US3064310A - Method and apparatus for making plastic articles - Google Patents

Method and apparatus for making plastic articles Download PDFInfo

- Publication number

- US3064310A US3064310A US23469A US2346960A US3064310A US 3064310 A US3064310 A US 3064310A US 23469 A US23469 A US 23469A US 2346960 A US2346960 A US 2346960A US 3064310 A US3064310 A US 3064310A

- Authority

- US

- United States

- Prior art keywords

- spout

- head

- mold

- cavity

- plunger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

Definitions

- the reciprocable unit normally comprises a plunger having at its lower end a piston, slidably received in a barrel or cylinder forming part of the stationary unit and, at the upper end of the plunger, a head having an integrally formed laterally directed discharge spout, the head being depressible by the finger while the container is held in the hand for the purpose of reciprocating the plunger and piston to discharge liquid upwardly through the interior of the head and out of the spout.

- the spout At its outer end the spout is frequently bent or curved downwardly to direct the discharging liquid where desired, for instance as shown in the patent to Stewart and Cooprider 2,846,124, granted August 5, 1958.

- the spout is formed separately from the head, and casting the spout in its final configuration oflers no problem, since the spout core can be made in two separable sections, withdrawn from the opposite ends of the spout.

- the spout is formed integrally with the head, it has heretofore been the practice to cast a straight spout, and thereafter to bend the outer end of the spout downwardly while maintaining the spout at an elevated temperature. While this latter procedure has involved no problems in casting, since the spout is readily withdrawn by lengthwise displacement from the die or mold and core by which it is formed, the added step required to provide the bent configuration of the outer end of the spout has involved additional time and expense.

- FIGURE 1 is a vertical sectional view of a dispenser of the type hereinbefore described, having an integrally formed head and spout to which the method of the present invention is applicable;

- FIGURE 2 is a sectional view of a die or mold suitable for the casting or injection molding of an integral head and spout of the type shown in FIGURE 1 by the method .of the present invention

- FIGURE 3 is a section on the line 33 of FIGURE 1;

- FIGURE 4 is a section on the line 4-4 of FIGURE 2, and

- FIGURE 5 is a section on the line 5-5 of FIG- URE 2.

- the dispenser there illustrated includes a stationary unit which may be molded in one piece to provide a barrel or cylinder 12 fromwhich a suction tube 13 depends and, at the upper end of the barrel 12, a collar portion 14, noting that throughout the following description the dispenser will be assumed to occupy the upright position in which it is normally used.

- the upper end of the barrel 12 is preferably slotted at circumferentially spaced points, as indicated at 18, for the purpose of preventing the formation of an airlock in the barrel 12 above the piston, to permit ingress to the container of air in order to replace discharged liquid, and to allow drainage into the container of liquid which may pass the piston and which would otherwise be trapped in the upper portion of barrel 12.

- a radial annular flange 20, formed on the collar portion 14, provides a seat for container cap 21.

- Cap 21 is apertured to receive collar portion 14 and is internally threaded as shown at 22 for cooperative engagement with external threads formed on the neck of the container; a gasket 24 may be positioned beneath flange 20.

- the collar portion 14 is further provided at its upper end with an interiorly threaded sleeve portion 25, and an annular lip 3% which is formed by deformation of sleeve portion 25 after assembly of the container cap 21 thereon, in order to lock the cap on the collar portion 14.

- the stationary and reciprocable units of the dispenser may be formed of any moldable plastic materials, preferably materials commonly designated thermoplastics, for instance, polyethylene and polypropylene. Excellent results are achieved by the use of a polyethylene sold under the trade mark Super Dylan by Koppers Company, Inc., of Pittsburgh, Pennsylvania. Vinyl chloride acetate is also highly effective, and in general, any plastic material subject to hot or cold flow, capable of being molded, and readily deformed after molding in response to heat and/ or pressure may be employed.

- the reciprocable unit of the dispenser comprises a plunger 35 and a dependent hollow piston 36, the piston being enlarged in diameter at its lower end to fit snugly the interior wall of barrel 12; the plunger and piston may be integrally formed by injection molding.

- plunger 35 defines a fluid passage 40, communicating at its upper end with a passage 41 which is provided with a valve seat 48 receiving a ball valve 45. Movement of fluid upwardly in the passages 40, 41 is thus normally unimpeded, the valve 45 serving merely as a check valve to prevent downward movement of fluid.

- the plunger 35 is preferably tapered upwardly to provide a conical portion 38.

- a discharge head 37 preferably cast separately, from thermoplastic resins of the type hereinbefore described, is recessed internally for reception with a snug fit on the upper end of the cylindrical portion of the plunger 35.

- a spout 78 bent or curved as shown, projects laterally from the head; discharge passage 79 extending through the spout communicates with head chamber 70. Assembly of the head 37 on the plunger 35 is effected by applying endwise pressure to force the head downwardly on the plunger until it assumes in its manufacture.

- the tapered portion 38 of the plunger 35 terminates short of the upper end of the head 37, providing a chamber 70, into which passage 41 opens.

- a stud 71, projecting downwardly from the finger rest portion 73 of the head into chamber 70 serves as a retainer for the ball valve 45.

- a coil compression spring 52 acting to urge the reciprocable unit upwardly.

- Ball valve 55 seating by gravity in the lower end of barrel 12, acts as a check valve to prevent drainage of liquid downwardly from the barrel 12.

- the seat 56 for-ball valve 55 forms an angle ofat least 45 with the axis of the dispenser to minimize the possibility of wedging of the valve in its seat.

- Spring 52 is formed with convolutions 60 of reduced diameter, preferably adjacent each end, as shown, to provide reversibility.

- the ball valve 55 is engaged by the adjacent small convolution 60 of spring 52 to hold the valve tightly against its seat, thus preventing flow of liquid into the barrel and. outwardly through passages 40 and 41 when the dispenser is inverted.

- the head At its lower end the head is formed to provide a depending skirt portion 42, formed with external threads which coast with the internal threads on the collar portion 14 of the barrel 12.

- coacting inclined surfaces 62 on the head and barrel are pressed together to form a seal preventing discharge of liquid from the container through the slots 18 and externally of the plunger 35. Since movement of liquid upwardly into the lower end ofthe barrel 12 and the plunger 35 is prevented in the fully depressed position of the plunger by direct engagement of the convolutions 60 of the spring 52 with the ball valve 55, leakage of liquid is prevented during handling and shipping, this being of particular importance when toxic liquids, such as insecticides, are used.

- the reciprocable unit is retained in position in the stationary unit by an inwardly directed annular part 66 which extends into close proximity with the plunger 35 and serves as a bearing surface for guiding the plunger during reciprocation thereof, while limiting outward movement of the plunger in response to the action of spring 52.

- the annular part 66 is formed after assembly of the two units, by assembling around plunger 35 a cylindrical tool, the tool 'being pressed downwardly against a shoulder formed at the junction of the barrel proper with the collar portion 14 of thelbarrel so as to cause the material to flow inwardly.

- dispenser forms nov part of the instant invention, but is typical of articles which may be formed more readily and with less time and expense when the present invention is employed

- the details of the dispenser, and more particularly. of the head and the spout, may vary ;widely' from that illustrated herein.

- FIG- URE 2 shows the mold sections in assembled relation and after injection of the fiowable plastic material.

- the free end 85 of core 84 projects into the cavity in which the head 37 is .formed, and is so shaped as to form internally of the head the chamber 70, the stud 71 projecting into the chamber, and the annular grooves for reception of the beads39' formed exteriorly of the plunger 35.

- the mold cavity in which the head 37 is cast is shaped to form the head illustrated in FIGURE 1, including the collar portion 42 with its external threads and its tapered sealing surface 62, and is closed by a sprue bushing 87 having a gate 88 therein through which the fiowable plastic material may be forced into the mold.

- Bushing 87 is retained in position by bolt 83 to provide easy removal for cleaning.

- Mold section 81 is provided with an elongated-spout cavity, circular in transverse section, and having a straight portion 89 communicating with the cavity in which the head 37 is cast, and a bent or curved portion 91.

- Portion 91 of the spout cavity is defined by a separately formed mold part, made in two sections 93, 94 which are bolted together, meeting on a plane containing the center line of the spout cavity portion 91.

- Cavity portions 89 and 91 communicate at their adjoining ends and may be tapered gradually from the head portion to the outer end of spout cavity 91 as shown.

- a spout core 96 closes the outer end of cavity portion 91, extends through spout cavity 89, 91 and seats at 97 in a recess in the outer end of head core 84, so as to provide with cavity 89, 91 the annular channel in which spout 78 is cast, the core 96 its substantial inflexibility, could not, otherwise be introduced in the position in which it is shown.

- the separable die section 80 In preparation for the casting operation, the separable die section 80, together with core 84, is moved into abutting relation with die section 81 (upwardly in FIG- URE 2) and clamped in position to close the head cavity.

- the plastic material is then forced under pressure through gate 88 in sprue bushing 87 until the head and spout cavities are filled. After filling, the pressure is increased during a pressure boost period. After a further dwell period, during which the plastic material cools somewhat, mold section and head core 84 are withdrawn from mold section 81 by displacing the same downwardly (FIGURE 2).

- the formed head 37 is carried downwardly with head core 84 to withdraw the spout 78 endwise from the cavity 89.

- the temperature of the plastic material during the casting operation will, of course, depend primarily on the nature of the plastic employed. As injected, the plastic must be fiowable at the pressure employed; conventional injection temperatures, suitable for the plastic material used, may be maintained. The minimum temperature will be that necessary to insure complete filling of the mold cavities; the maximum temperature will be estab- Dwell period, seconds Pressure boost, seconds Injection temperature, F.

- the temperature of the material which forms the spout cannot be accurately determined, but the dwell period is adjusted so that withdrawal of the spout can be efiected readily, and will be followed by resumption of the bend or curve to conform substantially to the desired configuration.

- the core 84 may be displaced laterally With the mold section 80 to withdraw the spout from the mold section 81, this being the pre ferred practice. Because of the flexibility of the spout, it has been found unnecessary to effect this displacement in the direction of the straight portion of the spout, and the displacement may be normal to the axis of the core 84 with the resultant simplification of operating mechanism. Following the release of the spout from the mold section 81, core 84 is displaced endwise with respect to mold section 80 (to the right in FIGURE 2) to release the head. A knockout pin (not shown), normally closing drill hole 95, may then be displaced against the cast head 37 to release the latter from mold section 80, if this be necessary.

- spout 78 extends downwardly from its point of intersection with head 37. It may project in a direction normal to the head, if desired. Similarly, the curve or bend in the spout may be altered substantially in magnitude and direction from that shown. For instance, the spout may be curved throughout its length, over a substantial portion of its length, or at one point only in its length.

- an integral plastic head for use in a fluid pump of the reciprocating type, having a hollow body portion and an elongated curved hollow spout portion protruding from and communicating with the interior of said hollow body portion, in a mold having cores which intersect to establish communication between the interior of said body portion and said spout portion and comprising a pair of mold blocks meeting in a plane transverse to the direction of the axis of said spout portion at its juncture with said body portion, the spout cavity and core having a nonlinear configuration over a portion of their length, comprising the steps of engaging said mold blocks to close said mold, with the cores positioned therein, injecting a thermoplastic resin in said mold under pressure and at a temperature at which said resin is suificiently fluid to fill the mold cavity, allowing said resin to harden sufliciently to retain the shape of the cavity, separating said mold blocks and maintaining the cavity for the spout portion closed with the core for the sp

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Description

Nov. 20, 1962 R. c. COOPREDER 3,054,310

METHOD AND APPARATUS FOR- MAKING PLASTIC ARTICLES Filed April 20, 1960 2 Sheets-Sheet 1 BY wmmteaGmaa-Fwmw ATTORNEYS Nov. 20, 1962 R. c. COOPRIDER 3,034,310

I METHOD AND APPARATUS F OR MAKING PLASTIC ARTICLES Filed April 20, 1960 2 Sheets-Sheet 2 I75 mvamoa 176% 6: Cay/527} BY 60:43. 00%, @MM. 'fLUaT/Em ATTORNEYS United States Patent Ofiiice Patented Nov. 20, 1962 Ohio Filed Apr. 2a, 1960, Ser. No. 23,469 Claims. ((31. 1842) This invention relates to an improved method of casting plastic articles by the injection molding process, and is more particularly concerned with the molding of a onepiece head and spout for fluid dispensers.

It has long been the practice to employ, for the dispensing of liquids from small containers, hand actuated pumps formed of moldable plastic material comprising, in assembled relation, a stationary unit for direct association with the container, and a reciprocable piston unit which is manipulated to effect discharge of the container contents. The reciprocable unit normally comprises a plunger having at its lower end a piston, slidably received in a barrel or cylinder forming part of the stationary unit and, at the upper end of the plunger, a head having an integrally formed laterally directed discharge spout, the head being depressible by the finger while the container is held in the hand for the purpose of reciprocating the plunger and piston to discharge liquid upwardly through the interior of the head and out of the spout.

At its outer end the spout is frequently bent or curved downwardly to direct the discharging liquid where desired, for instance as shown in the patent to Stewart and Cooprider 2,846,124, granted August 5, 1958. In that patent the spout is formed separately from the head, and casting the spout in its final configuration oflers no problem, since the spout core can be made in two separable sections, withdrawn from the opposite ends of the spout. Where, as in my prior application, Serial No. 777,264, filed December 1, 1958, the spout is formed integrally with the head, it has heretofore been the practice to cast a straight spout, and thereafter to bend the outer end of the spout downwardly while maintaining the spout at an elevated temperature. While this latter procedure has involved no problems in casting, since the spout is readily withdrawn by lengthwise displacement from the die or mold and core by which it is formed, the added step required to provide the bent configuration of the outer end of the spout has involved additional time and expense.

It is an object of the invention to avoid this additional step in the production of an inte ral head and spout by casting the spout initially in the bent or curved configura tion, and thereafter withdrawing the die and core by which it is formed While the spout is still sufliciently hot to permit the same to straighten out as it moves through the straight portion of the die. Contrary to What would be expected, the spout resumes, at least in part, its bent or curved configuration as soon as withdrawal from the die is complete, and the additional step of deforming the spout after withdrawal of the article from the die may thereby be eliminated.

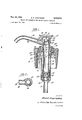

Further objects and features of the invention will be apparent from the following description taken in connection with the accompanying drawings, in which FIGURE 1 is a vertical sectional view of a dispenser of the type hereinbefore described, having an integrally formed head and spout to which the method of the present invention is applicable;

FIGURE 2 is a sectional view of a die or mold suitable for the casting or injection molding of an integral head and spout of the type shown in FIGURE 1 by the method .of the present invention;

FIGURE 3 is a section on the line 33 of FIGURE 1;

FIGURE 4 is a section on the line 4-4 of FIGURE 2, and

FIGURE 5 is a section on the line 5-5 of FIG- URE 2.

To promote an understanding of the invention, reference will now be made to the preferred embodiment thereof illustrated in the accompanying drawings and specific language will be used to describe the same. It will nevertheless be appreciated that no limitation of the scope of the invention is thereby intended, such further modifications and alterations being contemplated as would normally occur to one skilled in the art to which the invention relates.

Referring first to FIGURE 1, the dispenser there illustrated includes a stationary unit which may be molded in one piece to provide a barrel or cylinder 12 fromwhich a suction tube 13 depends and, at the upper end of the barrel 12, a collar portion 14, noting that throughout the following description the dispenser will be assumed to occupy the upright position in which it is normally used.

The upper end of the barrel 12 is preferably slotted at circumferentially spaced points, as indicated at 18, for the purpose of preventing the formation of an airlock in the barrel 12 above the piston, to permit ingress to the container of air in order to replace discharged liquid, and to allow drainage into the container of liquid which may pass the piston and which would otherwise be trapped in the upper portion of barrel 12.

A radial annular flange 20, formed on the collar portion 14, provides a seat for container cap 21. Cap 21 is apertured to receive collar portion 14 and is internally threaded as shown at 22 for cooperative engagement with external threads formed on the neck of the container; a gasket 24 may be positioned beneath flange 20.

The collar portion 14 is further provided at its upper end with an interiorly threaded sleeve portion 25, and an annular lip 3% which is formed by deformation of sleeve portion 25 after assembly of the container cap 21 thereon, in order to lock the cap on the collar portion 14.

The stationary and reciprocable units of the dispenser may be formed of any moldable plastic materials, preferably materials commonly designated thermoplastics, for instance, polyethylene and polypropylene. Excellent results are achieved by the use of a polyethylene sold under the trade mark Super Dylan by Koppers Company, Inc., of Pittsburgh, Pennsylvania. Vinyl chloride acetate is also highly effective, and in general, any plastic material subject to hot or cold flow, capable of being molded, and readily deformed after molding in response to heat and/ or pressure may be employed.

The reciprocable unit of the dispenser comprises a plunger 35 and a dependent hollow piston 36, the piston being enlarged in diameter at its lower end to fit snugly the interior wall of barrel 12; the plunger and piston may be integrally formed by injection molding.

The interior of plunger 35 defines a fluid passage 40, communicating at its upper end with a passage 41 which is provided with a valve seat 48 receiving a ball valve 45. Movement of fluid upwardly in the passages 40, 41 is thus normally unimpeded, the valve 45 serving merely as a check valve to prevent downward movement of fluid. At its upper end, the plunger 35 is preferably tapered upwardly to provide a conical portion 38. A discharge head 37, preferably cast separately, from thermoplastic resins of the type hereinbefore described, is recessed internally for reception with a snug fit on the upper end of the cylindrical portion of the plunger 35. A spout 78, bent or curved as shown, projects laterally from the head; discharge passage 79 extending through the spout communicates with head chamber 70. Assembly of the head 37 on the plunger 35 is effected by applying endwise pressure to force the head downwardly on the plunger until it assumes in its manufacture.

the position shown, in which annular beads 39 on the plunger seat in coacting annular grooves in the interior of the head, the head yielding sufiiciently to pass it over the beads. The head and plunger, thus assembled, are fitted together sutficiently tightly to prevent egress of fluid therebetween.

The tapered portion 38 of the plunger 35 terminates short of the upper end of the head 37, providing a chamber 70, into which passage 41 opens. A stud 71, projecting downwardly from the finger rest portion 73 of the head into chamber 70 serves as a retainer for the ball valve 45.

Received within piston 36 and seated in the lower end of barrel 12 is a coil compression spring 52, acting to urge the reciprocable unit upwardly. Ball valve 55, seating by gravity in the lower end of barrel 12, acts as a check valve to prevent drainage of liquid downwardly from the barrel 12. Preferably the seat 56 for-ball valve 55 forms an angle ofat least 45 with the axis of the dispenser to minimize the possibility of wedging of the valve in its seat.

At its lower end the head is formed to provide a depending skirt portion 42, formed with external threads which coast with the internal threads on the collar portion 14 of the barrel 12. When the head is thus screwed down within the collar, as shown in FIGURE 1, coacting inclined surfaces 62 on the head and barrel are pressed together to form a seal preventing discharge of liquid from the container through the slots 18 and externally of the plunger 35. Since movement of liquid upwardly into the lower end ofthe barrel 12 and the plunger 35 is prevented in the fully depressed position of the plunger by direct engagement of the convolutions 60 of the spring 52 with the ball valve 55, leakage of liquid is prevented during handling and shipping, this being of particular importance when toxic liquids, such as insecticides, are used.

It will be appreciated that in order to render the dispenser operative, it is only necessary to unscrew the head from the collar, whereupon the plunger 35 is raised by spring 52. Liquid may then be forced upwardly within the plunger 35 by finger pressure on the upper surface of the head to reciprocate the plunger in barrel 12, whereby the head and plunger are reciprocated in the usual manner.

The reciprocable unit is retained in position in the stationary unit by an inwardly directed annular part 66 which extends into close proximity with the plunger 35 and serves as a bearing surface for guiding the plunger during reciprocation thereof, while limiting outward movement of the plunger in response to the action of spring 52. The annular part 66 is formed after assembly of the two units, by assembling around plunger 35 a cylindrical tool, the tool 'being pressed downwardly against a shoulder formed at the junction of the barrel proper with the collar portion 14 of thelbarrel so as to cause the material to flow inwardly.

It will be understood that the dispenser described herein forms nov part of the instant invention, but is typical of articles which may be formed more readily and with less time and expense when the present invention is employed The details of the dispenser, and more particularly. of the head and the spout, may vary ;widely' from that illustrated herein.

Turning ,nowto, the remaining figures of the drawing, illustrating injection molding apparatus in which the head and spout unit of FIGURE 1 may be cast, it will be seen that the mold or diecomprises the sections designated 80 4 and 81, which are separable onla plane normal to FIG- URE 2 and containing the axis of head core 84. FIG- URE 2 shows the mold sections in assembled relation and after injection of the fiowable plastic material. It will be noted that the free end 85 of core 84 projects into the cavity in which the head 37 is .formed, and is so shaped as to form internally of the head the chamber 70, the stud 71 projecting into the chamber, and the annular grooves for reception of the beads39' formed exteriorly of the plunger 35. The mold cavity in which the head 37 is cast is shaped to form the head illustrated in FIGURE 1, including the collar portion 42 with its external threads and its tapered sealing surface 62, and is closed by a sprue bushing 87 having a gate 88 therein through which the fiowable plastic material may be forced into the mold. Bushing 87 is retained in position by bolt 83 to provide easy removal for cleaning.

these parts need not be separated during normal operation.

In preparation for the casting operation, the separable die section 80, together with core 84, is moved into abutting relation with die section 81 (upwardly in FIG- URE 2) and clamped in position to close the head cavity. The plastic material is then forced under pressure through gate 88 in sprue bushing 87 until the head and spout cavities are filled. After filling, the pressure is increased during a pressure boost period. After a further dwell period, during which the plastic material cools somewhat, mold section and head core 84 are withdrawn from mold section 81 by displacing the same downwardly (FIGURE 2). The formed head 37 is carried downwardly with head core 84 to withdraw the spout 78 endwise from the cavity 89. It will be appreciated that as the spout is thus withdrawn, the bent or curved portion thereof, formed in cavity 91, will be straightened out during its passage through cavity portion 89. However, immediately upon the completion of withdrawal of the spout, the latter resumes the bent or curved configuration shown in FIGURE 2, at least in large part, so that the finished spout has the appearance shown in FIGURE 1.

Mechanism for eifecting displacement of the several parts of the mold as described may be conventional and forms no part of the instant invention. Similarly, the details of the mold may vary considerably from that illustrated in the practice of the invention herein claimed.

The temperature of the plastic material during the casting operation will, of course, depend primarily on the nature of the plastic employed. As injected, the plastic must be fiowable at the pressure employed; conventional injection temperatures, suitable for the plastic material used, may be maintained. The minimum temperature will be that necessary to insure complete filling of the mold cavities; the maximum temperature will be estab- Dwell period, seconds Pressure boost, seconds Injection temperature, F.

Pressure Filling (p.s.i.) time,

seconds Plastic Material Pro-Fax No. PO2005,

clear (Hercules Powder Company, Wilmington, Del), 2. polypropylene resin Marlex N 0. 5000-40 (Phillips Chemical Company, Bartlesville, Okla), a polyethylene highdensity resin 450 The timing above indicated pertains to known procedure in which this initial filling of the mold is efiected at comparatively low pressure. Pressure is then built up to a point within an acceptable known range, usually about 10,000 to 20,000 p.s.i., whereupon the plastic material is allowed to set prior to opening of the mold. Obviously the temperature of the material which forms the spout cannot be accurately determined, but the dwell period is adjusted so that withdrawal of the spout can be efiected readily, and will be followed by resumption of the bend or curve to conform substantially to the desired configuration.

As is hereinbefore indicated, the core 84 may be displaced laterally With the mold section 80 to withdraw the spout from the mold section 81, this being the pre ferred practice. Because of the flexibility of the spout, it has been found unnecessary to effect this displacement in the direction of the straight portion of the spout, and the displacement may be normal to the axis of the core 84 with the resultant simplification of operating mechanism. Following the release of the spout from the mold section 81, core 84 is displaced endwise with respect to mold section 80 (to the right in FIGURE 2) to release the head. A knockout pin (not shown), normally closing drill hole 95, may then be displaced against the cast head 37 to release the latter from mold section 80, if this be necessary.

As illustrated, spout 78 extends downwardly from its point of intersection with head 37. It may project in a direction normal to the head, if desired. Similarly, the curve or bend in the spout may be altered substantially in magnitude and direction from that shown. For instance, the spout may be curved throughout its length, over a substantial portion of its length, or at one point only in its length.

Having thus described the invention, what is claimed as new and desired to be secured by Letters Patent is:

l. In a method of casting an integral plastic article having a hollow body portion and an elongated curved hollow spout portion protruding from said hollow body portion in a mold having cores which intersect to establish communication between the interior of said body portion and said spout portion, the cavity and core for the spout portion being substantially straight adajacent the intersection of said body and spout portions and being curved at a point remote from such intersection, said mold comprising a pair of mold blocks meeting in a plane transverse to the direction of the axis of said spout portion at its juncture with said body portion, comprising the steps of engaging said mold blocks to close said mold, injecting a thermoplastic resin in said mold under pressure and at a temperature at which said resin is sufi'iciently fluid to fill the mold cavity, allowing said resin to harden sufiiciently to retain the shape of the cavity, separating said mold blocks, and maintaining the cavity for the spout portion closed with the core for the spout portion therein while withdrawing said spout portion endwise while at a temperature such that the spout exhibits sufiicient elasticity to straighten during withdrawal and to resume a curved configuration after withdrawal.

2. In a method of casting by injection molding an integral plastic head for use in a fluid pump of the reciprocating type, having a hollow body portion and an elongated curved hollow spout portion protruding from and communicating with the interior of said hollow body portion, in a mold having cores which intersect to establish communication between the interior of said body portion and said spout portion and comprising a pair of mold blocks meeting in a plane transverse to the direction of the axis of said spout portion at its juncture with said body portion, the spout cavity and core having a nonlinear configuration over a portion of their length, comprising the steps of engaging said mold blocks to close said mold, with the cores positioned therein, injecting a thermoplastic resin in said mold under pressure and at a temperature at which said resin is suificiently fluid to fill the mold cavity, allowing said resin to harden sufliciently to retain the shape of the cavity, separating said mold blocks and maintaining the cavity for the spout portion closed with the core for the spout portion therein while withdrawing said spout portion endwise while at a temperature such that the spout portion exhibits sufiicient elasticity to alter its initial configuration during withdrawal and to resume an approximation of its initial configuration after withdrawal.

'3. In a method of casting a unitary plastic article having a hollow body portion and an elongated curved hollow spout portion protruding from and communicating with the interior of said hollow body portion in a mold having cores which intersect to establish communication between the interior of said body portion and said spout portion, the core for said spout portion being curved, said mold comprising a pair of mold blocks meeting in a plane transverse to the direction of the axis of said spout portion at its juncture with said body portion, comprising the steps of engaging said mold blocks to close said mold, injecting a thermoplastic resin in said mold under pressure and at a temperature at which said resin is sufficiently fluid to fill the mold cavity, allowing said resin to harden suiiiciently to retain the shape of the cavity, separating said mold blocks, and maintaining the cavity for the spout portion closed with the core for the spout portion therein while withdrawing said spout portion endwise while at a temperature such that the spout exhibits sufi'icient elasticity to straighten during withdrawal and to resume a curved configuration after Withdrawal.

4. A method of withdrawing from an injection molding die an integral article of thermoplastic resin having a hollow body and an elongated hollow spout protruding laterally from said body and communicating with the interior of said body, said die being formed to provide a body cavity and a spout cavity having therein cores which intersect to establish communication between the interior of said body and spout, said spout having as cast a straight portion adjacent said body and a curved portion remote from said body, which comprises the step of maintaining the cavity for the spout closed with the core for the spout therein while withdrawing said spout endwise from said die while at a temperature such that the spout exhibits suificient elasticity to straighten during withdrawal and to resume substantially its initial configuration after withdrawal.

5. In an injection molding machine for casting an integral plastic head and spout for a fluid dispenser from thermoplastic resin, said head and spout being 7 hollow land afiording a continuous fluid passage, said spout having a straight portion adjacent said head and a curved portion remote from said head, a pair of mold blocks shaped to provide a head cavity in which the head is formed, a'first one of said blocks being shaped to provide an elongated straight cavity in which the straight portion of the spout is formed, said blocks meeting in a plane transverse to the axis of said last named cavity, means secured to said first one of said blocks to provide an elongated curved cavity in which the curved portion of said spout is formed, an integral spout 0 core mounted in said means and extending through said curved and straight'cavities; and a core extending into said head cavity and engaging said spout core. 7

References Citedin the file of this patent UNITED STATES, PATENTS 1,916,692 Scribner 1 v July 4, 1933 2,396,406 Anderson Mar. 12, 1946 10 2,477,368 Gits July 26, 1949 2,860,376 Graves et a1 Nov. 18, 1958

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US23469A US3064310A (en) | 1960-04-20 | 1960-04-20 | Method and apparatus for making plastic articles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US23469A US3064310A (en) | 1960-04-20 | 1960-04-20 | Method and apparatus for making plastic articles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3064310A true US3064310A (en) | 1962-11-20 |

Family

ID=21815288

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US23469A Expired - Lifetime US3064310A (en) | 1960-04-20 | 1960-04-20 | Method and apparatus for making plastic articles |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3064310A (en) |

Cited By (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3182111A (en) * | 1962-07-31 | 1965-05-04 | Gen Electric | Sump construction for a food waste disposer |

| US3199150A (en) * | 1962-10-05 | 1965-08-10 | Clayton Corp Of Delaware | Mold for dispensing spout |

| US3343222A (en) * | 1963-12-12 | 1967-09-26 | Christ D Kacalieff | Molding apparatus |

| US3397266A (en) * | 1966-10-31 | 1968-08-13 | Dow Chemical Co | Method and apparatus for the injection molding of elongate cylindrical articles |

| US3485910A (en) * | 1965-09-16 | 1969-12-23 | Celanese Corp | Method for imparting coatability to polyoxylmethylene compositions |

| US3632277A (en) * | 1968-09-05 | 1972-01-04 | Nibco | Method and apparatus for molding elbows and the like |

| US3746493A (en) * | 1968-09-05 | 1973-07-17 | Nibco | Apparatus for molding elbows and the like |

| US3923949A (en) * | 1973-12-20 | 1975-12-02 | Neil G Kane | Method of forming a such-back-preventing check valve in a liquid dispenser |

| US4017582A (en) * | 1973-01-12 | 1977-04-12 | Naumann John R | Process for making a probe sheet |

| US4125247A (en) * | 1973-06-12 | 1978-11-14 | Chicago Rawhide Manufacturing Company | Apparatus for manufacturing fluid seals |

| US4127632A (en) * | 1975-07-29 | 1978-11-28 | Anton Anger Maschinenbau Gmbh | Method of producing undercut tubular synthetic plastic articles |

| US4519569A (en) * | 1984-04-05 | 1985-05-28 | Maxcap, Inc. | Molding |

| US4856980A (en) * | 1987-09-18 | 1989-08-15 | Schmid Laboratories, Inc. | Injection molding apparatus for making parts having complex geometric shapes |

| US5104606A (en) * | 1989-12-05 | 1992-04-14 | Donoghue Robert J | Method of molding a one-piece measuring and dispensing apparatus |

| US5183188A (en) * | 1989-11-02 | 1993-02-02 | Cebal | Method of making a dispensing head, and the corresponding head and dispenser |

| WO1993013927A1 (en) * | 1992-01-15 | 1993-07-22 | S.C. Johnson & Son, Inc. | In-mold formation and assembly of actuator-overcap and insert nozzle |

| US5470522A (en) * | 1992-08-26 | 1995-11-28 | Thome; Scott P. | Method of molding Y-adapter with a sideport radius |

| US6053371A (en) * | 1998-05-15 | 2000-04-25 | Owens-Illinois Closure Inc. | Pump dispenser and method for making same |

| US6610240B2 (en) * | 2000-09-07 | 2003-08-26 | C.J. Associates, Ltd. | Method of injection molding jointed linkage support |

| EP1075873A3 (en) * | 1999-08-09 | 2004-07-21 | Owens-Illinois Closure Inc. | Pump dispenser having a plunger seal |

| US20060060608A1 (en) * | 2002-02-06 | 2006-03-23 | Jean-Louis Bougamont | Pump liquid product dispenser |

| US7993356B2 (en) | 1998-02-13 | 2011-08-09 | Medtronic, Inc. | Delivering a conduit into a heart wall to place a coronary vessel in communication with a heart chamber and removing tissue from the vessel or heart wall to facilitate such communication |

| US11649982B2 (en) | 2013-12-17 | 2023-05-16 | Belimo Holding Ag | Systems and methods for using a smart valve to control conditioned air |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1916692A (en) * | 1930-05-05 | 1933-07-04 | Doonton Molding Company | Molding of plastic articles |

| US2396406A (en) * | 1944-07-17 | 1946-03-12 | Volney S Anderson | Molding apparatus |

| US2477368A (en) * | 1946-04-17 | 1949-07-26 | Joseph A Gits | Injection molding apparatus |

| US2860376A (en) * | 1954-07-16 | 1958-11-18 | Western Electric Co | Apparatus for molding telephone handset handles |

-

1960

- 1960-04-20 US US23469A patent/US3064310A/en not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1916692A (en) * | 1930-05-05 | 1933-07-04 | Doonton Molding Company | Molding of plastic articles |

| US2396406A (en) * | 1944-07-17 | 1946-03-12 | Volney S Anderson | Molding apparatus |

| US2477368A (en) * | 1946-04-17 | 1949-07-26 | Joseph A Gits | Injection molding apparatus |

| US2860376A (en) * | 1954-07-16 | 1958-11-18 | Western Electric Co | Apparatus for molding telephone handset handles |

Cited By (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3182111A (en) * | 1962-07-31 | 1965-05-04 | Gen Electric | Sump construction for a food waste disposer |

| US3199150A (en) * | 1962-10-05 | 1965-08-10 | Clayton Corp Of Delaware | Mold for dispensing spout |

| US3343222A (en) * | 1963-12-12 | 1967-09-26 | Christ D Kacalieff | Molding apparatus |

| US3485910A (en) * | 1965-09-16 | 1969-12-23 | Celanese Corp | Method for imparting coatability to polyoxylmethylene compositions |

| US3397266A (en) * | 1966-10-31 | 1968-08-13 | Dow Chemical Co | Method and apparatus for the injection molding of elongate cylindrical articles |

| US3632277A (en) * | 1968-09-05 | 1972-01-04 | Nibco | Method and apparatus for molding elbows and the like |

| US3746493A (en) * | 1968-09-05 | 1973-07-17 | Nibco | Apparatus for molding elbows and the like |

| US4017582A (en) * | 1973-01-12 | 1977-04-12 | Naumann John R | Process for making a probe sheet |

| US4125247A (en) * | 1973-06-12 | 1978-11-14 | Chicago Rawhide Manufacturing Company | Apparatus for manufacturing fluid seals |

| US3923949A (en) * | 1973-12-20 | 1975-12-02 | Neil G Kane | Method of forming a such-back-preventing check valve in a liquid dispenser |

| US4127632A (en) * | 1975-07-29 | 1978-11-28 | Anton Anger Maschinenbau Gmbh | Method of producing undercut tubular synthetic plastic articles |

| USRE31404E (en) * | 1975-07-29 | 1983-10-04 | Osterreichische Schiffswerften Aktiengesellschaft Linz-Korneuburg | Method of producing undercut tubular plastic articles |

| US4519569A (en) * | 1984-04-05 | 1985-05-28 | Maxcap, Inc. | Molding |

| US4856980A (en) * | 1987-09-18 | 1989-08-15 | Schmid Laboratories, Inc. | Injection molding apparatus for making parts having complex geometric shapes |

| US5183188A (en) * | 1989-11-02 | 1993-02-02 | Cebal | Method of making a dispensing head, and the corresponding head and dispenser |

| US5104606A (en) * | 1989-12-05 | 1992-04-14 | Donoghue Robert J | Method of molding a one-piece measuring and dispensing apparatus |

| WO1993013927A1 (en) * | 1992-01-15 | 1993-07-22 | S.C. Johnson & Son, Inc. | In-mold formation and assembly of actuator-overcap and insert nozzle |

| US5378422A (en) * | 1992-01-15 | 1995-01-03 | S. C. Johnson & Son, Inc. | Molding mechanism for the in-mold formation and assembly of an actuator-overcap and an insert nozzle and method for using such mechanism |

| US5470522A (en) * | 1992-08-26 | 1995-11-28 | Thome; Scott P. | Method of molding Y-adapter with a sideport radius |

| US7993356B2 (en) | 1998-02-13 | 2011-08-09 | Medtronic, Inc. | Delivering a conduit into a heart wall to place a coronary vessel in communication with a heart chamber and removing tissue from the vessel or heart wall to facilitate such communication |

| US6053371A (en) * | 1998-05-15 | 2000-04-25 | Owens-Illinois Closure Inc. | Pump dispenser and method for making same |

| EP1075873A3 (en) * | 1999-08-09 | 2004-07-21 | Owens-Illinois Closure Inc. | Pump dispenser having a plunger seal |

| US6610240B2 (en) * | 2000-09-07 | 2003-08-26 | C.J. Associates, Ltd. | Method of injection molding jointed linkage support |

| US20060060608A1 (en) * | 2002-02-06 | 2006-03-23 | Jean-Louis Bougamont | Pump liquid product dispenser |

| US7467732B2 (en) * | 2002-02-06 | 2008-12-23 | Rexam Dispensing Systems S.A.S | Pump liquid product dispenser |

| US11649982B2 (en) | 2013-12-17 | 2023-05-16 | Belimo Holding Ag | Systems and methods for using a smart valve to control conditioned air |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3064310A (en) | Method and apparatus for making plastic articles | |

| US2131319A (en) | Method and apparatus for making composite caps | |

| US3013308A (en) | Method for molding and assembling dispenser fitment | |

| US3062416A (en) | Liquid dispenser | |

| US2778533A (en) | Dispensing closure | |

| US5020692A (en) | Container including unitary blow molded bottle having drain-back dispensing spout and plastic insert | |

| US2801444A (en) | Method and apparatus for making hollow articles with one or both ends closed or with both ends open and also for making solid articles | |

| US3154615A (en) | Method of making and assembling a liquid dispenser | |

| US7141202B2 (en) | Method and apparatus for blow molding a bottle with a punched hole in a molded neck recess | |

| US2945266A (en) | Procedure for the manufacture of tubular containers | |

| US11738499B2 (en) | Method of installing a seal for a container prior to container ejection | |

| US2775369A (en) | Dispensing tube closures | |

| US5540582A (en) | Expandable cavity core element for use in an injection molding system | |

| US2794574A (en) | Collapsible tubes | |

| US2789313A (en) | Plastic bottle molding machine | |

| US4115496A (en) | Method for molding a threaded bunghole | |

| US3488805A (en) | Apparatus for forming molded plastic articles | |

| US3721513A (en) | Screw cap closure | |

| US3392861A (en) | Container with closure | |

| US2665945A (en) | Resilient container and closure therefor | |

| US3348744A (en) | Composite self-sealing cap | |

| US3006030A (en) | Manufacture of threaded plastic nipples | |

| EP0329881B1 (en) | Self-draining container | |

| US3829548A (en) | Injection molding process | |

| US11179874B2 (en) | Method of forming a container using a liquid |