WO2012121090A1 - Method for producing fermented milk having improved physical properties - Google Patents

Method for producing fermented milk having improved physical properties Download PDFInfo

- Publication number

- WO2012121090A1 WO2012121090A1 PCT/JP2012/055169 JP2012055169W WO2012121090A1 WO 2012121090 A1 WO2012121090 A1 WO 2012121090A1 JP 2012055169 W JP2012055169 W JP 2012055169W WO 2012121090 A1 WO2012121090 A1 WO 2012121090A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fermented milk

- milk

- glucose oxidase

- mix

- fermented

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Y—ENZYMES

- C12Y101/00—Oxidoreductases acting on the CH-OH group of donors (1.1)

- C12Y101/03—Oxidoreductases acting on the CH-OH group of donors (1.1) with a oxygen as acceptor (1.1.3)

- C12Y101/03004—Glucose oxidase (1.1.3.4)

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23C—DAIRY PRODUCTS, e.g. MILK, BUTTER OR CHEESE; MILK OR CHEESE SUBSTITUTES; MAKING THEREOF

- A23C9/00—Milk preparations; Milk powder or milk powder preparations

- A23C9/12—Fermented milk preparations; Treatment using microorganisms or enzymes

- A23C9/127—Fermented milk preparations; Treatment using microorganisms or enzymes using microorganisms of the genus lactobacteriaceae and other microorganisms or enzymes, e.g. kefir, koumiss

- A23C9/1275—Fermented milk preparations; Treatment using microorganisms or enzymes using microorganisms of the genus lactobacteriaceae and other microorganisms or enzymes, e.g. kefir, koumiss using only lactobacteriaceae for fermentation in combination with enzyme treatment of the milk product; using enzyme treated milk products for fermentation with lactobacteriaceae

Definitions

- the present invention has a good quality in which changes in physical properties associated with milk protein aggregation (occurrence of water separation, increase in the particle diameter of milk protein, or generation of roughness associated therewith) occurring during refrigerated storage and distribution are suppressed.

- the present invention relates to a method for producing fermented milk.

- Patent Document 1 proposes a method of blending a specific amount of whey hydrolyzate in the production of fermented milk and homogenizing it. It is described that aggregation and precipitation can be suppressed.

- Patent Documents 2 to 5 disclose that fermented milk raw material mix with lactic acid bacteria starter and peroxidase is fermented to suppress whey separation and protein aggregation during storage and distribution. However, it is described that a fermented dairy product having a fine and smooth texture can be produced. However, there is no teaching about the use of glucose oxidase.

- glucose oxidase has long been known to have an antibacterial effect. This antibacterial action is due to glucose being oxidized by glucose oxidase to produce hydrogen peroxide.

- Patent Document 6 glucose oxidase is added to raw milk with hydrogen peroxide in order to avoid antibody deactivation due to heating in the production of antibody-containing fermented food. It is described that raw milk is sterilized by adding it as a generator and then fermented with lactic acid bacteria.

- glucose oxidase is only disclosed as a hydrogen peroxide generator, ie, a bactericidal agent, with glucose which is the substrate.

- Patent Document 6 has no problem of suppressing changes in physical properties associated with milk protein aggregation, and does not suggest the use of glucose oxidase.

- the present invention relates to a fermented milk in which changes in physical properties associated with milk protein aggregation that occur during refrigerated storage and distribution are suppressed, specifically, generation of water separation, increase in the particle diameter of milk protein, or roughness associated therewith. It aims at providing the manufacturing method of fermented milk in which generation

- the present invention relates to the inventions of the following aspects.

- step (1) a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase

- step (2) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3)

- step C The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process.

- the physical property change accompanying the aggregation of milk protein is selected from the group consisting of generation of water separation (water separation), increase in particle diameter of milk protein (and / or fat), and generation of roughness of the tissue of fermented milk.

- the production method according to any one of (I-1) to (I-3), wherein the production method is at least one.

- (II) Method for improving physical properties of fermented milk (II-1) (1) A step of preparing a fermented milk mix using milk raw materials, (2) Changes in physical properties associated with aggregation of milk proteins in fermented milk produced by a method comprising a step of heat-sterilizing a fermented milk mix, and (3) adding a starter to the heat-sterilized fermented milk mix and fermenting the fermented milk mix A method of suppressing In the above steps (1) to (3), at least one of the following (A) to (C) is performed: (A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase, (B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3), (C) The process which adds the substance which can become a substrate of

- the physical property change accompanying the aggregation of milk protein is selected from the group consisting of generation of water separation (water separation), increase in particle diameter of milk protein (and / or fat), and generation of roughness of fermented milk tissue.

- the method of the present invention is a simple method that can be carried out while utilizing the current production process of fermented milk as it is, and does not impair the original flavor of fermented milk, and has appropriate physical properties and good flavor required for fermented milk. This is a method that can be stably maintained for a longer time.

- the method for producing fermented milk of the present invention comprises at least the following three steps (1) to (3): (1) a step of preparing a fermented milk mix using milk raw materials, (2) A method for producing fermented milk, comprising a step of heat-sterilizing a fermented milk mix, and (3) a step of adding a starter to the heat-sterilized fermented milk mix and fermenting the mixture.

- step (1) a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase

- step (2) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3)

- step (3) A process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to fermented milk after step (3), A manufacturing method characterized in that at least one of the processes is performed.

- “fermented milk” means “fermented with lactic acid bacteria or yeast containing milk or a non-fat milk solid content equal to or higher than milk, as defined in the ordinance of milk, etc.

- Yogurt non-fat milk solid content of 8% or more and containing 10 million or more lactic acid bacteria or yeast per ml: Ministry of Health, Labor and Welfare ordinance of Japan

- milk Product lactic acid bacteria beverage non-fat milk solid content is less than 8% and contains 10 million or more lactic acid bacteria or yeast per ml: Japan Ministry of Health, Labor and Welfare Ordinance

- lactic acid bacteria beverage non-fat milk solid content is 3 %, which contains 10 million or more lactic acid bacteria or yeasts per ml: Ministry of Health, Labor and Welfare of Japan), preferably yogurt.

- Yogurt is classified into two types, “pre-fermentation type” and “post-fermentation type”, depending on the preparation method.

- the former pre-fermentation type yogurt is fermented in a tank with a fermentation mix prepared by blending fermented milk starter with raw milk, and then the generated card is crushed and, if necessary, with a gelling agent. Manufactured by filling food containers.

- the latter post-fermentation type yogurt is manufactured by blending a fermented milk starter with raw material milk to prepare a fermentation mix, filling the fermentation mix into individual containers and fermenting in the container.

- the yogurt targeted by the present invention includes these two types of yogurt: “pre-fermentation type” and “post-fermentation type”.

- the production method of the present invention performs the operation of (A) in the above step (1) or (3) before the step (B). Performed by operation.

- the operation (A) is performed in the step (1) or the step (3) (B) or (C) is performed after step (3), or at least one of the operations can be performed.

- dairy ingredients means dairy products used as raw materials for fermented milk, such as raw milk, pasteurized milk (sterilized milk), skim milk , Whole milk powder, skim milk powder, butter, buttermilk, cream, whey protein concentrate (WPC), whey protein isolate (WPI), etc. it can. These can be used in combination of two or more.

- raw milk and / or sterilized milk in order to achieve a non-fat milk solid content of 8% or more in a state where calories are kept low ( Pasteurized milk), skim milk and / or skim milk can also be combined.

- “Fermented milk mix” is a raw material preparation in which raw materials for fermented milk are mixed, and, if necessary, sweeteners such as sugars and sweeteners including water and sugar, and flavoring agents, etc. Is added and blended, and if necessary, it is prepared by dissolving while warming. If necessary, stabilizers (gelling agents) such as gelatin, agar, carrageenan, guar gum, low methoxy pectin and high methoxy pectin can also be blended.

- sweeteners such as sugars and sweeteners including water and sugar, and flavoring agents, etc. Is added and blended, and if necessary, it is prepared by dissolving while warming.

- stabilizers such as gelatin, agar, carrageenan, guar gum, low methoxy pectin and high methoxy pectin can also be blended.

- blended with fermented milk mix is the ratio of non-fat milk solid content determined according to the kind of fermented milk (yogurt: 8% or more, dairy product lactic acid bacteria drink: less than 8%, lactic acid bacteria drink : Less than 3%), and as long as it is satisfied, there is no particular limitation.

- the blending ratio of raw milk (and / or pasteurized milk, etc.) is more than 0 wt% and not more than 100 wt%, preferably from 0 wt% 90% by weight or less, more preferably 20 to 80% by weight, further preferably 40 to 80% by weight; the blending ratio of skim milk powder is more than 0% by weight and 12% by weight or less, preferably 1 to 10% by weight 2 to 8% by weight, more preferably 2 to 6% by weight.

- glucose oxidase is added to and blended with the fermented milk mix as one of the raw materials of the fermented milk mix when preparing the fermented milk mix. It is characterized by that.

- the fermented milk mix does not contain a substance that can be a substrate for glucose oxidase

- a substance that can be a substrate for glucose oxidase is added and blended together with glucose oxidase.

- the enzyme may be deactivated.

- “substance that can be a substrate of glucose oxidase” means not only a substrate of glucose oxidase (glucose) but also a substance that produces the substrate (glucose). Although it does not restrict

- a commercially available glucose oxidase preparation can be used for glucose oxidase.

- Examples of commercially available glucose oxidase preparations include, for example, Shin Nippon Chemical Industry Co., Ltd., DKSH Japan Co., Ltd., Shonan Wako Pure Chemical Industries, Ltd., Nagase Biochemical Co., Ltd., Kyowa Enzyme Co., Ltd. ) (All of which are from Japan) and the like.

- the blending ratio of glucose oxidase (about 2000 to 4000 units / kg) in the fermented milk mix is 0.1 to 1% by weight, preferably 0.1 to 0. 5% by weight, more preferably 0.15 to 0.3% by weight, still more preferably 0.15 to 0.2% by weight; and the glucose content is 1 to 5% by weight, preferably 1 to 4% by weight. More preferred is 1.5 to 3% by weight, and still more preferred is 1.5 to 2.5% by weight.

- lactase preparation can be used as lactase.

- a commercially available lactase preparation as described above, for example, Shin Nippon Chemical Industry Co., Ltd., Amano Enzyme Co., Ltd., Daiwa Kasei Co., Ltd., Nagase ChemteX Co., Ltd. ) And other enzyme preparations.

- the blending ratio of lactase (about 4000 to 6000 units / kg) in the fermented milk mix is 0.01 to 0.1% by weight, preferably 0.02%.

- the lactose content is 2 to 10 wt%, preferably 2 to 8% by weight, more preferably 3 to 6% by weight, and still more preferably 3 to 5% by weight.

- the fermented milk mix to which lactase is added and blended is allowed to stand (preliminary) in advance at a temperature of 0 to 40 ° C., preferably 1 to 30 ° C., more preferably 3 to 15 ° C., and even more preferably 5 to 10 ° C. (Still).

- the standing time is not particularly limited, but is usually 1.5 hours or more, preferably 1.5 to 24 hours, more preferably 2 to 16 hours, further preferably 2 to 6 hours, and particularly preferably 2 to 4 hours. It's time.

- a fermented milk mix in which glucose oxidase is added and blended with glucose as a substrate of glucose oxidase, or an enzyme that produces the glucose and its substrate (for example, lactase and lactose as its substrate)

- the temperature is 0 to 40 ° C, preferably 1 to 30 ° C, more preferably 3 to 15 ° C, and still more preferably 5 to 10 ° C.

- the standing time is not particularly limited, but is usually 1.5 hours or more, preferably 1.5 to 24 hours, more preferably 2 to 16 hours, further preferably 2 to 6 hours, and particularly preferably 2 to 4 hours. It's time.

- an enzyme that produces glucose and its substrate and glucose oxidase are added almost simultaneously to the fermented milk mix, the fermented milk mix is left to stand immediately under the above conditions, without pre-standing as described in the previous paragraph. can do.

- Fermented milk mix prepared in step (Note that this mix was prepared through operation (A) and (A) Both of the prepared ones) are then subjected to a sterilization treatment by heating.

- the heating temperature and heating time are not particularly limited as long as the target sterilization is possible. It is sufficient that the temperature of the fermented milk mix itself is at least 90 ° C, preferably about 95 ° C.

- a method of treating the fermented milk mix at 90-100 ° C for 1-5 minutes, A method of treating at 95 ° C. for 1 to 3 minutes can be mentioned without limitation.

- the production method (B) before step (3) is to add and blend glucose oxidase into the fermented milk mix heat-sterilized by the above method in step (2). It is characterized by.

- the fermented milk mix targeted here is preferably prepared without going through the operation (A) in the step (1).

- a substance that can be a substrate for glucose oxidase is added and blended together with glucose oxidase.

- the enzyme may be deactivated.

- the “substance that can be a substrate for glucose oxidase” is as described above, and the amounts and sources of use of glucose oxidase and lactase, and the amounts of glucose (glucose) and lactose (lactose) used are also as described above. is there.

- “Starter” means an inoculum such as lactic acid bacteria or yeast inoculated to ferment a fermented milk mix.

- a known starter can be appropriately used as the “starter”, but a lactic acid bacteria starter is preferable.

- Lactic acid bacteria starters include Lactobacillus bulgaricus (L.bulgaricus), Streptococcus thermophilus (L.lactis), Lactobacillus lactis (L.lactis), Lactobacillus gasseri (L.gasseri) or Bifidobacterium ( In addition to Bifidobacterium), one or more of lactic acid bacteria generally used for the production of fermented milk can be used.

- a lactic acid bacteria starter based on a mixed starter of Lactobacillus bulgaricus (L.bulgaricus) and Streptococcus thermophilus (S. it can. Based on this lactic acid bacteria starter, after considering the fermentation temperature and fermentation conditions of the desired fermented milk, add other lactic acid bacteria such as Lactobacillus gasseri and Bifidobacterium Also good.

- the addition amount of the starter can be appropriately set according to the addition amount employed in the known method for producing fermented milk.

- the starter inoculation method is not particularly limited, and a method commonly used in the production of fermented milk can be appropriately used.

- the conditions for the fermentation treatment can be appropriately set in consideration of the type of fermented milk, the desired flavor, the type of starter to be used, and the like.

- a method in which the temperature in the fermentation chamber (fermentation temperature) is maintained in the range of 30 to 50 ° C. and the fermentation is performed while standing in the fermentation chamber can be mentioned. If it is such temperature conditions, since lactic acid bacteria generally tend to be active, fermentation can proceed effectively.

- the fermentation temperature is usually about 30 to 50 ° C., preferably 35 to 45 ° C., more preferably 37 to 43 ° C.

- Fermentation time can be appropriately set and adjusted with reference to the fact that the lactic acidity of the fermented milk mix reaches a predetermined ratio.

- the lactic acid acidity is, for example, about 1.5 to 2% in the case of “pre-fermentation type” yoghurt, and about 0.7 to 0.8% in the case of “post-fermentation type” yoghurt.

- the fermentation time is usually about 1 hour to 12 hours, preferably about 2 hours to 5 hours, more preferably about 3 hours to 4 hours.

- pre-fermentation type yogurt when the lactic acid acidity reaches about 1.5 to 2%, and in the case of “post-fermentation type” yogurt, when the lactic acid acidity reaches about 0.7 to 0.8%,

- the fermentation is stopped by cooling to 15 ° C. or less, preferably 0 to 10 ° C., more preferably 3 to 7 ° C.

- the operation (C) can be performed after the step (3). That is, glucose oxidase can be added to and blended with fermented milk prepared in advance.

- the manufacturing method containing the said (C) operation is 1 aspect of the manufacturing method of this invention.

- the fermented milk mix used here is preferably prepared without (A) operation in (1) step and without (B) operation before (3) step. .

- the fermented milk prepared in advance does not contain a substance that can serve as a substrate for glucose oxidase

- a substance that can serve as a substrate for glucose oxidase is added and blended together with glucose oxidase.

- the “substance that can be a substrate for glucose oxidase” is as described above, and the amounts and sources of use of glucose oxidase and lactase and the amounts of glucose and lactose used are also as described above.

- the fermented milk targeted by the present invention can be produced.

- the culture step (3) is performed using a tank (tank culture). After the tank culture, the fermented and coagulated curd is agitated and crushed and, if necessary, sterilized, cooled, emulsified, and aged, then filled into a retail container and prepared as a fermented milk product.

- the fermented milk is a “post-fermentation type” yogurt

- the fermented milk mix is filled in the retail container before the culturing step (3), and the culturing step (3) is performed in the container. (Culture in a container). After culturing in the container, it is cooled (refrigerated) and prepared as a product of fermented milk.

- the method for improving physical properties of fermented milk of the present invention includes at least the following three steps (1) to (3): (1) a step of preparing a fermented milk mix using milk raw materials, Changes in physical properties associated with milk protein aggregation in fermented milk products produced by a method comprising (2) heat-sterilizing the fermented milk mix and (3) adding a starter to the heat-sterilized fermented milk mix and fermenting A method of suppressing

- steps (1) to (3) at least one of the following (A) to (C) is performed:

- C The process which adds the substance which

- the fermented milk produced or processed in this way is produced without using any of the operations (A) to (C), that is, without using glucose oxidase, as shown in Examples described later.

- the physical property change accompanying the aggregation of the milk protein can include at least one selected from the generation of water separation, the increase in the particle diameter of the milk protein, and the generation of roughness of the tissue of the fermented milk.

- the texture of the fermented milk tissue is not particularly restricted, but is thought to be a phenomenon caused by an increase in the milk protein particle size.

- the fermented milk of the present invention also has an increase over time (change in physical properties) compared to the fermented milk of the control. It is also significantly suppressed.

- the method of the present invention is useful for maintaining the quality (appearance and texture) of fermented milk in a good state for as long as possible, at least during the expiration date.

- the period for maintaining the quality of the fermented milk in a good state can be about 10 days from the production, preferably 12 days or more, more preferably 14 days or more.

- the milk raw materials (fat content: 3.0% by weight, non-fat milk solid content: 9.7% by weight), raw water, and fermented milks 3 and 4 shown in Table 1 are further mixed with glucose.

- the solution was stirred and dissolved while heating to 60 ° C. After cooling this to 5 ° C., lactase and / or glucose oxidase was added and blended according to the formulation described in Table 1 for fermented milks 2 and 4.

- the fermented milk mix thus prepared was allowed to stand for about 14 hours under conditions of about 5 ° C., and then heat sterilized until the fermented milk mix reached 95 ° C. This was cooled to about 40 ° C.

- lactic acid bacteria starter mixed starter of Bulgarian bacterium OLL1073R-1 and Thermofilus bacterium OLS3059. This is filled in a retail container and statically cultured in a culture room set at about 40 ° C. (about 43 ° C.). When the lactic acid acidity becomes 0.72%, it is placed in a refrigerator at about 5 ° C. And cooled to stop the fermentation.

- the Bulgarian fungus OLL1073R-1 (Lactobacillus delbrueckii subspecies bulgaricus OLL1073R-1) is received by the independent administrative corporation National Institute of Advanced Industrial Science and Technology Patent Biological Depositary Center: FERM P-17227 (Indication for identification: Lactobacillus delbrueckii subspecies bulgaricus OLL1073R-1, deposit date (reception date: February 19, 1999).

- Thermophilus OLS3059 (Streptococcus thermophilus OLS3059) is received by the independent administrative agency National Institute of Advanced Industrial Science and Technology Patent Organism Depositary: Receipt No .: FERM P-15487 (Indication for identification: Streptococcus thermophilus OLS3059, date of deposit) (Receipt date): Deposited on February 29, 1996).

- (B) Measurement of Fermented Milk Particle Size The particle diameter ( ⁇ m) of coagulated particles mixed in fermented milk was measured using a laser diffraction particle size distribution meter (Shimadzu Corporation: SALD-2000).

- the occurrence / progress of milk protein aggregation is significantly suppressed, and at the same time, the occurrence / progress of the coarseness of the fermented milk tissue that causes the coarseness in the oral cavity is also suppressed. be able to.

- lactase is added and blended for the milk ingredients (fat content: 4.0% by weight, nonfat milk solids: 8.8% by weight), raw water, and fermented milk 6 listed in Table 4. And about fermented milk 7, lactase and glucose oxidase were added and mix

- the acidity after about 3 hours is 0.62% for fermented milk 5, 0.59% for fermented milk 6 and 0.59% for fermented milk 7, and after about 3.5 hours

- the acidity of the fermented milk 5 was 0.74%

- the fermented milk 6 was 0.74%

- the fermented milk 7 was 0.74%. That is, even if lactase or glucose oxidase was added and blended, no influence on the fermentation process (fermentation time and the like) was observed.

- “fermented milk 7” produced by adding glucose oxidase to the fermented milk mix and lactase that acts on lactose contained in the milk raw material to produce glucose does not add glucose oxidase.

- the water separation rate at the beginning of production is lower, the particle size is smaller, and the increase over time (water separation increase rate, particle size increase rate) is also significantly It was confirmed that it was suppressed to a low level.

- Fermented milk was prepared in the same manner as in Experimental Example 1 except that a mixed starter separated from the plain type or soft type of “Meiji Bulgaria Yogurt” (manufactured by Meiji Dairies) was used as the lactic acid bacteria starter.

- the acidity after about 3 hours was 0.62% for fermented milk 8, 0.64% for fermented milk 9, 0.62% for fermented milk 10, and 0.57% for fermented milk 11.

- the acidity after about 3.5 hours is 0.71% for fermented milk 8, 0.72% for fermented milk 9, 0.69% for fermented milk 10, and the acidity after about 3.75 hours is It was 0.66% for fermented milk 11.

- lactase is added to and blended with the milk ingredients listed in Table 10 (fat content: 4.0 wt%, non-fat milk solids: 8.8 wt%), raw water, and fermented milk 12

- fat content 4.0 wt%

- non-fat milk solids 8.8 wt%

- raw water raw water

- fermented milk 12 glucose oxidase was further added and blended in addition to lactase.

- the fermented milk mix thus prepared was allowed to stand for about 15 hours under conditions of about 5 ° C., and then heat sterilized until the fermented milk mix reached 95 ° C. This was cooled to about 40 ° C.

- lactic acid bacteria starter mixed starter of Bulgarian bacterium OLL1073R-1 and Thermofilus bacterium OLS3059. This is filled in a retail container, and this is statically cultured in a culture room set at about 40 ° C. (about 43 ° C.). When the lactic acid acidity becomes 0.72%, the yogurt card is added with a medicine sag. After breaking, it was placed in a refrigerator at about 5 ° C. and cooled to stop the fermentation.

- lactase is added to and blended with the milk ingredients listed in Table 13 (fat content: 4.0 wt%, non-fat milk solid content: 8.8 wt%), raw water, and fermented milk 14

- fermented milk 15 and 16 lactase and glucose oxidase were further added and blended.

- the fermented milk mix thus prepared was allowed to stand for about 15 hours under conditions of about 5 ° C., and then heat sterilized until the fermented milk mix reached 95 ° C. This was cooled to about 40 ° C.

- lactic acid bacteria starter mixed starter of Bulgarian bacterium OLL1073R-1 and Thermofilus bacterium OLS3059. This is filled in a retail container and statically cultured in a culture room set at about 40 ° C. (about 43 ° C.). When the lactic acid acidity becomes 0.72%, it is placed in a refrigerator at about 5 ° C. And cooled to stop the fermentation.

- This is filled in a retail container and statically cultured in a culture room set at about 40 ° C. (about 43 ° C.).

- a culture room set at about 40 ° C. (about 43 ° C.).

- the lactic acid acidity becomes 0.72%, it is placed in a refrigerator at about 5 ° C. And cooled to stop the fermentation.

- milk raw materials (fat content: 4.0% by weight, non-fat milk solid content: 8.8% by weight), raw water, and lactase and glucose oxidase described in Table 16 were added and blended.

- the fermented milk mix thus prepared was left to stand for about a predetermined time (about 2 hours, 6 hours, 16 hours) at about 5 ° C., and then heat-sterilized until the fermented milk mix reached 95 ° C. This was cooled to about 40 ° C. (about 43 ° C.) and inoculated with 2% by weight of a lactic acid bacteria starter (mixed starter of Bulgarian bacterium OLL1073R-1 and Thermofilus bacterium OLS3059).

- a lactic acid bacteria starter mixed starter of Bulgarian bacterium OLL1073R-1 and Thermofilus bacterium OLS3059.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Health & Medical Sciences (AREA)

- Biochemistry (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Microbiology (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Dairy Products (AREA)

Abstract

Description

(I-1)(1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する発酵乳の製造方法であって、

上記(1)~(3)の工程において、下記の(A)~(C)のいずれか少なくとも1の処理が行われることを特徴とする発酵乳の製造方法:

(A)(1)工程において、グルコースオキシダーゼの基質になり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理。 (I) Method for producing fermented milk with improved physical properties (I-1) (1) A step of preparing a fermented milk mix using milk raw materials,

(2) A method for producing fermented milk, comprising a step of heat-sterilizing a fermented milk mix, and (3) a step of adding a starter to the heat-sterilized fermented milk mix and fermenting the mixture.

In the above steps (1) to (3), at least one of the following (A) to (C) is performed:

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process.

(II-1)(1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する方法で製造される発酵乳について、乳タンパク質の凝集に伴う物性変化を抑制する方法であって、

上記(1)~(3)の工程において、下記の(A)~(C)のいずれか少なくとも1の処理を行うことを特徴とする上記方法:

(A)(1)工程において、グルコースオキシダーゼの基質になり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理。 (II) Method for improving physical properties of fermented milk (II-1) (1) A step of preparing a fermented milk mix using milk raw materials,

(2) Changes in physical properties associated with aggregation of milk proteins in fermented milk produced by a method comprising a step of heat-sterilizing a fermented milk mix, and (3) adding a starter to the heat-sterilized fermented milk mix and fermenting the fermented milk mix A method of suppressing

In the above steps (1) to (3), at least one of the following (A) to (C) is performed:

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process.

本発明の発酵乳の製造方法は、少なくとも下記の(1)~(3)の3工程:

(1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する発酵乳の製造方法であって、

上記(1)~(3)の工程において、下記の(A)~(C):

(A)(1)工程において、グルコースオキシダーゼの基質となり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

のいずれか少なくとも1つの処理が行われることを特徴とする製造方法である。 I. Method for Producing Fermented Milk with Improved Physical Properties The method for producing fermented milk of the present invention comprises at least the following three steps (1) to (3):

(1) a step of preparing a fermented milk mix using milk raw materials,

(2) A method for producing fermented milk, comprising a step of heat-sterilizing a fermented milk mix, and (3) a step of adding a starter to the heat-sterilized fermented milk mix and fermenting the mixture.

In the above steps (1) to (3), the following (A) to (C):

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) A process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to fermented milk after step (3),

A manufacturing method characterized in that at least one of the processes is performed.

(1)乳原料を用いて発酵乳ミックスを調製する工程

「乳原料」は、発酵乳の原料として使用される乳製品を意味し、例えば、生乳、殺菌処理した乳(殺菌乳)、脱脂乳、全脂粉乳、脱脂粉乳、バター、バターミルク、クリーム、ホエー蛋白質濃縮物(WPC)、及びホエー蛋白質単離物(WPI)などから、製造する発酵乳の種類に応じて、適宜選択することができる。これらは2種以上を組み合わせて用いることができ、例えば、ヨーグルトの場合、カロリーを低く抑えた状態で、無脂乳固形分を8%以上にするために、生乳及び/又は殺菌処理した乳(殺菌乳)や、脱脂乳及び/又は脱脂粉乳を組み合わせることもできる。 Hereinafter, the production steps (1) to (3) of the present invention will be described in order:

(1) Process of preparing fermented milk mix using dairy ingredients “dairy ingredients” means dairy products used as raw materials for fermented milk, such as raw milk, pasteurized milk (sterilized milk), skim milk , Whole milk powder, skim milk powder, butter, buttermilk, cream, whey protein concentrate (WPC), whey protein isolate (WPI), etc. it can. These can be used in combination of two or more. For example, in the case of yogurt, raw milk and / or sterilized milk (in order to achieve a non-fat milk solid content of 8% or more in a state where calories are kept low ( Pasteurized milk), skim milk and / or skim milk can also be combined.

本発明の1態様である(1)工程において(A)処理を行う製造方法は、上記発酵乳ミックスの調製に際して、発酵乳の原料の一つとして、発酵乳ミックスにグルコースオキシダーゼを添加・配合することを特徴とする。 "Fermented milk mix" is a raw material preparation in which raw materials for fermented milk are mixed, and, if necessary, sweeteners such as sugars and sweeteners including water and sugar, and flavoring agents, etc. Is added and blended, and if necessary, it is prepared by dissolving while warming. If necessary, stabilizers (gelling agents) such as gelatin, agar, carrageenan, guar gum, low methoxy pectin and high methoxy pectin can also be blended. In addition, the ratio of each raw material mix | blended with fermented milk mix is the ratio of non-fat milk solid content determined according to the kind of fermented milk (yogurt: 8% or more, dairy product lactic acid bacteria drink: less than 8%, lactic acid bacteria drink : Less than 3%), and as long as it is satisfied, there is no particular limitation. For example, when raw milk (and / or pasteurized milk, etc.) and skim milk powder are used as milk raw materials, the blending ratio of raw milk (and / or pasteurized milk, etc.) is more than 0 wt% and not more than 100 wt%, preferably from 0 wt% 90% by weight or less, more preferably 20 to 80% by weight, further preferably 40 to 80% by weight; the blending ratio of skim milk powder is more than 0% by weight and 12% by weight or less, preferably 1 to 10% by weight 2 to 8% by weight, more preferably 2 to 6% by weight.

In the production method of performing the process (A) in the step (1) which is one embodiment of the present invention, glucose oxidase is added to and blended with the fermented milk mix as one of the raw materials of the fermented milk mix when preparing the fermented milk mix. It is characterized by that.

(1)の工程で調製された発酵乳ミックス(なお、このミックスには(A)操作を経て調製されたもの、及び(A)操作を経ないで調製されたものの両方が含まれる)は、次いで加熱による殺菌処理に供される。 (2) Process of heat sterilizing fermented milk mix (1) Fermented milk mix prepared in step (Note that this mix was prepared through operation (A) and (A) Both of the prepared ones) are then subjected to a sterilization treatment by heating.

(2)の工程で加熱殺菌された発酵乳ミックス(なお、このミックスには(A)操作を経て調製されたもの、(B)操作を経て調製されたもの、(A)と(B)のいずれの操作も経ないで調製されたものが含まれる)は、次いで発酵処理に供される。 (3) Fermented milk mix heat-sterilized in the step (2) of adding fermented milk starter to the fermented milk mix that has been heat-sterilized and fermenting (Note that this mix was prepared through the operation (A) , (B) prepared through the operation, and those prepared without undergoing any of the operations (A) and (B) are then subjected to a fermentation treatment.

本発明の発酵乳の物性改良方法は、少なくとも下記の(1)~(3)の3工程:

(1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する方法で製造される発酵乳製品について、乳タンパク質凝集に伴う物性変化を抑制する方法であって、

上記(1)~(3)の工程において、下記の(A)~(C)のいずれか少なくとも1つの処理を行うことを特徴とする方法である:

(A)(1)工程において、グルコースオキシダーゼの基質となり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理。 II. Method for improving physical properties of fermented milk The method for improving physical properties of fermented milk of the present invention includes at least the following three steps (1) to (3):

(1) a step of preparing a fermented milk mix using milk raw materials,

Changes in physical properties associated with milk protein aggregation in fermented milk products produced by a method comprising (2) heat-sterilizing the fermented milk mix and (3) adding a starter to the heat-sterilized fermented milk mix and fermenting A method of suppressing

In the steps (1) to (3), at least one of the following (A) to (C) is performed:

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process.

(1-1)発酵乳の製造

表1に記載する処方に従って、4種類の発酵乳1~4を調製した。 Experimental example 1

(1-1) Production of fermented milk Four types of fermented milk 1 to 4 were prepared according to the formulation described in Table 1.

斯くして製造した発酵乳1~4について、それぞれ約5℃の条件下に16日間で静置保存し、下記の方法に従って、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、カードテンション(g)、粘度(Pa・s)を経時的(製造の当初(1日目)、製造から8日目及び16日目)に測定した。

(a)発酵乳の離水率の測定

発酵乳(10℃)の40gを、遠心沈降管(内径:20mm)に充填し、遠心分離機に供した(約180G [回転半径:160mm、回転数:1000rpm]、処理時間:10分間)。次いで、上清の重量を測定し、発酵乳の全量(40g)に対する上清の重量の割合(%)を離水率とした。

(b)発酵乳の粒子径の測定

発酵乳に混在する凝固粒子の粒子径(μm)を、レーザー回折式粒度分布計(島津製作所:SALD-2000)を用いて測定した。

(c)発酵乳の酸度(乳酸酸度)の測定

発酵乳にフェノールフタレインを指示薬として添加してから、水酸化ナトリウム(0.1規定)を滴定剤として用いて測定した。

(d)発酵乳の硬度(カードテンション、CT)の測定

発酵乳の硬度(g)を、ネオカードメーターM302(アイテクノエンジニアリング:旧・飯尾電機)を用いて測定した。このカードメーターでは、例えば、発酵乳(10℃)の100gを小型容器に充填し、ヨーグルトナイフ(直径が約20mmの円盤)を侵入させることで、硬度(カードテンション)や滑らかさなどを評価できる。

(e)発酵乳の粘度の測定

発酵乳の粘度を、回転式B型粘度計(東機産業:TV-10M)を用いて測定した。この粘度計では、例えば、発酵乳(10℃)の100gを小型容器に充填し、No.4ローター(コードM23)を侵入・回転(30rpm、30秒間)させることで、粘度を評価できる。 (1-2) Evaluation of Fermented Milk Fermented milks 1 to 4 thus produced were each stored for 16 days under conditions of about 5 ° C., and the water separation rate (%), milk was determined according to the following method. Protein particle size (μm), acidity (%), pH (20 ° C.), card tension (g), viscosity (Pa · s) with time (initial (first day) of production, eighth day after production, and Measurement was carried out on the 16th day).

(A) Measurement of water separation rate of fermented milk 40 g of fermented milk (10 ° C.) was filled into a centrifugal sedimentation tube (inner diameter: 20 mm) and subjected to a centrifuge (about 180 G [rotation radius: 160 mm, rotation speed: 1000 rpm], treatment time: 10 minutes). Next, the weight of the supernatant was measured, and the ratio (%) of the weight of the supernatant to the total amount of fermented milk (40 g) was taken as the water separation rate.

(B) Measurement of Fermented Milk Particle Size The particle diameter (μm) of coagulated particles mixed in fermented milk was measured using a laser diffraction particle size distribution meter (Shimadzu Corporation: SALD-2000).

(C) Measurement of Fermented Milk Acidity (Lactic Acid Acidity) After adding phenolphthalein as an indicator to fermented milk, it was measured using sodium hydroxide (0.1 N) as a titrant.

(D) Measurement of Fermented Milk Hardness (Card Tension, CT) Hardness (g) of fermented milk was measured using Neo Card Meter M302 (I Techno Engineering: former Iio Electric). In this card meter, for example, 100 g of fermented milk (10 ° C.) is filled into a small container and a yogurt knife (a disk having a diameter of about 20 mm) is allowed to enter to evaluate hardness (card tension), smoothness, and the like. .

(E) Measurement of viscosity of fermented milk The viscosity of fermented milk was measured using a rotary B-type viscometer (Toki Sangyo: TV-10M). In this viscometer, for example, 100 g of fermented milk (10 ° C.) is filled in a small container. Viscosity can be evaluated by allowing 4 rotors (code M23) to enter and rotate (30 rpm, 30 seconds).

(2-1)発酵乳の製造

表4に記載する処方に従って、3種類の発酵乳5~7を調製した。 Experimental example 2

(2-1) Production of fermented milk Three types of fermented milk 5 to 7 were prepared according to the formulation described in Table 4.

斯くして製造した発酵乳5~7について、実験例1と同様にして、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、硬度(カードテンション)(g)、粘度(Pa・s)を経時的に測定した。この測定結果を表5に示す。そして、実験例1と同様にして官能検査を実施した。この検査結果を表6に示す。 (2-2) Evaluation of Fermented Milk For fermented milk 5-7 thus produced, the water separation rate (%), milk protein particle diameter (μm), acidity (%), The pH (20 ° C.), hardness (card tension) (g), and viscosity (Pa · s) were measured over time. The measurement results are shown in Table 5. And the sensory test was implemented like Experimental example 1. The test results are shown in Table 6.

(3-1)発酵乳の製造

表7に記載する処方に従って、4種類の発酵乳8~11を調製した。 Experimental example 3

(3-1) Production of Fermented Milk Four types of fermented milk 8-11 were prepared according to the formulation described in Table 7.

斯くして製造した発酵乳8~11について、実験例1と同様にして、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、硬度(カードテンション)(g)、粘度(Pa・s)を経時的に測定した。この測定結果を表8に示す。そして、実験例1と同様にして官能検査を実施した。この検査結果を表9に示す。 (3-2) Evaluation of Fermented Milk For fermented milk 8-11 thus produced, the water separation rate (%), milk protein particle diameter (μm), acidity (%), The pH (20 ° C.), hardness (card tension) (g), and viscosity (Pa · s) were measured over time. The measurement results are shown in Table 8. And the sensory test was implemented like Experimental example 1. Table 9 shows the inspection results.

(4-1)発酵乳の製造

表10に記載する処方に従って、2種類の発酵乳12~13を調製した。 Experimental Example 4

(4-1) Production of fermented milk Two types of fermented milk 12 to 13 were prepared according to the formulation described in Table 10.

斯くして製造した発酵乳12~13について、実験例1と同様にして、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、粘度(Pa・s)を経時的に測定した。なお、ここでは、ソフトタイプを想定し、ヨーグルトカードを破壊しているため、硬度を測定していない。この測定結果を表11に示す。そして、実験例1と同様にして官能検査を実施した。この検査結果を表12に示す。 (4-2) Evaluation of each fermented milk About fermented milk 12-13 thus produced, the water separation rate (%), milk protein particle diameter (μm), acidity (%), The pH (20 ° C.) and viscosity (Pa · s) were measured over time. Here, since the yogurt card is destroyed assuming a soft type, the hardness is not measured. The measurement results are shown in Table 11. And the sensory test was implemented like Experimental example 1. The test results are shown in Table 12.

(5-1)発酵乳の製造

表13に記載する処方に従って、3種類の発酵乳14~16を調製した。 Experimental Example 5

(5-1) Manufacture of fermented milk Three types of fermented milk 14 to 16 were prepared according to the formulation described in Table 13.

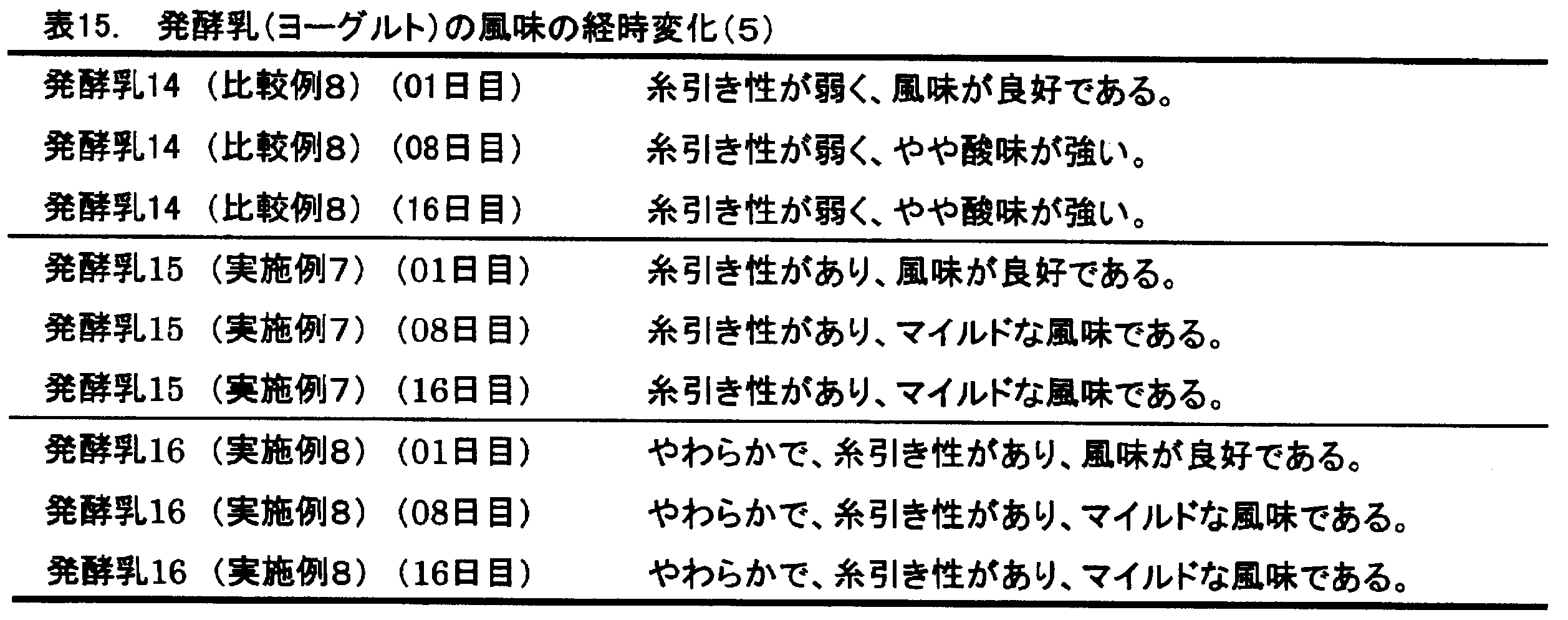

斯くして製造した発酵乳14~16について、実験例1と同様にして、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、硬度(カードテンション)(g)、粘度(Pa・s)を経時的に測定した。この測定結果を表14に示す。そして、実験例1と同様にして官能検査を実施した。この検査結果を表15に示す。 (5-2) Evaluation of each fermented milk For fermented milk 14-16 produced in this manner, the water separation rate (%), the milk protein particle diameter (μm), the acidity (%), The pH (20 ° C.), hardness (card tension) (g), and viscosity (Pa · s) were measured over time. The measurement results are shown in Table 14. And the sensory test was implemented like Experimental example 1. The test results are shown in Table 15.

(6-1)発酵乳の製造

表16に記載する処方に従って、3種類の発酵乳17~19を調製した。 Experimental Example 6

(6-1) Production of fermented milk Three types of fermented milk 17 to 19 were prepared according to the formulation described in Table 16.

斯くして製造した発酵乳17~19について、実験例1と同様にして、離水率(%)、乳タンパク質の粒子径(μm)、酸度(%)、pH(20℃)、硬度(カードテンション)(g)、粘度(Pa・s)を経時的に測定した。この測定結果を表14に示す。そして、実験例1と同様にして官能検査を実施した。この検査結果を表15に示す。 (6-2) Evaluation of Fermented Milk For fermented milk 17-19 thus produced, the water separation rate (%), milk protein particle diameter (μm), acidity (%), The pH (20 ° C.), hardness (card tension) (g), and viscosity (Pa · s) were measured over time. The measurement results are shown in Table 14. And the sensory test was implemented like Experimental example 1. The test results are shown in Table 15.

Claims (10)

- (1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する発酵乳の製造方法であって、

上記(1)~(3)の工程において、下記の(A)~(C)のいずれか少なくとも1の処理が行われることを特徴とする発酵乳の製造方法:

(A)(1)工程において、グルコースオキシダーゼの基質となり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理。 (1) a step of preparing a fermented milk mix using milk raw materials,

(2) A method for producing fermented milk, comprising a step of heat-sterilizing a fermented milk mix, and (3) a step of adding a starter to the heat-sterilized fermented milk mix and fermenting the mixture.

In the above steps (1) to (3), at least one of the following (A) to (C) is performed:

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process. - スターターとして、ブルガリア菌(Lactobacillus blugaricus)とサーモフィラス菌(Streptococcus thermophilus)を併用することを特徴とする請求項1記載の製造方法。 The production method according to claim 1, wherein a Bulgarian bacterium (Lactobacillus blugaricus) and a thermophilus bacterium (Streptococcus thermophilus) are used in combination as a starter.

- グルコースオキシダーゼを用いないで製造される発酵乳と比べて、乳タンパク質の凝集に伴う物性変化が抑制された発酵乳の製造方法である、請求項1又は2に記載する製造方法。 The manufacturing method of Claim 1 or 2 which is a manufacturing method of fermented milk by which the physical-property change accompanying the aggregation of milk protein was suppressed compared with fermented milk manufactured without using glucose oxidase.

- 乳タンパク質の凝集に伴う物性変化が離水発生、乳タンパク質及び/又は脂肪の粒子径の増大、及び発酵乳の組織のザラツキ発生からなる群から選択される少なくとも1つである、請求項3に記載する製造方法。 The physical property change accompanying aggregation of milk protein is at least one selected from the group consisting of generation of water separation, increase in particle diameter of milk protein and / or fat, and generation of roughness of tissue of fermented milk. Manufacturing method.

- 発酵乳がヨーグルトである請求項1に記載する製造方法。 The production method according to claim 1, wherein the fermented milk is yogurt.

- (1)乳原料を用いて発酵乳ミックスを調製する工程、

(2)発酵乳ミックスを加熱殺菌する工程、及び

(3)加熱殺菌した発酵乳ミックスにスターターを添加して発酵させる工程

を有する方法で製造される発酵乳について、乳タンパク質の凝集に伴う物性変化を抑制する方法であって、

上記(1)~(3)の工程において、下記の(A)~(C)のいずれか少なくとも1の処理を行うことを特徴とする上記方法:

(A)(1)工程において、グルコースオキシダーゼの基質になり得る物質を含有する乳原料にグルコースオキシダーゼを添加して発酵乳ミックスを調製する処理、

(B)(3)工程の前に、加熱殺菌した発酵乳ミックスにグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理、

(C)(3)工程の後に、発酵乳にグルコースオキシダーゼ及びグルコースオキシダーゼの基質となり得る物質を添加する処理。 (1) a step of preparing a fermented milk mix using milk raw materials,

(2) Changes in physical properties associated with aggregation of milk proteins in fermented milk produced by a method comprising a step of heat-sterilizing a fermented milk mix, and (3) adding a starter to the heat-sterilized fermented milk mix and fermenting the fermented milk mix A method of suppressing

In the above steps (1) to (3), at least one of the following (A) to (C) is performed:

(A) In the step (1), a process for preparing a fermented milk mix by adding glucose oxidase to a milk raw material containing a substance that can be a substrate for glucose oxidase,

(B) The process of adding glucose oxidase and a substance that can be a substrate for glucose oxidase to the heat-sterilized fermented milk mix before step (3),

(C) The process which adds the substance which can become a substrate of glucose oxidase and glucose oxidase to fermented milk after the (3) process. - スターターとして、ブルガリア菌(Lactobacillus blugaricus)とサーモフィラス菌(Streptococcus thermophilus)を併用することを特徴とする、請求項6記載の方法。 7. The method according to claim 6, wherein a Bulgarian bacterium (Lactobacillus blugaricus) and a thermophilus bacterium (Streptococcus thermophilus) are used in combination as a starter.

- グルコースオキシダーゼを用いないで製造される発酵乳と比べて、乳タンパク質の凝集に伴う物性変化を抑制する方法である、請求項6に記載する方法。 The method according to claim 6, which is a method for suppressing changes in physical properties associated with milk protein aggregation as compared with fermented milk produced without using glucose oxidase.

- 乳タンパク質の凝集に伴う物性変化が、離水発生、乳タンパク質及び/又は脂肪の粒子径の増大、及び発酵乳の組織のザラツキ発生からなる群から選択される少なくとも1つである、請求項6に記載する方法。 The physical property change accompanying the aggregation of milk protein is at least one selected from the group consisting of water separation, increase in milk protein and / or fat particle size, and generation of graininess in fermented milk tissue. How to describe.

- 発酵乳がヨーグルトである、請求項6に記載する方法。 The method according to claim 6, wherein the fermented milk is yogurt.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013503475A JP5995835B2 (en) | 2011-03-04 | 2012-03-01 | Method for producing fermented milk with improved physical properties |

| CN201280011563.XA CN103547162B (en) | 2011-03-04 | 2012-03-01 | The preparation method of the acidified milk that physical property is improved |

| HK14102112.3A HK1189127A1 (en) | 2011-03-04 | 2014-03-03 | Method for producing fermented milk having improved physical properties |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-047347 | 2011-03-04 | ||

| JP2011047347 | 2011-03-04 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012121090A1 true WO2012121090A1 (en) | 2012-09-13 |

Family

ID=46798058

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/055169 WO2012121090A1 (en) | 2011-03-04 | 2012-03-01 | Method for producing fermented milk having improved physical properties |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5995835B2 (en) |

| CN (1) | CN103547162B (en) |

| HK (1) | HK1189127A1 (en) |

| WO (1) | WO2012121090A1 (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014084340A1 (en) * | 2012-11-29 | 2014-06-05 | 株式会社 明治 | Yogurt and production method therefor, production method for extracellular functional product of lactic acid bacteria, and production-increasing agent for extracellular functional product of lactic acid bacteria |

| WO2015041194A1 (en) * | 2013-09-17 | 2015-03-26 | 株式会社明治 | Method for producing fermented milk having improved physical properties |

| WO2015068790A1 (en) * | 2013-11-08 | 2015-05-14 | 株式会社明治 | Fermented milk showing suppressed increase in acidity and method for producing same |

| EP3092907A4 (en) * | 2014-01-09 | 2017-10-25 | Ajinomoto Co., Inc. | Manufacturing method for improved protein-containing food and formulation for improving protein-containing food |

| JP2018143220A (en) * | 2017-03-09 | 2018-09-20 | 雪印メグミルク株式会社 | Fermented milk |

| JP2021023171A (en) * | 2019-08-01 | 2021-02-22 | 株式会社 伊藤園 | Method for producing packed milk-containing coffee drink and aggregation suppressing method |

| JP2021023170A (en) * | 2019-08-01 | 2021-02-22 | 株式会社 伊藤園 | Milk raw material for blending with drink liquid, packed beverage, and method for suppressing aggregation in drink liquid |

| WO2022181782A1 (en) * | 2021-02-26 | 2022-09-01 | 天野エンザイム株式会社 | Method for producing fermented food or beverage, and anaerobic fermentation method |

| WO2023027110A1 (en) | 2021-08-24 | 2023-03-02 | 天野エンザイム株式会社 | Method for producing vegetable-protein-fermented food or beverage |

| WO2023048195A1 (en) | 2021-09-21 | 2023-03-30 | 天野エンザイム株式会社 | Production method for protein fermented food or beverage |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108142554B (en) * | 2017-12-22 | 2020-11-03 | 内蒙古蒙牛乳业(集团)股份有限公司 | Yoghourt and preparation method thereof |

| KR102259148B1 (en) * | 2021-01-04 | 2021-06-01 | 이승종 | Manufacturing method of greek yogurt |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007053930A (en) * | 2005-08-23 | 2007-03-08 | Asama Chemical Co Ltd | Method for producing antibody-containing fermented food |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU761467B2 (en) * | 1998-06-09 | 2003-06-05 | Ajinomoto Co., Inc. | Novel enzyme-treated protein-containing food, and methods for producing the same |

| DK1443827T3 (en) * | 2001-11-02 | 2007-09-03 | Novozymes As | Process for producing a fermented dairy product |

-

2012

- 2012-03-01 WO PCT/JP2012/055169 patent/WO2012121090A1/en active Application Filing

- 2012-03-01 JP JP2013503475A patent/JP5995835B2/en active Active

- 2012-03-01 CN CN201280011563.XA patent/CN103547162B/en not_active Expired - Fee Related

-

2014

- 2014-03-03 HK HK14102112.3A patent/HK1189127A1/en not_active IP Right Cessation

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007053930A (en) * | 2005-08-23 | 2007-03-08 | Asama Chemical Co Ltd | Method for producing antibody-containing fermented food |

Non-Patent Citations (3)

| Title |

|---|

| CRUZ, A.G. ET AL.: "Processing optimization of probiotic yogurt containing glucose oxidase using response surface methodology.", J. DAIRY SCI., vol. 93, no. LL, November 2010 (2010-11-01), pages 5059 - 5068 * |

| HILLER, B. ET AL.: "Properties of set-style skim milk yoghurt as affected by an enzymatic or Maillard reaction induced milk protein oligomerisation.", LWT FOOD SCI. TECHNOL., vol. 44, no. 4, May 2011 (2011-05-01), pages 811 - 819 * |

| OZER, B. ET AL.: "Effects of lactoperoxidase and hydrogen peroxide on rheological properties of yoghurt.", J. DAIRY RES., vol. 70, no. 2, 2003, pages 227 - 232 * |

Cited By (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104780767A (en) * | 2012-11-29 | 2015-07-15 | 株式会社明治 | Yogurt and production method therefor, production method for extracellular functional product of lactic acid bacteria, and production-increasing agent for extracellular functional product of lactic acid bacteria |

| JPWO2014084340A1 (en) * | 2012-11-29 | 2017-01-05 | 株式会社明治 | Yogurt and method for producing the same, method for producing lactic acid bacteria extracellular functional product, and lactic acid bacteria extracellular functional product production agent |

| WO2014084340A1 (en) * | 2012-11-29 | 2014-06-05 | 株式会社 明治 | Yogurt and production method therefor, production method for extracellular functional product of lactic acid bacteria, and production-increasing agent for extracellular functional product of lactic acid bacteria |

| CN104780767B (en) * | 2012-11-29 | 2018-07-06 | 株式会社明治 | Yoghourt and its manufacturing method, the manufacturing method of lactic acid bacteria vitro functional product and lactic acid bacteria vitro functional product increasing agent |

| WO2015041194A1 (en) * | 2013-09-17 | 2015-03-26 | 株式会社明治 | Method for producing fermented milk having improved physical properties |

| JPWO2015041194A1 (en) * | 2013-09-17 | 2017-03-02 | 株式会社明治 | Method for producing fermented milk with improved physical properties |

| CN106061275B (en) * | 2013-11-08 | 2019-11-12 | 株式会社明治 | Acidity rises the acidified milk being inhibited by and its manufacturing method |

| WO2015068790A1 (en) * | 2013-11-08 | 2015-05-14 | 株式会社明治 | Fermented milk showing suppressed increase in acidity and method for producing same |

| CN106061275A (en) * | 2013-11-08 | 2016-10-26 | 株式会社明治 | Fermented milk showing suppressed increase in acidity and method for producing same |

| JPWO2015068790A1 (en) * | 2013-11-08 | 2017-03-09 | 株式会社明治 | Fermented milk with suppressed increase in acidity and method for producing the same |

| EP3092907A4 (en) * | 2014-01-09 | 2017-10-25 | Ajinomoto Co., Inc. | Manufacturing method for improved protein-containing food and formulation for improving protein-containing food |

| JP2018143220A (en) * | 2017-03-09 | 2018-09-20 | 雪印メグミルク株式会社 | Fermented milk |

| JP2021023171A (en) * | 2019-08-01 | 2021-02-22 | 株式会社 伊藤園 | Method for producing packed milk-containing coffee drink and aggregation suppressing method |

| JP2021023170A (en) * | 2019-08-01 | 2021-02-22 | 株式会社 伊藤園 | Milk raw material for blending with drink liquid, packed beverage, and method for suppressing aggregation in drink liquid |

| JP7297587B2 (en) | 2019-08-01 | 2023-06-26 | 株式会社 伊藤園 | Method for producing container-packed milk-containing coffee beverage and method for suppressing aggregation |

| JP7350557B2 (en) | 2019-08-01 | 2023-09-26 | 株式会社 伊藤園 | Dairy raw materials for blending beverages, packaged beverages, and methods for suppressing aggregation in beverages |

| WO2022181782A1 (en) * | 2021-02-26 | 2022-09-01 | 天野エンザイム株式会社 | Method for producing fermented food or beverage, and anaerobic fermentation method |

| WO2023027110A1 (en) | 2021-08-24 | 2023-03-02 | 天野エンザイム株式会社 | Method for producing vegetable-protein-fermented food or beverage |

| WO2023048195A1 (en) | 2021-09-21 | 2023-03-30 | 天野エンザイム株式会社 | Production method for protein fermented food or beverage |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103547162B (en) | 2016-03-23 |

| JPWO2012121090A1 (en) | 2014-07-17 |

| JP5995835B2 (en) | 2016-09-21 |

| HK1189127A1 (en) | 2014-05-30 |

| CN103547162A (en) | 2014-01-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5995835B2 (en) | Method for producing fermented milk with improved physical properties | |

| JP2019080573A (en) | Flavor improved fermented milk and method for producing same | |

| JP6018948B2 (en) | Method for producing concentrated fermented milk containing bifidobacteria | |

| JP6504878B2 (en) | Method of producing fermented milk | |

| JPWO2010001580A1 (en) | Method for producing fermented milk and fermented milk | |

| WO2010089381A2 (en) | Method for producing an acidified milk product | |

| JPWO2013039188A1 (en) | Low calorie fermented milk and method for producing the same | |

| TWI395549B (en) | Manufacture of fermented milk and fermented milk | |

| JP6463270B2 (en) | Method for producing fermented milk with improved physical properties | |

| JP2010207129A (en) | Low-temperature natural cheese and method for producing the same | |

| WO2018151249A1 (en) | Production method for low-acid fermented milk | |

| JPH1099018A (en) | Material for lactobacillus fermented milk in which increase in acidity of lactic acid is suppressed | |

| JP7232177B2 (en) | Method for producing lactic acid bacteria starter and fermented milk | |

| TWI580358B (en) | Yogurt for promoting propagation of Bulgarian bacteria and its manufacturing method | |

| WO2016009950A1 (en) | Fermented milk having enhanced lactobacillus bulgaricus growth and method for producing same | |

| JP2013233097A (en) | Drink type yoghurt with excellent flavor | |

| JP2012105577A (en) | Production method of whey fermented beverage | |

| JP6901837B2 (en) | Method of producing fermented milk using pasteurized raw material mix | |

| JP5660629B2 (en) | Lactic acid bacteria culture method and fermented milk production method | |

| JP7085303B2 (en) | Fermented milk production method | |

| JP2022136018A (en) | Fermentation composition having improved shape retentivity, and method for producing the same | |

| JP7292022B2 (en) | Method for producing fermented milk, method for shortening production time for fermented milk, method for increasing acidity of fermented milk | |

| JP2012080822A (en) | Fresh cheese | |

| JP2021073936A (en) | Method for producing fermented milk, fermented milk, fermented milk product, and method for enhancing flavor of fermented milk | |

| WO2023112941A1 (en) | Fermented composition and method for producing same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201280011563.X Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12755467 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2013503475 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 1301004882 Country of ref document: TH |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12755467 Country of ref document: EP Kind code of ref document: A1 |