WO1998018815A1 - Convergent process for the preparation of a growth hormone secretagogue - Google Patents

Convergent process for the preparation of a growth hormone secretagogue Download PDFInfo

- Publication number

- WO1998018815A1 WO1998018815A1 PCT/US1997/019063 US9719063W WO9818815A1 WO 1998018815 A1 WO1998018815 A1 WO 1998018815A1 US 9719063 W US9719063 W US 9719063W WO 9818815 A1 WO9818815 A1 WO 9818815A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- compound

- formula

- protecting group

- acid

- amino

- Prior art date

Links

- 0 CC(C)(C(N[C@](COCc1ccccc1)C(N(CC1)CCC11c2ccccc2N(*)C1)=O)=O)N Chemical compound CC(C)(C(N[C@](COCc1ccccc1)C(N(CC1)CCC11c2ccccc2N(*)C1)=O)=O)N 0.000 description 3

- JKJHSYFOCCLXIT-HSZRJFAPSA-N CC(C)(C(N[C@H](COCc1ccccc1)C(N(CC1)CCC11c(cccc2)c2N(C)C1)=O)=O)NC Chemical compound CC(C)(C(N[C@H](COCc1ccccc1)C(N(CC1)CCC11c(cccc2)c2N(C)C1)=O)=O)NC JKJHSYFOCCLXIT-HSZRJFAPSA-N 0.000 description 1

- QZZFMGVSBIAOHX-LLVKDONJSA-N CC(C)(C(N[C@H](COCc1ccccc1)C(O)=O)=O)NI Chemical compound CC(C)(C(N[C@H](COCc1ccccc1)C(O)=O)=O)NI QZZFMGVSBIAOHX-LLVKDONJSA-N 0.000 description 1

- GQTKRKFYGCTEEH-LYYPKXFYSA-N CC(C)(C)OC(NC(C)(C)C(NC(C1)([C@@H]1OCc1ccccc1)C(N(CC1)CCC11c2ccccc2NC1)=O)=O)=O Chemical compound CC(C)(C)OC(NC(C)(C)C(NC(C1)([C@@H]1OCc1ccccc1)C(N(CC1)CCC11c2ccccc2NC1)=O)=O)=O GQTKRKFYGCTEEH-LYYPKXFYSA-N 0.000 description 1

- CNESHALTAOMUKM-VLIAUNLRSA-N CC(C)(C)OC(NC(C)(C)C(N[C@@](C1)([C@@H]1OCc1ccccc1)C(O)=O)=O)=O Chemical compound CC(C)(C)OC(NC(C)(C)C(N[C@@](C1)([C@@H]1OCc1ccccc1)C(O)=O)=O)=O CNESHALTAOMUKM-VLIAUNLRSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D471/00—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, at least one ring being a six-membered ring with one nitrogen atom, not provided for by groups C07D451/00 - C07D463/00

- C07D471/02—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, at least one ring being a six-membered ring with one nitrogen atom, not provided for by groups C07D451/00 - C07D463/00 in which the condensed system contains two hetero rings

- C07D471/10—Spiro-condensed systems

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07K—PEPTIDES

- C07K5/00—Peptides containing up to four amino acids in a fully defined sequence; Derivatives thereof

- C07K5/04—Peptides containing up to four amino acids in a fully defined sequence; Derivatives thereof containing only normal peptide links

- C07K5/06—Dipeptides

- C07K5/06008—Dipeptides with the first amino acid being neutral

- C07K5/06017—Dipeptides with the first amino acid being neutral and aliphatic

- C07K5/06034—Dipeptides with the first amino acid being neutral and aliphatic the side chain containing 2 to 4 carbon atoms

Definitions

- Growth hormone which is secreted from the pituitary, stimulates growth of all tissues of the body that are capable of growing.

- growth hormone is known to have the following basic effects on the metabolic processes of the body: (1) Increased rate of protein synthesis in all cells of the body; (2) Decreased rate of carbohydrate utilization in cells of the body; (3) Increased mobilization of free fatty acids and use of fatty acids for energy.

- a deficiency in growth hormone secretion can result in various medical disorders, such as dwarf ⁇ sm.

- growth hormone Various ways are known to release growth hormone. For example, chemicals such as arginine, L-3,4-dihydroxyphenylalanine (L- DOPA), glucagon, vasopressin, and insulin induced hypoglycemia, as well as activities such as sleep and exercise, indirectly cause growth hormone to be released from the pituitary by acting in some fashion on the hypothalamus perhaps either to decrease somatostatin secretion or to increase the secretion of the known secretagogue growth hormone releasing factor (GRF) or an unknown endogenous growth hormone- releasing hormone or all of these.

- L- DOPA L-3,4-dihydroxyphenylalanine

- GRF growth hormone releasing factor

- certain spiro compounds are disclosed in U.S. Patent No. 5,536,716, PCT Patent Publication WO 94/13696 and Proc. Natl. Acad. Sci. USA. 92, 7001-7005 (July 1995) as being non- peptidal growth hormone secretagogues. These compounds have the ability to stimulate the release of natural or endogenous growth hormone and thus may be used to treat conditions which require the stimulation of growth hormone production or secretion such as in humans with a deficiency of natural growth hormone or in animals used for food or wool production where the stimulation of growth hormone will result in a larger, more productive animal.

- U.S. Patent No. 5,536,716 and PCT Patent Publication WO 94/13696 disclose methods for preparing this compound (see Examples 18, 19 and 55). However, the synthesis of the compound was accomplished by using the very expensive amino acid coupling agent EDC ($1100/kg); the use of numerous equivalents of trifluoroacetic acid as the catalyst for the BOC group deprotections; extensive chromatographic purifications; and resulted in "gumming" of the final product.

- PCT Patent Publication WO 97/15573 also discloses methods for preparing this compound.

- the advantages of the present invention include: manufacturing flexibility through a convergent route; synthesis of the dipeptide side-chain in high yield and high enantiomeric excess; avoidance of a large number of steps (i.e. coupling/deprotection sequences) in the presence of the spiroindoline; a high yielding non- isolation process; decreased expense through the use of DCC [$40/kg] instead of EDC [$1100/kg]; diminished environmental impact through the use of methanesulfonic acid instead of trifl uoroacetic acid as the catalyst (as well as lesser equivalents of catalyst) in the deprotections; and ease of isolation of the final product.

- the instant invention is directed to a novel convergent process for the preparation of the compound N-[l(R)-[(l,2-dihydro-l- methanesulfonyl-spiro[3H-indole-3,4'-piperdin]-l'-yl)carbonyl]-2-

- This compound has the ability to stimulate the release of natural or endogenous growth hormone and may be used to treat conditions which require the stimulation of growth hormone production or secretion such as in humans with a deficiency of natural growth hormone or in animals used for food or wool production where the stimulation of growth hormone will result in a larger, more productive animal.

- the present invention is directed to a novel convergent process for the preparation of the compound N-[l(R)-[(l,2-dihydro-l- methanesulfonyl-spiro[3H-indole-3,4'-piperdin]-l'-yl)carbonyl]-2- (phenylmethyl-oxy)ethyl]-2-amino-2-methyl-propanamide which has the structure:

- the instant process provides the desired compound from readily available inexpensive and environmentally acceptable starting materials reagents and solvents.

- the process does not require the use any chromatographic purifications, and it is possible to produce the final product from the intermediate spiroindoline sulfonamide without isolation of any of the intermediates.

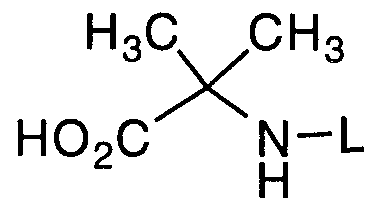

- a first process concerns the preparation of a compound of formula I:

- G is a carboxyl protecting group, with a compound of the formula :

- L is an amino protecting group, in the presence of an acid activating agent in an inert solvent in the presence of a catalytic agent, followed by removal of the carboxyl protecting group G to give the compound of formula I.

- Acid activating agents suitable for this process include: DCC, EDC, ECAC and BOP, in which the preferred acid activating agent is DCC (N,N'-dicyclohexylcarbodiimide).

- Catalytic agents suitable for this process include: HOBT, HONB, and the like in which a preferred catalytic agent is HOBT (hydroxybenzotriazole).

- Inert solvents appropriate for this processes include: acetonitrile; iso-propyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho-dichlorobenzene; benzene; toluene; xylenes; and the like; and mixtures thereof, in which the preferred solvent is either acetonitrile or isopropyl acetate and water.

- the preferred reaction temperature range is between -40 and 150°C, and the most preferred range is between 20 and 35°C.

- Suitable carboxyl protecting groups include: methyl, allyl, ethyl, isopropyl, benzyl, and the like, in which the preferred one is methyl.

- Removal of the carboxyl protecting group may be effected by methods well known in the art.

- hydrolysis of the methyl ester may be achieved with lithium hydroxide in a solution of toluene and water at a temperature of between about 0 and about 10°C, preferably about 4-5°C.

- the enantiomeric purity of the dipeptide may be upgraded by formation and crystalization of the dicyclohexyl amine salt.

- Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy),

- this coupling be conducted in situ without isolation of the compound of formula I following its preparation by the aforementioned process.

- Acid activating agents suitable for this process include: DCC, EDC, ECAC and BOP, in which the preferred acid activating agent is DCC (N,N'-dicyclohexylcarbodiimide).

- Catalytic agents suitable for this process include: HOBT, HONB, and the like in which a preferred catalytic agent is HOBT (hydroxybenzotriazole) or HONB (N-hydroxy-5-norbornene-2,3- dicarboximide) .

- Inert solvents appropriate for this processes include: acetonitrile; isopropyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho-dichlorobenzene; benzene; toluene; xylenes; and the like; and mixtures thereof.

- the catalytic agent is HOBT

- the preferred solvent is acetonitrile.

- the catalytic agent is HONB

- the preferred solvent is isopropyl acetate:water.

- the preferred reaction temperature range is between -40 and 150°C.

- the catalytic agent is HOBT

- the most preferred range is between about -20 and about -35°C

- the even more preferred temperature is about -25°C.

- the catalytic agent is HONB

- the most preferred range is between about -10 and about 15°C

- the even more preferred temperature range is between about 0 and 5°C

- Suitable amino protecting groups include: benzyl, benzyloxym ethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbob

- this coupling be conducted in situ without isolation of the compound of formula II following its preparation by the aforementioned process.

- the compound of formula II may be isolated as a discrete intermediate.

- a third process concerns the preparation of a compound of formula III, or a pharmaceutically acceptable salt thereof:

- Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy),

- the removal of the amino protecting group may be accomplished by use of an appropriate catalytic agent.

- Removal of a t-butoxycarbonyl protecting group may be carried out in a solvent such as methanol, ethanol, methylene chloride, ethyl acetate, or iso-propyl acetate, with a strong acid.

- Such strong acids include methanesulfonic acid, trifluoroacetic acid, hydrochloric acid, hydrogen chloride gas, hydrogen bromide; hydrogen iodide; trifluoromethane-sulfonic acid; camphorsulfonic acid; sulfuric acid; phosphoric acid; and an arylsulfonic acid, such as benzenesulfonic acid, p-toluenesulfonic acid, and p- chlorobenzene-sulfonic acid.

- Preferred catalytic agents include: trifluoroacetic acid; methanesulfonic acid; camphorsulfonic acid; benzenesulfonic acid, p-toluenesulfonic acid; and p-chlorobenzene-sulfonic acid.

- the most preferred catalytic agent is methanesulfonic acid. It is preferred that compound of formula III is isolated in the form of the methanesulfonate salt.

- the preferred solvent is methanol or ethanol, and the most preferred solvent is ethanol.

- the preferred reaction temperature range is between -40 and

- 150°C and the most preferred range is between 10 and 40°C.

- Removal of a benzyloxycarbonyl (carbobenzyloxy) group may be achieved by a number of methods, for example, catalytic hydrogenation with hydrogen in the presence of a noble metal or its oxide such as palladium on activated carbon in a protic solvent such as ethanol.

- the removal of benzyloxycarbonyl (carbobenzyloxy) group may also be achieved by treatment with a solution of hydrogen bromide in acetic acid, or by treatment with a mixture of TFA and dimethylsulfide.

- a fourth process concerns the preparation of a pharmaceutically acceptable salt of a compound of formula III, in particular, the methanesulfonate salt, i.e. a compound of formula TV:

- compound of formula r is isolated in the form of the methanesulfonate salt.

- the preferred solvent comprises ethyl acetate and ethanol, and the most preferrred solvent is a mixture of ethyl acetate and ethanol.

- the formation of the salt be conducted in situ without isolation of the compound of formula V following its preparation by the aforementioned process.

- the N-BOC-O-Benzyl-D-Serine 11 was treated with methane sulfonic acid in methanol at 65°C for ca. 5 hours to affect simultaneous BOC deprotection and methyl ester formation in 90-95% yield.

- the success of this reaction depended on a careful workup procedure that avoided hydrolysis of the methyl ester (12).

- the methanolic solution of 2 was solvent switched to iPAc (levels of residual MeOH of ⁇ 1% v/v are essential). A 15% aqueous NaCl solution was added and the biphasic mixture was cooled to 0°C.

- the enantiometric purity of 14 was upgraded to > 99.5% ee developed by the following procedure: 1) addition of DCHA in iPAC at 65°C ; 2) aging the resulting thick slurry at that temperature for 4-5 hours; and 3) aging at 25°C for 10 hours followed by filtration.

- the enantiomerically pure free acid, 14, was obtained in high overall yield (ca. 93%) by partitioning the DCHA salt in iPAc-1 M H2SO4 (aqueous) followed by separation of the layers, volume adjustment of the organic layer (ca. 3 volumes), and addition of heptane (ca. 9 volumes).

- the ethyl acetate solution of the free base 17 is concentrated to low bulk in ⁇ acuo and is azeotroped dry (KF ⁇ 500 mgml ) by "feeding and bleeding" 2x batch volumes of 90/10, ethyl acetate/ethanol followed by 2x batch volumes of ethyl acetate.

- KF ⁇ 500 mgml azeotroped dry

- Form II The conversion of Form II to Form I is accomplished where the salt is formed in EtOAc-EtOH as above, but instead of cooling the initial solution of the salt (at 55°C) to ambient temperature, it is cooled to 45°C. Crystals should start appearing at that temperature and the slurry should become thicker with time. The temperature is then raised to 51°C and the slurry is aged overnight. Complete conversion to Form I of 18 should be expected.

- the conversion of Form II to Form I is achieved by adding seed crystals of Form I to a solution of the free base in EtOAc- EtOH at 50-55°C followed by aging.

- the free base 17 may be treated with 1.1 equivs. of methanesulfonic acid in 8% ethanol in ethyl acetate at 50-55°C.

- the batch is then seeded with approximately 2% by weight of Form I of the methanesulfonate salt 18, and then aged at 55°C overnight.

- the batch is cooled to room temperature and aged for approximately 2-3 hours.

- the product is isolated by filtration at room temperature under a nitrogen atmosphere, dried at 35°C in ⁇ acuo and sieved to give the methanesulfonate salt 18.

- the methanesulfonic acid salt 18 may also be formed by alternating the stepwise addition of MsOH (1.1 eq) and seed crystals of Form I to a solution of the free base in EtOAc-EtOH at about 50°C, wherein the order of addition of the MsOH and the seed is not critical.

- peptide coupling reaction as used herein is intended to mean the coupling of a carboxylic acid with an amine using an acid activating agent such as EDC, DCC, and BOP in an inert solvent in the presence of a catalyst such as HOBT.

- Inert solvents appropriate for such couplings include: acetonitrile; iso-propyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho- dichlorobenzene; benzene; toluene; xylenes; and combinations thereof; and the like.

- variable "L” and the term "amino protecting group” is intended to indicate the presence of an appropriate protecting group for amino, such as those described in Greene, T.W., Wuts, P.G.M. Protective Groups in Organic Synthesis, 2nd ed., John Wiley & Sons, Inc., New York, 1991.

- An appropriate protecting group will be able to withstand the reaction conditions of intermediate processes, prior to being removed when desired.

- the amino protecting group is independently selected for each process within the entire processes.

- Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy), t-butoxy-carbony

- the removal of the amino protecting group may be accomplished by use of an appropriate catalytic agent. Removal of a t- butoxycarbonyl protecting group may be carried out in a solvent such as methanol, ethanol, methylene chloride, ethyl acetate, or iso-propyl acetate, with a strong acid.

- a solvent such as methanol, ethanol, methylene chloride, ethyl acetate, or iso-propyl acetate

- Such strong acids include methanesulfonic acid, trifluoroacetic acid, hydrochloric acid, hydrogen chloride gas, hydrogen bromide; hydrogen iodide; trifluoromethane-sulfonic acid; camphorsulfonic acid; sulfuric acid; phosphoric acid; and arylsulfonic acids, such as benzenesulfonic acid, p-toluenesulfonic acid, and p-chlorobenzene-sulfonic acid.

- Preferred catalytic agents include: trifluoroacetic acid; methanesulfonic acid; camphorsulfonic acid; benzenesulfonic acid, p- toluenesulfonic acid; and p-chlorobenzene-sulfonic acid.

- the most preferred catalytic agent is methanesulfonic acid.

- the preferred solvent is methanol or ethanol.

- Removal of a benzyloxycarbonyl (carbobenzyloxy) protecting group may be achieved by a number of methods, for example, catalytic hydrogenation with hydrogen in the presence of a noble metal or its oxide such as palladium on activated carbon in a protic solvent such as ethanol.

- the removal of benzyloxycarbonyl (carbobenzyloxy) group may also be achieved by treatment with a solution of hydrogen bromide in acetic acid, or by treatment with a mixture of TFA and dimethylsulfide.

- the amine compounds employed as starting materials for the process of the present invention may be present as their acid salts, such as the salts derived from using inorganic and organic acids.

- acids are hydrochloric, nitric, sulfuric, phosphoric, formic, acetic, trifluoroacetic, propionic, maleic, succinic, malonic, methane sulfonic and the like.

- the compounds produced by the processes of the instant invention may be isolated in the form of their pharmaceutically acceptable acid salts.

- certain compounds containing an acidic function such as a carboxy can be in the form of their inorganic salt in which the counterion can be selected from sodium, potassium, lithium, calcium, magnesium and the like, as well as from organic bases.

- the preparation of compounds with the process of the present invention may be carried out in sequential or convergent synthetic routes. It is noted that in some cases the order of carrying out the foregoing reaction schemes may be varied to facilitate the reaction or to avoid unwanted reaction products.

- the process of the present invention is conducted in a sequential manner as presented herein. Many of the starting materials are either commercially available or known in the literature and others can be prepared following literature methods described for analogous compounds. The skills required in carrying out the reaction and purification of the resulting reaction products are known to those in the art. Purification procedures include crystallization, normal phase or reverse phase chromatography. The following examples are provided for the purpose of further illustration only and are not intended to be limitations on the disclosed invention.

- the aqueous phase was acidified with 37% aqueous HC1 to pH 1.8. Carbon dioxide was evolved during the addition of HC1, but gas evolution was easily controlled. The addition of HC1 took ⁇ 1 h and required 10 L of cone. HC1.

- the aqueous phase was extracted with 3 x 6.6 L of toluene. The toluene extracts were dried with 2 kg of sodium sulfate and filtered through a pad of Solka-flocTM. The combined filtrates weighed 17.8 kg. The crude yield of carbamate 3 was 7.89 kg (97%) (as obtained by evaporation of weighed aliquots of the filtrates to dryness).

- the filtrates were transferred through a 10 ⁇ inline filter to a 100 L flask.

- the extracts were concentrated at 10 mbar at ⁇ 25°C to a volume of 18 L.

- the final concentration of carbamate 3 was 440 g/L.

- the product was 99.1 area % pure with 0.9 area % benzyl alcohol as the only impurity.

- the mixture was concentrated at 10 mbar and a temperature of 20-25°C until 5 L of solvent had been removed.

- the assay yield of aldehyde 3 was 94% by HPLC analysis.

- the crude aldehyde 5 solution from the previous step was transferred through a 10 ⁇ inline filter to a 100 L reactor equipped with Teflon coated copper coils for cooling or heating and a mechanical stirrer. Toluene (34.4 kg) and MeCN (7 L) were added, and the resulting solution was cooled to 0°C. Phenylhydrazine was added in portions and the temperature was maintained at -1 to 3 °C while nitrogen was continuously bubbled through the reaction mixture.

- HPLC conditions 25 cm Dupont Zorbax RXC8 column at 30°C with 1.0 mL/min flow and detection at 254 nm; gradient schedule:

- the color change from green to orange corresponds very closely to reaction end point.

- the quantity of NaBH4 required to complete the reaction is heavily dependent on the temperature and rate of addition of NaBH4, but the yield and quality of the product is virtually unaffected provided that the reaction is complete.

- the reaction mixture was cooled to 5°C over a period of 30 min.

- the washed toluene solution was combined with the washed organic phases of two other similarly processed reactions.

- the total aldehyde used in the three reactions was 5.06 kg, (20.5 mol).

- the total weight of CBZ-indoline 9 assayed in the combined organic phases was 5.91 kg, (18.3 mol, 90% assay yield).

- the combined organic phases were dried with 5 kg of sodium sulfate, treated with 250 g of Darco G60 carbon for 30 min, and filtered through Solka-flocTM.

- the filtrates were vacuum concentrated at 10 mbar at ⁇ 25°C until the residue was near dryness.

- the solvent switch was completed by slowly bleeding in 30 L of IPAC and reconcentrating to 14 L at 200 mbar at 50-60°C.

- the mixture was heated to reflux in order to obtain a clear homogeneous deep orange solution. ⁇ H NMR analysis indicated that the solution contained ca. 6 mol% of residual toluene after solvent switch.

- the solution was cooled to 68°C and seeded with 4 g of crystalline CBZ-indoline 9.

- the solution was allowed to gradually cool to 26°C over 6 h and aged for 9 h at 20-26°C.

- the slurry was cooled to 2°C over 1 h and aged at 2°C for lh.

- the product was isolated by filtration, and the filter cake was washed with 2 x 2 L of 5°C IPAC and 2 x 2 L of 5°C MTBE.

- the product was dried in the vacuum oven at 30°C under a nitrogen bleed to give 4.37 kg (74%) of the title compound 9 as a light tan crystalline powder.

- HPLC analysis of the product indicated 99.5 area % purity.

- the CBZ-aldehyde 5 was dissolved in dichloromethane in a 1

- reaction mixture was aged for 10 min at 0-2°C, and TFA was added by syringe maintaining the temperature between 2 and 7°C.

- the reaction mixture was warmed to 35°C over 30 min, and maintained for 17 h.

- the nitrogen sparge through the reaction mixture was stopped and a slow stream of nitrogen was maintained over the reaction mixture.

- the color gradually darkened to a rosy pink then to a deep green, and a relatively small amount of a white crystalline precipitate (ammonium trifluoroacetate) formed.

- HPLC analysis (same conditions as above) indicated that the reaction mixture contained 93 area % indolenine 8 and ⁇ 0.5% of unreacted phenylhydrazone remained. Aging the mixture for longer periods of time did not increase the assay yield of indolenine 8.

- the reaction mixture was cooled to 10°C, and a mixture containing 60 mL 28-30% ammonium hydroxide, 90 mL water and 150 g crushed ice was added with good stirring. The color of the mixture changed to a salmon color.

- the organic phase was separated and washed twice with 400 mL water then 100 mL saturated aqueous NaCl. The organic phase was dried over magnesium sulfate and filtered through a plug of 5 g of silica. The filtrate was evaporated to give 15.84 g (99%) of indolenine 8 as a pale orange oil.

- MeOH 50 mL A 2% (by volume) solution of MeCN in toluene was made up using 654 mL of toluene and 13.3 mL of MeCN.

- 617 ml of the above solution were degassed by passing a fine stream of nitrogen through the solution for 5 min. Phenylhydrazine and TFA were added to the mixture while still degassing.

- the mixture was warmed to 20°C, and 200 mL of 1M aqueous HCl was added.

- the mixture was warmed to 50°C, and the aqueous phase was separated.

- the organic phase was washed sequentialy with 100 mL water, 100 mL 5% aqueous sodium bicarbonate, and 100 mL water.

- the organic phase was transferred to a 1 L 3 neck flask equipped for mechanical stirring and distillation.

- the mixture (ca 400 mL) was distilled at atmospheric pressure until 150 mL of distillate had been collected.

- the head temperature reached 107°C; the pot temperature was 110°C.

- the distillation was continued with continuous addition of n- propanol at such a rate as to maintain a constant volume (ca 350 mL) in the pot.

- the distillation was stopped when a total of 525 mL of n-PrOH had been added and a total of 800 mL of distillate had been collected.

- the filtrate was distilled at atmospheric pressure in a 500 mL flask (pot temperature 80-85°C) until 100 g (100 mL) of residue remained. This solution was allowed to cool to 35°C over 3 h. Over a lh period, 116 mL of cyclohexane was added with good agitation at 35°C. The mixture was cooled to 20°C over 1 h and aged at 20°C for 12 h. At 35°C much of the sulfonamide has crystallized out and the mixture was thick. Addition of cyclohexane at 20°C makes agitation difficult. After the aging period, the supernatant was found to contain 2.5 mg 1 g.

- the crystalline slurry was filtered and the cake was washed with 77 mL of 2:1 cyclohexane-EtOAc and 2 x 77 mL of cyclohexane.

- the catalyst was suspended in 7 L of MeOH and transferred into the 5 gal autoclave followed by the solution of 1 in 8 L of THF.

- the mixture was hydrogenolyzed at 25°C at 80 psi of H2- After 2.5 h the temperature was raised to 35°C over 30 min.

- HPLC analysis indicated complete consumption of Cbz- spiroindoline-methanesulfonamide.

- HPLC conditions 25 cm Dupont Zorbax RXC8 column with 1.5 mL/min flow and detection at 254 nm.

- Gradient Schedule Time (min) 0.1% aq.

- the mixture was purged with nitrogen and the catalyst was removed by filtration through Solka-flocTM while still warm.

- the catalyst was washed with 4 L of THF and 2 L of MeOH.

- the pale yellow filtrates were concentrated to a thick oil at 10 mbar and ⁇ 25°C.

- the solvent switch was completed by slowly bleeding in 15 L of EtOAc and reconcentrating to dryness.

- the residue solidified to a hard off-white mass.

- MeOH (1.5 L) was added and the mixture was heated to 70°C to give a homogenous solution. While the solution was at 70°C, 10.5 L of EtOAc at 20°C was added. The temperature fell to 40°C, and the mixture remained homogenous.

- the hydrogenation was run three (3) times due to equipment limitations; this procedure refers to a single run.

- the catalyst loading and reaction time are a function of the purity of starting material 1. This material was unique requiring > 15% catalyst and long reaction time. Purer batches of spiroindoline required only 5% of catalyst and 4-6 hrs reaction time.

- the batch was hydrogenated at 65 °C with vigorous stirring under 40 psi hydrogen pressure for 3 hours, a second portion of 10% palladium on charcoal (75 g) was added, the batch was hydrogenated for a further 2 hours and then sealed overnight.

- the batch was transferred (still hot, 60-65 °C) to a 20 L Buchi apparatus and degassed in vacuo to remove formic acid by "feeding and bleeding" absolute ethanol (18 L total). This procedure was repeated twice more and the three batches were combined in a 10 gallon glass-lined vessel and the combined batch was degassed again by the addition and distillation (in vacuo) of absolute ethanol (2 x 10 L).

- Solka floeTM 0.5 kg was added to the batch and rinsed in with ethanol (10 L).

- An Estrella filter was loaded with SolkaflocTM (2 kg) as a slurry in ethanol (20 L). The resulting mixture was warmed to 60-65°C and then transferred at this temperature via heated filter using pump to two tared stainless-steel bins. The initial vessel, the filter, the pump and the lines were rinsed with a hot (60-65°C) mixture of aqueous ammonia (500 ml) in absolute ethanol (25 L). The filtrate and washings were combined in the two stainless-steel bins. The batch was then transferred to a vessel using an in-line filter containing a 10 micron cartridge, and then concentrated in vacuo to low bulk (-15 L).

- the ethanol was replaced by isopropyl acetate by the "feeding and bleeding" of 3x batch volumes of isopropyl acetate (45 L total), while maintaining a batch volume of -15 L.

- the solvent switch when complete, contained ⁇ 1% residual ethanol by GC.

- the batch was then diluted to -33 L by the addition of isopropyl acetate (20 L), and this solution of spiroindoline-amine 115(1.855 kg by LC analysis) in isopropyl acetate was used for the later steps of the process.

- reaction mixture was solvent switched to iPAc (final volume of 2.6 L); complete removal of MeOH is necessary.

- iPAc final volume of 2.6 L

- an aqueous solution of NaCl 15 wt%, 1.3 L

- 2N NaOH solution was added over 1 hour to a pH of 9.

- a solution of more dilute base 0.5 N NaOH

- the temperature and pH were constantly being monitored; the observed temperature and pH ranges were 4-8°C and 2.5-10.1, respectively.]

- the layers were separated and the iPAc volume was adjusted to the appropriate volume for the next reaction (20 volumes; 2.6 L).

- the assay yield was 133.3 g (97%).

- Isocratic solvent system 50:50% of Aqueous buffer (0.1%

- the toluene solution (6.25 L toluene / g intermediate), which contained the methyl ester dipeptide intermediate (100 g, 0.25 mol) from Example 12, was transferred to a 2 L, 3-neck flask, equipped with a circulating bath, a mechanical stirrer, and a temperature probe.

- deionized water 312.5 mL was added and the temperature of the mixture was cooled to 4°C.

- 2 N LiOH 312.5 mL was added over 2 hours via syringe pump; this reaction mixture was then aged overnight at 4°C.

- the salt was filtered and washed with iPAc (4 volumes).

- the solid, thus obtained, was air dried and resuspended in iPAc (15 volumes; based on starting free acid) and 1M H2SO4 (10 volumes) was added.

- the layers were separated and the organic was washed again with 1M H2SO4 (10 volumes).

- the reaction mixture was aged for 30 min with vigorous stirring; the resulting two clear layers were separated and the organic was evaporated to a low volume (ca. 3 volumes of iPAC).

- the slurry was heated to 55°C for ca. 1 hour and then cooled to ambient temperature.

- Isocratic solvent system 50:50% of Aqueous buffer (0.1%

- the spiroindoline 15 (5 g; 19.8 mmol) from Example lOA/lOB in acetonitrile (12.15 volumes: 61 mL) was treated with the dipeptide 14 (7.3 g; 1.02 eq; 19 mmol) from Example 13 followed by HOBT (2.8 g; 1.1 eq; 20.6 mmol) or HONB (N-hydroxy-5-norbornene-2,3-dicarboximide) (1.1 eq) at ambient temperature; both the substrate and the reagent were added as solids.

- the solution was then cooled to -25°C and a DCC solution (4.7 g; 1.2 eq; 22.8 mmol) in acetonitrile (22.5 mL). was added over 30 min via syringe pump. The reaction mixture was aged overnight. Upon completion (> 95% conversion of 16 as indicated by

- the organic layer was solvent switched to EtOH (final volume: 4 volumes based on assay yield for dipeptide-BOC 16: 100 mL) and seeded with 5 wt% of dipeptide-BOC 16 (1.2 g).

- the slurry was aged for 1 hour at 25°C to establish a good seed bed followed by addition of heptane (4 volumes: 100 mL) over 2 hours.

- the mixture was aged at 25°C for 1 hour, cooled to 0°C slowly, and aged at that temperature overnight.

- the mixture was then filtered at 0°C and washed with 1:1 EtOH-heptane (2 volumes: 50 mL) precooled at 0°C followed by a room temperature heptane wash (4 volumes: 100 mL).

- the material was dried in a vacuum oven at 40°C with a nitrogen sweep.

- the Boc spiroindoline 16 was dissolved in 6.2 L of EtOH and treated with MsOH (979 mL). The temperature rose from 20 to 30°C and the reaction was allowed to proceed overnight. After 12 hours at 20°C there was still 15 A% of starting material left so the mixture was heated to 35°C for 6 hours. Upon completion ( ⁇ 0.1 A% 14) the reaction was cooled to 20°C and 30 L of H2O were added and the solution was filtered through a glass funnel with a polypropylene filter to filter off residual DCU. The mixture was transferred to a 100 L extractor and 26 L of EtOAc were added. The aqueous layer was basified via addition of chilled IN NaOH (11 L) and 1 L of 50% NaOH. Addition of ice was required to keep the temperature below 14°C. Higher temperatures resulted in significant emulsion problems.

- Methanesulfonic acid (2.017 kg, 1.36 L, -3 equivs.) was added to the stirred solution of the Boc spiroindoline 16 (4.395 kg) in ethanol

- total volume -25 L total volume -25 L in a reaction vessel at room temperature.

- the batch was warmed to 35-40°C, and stirred overnight. On the next day, the batch contained -1.1 A% of starting material and so the reaction was continued for a further 4 hours, then LC showed ratio of product/ starting material to be 99.6/0.4.

- the batch was concentrated in vacuo to -15 L volume and then diluted with water (44 L).

- the batch was cooled to 5°C, stirred for 30 minutes and then filtered through a Sparkler in-line filter (containing a 10m cartridge) using a pump to another vessel to remove a small amount of residual DCU.

- the vessel, the pump, the filter and the lines were rinsed with water (10 L), and this was added to the vessel.

- the batch was concentrated in vacuo to -20 L volume and then a mixture of ethyl acetate (35 L) and ethanol (5 L) was fed in while maintaining the volume at -20 L. At the end of this distillation the KF was 9160 mgml " .

- the batch was solvent switched to ethyl acetate by

- the batch (58 L) had a KF of 2950 mgml " and so was redried by concentrating in vacuo to 20-25 L volume.

- the batch was diluted to 46 L volume (dipstick) by the addition of ethyl acetate (25 L).

- the KF was 363 mgml " .

- the batch was diluted to 62 L volume by the addition of ethyl acetate (17 L) and was used for the final stage of the process.

- the volume of the solution of 17 from the previous step was adjusted to 60 L with ethyl acetate and EtOH (4.8 L) was added.

- the MsOH (316 mL) was added in 3 L of EtOAc at 45°C.

- To the deep red homogeneous solution was added 496 g of the title compound Form I seed (10% seed based on the weight of the free amine was employed). The temperature rose to ca. 48°C and the reaction was aged at 52°C for 1.5 hours. Analysis indicated complete conversion to the title compound (Form I). (At less than 10% seed longer age (> 3 hours) was required). The slurry was allowed to cool to 20°C overnight and was filtered in a centrifuge under N2.

- Form I (99.9 A% purity; ⁇ 0.1% enantiomer).

- the conversion of Form II to Form I is also accomplished where the salt is formed in EtOAc-EtOH by addition of MsOH as above and the initial solution of the salt (at 55°C) is cooled to 45°C. Crystals start appearing at that temperature and the slurry becomes thicker with time. The temperature is then raised to 51°C and the slurry is aged overnight. Complete conversion to Form I of 18 should be expected. This procedure may also be employed to prepare seed crystals of Form I of 18.

- Absolute ethanol (6.4 L) was added to the solution of the amine (17) (3.1 kg) in ethyl acetate (total volume -62 L) in a reacttion vessel. The batch was warmed to 50°C and a solution of methanesulfonic acid (620 g, 412 ml, 1.1 equivs.) in ethyl acetate (11 L) was added over -5 minutes at 50-54°C.

- Form I of N-[l(R)-[(l,2-dihydro-l-methanesulfonyl-spiro[3H- indole-3,4'-piperdin]-l'-yl)carbonyl]-2-(phenylmethyl-oxy)ethyl]-2-amino-2- methylpropanamide methanesulfonate is an anhydrous polymorph characterized by the following properties: a melting point of 169°C and solubility in isopropanol of 4.6 mg/mL.

- Form I was characterized by an X-ray powder diffraction pattern with principal reflections at approximately: 6.5, 14.7, 16.9, 17.1, 17.9, 19.5, 21.1, 21.7, and 22.0° (2 theta). Data collected using a Philips APD3720 Automated Powder Diffraction instrument with copper Ka radiation. Measurements were made from 2° to 40° (2 theta) with the sample maintained at ambient room temperature. While the invention has been described and illustrated with reference to certain particular embodiments thereof, those skilled in the art will appreciate that various adaptations, changes, modifications, substitutions, deletions, or additions of procedures and protocols may be made without departing from the spirit and scope of the invention.

- reaction conditions other than the particular conditions as set forth herein above may be applicable as a consequence of variations in the reagents or methodology to prepare the compounds from the processes of the invention indicated above.

- specific reactivity of starting materials may vary according to and depending upon the particular substituents present or the conditions of manufacture, and such expected variations or differences in the results are contemplated in accordance with the objects and practices of the present invention. It is intended, therefore, that the invention be defined by the scope of the claims which follow and that such claims be interpreted as broadly as is reasonable.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biochemistry (AREA)

- Biophysics (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Medicinal Chemistry (AREA)

- Molecular Biology (AREA)

- Proteomics, Peptides & Aminoacids (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Nitrogen Condensed Heterocyclic Rings (AREA)

- Medicines That Contain Protein Lipid Enzymes And Other Medicines (AREA)

Abstract

The present invention is directed to a novel convergent process for the preparation of the compound N-[1(R)-[(1,2-dihydro-1-methanesulfonyl-spiro[3H-indole-3,4'-piperdin]-1'-yl)carbonyl]-2-(phenylmethyl-oxy)ethyl]-2-amino-2-methyl-propanamide, and salts thereof, which has the structure of formula (A), and which has the ability to stimulate the release of natural or endogenous growth hormone. This compound may be used to treat conditions which require the stimulation of growth hormone production or secretion such as in humans with a deficiency of natural growth hormone or in animals used for food or wool production where the stimulation of growth hormone will result in a larger, more productive animal.

Description

TITLE OF THE INVENTION

CONVERGENT PROCESS FORTHE PREPARATION OFA

GROWTH HORMONE SECRETAGOGUE

BACKGROUND OFTHE INVENTION

Growth hormone, which is secreted from the pituitary, stimulates growth of all tissues of the body that are capable of growing. In addition, growth hormone is known to have the following basic effects on the metabolic processes of the body: (1) Increased rate of protein synthesis in all cells of the body; (2) Decreased rate of carbohydrate utilization in cells of the body; (3) Increased mobilization of free fatty acids and use of fatty acids for energy. A deficiency in growth hormone secretion can result in various medical disorders, such as dwarfϊsm.

Various ways are known to release growth hormone. For example, chemicals such as arginine, L-3,4-dihydroxyphenylalanine (L- DOPA), glucagon, vasopressin, and insulin induced hypoglycemia, as well as activities such as sleep and exercise, indirectly cause growth hormone to be released from the pituitary by acting in some fashion on the hypothalamus perhaps either to decrease somatostatin secretion or to increase the secretion of the known secretagogue growth hormone releasing factor (GRF) or an unknown endogenous growth hormone- releasing hormone or all of these.

In cases where increased levels of growth hormone were desired, the problem was generally solved by providing exogenous growth hormone or by administering GRF or a peptidal compound which stimulated growth hormone production and/or release. In either case the peptidyl nature of the compound necessitated that it be administered by injection. Initially the source of growth hormone was the extraction of the pituitary glands of cadavers. This resulted in a very expensive product and carried with it the risk that a disease associated with the source of the pituitary gland could be transmitted to the recipient of the growth hormone. Recombinant growth hormone has become available which, while no longer carrying any risk of disease transmission, is still a very expensive product which must be

given by injection or by a nasal spray. Other compounds have been developed which stimulate the release of endogenous growth hormone.

In particular, certain spiro compounds are disclosed in U.S. Patent No. 5,536,716, PCT Patent Publication WO 94/13696 and Proc. Natl. Acad. Sci. USA. 92, 7001-7005 (July 1995) as being non- peptidal growth hormone secretagogues. These compounds have the ability to stimulate the release of natural or endogenous growth hormone and thus may be used to treat conditions which require the stimulation of growth hormone production or secretion such as in humans with a deficiency of natural growth hormone or in animals used for food or wool production where the stimulation of growth hormone will result in a larger, more productive animal.

Among the preferred compounds disclosed therein is spiro[3H-indole-3,4'-piperdin]-l'-yl)carbonyl]-2-(phenylmethyl-oxy)ethyl]- 2-amino-2-methylpropanamide which has the structure:

U.S. Patent No. 5,536,716 and PCT Patent Publication WO 94/13696 disclose methods for preparing this compound (see Examples 18, 19 and 55). However, the synthesis of the compound was accomplished by using the very expensive amino acid coupling agent EDC ($1100/kg); the use of numerous equivalents of trifluoroacetic acid as the catalyst for the BOC group deprotections; extensive chromatographic purifications; and resulted in "gumming" of the final product. PCT Patent Publication WO 97/15573 also discloses methods for preparing this compound.

The advantages of the present invention include: manufacturing flexibility through a convergent route; synthesis of the dipeptide side-chain in high yield and high enantiomeric excess; avoidance of a large number of steps (i.e. coupling/deprotection sequences) in the presence of the spiroindoline; a high yielding non- isolation process; decreased expense through the use of DCC [$40/kg] instead of EDC [$1100/kg]; diminished environmental impact through the use of methanesulfonic acid instead of trifl uoroacetic acid as the catalyst (as well as lesser equivalents of catalyst) in the deprotections; and ease of isolation of the final product.

SUMMARY OF THE INVENTION

The instant invention is directed to a novel convergent process for the preparation of the compound N-[l(R)-[(l,2-dihydro-l- methanesulfonyl-spiro[3H-indole-3,4'-piperdin]-l'-yl)carbonyl]-2-

(phenylmethyl-oxy)ethyl]-2-amino-2-methyl-propanamide which has the structure:

and salts thereof, in particular, the methanesulfonate salt. This compound has the ability to stimulate the release of natural or endogenous growth hormone and may be used to treat conditions which require the stimulation of growth hormone production or secretion such as in humans with a deficiency of natural growth hormone or in animals used for food or wool production where the stimulation of growth hormone will result in a larger, more productive animal.

DESCRIPTION OF THE INVENTION

The present invention is directed to a novel convergent process for the preparation of the compound N-[l(R)-[(l,2-dihydro-l- methanesulfonyl-spiro[3H-indole-3,4'-piperdin]-l'-yl)carbonyl]-2- (phenylmethyl-oxy)ethyl]-2-amino-2-methyl-propanamide which has the structure:

and salts thereof, in particular, the methanesulfonate salt.

The instant process provides the desired compound from readily available inexpensive and environmentally acceptable starting materials reagents and solvents. The process does not require the use any chromatographic purifications, and it is possible to produce the final product from the intermediate spiroindoline sulfonamide without isolation of any of the intermediates.

The individual processes within the general process are summarized as follows:

SCHEME I

Reduction of

SCHEME I (CONT'D)

"

(wherein G is an appropriate carboxyl protecting group, L is an appropriate amino protecting group and X" is an appropriate counterion).

Within this general process, a first process concerns the preparation of a compound of formula I:

I wherein L is an amino protecting group, by coupling an amino acid of the formula:

Ph O γ * NH2

wherein G is a carboxyl protecting group, with a compound of the formula :

wherein L is an amino protecting group, in the presence of an acid activating agent in an inert solvent in the presence of a catalytic agent, followed by removal of the carboxyl protecting group G to give the compound of formula I.

Acid activating agents suitable for this process include: DCC, EDC, ECAC and BOP, in which the preferred acid activating agent is DCC (N,N'-dicyclohexylcarbodiimide).

Catalytic agents suitable for this process include: HOBT, HONB, and the like in which a preferred catalytic agent is HOBT (hydroxybenzotriazole).

Inert solvents appropriate for this processes include: acetonitrile; iso-propyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho-dichlorobenzene;

benzene; toluene; xylenes; and the like; and mixtures thereof, in which the preferred solvent is either acetonitrile or isopropyl acetate and water.

The preferred reaction temperature range is between -40 and 150°C, and the most preferred range is between 20 and 35°C. Suitable carboxyl protecting groups include: methyl, allyl, ethyl, isopropyl, benzyl, and the like, in which the preferred one is methyl.

Removal of the carboxyl protecting group may be effected by methods well known in the art. For example, hydrolysis of the methyl ester may be achieved with lithium hydroxide in a solution of toluene and water at a temperature of between about 0 and about 10°C, preferably about 4-5°C. Optionally, the enantiomeric purity of the dipeptide may be upgraded by formation and crystalization of the dicyclohexyl amine salt.

Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy), t-butoxy-carbonyl groups, and in which the most preferred one is the t-butoxy-carbonyl group.

In the interest of efficiency, it is preferred that this coupling be conducted in situ without isolation of the compound of formula I following its preparation by the aforementioned process.

Within this general process, a second process concerns the preparation of a compound of formula II:

II wherein L is an amino protecting group, by coupling an amino acid of the formula:

H H H3C CH3 Ph-o^ N YL

C02H °

I wherein L is an amino protecting group, with a compound of the formula:

in the presence of an acid activating agent in an inert solvent in the presence of a catalytic agent, to give the compound of formula II.

Acid activating agents suitable for this process include: DCC, EDC, ECAC and BOP, in which the preferred acid activating agent is DCC (N,N'-dicyclohexylcarbodiimide).

Catalytic agents suitable for this process include: HOBT, HONB, and the like in which a preferred catalytic agent is HOBT (hydroxybenzotriazole) or HONB (N-hydroxy-5-norbornene-2,3- dicarboximide) . Inert solvents appropriate for this processes include: acetonitrile; isopropyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho-dichlorobenzene; benzene; toluene; xylenes; and the like; and mixtures thereof. When the catalytic agent is HOBT, the preferred solvent is acetonitrile. When the catalytic agent is HONB, the preferred solvent is isopropyl acetate:water. The preferred reaction temperature range is between -40 and 150°C. When the catalytic agent is HOBT, the most preferred range is between about -20 and about -35°C, and the even more preferred temperature is about -25°C. When the catalytic agent is HONB, the most preferred range is between about -10 and about 15°C, and the even more preferred temperature range is between about 0 and 5°C

Suitable amino protecting groups include: benzyl, benzyloxym ethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl, and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy), t-butoxy-carbonyl groups, and in which the most preferred one is the t-butoxy-carbonyl group.

In the interest of efficiency, it is preferred that this coupling be conducted in situ without isolation of the compound of formula II following its preparation by the aforementioned process. Alternatively, the compound of formula II may be isolated as a discrete intermediate.

Within this general process, a third process concerns the preparation of a compound of formula III, or a pharmaceutically acceptable salt thereof:

III which comprises reacting a compound of the formula II:

II wherein L is an amino protecting group, with an amino deprotecting agent to give the compound of formula III.

Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, allyloxycarbonyl,

and vinyloxycarbonyl groups, and the like, in which the preferred ones include benzyloxycarbonyl (carbobenzyloxy), t-butoxy-carbonyl groups, and in which the most preferred one is the t-butoxy-carbonyl group.

In this process, the removal of the amino protecting group may be accomplished by use of an appropriate catalytic agent. Removal of a t-butoxycarbonyl protecting group may be carried out in a solvent such as methanol, ethanol, methylene chloride, ethyl acetate, or iso-propyl acetate, with a strong acid. Such strong acids include methanesulfonic acid, trifluoroacetic acid, hydrochloric acid, hydrogen chloride gas, hydrogen bromide; hydrogen iodide; trifluoromethane-sulfonic acid; camphorsulfonic acid; sulfuric acid; phosphoric acid; and an arylsulfonic acid, such as benzenesulfonic acid, p-toluenesulfonic acid, and p- chlorobenzene-sulfonic acid. Preferred catalytic agents include: trifluoroacetic acid; methanesulfonic acid; camphorsulfonic acid; benzenesulfonic acid, p-toluenesulfonic acid; and p-chlorobenzene-sulfonic acid. The most preferred catalytic agent is methanesulfonic acid. It is preferred that compound of formula III is isolated in the form of the methanesulfonate salt. The preferred solvent is methanol or ethanol, and the most preferred solvent is ethanol. The preferred reaction temperature range is between -40 and

150°C, and the most preferred range is between 10 and 40°C.

Removal of a benzyloxycarbonyl (carbobenzyloxy) group may be achieved by a number of methods, for example, catalytic hydrogenation with hydrogen in the presence of a noble metal or its oxide such as palladium on activated carbon in a protic solvent such as ethanol. In cases where catalytic hydrogenation is contraindicated by the presence of other potentially reactive functionality, the removal of benzyloxycarbonyl (carbobenzyloxy) group may also be achieved by treatment with a solution of hydrogen bromide in acetic acid, or by treatment with a mixture of TFA and dimethylsulfide.

In the interest of efficiency, it is preferred that this acid- catalyzed deprotection be conducted in situ without isolation of the compound of formula III following its preparation by the aforementioned process.

Within this general process, a fourth process concerns the preparation of a pharmaceutically acceptable salt of a compound of formula III, in particular, the methanesulfonate salt, i.e. a compound of formula TV:

IV which comprises reacting a compound of the formula III:

III with an acid, preferably methanesulfonic acid, to give the compound of formula r .

It is preferred that compound of formula r is isolated in the form of the methanesulfonate salt. The preferred solvent comprises ethyl acetate and ethanol, and the most preferrred solvent is a mixture of ethyl acetate and ethanol.

In the interest of efficiency, it is preferred that the formation of the salt be conducted in situ without isolation of the compound of formula V following its preparation by the aforementioned process.

In a preferred embodiment of the present invention, the individual processes within the general process are outlined as follows:

SCHEME II:

The N-BOC-O-Benzyl-D-Serine 11 was treated with methane sulfonic acid in methanol at 65°C for ca. 5 hours to affect simultaneous BOC deprotection and methyl ester formation in 90-95% yield. The success of this reaction depended on a careful workup procedure that avoided hydrolysis of the methyl ester (12). To that end, the methanolic solution of 2 was solvent switched to iPAc (levels of residual MeOH of <1% v/v are essential). A 15% aqueous NaCl solution was added and the biphasic mixture was cooled to 0°C. A solution of NaOH (2 N) was added slowly to pH 9, at 0-4°C, and the pH was carefully adjusted to 10.2 with 0.5 N NaOH. A lower pH resulted in substantial losses of 12 in the aqueous layer, while at pH 11, substantial hydrolysis of the methyl ester was observed.

Coupling of 12 with N-BOC-amino isobutyric acid was accomplished in iPAC-H2θ (2:1 v/v) in the presence of DCC (1.1 eq) and

HOBT (0.05 eq), to afford 13 in 98% crude yield.

The crude methyl ester 13 was hydrolyzed in high yield (95- 97%) with minimal epimerization at the serine chiral center (ca. < 2%). The reproducibility of this reaction was initially tenuous, however, a reliable procedure was developed. Intermediate 13 was dissolved in toluene:H2θ (2:1 v/v), then cooled to 4°C and treated with 2 N LiOH (2.5

eq). The aqueous layer, containing the Li salt of 14, was separated; iPAc was added and the pH was adjusted to ca. 1 with 1.5 N HC1. The enantiometric purity of 14 was upgraded to > 99.5% ee developed by the following procedure: 1) addition of DCHA in iPAC at 65°C ; 2) aging the resulting thick slurry at that temperature for 4-5 hours; and 3) aging at 25°C for 10 hours followed by filtration. The enantiomerically pure free acid, 14, was obtained in high overall yield (ca. 93%) by partitioning the DCHA salt in iPAc-1 M H2SO4 (aqueous) followed by separation of the layers, volume adjustment of the organic layer (ca. 3 volumes), and addition of heptane (ca. 9 volumes).

SCHEME IV

Reaction of 15 with 14 in CH3CN (1.1 eq DCC; 0.2 eq HOBT) at -25°C produced 0.4% of the L-isomer (specification: < 0.5%) of 16 and eventually the final product 18. Similarly, reaction of 15 withl4 in 2:1 iPAc:H2O (1.1 eq DCC; 0.2 eq HONB) at 0°C produced very little of the L-isomer of 16.

The ethyl acetate solution of the free base 17 is concentrated to low bulk in υacuo and is azeotroped dry (KF <500 mgml ) by "feeding and bleeding" 2x batch volumes of 90/10, ethyl acetate/ethanol followed by 2x batch volumes of ethyl acetate. The resulting dry, slightly hazy solution of the free base 17 in ethyl acetate is treated with Darco

G-60 (25 weight %) at room temperature for about 10 hours. Removal of the Darco by filtration with a filtration agent gives the free base 17.

Formation of the methanesulfonic acid salt 18 from 17 is carried out in EtOAc with 1.1 eq of MsOH at about 50°C. The free base 17 is treated with 8 volume % of EtOH and 1 eq of H2O and heated to 55°C until complete dissolution. Cooling to ambient temperature and stirring the resulting slurry for 4 hours gives crystalline material of 18 designated as crystal Form II [solubility in IPA = 12 mg/mL].

The conversion of Form II to Form I is accomplished where the salt is formed in EtOAc-EtOH as above, but instead of cooling the initial solution of the salt (at 55°C) to ambient temperature, it is cooled to 45°C. Crystals should start appearing at that temperature and the slurry should become thicker with time. The temperature is then raised to 51°C and the slurry is aged overnight. Complete conversion to Form I of 18 should be expected.

Preferably, the conversion of Form II to Form I is achieved by adding seed crystals of Form I to a solution of the free base in EtOAc- EtOH at 50-55°C followed by aging. Accordingly, the free base 17 may be treated with 1.1 equivs. of methanesulfonic acid in 8% ethanol in ethyl acetate at 50-55°C. The batch is then seeded with approximately 2% by weight of Form I of the methanesulfonate salt 18, and then aged at 55°C overnight. The batch is cooled to room temperature and aged for approximately 2-3 hours. The product is isolated by filtration at room

temperature under a nitrogen atmosphere, dried at 35°C in υacuo and sieved to give the methanesulfonate salt 18.

The methanesulfonic acid salt 18 may also be formed by alternating the stepwise addition of MsOH (1.1 eq) and seed crystals of Form I to a solution of the free base in EtOAc-EtOH at about 50°C, wherein the order of addition of the MsOH and the seed is not critical.

Detailed solubility studies showed that no thermodynamic enrichment was possible during the isolation of 16 (EtOH/heptane) or 18 (EtOAc:EtOH, 92:8). In an attempt to prevent epimerization, a number of reaction parameters were examined; these included temperature, order of addition of the reagents, solvent, amount of HOBT, and coupling reagent. The results are summarized in Table 1.

TABLE I

In the optimal reaction conditions, spiroindoline 15 and dipeptide 14 were dissolved in 13 volumes of acetonitrile and HOBT was added (1.1 eq). Alternatively, HONB (N-hydroxy-5-norbornene-2,3- dicarboximide) may be employed in place of HOBT. The resulting homogenous mixture was treated with DCC in acetonitrile at -25°C overnight. [Note: This order of addition is crucial since 15 and HOBT form an insoluble complex throughout the reaction which makes stirring difficult and might be responsible for some initial irreproducibility in the results.] After workup, the dipeptide-BOC, 16, was isolated and carried to the final product to afford the final compound in ca. 70% overall yield from 11 in 99.9% purity and 99.2% ee.

Throughout the instant application, the following abbreviations are used with the following meanings:

Bu butyl

Bn benzyl

BOC, Boc t-butyloxycarbonyl

BOP Benzotriazol-1-yloxy tris(dimethylamino)- phosphonium hexafluorophosphate calc. calculated

CBZ, Cbz Benzyloxycarbonyl

DCC N,N'-Dicyclohexylcarbodiimide

DIEA Di-isopropylethylamine

DMF N,N-dimethylformamide

DMAP 4-Dimethylaminopyridine

EDC l-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride

EDAC Ethyl-3-(3-dimethylamino)-propylcarbodiimide

EI-MS Electron ion-mass spectroscopy

Et ethyl eq. equivalent(s)

FAB-MS Fast atom bombardment-mass spectroscopy h, hr. hours

HOBT, HOBt Hydroxybenzotriazole

HPLC High pressure liquid chromatography iPrOAc iso-Propyl acetate

KHMDS Potassium bis(trimethylsilyl)amide

LAH Lithium aluminum hydride

LHMDS Lithium bis(trimethylsilyl)amide

Me methyl

MF Molecular formula

MHz Megahertz

MPLC Medium pressure liquid chromatography

MsOH Methane sulfonic acid

NMM N-Methylmorpholine

NMR Nuclear Magnetic Resonance

Ph phenyl

Pr propyl prep. prepared

TFA Trifluoroacetic acid

THF Tetrahydrofuran TLC Thin layer chromatography

TMS Tetramethylsilane

In the above structural formula and throughout the instant specification, the following terms have the indicated meanings: The phrase "peptide coupling reaction" as used herein is intended to mean the coupling of a carboxylic acid with an amine using an acid activating agent such as EDC, DCC, and BOP in an inert solvent in the presence of a catalyst such as HOBT. Inert solvents appropriate for such couplings include: acetonitrile; iso-propyl acetate; ethyl acetate; propionitrile; water; chlorinated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, dichloroethane, chlorobenzene, ortho- dichlorobenzene; benzene; toluene; xylenes; and combinations thereof; and the like.

The variable "L" and the term "amino protecting group" is intended to indicate the presence of an appropriate protecting group for amino, such as those described in Greene, T.W., Wuts, P.G.M. Protective Groups in Organic Synthesis, 2nd ed., John Wiley & Sons, Inc., New York, 1991. An appropriate protecting group will be able to withstand the reaction conditions of intermediate processes, prior to being removed when desired. The amino protecting group is independently selected for each process within the entire processes.

Suitable amino protecting groups include: benzyl, benzyloxymethyl, benzyloxycarbonyl (carbobenzyloxy), benzylsulfonyl, 2- bromo-ethyloxycarbonyl, t-butoxy-carbonyl, 2-chloro-benzyloxy-carbonyl, 2-chloroethyloxycarbonyl, di-t-amyloxycarbonyl, 9-fluoroenyl- methyloxycarbonyl, isopropoxycarbonyl, 4-methoxy-benzyloxycarbonyl, 4- nitrobenzyloxycarbonyl, 2-nitrophenyl-sulfonyl, phthaloyl, 2,2,2-trichloro- t-butyloxycarbonyl, trifluoroacetyl, triphenylmethane, and vinyloxycarbonyl groups, and the like, in which the preferred ones include

benzyloxycarbonyl (carbobenzyloxy), t-butoxy-carbonyl groups, and in which the most preferred one is the t-butoxy-carbonyl group.

The removal of the amino protecting group may be accomplished by use of an appropriate catalytic agent. Removal of a t- butoxycarbonyl protecting group may be carried out in a solvent such as methanol, ethanol, methylene chloride, ethyl acetate, or iso-propyl acetate, with a strong acid. Such strong acids include methanesulfonic acid, trifluoroacetic acid, hydrochloric acid, hydrogen chloride gas, hydrogen bromide; hydrogen iodide; trifluoromethane-sulfonic acid; camphorsulfonic acid; sulfuric acid; phosphoric acid; and arylsulfonic acids, such as benzenesulfonic acid, p-toluenesulfonic acid, and p-chlorobenzene-sulfonic acid. Preferred catalytic agents include: trifluoroacetic acid; methanesulfonic acid; camphorsulfonic acid; benzenesulfonic acid, p- toluenesulfonic acid; and p-chlorobenzene-sulfonic acid. The most preferred catalytic agent is methanesulfonic acid. The preferred solvent is methanol or ethanol.

Removal of a benzyloxycarbonyl (carbobenzyloxy) protecting group may be achieved by a number of methods, for example, catalytic hydrogenation with hydrogen in the presence of a noble metal or its oxide such as palladium on activated carbon in a protic solvent such as ethanol. In cases where catalytic hydrogenation is contraindicated by the presence of other potentially reactive functionality, the removal of benzyloxycarbonyl (carbobenzyloxy) group may also be achieved by treatment with a solution of hydrogen bromide in acetic acid, or by treatment with a mixture of TFA and dimethylsulfide.

The amine compounds employed as starting materials for the process of the present invention may be present as their acid salts, such as the salts derived from using inorganic and organic acids. Examples of such acids are hydrochloric, nitric, sulfuric, phosphoric, formic, acetic, trifluoroacetic, propionic, maleic, succinic, malonic, methane sulfonic and the like. Similarly the compounds produced by the processes of the instant invention may be isolated in the form of their pharmaceutically acceptable acid salts. In addition, certain compounds containing an acidic function such as a carboxy can be in the form of their inorganic salt in

which the counterion can be selected from sodium, potassium, lithium, calcium, magnesium and the like, as well as from organic bases.

The preparation of compounds with the process of the present invention may be carried out in sequential or convergent synthetic routes. It is noted that in some cases the order of carrying out the foregoing reaction schemes may be varied to facilitate the reaction or to avoid unwanted reaction products. In general, the process of the present invention is conducted in a sequential manner as presented herein. Many of the starting materials are either commercially available or known in the literature and others can be prepared following literature methods described for analogous compounds. The skills required in carrying out the reaction and purification of the resulting reaction products are known to those in the art. Purification procedures include crystallization, normal phase or reverse phase chromatography. The following examples are provided for the purpose of further illustration only and are not intended to be limitations on the disclosed invention.

EXAMPLE 1 O^OBn

Isonipecotic acid-N-benzyl carbamate (3)

Materials:

Isonipecotic acid (2) T.C.I. 4.02 kg (31.1 mol) Benzyl chloroformate (Schweitzerhall) 6.91 kg (40.5 mol)

K2CO3 10.1 kg (72.9 mol)

Water 40.2 L

Isonipecotic acid (2) and K2CO3 were dissolved in 40.2 L of water in a 100 L 4 neck flask with mechanical stirring under N2 and the solution was cooled to 10°C. Benzyl chloroformate was added, maintaining the temperature between 9 and 14°C, and the mixture was warmed up to 22°C after the addition was complete and aged for 58 h. The addition was completed in 4 h at which point the pH was 9.0. After aging for 58 h there was no change in the pH.

The reaction mixture was transferred to a 200 L extractor and washed with 3 x 13 kg (15 L) of IPAC and 1 x 12 L of EtOAc. The aqueous layer was extracted with 8 L of toluene. After the washes the benzyl alcohol content was reduced from 3.8% to 1.4% by HPLC analysis. HPLC analytical: Dupont Zorbax 25 cm RXC8 column with 1.5 mL/min flow and detection at 254 nm; isocratic mixture with 35% MeCN, 65% of 0.1% aqueous H3PO4; retention times: 3 = 6.9 min, benzyl alcohol = 3.3 min, toluene = 17.3 min.

The aqueous phase was acidified with 37% aqueous HC1 to pH 1.8. Carbon dioxide was evolved during the addition of HC1, but gas evolution was easily controlled. The addition of HC1 took <1 h and required 10 L of cone. HC1. The aqueous phase was extracted with 3 x 6.6 L of toluene. The toluene extracts were dried with 2 kg of sodium sulfate and filtered through a pad of Solka-floc™. The combined filtrates weighed 17.8 kg. The crude yield of carbamate 3 was 7.89 kg (97%) (as obtained by evaporation of weighed aliquots of the filtrates to dryness). The filtrates were transferred through a 10 μ inline filter to a 100 L flask. The extracts were concentrated at 10 mbar at <25°C to a volume of 18 L. The final concentration of carbamate 3 was 440 g/L. The concentration of the toluene filtrate served to azeotropically remove final traces of water (final KF = 170mg/L). The product was 99.1 area % pure with 0.9 area % benzyl alcohol as the only impurity.

EXAMPLE 2

O^OBn

COCI

Isonipecotic acid chloride-Af-benzyl carbamate (4)

Materials:

Isonipecotic acid N-benzyl carbamate (3) 7.89 kg (30.0 mol) in in toluene. (MW = 263.30) 17.9 L

Oxalyl chloride (MW = 126.93) 3.94 kg (31.0 mol)

DMF (MW = 73.10) 10 mL Toluene 12 L

To the toluene solution of benzyl carbamate 3 from the preceding step was added 5 mL of DMF and 10 L of toluene. The oxalyl chloride was added over a period of 20 min. The reaction mixture was aged for 16 h at 18°C under a slow stream of nitrogen. HPLC analysis of the reaction mixture showed that 1.3% of the carboxylic acid 3 still remained unreacted. The reaction mixture was warmed to 26°C, and 5 mL of DMF were added. The mixture was aged for 2.5 h.

A 1.0 mL aliquot of the reaction mixture was quenched with 5.0 mL of tert-butylamine and analyzed after evaporation by HPLC: 25 cm Dupont Zorbax RXC8 column at 50°C with 1 mL/min flow and detection at 220 nm; isocratic 42% MeCN, 58% of 0.1% aqueous H3PO4. This method showed that <0.05% of the acid 3 remained (as judged by A) and showed >3 area % B (>1 mol% (COCD2).

A B

The mixture was concentrated at 10 mbar and a temperature of 20-25°C until 5 L of solvent had been removed.

The typical HPLC profile of concentrated toluene solution after t-BuNH2 quench described above is as follows:

Retention time (min) Area % Identity

2.1 <0.5% carboxylic acid 3

7.8 <0.5% benzyl chloride

11.0 >99% Cbz-t-butylcarboxamide A

12.1 NA toluene

12.7 <0.5% ditert-butyloxamide B

EXAMPLE 3

O^OBn

Materials:

Isonipecotic acid chloride iV-benzyl carbamate (4) 3.38 kg (12.0 mol) in toluene (MW = 281.74) in 5.54 kg

DIEA (KF = 18 mg/L) 1.55 kg (15.0 mol)

10% Pd C (KF < 20 mg/g) 101 g thioanisole (MW = 124.21, d = 1.058) 0.56 g

The DIEA and thioanisole were added to the solution of (4) in toluene from the previous step and the catalyst was suspended in this mixture. The mixture was immediately placed into the 5 gal autoclave and hydrogenated at 20°C and 40 psi of H2. After 18 h the reaction had taken up 70% the theoretical amount of hydrogen and HPLC analysis of an aliquot that was quenched with tert-butylamine indicated that 14.2 area % of acid chloride 2 remained. HPLC conditions same as above. Retention time: 5 = 8.1 min.

A second charge of catalyst (101 g) and thioanisole (0.54 g) were added as a slurry in 1375 mL toluene to the hydrogenator. After 23 h HPLC analysis of an aliquot that was quenched with tert-butylamine indicated that 1.8 area % of acid chloride 2 remained. The mixture was purged with nitrogen and the catalyst and precipitated DIEA»HC1 were removed by filtration through Solka-floc™. The filter cake was washed with 10 L of toluene. The filtrates were transferred through a 10 μ inline filter to a 50 L extractor and washed with 2 x 7.2 L of 1 M aqueous HC1 and 2 x 7.2 L of water. The mixture was concentrated at 10 mbar and a temperature of 25-30°C until 5 L of residue remained.

Retention time (min) Area % Identity

2.1 <2 carboxylic acid 3

6.6 <1 dimer 21

8.1 >95 aldehyde 5

The assay yield of aldehyde 3 was 94% by HPLC analysis.

EXAMPLE 4

CBZ-Spiroindoline (9)

Materials:

Piperidine-4-carboxaldehyde-l-benzyl 1.71 kg (6.89 mol) carbamate (5) in toluene solution in 21.4 kg Phenylhydrazine 900 mL, 981 g (9.15 mol)

Trifluoroacetic acid (TFA) 2.20 L, 3.26 kg (28.6 mol)

NaBH4 300 g, (7.93 mol)

Toluene 34.4 kg

MeCN 7.0 L MeOH 7.0 L

The crude aldehyde 5 solution from the previous step was transferred through a 10 μ inline filter to a 100 L reactor equipped with Teflon coated copper coils for cooling or heating and a mechanical stirrer. Toluene (34.4 kg) and MeCN (7 L) were added, and the resulting solution was cooled to 0°C. Phenylhydrazine was added in portions and the temperature was maintained at -1 to 3 °C while nitrogen was continuously bubbled through the reaction mixture.

The phenylhydrazine was added until TLC and HPLC analysis indicated complete consumption of the aldehyde 5 and the appearance of a slight excess (<5%) of phenylhydrazine. TLC conditions: Silica, E. Merck Kieselgel G60 F254 0.25 mm; diethyl ether/pentane (4/1); and developing agent 0.5% eerie sulfate, 14% ammonium molybdate in 10% aqueous sulfuric acid then heat; Rf aldehyde 5 = 0.52, phenylhydrazone 7 = 0.61, phenylhydrazine 6 = 0.21.

HPLC conditions: 25 cm Dupont Zorbax RXC8 column at 30°C with 1.0 mL/min flow and detection at 254 nm; gradient schedule:

Time (min) acetonitrile:water

0 57:43

10 65:35

15 75:25

18 75:25 retention times: phenylhydrazine 6 = 4.5 min, toluene = = 7.2 min, phenylhydrazone 7 = 11.4 min.

The reaction mixture was aged for 30 min at 0-2°C, and TFA was added maintaining the temperature between 2 and 7°C. The reaction mixture was warmed to 50°C over 30 min, and maintained for 17 h. The nitrogen sparge through the reaction mixture was stopped and a slow stream of nitrogen was maintained over the reaction mixture. During the first hour at 5°C the color gradually darkened to a deep green, and a relatively small amount of a white crystalline precipitate (ammonium trifluoroacetate) formed. After 17 h HPLC analysis (same conditions as above) indicated that the reaction mixture contained 91.6 area % indolenine 8 and 1.5% of unreacted phenylhydrazone remained. Aging the mixture for longer periods of time did not increase the assay yield of indolenine 8.