部(85n)の間への前記第2前止部(70n)の圧入により前記ファスナースライダー(80)が位置固定された前記ロック状態において前記前止部(70)付近での前記ファスナーテープ(51)の変位により前記ファスナースライダー(80)の前記ロック状態を解除可能である、と良い。

Press fitting of the first front stop (70m) between the connecting column (83) and the first flange portion (85m) and between the connecting column (83) and the second flange portion (85n). In the locked state in which the position of the fastener slider (80) is fixed by the press-fitting of the second front stop (70n), the fastener slider (51) is displaced by the fastener tape (51) in the vicinity of the front stop (70). 80) It is preferable that the locked state can be released.

前記前止部(70)が射出成形されたものであり、前記内側当接部(P1)は、型割線(L10)が設けられた部分である、と良い。

The front stop portion (70) is injection-molded, and the inner contact portion (P1) is preferably a portion provided with a parting line (L10).

前記連結柱(83)と前記第1フランジ部(85m)の間に前記第1前止部(70m)が圧入され、かつ前記連結柱(83)と前記第2フランジ部(85n)の間に前記第2前止部(70n)が圧入された前記ロック状態において、前記ファスナースライダー(80)が前記ロック状態を脱するために要求される前記ファスナースライダー(80)を引く力が、15N以下である、と良い。

The first front stop (70m) is press-fitted between the connecting column (83) and the first flange portion (85m), and between the connecting column (83) and the second flange portion (85n). In the locked state in which the second front stop (70n) is press-fitted, a force that pulls the fastener slider (80) required for the fastener slider (80) to release the locked state is 15 N or less. There is good.

前記ファスナースライダー(80)の移動方向を前後方向とする場合において、前記連結柱(83)の後端(83R)が、前記第1フランジ部(85m)のフランジ前端(85m5)及び前記第2フランジ部(85n)のフランジ前端(85n5)よりも前記ファスナースライダー(80)の後端(80R)側に位置する、と良い。

When the moving direction of the fastener slider (80) is the front-rear direction, the rear end (83R) of the connecting column (83) is the flange front end (85m5) of the first flange portion (85m) and the second flange. It is good to be located in the rear end (80R) side of the fastener slider (80) from the flange front end (85n5) of the portion (85n).

前記前止部(70)の前記連結柱(83)側の側面には、前記前止部(70)の厚み方向において傾斜する傾斜面(74j、74k)が設けられる、若しくは凸状に突出したリッジ部(78)が設けられる、と良い。

Inclined surfaces (74j, 74k) that are inclined in the thickness direction of the front stop portion (70) are provided on the side surface of the front stop portion (70) on the side of the connecting column (83) or projecting in a convex shape. A ridge portion (78) is preferably provided.

前記第1前止部(70m)及び前記第2前止部(70n)の前記連結柱(83)側の各側面には、当該前止部(70)の厚み中心に向かって前記連結柱(83)側へ傾斜する少なくとも1つの傾斜面(74j、74k)が設けられる、と良い。

On each side surface of the first front stop (70m) and the second front stop (70n) on the side of the connection pillar (83), the connection pillar (70) toward the thickness center of the front stop (70). 83) It is preferable that at least one inclined surface (74j, 74k) inclined to the side is provided.

前記第1前止部(70m)及び前記第2前止部(70n)の前記連結柱(83)側の各側面には、各前止部(70)の厚み方向に延びる凹状の窪み(R70)が設けられる、と良い。

A concave recess (R70) extending in the thickness direction of each front stop (70) on each side surface of the first front stop (70m) and the second front stop (70n) on the side of the connecting column (83). ) Should be provided.

前記凹状の窪み(R70)にはゲート痕(M70)が形成される、と良い。

It is preferable that a gate mark (M70) is formed in the concave depression (R70).

前記第1前止部(70m)及び前記第2前止部(70n)が、横並び時に重なり合い可能に構成されている、と良い。

The first front stop (70m) and the second front stop (70n) may be configured to be able to overlap when lined up side by side.

前記第1前止部(70m)及び前記第2前止部(70n)の一方が、前記スライドファスナー(80)の前記上翼板(81)及び前記連結柱(83)に対面可能な段差部(R14m、R14n)を有し、前記第1前止部(70m)及び前記第2前止部(70n)の他方が、前記スライドファスナー(80)の前記下翼板(82)及び前記連結柱(83)に対面可能な段差部(R14m、R14n)を有する、と良い。

One of the first front stop portion (70m) and the second front stop portion (70n) is a stepped portion that can face the upper wing plate (81) and the connecting column (83) of the slide fastener (80). (R14m, R14n), and the other of the first front stop (70m) and the second front stop (70n) is the lower wing plate (82) of the slide fastener (80) and the connecting column. It is good to have the level | step-difference part (R14m, R14n) which can face (83).

前記第1フランジ部(85m)が、前記下翼板(82)に連結した第1下部フランジ部(85m2)及び前記上翼板(81)に連結した第1上部フランジ部(85m1)を含み、前記第2フランジ部(85n)が、前記下翼板(82)に連結した第2下部フランジ部(85n2)及び前記上翼板(81)に連結した第2上部フランジ部(85n1)を含み、前記第1前止部(70m)が、前記第1下部フランジ部(85m2)と前記第1上部フランジ部(85m1)の間に配置可能な第1フィン部(107m)を有する、若しくは、前記第2前止部(70n)が、前記第2下部フランジ部(85n2)と前記第2上部フランジ部(85n1)の間に配置可能な第2フィン部(107n)を有する、と良い。

The first flange portion (85m) includes a first lower flange portion (85m2) connected to the lower wing plate (82) and a first upper flange portion (85m1) connected to the upper wing plate (81), The second flange portion (85n) includes a second lower flange portion (85n2) connected to the lower wing plate (82) and a second upper flange portion (85n1) connected to the upper wing plate (81), The first front stop (70m) has a first fin portion (107m) that can be disposed between the first lower flange portion (85m2) and the first upper flange portion (85m1), or the first 2 It is preferable that the front stop portion (70n) has a second fin portion (107n) that can be disposed between the second lower flange portion (85n2) and the second upper flange portion (85n1).

前記第2前止部(70n)には前記第2フランジ部(85n)に接触可能な爪部(79)が設けられている、若しくは前記第1前止部(70m)には前記第1フランジ部(85m)に接触可能な爪部(79)が設けられている、と良い。

The second front stop portion (70n) is provided with a claw portion (79) that can contact the second flange portion (85n), or the first front stop portion (70m) has the first flange. The nail | claw part (79) which can contact a part (85m) is good.

前記ファスナースライダー(80)が自由スライダーである、と良い。

It is good that the fastener slider (80) is a free slider.

前記ファスナーエレメント(60)及び前記前止部(70)が、前記ファスナーテープ(51)の前記対向側縁(52)に射出成形により一体的に固着する、と良い。

It is preferable that the fastener element (60) and the front stop (70) are integrally fixed to the opposite side edge (52) of the fastener tape (51) by injection molding.

本発明の他の側面に係るスライドファスナーの使用方法は、一組の主面(151)を有するファスナーテープ(51)の対向側縁(52)にファスナーエレメント(60)が設けられた一組のファスナーストリンガー(50)と、前記一組のファスナーストリンガー(50)の各ファスナーエレメント(60)が挿通されるファスナースライダー(80)であって、上翼板(81)、当該上翼板(81)に対向する下翼板(82)、前記上翼板(81)と前記下翼板(82)を連結する連結柱(83)、及び前記上翼板(81)及び下翼板(82)の少なくとも一方に連結したフランジ部(85)を備え、前記連結柱(83)と前記フランジ部(85)により前記ファスナーエレメント(60)の通路が規定される、ファスナースライダー(80)と、前記一組のファスナーストリンガー(50)に個別に設けられた一組の前止部(70)であって、各前止部(70)が、前記ファスナーテープ(51)の前記対向側縁(52)に一体的に固着する、一組の前止部(70)と、を備えるスライドファスナー(100)の使用方法であって、前記ファスナースライダー(80)を前記前止部(70)側である前側へ第1の力でスライド移動させて前記前止部(70)を部分的に前記ファスナースライダー(80)内に挿入し、前記第1の力よりも大きな第2の力で前記ファスナースライダー(80)を前記前側へ移動させて前記ファスナースライダー(80)の前記連結柱(83)と前記フランジ部(85)の間へ少なくとも1つの前記前止部(70)を圧入させる。