US3748458A - Disposable wedge-type bulb lamp - Google Patents

Disposable wedge-type bulb lamp Download PDFInfo

- Publication number

- US3748458A US3748458A US00191907A US3748458DA US3748458A US 3748458 A US3748458 A US 3748458A US 00191907 A US00191907 A US 00191907A US 3748458D A US3748458D A US 3748458DA US 3748458 A US3748458 A US 3748458A

- Authority

- US

- United States

- Prior art keywords

- bulb

- base

- lens cover

- contact elements

- reflector

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60Q—ARRANGEMENT OF SIGNALLING OR LIGHTING DEVICES, THE MOUNTING OR SUPPORTING THEREOF OR CIRCUITS THEREFOR, FOR VEHICLES IN GENERAL

- B60Q1/00—Arrangement of optical signalling or lighting devices, the mounting or supporting thereof or circuits therefor

- B60Q1/26—Arrangement of optical signalling or lighting devices, the mounting or supporting thereof or circuits therefor the devices being primarily intended to indicate the vehicle, or parts thereof, or to give signals, to other traffic

- B60Q1/2615—Arrangement of optical signalling or lighting devices, the mounting or supporting thereof or circuits therefor the devices being primarily intended to indicate the vehicle, or parts thereof, or to give signals, to other traffic mounted on the vehicle body, e.g. with magnets

Definitions

- ABSTRACT An unbased, wedge-type of lamp bulb is cemented to a reflector plate from which it projects in one direction into a sealed chamber formed in a lens cover to which the reflector plate is peripherally cemented.

- the base portion of the bulb projects into a socket of a holder within which the rim portion of the lens cover is releasably held.

- Lamp assemblies specially designed for installation on vehicles and vehicular trailers are well known. These lamp assemblies are often expensive to make because of installational requirements and environmental problems involving mounting space, vibration and extreme weather condition. Such lamp assemblies furthermore involve a considerable expense for replacement of a burned out bulb filament. It is, therefore, an important object of the present invention to provide a lamp assembly which is very economical to manufacture, install and maintain.

- the present invention features a bulb assembly in which an unbased, wedge-type bulb is cemented within an opening formed in a reflector plate so as to project into a sealed chamber enclosed by the reflector plate within a lens cover.

- the rim of the lens cover is received and releasably held within a flexibly elastic holder having a socket portion adapted to receive the base portion of the bulb projecting from the reflector.

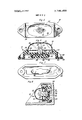

- FIG. 1 is a perspective view showing a typical lamp assembly constructed in accordance with the present invention.

- FIG. 2 is a perspective view showing the disassembled parts of the lamp assembly.

- FIG. 3 is a perspective view showing the power contact element associated with the lamp holder part.

- FIG. 4 is a perspective view showing the ground contact element associated with the lamp holder.

- FIG. 5 is a front elevational view of the lamp holder.

- FIG. 6 is a side sectional view through the lamp assembly.

- FIG. 7 is a rear elevational view of the lamp holder.

- FIG. 8 is a transverse sectional view through the lamp assembly mounted in a typical installation.

- a lamp assembly generally denoted by reference numeral 10 in FIG. 1 consists of a lamp holder base generally referred to by reference numeral l2-and a bulb assembly gener-' ally referred to by reference numeral 14.

- the lamp assembly shown assembled in FIG. 1 is readily disassembled as shown in FIG. 2 for replacement of the bulb assembly 14 which is a relatively inexpensive item.

- the bulb assembly 14 includes a transparent or translucent lens cover 16 of a suitable oblong shape having a peripheral rim portion 18.

- a reflector plate 20 is peripherally sealed to the lens cover by cementing or welding using ultra sonic energy, for example, thereby enclosing a sealed chamber 22.

- the lens cover 16 is made of a light transmissive, plastic material

- the reflector plate 20 is made of an opaque plastic material and is provided with a central opening 24 through which an unbased, wedge-type buld 26 extends.

- the bulb 26 is cemented to the reflector plate, completely filling the opening 24 so that its light emitting portion is enclosed within the chamber 22 while its base portion projects rearwardly therefrom.

- An incandescent filament 28 within the bulb provides the source of illumination when electrical current is conducted therethrough by means of a filament leads which extend into a pair of terminal portion 30 of the bulb.

- the bulb assembly is recieved within the holder base 12 which is made of a flexibly elastic material or a rigid plastic.

- the holder body 32 includes a front face 34 within which an oval recess 36 is formed adapted to receive the rim portion 18 of the bulb assembly.

- the periphery 38 of the recess is accordingly ribbed for frictional gripping of the bulb assembly.

- Projecting into the recess opening from the holder body is a socket portion 40.

- the socket portion is positioned for alignment with the projecting base portion of the bulb 26 when the bulb assembly is inserted into the recess 36.

- the holder body as more clearly seen in FIGS. 6 and 8, includes a rearwardly extending formation 46 within which the contact elements are embedded and located essentially between a pair of anchor portions 48.

- Each anchor portion is provided with an opening 50 through which a conductive fastener is adapted to extend for mounting the holder body on a suitable surface such as the channel formation 52 as shown in FIG. 8.

- the contact element 42 is completely embedded within the formation 46 and includes a clip portion 54 as more clearly seen in FIG. 3 into which one of the terminal portions 30 of the bulb is received.

- the clip portion 54 is connected by a pair of arms 56 to a pair of angularly related connector sleeves 58 that are adapted to hold a powerline connector60 exposed through an opening 62 in the formation 46 between the bulb and an anchor portion 48.

- the leads from a power cable 64 such as shown in FIG. 8, may be inserted through either end of the formation 46 in order to establish an electrical connection through the connector 60 and the contact element 42 with one terminal lead of the bulb.

- the other terminal lead of the bulb is adapted to be in contact with a clip portion 66 of the contact element 44 which is provided with ring formations 68 at opposite ends adapted to be aligned with the openings 50 in the anchor portions of the holder body to thereby establish through the fasteners, a ground connection.

- the connecting arm portion 70 of the contact element 44 is embedded within the holder body in spaced relation to the contact element 42 in order to position the clip portion 66 in close spaced relation to the clip portion 54 so that both clip portions will be aligned with the closely spaced terminal portions 30 of the bulb as more clearly seen in FIG. 8.

- a bulb assembly 14 may be readily inserted into the recess 36 of a holder body and electrical contact will be made with the wedge-type bulb projecting rearwardly therefrom when received within the socket portion 40.

- the bulb assembly will be frictionally held in position and may be readily removed for replacement purposes.

- a base having a face portion formed with a recess and a socket portion formed within the recess, and a replaceable bulb assembly held by the base within the recess, said bulb assembly including a lens cover having a rim portion received within the recess in releasable engagement with the base, said base thereby frictionally gripping the rim portion to hold the bulb assembly within said recess, a reflector secured to the lens cover in spaced relation to said socket portion of the base while the lens cover is releasably held within the recess of the base, and a bulb fixed to the reflector within the lens cover with an end thereof projecting into the socket portion of the base.

- said bulb is of the unbased type having a light emitting portion, a filament disposed therewithin, a terminal portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the terminal portion of the bulb.

- said base is made of a resiliently elastic material having a pair of anchor portions projecting from the face portion through which fasteners are adapted to extend, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion extending into the anchor portion of the base and the other of the contact elements having a connector portion exposed between said anchor and socket portions of the base rearwardly of the face portion.

- said bulb is of the wedge type having a light emitting portion, a filament disposed therewithin, a base portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the base portion of the bulb.

- a replaceable bulb assembly comprising a lens cover having a rim portion received within the base, a reflector, and an unbased type of bulb, said reflector being cemented directly to the bulb within the lens cover to form a sealed chamber, and said bulb having a light emitting portion enclosed within the chamber and a terminal portion projecting from the reflector into the base, said base frictionally gripping the rim portion to hold the bulb as sembly therein.

- said base is made of a resiliently elastic material, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

- a lamp unit having a lens cover, a reflector and a bulb

- a base made of a resiliently elastic material engaging the lens cover, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Fastening Of Light Sources Or Lamp Holders (AREA)

Abstract

An unbased, wedge-type of lamp bulb is cemented to a reflector plate from which it projects in one direction into a sealed chamber formed in a lens cover to which the reflector plate is peripherally cemented. The base portion of the bulb projects into a socket of a holder within which the rim portion of the lens cover is releasably held.

Description

United States Patent [1 1 Morrison et al.

DISPOSABLE WEDGE-TYPE BULB LAMP Inventors: Charles R. Morrison, Frewsburg;

Howard A. Sage; Edward R. Roberts, both of Jamestown, all of N.Y.

Truck-Lite Co., Inc., Jamestown, NY.

Filed: Oct. 22, 1971 Appl. No.: 191,907

Assignee:

US. Cl 240/4155, 240/8.2, 240/83, 240/413, 240/521, 240/41 SB Int. Cl. F21v 17/00 Field of Search 240/4155, 41.5, 240/413, 41 SB, 8.2, 8.3, 8.26, 52.1

References Cited UNITED STATES PATENTS Wiley 240/41.3 X Worden 240/82 X Sassmanshausen 240/83 1 July 24, 1973 2,459,151 1/1949 Curtis 240/41 SB 2,069,239 2/1937 Fraser... 240/8.2 X 3,218,448 11/1965 Cala 240/82 3,474,381 10/1969 Baldwin 240/82 X 3,321,731 5/1967 Goldbaum 240/82 X 2,922,875 1/1960 Buck 240/52.1 X 3,109,598 11/1963 Morgan 240/82 FOREIGN PATENTS OR APPLICATIONS 794,707 9/1968 Canada 240/82 Primary Examiner-Richard L. Moses Attorney-Harvey B. Jacobson [57] ABSTRACT An unbased, wedge-type of lamp bulb is cemented to a reflector plate from which it projects in one direction into a sealed chamber formed in a lens cover to which the reflector plate is peripherally cemented. The base portion of the bulb projects into a socket of a holder within which the rim portion of the lens cover is releasably held.

9 Claims, 8 Drawing Figures 1 DISPOSABLE WEDGE-TYPE BULB LAMP This invention relates to vehicle mounted types of lamps and, more particularly, to a lamp assembly featuring a replaceable type of bulb section.

Lamp assemblies specially designed for installation on vehicles and vehicular trailers, are well known. These lamp assemblies are often expensive to make because of installational requirements and environmental problems involving mounting space, vibration and extreme weather condition. Such lamp assemblies furthermore involve a considerable expense for replacement of a burned out bulb filament. It is, therefore, an important object of the present invention to provide a lamp assembly which is very economical to manufacture, install and maintain.

In accordance with the foregoing objects, the present invention features a bulb assembly in which an unbased, wedge-type bulb is cemented within an opening formed in a reflector plate so as to project into a sealed chamber enclosed by the reflector plate within a lens cover. The rim of the lens cover is received and releasably held within a flexibly elastic holder having a socket portion adapted to receive the base portion of the bulb projecting from the reflector.

These together with other objects and advantages which will become subsequently apparent reside in the details of construction and operation as more fully hereinafter described and claimed, reference being had to the accompanying drawings forming a part hereof, wherein like numerals refer to like parts throughout, and in which:

FIG. 1 is a perspective view showing a typical lamp assembly constructed in accordance with the present invention.

FIG. 2 is a perspective view showing the disassembled parts of the lamp assembly.

FIG. 3 is a perspective view showing the power contact element associated with the lamp holder part.

FIG. 4 is a perspective view showing the ground contact element associated with the lamp holder.

FIG. 5 is a front elevational view of the lamp holder.

FIG. 6 is a side sectional view through the lamp assembly.

FIG. 7 is a rear elevational view of the lamp holder.

FIG. 8 is a transverse sectional view through the lamp assembly mounted in a typical installation.

Referring now to the drawings in detail, a lamp assembly generally denoted by reference numeral 10 in FIG. 1 consists of a lamp holder base generally referred to by reference numeral l2-and a bulb assembly gener-' ally referred to by reference numeral 14. The lamp assembly shown assembled in FIG. 1 is readily disassembled as shown in FIG. 2 for replacement of the bulb assembly 14 which is a relatively inexpensive item.

Referring to FIGS. 6 and 8 in particular, the bulb assembly 14 includes a transparent or translucent lens cover 16 of a suitable oblong shape having a peripheral rim portion 18. A reflector plate 20 is peripherally sealed to the lens cover by cementing or welding using ultra sonic energy, for example, thereby enclosing a sealed chamber 22. While the lens cover 16 is made of a light transmissive, plastic material, the reflector plate 20 is made of an opaque plastic material and is provided with a central opening 24 through which an unbased, wedge-type buld 26 extends.

The bulb 26 is cemented to the reflector plate, completely filling the opening 24 so that its light emitting portion is enclosed within the chamber 22 while its base portion projects rearwardly therefrom. An incandescent filament 28 within the bulb provides the source of illumination when electrical current is conducted therethrough by means of a filament leads which extend into a pair of terminal portion 30 of the bulb.

The bulb assembly is recieved within the holder base 12 which is made of a flexibly elastic material or a rigid plastic. The holder body 32 includes a front face 34 within which an oval recess 36 is formed adapted to receive the rim portion 18 of the bulb assembly. The periphery 38 of the recess is accordingly ribbed for frictional gripping of the bulb assembly. Projecting into the recess opening from the holder body is a socket portion 40. The socket portion is positioned for alignment with the projecting base portion of the bulb 26 when the bulb assembly is inserted into the recess 36. When the bulb assembly is fully seated as shown in FIGS. 6 and 8, contact is made between the filament leads and a pair of contact elements 42 and 44 embedded within the holder body 34.

The holder body as more clearly seen in FIGS. 6 and 8, includes a rearwardly extending formation 46 within which the contact elements are embedded and located essentially between a pair of anchor portions 48. Each anchor portion is provided with an opening 50 through which a conductive fastener is adapted to extend for mounting the holder body on a suitable surface such as the channel formation 52 as shown in FIG. 8. The contact element 42 is completely embedded within the formation 46 and includes a clip portion 54 as more clearly seen in FIG. 3 into which one of the terminal portions 30 of the bulb is received. The clip portion 54 is connected by a pair of arms 56 to a pair of angularly related connector sleeves 58 that are adapted to hold a powerline connector60 exposed through an opening 62 in the formation 46 between the bulb and an anchor portion 48. Thus, the leads from a power cable 64 such as shown in FIG. 8, may be inserted through either end of the formation 46 in order to establish an electrical connection through the connector 60 and the contact element 42 with one terminal lead of the bulb.

The other terminal lead of the bulb is adapted to be in contact with a clip portion 66 of the contact element 44 which is provided with ring formations 68 at opposite ends adapted to be aligned with the openings 50 in the anchor portions of the holder body to thereby establish through the fasteners, a ground connection. The connecting arm portion 70 of the contact element 44 is embedded within the holder body in spaced relation to the contact element 42 in order to position the clip portion 66 in close spaced relation to the clip portion 54 so that both clip portions will be aligned with the closely spaced terminal portions 30 of the bulb as more clearly seen in FIG. 8.

It will, therefore, be apparent from the foregoing description that a bulb assembly 14 may be readily inserted into the recess 36 of a holder body and electrical contact will be made with the wedge-type bulb projecting rearwardly therefrom when received within the socket portion 40. The bulb assembly will be frictionally held in position and may be readily removed for replacement purposes.

The foregoing is considered as illustrative only of the principles of the invention. Further, since numerous mitt modifications and changes will readily occur to those skilled in the art, it is not desired to limit the invention to the exact construction and operation shown and described, and accordingly all suitable modifications and equivalents may be resorted to, falling within the scope of the invention.

What is elalimed as new is as follows:

1. In combination, a base having a face portion formed with a recess and a socket portion formed within the recess, and a replaceable bulb assembly held by the base within the recess, said bulb assembly including a lens cover having a rim portion received within the recess in releasable engagement with the base, said base thereby frictionally gripping the rim portion to hold the bulb assembly within said recess, a reflector secured to the lens cover in spaced relation to said socket portion of the base while the lens cover is releasably held within the recess of the base, and a bulb fixed to the reflector within the lens cover with an end thereof projecting into the socket portion of the base.

2. The combination of claim 1 wherein said bulb is of the unbased type having a light emitting portion, a filament disposed therewithin, a terminal portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the terminal portion of the bulb.

3. The combination of claim 1 wherein said base is made of a resiliently elastic material having a pair of anchor portions projecting from the face portion through which fasteners are adapted to extend, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion extending into the anchor portion of the base and the other of the contact elements having a connector portion exposed between said anchor and socket portions of the base rearwardly of the face portion.

4. The combination of claim 3 wherein said bulb is of the wedge type having a light emitting portion, a filament disposed therewithin, a base portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the base portion of the bulb.

5. The combination of claim 3 wherein said reflector is cemented directly to the lens cover and the bulb to form a sealed chamber from which light is emitted.

6. The combination of claim 4 wherein said reflector is cemented directly to the bulb and the lens cover to form a sealed chamber enclosing said light emitting portion of the bulb within which the filament is disposed and defining said rim portion in surrounding relation to the base portion of the bulb.

7. In combination with a lamp holder base, a replaceable bulb assembly comprising a lens cover having a rim portion received within the base, a reflector, and an unbased type of bulb, said reflector being cemented directly to the bulb within the lens cover to form a sealed chamber, and said bulb having a light emitting portion enclosed within the chamber and a terminal portion projecting from the reflector into the base, said base frictionally gripping the rim portion to hold the bulb as sembly therein.

8. The combination of claim 7 wherein said base is made of a resiliently elastic material, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

9. In combination with a lamp unit having a lens cover, a reflector and a bulb, a base made of a resiliently elastic material engaging the lens cover, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

Claims (9)

1. In combination, a base having a face portion formed with a recess and a socket portion formed within the recess, and a replaceable bulb assembly held by the base within the recess, said bulb assembly including a lens cover having a rim portion received within the recess in releasable engagement with the base, said base thereby frictionally gripping the rim portion to hold the bulb assembly within said recess, a reflector secured to the lens cover in spaced relation to said socket portion of the base while the lens cover is releasably held within the recess of the base, and a bulb fixed to the reflector within the lens cover with an end thereof projecting into the socket portion of the base.

2. The combination of claim 1 wherein said bulb is of the unbased type having a light emitting portion, a filament disposed therewithin, a terminal portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the terminal portion of the bulb.

3. The combination of claim 1 wherein said base is made of a resiliently elastic material having a pair of anchor portions projecting from the face portion through which fasteners are adapted to extend, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion extending into the anchor portion of the base and the other of the contact elements having a connector portion exposed between said anchor and socket portions of the base rearwardly of the face portion.

4. The combination of claim 3 wherein said bulb is of the wedge type having a light emitting portion, a filament disposed therewithin, a base portion received within the socket portion of the base and a pair of spaced terminals extending from the filament through the base portion of the bulb.

5. The combination of claim 3 wherein said reflector is cemented directly to the lens cover and the bulb to form a sealed chamber from which light is emitted.

6. The combination of claim 4 wherein said reflector is cemented directly to the bulb and the lens cover to form a sealed chamber enclosing said light emitting portion of the bulb within which the filament is disposed and defining said rim portion in surrounding relation to the base portion of the bulb.

7. In combination with a lamp holder base, a replaceable bulb assembly comprising a lens cover having a rim portion received within the base, a reflector, and an unbased type of bulb, said reflector being cemented directly to the bulb within the lens cover to form a sealed chamber, and said bulb having a light emitting portion enclosed within the chamber and a terminal portion projecting from the reflector into the base, said base frictionally gripping the rim portion to hold the bulb assembly therein.

8. The combination of claim 7 wherein said base is made of a resiliently elastic material, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

9. In combination with a lamp unit having a lens cover, a reflector and a bulb, a base made of a resiliently elastic material engaging the lens cover, a pair of contact elements embedded in the elastic material having spaced socket formations receiving the bulb, one of the contact elements having a grounding portion and the other of the contact elements having a connector portion.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US19190771A | 1971-10-22 | 1971-10-22 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3748458A true US3748458A (en) | 1973-07-24 |

Family

ID=22707401

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US00191907A Expired - Lifetime US3748458A (en) | 1971-10-22 | 1971-10-22 | Disposable wedge-type bulb lamp |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3748458A (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3939337A (en) * | 1973-12-07 | 1976-02-17 | Chrysler Corporation | Vehicle lamp construction |

| US4186432A (en) * | 1976-11-20 | 1980-01-29 | Martin Hamacher | Lamp for use in subterranean applications |

| US4380793A (en) * | 1980-12-19 | 1983-04-19 | Peterson Manufacturing Co. | Submersible vehicular lamp assembly |

| USD425224S (en) * | 1999-06-04 | 2000-05-16 | Asc Industries, Inc. | Vehicle interior lamp assembly adapted for use with recreational vehicles, outfitted vans, shuttlebuses and the like |

| USD434352S (en) * | 1998-06-30 | 2000-11-28 | Harley-Davidson Motor Company | Motorcycle air cleaner cover |

| FR2803903A1 (en) * | 2000-01-14 | 2001-07-20 | Electricite De France | Domestic or residential compact fluorescent sealed lighting unit |

| US6283621B1 (en) | 1999-06-04 | 2001-09-04 | Asc Industries, Inc. | Vehicle interior lamp assembly adapted for use with recreational vehicles, outfitted vans, shuttlebuses and the like |

| US20050185900A1 (en) * | 2004-01-22 | 2005-08-25 | Finisar Corporation | Integrated optical devices and methods of making same |

| US20050201695A1 (en) * | 2004-01-22 | 2005-09-15 | Mina Farr | Hermetically-sealed lasers and methods of manufacturing |

| US7182487B1 (en) * | 2003-07-23 | 2007-02-27 | Acuity Brands, Inc. | Housings for interchangeable optical assemblies |

| US20090095862A1 (en) * | 2006-04-22 | 2009-04-16 | Matthias Gimpel | Mounting System, Especially for Lamps |

| USD753653S1 (en) * | 2013-03-15 | 2016-04-12 | Samsung Electronics Co., Ltd. | Electronic device |

| USD800784S1 (en) | 2016-08-22 | 2017-10-24 | Harley-Davidson Motor Company Group, LLC | Engine air cleaner |

| USD871271S1 (en) | 2018-08-20 | 2019-12-31 | Harley-Davidson Motor Company Group, LLC | Motorcycle engine air intake |

| US11133630B2 (en) * | 2020-01-02 | 2021-09-28 | Dongguan Thailight Semiconductor Lighting Co., Ltd. | Lamp connector |

| US11670900B2 (en) | 2019-02-05 | 2023-06-06 | Emergency Technology, Inc. | Universal smart adaptor |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2069239A (en) * | 1936-04-08 | 1937-02-02 | Keeshin Motor Express Co Inc | Trailer light |

| US2459151A (en) * | 1945-09-28 | 1949-01-18 | Tungsol Lamp Works Inc | Sealed lighting unit and electric incandescent lamp therefor |

| US2806940A (en) * | 1954-08-27 | 1957-09-17 | C M Hall Lamp Co | Lamp assembly |

| US2922875A (en) * | 1958-03-12 | 1960-01-26 | Rae Metal Ind Ltd | Clearance lamp for automotive vehicles |

| US3109598A (en) * | 1961-08-14 | 1963-11-05 | King Bee Mfg Co | Lamp for vehicle |

| US3218448A (en) * | 1962-10-18 | 1965-11-16 | Truck Lite Co | Lamp mounting bracket |

| US3314331A (en) * | 1965-04-29 | 1967-04-18 | Gen Electric | Photographic projection system and lamp |

| US3321731A (en) * | 1964-07-13 | 1967-05-23 | Lehigh Valley Ind Inc | Marker lamp adapted for mounting on an automotive vehicle, and connection into an electrical circuit, without the use of tools |

| CA794707A (en) * | 1968-09-17 | D. Baldwin George | Adjustable mounting for vehicle lights | |

| US3474381A (en) * | 1967-09-27 | 1969-10-21 | Truck Lite Co | Lamp connection and mounting devices |

| US3633022A (en) * | 1969-12-08 | 1972-01-04 | Knut Otto Sassmanshausen | Lamp |

-

1971

- 1971-10-22 US US00191907A patent/US3748458A/en not_active Expired - Lifetime

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA794707A (en) * | 1968-09-17 | D. Baldwin George | Adjustable mounting for vehicle lights | |

| US2069239A (en) * | 1936-04-08 | 1937-02-02 | Keeshin Motor Express Co Inc | Trailer light |

| US2459151A (en) * | 1945-09-28 | 1949-01-18 | Tungsol Lamp Works Inc | Sealed lighting unit and electric incandescent lamp therefor |

| US2806940A (en) * | 1954-08-27 | 1957-09-17 | C M Hall Lamp Co | Lamp assembly |

| US2922875A (en) * | 1958-03-12 | 1960-01-26 | Rae Metal Ind Ltd | Clearance lamp for automotive vehicles |

| US3109598A (en) * | 1961-08-14 | 1963-11-05 | King Bee Mfg Co | Lamp for vehicle |

| US3218448A (en) * | 1962-10-18 | 1965-11-16 | Truck Lite Co | Lamp mounting bracket |

| US3321731A (en) * | 1964-07-13 | 1967-05-23 | Lehigh Valley Ind Inc | Marker lamp adapted for mounting on an automotive vehicle, and connection into an electrical circuit, without the use of tools |

| US3314331A (en) * | 1965-04-29 | 1967-04-18 | Gen Electric | Photographic projection system and lamp |

| US3474381A (en) * | 1967-09-27 | 1969-10-21 | Truck Lite Co | Lamp connection and mounting devices |

| US3633022A (en) * | 1969-12-08 | 1972-01-04 | Knut Otto Sassmanshausen | Lamp |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3939337A (en) * | 1973-12-07 | 1976-02-17 | Chrysler Corporation | Vehicle lamp construction |

| US4186432A (en) * | 1976-11-20 | 1980-01-29 | Martin Hamacher | Lamp for use in subterranean applications |

| US4380793A (en) * | 1980-12-19 | 1983-04-19 | Peterson Manufacturing Co. | Submersible vehicular lamp assembly |

| USD434352S (en) * | 1998-06-30 | 2000-11-28 | Harley-Davidson Motor Company | Motorcycle air cleaner cover |

| USD425224S (en) * | 1999-06-04 | 2000-05-16 | Asc Industries, Inc. | Vehicle interior lamp assembly adapted for use with recreational vehicles, outfitted vans, shuttlebuses and the like |

| US6283621B1 (en) | 1999-06-04 | 2001-09-04 | Asc Industries, Inc. | Vehicle interior lamp assembly adapted for use with recreational vehicles, outfitted vans, shuttlebuses and the like |

| FR2803903A1 (en) * | 2000-01-14 | 2001-07-20 | Electricite De France | Domestic or residential compact fluorescent sealed lighting unit |

| US7182487B1 (en) * | 2003-07-23 | 2007-02-27 | Acuity Brands, Inc. | Housings for interchangeable optical assemblies |

| US7296908B1 (en) | 2003-07-23 | 2007-11-20 | Abl Ip Holding Llc | Housing with releasable front and back portions with electrical connection means |

| US20050201695A1 (en) * | 2004-01-22 | 2005-09-15 | Mina Farr | Hermetically-sealed lasers and methods of manufacturing |

| US20050185900A1 (en) * | 2004-01-22 | 2005-08-25 | Finisar Corporation | Integrated optical devices and methods of making same |

| US7309174B2 (en) * | 2004-01-22 | 2007-12-18 | Finisar Corporation | Integrated optical devices and methods of making same |

| US20090095862A1 (en) * | 2006-04-22 | 2009-04-16 | Matthias Gimpel | Mounting System, Especially for Lamps |

| USD753653S1 (en) * | 2013-03-15 | 2016-04-12 | Samsung Electronics Co., Ltd. | Electronic device |

| USD800784S1 (en) | 2016-08-22 | 2017-10-24 | Harley-Davidson Motor Company Group, LLC | Engine air cleaner |

| USD871271S1 (en) | 2018-08-20 | 2019-12-31 | Harley-Davidson Motor Company Group, LLC | Motorcycle engine air intake |

| US11670900B2 (en) | 2019-02-05 | 2023-06-06 | Emergency Technology, Inc. | Universal smart adaptor |

| US11133630B2 (en) * | 2020-01-02 | 2021-09-28 | Dongguan Thailight Semiconductor Lighting Co., Ltd. | Lamp connector |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3748458A (en) | Disposable wedge-type bulb lamp | |

| US2853595A (en) | Vehicle light | |

| US2903570A (en) | Lamp assembly | |

| HU214535B (en) | Flashlight | |

| US3047829A (en) | Electric lamp base | |

| KR0160560B1 (en) | Vehicle lighting device with anti-vibration connector | |

| US3222512A (en) | Motor vehicle clearance and marker lamps with shock isolation | |

| US3218448A (en) | Lamp mounting bracket | |

| US4437145A (en) | Shock absorbing lamp assembly for baseless cartridge bulbs and the like | |

| US4385257A (en) | Lamp base | |

| US3749960A (en) | Miniature incadescent lamp having integral bulb and base | |

| US3735116A (en) | Rail mounted sidemarker and clearance light | |

| US4774644A (en) | Structure for mounting electric bulb in portable flashlight | |

| US3248531A (en) | Signal lamp | |

| US4241371A (en) | Single filament, dual function, vehicle signal lamp | |

| US3226537A (en) | Vehicle lamp | |

| ES426132A2 (en) | Sealed-beam headlight | |

| ATE242915T1 (en) | ELECTRIC LAMP AND LIGHTING DEVICE COMPRISING SUCH AN ELECTRIC LAMP | |

| CN214369454U (en) | Light source module and ceiling lamp | |

| US3196266A (en) | Truck clearance light | |

| ATE233016T1 (en) | ELECTRIC LAMP | |

| US3156416A (en) | Lamp housing | |

| US3008039A (en) | Vehicle light | |

| US2446455A (en) | Lamp construction | |

| CN113007625A (en) | Light source module and ceiling lamp |