WO1993022378A1 - Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use - Google Patents

Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use Download PDFInfo

- Publication number

- WO1993022378A1 WO1993022378A1 PCT/NO1993/000062 NO9300062W WO9322378A1 WO 1993022378 A1 WO1993022378 A1 WO 1993022378A1 NO 9300062 W NO9300062 W NO 9300062W WO 9322378 A1 WO9322378 A1 WO 9322378A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- weight

- glycidyl

- ageing

- vcm

- accordance

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L27/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Compositions of derivatives of such polymers

- C08L27/02—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Compositions of derivatives of such polymers not modified by chemical after-treatment

- C08L27/04—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Compositions of derivatives of such polymers not modified by chemical after-treatment containing chlorine atoms

- C08L27/06—Homopolymers or copolymers of vinyl chloride

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/02—Polymer mixtures characterised by other features containing two or more polymers of the same C08L -group

Definitions

- the present invention concerns a procedure for preventing the reduction of flexibility of a plasticised material containing vinyl chloride after ageing at high temperature, a thermoplastic material containing vinyl chloride and an application of this material.

- a cable must be able to withstand ageing at 170°C for 6 hours, and at 120°C for 1000 hours and then pass a cold bending test at -30°C.

- Polyvinyl chloride is a material which is easy to process and is relatively reasonably priced.

- PVC materials which are exposed to ageing at high temperature become more brittle on account of the fact that the material is broken down combined with a reduction in plasticiser.

- the loss of plasticiser means that there is a certain connection between the weight loss and the flexibility.

- the object of the invention is thus to produce a material containing vinyl chloride which is flexible after ageing at high temperature. It is of special interest to produce materials which can be used in cables, particularly vehicle cables, hoses, seals and packings.

- the invention consists in wholly or partly replacing PVC with a copolymer based on VCM and small parts of glycidyl-containing comonomers .

- glycidyl-containing comonomers such as glycidyl acrylate, glycidyl methacrylate or glycidyl Jbutacrylate. It is preferred t.o use glycidyl-containing comonomers in a quantity of 0.1-10 weight %.

- the thermoplastic PVC material which has good flexibility after ageing at high temperature, consists of polymer, plasticiser, thermostabiliser and other additives.

- the material contains 20-100 weight % of one copolymer in which the monomer consists of 80-99.9 weight % of VCM and 0.1-10 weight % of glycidyl-containing acrylate, and 0-80 weight %- of other copolymers based on at least 70 % VCM.

- the glycidyl-containing polymer may contain up to 10 weight % of another monomer such as, for example, vinyl acetate and acrylates which do not contain glycidyl such as methyl methacrylate, ethyl methacrylate and butyl methacrylate.

- plasticisers suited to PVC are used.

- polymers such as, for example, EVA (copolymer between ethene and vinyl acetate) or polyadipate as a plasticiser in such mixtures.

- Small quantities of other polymers can be added such as, for example, chlorinated polyethene, EVA, a terpolymer between ethene, vinyl acetate and carbon monoxide, EBA (a copolymer between ethene and butyl acrylate) , polyadipates and nitrile rubber without the material losing its properties.

- EVA copolymer between ethene and vinyl acetate

- EBA a copolymer between ethene and butyl acrylate

- polyadipates and nitrile rubber without the material losing its properties.

- the material is well suited for use

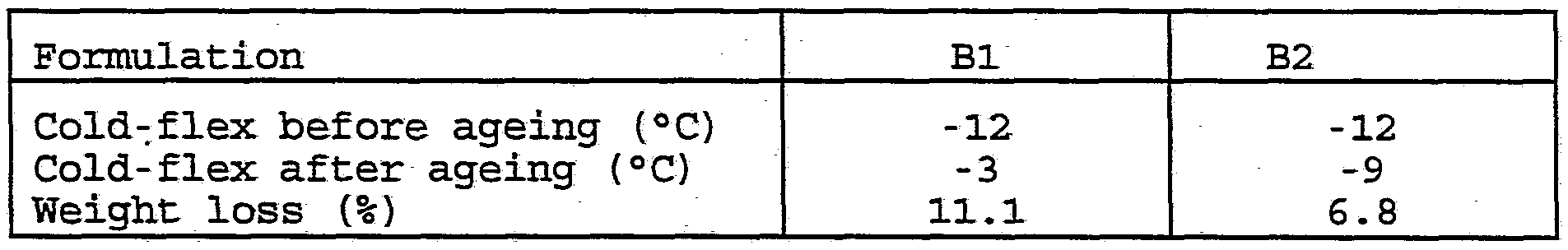

- the cold-flex according to Clash and Berg (ISO 547) was measured in samples which had not been aged and in samples which had been aged for 240 hours at 155°C.

- the cold-flex measures the temperature at which a sample strip of approximately 1 mm thickness has a flex modulus of 310 MPa. The lower the temperature indicated, the more flexible the sample.

- the reduction in weight was measured as a comparison between the sample's weight before and after ageing for 240 hours at 155°C.

- Table 2 shows that when PVC (homopolymer based on VCM) is replaced with a copolymer based on VCM and small parts of GMA, a material is obtained which tolerates ageing at high temperatures considerably better. While mixture Al, based on a homopolymer, has a 6.5 % weight loss after ageing at 155°C for 240 hours, mixtures A2 and A3, based on copolymers, have weight losses of about half of this. Mixture Al loses approximately 12°C in cold-flex on account of ageing while A2 and A3 lose 6°C and 2°C respectively.

- thermostability for the pure polymers, without additives, is poorer for copolymers than for the homopolymer.

- thermostabiliser added epoxidised soya bean oil and added antioxidant.

- Table 3 The formulations are shown in table 3.

- Table 4 shows the measurements carried out on the formulations indicated in table 3.

- Table 4 shows clearly that the effect of improved flexibility after ageing cannot be achieved by increasing the quantity of stabiliser. On the other hand it was sho-,n that an increased quantity of lead stabiliser gave rise to poorer flexibility after ageing. One possible cause of this might be that the lead stabiliser contributes to splitting and thus the reduction in softener. The addition of epoxidised soya bean oil or antioxidant did not produce the required effect either.

- the weight loss for the materials Al, A4, A5 and A6 in tables 3 and 4 is obviously greater than for mixtures A2 and A3 which contain the copolymer VCM:GMA.

- the cold-flex value is considerably worse for all the materials in tables 3 and 4 in comparison with A2 and A3.

- the stabiliser which is normally recommended for applications with extreme heat stress is dibasic lead phthalate. Comparative studies were therefore carried out with formulations with this type of stabiliser, see table 7.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Insulated Conductors (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Organic Insulating Materials (AREA)

- Materials For Medical Uses (AREA)

- Laminated Bodies (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

- Processes Of Treating Macromolecular Substances (AREA)

Abstract

Description

Claims

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU39629/93A AU670078B2 (en) | 1992-04-30 | 1993-04-14 | Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use |

| DE69303929T DE69303929D1 (en) | 1992-04-30 | 1993-04-14 | FELIXIBLE PVC MATERIAL CONTAINING GLYCIDYL ACRYLATE WITH HIGH RESISTANCE TO HEATING AGE, AND METHOD FOR THE PRODUCTION AND USE THEREOF |

| JP5519148A JPH07506139A (en) | 1992-04-30 | 1993-04-14 | Flexible PVC material containing glycidyl acrylate with high heat aging resistance, its manufacturing method and use |

| EP93909090A EP0638108B1 (en) | 1992-04-30 | 1993-04-14 | Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use |

| FI945084A FI945084A (en) | 1992-04-30 | 1994-10-28 | Flexible glycidyl acrylate PVC material with good thermal aging resistance, method and use |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| NO921739 | 1992-04-30 | ||

| NO921739A NO176146C (en) | 1992-04-30 | 1992-04-30 | Application of a vinyl chloride-containing material to materials where flexibility is required after aging at high temperature |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO1993022378A1 true WO1993022378A1 (en) | 1993-11-11 |

Family

ID=19895112

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/NO1993/000062 WO1993022378A1 (en) | 1992-04-30 | 1993-04-14 | Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use |

Country Status (13)

| Country | Link |

|---|---|

| EP (1) | EP0638108B1 (en) |

| JP (1) | JPH07506139A (en) |

| CN (1) | CN1080934A (en) |

| AT (1) | ATE141097T1 (en) |

| AU (1) | AU670078B2 (en) |

| CA (1) | CA2134349A1 (en) |

| DE (1) | DE69303929D1 (en) |

| FI (1) | FI945084A (en) |

| HU (1) | HUT69753A (en) |

| NO (1) | NO176146C (en) |

| RU (1) | RU94045971A (en) |

| TW (1) | TW269704B (en) |

| WO (1) | WO1993022378A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1176170A1 (en) * | 2000-07-25 | 2002-01-30 | HUBER & SUHNER AG | Sealing strips for the construction industry and method for producing and using the same |

| CN101875747B (en) * | 2009-04-28 | 2011-12-14 | 杭州德裕饰品有限公司 | Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0264916A2 (en) * | 1986-10-20 | 1988-04-27 | Union Carbide Corporation | Vinyl chloride resins and compositions incorporating such resins |

| EP0358067A2 (en) * | 1988-09-01 | 1990-03-14 | BASF Aktiengesellschaft | Vinyl chloride copolymers |

| EP0389208A1 (en) * | 1989-03-20 | 1990-09-26 | Nippon Zeon Co., Ltd. | Interlayer for laminated safety glass |

| EP0481325A2 (en) * | 1990-10-19 | 1992-04-22 | The Geon Company | Polyvinyl chloride compositions having improved processing stability |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55162451A (en) * | 1979-05-31 | 1980-12-17 | Sekisui Chem Co Ltd | Interlayer composition for safety laminated glass |

| JPH0333039A (en) * | 1989-06-29 | 1991-02-13 | Sekisui Chem Co Ltd | Intermediate film composition for laminated glass and intermediate film for laminated glass using the composition |

-

1992

- 1992-04-30 NO NO921739A patent/NO176146C/en unknown

-

1993

- 1993-04-14 DE DE69303929T patent/DE69303929D1/en not_active Expired - Lifetime

- 1993-04-14 RU RU94045971/04A patent/RU94045971A/en unknown

- 1993-04-14 EP EP93909090A patent/EP0638108B1/en not_active Expired - Lifetime

- 1993-04-14 CA CA002134349A patent/CA2134349A1/en not_active Abandoned

- 1993-04-14 AT AT93909090T patent/ATE141097T1/en not_active IP Right Cessation

- 1993-04-14 AU AU39629/93A patent/AU670078B2/en not_active Ceased

- 1993-04-14 WO PCT/NO1993/000062 patent/WO1993022378A1/en active IP Right Grant

- 1993-04-14 HU HU9403121A patent/HUT69753A/en unknown

- 1993-04-14 JP JP5519148A patent/JPH07506139A/en active Pending

- 1993-04-23 TW TW082103122A patent/TW269704B/zh active

- 1993-04-30 CN CN93105496A patent/CN1080934A/en active Pending

-

1994

- 1994-10-28 FI FI945084A patent/FI945084A/en not_active Application Discontinuation

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0264916A2 (en) * | 1986-10-20 | 1988-04-27 | Union Carbide Corporation | Vinyl chloride resins and compositions incorporating such resins |

| EP0358067A2 (en) * | 1988-09-01 | 1990-03-14 | BASF Aktiengesellschaft | Vinyl chloride copolymers |

| EP0389208A1 (en) * | 1989-03-20 | 1990-09-26 | Nippon Zeon Co., Ltd. | Interlayer for laminated safety glass |

| EP0481325A2 (en) * | 1990-10-19 | 1992-04-22 | The Geon Company | Polyvinyl chloride compositions having improved processing stability |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1176170A1 (en) * | 2000-07-25 | 2002-01-30 | HUBER & SUHNER AG | Sealing strips for the construction industry and method for producing and using the same |

| CN101875747B (en) * | 2009-04-28 | 2011-12-14 | 杭州德裕饰品有限公司 | Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| FI945084A0 (en) | 1994-10-28 |

| NO921739D0 (en) | 1992-04-30 |

| HUT69753A (en) | 1995-09-28 |

| AU3962993A (en) | 1993-11-29 |

| EP0638108B1 (en) | 1996-08-07 |

| HU9403121D0 (en) | 1995-02-28 |

| JPH07506139A (en) | 1995-07-06 |

| NO176146C (en) | 1995-02-08 |

| NO921739L (en) | 1993-11-01 |

| AU670078B2 (en) | 1996-07-04 |

| CA2134349A1 (en) | 1993-11-11 |

| TW269704B (en) | 1996-02-01 |

| ATE141097T1 (en) | 1996-08-15 |

| EP0638108A1 (en) | 1995-02-15 |

| RU94045971A (en) | 1996-10-10 |

| DE69303929D1 (en) | 1996-09-12 |

| FI945084A (en) | 1994-10-28 |

| NO176146B (en) | 1994-10-31 |

| CN1080934A (en) | 1994-01-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| GB1603205A (en) | Polymer compositions | |

| JPS63500177A (en) | Antistatic compositions and products made therefrom | |

| JP3706208B2 (en) | Vinyl chloride resin composition | |

| US3562195A (en) | Fluoride elastomer composition | |

| CA2020430A1 (en) | Electrostatic dissipating composition and method relating thereto | |

| JPS6344782B2 (en) | ||

| JPS6051503B2 (en) | Soft resin composition | |

| WO1993022378A1 (en) | Flexible pvc material containing glycidyl acrylate, with high resistance to heat ageing, method and use | |

| JPH11140263A (en) | Vinyl chloride-based resin composition and coated electric wire using the same | |

| JPH11176240A (en) | Vinyl chloride resin composition for covering heat resistant electric wire | |

| JP3051422B2 (en) | Electrically insulating resin composition for wire coating | |

| JP2001288303A (en) | Peroxide-cross-linkable rubber composition | |

| US4520169A (en) | Elastomeric sol/gel blends | |

| JP2791674B2 (en) | Vinyl chloride resin composition | |

| JP2531747B2 (en) | Rubber composition | |

| JPS62199641A (en) | Polyvinyl chloride resin composition | |

| JPH05171025A (en) | Resin composition | |

| JPS57125237A (en) | Resin composition for videodisk | |

| JPH05311022A (en) | Polyvinyl chloride composition | |

| JPH03149250A (en) | Heat-resistant resin composition | |

| JPS58219250A (en) | Vinyl chloride resin composition | |

| JPS6210153A (en) | Vinyl chloride polymer composition | |

| JPH0588268B2 (en) | ||

| JPH0782448A (en) | Cold-resistant resin composition and electric wires and cables | |

| GB2155483A (en) | Insulated wires |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AK | Designated states |

Kind code of ref document: A1 Designated state(s): AT AU BB BG BR CA CH CZ DE DK ES FI GB HU JP KP KR LK LU MG MN MW NL NO NZ PL PT RO RU SD SE SK UA US |

|

| AL | Designated countries for regional patents |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LU MC NL PT SE BF BJ CF CG CI CM GA GN ML MR NE SN TD TG |

|

| DFPE | Request for preliminary examination filed prior to expiration of 19th month from priority date (pct application filed before 20040101) | ||

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application | ||

| WWE | Wipo information: entry into national phase |

Ref document number: 2134349 Country of ref document: CA Ref document number: 1993909090 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 1994 325394 Country of ref document: US Date of ref document: 19941027 Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 945084 Country of ref document: FI |

|

| REG | Reference to national code |

Ref country code: DE Ref legal event code: 8642 |

|

| WWP | Wipo information: published in national office |

Ref document number: 1993909090 Country of ref document: EP |

|

| WWG | Wipo information: grant in national office |

Ref document number: 1993909090 Country of ref document: EP |