US7487990B2 - Semitrailer coupling - Google Patents

Semitrailer coupling Download PDFInfo

- Publication number

- US7487990B2 US7487990B2 US10/538,541 US53854103A US7487990B2 US 7487990 B2 US7487990 B2 US 7487990B2 US 53854103 A US53854103 A US 53854103A US 7487990 B2 US7487990 B2 US 7487990B2

- Authority

- US

- United States

- Prior art keywords

- bearing block

- bearing

- coupling plate

- region

- fastening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related, expires

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D53/00—Tractor-trailer combinations; Road trains

- B62D53/04—Tractor-trailer combinations; Road trains comprising a vehicle carrying an essential part of the other vehicle's load by having supporting means for the front or rear part of the other vehicle

- B62D53/08—Fifth wheel traction couplings

- B62D53/0807—Fifth wheel traction couplings adjustable coupling saddles mounted on sub-frames; Mounting plates therefor

Definitions

- the invention relates to a semitrailer coupling comprising a coupling plate and a bearing block for movable fastening of the coupling plate to a frame of a tractor, the bearing block having a bearing region and a fastening region, the bearing region being designed for pivotable bearing of the coupling plate and the fastening region being designed for detachable fastening of the coupling plate to the frame of the tractor.

- a tractor has a coupling plate, into which a pin, what is known as the king pin, of the trailer is engaged.

- the trailer lies relatively freely movably on a semitrailer coupling plate of the tractor.

- the semitrailer coupling plate is connected to the frame of the tractor via two bearing blocks.

- the bearing blocks comprise bearing elements, which are arranged transversely to the direction of travel of the tractor and make possible pivoting of the coupling plate about a pivoting axis transversely to the direction of travel.

- a semitrailer coupling of the generic type is known from WO 01/34454 A1.

- the bearing blocks which are in each case fastened on the left and right side of the vehicle frame, are interconnected parallel to the pivoting axis via a cross-strut.

- the cross-strut can also be designed on the inner side of the vehicle as a projection on the bearing block concerned.

- the bearing blocks, the projections and/or the cross-struts rest on the horizontal surface of the frame construction of the tractor.

- a semitrailer coupling comprising a coupling plate and a bearing block for movable fastening of the coupling plate to a frame of a tractor, the bearing block having a bearing region and a fastening region, the bearing region being designed for pivotable bearing of the coupling plate and the fastening region being designed for detachable fastening of the coupling plate to the frame of the tractor, and, sectioned in the direction of travel and parallel to the pivoting axis, the bearing region having a larger cross section than the fastening region.

- the semitrailer coupling can be constructed from as few individual parts as possible. This is achieved by virtue of the fact that the bearing blocks are formed from a one-piece casting.

- transverse forces which act on the semitrailer coupling can be compensated in the bearing blocks. This is achieved by virtue of the fact that the bearing region of the bearing blocks is designed in such a way on the inner side of the vehicle that a clearance for movements of the coupling plate in a direction transverse to the direction of travel is present between the bearing region and the semitrailer coupling plate.

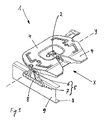

- FIG. 1 shows a three-dimensional view of a semitrailer coupling according to the invention

- FIG. 2 shows a view of the semitrailer coupling from FIG. 1 in the direction of travel

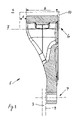

- FIG. 3 shows a section through a bearing block perpendicular to the direction of travel.

- a semitrailer coupling 1 is illustrated in three-dimensional form in FIG. 1 .

- the semitrailer coupling 1 is arranged on a tractor (not illustrated here) and serves for movable connection of the tractor to a trailer (likewise not illustrated here) of a semitrailer truck combination.

- a king pin which is arranged on the front lower side of the trailer, is located in a coupling claw 2 of the semitrailer coupling 1 .

- the semitrailer coupling 1 comprises essentially a coupling plate 4 and two bearing blocks 5 , only one bearing block 5 of which is illustrated here on the left side in the direction of travel x of the tractor.

- the bearing block 5 has two regions with different functions: a bearing region 6 and a fastening region 7 .

- Bearing elements which serve for pivotable mounting of the coupling plate 4 about a pivoting axis y, are located in the bearing region 6 .

- the pivoting axis y extends transversely to the direction of travel x of the tractor.

- Screws 8 with which the bearing block 5 is fastened to the frame 3 of the tractor, can be seen in the fastening region 7 .

- the bearing block 5 is advantageously fastened to the vertical side surface 9 of the vehicle frame 3 by means of screws 8 . Lateral screw fastening makes it possible for mounting and demounting to be carried out extremely easily on existing vehicle frames as well.

- FIG. 2 the semitrailer coupling 1 from FIG. 1 is again illustrated, seen in the direction of travel x of the tractor. It can be seen clearly here how the fastening region 7 of the bearing block 5 is fastened to the vertical side surface of the vehicle frame 3 with screws 8 . No fastening or support is necessary on the horizontal surface of the vehicle frame 3 , which is a surface with extremely poor access in the assembled state of the tractor.

- the second bearing block 5 on the right side of the coupling plate 4 has been omitted in FIG. 2 for greater clarity.

- the references in FIG. 2 refer to the same features as described in FIG. 1 .

- the bearing block 5 is illustrated on its own in a section perpendicular to the direction of travel x.

- a receiving region 10 which is provided on the underside of the coupling plate 4 for receiving the bearing block 5 , is indicated diagrammatically with broken lines in the bearing region 6 .

- the horizontal side surface 9 of the vehicle frame 3 for fastening the bearing block 5 is indicated with further broken lines in the fastening region 7 .

- the bearing block 5 has a width b in the bearing region 6 which is at least 2.5 times the width of the bearing block 5 in the fastening region 7 .

- the bearing block 5 is manufactured as a one-piece casting.

- the shape is calculated in such a way that the necessary rigidity is achieved with minimum weight of the casting.

- the bearing region 6 is machined in such a way after casting that a clearance S remains free in the assembled state between the bearing region 6 of the bearing block 5 and the receiving region 10 of the semitrailer coupling plate 4 .

- This clearance S left free on one side on the inner side of the vehicle serves for compensating movements of the coupling plate 4 in the direction of the pivoting axis y.

- Such a clearance S is likewise provided on the inner side of the vehicle in the case of the opposite bearing block (not shown here).

- the bearing blocks 5 can be adapted to existing semitrailer couplings and existing vehicle frames.

- the present semitrailer coupling 1 with the newly dimensioned bearing blocks 5 makes possible, with the same load-carrying capacity, a reduction in weight and consequently a fuel saving for the semitrailer truck combination.

Landscapes

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Vehicle Cleaning, Maintenance, Repair, Refitting, And Outriggers (AREA)

- Body Structure For Vehicles (AREA)

- Seats For Vehicles (AREA)

- Arrangement And Driving Of Transmission Devices (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Braking Arrangements (AREA)

- Agricultural Machines (AREA)

- Handcart (AREA)

- Control Of Motors That Do Not Use Commutators (AREA)

- Polysaccharides And Polysaccharide Derivatives (AREA)

Abstract

Description

Claims (8)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10257807.9A DE10257807B4 (en) | 2002-12-10 | 2002-12-10 | fifth wheel |

| DE10257807.9 | 2002-12-10 | ||

| PCT/EP2003/012171 WO2004052713A2 (en) | 2002-12-10 | 2003-10-31 | Semitrailer coupling |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20060170190A1 US20060170190A1 (en) | 2006-08-03 |

| US7487990B2 true US7487990B2 (en) | 2009-02-10 |

Family

ID=32336197

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/538,541 Expired - Fee Related US7487990B2 (en) | 2002-12-10 | 2003-10-31 | Semitrailer coupling |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US7487990B2 (en) |

| EP (1) | EP1578658B2 (en) |

| CN (1) | CN100391777C (en) |

| AT (1) | ATE350268T1 (en) |

| AU (1) | AU2003276229A1 (en) |

| DE (2) | DE10257807B4 (en) |

| DK (1) | DK1578658T3 (en) |

| ES (1) | ES2276163T5 (en) |

| PT (1) | PT1578658E (en) |

| WO (1) | WO2004052713A2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD837103S1 (en) * | 2016-09-19 | 2019-01-01 | Iveco S.P.A. | Towing attachment for vehicles |

| US10266022B2 (en) | 2013-05-22 | 2019-04-23 | Saf-Holland, Inc. | Fifth wheel hitch assembly having direct-mount mounting brackets |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1764290B1 (en) | 2005-09-15 | 2010-06-30 | SAF-HOLLAND Verkehrstechnik GmbH | Fifth wheel coupling |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0694467A2 (en) | 1994-07-28 | 1996-01-31 | ROCKINGER Spezialfabrik für Anhängerkupplungen GmbH & Co. | Semi-trailer tractor |

| US5746438A (en) * | 1995-03-03 | 1998-05-05 | Jost--Werke AG | Fifth wheel |

| US6182996B1 (en) * | 1997-06-27 | 2001-02-06 | Jost-Werke Gmbh & Co., Kg. | Fifth wheel |

| WO2001034454A1 (en) | 1999-11-12 | 2001-05-17 | Scania Cv Aktiebolag (Publ) | Connection arrangement comprising a fifth wheel |

| US6623024B1 (en) * | 1998-03-27 | 2003-09-23 | Jost-Werke Ag | Fifth wheel coupling |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2336939A (en) * | 1940-09-06 | 1943-12-14 | American Steel Foundries | Fifth wheel mounting |

| DE1031141B (en) * | 1956-04-09 | 1958-05-29 | American Steel Foundries | Semi-trailer coupling |

| CN86210718U (en) * | 1986-12-20 | 1987-12-12 | 湖南省汽车车桥厂 | Traction seat of modular graphite cast iron |

| US4762334A (en) * | 1987-11-03 | 1988-08-09 | Amsted Industries Incorporated | Fifth wheel bracket mounting assembly |

| US5368324A (en) * | 1994-01-10 | 1994-11-29 | Amsted Industries Incorporated | Mounting system for fifth wheels |

| US5464241A (en) * | 1994-07-25 | 1995-11-07 | Holland Hitch Company | Plural height powered fifth wheel hitch |

| JP3465836B2 (en) * | 1995-10-09 | 2003-11-10 | 株式会社 ソーシン | Buffer support structure in coupler |

| US5765849A (en) * | 1996-04-24 | 1998-06-16 | Fontaine Fifth Wheel Co. | Fifth wheel bracket |

| GB9821363D0 (en) * | 1998-10-02 | 1998-11-25 | Vbg Limited | Fifth wheel coupler |

| DE19952997C5 (en) * | 1999-11-04 | 2013-09-26 | Jost-Werke Gmbh | Fastening device for a fifth wheel to a vehicle frame |

| DE10213148C1 (en) * | 2002-03-23 | 2003-07-03 | Jost Werke Gmbh & Co Kg | Saddle coupling between tractor vehicle and boom has bearing trunnion bolted to vehicle frame beam and with bearing surface |

-

2002

- 2002-12-10 DE DE10257807.9A patent/DE10257807B4/en not_active Expired - Lifetime

-

2003

- 2003-10-31 AU AU2003276229A patent/AU2003276229A1/en not_active Abandoned

- 2003-10-31 EP EP03812582A patent/EP1578658B2/en not_active Expired - Lifetime

- 2003-10-31 DK DK03812582T patent/DK1578658T3/en active

- 2003-10-31 CN CNB200380105649XA patent/CN100391777C/en not_active Expired - Fee Related

- 2003-10-31 WO PCT/EP2003/012171 patent/WO2004052713A2/en active IP Right Grant

- 2003-10-31 ES ES03812582T patent/ES2276163T5/en not_active Expired - Lifetime

- 2003-10-31 US US10/538,541 patent/US7487990B2/en not_active Expired - Fee Related

- 2003-10-31 PT PT03812582T patent/PT1578658E/en unknown

- 2003-10-31 AT AT03812582T patent/ATE350268T1/en not_active IP Right Cessation

- 2003-10-31 DE DE50306229T patent/DE50306229D1/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0694467A2 (en) | 1994-07-28 | 1996-01-31 | ROCKINGER Spezialfabrik für Anhängerkupplungen GmbH & Co. | Semi-trailer tractor |

| US5746438A (en) * | 1995-03-03 | 1998-05-05 | Jost--Werke AG | Fifth wheel |

| US6182996B1 (en) * | 1997-06-27 | 2001-02-06 | Jost-Werke Gmbh & Co., Kg. | Fifth wheel |

| US6623024B1 (en) * | 1998-03-27 | 2003-09-23 | Jost-Werke Ag | Fifth wheel coupling |

| WO2001034454A1 (en) | 1999-11-12 | 2001-05-17 | Scania Cv Aktiebolag (Publ) | Connection arrangement comprising a fifth wheel |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10661621B2 (en) | 2013-03-14 | 2020-05-26 | Saf-Holland, Inc. | Fifth wheel hitch assembly having direct-mount mounting brackets |

| US10266022B2 (en) | 2013-05-22 | 2019-04-23 | Saf-Holland, Inc. | Fifth wheel hitch assembly having direct-mount mounting brackets |

| USD837103S1 (en) * | 2016-09-19 | 2019-01-01 | Iveco S.P.A. | Towing attachment for vehicles |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1578658B1 (en) | 2007-01-03 |

| EP1578658A2 (en) | 2005-09-28 |

| DE10257807A1 (en) | 2004-06-24 |

| DE50306229D1 (en) | 2007-02-15 |

| PT1578658E (en) | 2007-04-30 |

| WO2004052713A2 (en) | 2004-06-24 |

| WO2004052713A3 (en) | 2004-08-05 |

| ATE350268T1 (en) | 2007-01-15 |

| ES2276163T5 (en) | 2013-05-30 |

| EP1578658B2 (en) | 2013-02-27 |

| ES2276163T3 (en) | 2007-06-16 |

| DK1578658T3 (en) | 2007-05-07 |

| CN100391777C (en) | 2008-06-04 |

| CN1723148A (en) | 2006-01-18 |

| DE10257807B4 (en) | 2014-03-27 |

| AU2003276229A1 (en) | 2004-06-30 |

| US20060170190A1 (en) | 2006-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7793968B1 (en) | Integrated support structure for either a fifth wheel hitch or a gooseneck trailer hitch | |

| US8342557B2 (en) | Fifth wheel slider assembly | |

| EP2334539B1 (en) | Structural joint for a commercial vehicle frame and a frame made with a structural joint | |

| CA2590949A1 (en) | Articulated utility cart | |

| JP2000053030A (en) | General purpose body subframe assembly and general purpose body panel assembly | |

| US20220144347A1 (en) | Body structure for an electrically operated vehicle | |

| CA2705165C (en) | Supporting traverse | |

| CA2355494C (en) | End sill assembly with center plate casting | |

| US6199889B1 (en) | Reduced weight fifth wheel assembly | |

| EP1607249A1 (en) | Control arm for use in vehicle suspension system | |

| US7487990B2 (en) | Semitrailer coupling | |

| US7198282B2 (en) | Cross member | |

| US8434779B2 (en) | Fifth wheel | |

| CA2492633C (en) | Common cast draft sill for type e and f draft gear | |

| KR20040093014A (en) | Axle supporting structure for industrial vehicle and industrial vehicle having the same | |

| US11919432B2 (en) | Trailer unit for transporting tracked constructional machines | |

| JPH08198134A (en) | Cross-member of aluminum alloy | |

| CA2422661A1 (en) | Fifth wheel coupling | |

| AU696843B2 (en) | Articulated spine car | |

| CA2221535C (en) | Reduced weight fifth wheel assembly | |

| JPH10211889A (en) | Chassis for low-built cab | |

| EP0967139A2 (en) | A trailer | |

| CN217778802U (en) | Saddle support assembly | |

| JP3034449U (en) | Semi-trailer | |

| WO2011154903A1 (en) | Improvements in shipping containers and trailers for use with shipping containers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: GEORG FISCHER VERKEHRSTECHNIK GMBH, GERMANY Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:ROTH-SCHULER, CHRISTIAN;SCHNEIDER, DIRK;REEL/FRAME:017472/0121 Effective date: 20050103 |

|

| FEPP | Fee payment procedure |

Free format text: PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY |

|

| STCF | Information on status: patent grant |

Free format text: PATENTED CASE |

|

| AS | Assignment |

Owner name: SAF-HOLLAND VERKEHRSTECHNIK GMBH, GERMANY Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:GEORG FISCHER VERKEHRSTECHNIK GMBH;REEL/FRAME:026092/0997 Effective date: 20110323 |

|

| FPAY | Fee payment |

Year of fee payment: 4 |

|

| FPAY | Fee payment |

Year of fee payment: 8 |

|

| AS | Assignment |

Owner name: SAF-HOLLAND GMBH, GERMANY Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:SAF-HOLLAND VERKEHRSTECHNIK GMBH;REEL/FRAME:045689/0539 Effective date: 20180411 |

|

| FEPP | Fee payment procedure |

Free format text: MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY |

|

| LAPS | Lapse for failure to pay maintenance fees |

Free format text: PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY |

|

| STCH | Information on status: patent discontinuation |

Free format text: PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362 |

|

| FP | Lapsed due to failure to pay maintenance fee |

Effective date: 20210210 |