US2949202A - Loading and unloading device - Google Patents

Loading and unloading device Download PDFInfo

- Publication number

- US2949202A US2949202A US585582A US58558256A US2949202A US 2949202 A US2949202 A US 2949202A US 585582 A US585582 A US 585582A US 58558256 A US58558256 A US 58558256A US 2949202 A US2949202 A US 2949202A

- Authority

- US

- United States

- Prior art keywords

- fuel

- rod

- gripper

- unloading device

- arm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21C—NUCLEAR REACTORS

- G21C19/00—Arrangements for treating, for handling, or for facilitating the handling of, fuel or other materials which are used within the reactor, e.g. within its pressure vessel

- G21C19/16—Articulated or telescopic chutes or tubes for connection to channels in the reactor core

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21C—NUCLEAR REACTORS

- G21C19/00—Arrangements for treating, for handling, or for facilitating the handling of, fuel or other materials which are used within the reactor, e.g. within its pressure vessel

- G21C19/02—Details of handling arrangements

- G21C19/10—Lifting devices or pulling devices adapted for co-operation with fuel elements or with control elements

- G21C19/115—Lifting devices or pulling devices adapted for co-operation with fuel elements or with control elements with latching devices and ball couplings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E30/00—Energy generation of nuclear origin

- Y02E30/30—Nuclear fission reactors

Definitions

- This invention relates to a loading and unloading device and more particularly to one for loading and unloading the fuel elements contained in a pressurized reactorr

- Large, natural-uranium-fueled power reactors for central use are designed so that fuel may be loaded or unloaded at any time throughout the life of the plant. This requires some type of individual loading for each fuel element. In the case of a pressurized reactor, either liquid-- cooled or boiling, this involves separate unloading means for each of the many fuel elements. If individual fuel tubes were provided for each fuel element, this would result in a greatly weakened pressure-vessel structure due to the large number of holes perforating the shell of the vessel.

- the subject invention allows the number of holes to be considerably reduced by providing means by which any one of a particular group of fuel elements may be withdrawn through a single tube.

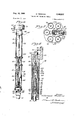

- Fig. 1 is an elevation, partly in section, showing the device suspended within a pressurized reactor

- Fig. 2 is an enlarged vertical sectional view taken on the line 22 of Fig. and showing the device in its collapsed position;

- Fig. 3 is a vertical sectional view taken on the same plane as Fig. 2 but showing the device in its maximum extended position;

- Fig. 4 is an enlarged elevational view of a portion of the device taken on the line 44 of Fig. 2;

- Fig. 5 is a horizontal sectional view taken on the line 5-5 of Fig. 3 and showing the respective position of each fuel element in a particular group;

- Fig. 6 is a sectional view of the gripper mechanism disclosed herein.

- a fuel-unloading device 10 is lowered into a sealed reactor tank 12 through an access tube 14 by means of a cable 16 suspended from a crane, not shown.

- the crane also controls a cable 18, the purpose of which will be disclosed later.

- the unloading device 10 generally consists of a carriage 20, a movable rod 22 within the carriage 20, an arm 24 supported from the carriage 20 by means of links 26, 28, and 30, and a gripper 32 attached to the arm 24.

- the carriage 20 comprises a hollow cylinder 34 having a top plug 36 and a bottom plug 38.

- the top plug 36 has attached at its center a lifting member 40 to receive the cable 16.

- the lower plug 38 has an upper circular portion 42'which is secured to the cylinder 34 such as by welding, and a lower portion 44 which is rectangular in transverse section and somewhat smaller in its greatest transverse 2,949,282 Patented--Aug. re, 1960 ice dimension than the cylinder 34 is in diameter.

- Attached to the sides of the portion 44 of plug 38 are two extensionplates 46 with a spacer 48 secured between the plates 46 at their lower extremity.

- the arm 24 is attached to the carriage 20 by two sets of parallel links 26 and 28 which are pivotally attached to the extension plates 46 and the arm 24 and maintains the arm 24 parallel to the carriage 28.

- the links 26 are pivotally attached to the upper end of the arm 24 and to the portions of the extension plates 46 that overlap the portion 44 of the plug 38.

- the links 28 are pivotally attached to the arm 24 near its lower end and to regions of the extension plates 46 spaced from the portion 44 ofv plug 38.

- the rod 22 is disposed within the carriage 20 and is axially movable parallel to the axis thereof by virtue of being slidably mounted in openings in the plugs 36 and 38.

- the links 30, which are two in number, are pivotally attached to the lower end of the rod 22 and to the arm 24 at its junction with links 26.

- An upper portion 50 of the rod 22 extends through the plug 36 and beyond the upper end of the carriage 20.

- the portion 50 is partially threaded and of a smaller diameter than the portion of the rod 22 below, so that a shoulder 54 is formed on the rod 22 which abuts the plug 36 and so constitutes a stop limitportion 58, formed'at the upper extremity of the rod 22, receives a hook 59 attached to the cable 18.

- An upward pull on the cable 18 shifts the rod 22 axially relative to the carriage 20, resulting in lateral movement of the arm 24 away from the carriage 20 from the position of Fig. 2 to that of Fig. 3.

- the gripper 32 which is attached to the lower end of the arm 24, is of the type shown and claimed in the copending Schultz application, Serial No. 392,531, filed Nohead and neck and is respectively smaller and larger in diameter than the head and neck.

- the balls 68 engage either an internal groove 82 in outer member 62 or an internal surface 84 at the end of the outer member.

- the internal surface 84 is larger in diameter than the groove 82 and is separated therefrom by a shoulder 86.

- Fig. 6 shows the fuel rod 72 engaged by the gripper 32 so that it can be lifted thereby.

- the balls 68 engage the shoulder on the fuel rod 72 and the groove 82 in the outer member 62.

- the gripper 32 is lowered to bring the balls 68 opposite the reduced neck 76.

- the balls 68 may move inwardly to permit the upward shifting of the outer member 62 by which relatively, the balls 68 move past the shoulder 86 to the internal surface 84.

- the balls 68 may move outwardly to permit movement of the head 78 past the balls, whereby the fuel rod 72 is released from the gripper 32.

- the plunger 66 which is spring-urged, follows it to the point where its head lies at the balls 68 and holds them against the internal surface 84 of the outer member 62 and prevents the outer member from returning to the position of Fig. 6 in which the groove 82 lies opposite the balls 68.

- the arm 24 and gripper 32 are positioned'with.

- the unloading device is lowered through the access tube 14 by the cable 1'6-until the arm 240i the unloading device 10 is within the reactor tank 12 and below the access tube 14.

- the gripper. is not, as shown in Fig. 2, inserted in a guide tube 114for the central fuel rod 72, but lies just above this guide tube.

- the unload ing device 1% is then rotated' so as to be oriented toward a particular outer fuel rod 72bymeansnot shown.

- the rod 22 of the device 10 is then raised by the cable 18 until the shoulder 54 of therod. 22 abuts the top plug 36.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- General Engineering & Computer Science (AREA)

- High Energy & Nuclear Physics (AREA)

- Monitoring And Testing Of Nuclear Reactors (AREA)

Description

Aug. 16, 1960 I Filed May 17, 1956 m l lllll z I I VIII/IA VIII; 'IIIIIl/II/I/l/II/I/A E w .l mu I M. TRESHOW LOADING AND UNLOADING DEVICE 2 Sheets-Sheet 1 INVENTOR.

777z'cizaeZ Trash ow LOADING AND UNLOADING DEVICE Filed May 17, 1956 2 Sheets-Sheet 2 g%k/az /&5 A 8 1' w 1: I .90 70-" 80 J66 5 -86 76 r 84 INVENTOR.

' 77Zz'c7zae2 j'upizow 32 I BY (AZ fie? QQ Ruin" LOADING AND UNLOADING DEVICE Michael Treshow, Hiusdale, 111., assignor to the United States of America as represented by the United States Atomic Energy Commission Filed May 17, 1956, Ser. No. 585,582

1 Claim. (Cl. 214658) This invention relates to a loading and unloading device and more particularly to one for loading and unloading the fuel elements contained in a pressurized reactorr Large, natural-uranium-fueled power reactors for central use are designed so that fuel may be loaded or unloaded at any time throughout the life of the plant. This requires some type of individual loading for each fuel element. In the case of a pressurized reactor, either liquid-- cooled or boiling, this involves separate unloading means for each of the many fuel elements. If individual fuel tubes were provided for each fuel element, this would result in a greatly weakened pressure-vessel structure due to the large number of holes perforating the shell of the vessel. The subject invention allows the number of holes to be considerably reduced by providing means by which any one of a particular group of fuel elements may be withdrawn through a single tube.

A pressurized reactor as set forth in the copending Untermyer application, Serial No. 518,427, filed June 28,

1955, is to be visualized. In this reactor the fuel rods are arranged in groups having a hexagonal pattern with a fuel access tube placed directly over the center of each group. The unloading device disclosed herein, operates through this fuel access tube.

This invention will be better understood by referenc to the following description and the appended drawings wherein:

Fig. 1 is an elevation, partly in section, showing the device suspended within a pressurized reactor;

Fig. 2 is an enlarged vertical sectional view taken on the line 22 of Fig. and showing the device in its collapsed position;

Fig. 3 is a vertical sectional view taken on the same plane as Fig. 2 but showing the device in its maximum extended position;

Fig. 4 is an enlarged elevational view of a portion of the device taken on the line 44 of Fig. 2;

Fig. 5 is a horizontal sectional view taken on the line 5-5 of Fig. 3 and showing the respective position of each fuel element in a particular group; and

Fig. 6 is a sectional view of the gripper mechanism disclosed herein.

As illustrated in Fig. 1, a fuel-unloading device 10 is lowered into a sealed reactor tank 12 through an access tube 14 by means of a cable 16 suspended from a crane, not shown. The crane also controls a cable 18, the purpose of which will be disclosed later.

The unloading device 10 generally consists of a carriage 20, a movable rod 22 within the carriage 20, an arm 24 supported from the carriage 20 by means of links 26, 28, and 30, and a gripper 32 attached to the arm 24.

The carriage 20 comprises a hollow cylinder 34 having a top plug 36 and a bottom plug 38. The top plug 36 has attached at its center a lifting member 40 to receive the cable 16. The lower plug 38 has an upper circular portion 42'which is secured to the cylinder 34 such as by welding, anda lower portion 44 which is rectangular in transverse section and somewhat smaller in its greatest transverse 2,949,282 Patented--Aug. re, 1960 ice dimension than the cylinder 34 is in diameter. Attached to the sides of the portion 44 of plug 38 are two extensionplates 46 with a spacer 48 secured between the plates 46 at their lower extremity.

The arm 24 is attached to the carriage 20 by two sets of parallel links 26 and 28 which are pivotally attached to the extension plates 46 and the arm 24 and maintains the arm 24 parallel to the carriage 28. The links 26 are pivotally attached to the upper end of the arm 24 and to the portions of the extension plates 46 that overlap the portion 44 of the plug 38. The links 28 are pivotally attached to the arm 24 near its lower end and to regions of the extension plates 46 spaced from the portion 44 ofv plug 38. The rod 22 is disposed within the carriage 20 and is axially movable parallel to the axis thereof by virtue of being slidably mounted in openings in the plugs 36 and 38. The links 30, which are two in number, are pivotally attached to the lower end of the rod 22 and to the arm 24 at its junction with links 26. An upper portion 50 of the rod 22 extends through the plug 36 and beyond the upper end of the carriage 20. The portion 50 is partially threaded and of a smaller diameter than the portion of the rod 22 below, so that a shoulder 54 is formed on the rod 22 which abuts the plug 36 and so constitutes a stop limitportion 58, formed'at the upper extremity of the rod 22, receives a hook 59 attached to the cable 18. An upward pull on the cable 18 shifts the rod 22 axially relative to the carriage 20, resulting in lateral movement of the arm 24 away from the carriage 20 from the position of Fig. 2 to that of Fig. 3.

' The gripper 32, which is attached to the lower end of the arm 24, is of the type shown and claimed in the copending Schultz application, Serial No. 392,531, filed Nohead and neck and is respectively smaller and larger in diameter than the head and neck. The balls 68 engage either an internal groove 82 in outer member 62 or an internal surface 84 at the end of the outer member. The internal surface 84 is larger in diameter than the groove 82 and is separated therefrom by a shoulder 86.

Fig. 6 shows the fuel rod 72 engaged by the gripper 32 so that it can be lifted thereby. In this position the balls 68 engage the shoulder on the fuel rod 72 and the groove 82 in the outer member 62. When the fuel rod 72 is to be released, it is supported from below, and the gripper 32 is lowered to bring the balls 68 opposite the reduced neck 76. Now the balls 68 may move inwardly to permit the upward shifting of the outer member 62 by which relatively, the balls 68 move past the shoulder 86 to the internal surface 84. Now the balls 68 may move outwardly to permit movement of the head 78 past the balls, whereby the fuel rod 72 is released from the gripper 32. As the head 78 moves out of the gripper 32, the plunger 66, which is spring-urged, follows it to the point where its head lies at the balls 68 and holds them against the internal surface 84 of the outer member 62 and prevents the outer member from returning to the position of Fig. 6 in which the groove 82 lies opposite the balls 68.

The most significant difference between the gripper 32 of the present application and the gripper of the aforementioned Sohultz application is that the outer member 62 is shifted upward with respect to the inner member 64 by means of fluid under pressure. As shown in Fig. 6, such fluid is supplied through a flexible line 88, an elbow 90, a passage 92 in a fitting 94, and passages 96 and 98 in the inner hollowmember64 to an annular space 100' enclosed by the inner and outer hollow members 64' and 62. The space 100is sealed by annular seals 102 and- 104 positioned in annular grooves formedin the" members 94 with which it has a threaded connection. The fitting 94 extends through the'lowerendi' of the. arm24 and is secured thereto by ainut lti'tt'thre'aded on=the fitting 94. When the gripper32 is being'loweredinto thefuel rod'72 for'engagement' therewith, the outer hollow member 62is shifted downward with respect to the. inner hollow member 64 by a coil spring 110 which surrounds an upper portion of the outermemberf 62 and acts'between an external'shoulder thereon and the" lower end of'the fitting 94 which it embraces for a short'distance. members 62 and 64 and the spring 110'are protected by a sleeve 112 which surrounds them in'spaced relation and has a threaded connection'with the fitting 94.

To unload any one of a group of six outer fuelrods 72 located around a centralfuel rod 72 as shown in Figs.

3 and 5, the arm 24 and gripper 32 are positioned'with.

respect to the carriage 20 as shown in Fig. 2; and the unloading device is lowered through the access tube 14 by the cable 1'6-until the arm 240i the unloading device 10 is within the reactor tank 12 and below the access tube 14. However, at this time the gripper. is not, as shown in Fig. 2, inserted in a guide tube 114for the central fuel rod 72, but lies just above this guide tube. The unload ing device 1% is then rotated' so as to be oriented toward a particular outer fuel rod 72bymeansnot shown. The rod 22 of the device 10 is then raised by the cable 18 until the shoulder 54 of therod. 22 abuts the top plug 36. With the rod 22 in this position, the arm 24 is disposed The hollow cable 18 results in the arm 24 returning to the relative position of Fig. 2, that is, adjacent the extension plates 46 of the carriage and free to enter the access tube 14. Now the unloading device 10 and the fuel rod 72 engaged thereby are lifted out of the reactor tank 12 through the access tube 14.

Installation of a new outer fuel rod 72 requires a reversal of the steps just described. The unloading device 10 and thenew fuel'rod 72 engaged thereby are lowered into the reactor tank 12 through the access tube 14, but the fuel rod is-not permitted to enter the central guide tube 114. Now the arm 24 is laterally shifted to the position of Fig. 3 by raising of the rod 22 until the shoulder 54 thereon contactsthe upper plug 36. Next the unloading device 10 and attached fuel rod 72 are lowered into the appropriate guide tube 114 until the fuel rod 72 is supported from below and raised with respect to the gripper 32 above the position of Fig. 3, so that the gripper may release the-fueLrod;

When the central" fuel rod 72 is tobe removed or installed, the position of thearm-24 and gripper 32 with r'espectto thecarriage20shown inFig. 2 is maintained throughout the operations: In this position the gripper 32 is aligned with the central guide tube114 so that it can readily-engage the central-fuel rod 72 for removal or lowering into correct positionfor installation.

Theintention isto limit the invention only within thescope of the appended claim.

What'is claimedis:

A device for'loading and unloading'fuel rods in and out of a reactor tank through an access tubein'the topthereofto and from guidetubes' in thetank parallel to but outof alignment with the access'tube, said device'compris= ing acarriagefittingthe'access tube and'slidably mounted therein for axial movement into and" out of the reactor, a gripper for engaging the ends of the'fuel rods; means including parallel links connecting the'gripper' and the carrier for enabling the gripper to remainparallel' to itselfin all positions'and thus to handle the fuelrods between the parallel guide tubes and a position of alignmentwith the access tube, and means fixing. the parallel links against movement, whereby a fuel rodis moved into or out of its guide tube or through the access tube by axial movement of the carriage in the access tube.

References Cited in-the file of this patent UNITED STATES PATENTS

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US585582A US2949202A (en) | 1956-05-17 | 1956-05-17 | Loading and unloading device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US585582A US2949202A (en) | 1956-05-17 | 1956-05-17 | Loading and unloading device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2949202A true US2949202A (en) | 1960-08-16 |

Family

ID=24342071

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US585582A Expired - Lifetime US2949202A (en) | 1956-05-17 | 1956-05-17 | Loading and unloading device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2949202A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3138535A (en) * | 1958-11-21 | 1964-06-23 | Fortescue Peter | Nuclear reactor having transfer mechanism |

| US3154474A (en) * | 1960-06-08 | 1964-10-27 | Sulzer Ag | Means for securing pressure tubes containing fuel elements in a nuclear reactor |

| US3253995A (en) * | 1963-09-17 | 1966-05-31 | Gen Dynamics Corp | Rod handling equipment for nuclear reactor |

| US4062723A (en) * | 1975-09-29 | 1977-12-13 | Combustion Engineering, Inc. | Core access system for nuclear reactor |

| US4064000A (en) * | 1975-09-29 | 1977-12-20 | Combustion Engineering, Inc. | Nuclear reactor core servicing apparatus |

| US4724607A (en) * | 1983-10-11 | 1988-02-16 | Fragema | Apparatus for rebuilding nuclear fuel assemblies |

| US11289222B2 (en) | 2018-03-16 | 2022-03-29 | Framatome Inc. | Method and device for unlatching control rod drive shafts in pressurized water reactors |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1319872A (en) * | 1919-10-28 | jones | ||

| US2565536A (en) * | 1947-10-30 | 1951-08-28 | Leon D Valentine | Patient lifting device |

| US2632574A (en) * | 1949-12-16 | 1953-03-24 | Raymond C Goertz | Remote-control manipulator |

| US2812587A (en) * | 1954-07-13 | 1957-11-12 | Schlumberger Well Surv Corp | Borehole calipering apparatus |

-

1956

- 1956-05-17 US US585582A patent/US2949202A/en not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1319872A (en) * | 1919-10-28 | jones | ||

| US2565536A (en) * | 1947-10-30 | 1951-08-28 | Leon D Valentine | Patient lifting device |

| US2632574A (en) * | 1949-12-16 | 1953-03-24 | Raymond C Goertz | Remote-control manipulator |

| US2812587A (en) * | 1954-07-13 | 1957-11-12 | Schlumberger Well Surv Corp | Borehole calipering apparatus |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3138535A (en) * | 1958-11-21 | 1964-06-23 | Fortescue Peter | Nuclear reactor having transfer mechanism |

| US3154474A (en) * | 1960-06-08 | 1964-10-27 | Sulzer Ag | Means for securing pressure tubes containing fuel elements in a nuclear reactor |

| US3253995A (en) * | 1963-09-17 | 1966-05-31 | Gen Dynamics Corp | Rod handling equipment for nuclear reactor |

| US4062723A (en) * | 1975-09-29 | 1977-12-13 | Combustion Engineering, Inc. | Core access system for nuclear reactor |

| US4064000A (en) * | 1975-09-29 | 1977-12-20 | Combustion Engineering, Inc. | Nuclear reactor core servicing apparatus |

| US4724607A (en) * | 1983-10-11 | 1988-02-16 | Fragema | Apparatus for rebuilding nuclear fuel assemblies |

| US11289222B2 (en) | 2018-03-16 | 2022-03-29 | Framatome Inc. | Method and device for unlatching control rod drive shafts in pressurized water reactors |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3770583A (en) | Fuel assembly hold-down device | |

| US3836429A (en) | Means for rapidly exposing the core of a nuclear reactor for refueling | |

| US3629062A (en) | Transfer machine for nuclear reactor | |

| US2949202A (en) | Loading and unloading device | |

| ES423370A1 (en) | Gripping apparatus of a lifting device, especially in a core reactor for setting down and lifting fuel elements and fuel rods | |

| US3398050A (en) | Nuclear reactor system | |

| GB1010987A (en) | Improvements in or relating to nuclear reactors | |

| CN103474112A (en) | Reactor internal hoisting tool | |

| US3990591A (en) | Multiple function nuclear handling apparatus | |

| US3383286A (en) | Core element handling system | |

| US3168444A (en) | Servicing apparatus for gas cooled thermal reactors | |

| US4019954A (en) | Safety device for a nuclear reactor and especially a fast reactor | |

| CN202736506U (en) | Reactor internal hoisting tool | |

| US3494827A (en) | Mechanical device for quickly disconnecting drive mechanism from control rod of nuclear reactor | |

| US4030973A (en) | Gripping device, especially for use in manipulating control bars in a nuclear reactor | |

| EP2948958B1 (en) | Nuclear fuel assembly handling apparatus | |

| US7424084B2 (en) | Fuel assembly nozzleless handling tool and method | |

| US4834934A (en) | Thimble grip fuel assembly handling tool | |

| KR900005481A (en) | Apparatus for extracting a closed sleeve from the removable guide tube of the reactor fuel assembly | |

| US20210366624A1 (en) | Nuclear reactor and corresponding maintenance method | |

| CN101850545B (en) | Manipulator for disassembling and assembling lifting bucket of fast reactor loading and unloading material hoister | |

| US3766006A (en) | Rapidly refuelable nuclear reactor | |

| DE102011003462B3 (en) | Device for pulling fuel element from core of pressurized water nuclear reactor provided in position below fuel element-exchanging machine in power plant, has gripping tool vertically adjustably mounted at lower beam at distance from axis | |

| US3359172A (en) | Device for operating neutron-absorbing rods in nuclear reactors | |

| CN115602349A (en) | Storage rack for control rods and guide cylinders and storage method for control rods and guide cylinders |