US3825195A - Drive roll for winders of filamentary material - Google Patents

Drive roll for winders of filamentary material Download PDFInfo

- Publication number

- US3825195A US3825195A US00304253A US30425372A US3825195A US 3825195 A US3825195 A US 3825195A US 00304253 A US00304253 A US 00304253A US 30425372 A US30425372 A US 30425372A US 3825195 A US3825195 A US 3825195A

- Authority

- US

- United States

- Prior art keywords

- roll

- drive

- shaft

- drive shaft

- friction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/40—Arrangements for rotating packages

- B65H54/42—Arrangements for rotating packages in which the package, core, or former is rotated by frictional contact of its periphery with a driving surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/40—Arrangements for rotating packages

- B65H54/46—Package drive drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/70—Other constructional features of yarn-winding machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2601/00—Problem to be solved or advantage achieved

- B65H2601/30—Facilitating or easing

- B65H2601/32—Facilitating or easing entities relating to handling machine

- B65H2601/321—Access

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a novel drive roll for such winders.

- Filament winders are required whereever filamentary materials must be processed.

- synthetic plastic filaments which have been newly produced must be wound onto bobbin or core tubes, for storage until further use. This is, of course, true also of yarns, threads and the like, irrespective of the particular material from which they are made.

- winders machines which have one or more chucks, i.e., devices which internally engage a bobbin tube so that it can rotate and thus wind up the filament onto it.

- chucks i.e., devices which internally engage a bobbin tube so that it can rotate and thus wind up the filament onto it.

- One such winder, with which my novel drive roll may be used to advantage, isdisclosed in my aforementioned copending application.

- These winders are divided into two basic categories, according ,to the manner in which their respective chucks are driven. In one of these, the chuck is center driven, i.e. the chuck is-connected with a drive shaft which rotates it.

- the chuck is surface driven, i.e., a driven friction roll is mounted adjacent the chuck and is brought into frictional contact with a bobbin tube on the chuck, or with a filament package which forms or is present on the bobbin tube.

- the rotary motion of the friction roll is thus frictionally transmitted to the bobbin tube and the chuck, both of which are rotated.

- Another object is to provide such a roll which is relatively simple in its construction, and therefore is rugged and can be economically produced.

- An additional object of the invention is to provide such a roll which can be used with existing winders.

- a drive roll for winders of filamentary material which drive roll comprises a support, a stationary hollow shaft cantilevered on said support, and a tubular friction roll surrounding and journalled on said hollow shaft for rotation relative to the same.

- a drive shaft which extends through the hollow shaft and has spaced endportions each of which extends axially beyond a respective end of the hollow shaft.

- One of these end portions is coupled via coupling means with the friction roll for rotating the same when a motive force is applied to the other end portion.

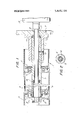

- FIG. 1 is an axial section through a drive roll according to the present invention.

- FIG. 2 is. a section taken on line Il-II of FIG. 1.

- reference numeral 1 designates the tubular friction roll per se, i.e., the element whose outer circumferential surface is to be brought into frictional contact with the circumference of a bobbin tube or of a package of filamentary material wound thereon.

- the outer circumferential surface of the friction roll may be suitably treated (e.g., roughened, provided with a friction-enhancing coating of rubber or the like, etc.) in order to obtain the desired degree of frictional engagement. This, however, is conventional and well within the skill of the art.

- the friction roll 1 surrounds a stationary mounting shaft 2 which has a center passage 11.

- one end of the shaft 2 (the left-hand end in FIG. 1) is located within the confines of roll 1, whereas the other end is located outside the roll 1.

- the latter is journalled on the shaft 2 for rotation thereabout, via the illustrated anti-friction bearings 3 and 5.

- the inner race 4 of bearing 3, and the inner race 6 of bearing 5, are both fixedly connected with the shaft 2, so that only the respective outer races (which are fixed to the inner surface of roll 1), rotate with the latter.

- the shaft 2 is telescoped into a mounting socket 7 wherein it is fixedly retained via one or more (one shown) threaded connectors 8.

- the mounting socket 7 extends in cantilever fashion from a support structure 10 (which may be part of the winder frame, or the like), to which it is connected via bolts 9 (only one shown).

- a drive shaft 12 extends through the passage 11 of shaft 2.

- the right-hand end portion 17 of the drive shaft extends outwardly beyond the' right-hand end of shaft 2 and is connected in any well-known manner with a drive, here illustrated as a motor 18.

- the left-hand end portion 16 of the drive shaft 12 also extends beyond the shaft 2, in this case beyond the left-hand end thereof. It is still located within the confines of the roll 1, however. Adjacent to it, and also within roll 1, is a coupling element 19 which in the illustrated embodiment is essentially cup-shaped but could also be otherwise configurated.

- This element 19 is rigidly connected with the circumferential wall of the roll 1, in any suitable manner, and has a hub or center portion provided with an axially extending polygonal (here quadratic) passage 15.

- the end portion 16 of shaft 12 is matingly configurated (see FIG. 2) and is received in the passage 15 so that the shaft 12, when rotated by the motor 18, takes along the element 19 and thus the roll 1.

- the shaft 12 is journalled for rotation in anti-friction bearings 13 and 14 which are located in the passage 11 of shaft 2.

- a drive roll for winders of filamentary material comprising a support; a stationary hollow support shaft, including a first tubular portion fixedly connected to and cantilevered on said support, a second tubular portion partly received in said first tubular portion projecting outwardly from said same, and having a free end, and connecting means connecting said tubular portions against relative displacement; a tubular friction roll surrounding said hollow support shaft with clearance; first anti-friction bearings in said clearance and journalling said friction roll on said support shaft for rotation with reference to the same; a drive shaft being substantially fully located in said hollow support shaft and having one end portion projecting from said free end and another end portion projecting through said support; second anti-friction bearings journalling said drive shaft in said hollow support shaft in the region of said support and said free end, respectively; and coupling means coupling said one end portion of said drive shaft adjacent said free end of said second tubular portion with said friction roll for rotating the same in response to the application of motive force to said other end portion of said drive shaft, whereby said drive shaft serves only to transmit

- a drive roll as defined in claim 1, said first antifriction bearings each having an outer race fixedly connected with said friction roll, and an inner race fixedly connected with said hollow shaft.

- a drive roll as defined in claim 3, said coupling member having a hub portion provided with a passage of polygonal outline, and wherein said one end portion of said drive shaft is of mating polygonal outline and received in said passage.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Winding Filamentary Materials (AREA)

Abstract

A hollow shaft is stationarily cantilevered on a support. A tubular friction roller is journalled on the shaft for rotation about the same. A drive shaft extends through the hollow shaft, being journalled therein, and has one endportion extending beyond one end of the hollow shaft but within the friction roll with which this endportion is drivingly connected. The other endportion of the drive shaft extends outwardly beyond the hollow shaft and friction roll for coupling with a drive.

Description

trite States Patent 1191 Miller July 23, 1974 DRIVE ROLL FOR WINDERS 0F 3,042,324 7/1962 Kinney 242/18 DD FILAMENTARY MATERIAL 3,254,850 6/1966 Martin et al. 242/18 G [75] Inventor: Harry B. Miller, Hopedale, Mass. FOREIGN PATENTS OR APPLICATIONS [73] Assignee: Industrie-Werke Karlswhe 817,763 8/1959 Great Britain 242/12 DD Augsburg Akfiengesenschaft, 1,161,505 1/1964 Germany 242/18 DD Karlsruhe, Germany Primary ExaminerStanley N. Gilreath [22] Flled' 1972 Attorney, Agent, or FirmMichael S. Striker [21] Appl. No.: 304,253

Related US. Application Data 57 ABSTRACT [63] ggl of June A hollow shaft is stationarily cantilevered on a support. A tubular friction roller is journalled on the shaft 52 US. Cl. 242 18 DD for rotation the Same- A drive Shaft extends i51i 1111. C1 B651i 54/46 thwugh the hollow Shaft, beingjwmalled therein and [5 Field f Search 242/1 DD 18 R 1 G has one endportion extending beyond one end Of the 4 hollow shaft but within the friction roll with which this endportion is drivingly connected. The other endpor- [56] References Cited tion of the drive shaft extends outwardly beyond the UNITED STATES PATENTS hollow shaft and friction roll for coupling with a drive.

2,336,963 12/1943 Schweiter 242/18 DD 5 Claims, 2 Drawing Figures til l DRIVE ROLL lFOlR WINDERS OF FILAMENTARY MATERIAL BACKGROUND OF THE INVENTION ably held on the winder chuck.

Still more particularly, the invention relates to a novel drive roll for such winders.

Filament winders are required whereever filamentary materials must be processed. Thus, for instance, synthetic plastic filaments which have been newly produced must be wound onto bobbin or core tubes, for storage until further use. This is, of course, true also of yarns, threads and the like, irrespective of the particular material from which they are made.

Such winding is accomplished on so-called winders, machines which have one or more chucks, i.e., devices which internally engage a bobbin tube so that it can rotate and thus wind up the filament onto it. One such winder, with which my novel drive roll may be used to advantage, isdisclosed in my aforementioned copending application. These winders are divided into two basic categories, according ,to the manner in which their respective chucks are driven. In one of these, the chuck is center driven, i.e. the chuck is-connected with a drive shaft which rotates it. In the other type of winder, with which the present invention is concerned, the chuck is surface driven, i.e., a driven friction roll is mounted adjacent the chuck and is brought into frictional contact with a bobbin tube on the chuck, or with a filament package which forms or is present on the bobbin tube. The rotary motion of the friction roll is thus frictionally transmitted to the bobbin tube and the chuck, both of which are rotated.

Very frequently these friction rolls must be quite long, in accordance with the length of the chuck and bobbin tube. They are mounted in cantilever fashion, it having been determined in the industry that there are many processing and operating advantages in such mounting. The increasing demand for higher production per unit of time, dictated by considerations of manufacturing economy, require that such rolls be rotated at high speeds, which have now in many instances risen as far as 8,000 RPM.

The desire to mount friction rolls in cantilever fashion has, however, created certain problems in conjunction with the requirements for length and high-speed rotation. In particular, run-out and excessive vibration is now frequently experienced, leading to improperoperation of the winder and to premature wear and destruction of many components, such as the bearings which journal the friction roll.

SUMMARY OF THE INVENTION It is thereforea general object of the present invention to overcome these disadvantages of the prior art.

More particularly, it is an object of the invention to provide a novel drive or friction roll for winders of filamentary material, which is free of such disadvantages.

Another object is to provide such a roll which is relatively simple in its construction, and therefore is rugged and can be economically produced.

An additional object of the invention is to provide such a roll which can be used with existing winders.

In keeping with these objects, and others which will become apparent, one feature of the invention resides in a drive roll for winders of filamentary material, which drive roll comprises a support, a stationary hollow shaft cantilevered on said support, and a tubular friction roll surrounding and journalled on said hollow shaft for rotation relative to the same. There is further provided a drive shaft which extends through the hollow shaft and has spaced endportions each of which extends axially beyond a respective end of the hollow shaft. One of these end portions is coupled via coupling means with the friction roll for rotating the same when a motive force is applied to the other end portion.

The novel features which are considered as charac teristic for the invention are set forth in particular in the appended claims. The invention itself, however, both as to its construction and its method of operation, together with additional objects and advantages thereof, will be best understood from the following description of specific embodiments when read in connection with the accompanying drawing.

BRIEF DESCRIPTION OF THE DRAWING FIG. 1 is an axial section through a drive roll according to the present invention; and

FIG. 2 is. a section taken on line Il-II of FIG. 1.

DESCRIPTION OF THE PREFERRED EMBODIMENTS In the embodiment illustrated in FIGS. 1 and 2, reference numeral 1 designates the tubular friction roll per se, i.e., the element whose outer circumferential surface is to be brought into frictional contact with the circumference of a bobbin tube or of a package of filamentary material wound thereon. It goes without saying that the outer circumferential surface of the friction roll may be suitably treated (e.g., roughened, provided with a friction-enhancing coating of rubber or the like, etc.) in order to obtain the desired degree of frictional engagement. This, however, is conventional and well within the skill of the art.

The friction roll 1 surrounds a stationary mounting shaft 2 which has a center passage 11. In the illustrated embodiment, one end of the shaft 2 (the left-hand end in FIG. 1) is located within the confines of roll 1, whereas the other end is located outside the roll 1. The latter is journalled on the shaft 2 for rotation thereabout, via the illustrated anti-friction bearings 3 and 5. The inner race 4 of bearing 3, and the inner race 6 of bearing 5, are both fixedly connected with the shaft 2, so that only the respective outer races (which are fixed to the inner surface of roll 1), rotate with the latter.

One end of the shaft 2, the right-hand one in FIG. 1, is telescoped into a mounting socket 7 wherein it is fixedly retained via one or more (one shown) threaded connectors 8. The mounting socket 7 extends in cantilever fashion from a support structure 10 (which may be part of the winder frame, or the like), to which it is connected via bolts 9 (only one shown).

A drive shaft 12 extends through the passage 11 of shaft 2. The right-hand end portion 17 of the drive shaft extends outwardly beyond the' right-hand end of shaft 2 and is connected in any well-known manner with a drive, here illustrated as a motor 18.

The left-hand end portion 16 of the drive shaft 12 also extends beyond the shaft 2, in this case beyond the left-hand end thereof. It is still located within the confines of the roll 1, however. Adjacent to it, and also within roll 1, is a coupling element 19 which in the illustrated embodiment is essentially cup-shaped but could also be otherwise configurated. This element 19 is rigidly connected with the circumferential wall of the roll 1, in any suitable manner, and has a hub or center portion provided with an axially extending polygonal (here quadratic) passage 15. The end portion 16 of shaft 12 is matingly configurated (see FIG. 2) and is received in the passage 15 so that the shaft 12, when rotated by the motor 18, takes along the element 19 and thus the roll 1. The shaft 12 is journalled for rotation in anti-friction bearings 13 and 14 which are located in the passage 11 of shaft 2.

ln this construction, the components 2, 4, 6, 7, and outer races of bearings 13 and 14 are stationary. This, in conjunction with the fact that construction provides for a stiff and rather massive support (components 2 and 7) which are relatively short and rigidly mounted closely adjacent one end of the roll 1, assures that in operation of the novel drive roll the disadvantages of the prior art are avoided. In particular, run-out and vibration are prevented and the roll cannot behave in a manner which would disadvantageously influence the operation of the winder, nor will premature wear of its components (e.g., of the bearings) occur for the reasons which cause such problems in the prior art.

It will be understood that each of the elements described above, or two or more together, may also find a useful application in other types of applications differing from the types described above.

While the invention has been illustrated and described as embodied in a drive roll for winders of filamentary material, it is not intended to be limited to the details shown, since various modifications and structural changes may be made without departing in any way from the spirit of the present invention.

Without further analysis, the foregoing will so fully reveal the gist of the present invention that others can by applying current knowledge readily adapt it for various applications without omitting features that, from the standpoint of prior art, fairly constitute essential characteristics of the generic or specific aspects of this invention and, therefore such adaptations should and are intended to be comprehended within the meaning and range of equivalence of the following claims.

What is claimed as new and desired to be protected by Letters Patent is set forth in the appended:

1. A drive roll for winders of filamentary material, comprising a support; a stationary hollow support shaft, including a first tubular portion fixedly connected to and cantilevered on said support, a second tubular portion partly received in said first tubular portion projecting outwardly from said same, and having a free end, and connecting means connecting said tubular portions against relative displacement; a tubular friction roll surrounding said hollow support shaft with clearance; first anti-friction bearings in said clearance and journalling said friction roll on said support shaft for rotation with reference to the same; a drive shaft being substantially fully located in said hollow support shaft and having one end portion projecting from said free end and another end portion projecting through said support; second anti-friction bearings journalling said drive shaft in said hollow support shaft in the region of said support and said free end, respectively; and coupling means coupling said one end portion of said drive shaft adjacent said free end of said second tubular portion with said friction roll for rotating the same in response to the application of motive force to said other end portion of said drive shaft, whereby said drive shaft serves only to transmit rotary motion to said friction roll whereas all forces acting upon said drive roll in direction transversely of said drive shaft are transmitted to said support shaft so that flexing and analogous stressing of said drive shaft due to such forces are avoided.

2. A drive roll as defined in claim 1, said first antifriction bearings each having an outer race fixedly connected with said friction roll, and an inner race fixedly connected with said hollow shaft.

3. A drive roll as defined in claim 1, said one end portion of said drive shaft being located within the confines of said friction roll, and wherein said coupling means comprises a coupling member connected in motion-transmitting relationship with a peripheral wall of said friction roll, and in motion-receiving relationship with said one end portion of said drive shaft.

4. A drive roll as defined in claim 3, said coupling member having a hub portion provided with a passage of polygonal outline, and wherein said one end portion of said drive shaft is of mating polygonal outline and received in said passage.

5. A drive roll as defined in claim 1, and further comprising drive means operatively associated with said other end portion of said drive shaft for effecting rotation of said drive shaft.

Claims (5)

1. A drive roll for winders of filamentary material, comprising a support; a stationary hollow support shaft, including a first tubular portion fixedly connected to and cantilevered on said support, a second tubular portion partly received in said first tubular portion projecting outwardly from said same, and having a free end, and connecting means connecting said tubular portions against relative displacement; a tubular friction roll surrounding said hollow support shaft with clearance; first antifriction bearings in said clearance and journalling said friction roll on said support shaft for rotation with reference to the same; a drive shaft being substantially fully located in said hollow support shaft and having one end portion projecting from said free end and another end portion projecting through said support; second anti-friction bearings journalling said drive shaft in said hollow support shaft in the region of said support and said free end, respectively; and coupling means coupling said one end portion of said drive shaft adjacent said free end of said second tubular portion with said friction roll for rotating the same in response to the application of motive force to said other end portion of said drive shaft, whereby said drive shaft serves only to transmit rotary motion to said friction roll whereas all forces acting upon said drive roll in direction transversely of said drive shaft are transmitted to said support shaft so that flexing and analogous stressing of said drive shaft due to such forces are avoided.

2. A drive roll as defineD in claim 1, said first anti-friction bearings each having an outer race fixedly connected with said friction roll, and an inner race fixedly connected with said hollow shaft.

3. A drive roll as defined in claim 1, said one end portion of said drive shaft being located within the confines of said friction roll, and wherein said coupling means comprises a coupling member connected in motion-transmitting relationship with a peripheral wall of said friction roll, and in motion-receiving relationship with said one end portion of said drive shaft.

4. A drive roll as defined in claim 3, said coupling member having a hub portion provided with a passage of polygonal outline, and wherein said one end portion of said drive shaft is of mating polygonal outline and received in said passage.

5. A drive roll as defined in claim 1, and further comprising drive means operatively associated with said other end portion of said drive shaft for effecting rotation of said drive shaft.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US00304253A US3825195A (en) | 1972-06-15 | 1972-11-06 | Drive roll for winders of filamentary material |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US00262973A US3807647A (en) | 1972-06-15 | 1972-06-15 | Yarn take-up arrangement |

| US00304253A US3825195A (en) | 1972-06-15 | 1972-11-06 | Drive roll for winders of filamentary material |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3825195A true US3825195A (en) | 1974-07-23 |

Family

ID=26949583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US00304253A Expired - Lifetime US3825195A (en) | 1972-06-15 | 1972-11-06 | Drive roll for winders of filamentary material |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3825195A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4091604A (en) * | 1976-04-01 | 1978-05-30 | Hamel Gmbh, Zwirnmaschinen | Device for the driving of yarn-takeup packages, especially for double twisting machines |

| US5042734A (en) * | 1990-04-27 | 1991-08-27 | E. I. Du Pont De Nemours And Company | Drive roll assembly for strand winding apparatus |

| WO1997047407A1 (en) * | 1993-11-08 | 1997-12-18 | Sherwood William L | Rolling mill stand |

| EP1260475A1 (en) * | 2001-05-22 | 2002-11-27 | Toray Industries, Inc. | Yarn winding apparatus and method of producing a yarn package |

| US20070278340A1 (en) * | 2004-02-18 | 2007-12-06 | Saurer Gmbh & Co. Kg | Drive Roller For A Textile Machine Producing Cross-Wound Bobbins |

| CN104326306A (en) * | 2014-10-20 | 2015-02-04 | 湖州宏鑫绸厂 | Yarn cone kinetic energy storage structure |

-

1972

- 1972-11-06 US US00304253A patent/US3825195A/en not_active Expired - Lifetime

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4091604A (en) * | 1976-04-01 | 1978-05-30 | Hamel Gmbh, Zwirnmaschinen | Device for the driving of yarn-takeup packages, especially for double twisting machines |

| US5042734A (en) * | 1990-04-27 | 1991-08-27 | E. I. Du Pont De Nemours And Company | Drive roll assembly for strand winding apparatus |

| WO1997047407A1 (en) * | 1993-11-08 | 1997-12-18 | Sherwood William L | Rolling mill stand |

| EP1260475A1 (en) * | 2001-05-22 | 2002-11-27 | Toray Industries, Inc. | Yarn winding apparatus and method of producing a yarn package |

| CN1329270C (en) * | 2001-05-22 | 2007-08-01 | 东丽株式会社 | Yarn winding device and method for producing yarn package |

| US20070278340A1 (en) * | 2004-02-18 | 2007-12-06 | Saurer Gmbh & Co. Kg | Drive Roller For A Textile Machine Producing Cross-Wound Bobbins |

| CN104326306A (en) * | 2014-10-20 | 2015-02-04 | 湖州宏鑫绸厂 | Yarn cone kinetic energy storage structure |

| CN104326306B (en) * | 2014-10-20 | 2017-02-15 | 青岛橡胶谷知识产权有限公司 | Yarn cone kinetic energy storage structure |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3185276A (en) | Electro-magnetically actuated normally disengaged spring clutches | |

| US3917182A (en) | Winding machine | |

| US3877212A (en) | Apparatus for driving and supporting a spinning element | |

| US3825195A (en) | Drive roll for winders of filamentary material | |

| US3856229A (en) | Web winding spool | |

| US4090677A (en) | Apparatus for storing and feeding yarn to yarn using machines | |

| US4028911A (en) | Inclined pin wheel for yarn storage drum | |

| US4280668A (en) | Thread-storage and delivery device for textile machines | |

| GB1498244A (en) | Tube ejector | |

| US1994403A (en) | Winding machine with individual driving for the spindle units | |

| US2865577A (en) | Spool holding arrangement | |

| US3302384A (en) | Apparatus for driving filamentary material collectors or bobbins | |

| US3575357A (en) | Device for winding textile threads | |

| US3793820A (en) | Device for ringless spinning of fibers | |

| US2639576A (en) | Spindle adapter for high-speed strand twisting machines | |

| US3973739A (en) | Winding apparatus | |

| JPH03115064A (en) | Rewinding device | |

| JP5044574B2 (en) | Device and winder for guiding yarn | |

| US3291405A (en) | Winding machine | |

| US2794517A (en) | Traverse cam lubrication | |

| US4765562A (en) | Device for positioning and holding a yarn support tube during an operation of unwinding or winding | |

| US4141513A (en) | Device for accelerating yarn winder chucks | |

| US2145935A (en) | Yarn winding machine | |

| US3398907A (en) | Apparatus for driving filamentary material collectors | |

| US3879924A (en) | Lacing device for stranding machines |