US3403368A - Waterproof heating assembly - Google Patents

Waterproof heating assembly Download PDFInfo

- Publication number

- US3403368A US3403368A US622234A US62223467A US3403368A US 3403368 A US3403368 A US 3403368A US 622234 A US622234 A US 622234A US 62223467 A US62223467 A US 62223467A US 3403368 A US3403368 A US 3403368A

- Authority

- US

- United States

- Prior art keywords

- heating element

- chamber

- core

- lathering

- tube

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/40—Heating elements having the shape of rods or tubes

- H05B3/54—Heating elements having the shape of rods or tubes flexible

- H05B3/56—Heating cables

Definitions

- a conductor lead having a flexible waterproof insulation sheath.

- a tube of vinyl coated glass fiber surrounds the resistance wire and core and extends therebeyond over inner end portions of both conductor sheaths.

- Sleeves of heat shrinkable plastic snugly surround the end portions of the tube and their outwardly adjacent portions of the conductor sheaths to provide moisture seals.

- This invention relates to electrical resistance heating elements and refers more particularly to an elongated immersi-ble heating element which can be flexed on short radius turns.

- the general object of this invention is to provide an electric resistance heating element which is well adapted for use in environments where it is subjected to wetting or immersion, and which is pliant enough to be bent on short radii to a wide variety of shapes so as to be capable of installation in a limited space or in a chamber or the like of such peculiar shape as to 'be inaccessible to a heating element which is rigid or which is likely to be damaged by severe flexing or bending.

- Another object of this invention is to provide an elongated and pliant resistance heating element that comprises a core of heat resistant material such as asbestos fibres about which a resistance wire is helically coiled and which is capable of withstanding a substantially high lengthwise tension without being damaged.

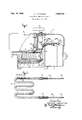

- FIGURE 1 is a view partly in side elevation and partly in vertical section of a lather making machine incorporating a heating element that embodies the principles of this invention.

- FIGURE 2 is a plan view of the heating element per se with portions thereof'broken away.

- the numeral 5 designates generally a lather making machine which is for the most part conventional but which incorporates a heating element 6 of this invention for heating the lather which it produces.

- the lather making machine 5 is thus illustrative of a typical installation of the heating element of this invention.

- the lather making machine is powered by an electric motor 7 having an elongated horizontal shaft 8 to which is fixed a worrnor screw-type agitator 9 that rotates subs-tantially coaxial-1y in a horizontal elongated lathering chamber 10.

- a liquid vessel 11 which is adapted to hold a supply of soap solution and which is communicable with the lathering chamber by way of a short duct or port 13 that is controlled by a valve 14.

- the operator depresses an actuator knob 15 that closes a switch 16 through which the motor 7 can be energized and substantially simultaneously opens the valve 14, so that soap solution begins to enter the lathering chamber from the liquid vessel as the agitator 9 begins to rotate.

- the lathering chamber 10 has a substantially large opening 17 in its end adjacent to the motor through which air is drawn for frothing the lather.

- the soap solution inlet port 13 is located near the end of of the lathering chamber just mentioned. Opening from the opposite end of the lathering chamber is a horizontally elongated lather delivery spout 18. As the agitator 9 rotates, it agitates soap solution delivered to the lathering chamber through the port 13, draws air in through the opening 17, and propels finished lather out through the spout 18.

- a small compartment 20 that houses the heating element 6 of this invention.

- the lathering chamber and the heating element compartment 20 have a common wall 21 that defines the top of the heating element compartment and the bottom of the lathering chamber and which thus serves to conduct heat from the former to the latter for the purpose of warming soap solution as it is being agitated.

- the heating element 6 is connected across the line to maintain heat at all times.

- the heating element 6 comprises, in general, a core 23 of supple heat resistant insulating material such as asbestos fibres about which a strand 24 of resistance wire is helically coiled, a pair of conductor leads 25, each having an insulating sheath 26 and having a bared end portion'27 that is electrically and mechanically connected to the core and to the resistance wire, a tube 28 of heat resistant insulation material surrounding the core and resistance wire along their entire lengths and extending therebeyond partway over the insulating sheath on each conductor lead, and a sleeve 29 of heat shrinkable plastic, snugly surrounding each end portion of the tube 28 and extending lengthwise therebeyond to embrace an axially adjacent portion of the insulation sheath 26.

- a core 23 of supple heat resistant insulating material such as asbestos fibres about which a strand 24 of resistance wire is helically coiled

- a pair of conductor leads 25 each having an insulating sheath 26 and having a bared

- each conductor lead 25 should be ailexible waterproof material, such as polyvinyl chloride, that has some ability to withstand heat, and the conductor itself should be stranded so as to accommodate flexing.

- the bared end portion 27 of each conductor lead that is within the tube 28 is preferably disposed in overlapping relationship to its adjacent end portions of the core and resistance wire and a small metal ferrule or sleeve 30 is clamped tightly around them to provide the necessary mechanical and electrical connection.

- the tube 28 is preferably of glass fiber having a coating of vinyl, silicon or the like on its exterior.

- Such material has the advantages of possessing good electrical insulation qualities, ability to withstand high temperatures, and ability to be flexed or bent around small radius turns, and at the same time, it is substantially incapable of being stretched lengthwise.

- the last mentioned characteristic is very important because any lengthwise stretching of the heating element might break the core (which, although supple, has low tensile strength) and could therefore also break the resistance wire.

- the sleeves 29 are of a known type of flexible heat shrinkable plastic material, commercially available under such trade designations as Flexite Shrinkable HT-l and Scotchtite 105.

- the sleeves are installed in expanded condition, each being slipped over the free end of a conductor lead and moved axially to a position in which it overlaps an end portion of the tube 28 and its outwardly adjacent portion of the insulation sheath 26 on the conductor lead.

- the sleeves are capable of shrinking about 50% in diameter when heated, and since they have only an easy fit when initially installed, heating them to the critical shrinking temperature contracts them into very snug sealing engagement with the tube and conductor sheaths, whereby entry of water and moisture into the end portions of the tube is prevented.

- the assembled heating element can be looped, coiled or otherwise flexibly bent without being damaged.

- the medial portion of the heating element is sinusoidally flexed so that its sinuosities can be compressed accordion-fashion and inserted into the heating chamber without diificulty.

- the end of the heating chamber adjacent to the motor has an opening 32 through which the conductor leads extend for connection to the switch. Even though there is an ever present possibility that soap solution can drip out of the air inlet 17 of the lathering chamber and down into the heating element compartment through said opening 32, there is no need to close said opening, much less to seal it, because of the waterproof construction of the heating element of this invention.

- this invention provides an immersible, electrically insulated heating element which can be subjected to substantial tension without likelihood of damage and which is extremely pliant so as to be well adapted for installation in tight-fitting and unusually shaped receptacles, chambers and the like.

- An elongated immersible electric heating element capable of being bent on short radii to accommodate various installations, comprising, in combination:

- each of said connecting means comprising a metal ferrule snugly surrounding the adjacent end portions of a conductor lead, the core and the resistance heating wire.

- said tube being of coated glass fiber coated with a flexible moisture resistant dielectric material.

Landscapes

- Resistance Heating (AREA)

Description

Sept. 24, 1968 v. J. SCARDINA 3,403,368

WATERPROOF HEAT ING ASSEMBLY Filed March 10, 1967 VIII/II m Omwfim/ United States Patent Office 3,403,368 Patented Sept. 24, 1968 3,403,368 WATERPROOF HEATING ASSEMBLY Vincent J. Scardina, Elk Grove, Ill., assignor to Deltrol Corp., doing business as Campbell Products, Inc., Bellwood, Ill., a corporation of Illinois Filed Mar. 10, 1967, Ser. No. 622,234 3 Claims. (Cl. 338-270) ABSTRACT OF THE DISCLOSURE A resistance wire is helically coiled around a core of heat resistant supple material. To each end of this unit is electrically and mechanically connected a conductor lead having a flexible waterproof insulation sheath. A tube of vinyl coated glass fiber surrounds the resistance wire and core and extends therebeyond over inner end portions of both conductor sheaths. Sleeves of heat shrinkable plastic snugly surround the end portions of the tube and their outwardly adjacent portions of the conductor sheaths to provide moisture seals.

This invention relates to electrical resistance heating elements and refers more particularly to an elongated immersi-ble heating element which can be flexed on short radius turns.

The general object of this invention is to provide an electric resistance heating element which is well adapted for use in environments where it is subjected to wetting or immersion, and which is pliant enough to be bent on short radii to a wide variety of shapes so as to be capable of installation in a limited space or in a chamber or the like of such peculiar shape as to 'be inaccessible to a heating element which is rigid or which is likely to be damaged by severe flexing or bending.

It is also an object of this invention to provide an immersible resistance heating element that is completely insulated so that it can be safely installed, if desired, in contact with a metal surface to which it is intended to conduct heat.

Another object of this invention is to provide an elongated and pliant resistance heating element that comprises a core of heat resistant material such as asbestos fibres about which a resistance wire is helically coiled and which is capable of withstanding a substantially high lengthwise tension without being damaged.

With the above and other objects in view which will appear as the description proceeds, this invention resides in the novel construction, combination and arrangement of parts substantially as hereinafter described and more particularly defined by the appended claims, it being understood that such changes in the precise embodiment of the herein disclosed invention may be made as come within the scope of the claims.

The accompanying drawing illustrates one complete example of the physical embodiment of the invention, constructed according to the best mode so far devised for the practical application of the principles thereof, and in which:

FIGURE 1 is a view partly in side elevation and partly in vertical section of a lather making machine incorporating a heating element that embodies the principles of this invention; and

FIGURE 2 is a plan view of the heating element per se with portions thereof'broken away.

Referring now more particularly to the accompanying drawings, the numeral 5 designates generally a lather making machine which is for the most part conventional but which incorporates a heating element 6 of this invention for heating the lather which it produces. The lather making machine 5 is thus illustrative of a typical installation of the heating element of this invention.

The lather making machine is powered by an electric motor 7 having an elongated horizontal shaft 8 to which is fixed a worrnor screw-type agitator 9 that rotates subs-tantially coaxial-1y in a horizontal elongated lathering chamber 10.Above the lathering chamber there is a liquid vessel 11 which is adapted to hold a supply of soap solution and which is communicable with the lathering chamber by way of a short duct or port 13 that is controlled by a valve 14.

When lather is to be produced by means of the machine, the operator depresses an actuator knob 15 that closes a switch 16 through which the motor 7 can be energized and substantially simultaneously opens the valve 14, so that soap solution begins to enter the lathering chamber from the liquid vessel as the agitator 9 begins to rotate.

The lathering chamber 10 has a substantially large opening 17 in its end adjacent to the motor through which air is drawn for frothing the lather. It will be noted that the soap solution inlet port 13 is located near the end of of the lathering chamber just mentioned. Opening from the opposite end of the lathering chamber is a horizontally elongated lather delivery spout 18. As the agitator 9 rotates, it agitates soap solution delivered to the lathering chamber through the port 13, draws air in through the opening 17, and propels finished lather out through the spout 18.

Directly beneath the lathering chamber is a small compartment 20 that houses the heating element 6 of this invention. The lathering chamber and the heating element compartment 20 have a common wall 21 that defines the top of the heating element compartment and the bottom of the lathering chamber and which thus serves to conduct heat from the former to the latter for the purpose of warming soap solution as it is being agitated. The heating element 6 is connected across the line to maintain heat at all times.

The heating element 6 comprises, in general, a core 23 of supple heat resistant insulating material such as asbestos fibres about which a strand 24 of resistance wire is helically coiled, a pair of conductor leads 25, each having an insulating sheath 26 and having a bared end portion'27 that is electrically and mechanically connected to the core and to the resistance wire, a tube 28 of heat resistant insulation material surrounding the core and resistance wire along their entire lengths and extending therebeyond partway over the insulating sheath on each conductor lead, and a sleeve 29 of heat shrinkable plastic, snugly surrounding each end portion of the tube 28 and extending lengthwise therebeyond to embrace an axially adjacent portion of the insulation sheath 26.

The insulation sheath 26 on each conductor lead 25 should be ailexible waterproof material, such as polyvinyl chloride, that has some ability to withstand heat, and the conductor itself should be stranded so as to accommodate flexing. The bared end portion 27 of each conductor lead that is within the tube 28 is preferably disposed in overlapping relationship to its adjacent end portions of the core and resistance wire and a small metal ferrule or sleeve 30 is clamped tightly around them to provide the necessary mechanical and electrical connection.

The tube 28 is preferably of glass fiber having a coating of vinyl, silicon or the like on its exterior. Such material has the advantages of possessing good electrical insulation qualities, ability to withstand high temperatures, and ability to be flexed or bent around small radius turns, and at the same time, it is substantially incapable of being stretched lengthwise. The last mentioned characteristic is very important because any lengthwise stretching of the heating element might break the core (which, although supple, has low tensile strength) and could therefore also break the resistance wire.

The sleeves 29 are of a known type of flexible heat shrinkable plastic material, commercially available under such trade designations as Flexite Shrinkable HT-l and Scotchtite 105. The sleeves are installed in expanded condition, each being slipped over the free end of a conductor lead and moved axially to a position in which it overlaps an end portion of the tube 28 and its outwardly adjacent portion of the insulation sheath 26 on the conductor lead. The sleeves are capable of shrinking about 50% in diameter when heated, and since they have only an easy fit when initially installed, heating them to the critical shrinking temperature contracts them into very snug sealing engagement with the tube and conductor sheaths, whereby entry of water and moisture into the end portions of the tube is prevented.

The assembled heating element can be looped, coiled or otherwise flexibly bent without being damaged. In the illustrated case, the medial portion of the heating element is sinusoidally flexed so that its sinuosities can be compressed accordion-fashion and inserted into the heating chamber without diificulty.

The end of the heating chamber adjacent to the motor has an opening 32 through which the conductor leads extend for connection to the switch. Even though there is an ever present possibility that soap solution can drip out of the air inlet 17 of the lathering chamber and down into the heating element compartment through said opening 32, there is no need to close said opening, much less to seal it, because of the waterproof construction of the heating element of this invention.

From the foregoing description taken with the accompanying drawing it will be apparent that this invention provides an immersible, electrically insulated heating element which can be subjected to substantial tension without likelihood of damage and which is extremely pliant so as to be well adapted for installation in tight-fitting and unusually shaped receptacles, chambers and the like.

What is claimed as my invention is:

1. An elongated immersible electric heating element capable of being bent on short radii to accommodate various installations, comprising, in combination:

" (a)'a supple elongated core of ant insulating material;

(b) a resistance heating wire helically wound about said core;

5 (c) a pair of conductor leads, each having a sheath of waterproof insulation surrounding it along a substantial portion of its length but terminating short of one of its ends; I

(d) means mechanically and electrically connecting said end portions of the conductor leads with the opposite end portions of said resistance wire and of the core;

(e) a tube of waterproof, supple and substantially heat resistant insulating material surrounding the core and resistance heating wire and extending outwardly beyond their connections with the conductor leads to also surround end portions of the sheaths adjacent to said connections; and

(f) a sleeve of heat shrinkable plastic material snugly surrounding each end portion of said tube and extending outwardly therebeyond and snugly embracing the adjacent portion of the conductor sheath, to thus provide a flexible waterproof seal between the tube and the sheath.

2. The combination of claim 1, further characterized by:

each of said connecting means comprising a metal ferrule snugly surrounding the adjacent end portions of a conductor lead, the core and the resistance heating wire.

3. The combination of claim 1, further characterized by:

said tube being of coated glass fiber coated with a flexible moisture resistant dielectric material.

substantially heat resist- References Cited UNITED STATES PATENTS 1/1929 Richter 338-270 X 7/1957 Schrotter 338322

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US622234A US3403368A (en) | 1967-03-10 | 1967-03-10 | Waterproof heating assembly |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US622234A US3403368A (en) | 1967-03-10 | 1967-03-10 | Waterproof heating assembly |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3403368A true US3403368A (en) | 1968-09-24 |

Family

ID=24493434

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US622234A Expired - Lifetime US3403368A (en) | 1967-03-10 | 1967-03-10 | Waterproof heating assembly |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3403368A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4029942A (en) * | 1975-08-27 | 1977-06-14 | The Sierracin Corporation | Transparent prelaminate with electrical connectors |

| US4100398A (en) * | 1975-08-27 | 1978-07-11 | The Sierracin Corporation | Laminated electrically heatable window with electrical connectors |

| US4158764A (en) * | 1975-06-24 | 1979-06-19 | Yane Frank J | Device for heating liquid in a container |

| US4197449A (en) * | 1978-07-05 | 1980-04-08 | Springfield Wire Inc. | Flexible electrical heater |

| US5109473A (en) * | 1990-12-18 | 1992-04-28 | Process Technology Inc. | Heater assembly for use in a corrosive environment |

| US5380987A (en) * | 1993-11-12 | 1995-01-10 | Uop | Electric heater cold pin insulation |

| US20150341987A1 (en) * | 2012-07-24 | 2015-11-26 | Al Bernstein | Radiator element |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1697406A (en) * | 1927-12-17 | 1929-01-01 | Electrad Inc | Electric resistance unit |

| US2800560A (en) * | 1956-04-30 | 1957-07-23 | Riverside Mfg And Electrical S | Water-proof electrical connection and method of making the same |

-

1967

- 1967-03-10 US US622234A patent/US3403368A/en not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1697406A (en) * | 1927-12-17 | 1929-01-01 | Electrad Inc | Electric resistance unit |

| US2800560A (en) * | 1956-04-30 | 1957-07-23 | Riverside Mfg And Electrical S | Water-proof electrical connection and method of making the same |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4158764A (en) * | 1975-06-24 | 1979-06-19 | Yane Frank J | Device for heating liquid in a container |

| US4029942A (en) * | 1975-08-27 | 1977-06-14 | The Sierracin Corporation | Transparent prelaminate with electrical connectors |

| US4100398A (en) * | 1975-08-27 | 1978-07-11 | The Sierracin Corporation | Laminated electrically heatable window with electrical connectors |

| US4197449A (en) * | 1978-07-05 | 1980-04-08 | Springfield Wire Inc. | Flexible electrical heater |

| US5109473A (en) * | 1990-12-18 | 1992-04-28 | Process Technology Inc. | Heater assembly for use in a corrosive environment |

| US5380987A (en) * | 1993-11-12 | 1995-01-10 | Uop | Electric heater cold pin insulation |

| US20150341987A1 (en) * | 2012-07-24 | 2015-11-26 | Al Bernstein | Radiator element |

| US9936538B2 (en) * | 2012-07-24 | 2018-04-03 | Al Bernstein | Radiator element |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4815769A (en) | Connector for heatable hoses and heatable hose assembly | |

| US3715459A (en) | Cable coupling covering and moisture barrier | |

| US3476915A (en) | Immersion heaters | |

| US3849630A (en) | Electric heating device | |

| US3403368A (en) | Waterproof heating assembly | |

| US3674985A (en) | Immersion heater element | |

| US2544343A (en) | Connector block with strain relief | |

| US3341690A (en) | Heater cable assembly | |

| US4158764A (en) | Device for heating liquid in a container | |

| US2910524A (en) | Breather cable | |

| US3214571A (en) | Heating cable and connectors therefor | |

| US4727222A (en) | Flexible shielded coaxial cable | |

| US3428993A (en) | Electrically heated windshield wiper assembly | |

| US2915615A (en) | Electric heating unit with control thermostat | |

| US4900897A (en) | Sheathed electric heating element assembly | |

| US3324441A (en) | Hermetically sealed electrical connections | |

| US3663799A (en) | Fluoroplastic encapsulated electrical resistance heaters | |

| CN114040695B (en) | Low-temperature vacuum cooking utensil | |

| US2712590A (en) | Portable heater | |

| GB2194719A (en) | Electrical heating cable | |

| US3510824A (en) | Wiring chain of indefinite length | |

| US1565321A (en) | Electric connection | |

| US2515897A (en) | Spark plug cable | |

| US1987918A (en) | Electrical conductor | |

| US2905918A (en) | Heating unit for mechanical refrigerators and the like |