US3177893A - Valve unit for air compressor - Google Patents

Valve unit for air compressor Download PDFInfo

- Publication number

- US3177893A US3177893A US309732A US30973263A US3177893A US 3177893 A US3177893 A US 3177893A US 309732 A US309732 A US 309732A US 30973263 A US30973263 A US 30973263A US 3177893 A US3177893 A US 3177893A

- Authority

- US

- United States

- Prior art keywords

- valves

- channels

- valve

- guide

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/10—Adaptations or arrangements of distribution members

- F04B39/102—Adaptations or arrangements of distribution members the members being disc valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/10—Adaptations or arrangements of distribution members

- F04B39/1053—Adaptations or arrangements of distribution members the members being Hoerbigen valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K15/00—Check valves

- F16K15/02—Check valves with guided rigid valve members

- F16K15/06—Check valves with guided rigid valve members with guided stems

- F16K15/063—Check valves with guided rigid valve members with guided stems the valve being loaded by a spring

- F16K15/066—Check valves with guided rigid valve members with guided stems the valve being loaded by a spring with a plurality of valve members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K17/00—Safety valves; Equalising valves, e.g. pressure relief valves

- F16K17/02—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side

- F16K17/04—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded

- F16K17/0413—Safety valves; Equalising valves, e.g. pressure relief valves opening on surplus pressure on one side; closing on insufficient pressure on one side spring-loaded in the form of closure plates

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7838—Plural

- Y10T137/7839—Dividing and recombining in a single flow path

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7838—Plural

- Y10T137/7845—With common biasing means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/785—With retarder or dashpot

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7859—Single head, plural ports in parallel

- Y10T137/7861—Annular head

Definitions

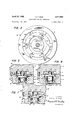

- FIG. 1 A first figure.

- This invention relates to new and useful improvements in ring plate valve units for use in air compressors, such as those of the piston type.

- a valve unit for this purpose as comprising concentrically arranged ring plate valves confined between complementary keeper and seat members wherein the valves move relative to openings in the valve seat and are guided in this movement by pins.

- These pins not only guide the valves as they move to and from the valve openings, but they also restrain radial movement of the valves relative to one another and relative to the valve openings.

- These pins are subject to Wear, and from time to time must be repositioned relative to the ring plate valves and eventually replaced by new pins.

- An object of this invention is to provide a valve unit of the concentric ring plate valve type which provides a desirable solution to the foregoing problem.

- Another object of this invention is to provide a valve unit of the concentric ring plate valve type which, because of its wear resistance, is especially suited for use in nonlube type air compressors.

- a feature of the invention is a group of ring plate valve guide assemblies so arranged relative to associated concentirc ring plate valves as to move in unison with the valves and at the same time to guide and support the valves in their opening and closing movements.

- each ring plate valve guide assembly is a spring supported non-lube guide member which guides the valves in their opening and closing movements, restrains them against relative radial movement, and moves in unison with the valves as the latter open and close.

- each ring plate valve guide assembly is a bushing relative to which a valve guide member moves, which bushing provides an air pocket beneath the valve guide member, the air in which serves to cushion the movements of the valve guide member.

- each ring plate guide assembly is a friction free valve guide member formed of a material having inherent lubricant properties.

- the invention further lies in the particular construction of its various components and also in their relative arrangement and cooperative association, whereby the beneficial results intended herein are obtained.

- FIG. 1 is a cross section of a ring plate valve unit embodying the invention, and showing the valve unit as seated in the intake opening of a non-lube type air compressor of the piston type, only a fragmentary portion of the compressor being shown;

- FIG. 2 is a section taken on line 22 of FIG. 1;

- FIG. 3 is a section taken on line 3-3 of FIG. 1;

- FIGS. 4-8 are drawn to a larger scale than FIGS. 1-3;

- FIG. 4 is a top plan view of the bushing

- FIG. 5 is a fragmentary section of the valve unit showing the ring plate valves in their open condition

- FIG. 6 is a fragmentary cross sectional view of the valve unit of FIG. 1, but wherein the form of the bushing is modified;

- FIG. 7 is a view similar to FIG. 5, but showing the collar portion of the guide member as being slightly thicker than that shown in FIG. 5;

- FIG. 8 is an elevational View of the valve guide memher.

- valve unit 10 In the drawings is disclosed a valve unit, generally designated 10.

- the valve unit is shown seated in the intake opening 11 of a conventional non-lube type air compressor, generally indicated at 12.

- the compressor is of a type having a piston 13 which reciprocates in a chamber 14. As the piston moves on its intake stroke in one direction it draws air through the valved intake opening 11 into the piston chamber; and as the piston moves in the opposite direction it compresses the air and forces it through a valved discharge opening, not shown.

- the function of the non-lube type compressor is to supply oilfree compressed air through its discharge end. In compressors of this type the piston operates in an oil free cylinder. While the valve unit embodying the invention can also be used in lube type air compressors, it is particularly suited for use in the non-lube type compressor because of its wear resistance.

- the valve unit 10 includes (FIGS. 1-3 and 5) a body or housing comprising a circular valve seat member 15 and a complementary mating valve keeper member 16.

- the keeper and seat members are bolted fast together in face to face contact by means of a headed screw 17.

- the shank 18 of the latter has a slide fit in a central hole 19 of the seat member; and it is threaded in a central hole 21 of the keeper member so that the head of the screw is drawn tight against the outer face 23 of the seat member.

- the body of the keeper member 16 has an outer reduced cylindrical end portion 24 adjacent to an enlarged inner cylindrical end portion 25, whereby an annular shoulder 26 is provided.

- the body of the seat member 15 has an outer reduced cylindrical end portion 27 adjacent to an inner enlarged cylindrical end portion 28, whereby an annular shoulder 29 is provided.

- the diameters of the outer reduced portion 24 and the inner enlarged portion 25 of the keeper member correspond respectively to the diameters of the outer portion 27 and the inner portion 28 of the keeper member.

- This clamp means is employed to hold the valve unit seated in the intake opening of the compressor.

- This clamp means which is shown in part, includes a sleeve clamp 32 which sleeves over the outer reduced end 27 of the seat member 15 and presses upon the shoulder 29.

- the sleeve clamp 32 is anchored to the housing of the compressor in conventional manner, not shown, whereby the valve unit is held fast upon the shoulder 31 of the compressor.

- the keeper member 16 of the valve unit further has an inner level face 33 which is held by the screw 17 in contact with an opposed inner level face 34 of the seat member.

- the keeper member further has an annular air flow recess 35. in its inner face 33 which communicates by means of a plurality of recessed arcuate ports 36 through the bottom end of the keeper member with the piston chamber 14 of the air compressor (FIG. 1).

- Recessed in the inner face 34 of the seat member (FIGS. 1, 3, is a pair of annular air flow channels comprising an inner channel 37 and an outer channel 38. These channels are concentric to one another and are spaced apart by an annular portion 39 of the inner face 33 of the seat member.

- channels are cen tered above and concentrically arranged relative to the recess 35 of the keeper member so as to open directly into the latter.

- the radial extent of the recess 35 of the keeper member is greater than the combined radial extent of the channels 37, 38 and the space 39 between them.

- a plurality of arcuate ports 41 formed in the body of the seat member communicate the channels 37, 38 through the outer face 23 of the seat member, whereby intake air entering through-a port 30 into the clamping sleeve 32 may flow through the arcuate ports 41 into the channels 37, 38.

- the arcuate ports 41 are separated from one another by radial rib portions 42 of the body of the seat member.

- valve 43, 44 The area of the inner face 34 of the seat member bordering the channels 37 and 38 defines a seat which is common to a pair of radially spaced concentric ring plate or disc valve elements 43, 44. The latter are also concentric with the channels 37, 38 and with the recess 35. These valves control flow of intake air to the recess 35 of the keeper member.

- Valve 43 is adapted to seat flat over the channel 37; and valve 44 is adapted to similarly seat over the channel 38.

- These valves are rigid, and are formed of hardened stainless steel. This structural nature of the valves avoids not only rusting and distortion thereof, but also avoids consequent undesirable valve seating.

- a plurality of ring plate valve guide assemblies 45 (FIGS. 1, 2, 5 here three in number and spaced circumferentially 120 degrees apart, yieldingly support and press the valves 43, 44 upon their seat, and hold them closed over the channels 37, 38.

- the guide assemblies 45 are of identical construction. Each guide assembly 45 is centered between the valves and the channels 37, 38. Each assembly 45 is seated in a separate well 46, hereinafter defined, formed in the body of the keeper member.

- Each well 46 is defined by a series of coaxial bores centered relative to the bottom wall 47 of the annular recess 35.

- the bores defining a well 46 comprise an upper enlarged bore 48 having a diameter relatively smaller than the cross dimension of the bottom 47 of the annular recess 35. Extending down from this upper bore 48 is an intermediate bore 49 of reduced diameter; and extending down from the latter is a further reduced bore 51 which opens through the bottom face 52 of the keeper member.

- valve guide bushing 54 Seated on an internal shoulder 53 at the bottom of the intermediate bore 49 is a valve guide bushing 54 (FIGS. 1, 4, 5).

- the bushing has an enlarged cylindrical base 55, the periphery of which bears against the internal wall of the intermediate bore.

- Extending axially upward from the base 55 of the bushing is a re Jerusalem cylindrical stem portion 56, the interior of which serves as a bearing and guide for sliding movement of a depending cylindrical stem portion 57 of a valve guide member 58 (FIGS. 1, 5, 8).

- an enlarged flat surfaced collar 59 At the upper end of the stem 57 of the valve guide 58 and extending radially beyond the stem is an enlarged flat surfaced collar 59; and extending axially upward from the collar is a cylindrical and relatively reduced pilot portion 61.

- valves 43, 44 extends with a slide fit (FIGS. 1, 2) between the valves 43, 44, thereby restraining the latter against radial movement relative to the channels 37, 38.

- the pilot 61 projects with a slight clearance, as at 62, into a cylindrical bore 63 formed in the body 'of the seat member.

- the valve elements 43, 44 rest in a level plane upon the upper flat surface of the collar 59. A narrow portion of each valve extends radially beyond the periphery of the collar, and a relatively greater radial opposed portion of each valve rests upon the collar.

- the spring also serves to hold the bushing 54 seated upon the shoulder 53.

- the valve guide 58 has a fully retracted position, as in FIG. 5, wherein the collar portion 59 thereof limits upon a shoulder 66 at the bottom of the enlarged bore 48.

- the overall height of the bushing 54 is such that the stem portion 56 thereof does not extend above the shoulder 66 formed at the bottom of the enlarged bore 48; accordingly, the bushing does not interfere with retractive movement of the valve guide. It is to be noted that in the fully retracted position of the valve guide, the periphery of the collar 59 is clear of the surrounding wall of the bore 48.

- the valve unit 10 may be used in the intake opening as well as in the discharge opening of an air compressor because of the symmetric formation of the inner portions 25, 28 and outer portions 24, 27 of the seat and keeper members as earlier described. In the discharge opening the valve unit will obviously have a position reverse to the position that it has in the intake opening.

- valve unit In the operation of the valve unit, as the piston 13 of the air compressor moves on an intake stroke, a resulting suction action created in the piston chamber 14 and acting through the ports of the keeper member causes intake air rushing into the channels 37, 38 of the seat member in response to the action of the piston to force the valves 43, 44 downward to open condition (FIG. 5) against the opposing force of the spring loaded valve guide assemblies 45. When this occurs, the air from the channels 37, 38 of the seat member flows into the annular recess 35 of the keeper member, and then flows from the arcuate discharge ports 36 of the latter into the piston chamber. As the springs 64 relax toward the end of the suction strokeof the piston, they return the valves to closed condition.

- valved discharge opening On the return stroke of the piston, the air previously drawn into the piston chamber is compressed and discharged through a valved discharge opening, not shown. Accordingly, as the piston reciprocates, the valves open and close relative to their seat. In this movement of the valves, each of the valve guides 58 moves up and down in unison with the valves. In moving to open condition, the valves force the valve guides 58 slidably downward in the bushings 54. As the valves are caused to close under the return force of the valve guide springs 64, the valve guides 58 are held by the springs in constant contact with and move pilot and the wall of the pilot hole.

- the clearance 62- serves a further purpose in that it allows air in the pilot hole 63 to escape as the pilot 61 moves upwardly therein, thereby avoiding the development of an air block in the pilot hole. Nor does any frictional wear occur between the periphery of the collar 59 of a valve guide and the surrounding wall of the related enlarged bore 48, because of the slight clearance 67 that exists between the two.

- valve guide 58 is friction free, having an inherently greasy or slippery surface.

- Teflon plastic which is characterized as having an inherently greasy and slippery property, is used in forming the valve guide.

- the valve guide is a one-piece structure, and is preferably formed by moulding.

- each of the valves overhangs the collar 59 of the valve guide 58.

- the collar of the valve guide has a thickness equal to the height of the wall 60 of the enlarged bore 48 so that when the valve guide is fully retracted and seated in the enlarged bore the upper surface of the collar will be level with the bottom surface 47 of the annular recess 35; and the valves will lie flat and level, resting both upon the collar 59 and upon the bottom surface 47 of the annular recess. Tilting of the valve elements may also be avoided, as indicated in FIG.

- valve guide bushing 54 in the valve guide assembly 58 shown in FIG. 1 is open at its bottom end and communicates through the bottom bore 51.

- the opening action of the valves is cushioned by the spring 64 of each valve guide assembly as each of the valve guides retracts.

- valve guide assembly is disclosed as having a valve guide bushing 54a which, except for a bleeder hole 69, is closed at its bottom by a wall 71. Air trapped in the space beneath the stem 57 of the valve is slow to escape through the restricted bleeder hole 69 and consequently supplements the spring 64 in cushioning the valve guide in its retractive movement.

- the space beneath the stem 57 of the valve guide is substantially free of air. Because of the bleeder hole 71 a slight suction action developing beneath the stem 57 of the valve guide in the retracted condition of the latter slightly counteracts the force of the spring 64 on the guide member when the spring acts to return the valves to closed condition.

- a valve unit for a piston type air compressor comprising a seat member having a pair of concentrically arranged air intake channels, a pair of concentrically disposed rigid ring plate valves in opposed relation to the channels and reciprocable axially to open and closed position relative to the channels, a keeper member having an annular air discharge recess in opposed parallel relation to the channels allowing opening and closing movement of the valves relative to the channels, a plurality of wells formed in the air flow recess spaced circumferentially equally apart and centered below the valves in common relation to both valves, and a valve guide plunger means in each well arranged so as to simultaneously support the valves, reciprocate in unison with the valves, guide the valves in their reciprocatory movement and restrain the valves against relative radial movement.

- a valve unit for a piston type air compressor comprising a seat member having a pair of concentrically arranged air intake channels, a pair of concentrically disposed rigid ring plate valves in opposed relation to the channels and movable to open and closed position relative to the channels, a keeper member having an annular air discharge recess in opposed parallel relation to the channels allowing opening and closing movement of the valves relative to the channels, a plurality of wells formed in the air flow recess spaced circumferentially equally apart and centered below the valves in common relation to both valves, and a valve guide plunger means in each well supporting the valves for moving together with the valves as a unit and simultaneously guiding the valves as the latter move relative to the channels; wherein stationary bushing means is provided in each well for guiding the movement of the valve guide plunger means; and wherein the valve guide plunger means includes a valve guide having a support portion common to both valves and a pilot extension portion beyond the support portion passing between the valves in bearing relation thereto and movable

- valve guide has a stem portion depending fromthe support portion and sleeved by the bushing.

- a guide assembly for guiding the valves in their reciprocable movement comprising a well formed in the keeper member in centered relation below both valves, a spring supported plunger seated in the well having an abutment constantly pressing against both valves urging them to closed relation over the channels, and the plunger having a pilot extension extending in bearing relation between the valves and movable in a hole of the seat member.

- pilot extension has a diameter less than that of the hole in which it moves so as to provide a clearance between it and the Wall of the hole enabling escape of trapped air from the hole.

- valve unit for an air compressor of the piston type comprising a valve seat member having an inner level face and a pair of concentric air intake channels recessed in the said face, a keeper member complementing the seat member having an inner level face and having an annular channel recessed therein in opposed parallel relation to the intake channels of the seat member, a pair of concentrically arranged ring plate valves movable in the annular channel to open and closed condition over the channels, the improvement comprising a plurality of wells spaced circumferentially equally apart in the keeper and each centered relative to the intake channels; a bushing seated in each Well; a valve guide member in each well having an annular flanged portion abutting underface portions of both valves, a stem portion depending from the flanged portion having slidable movement in the bushing, and a pilot portion extending beyond the flanged portion between the valves and in bearing relation thereto; and a spring seated in each, well in surrounding relation to the bushing pressing upwardly against the

- valve unit having a pair of concentrically arranged intake channels normally clo-sed over by a pair of concentrically arranged rigid ring plate valves which are subject to being moved axially to open condition by pressure of air entering the intake channels in response to the intake stroke of the compressor, spring biased plunger means common to both valves constantly abutting the valves and yieldably holding them in their closed condition over the channels, and the plunger means having a i g 7 pilot means extending between the valves and in bearing relation thereto whereby the valves are restrained against relative radial movement, the plunger means being movable in unison with the valves, and bushing means pro- 5 vided for guiding the movement of the plunger means.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Compressor (AREA)

Description

April 13, 1965 s. F. KING 77 VALVE UNIT FOR AIR COMPRESSOR Filed Sept. 18, 1963 2 Sheets-Sheet 1 affimiz.

FIG.

ll/IA 24 f I I Y A? I FIG 8 INVENTOR.

544/7 K/A/G m I A 3 VALVE UNIT FOR AIR COMPRESSOR Filed Sept. 18, 1963 2 Sheets-Sheet 2 47 I F 6 4a 49 60 26 64 M 26 6! Z4 52 24 f; A?

I L 5 3a 37 l 28 1 A F/G'. 7 I 2;

{l 43 w/ 66 INVENTOR. Z 68 544/779 F. e/A/s 6 48 59a, 6 BY 24 5 g {4 //V l United States Patent ice 3,177,893 VALVE UNIT FOR AIR COMPRESSGR Smith F. King, Franklin, Pm, assignor to Chicago Pneumatic Tool Company, New York, N.Y., a corporation of New Jersey Filed Sept. 18, 1963, Ser. No. 369,732 16 (Ilairns. (Cl. 137512.1)

This invention relates to new and useful improvements in ring plate valve units for use in air compressors, such as those of the piston type.

A valve unit is known for this purpose as comprising concentrically arranged ring plate valves confined between complementary keeper and seat members wherein the valves move relative to openings in the valve seat and are guided in this movement by pins. These pins not only guide the valves as they move to and from the valve openings, but they also restrain radial movement of the valves relative to one another and relative to the valve openings. These pins are subject to Wear, and from time to time must be repositioned relative to the ring plate valves and eventually replaced by new pins. This wearing down of the guide pins takes place whether the valve unit in which they are assembled is used in a lube type or non-lube type air compressor, but it is materially greater in non-lube type compressors wherein there is no lubricating oil flowing to the guide pins. Non-lube type air compressors are employed in those situations where it is desired that the air discharged from the compressor will be oil free. Accordingly, a particular problem associated with these compressors is the wear that takes place not only with respect to the guide pins of the valve units, but also the wear that takes place with respect to the ring plate valves which move relative to the guide pins as they open and close.

An object of this invention is to provide a valve unit of the concentric ring plate valve type which provides a desirable solution to the foregoing problem.

Another object of this invention is to provide a valve unit of the concentric ring plate valve type which, because of its wear resistance, is especially suited for use in nonlube type air compressors.

A feature of the invention is a group of ring plate valve guide assemblies so arranged relative to associated concentirc ring plate valves as to move in unison with the valves and at the same time to guide and support the valves in their opening and closing movements.

A feature of each ring plate valve guide assembly is a spring supported non-lube guide member which guides the valves in their opening and closing movements, restrains them against relative radial movement, and moves in unison with the valves as the latter open and close.

A further feature of each ring plate valve guide assembly is a bushing relative to which a valve guide member moves, which bushing provides an air pocket beneath the valve guide member, the air in which serves to cushion the movements of the valve guide member.

Another feature of each ring plate guide assembly is a friction free valve guide member formed of a material having inherent lubricant properties.

The invention further lies in the particular construction of its various components and also in their relative arrangement and cooperative association, whereby the beneficial results intended herein are obtained.

The foregoing and other objects and advantages of this invention will appear more fully hereinafter from a consideration of the detailed description which follows, taken together with the accompanying drawings wherein an embodiment of the invention is illustrated. It is to be expressly understood, however, that the drawings are for purposes of illustration and description, and they are not to be construed as defining the limits of the invention.

3,177,893 Patented Apr. 13, 1965 In the accompanying drawings:

FIG. 1 is a cross section of a ring plate valve unit embodying the invention, and showing the valve unit as seated in the intake opening of a non-lube type air compressor of the piston type, only a fragmentary portion of the compressor being shown;

FIG. 2 is a section taken on line 22 of FIG. 1;

FIG. 3 is a section taken on line 3-3 of FIG. 1;

FIGS. 4-8 are drawn to a larger scale than FIGS. 1-3;

FIG. 4 is a top plan view of the bushing;

FIG. 5 is a fragmentary section of the valve unit showing the ring plate valves in their open condition;

FIG. 6 is a fragmentary cross sectional view of the valve unit of FIG. 1, but wherein the form of the bushing is modified;

FIG. 7 is a view similar to FIG. 5, but showing the collar portion of the guide member as being slightly thicker than that shown in FIG. 5; and

FIG. 8 is an elevational View of the valve guide memher.

In the drawings is disclosed a valve unit, generally designated 10. The valve unit is shown seated in the intake opening 11 of a conventional non-lube type air compressor, generally indicated at 12. The compressor is of a type having a piston 13 which reciprocates in a chamber 14. As the piston moves on its intake stroke in one direction it draws air through the valved intake opening 11 into the piston chamber; and as the piston moves in the opposite direction it compresses the air and forces it through a valved discharge opening, not shown. The function of the non-lube type compressor is to supply oilfree compressed air through its discharge end. In compressors of this type the piston operates in an oil free cylinder. While the valve unit embodying the invention can also be used in lube type air compressors, it is particularly suited for use in the non-lube type compressor because of its wear resistance.

The valve unit 10 includes (FIGS. 1-3 and 5) a body or housing comprising a circular valve seat member 15 and a complementary mating valve keeper member 16. The keeper and seat members are bolted fast together in face to face contact by means of a headed screw 17. The shank 18 of the latter has a slide fit in a central hole 19 of the seat member; and it is threaded in a central hole 21 of the keeper member so that the head of the screw is drawn tight against the outer face 23 of the seat member.

The body of the keeper member 16 has an outer reduced cylindrical end portion 24 adjacent to an enlarged inner cylindrical end portion 25, whereby an annular shoulder 26 is provided. The body of the seat member 15 has an outer reduced cylindrical end portion 27 adjacent to an inner enlarged cylindrical end portion 28, whereby an annular shoulder 29 is provided. The diameters of the outer reduced portion 24 and the inner enlarged portion 25 of the keeper member correspond respectively to the diameters of the outer portion 27 and the inner portion 28 of the keeper member. When the valve unit is assembled in the air compressor, as indicated in FIG. 1, the reduced end portion 24 of the keeper member 16 has a slide fit in the intake opening 11 of the compressor, and the shoulder 26 rests upon a complementary shoulder 31 of the housing of the compressor. Conventional clamp means is employed to hold the valve unit seated in the intake opening of the compressor. This clamp means, which is shown in part, includes a sleeve clamp 32 which sleeves over the outer reduced end 27 of the seat member 15 and presses upon the shoulder 29. The sleeve clamp 32 is anchored to the housing of the compressor in conventional manner, not shown, whereby the valve unit is held fast upon the shoulder 31 of the compressor.

The keeper member 16 of the valve unit further has an inner level face 33 which is held by the screw 17 in contact with an opposed inner level face 34 of the seat member. The keeper member further has an annular air flow recess 35. in its inner face 33 which communicates by means of a plurality of recessed arcuate ports 36 through the bottom end of the keeper member with the piston chamber 14 of the air compressor (FIG. 1). Recessed in the inner face 34 of the seat member (FIGS. 1, 3, is a pair of annular air flow channels comprising an inner channel 37 and an outer channel 38. These channels are concentric to one another and are spaced apart by an annular portion 39 of the inner face 33 of the seat member. These channels are cen tered above and concentrically arranged relative to the recess 35 of the keeper member so as to open directly into the latter. The radial extent of the recess 35 of the keeper member is greater than the combined radial extent of the channels 37, 38 and the space 39 between them. A plurality of arcuate ports 41 formed in the body of the seat member communicate the channels 37, 38 through the outer face 23 of the seat member, whereby intake air entering through-a port 30 into the clamping sleeve 32 may flow through the arcuate ports 41 into the channels 37, 38. The arcuate ports 41 are separated from one another by radial rib portions 42 of the body of the seat member.

The area of the inner face 34 of the seat member bordering the channels 37 and 38 defines a seat which is common to a pair of radially spaced concentric ring plate or disc valve elements 43, 44. The latter are also concentric with the channels 37, 38 and with the recess 35. These valves control flow of intake air to the recess 35 of the keeper member. Valve 43 is adapted to seat flat over the channel 37; and valve 44 is adapted to similarly seat over the channel 38. These valves are rigid, and are formed of hardened stainless steel. This structural nature of the valves avoids not only rusting and distortion thereof, but also avoids consequent undesirable valve seating.

A plurality of ring plate valve guide assemblies 45 (FIGS. 1, 2, 5 here three in number and spaced circumferentially 120 degrees apart, yieldingly support and press the valves 43, 44 upon their seat, and hold them closed over the channels 37, 38. The guide assemblies 45 are of identical construction. Each guide assembly 45 is centered between the valves and the channels 37, 38. Each assembly 45 is seated in a separate well 46, hereinafter defined, formed in the body of the keeper member. Each well 46 is defined by a series of coaxial bores centered relative to the bottom wall 47 of the annular recess 35. The bores defining a well 46 comprise an upper enlarged bore 48 having a diameter relatively smaller than the cross dimension of the bottom 47 of the annular recess 35. Extending down from this upper bore 48 is an intermediate bore 49 of reduced diameter; and extending down from the latter is a further reduced bore 51 which opens through the bottom face 52 of the keeper member.

Seated on an internal shoulder 53 at the bottom of the intermediate bore 49 is a valve guide bushing 54 (FIGS. 1, 4, 5). The bushing has an enlarged cylindrical base 55, the periphery of which bears against the internal wall of the intermediate bore. Extending axially upward from the base 55 of the bushing is a re duced cylindrical stem portion 56, the interior of which serves as a bearing and guide for sliding movement of a depending cylindrical stem portion 57 of a valve guide member 58 (FIGS. 1, 5, 8). At the upper end of the stem 57 of the valve guide 58 and extending radially beyond the stem is an enlarged flat surfaced collar 59; and extending axially upward from the collar is a cylindrical and relatively reduced pilot portion 61. The latter extends with a slide fit (FIGS. 1, 2) between the valves 43, 44, thereby restraining the latter against radial movement relative to the channels 37, 38. The pilot 61 projects with a slight clearance, as at 62, into a cylindrical bore 63 formed in the body 'of the seat member. The valve elements 43, 44 rest in a level plane upon the upper flat surface of the collar 59. A narrow portion of each valve extends radially beyond the periphery of the collar, and a relatively greater radial opposed portion of each valve rests upon the collar. A coil or compression spring 64 surrounding the stem 56 of the bushing and compressed between a shoulder 65 of the base portion of the bushing and the undersurface of the collar 59 biases the valve guide 58 upwardly so as to press the valve elements closed upon their seat over the channels 37, 38. The spring also serves to hold the bushing 54 seated upon the shoulder 53.

The valve guide 58 has a fully retracted position, as in FIG. 5, wherein the collar portion 59 thereof limits upon a shoulder 66 at the bottom of the enlarged bore 48. The overall height of the bushing 54 is such that the stem portion 56 thereof does not extend above the shoulder 66 formed at the bottom of the enlarged bore 48; accordingly, the bushing does not interfere with retractive movement of the valve guide. It is to be noted that in the fully retracted position of the valve guide, the periphery of the collar 59 is clear of the surrounding wall of the bore 48.

The valve unit 10 may be used in the intake opening as well as in the discharge opening of an air compressor because of the symmetric formation of the inner portions 25, 28 and outer portions 24, 27 of the seat and keeper members as earlier described. In the discharge opening the valve unit will obviously have a position reverse to the position that it has in the intake opening.

In the operation of the valve unit, as the piston 13 of the air compressor moves on an intake stroke, a resulting suction action created in the piston chamber 14 and acting through the ports of the keeper member causes intake air rushing into the channels 37, 38 of the seat member in response to the action of the piston to force the valves 43, 44 downward to open condition (FIG. 5) against the opposing force of the spring loaded valve guide assemblies 45. When this occurs, the air from the channels 37, 38 of the seat member flows into the annular recess 35 of the keeper member, and then flows from the arcuate discharge ports 36 of the latter into the piston chamber. As the springs 64 relax toward the end of the suction strokeof the piston, they return the valves to closed condition. On the return stroke of the piston, the air previously drawn into the piston chamber is compressed and discharged through a valved discharge opening, not shown. Accordingly, as the piston reciprocates, the valves open and close relative to their seat. In this movement of the valves, each of the valve guides 58 moves up and down in unison with the valves. In moving to open condition, the valves force the valve guides 58 slidably downward in the bushings 54. As the valves are caused to close under the return force of the valve guide springs 64, the valve guides 58 are held by the springs in constant contact with and move pilot and the wall of the pilot hole. The clearance 62- serves a further purpose in that it allows air in the pilot hole 63 to escape as the pilot 61 moves upwardly therein, thereby avoiding the development of an air block in the pilot hole. Nor does any frictional wear occur between the periphery of the collar 59 of a valve guide and the surrounding wall of the related enlarged bore 48, because of the slight clearance 67 that exists between the two.

There is, however, a sliding relation between the stem 57 of the valve guide and the interior wall of the bushing 54. To avoid frictional wear here, the inner wall of the bushing has a smooth bearing surface, and the valve guide 58 is friction free, having an inherently greasy or slippery surface. Teflon plastic, which is characterized as having an inherently greasy and slippery property, is used in forming the valve guide. The valve guide is a one-piece structure, and is preferably formed by moulding.

It is to be noted in FIGS. 1 and 2 that a relatively narrow peripheral portion of each of the valves overhangs the collar 59 of the valve guide 58. To avoid tilting of the valves relative to the valve guide when the latter is fully retracted, the collar of the valve guide has a thickness equal to the height of the wall 60 of the enlarged bore 48 so that when the valve guide is fully retracted and seated in the enlarged bore the upper surface of the collar will be level with the bottom surface 47 of the annular recess 35; and the valves will lie flat and level, resting both upon the collar 59 and upon the bottom surface 47 of the annular recess. Tilting of the valve elements may also be avoided, as indicated in FIG. 7, by making the thickness of the collar 59a of the valve guide slightly greater than the height of the wall 60 of the enlarged bore 48 so that when the collar is seated in the latter, the valves will rest in a level plane on the collar and the overhanging portions of the valves will be slightly clear of the bottom wall 47 of the recess 35, as indicated by the clearance 68 in FIG. 7.

It is to be further noted that the valve guide bushing 54 in the valve guide assembly 58 shown in FIG. 1 is open at its bottom end and communicates through the bottom bore 51. In this construction, the opening action of the valves is cushioned by the spring 64 of each valve guide assembly as each of the valve guides retracts.

In FIG. 6, the valve guide assembly is disclosed as having a valve guide bushing 54a which, except for a bleeder hole 69, is closed at its bottom by a wall 71. Air trapped in the space beneath the stem 57 of the valve is slow to escape through the restricted bleeder hole 69 and consequently supplements the spring 64 in cushioning the valve guide in its retractive movement. In the fully retracted condition of the valve guide 59 in this modified form of the bushing, the space beneath the stem 57 of the valve guide is substantially free of air. Because of the bleeder hole 71 a slight suction action developing beneath the stem 57 of the valve guide in the retracted condition of the latter slightly counteracts the force of the spring 64 on the guide member when the spring acts to return the valves to closed condition.

Having described and illustrated the invention as above, it is intended to claim the invention not only as shown and described but also in all such forms and modifications as may reasonably be construed to fall within the spirit of the invention and the scope of the appended claims.

What is claimed is:

1. A valve unit for a piston type air compressor comprising a seat member having a pair of concentrically arranged air intake channels, a pair of concentrically disposed rigid ring plate valves in opposed relation to the channels and reciprocable axially to open and closed position relative to the channels, a keeper member having an annular air discharge recess in opposed parallel relation to the channels allowing opening and closing movement of the valves relative to the channels, a plurality of wells formed in the air flow recess spaced circumferentially equally apart and centered below the valves in common relation to both valves, and a valve guide plunger means in each well arranged so as to simultaneously support the valves, reciprocate in unison with the valves, guide the valves in their reciprocatory movement and restrain the valves against relative radial movement.

2. A valve unit according to claim 1, wherein stationary bushing means is provided in each well for guiding the movement of the valve guide plunger means.

3. A valve unit for a piston type air compressor, comprising a seat member having a pair of concentrically arranged air intake channels, a pair of concentrically disposed rigid ring plate valves in opposed relation to the channels and movable to open and closed position relative to the channels, a keeper member having an annular air discharge recess in opposed parallel relation to the channels allowing opening and closing movement of the valves relative to the channels, a plurality of wells formed in the air flow recess spaced circumferentially equally apart and centered below the valves in common relation to both valves, and a valve guide plunger means in each well supporting the valves for moving together with the valves as a unit and simultaneously guiding the valves as the latter move relative to the channels; wherein stationary bushing means is provided in each well for guiding the movement of the valve guide plunger means; and wherein the valve guide plunger means includes a valve guide having a support portion common to both valves and a pilot extension portion beyond the support portion passing between the valves in bearing relation thereto and movable in a hole of the seat, and a spring pressing against the support portion biasing the valves to closed condition over the channels.

4. A valve unit according to claim 3, wherein the valve guide has a stem portion depending fromthe support portion and sleeved by the bushing.

5. A valve unit according to claim 4, wherein the stem of the valve guide has an inherently greasy and slippery surface.

6. A valve unit according to claim 4, wherein the bushing has a wall closing its bottom end so as to provide an air-trap chamber below the said stem, and a bleeder hole is provided in the said wall so as to provide means allowing restricted escape of air from the chamber.

7. In a valve unit for a piston type air compressor, having opposed keeper and seat members and having a pair of concentrically disposed rigid ring plate valves reciprocable in an annular recess between the keeper and seat members to open and closed position relative to a pair of concentrically arranged channels in the seat member, a guide assembly for guiding the valves in their reciprocable movement comprising a well formed in the keeper member in centered relation below both valves, a spring supported plunger seated in the well having an abutment constantly pressing against both valves urging them to closed relation over the channels, and the plunger having a pilot extension extending in bearing relation between the valves and movable in a hole of the seat member.

8. In a valve unit as in claim 7, wherein the pilot extension has a diameter less than that of the hole in which it moves so as to provide a clearance between it and the Wall of the hole enabling escape of trapped air from the hole.

9. In a valve unit for an air compressor of the piston type, comprising a valve seat member having an inner level face and a pair of concentric air intake channels recessed in the said face, a keeper member complementing the seat member having an inner level face and having an annular channel recessed therein in opposed parallel relation to the intake channels of the seat member, a pair of concentrically arranged ring plate valves movable in the annular channel to open and closed condition over the channels, the improvement comprising a plurality of wells spaced circumferentially equally apart in the keeper and each centered relative to the intake channels; a bushing seated in each Well; a valve guide member in each well having an annular flanged portion abutting underface portions of both valves, a stem portion depending from the flanged portion having slidable movement in the bushing, and a pilot portion extending beyond the flanged portion between the valves and in bearing relation thereto; and a spring seated in each, well in surrounding relation to the bushing pressing upwardly against the flanged portion of the guide member so as to yieldably hold the valves by means of the flanged portion seated over the channels.

10. In a valve unit having a pair of concentrically arranged intake channels normally clo-sed over by a pair of concentrically arranged rigid ring plate valves which are subject to being moved axially to open condition by pressure of air entering the intake channels in response to the intake stroke of the compressor, spring biased plunger means common to both valves constantly abutting the valves and yieldably holding them in their closed condition over the channels, and the plunger means having a i g 7 pilot means extending between the valves and in bearing relation thereto whereby the valves are restrained against relative radial movement, the plunger means being movable in unison with the valves, and bushing means pro- 5 vided for guiding the movement of the plunger means.

References Cited by the Examiner UNITED STATES PATENTS 1,322,600 11/19 Nestor "137-51621 2,124,323 7/38 Voss 137454.4

FOREIGN PATENTS 502,381 6/30 Germany.

M. CARY NELSON, Primary Examiner.

Claims (1)

1. A VALVE UNIT FOR A PISTON TYPE AIR COMPRESSOR COMPRISING A SEAT MEMBER HAVING A PAIR OF CONCENTRICALLY ARRANGED AIR INTAKE CHANNELS, A PAIR OF CONCENTRICALLY DISPOSED RIGID RING PLATE VALVES IN OPPOSED RELATION TO THE CHANNELS AND RECIPROCABLE AXIALLY TO OPEN AND CLOSED POSITION RELATIVE TO THE CHANNELS, A KEEPER MEMBER HAVING AN ANNULAR AIR DISCHARGE RECESS IN OPPOSED PARALLEL RELATION TO THE CHANNELS ALLOWING OPENING AND CLOSING MOVEMENT OF THE VALVES RELATIVE TO THE CHANNELS, A PLURALITY OF WELLS FORMED IN THE AIR FLOW RECESS SPACED CIRCUMFERENTIALLY EQUALLY APART AND CENTERED BELOW THE VALVES IN COMMON RELATION TO BOTH VALVES, AND A VALVE GUIDE PLUNGER MEANS IN EACH WELL ARRANGED SO AS TO SIMULTANEOUSLY SUPPORT THE VALVES, RECIPROCATE IN UNISON WITH THE VALVES, GUIDE THE VALVES IN THEIR RECIPROCATORY MOVEMENT AND RESTRAIN THE VALVES AGAINST RELATIVE RADIAL MOVEMENT.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US309732A US3177893A (en) | 1963-09-18 | 1963-09-18 | Valve unit for air compressor |

| GB28837/64A GB1070291A (en) | 1963-09-18 | 1964-07-13 | Valve unit for air compressor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US309732A US3177893A (en) | 1963-09-18 | 1963-09-18 | Valve unit for air compressor |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3177893A true US3177893A (en) | 1965-04-13 |

Family

ID=23199435

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US309732A Expired - Lifetime US3177893A (en) | 1963-09-18 | 1963-09-18 | Valve unit for air compressor |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US3177893A (en) |

| GB (1) | GB1070291A (en) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3428081A (en) * | 1966-12-08 | 1969-02-18 | Harry G Kauffman | Compressor valve |

| US3556136A (en) * | 1969-03-19 | 1971-01-19 | Ingersoll Rand Co | Fluid-control valve |

| US3656500A (en) * | 1970-05-18 | 1972-04-18 | Worthington Corp | Check valve |

| US3703912A (en) * | 1970-02-18 | 1972-11-28 | Hoerbiger Ventilwerke Ag | Plate valve |

| US4531541A (en) * | 1984-02-16 | 1985-07-30 | Ingersoll-Rand Company | Plate-type valve, and an improved valve seat and a valve seat assembly therefor |

| US5483992A (en) * | 1992-06-02 | 1996-01-16 | Maschinenfabrik Sulzer-Burckhardt Ag | Annular valve for a piston compressor |

| AT403947B (en) * | 1994-07-15 | 1998-06-25 | Hoerbiger Ventilwerke Ag | DISC VALVE |

| US5775886A (en) * | 1996-08-08 | 1998-07-07 | Terwilliger; Gerald L. | Gas compressor with reciprocating piston with valve sheath |

| WO2004065790A1 (en) * | 2003-01-22 | 2004-08-05 | Hoerbiger Kompressortechnik Holding Gmbh | Annular plate valve for piston compressors |

| US20180306176A1 (en) * | 2015-10-12 | 2018-10-25 | Burckhardt Compression Ag | Poppet valve |

| US20240003446A1 (en) * | 2022-07-01 | 2024-01-04 | Siemens Energy, Inc. | Anti-spin outer diameter guided compressor valve |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT412302B (en) * | 2000-03-28 | 2004-12-27 | Hoerbiger Ventilwerke Gmbh | AUTOMATIC VALVE |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1322600A (en) * | 1919-11-25 | nestor | ||

| DE502381C (en) * | 1930-07-14 | Eisen Und Emaillierwerke Akt G | Pump valve | |

| US2124323A (en) * | 1937-04-07 | 1938-07-19 | Johann H H Voss | Ring plate valve |

-

1963

- 1963-09-18 US US309732A patent/US3177893A/en not_active Expired - Lifetime

-

1964

- 1964-07-13 GB GB28837/64A patent/GB1070291A/en not_active Expired

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1322600A (en) * | 1919-11-25 | nestor | ||

| DE502381C (en) * | 1930-07-14 | Eisen Und Emaillierwerke Akt G | Pump valve | |

| US2124323A (en) * | 1937-04-07 | 1938-07-19 | Johann H H Voss | Ring plate valve |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3428081A (en) * | 1966-12-08 | 1969-02-18 | Harry G Kauffman | Compressor valve |

| US3556136A (en) * | 1969-03-19 | 1971-01-19 | Ingersoll Rand Co | Fluid-control valve |

| US3703912A (en) * | 1970-02-18 | 1972-11-28 | Hoerbiger Ventilwerke Ag | Plate valve |

| US3656500A (en) * | 1970-05-18 | 1972-04-18 | Worthington Corp | Check valve |

| US4531541A (en) * | 1984-02-16 | 1985-07-30 | Ingersoll-Rand Company | Plate-type valve, and an improved valve seat and a valve seat assembly therefor |

| US5483992A (en) * | 1992-06-02 | 1996-01-16 | Maschinenfabrik Sulzer-Burckhardt Ag | Annular valve for a piston compressor |

| AT403947B (en) * | 1994-07-15 | 1998-06-25 | Hoerbiger Ventilwerke Ag | DISC VALVE |

| US5775886A (en) * | 1996-08-08 | 1998-07-07 | Terwilliger; Gerald L. | Gas compressor with reciprocating piston with valve sheath |

| WO2004065790A1 (en) * | 2003-01-22 | 2004-08-05 | Hoerbiger Kompressortechnik Holding Gmbh | Annular plate valve for piston compressors |

| US20180306176A1 (en) * | 2015-10-12 | 2018-10-25 | Burckhardt Compression Ag | Poppet valve |

| US10859078B2 (en) * | 2015-10-12 | 2020-12-08 | Burckhardt Compression Ag | Poppet valve |

| US20240003446A1 (en) * | 2022-07-01 | 2024-01-04 | Siemens Energy, Inc. | Anti-spin outer diameter guided compressor valve |

| US11913556B2 (en) * | 2022-07-01 | 2024-02-27 | Siemens Energy, Inc. | Anti-spin outer diameter guided compressor valve |

Also Published As

| Publication number | Publication date |

|---|---|

| GB1070291A (en) | 1967-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3177893A (en) | Valve unit for air compressor | |

| US4228820A (en) | Seat guided poppet valve having flow and dampening control means | |

| US4154434A (en) | Boot arrangement for piston-cylinder assembly | |

| US2524142A (en) | Fluid valve | |

| US2805038A (en) | Pressure actuated bye-pass valves | |

| US4326402A (en) | Stock lifter for progressive dies | |

| CA1047416A (en) | Lubricating means for gas-operated cylinders | |

| US2624587A (en) | Valve assembly | |

| US3829253A (en) | Plate valve structure | |

| US2608376A (en) | Valve construction | |

| US2339352A (en) | Fluid control valve | |

| CN101815848B (en) | Hydraulic lash compensation device with mechanical lift loss feature | |

| US2903014A (en) | Check valve for diesel engine fuel pump | |

| US1833216A (en) | Rapid puncher and riveter | |

| US2703102A (en) | Spring loaded valve for high-speed air and gas compressors | |

| US2140328A (en) | Valve construction | |

| US5483992A (en) | Annular valve for a piston compressor | |

| US2408708A (en) | Hydraulic relief valve | |

| US2416855A (en) | High-pressure diaphragm relief valve | |

| US3357449A (en) | Valve unit for non-lube air compressors | |

| GB1125643A (en) | Fluid radial and thrust bearing | |

| US2141069A (en) | Compressor unloader | |

| US2171613A (en) | Valve | |

| US2404529A (en) | Valve | |

| US3273591A (en) | Compressor valve with removable guide means |