US2696285A - Apparatus for orderly arranging bottle caps or the like - Google Patents

Apparatus for orderly arranging bottle caps or the like Download PDFInfo

- Publication number

- US2696285A US2696285A US130543A US13054349A US2696285A US 2696285 A US2696285 A US 2696285A US 130543 A US130543 A US 130543A US 13054349 A US13054349 A US 13054349A US 2696285 A US2696285 A US 2696285A

- Authority

- US

- United States

- Prior art keywords

- tube

- caps

- hopper

- articles

- cap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67B—APPLYING CLOSURE MEMBERS TO BOTTLES JARS, OR SIMILAR CONTAINERS; OPENING CLOSED CONTAINERS

- B67B3/00—Closing bottles, jars or similar containers by applying caps

- B67B3/02—Closing bottles, jars or similar containers by applying caps by applying flanged caps, e.g. crown caps, and securing by deformation of flanges

- B67B3/06—Feeding caps to capping heads

- B67B3/064—Feeding caps to capping heads from a hopper

- B67B3/0645—Feeding caps to capping heads from a hopper with means for orientating the caps to a position ready to be applied to the container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23D—PLANING; SLOTTING; SHEARING; BROACHING; SAWING; FILING; SCRAPING; LIKE OPERATIONS FOR WORKING METAL BY REMOVING MATERIAL, NOT OTHERWISE PROVIDED FOR

- B23D33/00—Accessories for shearing machines or shearing devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q7/00—Arrangements for handling work specially combined with or arranged in, or specially adapted for use in connection with, machine tools, e.g. for conveying, loading, positioning, discharging, sorting

- B23Q7/12—Sorting arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/02—Devices for feeding articles or materials to conveyors

- B65G47/04—Devices for feeding articles or materials to conveyors for feeding articles

- B65G47/06—Devices for feeding articles or materials to conveyors for feeding articles from a single group of articles arranged in orderly pattern, e.g. workpieces in magazines

- B65G47/08—Devices for feeding articles or materials to conveyors for feeding articles from a single group of articles arranged in orderly pattern, e.g. workpieces in magazines spacing or grouping the articles during feeding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/02—Devices for feeding articles or materials to conveyors

- B65G47/04—Devices for feeding articles or materials to conveyors for feeding articles

- B65G47/12—Devices for feeding articles or materials to conveyors for feeding articles from disorderly-arranged article piles or from loose assemblages of articles

- B65G47/14—Devices for feeding articles or materials to conveyors for feeding articles from disorderly-arranged article piles or from loose assemblages of articles arranging or orientating the articles by mechanical or pneumatic means during feeding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/22—Devices influencing the relative position or the attitude of articles during transit by conveyors

- B65G47/24—Devices influencing the relative position or the attitude of articles during transit by conveyors orientating the articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/52—Devices for transferring articles or materials between conveyors i.e. discharging or feeding devices

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S29/00—Metal working

- Y10S29/046—Vibration

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Feeding Of Articles To Conveyors (AREA)

Description

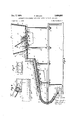

P. ZENLEA Deg. 7, 19 54 APPARATUS FOR ORDERLY ARRANGING BOTTLE CAPS OR THE LIKE Filed Dec. 1,}1949 2 Sheets$heet 1 INVENTOR. Per -y Zezzlea BY m M L m Q-L 146 tornq'g/s.

P. ZENLEA 2,696,285

2 Sheets-Sheet 2 Dec. 7, 1954 APPARATUS FOR ORDERLY ARRANGING BOTTLE CAPS ORTHE LIKE Filed Dec. 1, 1949 a, e Ww J v R. m Q nwv-u rm m W V r r A $3? M mm QQ fi United States Patent C) APPARATUS FOR ORDERLY ARRANGING BOTTLE CAPS OR THE LIKE Perry Zenlea, Forest; Hills, N. Y.

Application December 1, 1949, Serial No. 130,543

" Claims. (Cl. 193-43) This invention. relates tov apparatus for, and. a method of; arranging articles, especially bottle; caps or the like.

It. is an object of the present invention to provide apparatus for arranging bottle. caps or similar cup-shaped articles. from, a dumped supply thereof in. predetermined orderly disposition, without subjecting them. to any considerable jars in the course of their arrangement.

It is a more particular object of the present invention to provide apparatus of thisv type in which highly polished, light-Weight metal caps, such as, are. used for closing perfume. bottles, for instance, are arranged. in orderly disposition withoutv becoming marred in any way.

It is another object of the present invention to provide apparatus of this type. in which the caps are. orderly arranged by supporting thern on a curved surface on which they may readily turn over into correct disposition with their centers. of gravity lowermost, i. e., with their bottoms; down, and by subjecting them to vibration. of such. small. amplitude and. high frequency that they barely rub and. never mar each other, yet are compelled. to turn into correct disposition on the curved supporting surface unless. they are already correctly disposed thereon.

It is. another object. of the. present invention. to provide apparatus of this type. in which the curved supporting surface for the caps is formed. by the. interior Wall of a. tube which isv in alignment with, and slightly inclined to.- ward, a, chute, and. which is, itself vibrated. and. imparts its vibrations to the caps. therein so. that the latter are, solely by the vibrations imparted thereto, advanced. in the. tube in a substantially continuous motion toward. and into. the. chute. in which they are guided to a station at which they may be. applied to bottles.

It is. another object of thepresent invention to provide. apparatus of this type which. is-v very simple in. construction, yet; reliable in operation, and. which. affords readyinspection of the caps in the course of their orderly arrangement for the detection and ready removal of any cap or caps that may be misarranged and. has no. further opportunity to become properly arranged.

The above and other objects, features and. advantages of: the. present invention will be more. fully understood from the, following description considered in connection with the accompanying illustrative. drawings.

In. the drawings:

Fig. 1 is a fragmentary top. plan view of apparatus em.- bodying the present. invention;

Fig. 2 is a section, partly in elevation, of the apparatus, tlz he, slection being taken substantially on the line. 22' of- F Fig. 3. is an enlarged section taken onthe line 3-3 of Figs. 4 and 5 are sections similar to Fig. 3, showing a cap to be arranged. in a certain part of the apparatus in different positions therein;

Fig. 6, is a side elevation partly in section, of a part of. the apparatus; and

Fig. 7 is a view taken: on the line 7.7 ofFig. 6.

Referring to the drawings, the reference numeral 10. designates a main support or table. on which is mountedla raised platform 14 through intermediation of a plurality of upright posts 12. Arranged above the platform 14 is ahopper 16 and a. cap-arranging device D. Dumpedv into the hopper 16 may be. a. supply of bottle caps. c, for in.- stance, for their orderIy arrangement; in the present apparatus to be ultimately applied. to bottles, preferably inthe. same apparatus. Sin e the hopper; 16, is, in accord? ance with. the present. invention, vibrated. substantially Patented Dec. 7, 1954 "ice 2,. vertically for the continuous discharge therefrom of the caps e therein, the same is resiliently mounted at its; bottom on. upright posts 20: which are, in turn, mounted at 22 on the platform 14., Conveniently, the hopper 16 is mounted at 24 onrubber or like resilient pads. 26 in cas.- lugs 28 on the. top ends of the posts 20, respectively. The hopper 16 is vibrated by any conventional, preferably electrically operated vibrator V which is suitably mounted at 30 on the bottom of the. hopper 16. The hopper 16 is, in the. present instance, provided with a bottom wa1l32 of, sheet metal, for instance, and. side and end walls 34 and 3.6, respectively, which are preferably made. of transparent. plastic, Preferably, the bottom wall. 32' of. the hopper is; lined. with a plastic sheet37. The side and end walls 3'4 and 36 of the hopper 16. may conveniently be mounted on corner angles. 38 which are, in turn, mounted in any suitable: manner on the bottom wall 32.

Suitably secured to, and extending forwardly from, the bottom wall. 32- of the hopper 16 is a supporting. plate; 42 on which is suitably mounted a guide 44 in which. caps. leaving the hopper 16 through a discharge opening 46 in the end. wall 36' thereof are directed toward and into the. device. D. The guide 44 may be generally U-shaped' in cross-section. so as. to compel the discharged caps c to pass in single file therethrough (Fig. 1'). For ready inspection of the caps c, the guide 44 is, like the side and end walls. of the hopper 16, preferably made. of any suit.- able transparent plastic material. For the ready discharge of the caps 0 through the opening 46. in the vibrating hopper 16,. the latter is, with its: bottom wall 32 slightly inclined to a horizontal plane as. shown in Fig. 2. The guide 44, which vibrates with the hopper 16,. is likewise inclined to a horizontal plane to compel. the caps c therein to move toward the discharge end 45 thereof. Further, the. hopper 1.6.: is divided. into main and auxiliary compartments 50 and. 52, respectively, by a transverse partition, 54 (Fig. 2), which: has an opening 56 for the passage of caps c from the main compartment. 50 to the auxiliary compartment 52. The. partition 54 rests on the bottom of the hopper. 16 and also against, a transverse bracev 55 in the latter, and is, otherwise suitably mounted in. the hopper. The opening 56 in the partition 54 is of a height to permit the. simultaneous passage therethrough of only a few superposed caps, but may beof a width transversely of thehopper. to permit the simultaneous passage therethrough of a. larger number of side-by-side arranged caps (Fig. 1).,

By these. provisions, the caps moving into the auxiliary compartment 52 are prevented frompiling up therein and, instead, are compelled, by the vibration impulses imparted. to them by the hopper 1.6, to arrange themselves in a single layer. Further, the caps c in the auxiliary compartment 52 of the hopper are,,soon after their passage. through the opening 56. in. the partition 54, directed into single fileby upright; Walls 6.0. and 62. which are located in the aux.- iliary compartment 52 and converge toward the discharge opening 4.6. in the manner shown in Fig. l. The discharge opening; 46 in the. hopper 16. is of. such dimensions as to. permit the passage therethrough of only a. single cap 0 (Figs. 1 and 2). Suitably carried on the. bottom. of the main. compartment 50 of the hopper, preferably near the opening 56 in the partition 54-, is an obstacle 7.0, presently in; the form of. an angle. (Fig. 1,), which. serves to prevent capsin. the main compartment from jamming, in front of, or; in, the opening. 56 in the partition 54-, as will be readily understood. Thus,.the caps c in. the main. compartment 50: of the hopper 16 will, under the vibration impulses imparted to them by the latter, pass; in a steady flow to and through, the opening 56: in. the: partition 54 into. the auxiliary compartmentSZ, whereinv they rearrange themselves in a single layer and are directed into single file prior to their passage from the hopper through the discharge opening 46. therein. The amplitude and frequency of the vibrations of. the hopper 16 are such as to cause the described discharge of caps from the latter and their sub.- stantially continuous travel. through the guidev 44- without marring them in any way.

The cap-arranging device. D is in. the present instance, in. the form of. a tube. 18 which is made of. preferably transparent plastic material, and conveniently mounted,

which receives the caps c as they are discharged from the {1, a) hopper 16 and leave the guide 44, is, for the correct arrangement of the caps therein vibrated similarly as, but

separately from, the hopper 16. To this end, there is suitably mounted at 80 on the' bottom surface of the support plate 78 a vibrator V which may be of the same type as the vibrator V for the hopper 16. In order that the vibrations imparted by the vibrator V to the tube 18 will not be transmitted to the rest of the apparatus, the support plate 78 is preferably resiliently mounted, similarly as the hopper 16. Thus, the support plate 78 is at its bottom mounted at 82 on rubber or like resilient pads 84 in casings 86 on the top ends of upright posts 88, respectively, which are suitably mounted at 90 on the platform 14. Moreover, the support plate 78 and tube 18 thereon are, for inducing the caps c in the latter to move therethrough in a steady flow, inclined to a horizontal plane similarly as the hopper 16 and guide 44 (Fig. 2). The inlet end 92 of the tube 18 has a tubular upward extension 94 into which gravitate the caps c as they leave the guide 44 (Fig. 2). To prevent the caps from jamming at the inlet end 92 of the tube 18 and to assure their uninterrupted progress from the tube extension 94 into the tube 18, there is provided at their junction a smoothly curved fillet 100 (Fig. 2).

As will be described hereinafter, the caps c in the tube 18 pass therethrough in single file and, unless they are already correctly disposed therein with their bottoms down, are in the course of their passage therethrough turned over into correct disposition, so that the caps c are unfailingly in correct disposition as they leave the tube 18 at the discharge end 102 thereof. The discharge end 102 of the tube 18 is in alignment with the inlet end 104 of a chute 106 which is curved downwardly as shown in Fig. 2, so that the caps c therein at and near the discharge end 108 thereof are disposed with their bottoms up for their successive removal from the chute 106 and application to the threaded necks of bottles which may pass underneath the chute 106.

With reference to Figs. 2, 6, and 7, the chute 106 is at the discharge end 108 open at the top to afford access thereat to the foremost caps in the chute for the removal of any misarranged, or defective cap. The caps c are held against gravitation from the chute by the resilient gates 120 and 122 which are in the form of arcuate leaf springs secured to the opposite side walls of the chute. The gates 120 and 122 project forwardly from the discharge end of the chute so as to retain the foremost cap in the position best shown in Fig. 6 in which it is in the path of, and will be picked up by, the neck N of the next bottle to pass the station S at which the bottle is closed. A cap thus picked up by the neck of a bottle is in position thereon ready to be turned into tight closing engagement therewith at a subsequent station (not shown). While the gates 120 and 122 will yield outwardly and permit the transfer of each foremost cap from the chute onto the neck of each passing bottle, they will immediately after the passage of a cap c close on the next following cap in the chute and thus hold the remaining caps therein from escaping through the discharge end.

The bottles b are placed on the conveyor 124 at a loading station and are carried on said conveyor through the transfer station S. The conveyor 124 may be of any suitable construction and in the illustrated embodiment said conveyor is of the endless chain type of which the usual pivotally connected links carry plates 126 that are arranged to form a fiat continuous surface in the top run of the conveyor on which the bottles b will be properly supported. The bottles placed on the top run of the conveyor are held in line and guided by opposite guide rails 128, one of which is shown in the drawings. In order to prevent the transferred cap on any bottle on the conveyor 124 to drop from the neck thereof, there is provided a retainer bar 130 which bears against the transferred caps with such a light force as safely to prevent their escape from the respective bottle necks without in any way impeding the forward progress of the bottles on the conveyor. The retainer bar 130 may be secured to the apparatus in any conventional manner.

The chute 106, which may be of rectangular cross-section so as to receive a single line of correctly disposed caps c with a sliding fit, may be mounted on a forwardly extending plate 110 on the platform 14, conveniently by being clamped between slightly resilient prongs 112 of the plate 110 by means of screws 114 of which one is show in the drawings.

1 arrangement of caps which are used for certain kinds of perfume bottles, for instance, and which comprise relatively thin-walled cups 120' of externally plated and highly polished aluminum and inserted threaded metallic liners 122', respectively (Fig. 3). Caps of this latter type will I never become marred in the course of their arrangement in the present apparatus, because they are for their arrangement subjected only to vibrations which will never jar them or throw them against each other or any other object to the extent where they would become marred.

As the discharge caps c drop off the guide 44 into the tube 18, all of them will arrange themselves successively in a single line, and part of them, such as the caps c (Fig. 2), will be positioned with their bottoms up, while most of the remaining caps will be correctly positioned, i. e., with their bottoms down. Some of the caps, such as the caps c in the present instance in Fig. 2, will, in the course of their travel through the tube 18 and through pressure from adjacent caps c, be upset from either bottom-down or bottom-up position, but will in the course of their continued travel through the tube 18 be correctly poslisigned before leaving the latter and entering the chute Considering first the caps c in the tube 18 which are incorrectly positioned therein with their bottoms up, it will be noted in Fig. 3 that the cap 0' is in the tube 18 in a state of equilibrium from which it will soon, under the substantially vertical vibration impulses imparted to it by the tube, be displaced and turn over into correct disposition (Fig. 5) in the course of which the cap c may assume the momentary progressive positions shown in dot-anddash lines and full lines, respectivelygin Fig. 4. Obviously, the center of gravity g of the vibrating cap c is, on the slightest displacement of the latter from the position of Fig. 3, instrumental in setting up a rotary moment in the cap, clockwise in the present instance as viewed in Figs.

3 and 4, and this rotary moment will, under the vibration impulses of the cap, exert itself until the center of gravity g of the cap is substantially lowermost, i. e., when the cap c is correctly positioned with its bottom down (Fig. Thus, most, if not all, of the incorrectly positioned caps c in the tube 18 will, during their travel through a portion only of the latter, become correctly positioned therein. However, in order to prevent even a single cap 0 among the many caps in the tube 18 from reaching the discharge end of the latter in incorrect bottom-up position or any other position in which it would not freely enter the chute 106 and cause a jam at the inlet end 104 of the latter, a substantial end length 18 of the tube projects forwardly from the support plate 78. This projecting end length 18' of the tube 18 is, under the vibration impulses imparted to the tube and by virtue of the inherent resiliency of the plastic tube material, additionally whipped vertically to such an extent that any incorrectly positioned cap therein will without fail flip over into correct position for the same reasons which compel incorrectly positioned caps in the remainder of the tube to turn over into correct position therein. Thus it may be mentioned by way of example, but not as a limitation, that excellent results have been obtained by leaving substantially one third of the length of the tube 18 beyond the vibrator V projecting forwardly from the support plate 78. Inasmuch as reactive forces from the interior wall of the vibrating tube 18 are also instrumental in setting up the turning moments in incorrectly positioned caps therein, it is obvious that for the success of the instant method of correctly ar- 'in a tube which, in comparison to the outside diameters of the caps therein, has such a large inside diameter that the wall portion thereof which is bridged by a cap is much flatter than the wall portion of the tube bridged by the cap in Fig. 3, regardless of the amplitude and frequency 1 of the vibrations of the tube. As already mentioned, mo-

mentarily upset caps in the tube 18, such as the caps c",'

will in the course of their continued travel through the tube and by the vibration impulses imparted to them by the latter, arrange themselve: in bottom-up or bottomdown position and, if then arranged in bottom-up position, subsequently rearrange themselves in correct bottomdown position, as will be readily understood. Upsetting of the caps in the tube 18, such as the caps c" therein, is to a large extent determined by the inclination of the tube 18, and the inclination of the latter is selected so as to have a minimum number of these upset caps in the tube while caps travel through the latter at a speed consistent with the demand for correctly arranged caps by a capapplying device (not shown).

While I have shown and described the preferred embodiment of my invention, it will be understood that various changes may be made in the present invention without departing from the underlying idea or principles of the invention within the scope of the appended claims.

Having thus described my invention, what I claim and desire to secure by Letters Patent, is:

1. Apparatus for arranging a series of cup-shaped articles with their closed bottom ends down and open top ends up, comprising a cylindrical tube of slightly resilient material, a support on which a length of said tube is mounted so that a substantial end length of the latter projects freely beyond said support, said support being so arranged that said tube is axially slightly inclined to a horizontal plane with said end length thereof lowermost, and said tube being adapted for the reception and support of a plurality of articles in single file with either of their ends down and having an internal diameter such that any article disposed in said tube with either of its ends down contacts said tube with peripherally opposite portions only of its downwardly disposed end, and means for imparting to said support substantially vertical vibrations of such amplitude and frequency as to induce in the articles disposed in said tube with their bottom-ends up turning moments, respectively, which will invert them into correct position in said tube with their bottom ends down, and further to induce motion of the articles in said tube toward the end of said end length of said tube with the aid of gravitational forces, said tube end length being by virtue of its resiliency and positioning and under the vibration impulses imparted to said tube by said support, vibrated at a greater amplitude than the tube length on said support to correctly arrange any articles in said end length that enter the latter incorrectly arranged.

2. Apparatus for arranging a series of cup-shaped articles with their closed bottom ends down and open top ends up, comprising a longitudinally extending generally straight member having an inner surface for the support of a plurality of articles, said surface being cross-sectionally curved uniformly for the length of said member so that all articles thereon are disposed in single file longitudinally of said surface and any article may be supported thereon on the peripherally opposite portions of either of its ends, and means for imparting to said surface vibrations in a direction laterally thereof and of such amplitude and frequency as to induce in the articles disposed in bottom-up position on said surface turning moments, respectively, which will invert them into correct bottomdown position on said surface, said member being longitudinally inclined to a horizontal plane to induce motion of the articles thereon towards the lower end of said member under the vibration impulses imparted to them by said member, and a chute in alignment with said end of said member in which articles from said surface are in their bottom-down position and single-file arrangement receivable with a sliding fit.

3. Apparatus for arranging cup-shaped articles with their closed bottom ends down and opentop ends up, comprising a reclining generally straight cylindrical tube in which may be supported a plurality of articles in single file with either of their ends down, the internal diameter of said tube being such that any article disposed therein with either of its ends down contacts said tube with peripherally opposite portions only of its downwardly disposed end,

means for imparting to said tube vibrations in a direc' tion laterally thereof and of such amplitude and frequency as to induce in the articles disposed in said tube with their bottom ends up turning moments, respectively, which will invert them into correct position in said tube with their bottom ends down as said articles progressively travel along the inside of said tube, and a support on which a length of said tube is mounted so that a substantial end length of the latter projects freely beyond said support, said tube end length being by virtue of its positioning and under the vibration impulses imparted to said tube, vibrated at a greater amplitude than the tube length on said support.

4. Apparatus for arranging a series of cup-shaped articles with their closed bottom ends down and open top ends up, comprising a cylindrical tube which is axially slightly inclined to a horizontal plane and in which may be supported a plurality of articles in single file with either of their ends down, the internal diameter of said tube being such that any article disposed therein with either of its ends down contacts said tube with peripherally opposite portions only of its downwardly disposed end, means for imparting to said tube substantially vertical vibrations of such amplitude and frequency as to induce in the articles disposed in said tube with their bottom ends up turning moments, respectively, which will invert them into correct position in said tube with their bottom ends down as said articles progressively travel along said tube, and further to induce motion of the articles in said tube toward the lower end thereof with the aid of gravitational forces, and a chute in alignment with said lower tube end and dimensioned to receive with a sliding fit the articles from said tube in their correct bottom-down position and single-file arrangement.

5. Apparatus for arranging a series of cup-shaped articles with their closed bottom ends down and open top ends up, comprising a cylindrical tube of slightly resilient material, a support on which a length of said tube is mounted so that a substantial end length of the latter projects freely beyond said support, said support being so arranged that said tube is axially slightly inclined to a horizontal plane with said end length thereof lowermost, and said tube being adapted for the reception and support of a plurality of articles in single file with either of their ends down and having an internal diameter such that any article disposed in said tube with either of its ends down contacts said tube with peripherally opposite portions only of its downwardly disposed end, and means for imparting to said support substantially vertical vibrations of such amplitude and frequency as to induce in the articles disposed in said tube with their bottom-ends up turning moments, respectively, which will invert them into correct position in said tube with their bottom ends down, and further to induce motion of the articles in said tube toward the end of said length of said tube with the aid of gravitational forces, said tube end length being by virtue of its resiliency and positioning and under the vibration impulses imparted to said tube by said support, vibrated at a greater amplitude than the tube length on said support to correctly arrange any articles in said end length that enter the latter incorrectly arranged, and a chute in alignment with said tube end length and dimensioned to receive with a sliding fit the articles from said tube in their correct bottom-down position and single-file arrangement.

References Cited in the file of this patent UNITED STATES PATENTS Number Name Date 1,197,292 Hunter Sept. 5, 1916 2,337,294 Kok Dec. 21, 1943 2,337,667 Kuehlman Dec. 28, 1943 2,462,276 Mueller Feb. 22, 1949 FOREIGN PATENTS Number Country Date 284,514 Italy Apr. 15, 1931

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US130543A US2696285A (en) | 1949-12-01 | 1949-12-01 | Apparatus for orderly arranging bottle caps or the like |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US130543A US2696285A (en) | 1949-12-01 | 1949-12-01 | Apparatus for orderly arranging bottle caps or the like |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2696285A true US2696285A (en) | 1954-12-07 |

Family

ID=22445179

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US130543A Expired - Lifetime US2696285A (en) | 1949-12-01 | 1949-12-01 | Apparatus for orderly arranging bottle caps or the like |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2696285A (en) |

Cited By (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2769419A (en) * | 1949-01-06 | 1956-11-06 | Crown Cork & Seal Co | Closure cap element feeding apparatus |

| US2797541A (en) * | 1951-12-26 | 1957-07-02 | Upjohn Co | Bottle stoppering apparatus |

| US2817746A (en) * | 1955-08-29 | 1957-12-24 | Rca Corp | Stud welder |

| US2825489A (en) * | 1952-06-13 | 1958-03-04 | Batchelder Engineering Co Inc | Feeding machine |

| US2853170A (en) * | 1955-01-24 | 1958-09-23 | Armstrong Cork Co | Article orienting device |

| US2892568A (en) * | 1955-08-09 | 1959-06-30 | Gen Electric | Apparatus for feeding coiled filaments |

| US2907494A (en) * | 1956-01-27 | 1959-10-06 | Frank H Ine | Automatic packaging clip feeding and fastening device |

| US2916125A (en) * | 1956-01-30 | 1959-12-08 | Western Electric Co | Article feeding device and guiding mechanism |

| US2982386A (en) * | 1957-11-21 | 1961-05-02 | Miles Lab | Flexible chute |

| US2983374A (en) * | 1956-07-05 | 1961-05-09 | Crompton & Knowles Packaging C | Tablet feeding mechanism |

| US2997202A (en) * | 1957-01-04 | 1961-08-22 | Bristol Company | Orienting and feeding apparatus |

| DE1129104B (en) * | 1957-11-11 | 1962-05-03 | Kilian & Co G M B H | Feed slide for tablet cores to be dispensed lying in the same direction |

| US3040784A (en) * | 1958-12-30 | 1962-06-26 | Friden Inc | Automatic spring looping machine |

| US3054167A (en) * | 1960-07-29 | 1962-09-18 | Bryner Ernest James | Capping machine |

| US3055051A (en) * | 1957-06-21 | 1962-09-25 | Schuller Werner Hugo Wilhelm | Spinning of glass or other thermoplastic masses from rods |

| US3069049A (en) * | 1955-06-09 | 1962-12-18 | Set Serew & Mfg Company | Machine for feeding and orienting headless screws |

| US3099359A (en) * | 1960-05-12 | 1963-07-30 | Gen Motors Corp | Parts feeding device |

| US3155272A (en) * | 1958-04-24 | 1964-11-03 | Motorola Inc | Method and apparatus for loading a receiver with a plurality of beads |

| US3259226A (en) * | 1965-02-05 | 1966-07-05 | Ampex | Article handling apparatus |

| DE1247931B (en) * | 1963-08-22 | 1967-08-17 | Noack E Th Verpackungsmasch | Packaging machine for the individual sealing of capsules u. like |

| US3361296A (en) * | 1965-10-18 | 1968-01-02 | Reynolds Metals Co | Core orienting and feeding apparatus |

| US3374525A (en) * | 1965-10-14 | 1968-03-26 | Fabri Tek Inc | Component placement apparatus |

| DE1272264B (en) * | 1958-12-30 | 1968-07-11 | Friden Inc | Machine for anointing coil springs |

| US3480132A (en) * | 1967-03-06 | 1969-11-25 | Hideo Tatibana | Apparatus for arranging ampules in regular order |

| US3930557A (en) * | 1973-09-17 | 1976-01-06 | Continental Can Company, Inc. | Noise reduction kit for can closing machine |

| US3970218A (en) * | 1975-02-20 | 1976-07-20 | Lee Wing J | Cap selecting and feeding mechanism |

| US4145981A (en) * | 1977-12-15 | 1979-03-27 | S & T Venture | Vibrating seed planter delivery chute for singular seed dispensing |

| EP0206095A2 (en) * | 1985-06-24 | 1986-12-30 | Polaroid Corporation | Part positioning apparatus and method |

| US5014889A (en) * | 1986-12-24 | 1991-05-14 | Akatake Engineering Co., Ltd. | Powder feeding apparatus |

| DE19545419A1 (en) * | 1995-12-06 | 1997-06-12 | Fraunhofer Ges Forschung | Workpiece-preparation and orientation system |

| US6135676A (en) * | 1997-12-23 | 2000-10-24 | Crown Cork & Seal Technologies Corporation | System and method for bulk handling closures |

| US7066620B1 (en) * | 2004-07-13 | 2006-06-27 | Warren Millet | Novelty item for cooperating with a cap of a bottle subsequent to cooperation of the cap with a bottle opener but prior to cooperation of the cap with a cap catcher |

| CN101734473B (en) * | 2009-11-17 | 2011-11-30 | 广州市博仕机电工贸有限公司 | Positive and reverse screening type cap sorter |

| US20140137512A1 (en) * | 2012-11-19 | 2014-05-22 | Krones Ag | Device for feeding container closures to a capper |

| WO2022157219A1 (en) * | 2021-01-22 | 2022-07-28 | Syntegon Technology Gmbh | System for transporting loose sterile closure elements |

| IT202100004874A1 (en) * | 2021-03-02 | 2022-09-02 | Pelliconi & C Spa | EQUIPMENT FOR DIGITAL PRINTING OF CLOSURES FOR CONTAINERS. |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1197292A (en) * | 1916-04-26 | 1916-09-05 | Tifton Farm Tool Mfg Company | Combined seeder and guano-distributer. |

| US2337294A (en) * | 1942-02-18 | 1943-12-21 | Taylor Winfield Corp | Fabrication method |

| US2337667A (en) * | 1941-07-10 | 1943-12-28 | Nat Lock Washer Co | Feed mechanism for assembly machines |

| US2462276A (en) * | 1946-12-06 | 1949-02-22 | John A Mueller | Seeder conveyer |

-

1949

- 1949-12-01 US US130543A patent/US2696285A/en not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1197292A (en) * | 1916-04-26 | 1916-09-05 | Tifton Farm Tool Mfg Company | Combined seeder and guano-distributer. |

| US2337667A (en) * | 1941-07-10 | 1943-12-28 | Nat Lock Washer Co | Feed mechanism for assembly machines |

| US2337294A (en) * | 1942-02-18 | 1943-12-21 | Taylor Winfield Corp | Fabrication method |

| US2462276A (en) * | 1946-12-06 | 1949-02-22 | John A Mueller | Seeder conveyer |

Cited By (42)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2769419A (en) * | 1949-01-06 | 1956-11-06 | Crown Cork & Seal Co | Closure cap element feeding apparatus |

| US2797541A (en) * | 1951-12-26 | 1957-07-02 | Upjohn Co | Bottle stoppering apparatus |

| US2825489A (en) * | 1952-06-13 | 1958-03-04 | Batchelder Engineering Co Inc | Feeding machine |

| US2853170A (en) * | 1955-01-24 | 1958-09-23 | Armstrong Cork Co | Article orienting device |

| US3069049A (en) * | 1955-06-09 | 1962-12-18 | Set Serew & Mfg Company | Machine for feeding and orienting headless screws |

| US2892568A (en) * | 1955-08-09 | 1959-06-30 | Gen Electric | Apparatus for feeding coiled filaments |

| US2817746A (en) * | 1955-08-29 | 1957-12-24 | Rca Corp | Stud welder |

| US2907494A (en) * | 1956-01-27 | 1959-10-06 | Frank H Ine | Automatic packaging clip feeding and fastening device |

| US2916125A (en) * | 1956-01-30 | 1959-12-08 | Western Electric Co | Article feeding device and guiding mechanism |

| US2983374A (en) * | 1956-07-05 | 1961-05-09 | Crompton & Knowles Packaging C | Tablet feeding mechanism |

| US2997202A (en) * | 1957-01-04 | 1961-08-22 | Bristol Company | Orienting and feeding apparatus |

| US3055051A (en) * | 1957-06-21 | 1962-09-25 | Schuller Werner Hugo Wilhelm | Spinning of glass or other thermoplastic masses from rods |

| US3055050A (en) * | 1957-06-21 | 1962-09-25 | Schuller Werner Hugo Wilhelm | Continuous spinning of glass or like thermoplastic masses from rods |

| DE1129104B (en) * | 1957-11-11 | 1962-05-03 | Kilian & Co G M B H | Feed slide for tablet cores to be dispensed lying in the same direction |

| US2982386A (en) * | 1957-11-21 | 1961-05-02 | Miles Lab | Flexible chute |

| US3155272A (en) * | 1958-04-24 | 1964-11-03 | Motorola Inc | Method and apparatus for loading a receiver with a plurality of beads |

| US3040784A (en) * | 1958-12-30 | 1962-06-26 | Friden Inc | Automatic spring looping machine |

| DE1272264B (en) * | 1958-12-30 | 1968-07-11 | Friden Inc | Machine for anointing coil springs |

| US3099359A (en) * | 1960-05-12 | 1963-07-30 | Gen Motors Corp | Parts feeding device |

| US3054167A (en) * | 1960-07-29 | 1962-09-18 | Bryner Ernest James | Capping machine |

| DE1247931B (en) * | 1963-08-22 | 1967-08-17 | Noack E Th Verpackungsmasch | Packaging machine for the individual sealing of capsules u. like |

| US3259226A (en) * | 1965-02-05 | 1966-07-05 | Ampex | Article handling apparatus |

| US3374525A (en) * | 1965-10-14 | 1968-03-26 | Fabri Tek Inc | Component placement apparatus |

| US3361296A (en) * | 1965-10-18 | 1968-01-02 | Reynolds Metals Co | Core orienting and feeding apparatus |

| US3480132A (en) * | 1967-03-06 | 1969-11-25 | Hideo Tatibana | Apparatus for arranging ampules in regular order |

| US3930557A (en) * | 1973-09-17 | 1976-01-06 | Continental Can Company, Inc. | Noise reduction kit for can closing machine |

| US3970218A (en) * | 1975-02-20 | 1976-07-20 | Lee Wing J | Cap selecting and feeding mechanism |

| US4145981A (en) * | 1977-12-15 | 1979-03-27 | S & T Venture | Vibrating seed planter delivery chute for singular seed dispensing |

| EP0206095A2 (en) * | 1985-06-24 | 1986-12-30 | Polaroid Corporation | Part positioning apparatus and method |

| EP0206095A3 (en) * | 1985-06-24 | 1987-12-23 | Polaroid Corporation | Part positioning apparatus and method |

| US5014889A (en) * | 1986-12-24 | 1991-05-14 | Akatake Engineering Co., Ltd. | Powder feeding apparatus |

| DE19545419A1 (en) * | 1995-12-06 | 1997-06-12 | Fraunhofer Ges Forschung | Workpiece-preparation and orientation system |

| DE19545419C2 (en) * | 1995-12-06 | 2000-03-23 | Fraunhofer Ges Forschung | Device for the provision, orientation and organization of workpieces |

| US6135676A (en) * | 1997-12-23 | 2000-10-24 | Crown Cork & Seal Technologies Corporation | System and method for bulk handling closures |

| US7066620B1 (en) * | 2004-07-13 | 2006-06-27 | Warren Millet | Novelty item for cooperating with a cap of a bottle subsequent to cooperation of the cap with a bottle opener but prior to cooperation of the cap with a cap catcher |

| CN101734473B (en) * | 2009-11-17 | 2011-11-30 | 广州市博仕机电工贸有限公司 | Positive and reverse screening type cap sorter |

| US20140137512A1 (en) * | 2012-11-19 | 2014-05-22 | Krones Ag | Device for feeding container closures to a capper |

| EP2733111A3 (en) * | 2012-11-19 | 2014-12-10 | Krones AG | Device for feeding of container closures to a closing machine |

| WO2022157219A1 (en) * | 2021-01-22 | 2022-07-28 | Syntegon Technology Gmbh | System for transporting loose sterile closure elements |

| DE102021101384C5 (en) | 2021-01-22 | 2024-04-11 | Syntegon Technology Gmbh | System for transporting sterile pourable closure elements |

| IT202100004874A1 (en) * | 2021-03-02 | 2022-09-02 | Pelliconi & C Spa | EQUIPMENT FOR DIGITAL PRINTING OF CLOSURES FOR CONTAINERS. |

| WO2022185192A1 (en) * | 2021-03-02 | 2022-09-09 | Pelliconi & C. S.P.A. | Apparatus for digital printing on closures for containers. |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2696285A (en) | Apparatus for orderly arranging bottle caps or the like | |

| US3012651A (en) | Apparatus for orienting and feeding articles | |

| AU658755B2 (en) | Machine for automatically positioning and aligning containers | |

| CN100506647C (en) | Unit for filling containers with products, in particular, pharmaceutical products | |

| US2461290A (en) | Bottle chute | |

| US2282474A (en) | Receptacle cleaning machine | |

| US2815113A (en) | Article positioning apparatus | |

| US2645399A (en) | Machine for applying and sealing closures to bottles | |

| US2428103A (en) | Bullet handling apparatus | |

| US2715978A (en) | Closure-handling machine | |

| US3537567A (en) | Bottle orienting mechanism | |

| KR890015940A (en) | Goods Distribution Conveyor Device | |

| US3254753A (en) | Hopper feed apparatus | |

| US3974624A (en) | Apparatus for distributing articles into receptacles | |

| US6401904B1 (en) | Method and apparatus for separating objects | |

| US3261442A (en) | Cap turnover device | |

| US3120888A (en) | Vibrating feeder trough | |

| US3106281A (en) | Automatic feeder mechanism for orienting relatively small articles | |

| US3357537A (en) | Automatic container separator and method of separating containers | |

| US3788456A (en) | Method and apparatus for automatically separating entangled springs | |

| US2420299A (en) | Transfer mechanism | |

| US3044642A (en) | Shipping case unloading machine | |

| US2208474A (en) | Fruit handling mechanism | |

| US3278971A (en) | Case cleaning apparatus | |

| US2393370A (en) | Dispensing device |