WO2010126922A1 - Benzimidazolecarboxamides as inhibitors of fak - Google Patents

Benzimidazolecarboxamides as inhibitors of fak Download PDFInfo

- Publication number

- WO2010126922A1 WO2010126922A1 PCT/US2010/032644 US2010032644W WO2010126922A1 WO 2010126922 A1 WO2010126922 A1 WO 2010126922A1 US 2010032644 W US2010032644 W US 2010032644W WO 2010126922 A1 WO2010126922 A1 WO 2010126922A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mmol

- amino

- product

- benzimidazol

- mhz

- Prior art date

Links

- BSLQMLFKTUWHNL-UHFFFAOYSA-N CCC[n]1c(NC(c(cc2)cc(NS(c3ccccc3)(=O)=O)c2Cl)=O)nc2c1ccc(N(C)C(C)=O)c2 Chemical compound CCC[n]1c(NC(c(cc2)cc(NS(c3ccccc3)(=O)=O)c2Cl)=O)nc2c1ccc(N(C)C(C)=O)c2 BSLQMLFKTUWHNL-UHFFFAOYSA-N 0.000 description 1

- QGENDLSQZHTHRO-UHFFFAOYSA-N CCC[n]1c(NC(c2cc(N)ccc2)=O)nc2c1cccc2 Chemical compound CCC[n]1c(NC(c2cc(N)ccc2)=O)nc2c1cccc2 QGENDLSQZHTHRO-UHFFFAOYSA-N 0.000 description 1

- CXUCEMPUYGMLKO-UHFFFAOYSA-N CCC[n]1c(NC(c2cc(NS(c3ccccc3)(=O)=O)ccc2)=O)nc(cc2)c1cc2NC(C)=O Chemical compound CCC[n]1c(NC(c2cc(NS(c3ccccc3)(=O)=O)ccc2)=O)nc(cc2)c1cc2NC(C)=O CXUCEMPUYGMLKO-UHFFFAOYSA-N 0.000 description 1

- SQGYHYYFSFINRY-UHFFFAOYSA-N CCC[n]1c(NC(c2cccc(NS(c3cccc(Cl)c3)(=O)=O)c2)=O)nc2c1cccc2 Chemical compound CCC[n]1c(NC(c2cccc(NS(c3cccc(Cl)c3)(=O)=O)c2)=O)nc2c1cccc2 SQGYHYYFSFINRY-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D235/00—Heterocyclic compounds containing 1,3-diazole or hydrogenated 1,3-diazole rings, condensed with other rings

- C07D235/02—Heterocyclic compounds containing 1,3-diazole or hydrogenated 1,3-diazole rings, condensed with other rings condensed with carbocyclic rings or ring systems

- C07D235/04—Benzimidazoles; Hydrogenated benzimidazoles

- C07D235/24—Benzimidazoles; Hydrogenated benzimidazoles with hetero atoms or with carbon atoms having three bonds to hetero atoms with at the most one bond to halogen, e.g. ester or nitrile radicals, directly attached in position 2

- C07D235/30—Nitrogen atoms not forming part of a nitro radical

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D401/00—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, at least one ring being a six-membered ring with only one nitrogen atom

- C07D401/02—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, at least one ring being a six-membered ring with only one nitrogen atom containing two hetero rings

- C07D401/12—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, at least one ring being a six-membered ring with only one nitrogen atom containing two hetero rings linked by a chain containing hetero atoms as chain links

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D403/00—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00

- C07D403/02—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings

- C07D403/04—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings directly linked by a ring-member-to-ring-member bond

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D403/00—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00

- C07D403/02—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings

- C07D403/12—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings linked by a chain containing hetero atoms as chain links

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D405/00—Heterocyclic compounds containing both one or more hetero rings having oxygen atoms as the only ring hetero atoms, and one or more rings having nitrogen as the only ring hetero atom

- C07D405/02—Heterocyclic compounds containing both one or more hetero rings having oxygen atoms as the only ring hetero atoms, and one or more rings having nitrogen as the only ring hetero atom containing two hetero rings

- C07D405/12—Heterocyclic compounds containing both one or more hetero rings having oxygen atoms as the only ring hetero atoms, and one or more rings having nitrogen as the only ring hetero atom containing two hetero rings linked by a chain containing hetero atoms as chain links

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D413/00—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and oxygen atoms as the only ring hetero atoms

- C07D413/02—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and oxygen atoms as the only ring hetero atoms containing two hetero rings

- C07D413/12—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and oxygen atoms as the only ring hetero atoms containing two hetero rings linked by a chain containing hetero atoms as chain links

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D417/00—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and sulfur atoms as the only ring hetero atoms, not provided for by group C07D415/00

- C07D417/02—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and sulfur atoms as the only ring hetero atoms, not provided for by group C07D415/00 containing two hetero rings

- C07D417/12—Heterocyclic compounds containing two or more hetero rings, at least one ring having nitrogen and sulfur atoms as the only ring hetero atoms, not provided for by group C07D415/00 containing two hetero rings linked by a chain containing hetero atoms as chain links

Definitions

- This invention relates to a class of heterocycloaminopyridines that inhibit Focal Adhesion Kinase (FAK), as well as compositions thereof. These compounds treat proliferative diseases.

- FAK Focal Adhesion Kinase

- Tyrosine kinases play an important role in the regulation of many cell processes including cell proliferation, cell survival, and cell migration. It is known that certain tyrosine kinases become activated by mutation or are abnormally expressed in many human cancers. For example, the epidermal growth factor receptor (EGFR) is found mutated and/or overexpressed in breast, lung, brain, squamous cell, gastric, and other human cancers. Selective inhibitors of the tyrosine kinase activity of EGFR have been shown to be of clinical value in treatment of cancers with mutated and/or overexpressed EGFR. Thus, selective inhibitors of particular tyrosine kinases are useful in the treatment of proliferative diseases such as cancer.

- EGFR epidermal growth factor receptor

- FAK (encoded by the gene PTK2) is a non-receptor tyrosine kinase that integrates signals from integrins and growth factor receptors. FAK has been reported to play a role in the regulation of cell survival, growth, adhesion, migration, and invasion (McLean et al 2005, Nat Rev Cancer 5:505-515). Furthermore, FAK is regulated and activated by phosphorylation on multiple tyrosine residues.

- FAK mRNA and/or protein has been documented in many solid human tumors, including but not limited to, cancers of the breast, colon, thyroid, lung, ovary, and prostate; but also including cancers of hematological origin, including but not limited to leukemia such as acute myeloid leukemia (AML).

- AML acute myeloid leukemia

- FAK activity is clearly implicated in advanced and metastatic human cancer.

- this invention relates compounds of formula (I) or a salt thereof

- R 1 is H, R 5 -Y-N(R 6 )-; R 7 -N(R 6 )-Y-; R 7 -N(R 6 )- or -COOH;

- R 2 is H or C 1 -C 6 -R 9 ;

- R 3 is H, or halo;

- X is -NH-SO 2 - or -SO 2 -NH-;

- Y is -C(O)- or -S(O) 2 -;

- R 4 is phenyl-(R 8 ) m , C 5 -C 6 -heteroaryl-(R u ) p , or C r C 6 -alkyl-R 9 ;

- R 5 is phenyl-(R 8 ) m , C r C 6 -alkyl-R 9 , C r C 6 -alkoxy, C 3 -C 6 -cycloalkyl, C 5 -C 6 - heterocycloalkyl-(R 10 ) n ; C 5 -C 6 -heteroaryl-(R u ) p or -N(R 12 ) 2 ;

- R 6 is H or Ci-C ⁇ -alkyl;

- R 7 is phenyl-(R 8 ) m ; C r C 6 -alkyl-R 9 ; C 3 -C 6 -cycloalkyl, C 5 -C 6 -heterocycloalkyl-(R 10 ) n , or C 5 -C 6 -heteroaryl-(R u ) p , or R 6 and R 7 , together with the nitrogen atom to which they are attached, form a 5- to 6- membered heterocycloalkyl group; each R 8 is independently Ci-C 6 -alkyl, Ci-C 6 -alkoxy, cyano, dimethylamino, trifluoromethyl, fluoro, or chloro;

- R 9 is H, Ci-C 6 -alkoxy, -C(O)NH 2 , -N(R 13 ) 2 , hydroxy;

- R 13 is H, Ci-C 6 -alkyl, or together with the nitrogen atom to which they are attached, form a 5- to 6-membered heterocycloalkyl group; m is O, 1, or 2; n is 0 or 1 ; and p is 0, 1, or 2.

- this invention relates to compositions comprising a compound of formula (I) and a pharmaceutically acceptable excipient.

- this invention relates to a method for treating proliferative diseases by inhibiting the Focal Adhesion Kinase (FAK) enzyme.

- FAK Focal Adhesion Kinase

- this invention relates to the use of a compound of formula (I) or a pharmaceutically acceptable salt thereof in the manufacture of a medicament for the treatment of a condition which can be treated by inhibiting the activity of the FAK enzyme.

- this invention relates to the use of a compound of formula (I) or a pharmaceutically acceptable salt thereof in therapy.

- halo refers to fluoro, chloro, or bromo.

- Ci-C 6 -alkyl or “Ci-C 6 -” refers to a linear or branched alkyl group including methyl, ethyl, w-propyl, isopropyl, n-butyl, isobutyl, ?-butyl, «-pentyl, and n-hexyl.

- Ci-C 6 -alkoxy refers to Ci-C 6 -alkyl-O- groups, including methoxy, ethoxy, n-propoxy, z ' so-propoxy, and n-butoxy groups.

- C 3 -C 6 -cycloalkyl refers to a cyclopropyl, cyclobutyl, cyclopentyl, or cyclohexyl group.

- 5- or 6-membered heterocycloalkyl refers to a 5- or 6-membered cycloaliphatic group that includes an O, N, or S heteroatom or a combination thereof.

- suitable heterocycloalkyl groups include pyrrolidinyl, pyrrolidinonyl, piperidinyl, piperazinyl, oxopiperazinyl, morpholino, and thiomorpholino groups.

- the R 8 groups may, together with the nitrogen atom to which they are attached, form a 5- to 6-membered cyclic ring, examples of which include pyrrolidinyl, pyrrolidinonyl, piperidinyl, piperazinyl, oxopiperazinyl, morpholino, and thiomorpholino groups.

- heteroaryl refers to a 5- or 6-membered aromatic group containing at least one N, O, or S atom.

- heteroaryl groups examples include pyridinyl, pyridazinyl, pyrimidinyl, pyrazinyl, pyrrolyl, furyl, thienyl, pyrazolyl, imidazolyl, furazanyl, oxazolyl, thiazolyl, isoxazolyl, 1,2,3-triazolyl, 1 ,2,4-triazolyl, tetrazolyl, and isothiazolyl.

- pharmaceutically acceptable refers to those compounds, materials, compositions, and dosage forms which are, within the scope of sound medical judgment, suitable for use in contact with the tissues of human beings and animals without excessive toxicity, irritation, or other problem or complication.

- the present invention covers all combinations of particular and preferred groups described hereinabove. It is also to be understood that the present invention encompasses compounds in which a particular group or parameter, e.g. S(0)m, etc. may occur more than once. In such compounds it will be appreciated that each group or parameter is independently selected from the values listed. When any variable occurs more than one time in a formula, its definition on each occurrence is independent of its definition at every other occurrence.

- salts and solvates of compounds of the invention which are suitable for use in medicine are those wherein the counter-ion or associated solvent is pharmaceutically acceptable.

- salts and solvates having non-pharmaceutically acceptable counter-ions or associated solvents are within the scope of the present invention, for example, for use as intermediates in the preparation of other compounds of the invention and their pharmaceutically acceptable salts and solvates.

- the compounds of the present invention may be in the form of and/or may be administered as a pharmaceutically acceptable salt.

- a pharmaceutically acceptable salt may be readily prepared by using a desired acid or base as appropriate. The salt may precipitate from solution and be collected by filtration or may be recovered by evaporation of the solvent.

- Salts of the compounds of the present invention may, for example, comprise acid addition salts resulting from reaction of an acid with a nitrogen atom present in a compound of formula (I).

- Suitable addition salts are formed from acids which form non- toxic salts and examples are acetate, benzenesulfonate, benzoate, bicarbonate, bisulfate, bitartrate, borate, bromide, calcium edetate, camsylate, carbonate, chloride, clavulanate, citrate, dihydrochloride, edetate, edisylate, estolate, esylate, ethanesulphonate, formate, fumarate, gluceptate, gluconate, glutamate, glycollylarsanilate, hexylresorcinate, hydrabamine, hydrobromide, hydrochloride, hydrogen phosphate, hydroiodide, hydroxynaphthoate, iodide, isethionate, lac

- Pharmaceutically acceptable base salts include ammonium salts such as a trimethylammonium salt, alkali metal salts such as those of sodium and potassium, alkaline earth metal salts such as those of calcium and magnesium and salts with organic bases, including salts of primary, secondary and tertiary amines, such as isopropylamine, diethylamine, ethanolamine, trimethylamine, dicyclohexyl amine and N-methyl-D-glucamine.

- ammonium salts such as a trimethylammonium salt

- alkali metal salts such as those of sodium and potassium

- alkaline earth metal salts such as those of calcium and magnesium

- salts with organic bases including salts of primary, secondary and tertiary amines, such as isopropylamine, diethylamine, ethanolamine, trimethylamine, dicyclohexyl amine and N-methyl-D-glucamine.

- solvates refers to a complex of variable stoichiometry formed by a solute (in this invention, a compound of Formula (I), or a salt thereof) and a solvent.

- solvents for the purpose of the invention may not interfere with the biological activity of the solute.

- suitable solvents include water, methanol, ethanol and acetic acid.

- the solvent used is a pharmaceutically acceptable solvent.

- suitable pharmaceutically acceptable solvents include water, ethanol and acetic acid.

- the solvent used is water.

- a complex with water is known as a "hydrate”. Solvates of the compound of the invention are within the scope of the invention.

- the term "optionally” means that the subsequently described event(s) may or may not occur, and includes both event(s) which occur and events that do not occur.

- substituted refers to substitution with the named substituent or substituents, multiple degrees of substitution being allowed unless otherwise stated.

- the compounds herein may have one or more asymmetric carbon atoms and may occur as racemates, racemic mixtures and as individual enantiomers or diastereomers. All such isomeric forms are included within the present invention, including mixtures thereof.

- Cis (E) and trans (Z) isomerism may also occur.

- the present invention includes the individual stereoisomers of the compound of the invention and where appropriate, the individual tautomeric forms thereof, together with mixtures thereof.

- Separation of diastereoisomers or cis and trans isomers may be achieved by conventional techniques, e.g. by fractional crystallisation, chromatography or H.P.L.C.

- a stereoisomeric mixture of the agent may also be prepared from a corresponding optically pure intermediate or by resolution, such as H.P.L.C. of the corresponding racemate using a suitable chiral support or by fractional crystallisation of the diastereoisomeric salts formed by reaction of the corresponding racemate with a suitable optically active acid or base, as appropriate.

- Exemplified compounds of the compounds of this invention include the racemates, or optically active forms of the compounds of the working examples herein, and pharmaceutically acceptable salts thereof.

- R 1 is substituted on the 5 or 6 position, particularly at the 5 position.

- R 1 those of particular interest may be R 5 -Y-N(R 6 )-, R 7 -N(R 6 )-Y-, R 7 -N(R 6 )-, -COOH or H.

- groups of particular interest are propyl or isopropyl, or a group a Ci-C 6 alkyl group, or Ci-C 6 alkyl-R 9 or H.

- those of particular interest are H, F, or Cl.

- the groups of particular interest are -NH-SO 2 - or -SO 2 -NH-.

- radicals of greater interest are -C(O)- and -S(O) 2 -;

- R 4 group those of particular interest are phenyl-(R 8 ) m , C 5 -C 6 -heteroaryl-(R u ) p , and Ci- C 6 -alkyl-R 9 ;

- R 5 the groups C 5 -C 6 -heteroaryl-(R u ) p , Ci-C 6 -alkyl-R 9 , phenyl-(R 8 ) m , C 3 -C 6 - cycloalkyl, Ci-C 6 -alkoxy, C 5 -C 6 - heterocycloalkyl-(R 10 ) n and -N(R 12 ) 2 are of interest.

- the groups Ci-Ce-alkyl-R 9 > C 3 -C 6 -cycloalkyl > C 5 -C 6 - heterocycloalkyl-(R 10 ) n > phenyl-(R 8 ) m ; or C 5 -C 6 -heteroaryl-(R u ) p , are of interest; or those groups where R 6 and R 7 , together with the nitrogen atom to which they are attached, form a 5- to 6- membered heterocycloalkyl group.

- radicals of interest include H, F, Cl, Ci-C 6 -alkyl, Ci-C 6 -alkoxy, cyano, dimethylamino, or trifluoromethyl.

- the radicals set out in the immediate preceding paragraphs as being of interest, are given in descending order of interest.

- a compound of Formula (I) or a pharmaceutically acceptable salt thereof in therapy it will normally be formulated into a pharmaceutical composition in accordance with standard pharmaceutical practice.

- This invention also relates to a pharmaceutical composition comprising an effective amount of a compound of Formula (I) and a pharmaceutically acceptable carrier or diluent.

- Compounds of Formula (I), pharmaceutically acceptable salts thereof, and pharmaceutical compositions incorporating such may conveniently be administered by any of the routes conventionally used for drug administration, for instance, orally, topically, parenterally or by inhalation.

- the compounds of Formula (I) may be administered in conventional dosage forms prepared by combining a compound of Formula (I) with standard pharmaceutical carriers according to conventional procedures.

- the compounds of Formula (I) may also be administered in conventional dosages in combination with a known, second therapeutically active compound. These procedures may involve mixing, granulating and compressing or dissolving the ingredients as appropriate to the desired preparation. It will be appreciated that the form and character of the pharmaceutically acceptable character or diluent is dictated by the amount of active ingredient with which it is to be combined, the route of administration and other well-known variables.

- the carrier(s) must be "acceptable" in the sense of being compatible with the other ingredients of the formulation and not deleterious to the recipient thereof.

- the pharmaceutical carrier employed may be, for example, either a solid or liquid.

- solid carriers are lactose, terra alba, sucrose, talc, gelatin, agar, pectin, acacia, magnesium stearate, stearic acid and the like.

- liquid carriers are syrup, peanut oil, olive oil, water and the like.

- the carrier or diluent may include time delay material well known to the art, such as glyceryl mono-stearate or glyceryl distearate alone or with a wax.

- the preparation can be a tablet, the active and, optionally, a carrier can be placed in a hard gelatin capsule in powder or pellet form, or the preparation may be in the form of a troche or lozenge.

- the amount of solid carrier will vary widely but preferably will be from about 25mg to about Ig.

- the preparation will be in the form of a syrup, emulsion, soft gelatin capsule, sterile injectable liquid such as an ampule or nonaqueous liquid suspension.

- Compounds of Formula (I) may be administered parenterally, that is by intravenous, intramuscular, subcutaneous intranasal, intrarectal, intravaginal or intraperitoneal administration.

- the subcutaneous and intramuscular forms of parenteral administration are generally preferred.

- Appropriate dosage forms for such administration may be prepared by conventional techniques.

- Compounds of Formula (I) may also be administered by inhalation, that is by intranasal and oral inhalation administration.

- Appropriate dosage forms for such administration such as an aerosol formulation or a metered dose inhaler, may be prepared by conventional techniques.

- the daily topical dosage regimen will preferably be from 0.01 mg to 1000 mg, administered one to four times daily. It will also be recognized by one of skill in the art that the optimal quantity and spacing of individual dosages of a compound of Formula (I) or a pharmaceutically acceptable salt thereof will be determined by the nature and extent of the condition being treated, the form, route and site of administration, and the particular patient being treated, and that such optimums can be determined by conventional techniques.

- formulations of this invention may include other agents conventional in the art having regard to the type of formulation in question, for example those suitable for oral administration may include flavoring agents, or those for inhalation may include carriers, such as lactose.

- flavors such as lactose.

- carriers such as lactose.

- Scheme 1 illustrates methods for synthesizing compounds of formula (VI).

- Treatment of commercially available benzimidazole (I) with an alkyl bromide and potassium hyroxide, in a solvent mixture of tetrahydrofuran and ethanol with heating at 65° C for 72 h furnishes compounds of formula (II).

- Treatment of (VIII) with an alkyl bromide and potassium carbonate in a solvent mixure of N,N-dimethyl formamide, acetone, and water in a sealed flask at about 20° to 55° C for up to 24 h furnishes a compound of formula (IX).

- Scheme 2 illustrates a method of synthesizing compounds of formula (XVI) and (XVII).

- 3-nitro-4-fluoro-aniline (X) is protected with either tert-butoxycarbonyl anydride in tetrahydrofuran with heating at about 65° C for up to 48 h, or acetic anhydride (neat) at room temperature for about 3 h.

- the resultant product may be alkylated on the anilino nitrogen using iodomethane and sodium hydride, in a polar aprotic solvent such as N,N-dimethyl formamide, at a temperature between about 0° and 20° C for 3 h.

- Treatment of the anilino product (XI) either as its fully substituted (i.e.

- a polar aprotic solvent such as N,N-dimethyl formamide

- Reduction of the nitro group of (XII) using hydrogen gas (1 arm) and a catalytic amount of palladium on carbon in a polar solvent such as ethanol, at about 20° C for 3 - 24 h followed by treatment with cyanogen bromide at 20° C for 0.5 - 24 h furnishes a compound of formula (XIII).

- Scheme 3 illustrates a method for synthesizing compounds of formula (XXI).

- Treatment of compound (XVIII) with a compound of formula (III) under standard amide coupling conditions followed by removal of the tert-butyl ester group using trifluoroacetic acid furnishes a compound of formula (XIX).

- Treatment of compound (XIX) with a sulfonyl chloride (XX) and base, preferably pyridine, in DCM at room temperature for 3-12 h furnishes a compound of formula (XXI).

- Scheme 4 illustrates a method for synthesizing compounds of formula (XXI).

- Scheme 4 illustrates a method for synthesizing compounds of formula (XXVII).

- N-(3-chlorophenyl)acetamide (XXII) is nitrated under standard conditions using nitric acid and sulfuric acid to afford a mixture of 2-nitro and 5-nitro compounds, which can be separated.

- the desired product N-(5-chloro-2-nitrophenyl)acetamide (XXIII) may be alkylated on the acetamide nitrogen using iodomethane and sodium hydride, in a polar aprotic solvent such as N,N-dimethyl formamide, at a temperature between about 0° and 20° C for 3 h.

- the acetamide product (XXIV) either as its fully substituted (i.e.

- a polar aprotic solvent such as N-methyl-2-pyrrolidone

- Reduction of the nitro group of (XXV) using hydrogen gas (1 arm) and catalytic palladium on carbon in a polar solvent such as ethanol at about 20° C for 24 h followed by treatment with cyanogen bromide at about 20° C for 0.5 - I h furnishes benzimidazole (XXVI).

- Treatment of (XXVI) with compounds of formula (XIV) using standard amidation conditions affords compounds of formula (XXVII).

- Magnesium sulfate and sodium sulfate used as drying agents were of anhydrous grade, and were used interchangeably. Solvents removed in vacuo were done so by rotary evaporation. Preparative normal phase silica gel chromatography was carried out using a Teledyne

- the nebulizing gas was generated from a zero air generator (Balston Inc., Haverhill, MA, USA) and delivered at 65 psi and the curtain gas was high purity nitrogen delivered from a Dewar liquid nitrogen vessel at 50 psi.

- the voltage applied to the electrospray needle was 4.8 kV.

- the orifice was set at 25 V and mass spectrometer was scanned at a rate of 0.5 scan/sec using a step mass of 0.2 amu and collecting profile data.

- Method A LCMS Method A LCMS. Samples were introduced into the mass spectrometer using a CTC PAL autosampler (LEAP Technologies, Carrboro, NC) equipped with a hamilton 10 uL syringe which performed the injection into a Valco 10-port injection valve.

- the HPLC pump was a Shimadzu LC-10ADvp (Shimadzu Scientific Instruments, Columbia, MD) operated at 0.3 mL/min and a linear gradient 4.5% A to 90% B in 3.2 min. with a 0.4 min. hold.

- the mobile phase was composed of 100% (H 2 O 0.02% TFA) in vessel A and 100% (CH 3 CN 0.018% TFA) in vessel B.

- the stationary phase is Aquasil (C 18) and the column dimensions were 1 mm x 40 mm. Detection was by UV at 214 nm, evaporative light-scattering (ELSD) and MS. Method B, LCMS. Alternatively, an Agilent 1100 analytical HPLC system with an

- LC/MS was used and operated at 1 mL/min and a linear gradient 5% A to 100% B in 2.2 min with a 0.4 min hold.

- the mobile phase was composed of 100% (H 2 O 0.02% TFA) in vessel A and 100% (CH 3 CN 0.018% TFA) in vessel B.

- the stationary phase was Zobax (C8) with a 3.5 urn particle size and the column dimensions were 2.1 mm x 50 mm. Detection was by UV at 214 nm, evaporative light- scattering (ELSD) and MS.

- Method C LCMS.

- an MDSSCIEX API 2000 equipped with a capillary column of (50 x 4.6 mm, 5 ⁇ va) was used.

- HPLC was done on Agilent- 1200 series UPLC system equipped with column Zorbax SB-Cl 8 (50 x 4.6 mm, 1.8 ⁇ m) eluting with CH 3 CN: ammonium acetate buffer.

- the reactions were performed in the microwave (CEM, Discover).

- 1 H-NMR spectra were recorded at 400 MHz using a Bruker AVANCE 400 MHz instrument, with ACD Spect manager v. 10 used for reprocessing.

- Analytical HPLC Products were analyzed by Agilent 1100 Analytical Chromatography system, with 4.5 x 75 mm Zorbax XDB-Cl 8 column (3.5 urn) at 2 mL/min with a 4 min gradient from 5% CH 3 CN (0.1% formic acid) to 95% CH 3 CN (0.1% formic acid) in H 2 O (0.1% formic acid) and a 1 min hold.

- the title compound was prepared from 3-amino-N-(l-propyl-l ⁇ -benzimidazol-2- yl)benzamide (0.080 g, 0.22 mmol), 3-chloro-benzenesulfonyl chloride (0.046 mL, 0.22 mmol) and triethylamine (0.106 mL, 0.762 mmol) substantially according to the procedure of Example 1 step d.

- the product was collected as an off-white solid (0.056 g, 55%).

- N-l ⁇ -2-amino-benzimidazole (3.0 g, 22.5 mmol,), 3-nitro-benzoic acid (4.14 g, 24.8 mmol g), EDC (4.75 g, 24.8 mmol), HOAT (3.37 g, 24.78 mmol) and NMM (5.45 mL, 49.6 mmol) were suspended in DMF (80 mL) and stirred at room temperature, overight. The mixture was quenched with 200 mL aq. NaHC ⁇ 3, filtered, and the filtered solid washed with water. The product was collected as a yellow solid (5.27 g, 83%).

- N- l ⁇ -benzimidazol-2-yl-3- nitrobenzamide (0.500 g, 1.77 mmol) in acetone (10 mL), DMF (2 mL) and water (0.2 mL).

- K 2 CO 3 490 mg, 3.54 mmol

- methyl 3-bromopropanoate 0.296 g, 1.77 mmol.

- the reaction mixture was stirred at room temperature for 16 h, followed by heating at 55 0 C for 24 h. After cooling to room temperature, the reaction mixture was concentrated to near dryness and then suspended in water (5 mL). The contents were extracted with 10% THF in EtOAc (3x).

- the product was prepared from N-l ⁇ -benzimidazol-2-yl-3-nitrobenzamide (0.750 g, 2.62 mmol), acetone (15 mL), DMF (3 mL) water (0.3 mL) K 2 CO 3 (0.734 g, 5.31 mmol), and methyl 5-bromopentanoate (0.570 g, 2.92 mmol) substantially according to the procedure of example 3, step b.

- the product was collected as a yellow solid (0.856 g, 81%).

- the product was prepared from methyl 5-(2- ⁇ [(3-nitrophenyl)carbonyl]amino ⁇ -lH- benzimidazol-l-yl)pentanoate (0.850 g, 2.14 mmol), Pd/C (0.17Og, 10%) and hydrogen gas (1 arm) substantially according to the procedure of example 3, step c, wherein the contents were stirred under at atmosphere of hydrogen for 4 h.

- the product was collected as a white solid (0.447 g, 57%).

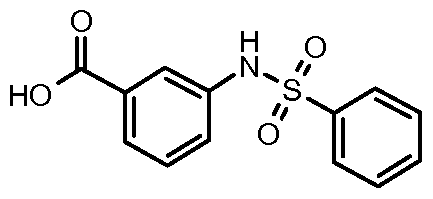

- Step 1 Methyl 3-aminobenzoate (10 g, 66.2 mmol) was dissolved in pyridine (100 mL) and cooled in an ice bath for 15 min. Benzenesulfonyl chloride (8.53 ml, 66.2 mmol) was added via syringe over 5 min, and the solution then stirred with warming to room temperature over a 16 h period. The reaction mixture was poured onto ice and IM HCl (250 mL total volume) to afford a heterogenous acidic mixture (pH 2-3). The solid was filtered and washed with water. The collected solid was dried under hi-vacuum for 12 h to afford the coupled product (19.3, 100%) as an off-white solid.

- Step 2 The solid product from step 1 was added to THF (100 mL), and stirred for 15 min. NaOH (110 mL, 331 mmol) was added slowly via an addition funnel and the reaction mixture stirred at room temperature for 16 h. The contents were gently heated at 45°C for 30 min, and the volatiles then removed in vacuo. The crude residue was diluted with water and acidfied to pH 3-4 using IM HCl. The heterogenous contents were allowed to stand at room temperature for 15 min , and then filtered. The filtered solid was further washed with water, and then dried under hi- vacuum for 20 h. The product was collected as an off- white solid (17.5 g, 95% overall) that was used without further purification.

- the product was prepared from 1 , 1 -dimethylethylmethyl[3-nitro-4-

- the aminobenzimidazole carboxamide compounds illustrated in table 1 were prepared from either N-[5-(methylamino)- 1 -propyl- lH-benzimidazol-2-yl]-3- [(phenylsulfonyl)amino]benzamide or N-(5-amino-l-propyl-lH-benzimidazol-2-yl)-3- [(phenylsulfonyl)amino]benzamide and various carboxylic acids substantially according to the procedure of Example 9. Reaction stir times ranged from 3-36 h. Additional purification by reverse phase ⁇ PLC was utilized for some examples. In the following tables, the dashed lines indicate the points of attachment. Thus, for Example 10, the compound corresponds to the following structure:

- Methanesulfonyl chloride (0.016 mL, 0.20 mmol) and pyridine (0.040 mL, 0.5 mmol) were sequentially added to the stirring solution, and the reaction mixture was stirred while warming to room temperature. After 2.5 h, additional methanesulfonyl chloride (0.016 mL, 0.20 mmol) and pyridine (0.040 mL, 0.5 mmol) were added After stirring for an additional 1.5 h, the contents were concentrated in vacuo. The solid residue was washed with water (7 mL), and the solvent layer decanted. The collected solid was triturated from MeOH (2 x 5 mL) and dried in vacuum oven at 40 0 C overnight.

- N-(5-Amino- 1 -propyl- lH-benzimidazol-2-yl)-3-[(phenylsulfonyl)amino]benzamide (0.090 g, 0.20 mmol) was dissolved in DCM (2 mL), and the solution was cooled to 0 0 C.

- Benzenesulfonyl chloride (0.026 mL, 0.20 mmol) and pyridine (0.040 mL, 0.5 mmol) were sequentially added to the stirring solution, and the reaction mixture was stirred while warming to room temperature. After 3 h, the contents were concentrated in vacuo. The oil was suspended in water (4 mL), stirred for 45 min., and the resultant heterogenous mixture filtered. The collected solid was triturated from MeOH (3 mL) and dried. The product was collected as a nearly white solid (0.060 g, 51%).

- the title compound was prepared from N-[5-(methylamino)-l -propyl- lH-benzimidazol-2- yl]-3 [(phenylsulfonyl)amino]benzamide (0.093 g, 0.20 mmol), benzenesulfonyl chloride (0.026 mL, 0.20 mmol) and pyridine (0.043 mL, 0.5 mmol) substantially according to the procedure of example 47, wherein the reaction stir time was 2 h. The product was collected as an off-white solid (0.098 g, 81%).

- N- ⁇ 5-[(4-Chlorobutanoyl)amino]- 1 -propyl- lH-benzimidazol-2-yl ⁇ -3- [(phenylsulfonyl)amino]benzamide (225 mg, 0.406 mmol) and K 2 CO3 (112 mg, 0.812 mmol) were suspended in NMP (3 mL) and stirred at 60 0 C for 18 h. After cooling to room temperature, the reaction mixture was poured onto water/EtOAc. The layers were separated and the organic extract was washed with brine, dried, and solvent removed.

- N-(5-Amino-l -propyl- l ⁇ -benzimidazol-2-yl)-3-[(phenylsulfonyl)amino]benzamide 100 mg, 0.222 mmol

- 2-chloropyrimidine 127 mg, 1.112 mmol

- Cs 2 CO 3 145 mg, 0.445 mmol

- the mixture was partitioned between EtOAc and water.

- the organic layer was washed with water and then brine.

- the organic layer was dried over MgSO 4 , filtered, and concentrated in vacuo to dryness.

- N-(4-Fluoro-3-nitrophenyl)acetamide (11.74 g, 59.2 mmol) was dissolved in 200 mL THF at 0 0 C, followed by portion wise addition of sodium hydride (3.55 g, 89 mmol, 60% in hexanes). After stirring for 20 min, iodomethane (1 1.11 mL, 178 mmol) was added. The ice bath was removed, and the reaction mixture was stirred at room temperature for 3 h. The reaction mixture was then quenched with saturated NaHC ⁇ 3, and extracted with EtOAc (3x). The combined organic extracts were washed with brine (2x), dried over Na 2 SOz I , and filtered in vacuo.

- N-Methyl-N-[3-nitro-4-(propylamino)phenyl]acetamide (13.56 g, 54.0 mmol) and 10% Pd/C (2.71 g, 2.55 mmol) were dissolved in ethanol (300 mL) under a blanket of argon. The contents were stirred under an atmosphere of hydrogen (1 arm) for 24 h, after which time LC/MS analysis indicated the reaction was complete. The system was then purged with argon. The reaction mixture was vacuum filtered through a pad of Celite, and the filter cake washed with additional EtOH (100 mL). The combined filtrates (400 mL) were stirred and treated with cyanogen bromide (8.58 g, 81 mmol).

- N-(2 -Amino- 1 -propyl- lH-benzimidazol-5-yl)-N-methylacetamide (4.0 g, 16.2 mmol) was dissolved in 50 mL dry DMF, followed by sequential addition of 3 -( ⁇ [(1,1 - dimethylethyl)oxy]carbonyl ⁇ amino)benzoic acid (4.24 g, 17.9 mmol), EDC (3.42 g, 17.9 mmol), and ⁇ OAT (2.43 g, 17.9 mmol).

- NMM (5.36 mL, 48.7 mmol) was added dropwise via syringe, and the contents were stirred at room temperature.

- N- ⁇ 5-[Acetyl(methyl)amino]- 1 -propyl- l ⁇ -benzimidazol-2-yl ⁇ -3-aminobenzamide (100 mg, 0.274 mmol) was dissolved in 5 mL DCM followed by addition of 3-fluorobenzenesulfonyl chloride (53.3 mg, 0.274 mmol) and pyridine (0.066 mL, 0.821 mmol). The reaction mixture was stirred at room temperature for 12 h. The reaction mixture was then quenched with water (3 mL), and the layers were separated.

- aminobenzimidazole carboxamide compounds illustrated in table 2 were prepared from N- ⁇ 5-[acetyl(methyl)amino]- 1 -propyl- lH-benzimidazol-2-yl ⁇ -3-aminobenzamide and various sulfonyl chloride-containing compounds substantially according to the procedure of example 56.

- the product was prepared from 2-fluoro-5-amino-benzoic acid (0.776 g, 5.0 mmol), benzenesulfonyl chloride (0.774 mL, 6.0 mmol) and sodium carbonate (1.17 g, 11.0 mmol) substantially according to the procedure of Example 70, step a.

- the product was washed with DCM (10 mL), and collected as a wine colored solid (1.02 g, 69%).

- the title compound was prepared from N-(2-amino-l -propyl- lH-benzimidazol-5-yl)-N- methylacetamide (0.074 g, 0.3 mmol), 2-fluoro-5-[(phenylsulfonyl)amino]benzoic acid (0.115 g, 0.39 mmol g), EDC (0.074 g, 0.39 mmol), ⁇ OAT (0.053 g, 0.39 mmol) and ⁇ MM (0.043 mL, 0.39 mmol) substantially according to the procedure of Example 7, step f, wherein the reaction stir time was 20 h. The product was collected as an off- white solid (0.123 g, 75%).

- the product was prepared from 4-chloro-3 -amino-benzoic acid (0.257 g, 1.5 mmol), benzenesulfonyl chloride (0.232 mL, 1.8 mmol) and Na 2 C ⁇ 3 (0.334 g, 3.15 mmol) substantially according to the procedure of Example 70, step a, wherein the reaction stir time was 4 h.

- the product was collected as a white solid (0.210 g, 45 %).

- Methyl 3-amino-4-fluorobenzoate (2 g, 13 mmol) and pyridine (2.1 g, 76.4 mmol) were suspended in DCM (25 mL), and to the stirring solution was slowly added 2-trifluoromethyl- benzenesulfonyl chloride (3.24 g, 13 mmol) at room temperature. After stirring for 2 h, the reaction mixture was washed with water and then extracted with DCM. The combined organic layers were dried over Na 2 SOz I , filtered, and concentrated in vacuo. The crude residue was suspended in water (30 mL) followed by slow addition of NaOH (1.1 g, 28 mmol), and the mixture heated at reflux overnight. After cooling to room temperature, the reaction mixture was extracted with DCM.

- the product was prepared from methyl 3-aminobenzoate (2.0 g, 13.2 mmol), 3-fluoro- benzenesulfonyl chloride (2.57 g, 13.2 mmol), pyridine (2.1 g, 26.4 mmol), and sodium hydroxide (0.9 g, 22.6 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid (2.42 g, 62%).

- LC-MS (ES) m/z 296.1 (M+H) + 1 H NMR (400 MHz, DMSO-d 6 ) ⁇ ppm 10.77 (br, 1 H), 7.71 (m, 6 H), 7.40 (m, 2 H).

- the product was prepared from methyl 3-aminobenzoate (2.0 g, 13.0 mmol), 4-methoxy- benzenesulfonyl chloride (2.7 g, 13.0 mmol), pyridine (2.7 g, 26.0 mmol), and sodium hydroxide (1.1 g, 28.0 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid.

- LC-MS (ES) m/z 330.1 (M+H) + 1 H NMR (400 MHz, DMSOd 6 ) ⁇ ppm 7.68 (m, 3 H), 7.57 (m, 1 H), 7.32 (m, 2 H), 7.02 (m, 2 H), 3.76 (s, 3 H).

- the product was prepared from methyl 3-aminobenzoate (1.3 g, 8.6 mmol), 3,5-difluoro- benzenesulfonyl chloride (1.51 g, 8.6 mmol), pyridine (1.3 g, 17,.2 mmol), and sodium hydroxide (0.59 g, 14.6 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid (2.0 g, 70%).

- LC-MS (ES) m/z 336.0 (M+H) + 1 H NMR (400 MHz, DMSO- d 6 ) ⁇ ppm 7.71 (m, 1 H), 7.63 (m, 1 H), 7.31 (m, 4 H), 6.92 (m, 1 H).

- the product was prepared from methyl 4-fluoro-3-aminobenzoate (2.0 g, 11.8 mmol), 3- fluoro-benzenesulfonyl chloride (2.3 g, 11.8 mmol), pyridine (1.87 g, 23.6 mmol), and sodium hydroxide (0.93 g, 23.2 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid (3.0 g, 81%).

- the product was prepared from methyl 4-fluoro-3-aminobenzoate (2.0 g, 11.8 mmol), 4- methoxy-benzenesulfonyl chloride (2.44 g, 11.8 mmol), pyridine (1.79 g, 23.6 mmol), and sodium hydroxide (1.0 g, 26.0 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid (3.7 g, 88%).

- the product was prepared from methyl 4-fluoro-3-aminobenzoate (1.6 g, 9.46 mmol), 3,5- difluoro-benzenesulfonyl chloride (2.0 g, 9.46 mmol), pyridine (1.5 g, 18.92 mmol), and sodium hydroxide (0.74 g, 18.6 mmol) substantially according to the procedure of example 76c.

- the product was collected as a solid (3.0 g, 96%).

- 1 H NMR 400 MHz, DMSOd 6 ) ⁇ ppm 10.70 (br, 1 H), 7.81 (m, 2 H), 7.67 (m, 1 H), 7.39 (m, 3 H).

- the aminobenzimidazole carboxamide compounds illustrated in table 3 were prepared from 1 , 1 -dimethylethyl (2-amino-l -propyl- lH-benzimidazol-5-yl)methylcarbamate and the bisphenylsulfonyl carboxylic acids listed as intermediates 1 -7, and the product from step c of Example 76, substantially according to the procedures of Example 76, steps d-e.

- the position number listed corresponds to the attachment point on the molecule.

- the compound corresponds to the following structure:

- Example 4 The aminobenzimidazole carboxamide compounds illustrated in table 4 were prepared from the substituted N-[5-(methylamino)- 1 -propyl- lH-benzimidazol-2-yl]-3- [(phenylsulfonyl)amino]benzamides (Examples 77-83) and various carboxylic acids substantially according to the procedure of Example 84. Reactions were typically conducted at room temperature, or with heating up to 80 0 C. In the following table, the dashed lines indicate point of attachment. The position number listed corresponds to the attachment point on the molecule as per the numbering shown. Thus, for Example 85, the compound corresponds to the following structure:

- the product was prepared from N-(4-fluoro-3-nitrophenyl)-N-methylacetamide (4.0 g, 18.8 mmol), isopropylamine (1.67 g, 28.3 mmol), K 2 CO 3 (5.2 g, 37.7 mmol), and DMF (30 mL) substantially according to the procedure of Example 55, step c, wherein the reaction stir time was overnight.

- the product was collected as a solid, 0.5 g (11 %).

- N-Methyl-N- ⁇ 4-[(l-methylethyl)amino]-3-nitrophenyl ⁇ acetamide (0.50 g, 1.99 mmol) and 10% Pd/C (0.050 g) in ethanol (10 mL) were stirred under an atmosphere of hydrogen (1 atm) for 4 h.

- the reaction mixture was vacuum filtered through a pad of Celite.

- the filtrate was treated with cyanogen bromide (0.316 g, 2.98 mmol) and stirred at room temperature overnight.

- the reaction mixture was poured onto water, stirred for 15 min, and neutralized to p ⁇ 7 with IN NaOH. The aq. layer was separated and extrated with EtOAc.

- the product was prepared from ⁇ -(4-fluoro-3-nitrophenyl)- ⁇ -methylacetamide (4.0 g, 18.8 mmol),n-butylamine (1.67 g, 28.3 mmol), K 2 CO 3 (5.2 g, 37.7 mmol), and DMF (30 mL) substantially according to the procedure of Example 55, step c, wherein the reaction stir time was overnight.

- the product was collected as a solid (4.0 g, 80%).

- the product was prepared from N-[4-(butylamino)-3-nitrophenyl]-N-methylacetamide (4.0 g, 15.1 mmol) using 10% Pd/C (0.427 g, 0.395 mmol), EtOH (40 mL), and cyanogen bromide (2.4 g, 22.6 mmol), substantially according to the procedure of example 158 step b.

- the product was prepared from N-(4-fluoro-3-nitrophenyl)-N-methylacetamide (0.62 g, 2.92 mmol), K 2 CO 3 (0.492 g, 3.51 mmol), ethyl ⁇ -alaninate (0.90 g, 5.84 mmol) and DMF (8 mL) substantially according to the procedure of Example 8, step b, with a reaction stir time of 20 h.

- the product was suspended in an equal volume of DCM and hexanes, concentrated in vacuo, and dried under hi-vacuum for 3 h.

- the product was collected as a dark reddish-brown solid (0.90 g, 100%). The collected solid was used without further purification.

- the crude residue was treated with 7 mL DCM, sonicated at RT, and then placed in freezer for 1 h. The solution was removed and filtered to afford a minor amount of a sticky solid. The filtrate was concentrated in vacuo.

- the crude residue purified by silica gel chromatography (eluent: l%NH 4 0H/9%Me0H/CHCl 3 ) and furnished the final product as a white solid (0.40 g, 43% overall).

- N-(3-Chloro-4-nitrophenyl)acetamide (0.50 g, 2.33 mmol) and K 2 CO3 were suspended in NMP (5 mL) at room temperature followed by addition of n-propylamine (0.575 mL, 6.99 mmol) to the stirring mixture. The contents were stirred at 50 0 C for 18 h then at 65°C for 8 h. After cooling to room temperature, the mixture was partitioned between EtOAc and water. The organic layer was washed with brine, dried over MgSO/t, filtered, and concentrated in vacuo.

- the heterogenous mixture was allowed to stand at room temperature for 20 min, and then filtered.

- the crude solid was purified by silica gel chromatography (eluent: 2-8% MeOH in CHCl 3 ) to afford the product as an off-white solid (1.6 g, 72%).

- the product was prepared from 3-fluoro-4-nitrobenzoic acid (5.13 g, 27.7 mmol), tert- butyl 2,2,2-trichloroacetimidate (6.200 ml, 33.2 mmol, 1.2 eq), and BF 3 OEt 2 (0.140 ml, 1.108 mmol) substantially according to the procedure of Example 163, step a.

- the product was obtained as an off-white solid.

- the product was prepared from 1,1 -dimethylethyl 4-nitro-3-(propylamino)benzoate (4.63 g, 161.5 mmol) and 10% palladium on carbon (0.879 g, 0.826 mmol), according to the procedure of Example 163, step c.

- the product was obtained as a solid (4.13g, 100%).

- the product was prepared from 1,1 -dimethylethyl 4-amino-3-(propylamino)benzoate (4.17 g, 16.7 mmol) and cyanogen bromide (2.65 g, 25.0 mmol), according to the procedure of Example 163, step d.

- the product was obtained as a solid (3.61g, 79%).

- the product was prepared from 1 , 1 -dimethylethyl 2-amino- 1 -propyl- lH-benzimidazole-6- carboxylate (1.15 g, 4.18 mmol), 3-[(phenylsulfonyl)amino]benzoic acid (1.74 g, 6.26 mmol), EDC (1.68 g, 8.77 mmol), ⁇ OAT (1.19 g, 8.77 mmol), and NMM (1.38 ml, 12.5 mmol) substantially according to the procedure of Example 163, step e. The product was collected as an off-white solid (1.6 g, 71%).

- Example 166 [(phenylsulfonyl)amino]phenyl ⁇ carbonyl)amino]-l-propyl-lH-benzimidazole and various amines substantially according to the procedure of Example 165.

- the dashed lines indicate point of attachment. The position number listed corresponds to the attachment point on the molecule as per the numbering shown.

- the compound corresponds to the following structure:

- GST-tagged FAK (GST - glutathione-S-transferase) was purchased from Invitrogen [www.Invitrogen.com].

- the activity of FAK was measured by monitoring the phosphorylation of the tyrosine residues of the FAK-tide substrate (PerkinElmer CUSN64935, NH 2 -(ULightTM)- CSETDDYAEIID-COOH, i.e - NH2-Cysteine(S-ULight)-Serine-Glutamic Acid-Threonine- Aspartic Acid-Aspartic Acid- Tyrosine -Alanine-Glutamic Acid-Isoleucine-Isoleucine-Aspatic Acid-COOH) in the presence of ATP and peptide.

- Flag-His-TEV-FAKl was prepared in-house. The activity of FAK was measured by monitoring the phosphorylation of LANCE Ultra NH2-(ULight)-CSETDDYAEIID-COOH substrate (purchased from Perkin Elmer Life Sciences). To measure inhibitors of FAK, compounds were first prepared as a IOOX stock in 100% DMSO. A small portion of each compound solution (50 nL) was added to a black 384-well low-volume microtiter plate (Greiner 784076).

- a 1.2nM Flag-His-TEV-FAKl solution was prepared in IX reaction buffer containing 4OmM Tris/Tris-HCL, 1OmM MgC12, ImM CHAPS, at a pH of 7.5, with ImM DTT added. 2.5ul of the 1.2 nM Flag-FAK solution was added to the plates and pre-incubated with the compounds for 30 min at room temperature. Then, 2.5 ⁇ L of substrate solution (0.1 ⁇ M of P2 FAK-tide specific substrate (Lance Ultra NH2-(ULight)-CSETDDYAEIID-COOH from Perkin Elmer), lO ⁇ M ATP and the Ix reaction buffer described above), was added to the plate to initiate the reaction.

- substrate solution 0.1 ⁇ M of P2 FAK-tide specific substrate (Lance Ultra NH2-(ULight)-CSETDDYAEIID-COOH from Perkin Elmer), lO ⁇ M ATP and the Ix reaction buffer described above

- the reaction is quenched by adding 5 uL of 2OmM EDTA and 5nMEu-Anti-pTyr antibody in IX LANCE detection buffer. After a 30 minute incubation at room temperature, the plate is read on a Perkin Elmer Viewlux with a 320- 340nm excitation filter and measuring emission at 615nm and 665nm. The ratio of 665nm/615nm is used for data normalization.

- the compounds set out in Examples 73-76, 84-159 had an IC 5 O range between -500 nM and 2 nM.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

Abstract

This invention relates to benzimadolecarboxamides of formula (I) which are inhibitors of focal adhesion kinase, and as such are useful for treating proliferative diseases.

Description

BENZIMIDAZOLECARBOXAMIDES AS INHIBITORS OF FAK

Background of the Invention

This invention relates to a class of heterocycloaminopyridines that inhibit Focal Adhesion Kinase (FAK), as well as compositions thereof. These compounds treat proliferative diseases.

Tyrosine kinases play an important role in the regulation of many cell processes including cell proliferation, cell survival, and cell migration. It is known that certain tyrosine kinases become activated by mutation or are abnormally expressed in many human cancers. For example, the epidermal growth factor receptor (EGFR) is found mutated and/or overexpressed in breast, lung, brain, squamous cell, gastric, and other human cancers. Selective inhibitors of the tyrosine kinase activity of EGFR have been shown to be of clinical value in treatment of cancers with mutated and/or overexpressed EGFR. Thus, selective inhibitors of particular tyrosine kinases are useful in the treatment of proliferative diseases such as cancer.

FAK (encoded by the gene PTK2) is a non-receptor tyrosine kinase that integrates signals from integrins and growth factor receptors. FAK has been reported to play a role in the regulation of cell survival, growth, adhesion, migration, and invasion (McLean et al 2005, Nat Rev Cancer 5:505-515). Furthermore, FAK is regulated and activated by phosphorylation on multiple tyrosine residues. Overexpression of FAK mRNA and/or protein has been documented in many solid human tumors, including but not limited to, cancers of the breast, colon, thyroid, lung, ovary, and prostate; but also including cancers of hematological origin, including but not limited to leukemia such as acute myeloid leukemia (AML). (Owens et al. 1995, Cancer Research 55: 2752-2755; Agochiya et al. 1999, Oncogene 18: 5646-5653; Gabarro-Niecko et al. 2003, Cancer Metastasis Rev. 22:359-374; Recher et al. 2004, Cancer Research 64:3191-3197; Zhao and Guan, 2009. Cancer Metastasis Rev.). More significantly, there is evidence that phosphorylated FAK is increased in malignant compared to normal tissues (Grisaru-Granovsky et al. 2005, Int. J. Cancer 113: 372-378) and could represent a prognostic marker of metastasis. FAK activity is clearly implicated in advanced and metastatic human cancer.

Inhibition of FAK by RNAi or expression of a FAK dominant negative has been shown to induce loss of adhesion and cell death in human breast and melanoma cell lines, and to augment docetaxel-mediated apoptosis in ovarian cancer cells (Beviglia et al 2003, Biochem J. 373:201- 210, Smith et al 2005, Melanoma Res. 15:357-362, Haider et al 2005, Clin. Cancer Res. 11 :8829- 8836). However, inhibition of FAK in normal human fibroblasts or immortalized mammary cells (MCFlOA) was found not to cause loss of attachment or apoptosis (Xu et al. 1996 Cell Growth and Diff 7:413-418). Inhibition of FAK by dominant negative expression has also been shown to reduce tumor growth and eliminate lung metastasis of mammary adenocarcinoma cells in a

syngeneic rat model (van Nimwegen et al 2005, Cancer Res. 65:4698-4706). Similarly, inhibition of FAK by shRNA inhibited lung metastasis and reduced lethality by 40% in a syngeneic mouse model (Mitra et al 2006, Oncogene 25: 4429-4440). In this study, transient re-expression of wild- type, but not kinase-dead FAK, reversed the shRNA phenotypes. Inhibition of FAK by dominant negative expression in mouse 4Tl carcinoma cells reduced tumor growth and angiogenesis in mice (Mitra et al 2006, Oncogene 25:5969-5984). Furthermore, loss of FAK catalytic activity (reconstitution of FAK-/- cells with kinase-dead FAK) reduced growth of v-Src tumors in mice and decreased angiogenesis.

Thus, there is strong evidence to suggest that inhibition of FAK activity induces, for example, apoptosis, loss of adhesion, inhibition of cell growth and migration, and that such inhibition reduces angiogenesis. Accordingly, compounds that inhibit FAK activity would be useful for the treatment of cancer.

Summary of the Invention In a first aspect, this invention relates compounds of formula (I) or a salt thereof

R1 is H, R5 -Y-N(R6)-; R7-N(R6)-Y-; R7-N(R6)- or -COOH; R2 is H or C1-C6-R9; R3 is H, or halo;

X is -NH-SO2- or -SO2-NH-; Y is -C(O)- or -S(O)2-;

R4 is phenyl-(R8)m, C5-C6-heteroaryl-(Ru)p, or CrC6-alkyl-R9; R5 is phenyl-(R8)m, CrC6-alkyl-R9, CrC6-alkoxy, C3-C6-cycloalkyl, C5-C6- heterocycloalkyl-(R10)n; C5-C6-heteroaryl-(Ru)p or -N(R12)2; R6 is H or Ci-Cβ-alkyl;

R7 is phenyl-(R8)m; CrC6-alkyl-R9; C3-C6-cycloalkyl, C5-C6-heterocycloalkyl-(R10)n, or C5-C6-heteroaryl-(Ru)p, or R6 and R7, together with the nitrogen atom to which they are attached, form a 5- to 6- membered heterocycloalkyl group; each R8 is independently Ci-C6-alkyl, Ci-C6-alkoxy, cyano, dimethylamino,

trifluoromethyl, fluoro, or chloro;

R9 is H, Ci-C6-alkoxy, -C(O)NH2, -N(R13)2, hydroxy; R10 is Ci-Cβ-alkyl; each R11 is independently H, Ci-C6-alkyl each R12 is independently H or CrC6-alkyl, phenyl;

R13 is H, Ci-C6-alkyl, or together with the nitrogen atom to which they are attached, form a 5- to 6-membered heterocycloalkyl group; m is O, 1, or 2; n is 0 or 1 ; and p is 0, 1, or 2.

In a second aspect, this invention relates to compositions comprising a compound of formula (I) and a pharmaceutically acceptable excipient.

In yet another aspect, this invention relates to a method for treating proliferative diseases by inhibiting the Focal Adhesion Kinase (FAK) enzyme. In addition, it relates to the use of a compound of formula (I) or a pharmaceutically acceptable salt thereof in the manufacture of a medicament for the treatment of a condition which can be treated by inhibiting the activity of the FAK enzyme.

Furthermore, this invention relates to the use of a compound of formula (I) or a pharmaceutically acceptable salt thereof in therapy.

Detailed description of the Invention As used herein, "halo" refers to fluoro, chloro, or bromo.

"Ci-C6-alkyl" or "Ci-C6-" refers to a linear or branched alkyl group including methyl, ethyl, w-propyl, isopropyl, n-butyl, isobutyl, ?-butyl, «-pentyl, and n-hexyl. "Ci-C6-alkoxy" refers to Ci-C6-alkyl-O- groups, including methoxy, ethoxy, n-propoxy, z'so-propoxy, and n-butoxy groups.

"C3-C6-cycloalkyl" refers to a cyclopropyl, cyclobutyl, cyclopentyl, or cyclohexyl group. As used herein, "5- or 6-membered heterocycloalkyl" refers to a 5- or 6-membered cycloaliphatic group that includes an O, N, or S heteroatom or a combination thereof. Examples of suitable heterocycloalkyl groups include pyrrolidinyl, pyrrolidinonyl, piperidinyl, piperazinyl, oxopiperazinyl, morpholino, and thiomorpholino groups.

The R8 groups may, together with the nitrogen atom to which they are attached, form a 5- to 6-membered cyclic ring, examples of which include pyrrolidinyl, pyrrolidinonyl, piperidinyl, piperazinyl, oxopiperazinyl, morpholino, and thiomorpholino groups.

The term "heteroaryl" refers to a 5- or 6-membered aromatic group containing at least one N, O, or S atom. Examples of suitable heteroaryl groups include pyridinyl, pyridazinyl, pyrimidinyl, pyrazinyl, pyrrolyl, furyl, thienyl, pyrazolyl, imidazolyl, furazanyl, oxazolyl, thiazolyl, isoxazolyl, 1,2,3-triazolyl, 1 ,2,4-triazolyl, tetrazolyl, and isothiazolyl. As used herein, "pharmaceutically acceptable" refers to those compounds, materials, compositions, and dosage forms which are, within the scope of sound medical judgment, suitable for use in contact with the tissues of human beings and animals without excessive toxicity, irritation, or other problem or complication.

It is to be understood that the present invention covers all combinations of particular and preferred groups described hereinabove. It is also to be understood that the present invention encompasses compounds in which a particular group or parameter, e.g. S(0)m, etc. may occur more than once. In such compounds it will be appreciated that each group or parameter is independently selected from the values listed. When any variable occurs more than one time in a formula, its definition on each occurrence is independent of its definition at every other occurrence.

As used herein, the term "pharmaceutically acceptable" means a compound which is suitable for pharmaceutical and veterinary usage. Salts and solvates of compounds of the invention which are suitable for use in medicine are those wherein the counter-ion or associated solvent is pharmaceutically acceptable. However, salts and solvates having non-pharmaceutically acceptable counter-ions or associated solvents are within the scope of the present invention, for example, for use as intermediates in the preparation of other compounds of the invention and their pharmaceutically acceptable salts and solvates.

The compounds of the present invention may be in the form of and/or may be administered as a pharmaceutically acceptable salt. For a review on suitable salts see Berge et al., J. Pharm. Sci., 1977, 66, 1-19. Typically, a pharmaceutical acceptable salt may be readily prepared by using a desired acid or base as appropriate. The salt may precipitate from solution and be collected by filtration or may be recovered by evaporation of the solvent.

Salts of the compounds of the present invention may, for example, comprise acid addition salts resulting from reaction of an acid with a nitrogen atom present in a compound of formula (I). Suitable addition salts are formed from acids which form non- toxic salts and examples are acetate, benzenesulfonate, benzoate, bicarbonate, bisulfate, bitartrate, borate, bromide, calcium edetate, camsylate, carbonate, chloride, clavulanate, citrate, dihydrochloride, edetate, edisylate, estolate, esylate, ethanesulphonate, formate, fumarate, gluceptate, gluconate, glutamate, glycollylarsanilate, hexylresorcinate, hydrabamine, hydrobromide, hydrochloride, hydrogen phosphate, hydroiodide, hydroxynaphthoate, iodide, isethionate, lactate, lactobionate, laurate, malate, maleate, mandelate,

mesylate, methylbromide, methylnitrate, methylsulfate, monopotassium maleate, mucate, napsylate, nitrate, N-methylglucamine, oxalate, oxaloacetate, pamoate (embonate), palmitate, pantothenate, phosphate/diphosphate, piruvate, polygalacturonate, saccharate, salicylate, stearate, subacetate, succinate, sulphate, tannate, tartrate, teoclate, tosylate, triethiodide, trifluoroacetate and valerate.

Pharmaceutically acceptable base salts include ammonium salts such as a trimethylammonium salt, alkali metal salts such as those of sodium and potassium, alkaline earth metal salts such as those of calcium and magnesium and salts with organic bases, including salts of primary, secondary and tertiary amines, such as isopropylamine, diethylamine, ethanolamine, trimethylamine, dicyclohexyl amine and N-methyl-D-glucamine.

Those skilled in the art of organic chemistry will appreciate that many organic compounds can form complexes with solvents in which they are reacted or from which they are precipitated or crystallized. These complexes are known as "solvates". As used herein, the term "solvate" refers to a complex of variable stoichiometry formed by a solute (in this invention, a compound of Formula (I), or a salt thereof) and a solvent. Such solvents for the purpose of the invention may not interfere with the biological activity of the solute. Examples of suitable solvents include water, methanol, ethanol and acetic acid. Preferably the solvent used is a pharmaceutically acceptable solvent. Examples of suitable pharmaceutically acceptable solvents include water, ethanol and acetic acid. Most preferably the solvent used is water. A complex with water is known as a "hydrate". Solvates of the compound of the invention are within the scope of the invention.

As used herein, the term "optionally" means that the subsequently described event(s) may or may not occur, and includes both event(s) which occur and events that do not occur.

As used herein, the term "substituted" refers to substitution with the named substituent or substituents, multiple degrees of substitution being allowed unless otherwise stated. With regard to stereoisomers, the compounds herein may have one or more asymmetric carbon atoms and may occur as racemates, racemic mixtures and as individual enantiomers or diastereomers. All such isomeric forms are included within the present invention, including mixtures thereof.

Cis (E) and trans (Z) isomerism may also occur. The present invention includes the individual stereoisomers of the compound of the invention and where appropriate, the individual tautomeric forms thereof, together with mixtures thereof.

Separation of diastereoisomers or cis and trans isomers may be achieved by conventional techniques, e.g. by fractional crystallisation, chromatography or H.P.L.C. A stereoisomeric mixture of the agent may also be prepared from a corresponding optically pure intermediate or by resolution, such as H.P.L.C. of the corresponding racemate using a suitable chiral support or by

fractional crystallisation of the diastereoisomeric salts formed by reaction of the corresponding racemate with a suitable optically active acid or base, as appropriate.

Furthermore, some of the crystalline forms of the compounds herein may exist as polymorphs, which are included in the present invention.

Exemplified compounds of the compounds of this invention include the racemates, or optically active forms of the compounds of the working examples herein, and pharmaceutically acceptable salts thereof.

Compounds of particular interest are those of formula (I)

wherein:

R1 is substituted on the 5 or 6 position, particularly at the 5 position.

As for the definition of R1 those of particular interest may be R5-Y-N(R6)-, R7-N(R6)-Y-, R7-N(R6)-, -COOH or H.

For R2, groups of particular interest are propyl or isopropyl, or a group a Ci-C6alkyl group, or Ci-C6alkyl-R9 or H.

In an R group, those of particular interest are H, F, or Cl.

As for X, the groups of particular interest are -NH-SO2- or -SO2-NH-.

In a Y group, the radicals of greater interest are -C(O)- and -S(O)2-;

In a R4 group those of particular interest are phenyl-(R8)m, C5-C6-heteroaryl-(Ru)p, and Ci- C6-alkyl-R9;

As for R5, the groups C5-C6-heteroaryl-(Ru)p, Ci-C6-alkyl-R9, phenyl-(R8)m, C3-C6- cycloalkyl, Ci-C6-alkoxy, C5-C6- heterocycloalkyl-(R10)n and -N(R12)2 are of interest.

For R6 the methyl or H are of interest.

As regards R7, the groups Ci-Ce-alkyl-R9 > C3-C6-cycloalkyl > C5-C6- heterocycloalkyl-(R10)n > phenyl-(R8)m; or C5-C6-heteroaryl-(Ru)p, are of interest; or those groups where R6 and R7, together with the nitrogen atom to which they are attached, form a 5- to 6- membered heterocycloalkyl group.

And for R8 the radicals of interest include H, F, Cl, Ci-C6-alkyl, Ci-C6-alkoxy, cyano, dimethylamino, or trifluoromethyl.

The radicals set out in the immediate preceding paragraphs as being of interest, are given in descending order of interest.

METHODS OF TREATMENT In order to use a compound of Formula (I) or a pharmaceutically acceptable salt thereof in therapy, it will normally be formulated into a pharmaceutical composition in accordance with standard pharmaceutical practice. This invention, therefore, also relates to a pharmaceutical composition comprising an effective amount of a compound of Formula (I) and a pharmaceutically acceptable carrier or diluent. Compounds of Formula (I), pharmaceutically acceptable salts thereof, and pharmaceutical compositions incorporating such may conveniently be administered by any of the routes conventionally used for drug administration, for instance, orally, topically, parenterally or by inhalation. The compounds of Formula (I) may be administered in conventional dosage forms prepared by combining a compound of Formula (I) with standard pharmaceutical carriers according to conventional procedures. The compounds of Formula (I) may also be administered in conventional dosages in combination with a known, second therapeutically active compound. These procedures may involve mixing, granulating and compressing or dissolving the ingredients as appropriate to the desired preparation. It will be appreciated that the form and character of the pharmaceutically acceptable character or diluent is dictated by the amount of active ingredient with which it is to be combined, the route of administration and other well-known variables. The carrier(s) must be "acceptable" in the sense of being compatible with the other ingredients of the formulation and not deleterious to the recipient thereof.

The pharmaceutical carrier employed may be, for example, either a solid or liquid. Exemplary of solid carriers are lactose, terra alba, sucrose, talc, gelatin, agar, pectin, acacia, magnesium stearate, stearic acid and the like. Exemplary of liquid carriers are syrup, peanut oil, olive oil, water and the like. Similarly, the carrier or diluent may include time delay material well known to the art, such as glyceryl mono-stearate or glyceryl distearate alone or with a wax.

A wide variety of pharmaceutical forms can be employed. Thus, if a solid carrier is used, the preparation can be a tablet, the active and, optionally, a carrier can be placed in a hard gelatin capsule in powder or pellet form, or the preparation may be in the form of a troche or lozenge.

The amount of solid carrier will vary widely but preferably will be from about 25mg to about Ig. When a liquid carrier is used, the preparation will be in the form of a syrup, emulsion, soft gelatin capsule, sterile injectable liquid such as an ampule or nonaqueous liquid suspension.

Compounds of Formula (I) may be administered parenterally, that is by intravenous, intramuscular, subcutaneous intranasal, intrarectal, intravaginal or intraperitoneal administration.

The subcutaneous and intramuscular forms of parenteral administration are generally preferred. Appropriate dosage forms for such administration may be prepared by conventional techniques. Compounds of Formula (I) may also be administered by inhalation, that is by intranasal and oral inhalation administration. Appropriate dosage forms for such administration, such as an aerosol formulation or a metered dose inhaler, may be prepared by conventional techniques.

For all methods of use disclosed herein for the compounds of Formula (I), the daily topical dosage regimen will preferably be from 0.01 mg to 1000 mg, administered one to four times daily. It will also be recognized by one of skill in the art that the optimal quantity and spacing of individual dosages of a compound of Formula (I) or a pharmaceutically acceptable salt thereof will be determined by the nature and extent of the condition being treated, the form, route and site of administration, and the particular patient being treated, and that such optimums can be determined by conventional techniques. It will also be appreciated by one of skill in the art that the optimal course of treatment, i.e., the number of doses of a compound of Formula (I) or a pharmaceutically acceptable salt thereof given per day for a defined number of days, can be ascertained by those skilled in the art using conventional course of treatment determination tests.

It should be understood that in addition to the ingredients particularly mentioned above, the formulations of this invention may include other agents conventional in the art having regard to the type of formulation in question, for example those suitable for oral administration may include flavoring agents, or those for inhalation may include carriers, such as lactose. The compounds of the present invention are prepared according to the following schemes

1-5 described in detail below. The groups and substituents shown in the schemes 1-5, such as X, Y, and the various R groups have same definition in what follows as they have herein above. The solvents and conditions referred to are illustrative and are not intended to be limiting.

Schemes

Scheme 1

Scheme 1 illustrates methods for synthesizing compounds of formula (VI). Treatment of commercially available benzimidazole (I) with an alkyl bromide and potassium hyroxide, in a solvent mixture of tetrahydrofuran and ethanol with heating at 65° C for 72 h furnishes compounds of formula (II). Treatment of (II) with a compound of formula (III) (X = NH-Boc or SO2Cl), which is commercially available or can be prepared by one skilled in the art, under standard amidation conditions followed by removal of the tert-butyl ester group using a strong acid such as hydrochloric acid furnishes a compound of formula (IV). A compound of formula (IV) wherein X = NH2 may also be prepared by treating benzimidazole (I) with a compound of formula (VII), which is commercially available or can be prepared by one skilled in the art, under standard amide coupling conditions to afford a compound of formula (VIII). Treatment of (VIII) with an alkyl bromide and potassium carbonate in a solvent mixure of N,N-dimethyl formamide, acetone, and water in a sealed flask at about 20° to 55° C for up to 24 h furnishes a compound of formula (IX). Reduction of the nitro group of (IX) using hydrogen gas (1 atm) and catalytic palladium on carbon in a solvent mixture of ethyl acetate, methanol, and water at 20° C for 2-3 h furnishes compound (IV). Compounds of fomula (VI) can be prepared from (IV) by one skilled in the art, using an appropriate amine or sulfonyl chloride reagent R4 (V) under standard conditions.

Scheme 2

R6

H2N. ,NO, R6 R6

PG -NO0 .N

PG -NO2

PG

"NH HTVNH2

-N

(X) (Xl) R2 R2

(XII) (XlIl)

Commercially available 3-nitro-4-fluoro-aniline (X) is protected with either tert-butoxycarbonyl anydride in tetrahydrofuran with heating at about 65° C for up to 48 h, or acetic anhydride (neat) at

room temperature for about 3 h. The resultant product may be alkylated on the anilino nitrogen using iodomethane and sodium hydride, in a polar aprotic solvent such as N,N-dimethyl formamide, at a temperature between about 0° and 20° C for 3 h. Treatment of the anilino product (XI) either as its fully substituted (i.e. R6 = methyl) or di-substituted form (R6 = H) with an alkyl amine and base, typically potassium carbonate, in a polar aprotic solvent such as N,N-dimethyl formamide at a temperature between about 20° and 85° C for 3 - 24 h furnishes compound (XII). Reduction of the nitro group of (XII) using hydrogen gas (1 arm) and a catalytic amount of palladium on carbon in a polar solvent such as ethanol, at about 20° C for 3 - 24 h followed by treatment with cyanogen bromide at 20° C for 0.5 - 24 h furnishes a compound of formula (XIII). Treatment of (XIII) with (XIV), which can be prepared by one skilled in the art using commercially available starting materials, under standard amidation conditions affords the coupled product (XV). Removal of the tert-butyl ester group of (XV) can be accomplished using a strong acid, such as trifluoroacetic or hydrochloric acid, under standard conditions. Compounds of formula (XVI) and (XVII) can then be prepared from (XV) by one skilled in the art, using the appropriate reagents under standard reaction conditions.

Scheme 3

(XVIII) (XXJ)

Scheme 3 illustrates a method for synthesizing compounds of formula (XXI). Treatment of compound (XVIII) with a compound of formula (III) under standard amide coupling conditions followed by removal of the tert-butyl ester group using trifluoroacetic acid furnishes a compound of formula (XIX). Treatment of compound (XIX) with a sulfonyl chloride (XX) and base, preferably pyridine, in DCM at room temperature for 3-12 h furnishes a compound of formula (XXI).

Scheme 4

Scheme 4 illustrates a method for synthesizing compounds of formula (XXVII).

Commercially available N-(3-chlorophenyl)acetamide (XXII) is nitrated under standard conditions using nitric acid and sulfuric acid to afford a mixture of 2-nitro and 5-nitro compounds, which can be separated. The desired product N-(5-chloro-2-nitrophenyl)acetamide (XXIII) may be alkylated on the acetamide nitrogen using iodomethane and sodium hydride, in a polar aprotic solvent such as N,N-dimethyl formamide, at a temperature between about 0° and 20° C for 3 h. The acetamide product (XXIV) either as its fully substituted (i.e. R6 = methyl) or di-substituted form (R6 = H) is treated with an alkyl amine and base, typically potassium carbonate, in a polar aprotic solvent such as N-methyl-2-pyrrolidone at a temperature between about 50° and 70° C for about 18 - 24 h to afford (XXV). Reduction of the nitro group of (XXV) using hydrogen gas (1 arm) and catalytic palladium on carbon in a polar solvent such as ethanol at about 20° C for 24 h followed by treatment with cyanogen bromide at about 20° C for 0.5 - I h furnishes benzimidazole (XXVI). Treatment of (XXVI) with compounds of formula (XIV) using standard amidation conditions affords compounds of formula (XXVII).

Commercially available 3-nitro-4-fluoro-benzoic acid and 3-fluoro-4-nitro-benzoic acid (XXVIII) are converted to their corresponding tert-butyl esters using tert-butyl 2,2,2-trichloroacetimidate and a catalytic amount of boron trifluoride diethyl etherate in ether at room temperature for 12 h. Treatment of either isomer of (XXIX) with an alkyl amine and potassium carbonate, in a polar aprotic solvent such as N,N-dimethyl formamide at about 20° C for 12 h affords a compound of formula (XXX). Reduction of the nitro group of (XXX) using hydrogen gas (45 psi) and catalytic palladium on carbon in a polar solvent such as ethanol at about 20° C for 1.5 h, followed by treatment with cyanogen bromide at about 20° C for 0.5 - I h furnishes benzimidazole (XXXI). Treatment of (XXXI) with compounds of formula (XIV) using standard amidation conditions affords a compound of formula (XXXII). Removal of the tert-butyl ester of (XXXII) can be accomplished using trifluoroacetic acid, under standard conditions. Compounds of formula

(XXXIII) can then be prepared by one skilled in the art using the appropriate reagents under the reaction conditions descibed herein.

Experimentals

General Experimental Methods

The following abbreviations are used throughout the experimental and have the following meaning: aq aqueous ca. circa

CDCl3-(Z chloroform-<i

CD3OD-(Z4 methanol-^

Cs2CO3 cesium carbonate CHCl3 chloroform

CH3CN acetonitrile

Celite® registered trademark of Celite Corp. brand of diatomaceous earth

DCE dichloroethane

DCM methylene chloride DME l,2 dimethoxyethane

DMF N,N-dimethyl formamide

DIEA diisopropyl ethylamine

DMSO-(Z6 dimethylsulfoxide-(5?6

EtOAc ethyl acetate EDC l-(3-Dimethylaminopropyl)-3-ethylcarbodimmide hydrochloride

h hours(s)

1H NMR proton nuclear magnetic resonance

HCl hydrochloric acid

HOAT l-hydroxy-7-azabenzotriazole HPLC high performance liquid chromatography

IPA 2-propanol

K2CO3 potassium carbonate

KOH potassium hydroxide

LC/MS liquid chromatography/mass spectroscopy LDA lithium diisopropylamide

MgSθ4 magnesium sulfate

MeOH methanol min minute(s)

MTBE methyl tert-butyl ether MS mass spectrometry

NaOH sodium hydroxide

Na2Sθ4 sodium sulfate

NH4OH ammonium hydroxide

NMM 4-methylmorpholine NMP N-Methyl-2-pyrrolidone

Pd/C Palladium ( 10% by wt) on carbon

PyBop Benzotriazole- 1 -ly-oxy-tris-pyrrolidinophosphonium hexafluorphosphate

SOCl2 thionyl chloride

TBTU O-(lH-Benzotriazol-l-yl)-N,N,N',N'-tetramethyluronium tetrafluoroborate TFA trifluoroacetic acd

THF tetrahydrofuran

TLC thin layer chromatography

The following guidelines apply to the experimental procedures described herein. All reactions were conducted under a positive pressure of nitrogen using oven-dried glassware, unless otherwise indicated. Temperatures designated are external (i.e. bath temperatures), and are approximate. Air and moisture-sensitive liquids were transferred via syringe. Reagents were used as received. Solvents utilized were those listed as "anhydrous" by vendors. Molarities listed for reagents in solutions are approximate, and were used without prior titration against a corresponding standard. All reactions were agitated by stir bar, unless otherwise indicated.

Heating was conducted using heating baths containing silicon oil. Cooling to temperatures below - 70° C was conducted using dry ice/acetone or dry ice/2 -propanol. Magnesium sulfate and sodium sulfate used as drying agents were of anhydrous grade, and were used interchangeably. Solvents removed in vacuo were done so by rotary evaporation. Preparative normal phase silica gel chromatography was carried out using a Teledyne