US2713092A - Push button switch assemblage - Google Patents

Push button switch assemblage Download PDFInfo

- Publication number

- US2713092A US2713092A US217272A US21727251A US2713092A US 2713092 A US2713092 A US 2713092A US 217272 A US217272 A US 217272A US 21727251 A US21727251 A US 21727251A US 2713092 A US2713092 A US 2713092A

- Authority

- US

- United States

- Prior art keywords

- switch

- buttons

- push button

- button switch

- fixed contacts

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/68—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having two operating members, one for opening and one for closing the same set of contacts

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/20—Control lever and linkage systems

- Y10T74/20207—Multiple controlling elements for single controlled element

- Y10T74/20238—Interlocked

- Y10T74/20244—Push button

Definitions

- Push button controls are utilized extensively in conjunction with various types of electrical equipment and systems, and it is exceedingly desirable in order to reumble the cost of production of these switches to a mininum, for the manufacturer to be able to interchangeably convert the same general type of switch assemblage from one form into another. Since it is preferable to mold the bodies and the buttons of these switches of insulation material the major cost of producing the switch units lies in these parts, and We have discovered that by the addition or modification of relatively few of the other minor parts of such assemblages they may be readily transformed from one type of switch into another at vast savings in cost while still maintaining maximum operating efliciency.

- Another important object of this invention is to pro vide an improved push button switch unit having two separate sets of fixed and movable contacts, but wherein one of the fixed contacts of each set may be electrically connected with a fixed contact of the adjacent set by means of a single metallic jumper plate located within the contact confining recess of the switch body.

- a further important object of the invention is to provide an improved push button switch assemblage embodying several push buttons for actuating independent switch units, and wherein simultaneous actuation of the buttons is positively prevented by a simple tumbler conceaied within the switch body.

- Still another important object of our invention is to provide improved dual push button switch assembly having a unitary body of insulating material and a pair of push buttons of like material, both adapted to interchangeably cooperate with contacts of various types so as to convert the assembly from one usage to another without materially altering the body or the buttons.

- An additional object of the present invention is to provide a compact and durable twin button switch which is exceedingly flexible in its adaptations and effectively cooperable as a control unit with diverse types of electricsl equipment and systems.

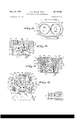

- Fig. l is a front view of a typical two button forward and reverse switch wherein both circuits are normally open but cannot be simultaneously closed, and in which corresponding fixed contacts of the two sets are electrically interconnected, the switch having been removed from its housing;

- Fig. 2 is a section through the push button switch of Fig. 1 taken along the line 22 of Fig. 4 and showing one of the improved interlock tumblers for prevents ing simultaneous closing of both circuits.

- Fig. 3 is another section through the same switch taken centraily therethrough along the line 33 of Fig. 4 and showing the two normally open sets of fixed and movabie contacts;

- Fig. 4 is a rear view of the switch of Fig. 1 with the rear closure plate swung open to reveal the normally open contact assemblages;

- Fig. 5 is a front view of a typical two button starting and stopping switch in which one circuit is normally closed while the other is open, and wherein corresponding fixed contacts of the two sets are electrically inter: connected, the switch having been removed from its housing;

- Fig. 6 is a section through the push button switch of Fig. 5 taken along the line 66 of Fig. 8 and showing a filler plate substituted for the interlock tumbler of Fig. 2;

- Fig. 7 is another section through the switch of Fig. 5 taken centrally thcrethrough along the line '7-7 of Fig. 8 and showing the one normally open and another normally closed set or" switch contacts;

- Fig. 8 is a rear view of the switch of Fig. 5 with the rear closure plate swung open to reveal the two sets of fixed and movable contacts;

- Fig. 9 is a side elevation of a switch such as is shown in Fig. l or 5 mounted within a typical housing which is shown partially in section;

- Fig. 10 is a typical wiring diagram showing the installation of several starting and stopping switch units of the type shown in Figs. 5 to 8 inclusive;

- Fig. 11 is a typical wiring diagram showing the installation of a forward and reverse control switch of the type shown in Figs. 1 to 4 inclusive.

- the gist of the present invention is the provision of a twin push button switch unit wherein the same body and similar button and movable contact assemblages may be interchangeably converted from one kind of usage or functioning to another by mere replacement, addition or rearragement of a few simple parts, and while only two modifications have been shown and described, it is not our desire or intention to unnecessarily restrict the utility of the improved features by virtue of these limited showings. It is moreover contemplated that specific descriptive terms employed herein be given the broadest interpretation consistent with the actual disclosure.

- the forward and reverse push button switch shown therein comprises in general a unitary body 14 having an integral transverse web 15 penetrated by a.

- the body 14 and the push buttons 2%), 21 as well as the tumblers 28 and saddles 29, are preferably formed of suitable insulating materials, and the body 14 is molded as a unitary structure and normally has the rear recess 18 thereof enclosed by a plate 31 also formed of insulation and swingably attached to the rear of the body by a pivot 32 as shown in Figs. 2, 3 and 4.

- the polygonal openings 16 in the web 15 and the rear projections 22 of the buttons 20, 21 may be square or of any other polygonal cross-section in order to prevent the buttons from rotating about their axes, and the front circular recesses 17 are segregated from each other by material of the body 14 while the transverse wall 19 also segregates the rear recess 18 into a pair of deep pockets within which the fixed contacts 25, 26 are confined, see Figs.

- the rear bounding wall of the body recess 18 may also be provided with several conductor outlets 33, and the helical springs 23 which urge the buttons 20, 21 forwardly surround the button projections 22 and are seated in rear grooves 34 formed in the buttons as depicted in Fig. 3.

- the annular fiat movable contacts 24 are washers of metal firmly secured to the rear extremities of the button projections 22 by special screws 36; and, as illustrated in Figs. 2, 3 and 4, the fixed contacts 25, 26 which are also formed of metal, are fastened to the body web 15 by screws 37 and are formed with contact points reaching in back of the movable contacts 24 so as to complete electric circuits thereacross whenever the corresponding buttons 20, 21 are depressed against their springs 23.

- the circuits are therefore normally open, but for certain uses these circuits may be caused to be normally closed by merely reversing the fixed contacts 25, 26 so that the contact points which normally engage the movable contacts 24 are located in front of the latter instead of rearwardly thereof as shown.

- Each of the fixed contacts 25, 26 is also provided with a terminal attaching screw 38; and when it becomes desirable to short-circuit two of the fixed contacts, this may be done by merely applying a metallic U-shaped jumper plate 27 to the screws 38 of the adjacent contacts 25 or 26, in the manner shown in Figs. 2, 3 and 4.

- the improved interlock bars or tumblers 28 which are pivotally detachably pivotally confined between approximately semi-cylindrical sockets 39 formed on the body 14 and similar sockets 39 formed upon the saddles 29, are provided for this specific purpose, and the mid-portion 4d of each tumbler 28 is enlarged to provide a cylindrical pivot coacting with one of the body sockets 39 and with the corresponding sockets 39 of the adjacent saddle 29 while the opposite ends 41 of each tumbler bar are rounded and are normally spaced from the inner ends of the adjacent buttons 29, 21 as depicted in Fig.

- the saddles 29 which are held in place by the adjacent fixed contacts 25, 26 as well as the tumblers 28 are normally concealed within the body 14 but may be readily removed upon removal of the fixed contacts 25, 26; and when these tumbler bars have been applied as shown, they will permit free individual actuation of the two push buttons 20, 21 but will positively prevent simultaneous actuation thereof.

- the typical starting and stopping twin button switch illustrated therein embodies identically the same kind of body 14, movable contacts 24, springs 23, cover plate 31, jumper plate 27, and fixed contacts and buttons, except that the buttons 20, 21' bear different markings or indicia and the fixed contacts 25', 26' have been reversed so as to provide one normally open switch component and another normally closed component.

- the interlock bars or tumblers 28 ordinarily would serve no useful purpose in this type of push button switch, they may be omitted and replaced by specially constructed filler plates 28' as shown in Figs. 6, 7 and 8, which are held in place by the fixed contacts and screws 37. It is to be noted that the.

- the fixed contacts 25, 25' are substantially identical except that they are reversely disposed relative to the web 15, and the same is true of the complementary fixed contacts 26, 26' of the two sets.

- the jumper plate 27 may be applied to either adjacent pair of terminal screws 38, or it may be omitted when no short-circuiting is desired.

- Either of the improved push button switches shown in Figs. 1 and 5 may be mounted within a housing as shown in Fig. 9, and this housing comprises a cup shaped metal casing 43 and a metal cover 44 detachably secured to the casing 43 by means of screws 45 or the like.

- the switch body 14 is provided with sturdy opposite end flanges 46 formed integral therewith, and the outer faces of these flanges 46 coact with and are clamped against the interior of the cover 44 by means of metal clamping plates 47 engaging the opposite faces of the flanges and which are secured to the cover by clamping screws 48.

- The-switch assemblage is thus suspended from the housing cover 44 and is removable therewith in order to facilitate attachment of the conductors and inspection of the inner switch mechanism, and all parts of the improved push button switch may obviously be readily assembled or removed for inspection or replacement.

- two or more of these switch units may be provided at remote stations to operate a common magnetic starter or other electrical apparatus.

- Fig. 10 when several switches are thus employed, it is necessary to remove the U shaped jumper plate 27 from all of the switches except the last station, and all of the switches thus installed may be of identical construction except for the use of the jumper on the end switch.

- the provision of the detachable jumper plate 27 therefore makes it unnecessary to furnish specially constructed end switches and makes it possible to use standard starting and stopping switches at all stations throughout the system.

- this type of switch with its interlock tumblers 28 may be utilized as shown in Fig. 11 to control the operation of magnetic reversing controllers or the like.

- the tumbler bars 28 will then positively prevent an operator from damaging the controller by simultaneously depressing both push buttons 20, 21; and by merely removing the tumblers 28 of Fig. 2 and applying filler plates 28' as in Fig. 6, these switches can be conveniently converted into a type wherein both buttons may if desired be simultaneously manipulated.

- the markings on the exposed faces of the buttons 20, 21 may also be varied to suit the intended usage, and the fixed terminals 25, 26 may be readily assembled so that both circuits will be normally closed, thus introducing extreme flexibility with the aid of only a few interchangeable minor parts.

- buttons 20, 21, springs 23, movable contacts 24, fixed contacts 25, 26, and closure plate 31 may all be utilized in the alternate assemblages, the cost of construction may be reduced to a minimum and erroneous shipments are eliminated.

- the shortcircuiting jumper plates 27 may be quickly applied or removed and make it unnecessary to provide special fixed bridging contacts in these dual switches, and the interlock tumblers 2% and the adjacent saddles 29 may be likewise applied or removed and replaced by inexpensive filler plates 23.

- the improved twin switch assemblages have proven highly satisfactory and successful in actual use, and may be manufactured in various sizes for diverse uses.

- a unitary body of insulation having a pair of front recesses and a rear recess separated by a web provided with openings connecting the front recesses with the rear recess and also having therein a pair of rearwardly open approximately semi-cylindrical pivot sockets adjoining the opposite sides of said front recesses, a push button slidable within each of said front recesses and each having a rear projection extending through the adjacent connecting opening, a movable contact secured to each of said button projections within said rear recess, several fixed contacts detachably secured to said web within said rear recess rearwardly remote from said sockets and being cooperable with said movable contacts, a pair of pivot saddles detachably confined within said rear recess by said fixed contacts and each having a forwardly open approximately semi-cylindrical socket cooperable with one of said body sockets to provide a journal bearing, and a pair of independent interlock tumblers located on opposite sides of said button projections and each having an

- a unitary body of insulation having a pair of front recesses and a rear recess separated by a web provided with openings connecting the front recesses with the rear recess and also having therein a pair of rearwardly open approximately semi-cylindrical pivot sockets adjoining the opposite sides of said front recesses, a push button slidable within each of said front recesses and each having a rear projection extending through the adjacent connecting opening, a movable contact secured to each of said button projections within said rear recess, several fixed contacts detachably secured to said web within said rear recess rearwardly remote from said sockets and being ooperable with said movable contacts, a pair of pivot saddles detachably confined within said rear recess by said fixed contacts and each having a forwardly open approximately semi-cylindrical socket cooperable with one of said body sockets to provide a cylindrical bearing, and a pair of independent interlock tumblers located on opposite sides of said button projections and each having

Landscapes

- Tumbler Switches (AREA)

- Push-Button Switches (AREA)

- Switch Cases, Indication, And Locking (AREA)

Description

J y 1955 E. 1.. RUCKS ET AL 2,713,092

PUSH BUTTON SWITCH ASSEMBLAGE Filed March 23, 1951 3 Sheets-Sheet 1 I w I". y??

Ju y 1955 E. L. RUCKS ET AL 2,713,092

PUSH BUTTON SWITCH ASSEMBLAGE Filed March 23, 1951 3 Sheets-Sheet 2 NVENTOR5 f y 9 1955 E. L. RUCKS ET AL 251.33%2

PUSH BUTTON SWITCH ASSEMBLAGE Filed March 25, 1951 5 Sheets-Sheet 3 I IN VEN TORS MWZMW tates hatent fifice FUSE ii TTUN SWITCH ASSEMBLAGE L. Ruclrs, Aurora, and Nobel H. Koertge, Glen Ell n, ilL, assignors to Furnas Electric Company,

avia, iii, a corporation of Illinois Appiication March 23, 1951, Serial No. 217,272

2 Claims. (Cl. 2iitl5) Push button controls are utilized extensively in conjunction with various types of electrical equipment and systems, and it is exceedingly desirable in order to re duce the cost of production of these switches to a mininum, for the manufacturer to be able to interchangeably convert the same general type of switch assemblage from one form into another. Since it is preferable to mold the bodies and the buttons of these switches of insulation material the major cost of producing the switch units lies in these parts, and We have discovered that by the addition or modification of relatively few of the other minor parts of such assemblages they may be readily transformed from one type of switch into another at vast savings in cost while still maintaining maximum operating efliciency.

it is therefore an important object of our present invention to provie an improved push button switch which may be readily converted for use in one type of control system to another, at minimum cost and without impairing its efficiency.

Another important object of this invention, is to pro vide an improved push button switch unit having two separate sets of fixed and movable contacts, but wherein one of the fixed contacts of each set may be electrically connected with a fixed contact of the adjacent set by means of a single metallic jumper plate located within the contact confining recess of the switch body.

A further important object of the invention is to provide an improved push button switch assemblage embodying several push buttons for actuating independent switch units, and wherein simultaneous actuation of the buttons is positively prevented by a simple tumbler conceaied within the switch body.

Still another important object of our invention is to provide improved dual push button switch assembly having a unitary body of insulating material and a pair of push buttons of like material, both adapted to interchangeably cooperate with contacts of various types so as to convert the assembly from one usage to another without materially altering the body or the buttons.

An additional object of the present invention is to provide a compact and durable twin button switch which is exceedingly flexible in its adaptations and effectively cooperable as a control unit with diverse types of electricsl equipment and systems.

These and other objects and advantages of the invention will be apparent from the following detailed description.

tit)

A clear conception of the features constituting the present improvement, and of the construction and operation of several typical embodiments of the invention, may be had by referring to the. drawings accompanying and forming a part of this specification in which like reference characters designate the same or similar parts in the various views.

Fig. l is a front view of a typical two button forward and reverse switch wherein both circuits are normally open but cannot be simultaneously closed, and in which corresponding fixed contacts of the two sets are electrically interconnected, the switch having been removed from its housing;

Fig. 2 is a section through the push button switch of Fig. 1 taken along the line 22 of Fig. 4 and showing one of the improved interlock tumblers for prevents ing simultaneous closing of both circuits.

Fig. 3 is another section through the same switch taken centraily therethrough along the line 33 of Fig. 4 and showing the two normally open sets of fixed and movabie contacts;

Fig. 4 is a rear view of the switch of Fig. 1 with the rear closure plate swung open to reveal the normally open contact assemblages;

Fig. 5 is a front view of a typical two button starting and stopping switch in which one circuit is normally closed while the other is open, and wherein corresponding fixed contacts of the two sets are electrically inter: connected, the switch having been removed from its housing;

Fig. 6 is a section through the push button switch of Fig. 5 taken along the line 66 of Fig. 8 and showing a filler plate substituted for the interlock tumbler of Fig. 2;

Fig. 7 is another section through the switch of Fig. 5 taken centrally thcrethrough along the line '7-7 of Fig. 8 and showing the one normally open and another normally closed set or" switch contacts;

Fig. 8 is a rear view of the switch of Fig. 5 with the rear closure plate swung open to reveal the two sets of fixed and movable contacts;

Fig. 9 is a side elevation of a switch such as is shown in Fig. l or 5 mounted within a typical housing which is shown partially in section;

Fig. 10 is a typical wiring diagram showing the installation of several starting and stopping switch units of the type shown in Figs. 5 to 8 inclusive; and

Fig. 11 is a typical wiring diagram showing the installation of a forward and reverse control switch of the type shown in Figs. 1 to 4 inclusive.

The gist of the present invention is the provision of a twin push button switch unit wherein the same body and similar button and movable contact assemblages may be interchangeably converted from one kind of usage or functioning to another by mere replacement, addition or rearragement of a few simple parts, and while only two modifications have been shown and described, it is not our desire or intention to unnecessarily restrict the utility of the improved features by virtue of these limited showings. It is moreover contemplated that specific descriptive terms employed herein be given the broadest interpretation consistent with the actual disclosure.

Referring particularly to Figs. 1 to 4 and 11 of. thedrawings, the forward and reverse push button switch shown therein, comprises in general a unitary body 14 having an integral transverse web 15 penetrated by a.

ward and reverse cylindrical push buttons 29, 21 slidably confined within the two front recesses 17 and each having an integral polygonal rear projection 22 slidable through the adjacent web opening 16; a helical compression spring 23 coacting with the web 15 and with each button 20, 21 within each front recess 17 for constantly urging the buttons forwardly within their confining recesses; an annular fiat movable contact 24 secured to the rear extremity of each of the polygonal button projections 22 and being engageable with the web 15 to limit the forward movement of the corresponding button 20, 21; a pair or set of fixed contacts 25, 26 secured to the web 15 within the rear recess 18 on each side of the wall 19 and being alternately cooperable with the movable contacts 24 carried by the buttons 20, 21; a U-shaped jumper plate 27 spanning the wall 19 and detachably uniting the fixed contacts 25 of the segregated sets; and a pair of laterally spaced interlock bars or tumblers 28 pivotally mounted in removable saddles 29 disposed on opposite sides of the button projections 22 and held in place by the fixed contacts 25, 26, these tumblers 28 being cooperable with the buttons 20, 21 to positively prevent simultaneous closing of the two electric circuits controlled by these buttons.

The body 14 and the push buttons 2%), 21 as well as the tumblers 28 and saddles 29, are preferably formed of suitable insulating materials, and the body 14 is molded as a unitary structure and normally has the rear recess 18 thereof enclosed by a plate 31 also formed of insulation and swingably attached to the rear of the body by a pivot 32 as shown in Figs. 2, 3 and 4. The polygonal openings 16 in the web 15 and the rear projections 22 of the buttons 20, 21 may be square or of any other polygonal cross-section in order to prevent the buttons from rotating about their axes, and the front circular recesses 17 are segregated from each other by material of the body 14 while the transverse wall 19 also segregates the rear recess 18 into a pair of deep pockets within which the fixed contacts 25, 26 are confined, see Figs.

1, 3 and 4. The rear bounding wall of the body recess 18 may also be provided with several conductor outlets 33, and the helical springs 23 which urge the buttons 20, 21 forwardly surround the button projections 22 and are seated in rear grooves 34 formed in the buttons as depicted in Fig. 3.

The annular fiat movable contacts 24 are washers of metal firmly secured to the rear extremities of the button projections 22 by special screws 36; and, as illustrated in Figs. 2, 3 and 4, the fixed contacts 25, 26 which are also formed of metal, are fastened to the body web 15 by screws 37 and are formed with contact points reaching in back of the movable contacts 24 so as to complete electric circuits thereacross whenever the corresponding buttons 20, 21 are depressed against their springs 23. In this particular switch the circuits are therefore normally open, but for certain uses these circuits may be caused to be normally closed by merely reversing the fixed contacts 25, 26 so that the contact points which normally engage the movable contacts 24 are located in front of the latter instead of rearwardly thereof as shown. Each of the fixed contacts 25, 26 is also provided with a terminal attaching screw 38; and when it becomes desirable to short-circuit two of the fixed contacts, this may be done by merely applying a metallic U-shaped jumper plate 27 to the screws 38 of the adjacent contacts 25 or 26, in the manner shown in Figs. 2, 3 and 4.

In a push button switch of the type illustrated in Figs. 1 to 4 inclusive, and wherein manipulation of the two buttons either closes or opens each of the two circuits, it is ordinariliy desirable to prevent simultaneous depression of both buttons 20, 21. The improved interlock bars or tumblers 28 which are pivotally detachably pivotally confined between approximately semi-cylindrical sockets 39 formed on the body 14 and similar sockets 39 formed upon the saddles 29, are provided for this specific purpose, and the mid-portion 4d of each tumbler 28 is enlarged to provide a cylindrical pivot coacting with one of the body sockets 39 and with the corresponding sockets 39 of the adjacent saddle 29 while the opposite ends 41 of each tumbler bar are rounded and are normally spaced from the inner ends of the adjacent buttons 29, 21 as depicted in Fig. 2. The saddles 29 which are held in place by the adjacent fixed contacts 25, 26 as well as the tumblers 28 are normally concealed within the body 14 but may be readily removed upon removal of the fixed contacts 25, 26; and when these tumbler bars have been applied as shown, they will permit free individual actuation of the two push buttons 20, 21 but will positively prevent simultaneous actuation thereof.

Referring especially to Figs. 5 to 8 and 11 of the drawings, the typical starting and stopping twin button switch illustrated therein embodies identically the same kind of body 14, movable contacts 24, springs 23, cover plate 31, jumper plate 27, and fixed contacts and buttons, except that the buttons 20, 21' bear different markings or indicia and the fixed contacts 25', 26' have been reversed so as to provide one normally open switch component and another normally closed component. Since the interlock bars or tumblers 28 ordinarily would serve no useful purpose in this type of push button switch, they may be omitted and replaced by specially constructed filler plates 28' as shown in Figs. 6, 7 and 8, which are held in place by the fixed contacts and screws 37. It is to be noted that the. fixed contacts 25, 25' are substantially identical except that they are reversely disposed relative to the web 15, and the same is true of the complementary fixed contacts 26, 26' of the two sets. As in the case of the forward and reverse switch, the jumper plate 27 may be applied to either adjacent pair of terminal screws 38, or it may be omitted when no short-circuiting is desired.

Either of the improved push button switches shown in Figs. 1 and 5 may be mounted within a housing as shown in Fig. 9, and this housing comprises a cup shaped metal casing 43 and a metal cover 44 detachably secured to the casing 43 by means of screws 45 or the like. The switch body 14 is provided with sturdy opposite end flanges 46 formed integral therewith, and the outer faces of these flanges 46 coact with and are clamped against the interior of the cover 44 by means of metal clamping plates 47 engaging the opposite faces of the flanges and which are secured to the cover by clamping screws 48. The-switch assemblage is thus suspended from the housing cover 44 and is removable therewith in order to facilitate attachment of the conductors and inspection of the inner switch mechanism, and all parts of the improved push button switch may obviously be readily assembled or removed for inspection or replacement.

When the improved starting and stopping switches have been properly constructed and assembled, two or more of these switch units may be provided at remote stations to operate a common magnetic starter or other electrical apparatus. As depicted in Fig. 10, when several switches are thus employed, it is necessary to remove the U shaped jumper plate 27 from all of the switches except the last station, and all of the switches thus installed may be of identical construction except for the use of the jumper on the end switch. The provision of the detachable jumper plate 27 therefore makes it unnecessary to furnish specially constructed end switches and makes it possible to use standard starting and stopping switches at all stations throughout the system.

When the improved forward and reverse switches have been properly constructed and assembled, this type of switch with its interlock tumblers 28 may be utilized as shown in Fig. 11 to control the operation of magnetic reversing controllers or the like. The tumbler bars 28 will then positively prevent an operator from damaging the controller by simultaneously depressing both push buttons 20, 21; and by merely removing the tumblers 28 of Fig. 2 and applying filler plates 28' as in Fig. 6, these switches can be conveniently converted into a type wherein both buttons may if desired be simultaneously manipulated. The markings on the exposed faces of the buttons 20, 21 may also be varied to suit the intended usage, and the fixed terminals 25, 26 may be readily assembled so that both circuits will be normally closed, thus introducing extreme flexibility with the aid of only a few interchangeable minor parts.

From the foregoing detailed description it should be apparent that we have in fact produced an improved push button switch assemblage which is simple, compact and durable in construction, and which is also flexible in its adaptations and highly efiicient in use. Since the major parts such as the body 14, buttons 20, 21, springs 23, movable contacts 24, fixed contacts 25, 26, and closure plate 31 may all be utilized in the alternate assemblages, the cost of construction may be reduced to a minimum and erroneous shipments are eliminated. The shortcircuiting jumper plates 27 may be quickly applied or removed and make it unnecessary to provide special fixed bridging contacts in these dual switches, and the interlock tumblers 2% and the adjacent saddles 29 may be likewise applied or removed and replaced by inexpensive filler plates 23. All parts of the improved switches are moreover well insulated to insure safe operation and to avoid undesirable short-circuiting, and these switches may be either mounted within housings or otherwise supported when in actual use. The improved twin switch assemblages have proven highly satisfactory and successful in actual use, and may be manufactured in various sizes for diverse uses.

It should be understood that it is not intended to limit the present invention to the exact details of construction or to the precise mode of use of the two typical push button switch assemblages herein illustrated, for various modifications within the scope of the appended claims may occur to persons skilled in the art.

We claim:

1. In an electric switch, a unitary body of insulation having a pair of front recesses and a rear recess separated by a web provided with openings connecting the front recesses with the rear recess and also having therein a pair of rearwardly open approximately semi-cylindrical pivot sockets adjoining the opposite sides of said front recesses, a push button slidable within each of said front recesses and each having a rear projection extending through the adjacent connecting opening, a movable contact secured to each of said button projections within said rear recess, several fixed contacts detachably secured to said web within said rear recess rearwardly remote from said sockets and being cooperable with said movable contacts, a pair of pivot saddles detachably confined within said rear recess by said fixed contacts and each having a forwardly open approximately semi-cylindrical socket cooperable with one of said body sockets to provide a journal bearing, and a pair of independent interlock tumblers located on opposite sides of said button projections and each having an enlarged cylindrical medial portion oscillatably confined within one of said journal bearings and also having opposite ends engageable with peripheral portions of both of said push buttons.

2. In an electric switch, a unitary body of insulation having a pair of front recesses and a rear recess separated by a web provided with openings connecting the front recesses with the rear recess and also having therein a pair of rearwardly open approximately semi-cylindrical pivot sockets adjoining the opposite sides of said front recesses, a push button slidable within each of said front recesses and each having a rear projection extending through the adjacent connecting opening, a movable contact secured to each of said button projections within said rear recess, several fixed contacts detachably secured to said web within said rear recess rearwardly remote from said sockets and being ooperable with said movable contacts, a pair of pivot saddles detachably confined within said rear recess by said fixed contacts and each having a forwardly open approximately semi-cylindrical socket cooperable with one of said body sockets to provide a cylindrical bearing, and a pair of independent interlock tumblers located on opposite sides of said button projections and each having an enlarged cylindrical midportion oscillatably confined within one of said bearings and also having integral opposite ends engageable with peripheral rear portions of both of said push buttons, said tumblers being freely rearwardly removable upon release of said fixed contacts.

References Cited in the file of this patent UNITED STATES PATENTS 1,257,287 Kaisling Feb. 19, 1918 1,293,794 Kaisling Feb. 11, 1919 2,303,833 Furnas et a1. Dec. 1, 1942 2,363,854 Bierenfeld Nov. 28, 1944 2,550,777 Cobb et al May 1, 1951

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US217272A US2713092A (en) | 1951-03-23 | 1951-03-23 | Push button switch assemblage |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US217272A US2713092A (en) | 1951-03-23 | 1951-03-23 | Push button switch assemblage |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2713092A true US2713092A (en) | 1955-07-12 |

Family

ID=22810355

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US217272A Expired - Lifetime US2713092A (en) | 1951-03-23 | 1951-03-23 | Push button switch assemblage |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2713092A (en) |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2832850A (en) * | 1955-05-20 | 1958-04-29 | Square D Co | Interlock push button electric switch |

| US2843686A (en) * | 1948-08-05 | 1958-07-15 | Fed Pacific Electric Co | Push button stations |

| US2989599A (en) * | 1951-09-08 | 1961-06-20 | Fawick Corp | Automatic overdrive and transmission system |

| US3051799A (en) * | 1957-04-17 | 1962-08-28 | Siemens Ag | Keyboard for use in signalling systems |

| US3086090A (en) * | 1958-12-05 | 1963-04-16 | Duff Norton Co | Electric switching mechanism |

| US3164688A (en) * | 1961-02-13 | 1965-01-05 | Itt | Manually operated, multi-button interlocking pushbutton key set |

| US3204068A (en) * | 1962-11-08 | 1965-08-31 | Gen Electric | Electric switch having contacts convertible between normally open and normally closed conditions |

| US3303295A (en) * | 1965-08-11 | 1967-02-07 | Cutler Hammer Inc | Pushbutton selector switches |

| US3368173A (en) * | 1967-04-27 | 1968-02-06 | Byron F. Wolford | Hermetically sealed, pressure responsive, magnetically actuated switch device |

| US3391257A (en) * | 1967-02-14 | 1968-07-02 | Westinghouse Electric Corp | Maintained-position interlocking mechanism for interlocking a pair of pushbutton switches |

| US3392598A (en) * | 1966-02-24 | 1968-07-16 | Cutler Hammer Inc | Pushbutton adapter for electrical switch assembly with latched and momentary pushbuttons |

| US3501603A (en) * | 1968-07-05 | 1970-03-17 | Furnas Electric Co | Contact block assembly with interlock secured by means of a single screw |

| US4356363A (en) * | 1979-09-18 | 1982-10-26 | Siemens Aktiengesellschaft | Locking device for contact carriers |

| US5045647A (en) * | 1989-03-17 | 1991-09-03 | Shinkoh Electric To., Ltd. | Interlocking device for push-button switch |

| US5614701A (en) * | 1995-06-27 | 1997-03-25 | Hung; Michael | Control switch for electric winch |

| US5646382A (en) * | 1994-08-18 | 1997-07-08 | Kasuga Denki Kabushiki Kaisha | Multiple push button switch assembly with multistage actuator interlock |

| US20050138972A1 (en) * | 2003-12-26 | 2005-06-30 | Park Hye Y. | Button assembly and washing machine having the same |

| US20170287657A1 (en) * | 2014-12-15 | 2017-10-05 | Omron Corporation | Push button switch |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1257287A (en) * | 1914-06-05 | 1918-02-19 | Kellogg Switchboard & Supply | Switch device. |

| US1293794A (en) * | 1913-10-27 | 1919-02-11 | Kellogg Switchboard & Supply | Electrical switch. |

| US2303833A (en) * | 1941-05-31 | 1942-12-01 | William C Furnas | Push button switch assembly |

| US2363854A (en) * | 1937-12-01 | 1944-11-28 | Square D Co | Push button switch and mounting |

| US2550777A (en) * | 1949-10-12 | 1951-05-01 | Furnas Electric Co | Push-button electric switch |

-

1951

- 1951-03-23 US US217272A patent/US2713092A/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1293794A (en) * | 1913-10-27 | 1919-02-11 | Kellogg Switchboard & Supply | Electrical switch. |

| US1257287A (en) * | 1914-06-05 | 1918-02-19 | Kellogg Switchboard & Supply | Switch device. |

| US2363854A (en) * | 1937-12-01 | 1944-11-28 | Square D Co | Push button switch and mounting |

| US2303833A (en) * | 1941-05-31 | 1942-12-01 | William C Furnas | Push button switch assembly |

| US2550777A (en) * | 1949-10-12 | 1951-05-01 | Furnas Electric Co | Push-button electric switch |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2843686A (en) * | 1948-08-05 | 1958-07-15 | Fed Pacific Electric Co | Push button stations |

| US2989599A (en) * | 1951-09-08 | 1961-06-20 | Fawick Corp | Automatic overdrive and transmission system |

| US2832850A (en) * | 1955-05-20 | 1958-04-29 | Square D Co | Interlock push button electric switch |

| US3051799A (en) * | 1957-04-17 | 1962-08-28 | Siemens Ag | Keyboard for use in signalling systems |

| US3086090A (en) * | 1958-12-05 | 1963-04-16 | Duff Norton Co | Electric switching mechanism |

| US3164688A (en) * | 1961-02-13 | 1965-01-05 | Itt | Manually operated, multi-button interlocking pushbutton key set |

| US3204068A (en) * | 1962-11-08 | 1965-08-31 | Gen Electric | Electric switch having contacts convertible between normally open and normally closed conditions |

| US3303295A (en) * | 1965-08-11 | 1967-02-07 | Cutler Hammer Inc | Pushbutton selector switches |

| US3392598A (en) * | 1966-02-24 | 1968-07-16 | Cutler Hammer Inc | Pushbutton adapter for electrical switch assembly with latched and momentary pushbuttons |

| US3391257A (en) * | 1967-02-14 | 1968-07-02 | Westinghouse Electric Corp | Maintained-position interlocking mechanism for interlocking a pair of pushbutton switches |

| US3368173A (en) * | 1967-04-27 | 1968-02-06 | Byron F. Wolford | Hermetically sealed, pressure responsive, magnetically actuated switch device |

| US3501603A (en) * | 1968-07-05 | 1970-03-17 | Furnas Electric Co | Contact block assembly with interlock secured by means of a single screw |

| US4356363A (en) * | 1979-09-18 | 1982-10-26 | Siemens Aktiengesellschaft | Locking device for contact carriers |

| US5045647A (en) * | 1989-03-17 | 1991-09-03 | Shinkoh Electric To., Ltd. | Interlocking device for push-button switch |

| US5646382A (en) * | 1994-08-18 | 1997-07-08 | Kasuga Denki Kabushiki Kaisha | Multiple push button switch assembly with multistage actuator interlock |

| US5614701A (en) * | 1995-06-27 | 1997-03-25 | Hung; Michael | Control switch for electric winch |

| US20050138972A1 (en) * | 2003-12-26 | 2005-06-30 | Park Hye Y. | Button assembly and washing machine having the same |

| US7395682B2 (en) * | 2003-12-26 | 2008-07-08 | Lg Electronics Inc. | Button assembly and washing machine having the same |

| US20170287657A1 (en) * | 2014-12-15 | 2017-10-05 | Omron Corporation | Push button switch |

| US10056202B2 (en) * | 2014-12-15 | 2018-08-21 | Omron Corporation | Push button switch |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2713092A (en) | Push button switch assemblage | |

| US2626334A (en) | Electric switch | |

| US2352815A (en) | Electric switch | |

| US2748208A (en) | Oiltight rotary selector switch | |

| US3388358A (en) | Circuit breaker | |

| US2128373A (en) | Circuit controlling device | |

| US2814681A (en) | Electric switch assemblage | |

| US2620409A (en) | Single pole double throw switch | |

| US1394087A (en) | Cut-out switch | |

| US2681393A (en) | Switch | |

| US2201875A (en) | Outlet receptacle switch | |

| US2574290A (en) | Multiple unit switch with single actuator | |

| US2849572A (en) | Fusible electric switch | |

| US1610479A (en) | Switch-housing structure | |

| US2210037A (en) | Electric switch | |

| US2303833A (en) | Push button switch assembly | |

| US3598935A (en) | Multiple pole electrical switch with improved snap-action actuator structure | |

| US2438640A (en) | Switch assembly | |

| US2557493A (en) | Electric switch using a bridge contact for either single throw or double throw operation | |

| GB1002370A (en) | Improvements relating to high voltage circuit-breaker systems | |

| US2617903A (en) | Electric switch | |

| US2603733A (en) | Electrical switch | |

| US594944A (en) | Electric switch | |

| US2614194A (en) | Switch structure | |

| US2894080A (en) | 100 ampere disconnect push switch |