US2645346A - Paper machinery - Google Patents

Paper machinery Download PDFInfo

- Publication number

- US2645346A US2645346A US163112A US16311250A US2645346A US 2645346 A US2645346 A US 2645346A US 163112 A US163112 A US 163112A US 16311250 A US16311250 A US 16311250A US 2645346 A US2645346 A US 2645346A

- Authority

- US

- United States

- Prior art keywords

- chamber

- stock

- gap

- conduit

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002245 particle Substances 0.000 description 62

- 208000028659 discharge Diseases 0.000 description 47

- 239000007788 liquid Substances 0.000 description 26

- 239000000463 material Substances 0.000 description 16

- 239000002002 slurry Substances 0.000 description 8

- 238000000926 separation method Methods 0.000 description 6

- 239000010802 sludge Substances 0.000 description 5

- 238000010276 construction Methods 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 238000007599 discharging Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 230000002265 prevention Effects 0.000 description 2

- 239000004576 sand Substances 0.000 description 2

- 241001077878 Neurolaena lobata Species 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B5/00—Packaging individual articles in containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, jars

- B65B5/06—Packaging groups of articles, the groups being treated as single articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C3/00—Apparatus in which the axial direction of the vortex flow following a screw-thread type line remains unchanged ; Devices in which one of the two discharge ducts returns centrally through the vortex chamber, a reverse-flow vortex being prevented by bulkheads in the central discharge duct

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/02—Construction of inlets by which the vortex flow is generated, e.g. tangential admission, the fluid flow being forced to follow a downward path by spirally wound bulkheads, or with slightly downwardly-directed tangential admission

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/02—Construction of inlets by which the vortex flow is generated, e.g. tangential admission, the fluid flow being forced to follow a downward path by spirally wound bulkheads, or with slightly downwardly-directed tangential admission

- B04C5/06—Axial inlets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/14—Construction of the underflow ducting; Apex constructions; Discharge arrangements ; discharge through sidewall provided with a few slits or perforations

- B04C5/15—Construction of the underflow ducting; Apex constructions; Discharge arrangements ; discharge through sidewall provided with a few slits or perforations with swinging flaps or revolving sluices; Sluices; Check-valves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/14—Construction of the underflow ducting; Apex constructions; Discharge arrangements ; discharge through sidewall provided with a few slits or perforations

- B04C5/18—Construction of the underflow ducting; Apex constructions; Discharge arrangements ; discharge through sidewall provided with a few slits or perforations with auxiliary fluid assisting discharge

Definitions

- This invention relates to a vortex separator for separating heavy particles from paper making stock and other liquid slurrles.

- the invention relates more particularlyto a vortex separator of the type wherein a whirling motion initially imparted to the stock as it enters a separating chamber is relied upon to set up deslred conditions of centrifugal force for effecting separation of the heavy particles therefrom.

- the present invention provides a vortex separator wherein the stock ilows in a substantially straight line from the inlet of the separating chamber to the outlet across an annular or circumferential discharge passage or ⁇ gap of substantial length within the separating chamber under controlled conditions such that heavy ⁇ particles are discharged through this passage into the interior of the separating chamber while the resulting clean stock ows directly to the outlet from the chamber.

- the invention provides operating conditions such that the rate of now of the clean Stock leaving the separating chamber may be decelerated after the stock crosses the discharge passage, thus further assuring effective separation of the heavy particles and minimizing the carrying capacity of the clean stock for reject material.

- conduits rectly from the inlet conduit and in substantially straight line flow.

- the adjacent ends of these conduits are spaced from each other to leave an annular or circumferential discharge passage therebetween of substantial axial extent which opens into the interior of the separating chamber, and a core is provided which extends axially through this passage between the conduits.

- One ofthe conduits includes a portion of substantial length which is positioned within the chamber but is of substantially smaller diameter than the chamber to provide therein an annular portion 0r space surrounding the annular discharge passage and extending downwardly below the level of this passage within the chamber.

- the bottom of the separating chamber is provided with a horizontally arranged screw conveyor which is motor driven at one end and isprovided at the other end with an outlet having a counterweighted closure.

- This conveyor collects reject material settling to the bottom of the separating chamber and conveys it to its outlet until there is sufiicient accumulation vof reject material at the outlet to force open When this occurs, the reject material is discharged as a damp sludge comparable in consistency to wet sand or gravel, but since the accumulated, slug of material between the conveyor and the outlet remains in place, it effectively seals against loss of liquid through the outlet except for the relatively small amount of liquid which adheres to the reject particles.

- Another object is to Yprovide a vortex separator wherein the direction and rate of now through the separating chamber of the stock to be cleaned areV readily controlled and maintained under conditions of low turbulence which effectively minimize the carrying capacity of thestock for heavy particles and thus facilitate efficient operation of the device with low power requirementsr to give resulting economy of operation and maintenance.

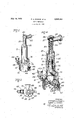

- FIG. 1 is a perspective view of a vortex separator in accordance with the invention

- Fig. 2 is a diagrammatic View of the separator on a larger scale than Fig. 1 and with portions of the casing broken away to illustrate details of internal construction and operation;

- Fig. 3 is a top plan view of the device.

- the main base I E supports a cylindrical casing il which encloses a separatingchamber I2 oi substantial volume and vertical extent.

- the casing ll is mounted on base III by means of a nange I3, and it includes an outlet conduit i5 which projects upwardly for a substantial distance within chamber I2 and is curved forwardly through the front of the casing for attachment at It to a suitable discharge pipe.

- An inlet conduit 2li is mounted on the upper end of casing I I by means of a flange 2 I, and it includes a tangentially arranged inlet connection 22 at its upper end.

- a helix comprising a core 25 and a helical vane 26 is vmounted within the inlet conduit 2D by means of a flanged upper end portion 2l and a twopiece clamping ring 28V provided with an-annular gasket 29.

- annular space 33 is provided within chamber I2 which includes an upper portion surrounding the discharge gap 30 and a lower portion continuing downwardly therefrom around conduit 20 to the lower end of the chamber.

- the core 25 of the helix in the inlet conduit 2B is of increasing diameter in the direction of flow through conduit 20 to provide a progressively decreasing cross sectional flow area through the inletconduit and thus to effect acceleration of the rate of flow of the incoming stock.

- a cylindrical portion which extends downwardly below vane 26 and completely through the interior of the discharge gap 3l) into the upper end of the outlet conduit I5.

- the base I includes a tapered throat portion 35 which provides the bottom for separating chamber I2, to receive reject material settling in the chamber, and a cylindrical passage 35 extends horizontally through the base below and in com- 35.

- a screw conveyor All is mounted in the passage 3d for removing reject material settling therein, and it is lconnected through a exibie coupling 4I with a drive motor l2 mounted in the back of the base by means of a housing d3.

- the forward end of the passage 36 is provided with an outlet 44 which-extends forwardly beyond the end of screw 40, and a closure door i5 :or'this outlet is pivoted at the top of the outlet casting and provided with one or morecounterweights t@ for normally holding the door l5 in sealing position on the outer end of the outlet de.

- the heavy particles which are discharged into the space 33 will also whirl but in a larger spiral as indicated by the stippled arrows 55, thus effectively concentrating the reject material along the outer wall of chamber l2 as settling thereof takes place downwardly inthe chamber towards the conveyor 40, and it will thus be seen that the conditions set up within the chamber l2 all contribute to effective separation of heavymaterial andto prevention of remixing of the separated material with the clean stock. Since all of the stock is forced to whirl as it traverses the inlet conduit and the discharge passage,there is no relatively stagnant central portion such as might exist if the core 25 were not present, and at the same time the construction of the device as shown effectively prevents shortcircuiting of the stock of a high pressure inlet to a low pressure outlet.

- the arrangement with the outlet conduit located centrally within the annular space 33 is also of assistance in maintaining continued separation of the reject once it has been discharged through passage 3D. Not only does the whirling of the reject in itself tend to prevent remixing, but since the space 33 continuesbelow the level of gap 30 to the lower portion of chamber I2, gravity also acts on the separated material and causes it to settle until it reaches the conveyor 40.

- Effective separation is aided by the inward flow of clean liquid fromV the passage 5U; which is maintained at a low volumetric rate approximately the volumetric rate atV which the reject material is removed, for example approximately two gallons per minute under the operating conditions described above.

- This clean' liquid replaces the reject in the flow of clean stock into the outlet conduit, and it provides a back pressure across thev discharge gap which tends to maintain the clean stock on its desired course and is particularly useful in thecase of paper stock since it aids in preventing discharge of fiber with the heavy particles.

- bits of fiber should initially be discharged through gap 3

- this back pressure provided by the added flow of clean liquid can be readily predetermined and controlled as desired to regulate the discharge through gap 30.

- a further aid to effective separating action an the prevention of remixing of reject material with the clean stock is provided by the arrangement of the core 25 with its lower end extending a substantial distance into the outlet conduit and then terminating. The presence of the core in the upper end of the outlet conduit aids in maintaining the -desired whirling motion of all of the stock until after it has entered the discharge conduit, since it maintains the effective flow area of this portion of the outlet conduit substantially equal to that of the discharge end of the inlet conduit.

- the termination of the core at a position as shown within the outlet conduit increases the effective flow area of the outlet conduit beyond that point and thus produces a corresponding deceleration of the rate of ilow of the clean stock, Iwhich is desirable in effectuating the proper separation of the reject material since the resulting reduced rate of flow of the clean stock materially reduces its carrying capacity for heavy particles.

- both reject material and fiber are prevented from accumulating at ⁇ any point in such manner as to cause possible change in the flow vrelatively solid slug between the end of the conveyor and the door 45.

- This sludge is accordingly easy to handle for disposal by shovels Yor in any other convenient Way and without also den change inthe pressure within the unit such as may result from intermittent cleaning or the opening and closing of a continuously operated port type valve, and the pressure within the unit Y therefore remains constant with no peaks and valleys in the resulting efficiency curve.

- a vortex separator ior separating heavy particles from a liquid slurry stock comprising a casing forming a chamber adapted to be filied with liquid, a cylindrical inlet conduit adapted to deliver stock Vinto said chamber in substantially vertical flow, a cylindrical outlet conduit from said chamber aligned with said inlet conduit to receive said stock directly from said inlet conduit, means maintaining the adjacent ends of said conduits in axially spaced relation within said chamber to provide a circumferential dis charge gap therebetween for radial discharge of particles out of the line of flow therebetween into said chamber, said inlet and outlet conduits being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said vstock through said inlet conduit with a whirling helical motion to cause solid particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said annular space continuing downwardly in said chamber below said gap to receive said discharged particles settling downwardly v

- outlet conduit from said chamber including a portion of substantial length arranged within said chamber in position to receive said stock directly from said inlet conduit, meansrmaintaining said conduits with their adjacent ends in axially spaced relation within said chamber to Vprovide a circumferential discharge gapbetween said conduits for radial discharge of particles out of the line of flow therebetweenA into the interior of said chamber, the portion of said discharge conduit within said chamber and the adjacent end of said inlet conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said stock through said inlet with a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit tosaid outlet conduit, said annular space continuing downwardly in said chamber below said gap to Vreceive said discharged particles settling downwardly from said gap, and means forming a core extending axially through the interior of said inlet conduit and said discharge gap into the interior of said discharge conduit to cause all

- a vortex separator for separating heavy particles from a liquid slurry stock comprising a casing forming a chamber adapted to be lled with liquid, an inlet conduit openingY into the upper end of said chamber and extending generally vertically with respect to said casing, an outlet conduit including a portion within said chamber in axially spaced alignment with said inlet conduit providing a circumferential discharge gap between said conduits within said chamber, the portion of said discharge conduit within said chamber and the adjacent end of said inlet conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said stock through said-inlet with a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said annular space continuing downwardly in said chamber below said gap to receive said discharged particles settling downwardly from said gap, and means forming a core extending axially through the interior of said inlet conduit and said discharge gap

- a vortex separator for separating heavy particles from a liquid slurry stock comprising a base, a cylindrical casing mounted on said base 1n substantially upright position to define a sepi 9 arating chamber adapted to be filled with liquid, an inlet conduit extending upwardly from the top of said casing in coaxial relationV with said chamber, an outlet conduit extending through Said casing adjacent ,the lower end thereof and projecting upwardly within said casing in alignment with said inlet conduit, said outlet conduit terminating in axially spaced relation with said inlet conduit to provide a circumferential discharge gap therebetween within said chamber, said outlet conduit and the lower end of said inlet conduit being of smaller diameter than said casing to define therewith an annular space surrounding said gap and extending downwardly therefrom within said chamber to said base a helix mounted within said inlet conduit for causing stock to be delivered through said conduit with a ⁇ whirling helical motion for effecting radial discharge of heavy particles therein through said gap into said surrounding annular space as said stock passes from said inlet

- a vortex separator for separating heavy particles from a liquid slurry stock, comprising a base, a cylindrical casing mounted on said base in substantially upright position to define aseparating chamber adapted to be lled with liquid, an inlet conduit Vextending upwardly from the top of said casing in coaxial relation tov said chamber,l an outlet conduit extending through said casing adjacent the lower end thereof and projecting upwardly within said casing ⁇ in alignment with said inlet conduit, said outlet conduit terminating in axially spaced relation with said inlet conduit toV provide a circumferential discharge gap therebetween within said chamber, said outlet conduit and the lower endof said inlet conduit being of smaller diameter than said casing to define therewith an annular space surrounding said gap and extending rdownwardly therefrom within said chamber to said base, a helix mounted within said inlet conduit for causing stock to be delivered through said conduit with a whirling helical motion for effecting radial discharge of heavy particles therein through said gap into said surrounding annular space as said stock passes from said inlet conduit

- a vortex separator for separating heavy particles from a liquid slurry stock comprising a casing forming a chamber adapted vto be filled.

- an inlet adapted to deliver stock into said chamber, an outlet from said chamber i aligned with said inlet to receive said stock directly from said inlet, means supporting said inlet ⁇ and said outlet with their adjacent ends spaced in the directionvof flow therebetween by a substantialv distanceto form within said chamber a circumferential gap of substantial axial length for radial ⁇ discharge of particles into the interior of said chamber from the line of liow fromsaid inlet to said outlet, saidinlet and outlet being of smaller diameter than said chamber to provide-an annular Space within said chamber surrounding ⁇ said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent -end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock to said chamber with a whirling helical motion to cause heavy particles therein to be -discharged radially outwardly ⁇ through said gap into said surrounding annular spaceas said stock passes from said inlet to said outlet, said

- a vortex separator for separating heavy particles from a liquid Vslurry stock comprising a casing forming a chamber of substantial verof said chambera circumferential gap of sub- ,stantial axial extent for radial discharge of particles into said chamber from the line of flow from said inlet to said outlet, a substantial portion of one of said conduits extending downwardly within said chamber below said gap from the end thereof adjacent the other said conduit, said conduit portion and the adjacent end of the other conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock.

- a vortex separator for separating heavy particles from a liquid slurry stock comprising a casing forming a chamber adapted to be filled with liquid, an inlet adapted to deliver stock into said chamber, an outlet from said chamber aligned with said' inlet to receive said stock digeiser@ ⁇ ber Vto provide ail-annular space within said chamber surrounding said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock to said chamber with -a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surroundingA annular space-as said stock passes from said inlet to said outlet, said core extending within said gap from within said inlet conduit to said outlet to cause all of said stock passing from said inlet conduit to said voutlet t'o flow with said helical motion, said annular space being circumferentially unobst

- a Vortex separator forvfseparating Yheavy particles from Va liquid slurry stock comprising -a casing forming a chamber-of substantial verytical extent adapted to be filled with liquid, an

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cyclones (AREA)

- Centrifugal Separators (AREA)

- Separation Of Solids By Using Liquids Or Pneumatic Power (AREA)

Description

Julyl 14, 1953 s. A. sTAEGE ETAL PAPER MACHINERY Filed May 20, 1950 lill/l.

INVENToRs' STEPHEN A. STAEGE BY ALBERT G. G/BSON Mya-M ATTORNEYS Patented July 14, :1953

PAPER MACHINERY Stephen A. Staege,` Hamilton, and Albert G. Gibson, Middletown, Ohio, assignors to The Black- Clawson Company, Hamilton, Ohio, a corporation of Ohio Application May 20, 1950, Serial No. 163,112

This invention relates to a vortex separator for separating heavy particles from paper making stock and other liquid slurrles.

The invention relates more particularlyto a vortex separator of the type wherein a whirling motion initially imparted to the stock as it enters a separating chamber is relied upon to set up deslred conditions of centrifugal force for effecting separation of the heavy particles therefrom. However, in place of relying upon a reversal of flow within the separating chamber such that an inner helix of clean stock flows within an outer helix of uncleaned stock and in the opposite direction, the present invention provides a vortex separator wherein the stock ilows in a substantially straight line from the inlet of the separating chamber to the outlet across an annular or circumferential discharge passage or` gap of substantial length within the separating chamber under controlled conditions such that heavy `particles are discharged through this passage into the interior of the separating chamber while the resulting clean stock ows directly to the outlet from the chamber.

In addition to this operating characteristic `of straight through now of the stock across an annular discharge passage of substantial axial ex- `tent for the reject particles, and the resulting avoidance of reversal of iiow and conditions of force with lower pressure and lower power consumption than when the stock is operated upon within a cylindrical separating chamber or when reversal of the flow within itself is relied upon. Furthermore, the invention provides operating conditions such that the rate of now of the clean Stock leaving the separating chamber may be decelerated after the stock crosses the discharge passage, thus further assuring effective separation of the heavy particles and minimizing the carrying capacity of the clean stock for reject material.

These operating characteristics are obtained in accordance with the invention by a construction of the separator wherein the inlet and outlet conduits for the separating chamber are positioned with their adjacent ends aligned within fthe upper part of the separating chamber insuch manner that the outlet .CQrlduitreceives stock ldi- 9 Claims.` (C1. 209-211) the closure.

rectly from the inlet conduit and in substantially straight line flow. The adjacent ends of these conduits are spaced from each other to leave an annular or circumferential discharge passage therebetween of substantial axial extent which opens into the interior of the separating chamber, and a core is provided which extends axially through this passage between the conduits. One ofthe conduits includes a portion of substantial length which is positioned within the chamber but is of substantially smaller diameter than the chamber to provide therein an annular portion 0r space surrounding the annular discharge passage and extending downwardly below the level of this passage within the chamber.

With this arrangement, when the stock is fed in through the inlet conduit in such manner as to impart to it a whirling helical motion as it enters the chamber, it will continue to whirl as it continues to ow across the discharge passage and thus cause heavy particles therein to be discharged through the discharge passage into the annular portion of the chamber while the clean stock'passes directly to the outlet conduit. The heavy particles which are thus discharged are then free to settle within the outer annular space and down to the bottom of the chamber, and the same whirling motion which causes their initial discharge through the discharge passage causes a continuing whirling of the particles as they settle and thus eiectively prevents their return into the flow of clean stock.

Provision is .also made in accordance 'with the invention for elfecting a controlled continuous discharge of heavy particles accumulating in the separating chamber while substantially preventing discharge of liquid other than the comparatively insignificant amount which may adhere to the reject particles. The bottom of the separating chamber is provided with a horizontally arranged screw conveyor which is motor driven at one end and isprovided at the other end with an outlet having a counterweighted closure. This conveyor collects reject material settling to the bottom of the separating chamber and conveys it to its outlet until there is sufiicient accumulation vof reject material at the outlet to force open When this occurs, the reject material is discharged as a damp sludge comparable in consistency to wet sand or gravel, but since the accumulated, slug of material between the conveyor and the outlet remains in place, it effectively seals against loss of liquid through the outlet except for the relatively small amount of liquid which adheres to the reject particles.

It is accordingly one of the principal objects of the present invention to provide a vortex separator which is free of small orifices and restrictions capable of plugging with reject material or of excessive wear in use, and which eiectively A separates heavy particles from a liquid slurry stock by causing all of the stock to flow with a helical motion as it crosses an annular discharge passage of substantial axial extent located between the inlet and outlet conduits for the separating chamber.

Another object is to Yprovide a vortex separator wherein the direction and rate of now through the separating chamber of the stock to be cleaned areV readily controlled and maintained under conditions of low turbulence which effectively minimize the carrying capacity of thestock for heavy particles and thus facilitate efficient operation of the device with low power requirementsr to give resulting economy of operation and maintenance.

It is also an object of the invention to provide a vortex separator wherein the heavy particles are separated from the stock and caused to settle in the separating chamber under conditions tending to minimize possible remixing with the clean stock and wherein the reject material is collected and continuously discharged as a damp sludge substantially free of entrained liquid.

Other objects and advantages of the invention will be apparent from the following description, the accompanying drawing and the appended claims.4

In the drawing- Fig. 1 is a perspective view of a vortex separator in accordance with the invention;

Fig. 2 is a diagrammatic View of the separator on a larger scale than Fig. 1 and with portions of the casing broken away to illustrate details of internal construction and operation; and

Fig. 3 is a top plan view of the device.

Referring to the drawing, which illustrates a preferred embodiment of the invention, the main base I E) supports a cylindrical casing il which encloses a separatingchamber I2 oi substantial volume and vertical extent. The casing ll is mounted on base III by means of a nange I3, and it includes an outlet conduit i5 which projects upwardly for a substantial distance within chamber I2 and is curved forwardly through the front of the casing for attachment at It to a suitable discharge pipe. An inlet conduit 2li is mounted on the upper end of casing I I by means of a flange 2 I, and it includes a tangentially arranged inlet connection 22 at its upper end. A helix comprising a core 25 and a helical vane 26 is vmounted within the inlet conduit 2D by means of a flanged upper end portion 2l and a twopiece clamping ring 28V provided with an-annular gasket 29.

The adjacent Aends of the inlet and outlet conduits 20 and I5 are maintained in axially spaced relation as shown to provide an annular or circumferential gap 3G of substantial length between the lower end of the inlet conduit 2Q and Vmunication with this tapered throat approximately 13 inches in inner diameter. It will also be noted that with the conduits and chamber` I2 of these relative dimensions, an annular space 33 is provided within chamber I2 which includes an upper portion surrounding the discharge gap 30 and a lower portion continuing downwardly therefrom around conduit 20 to the lower end of the chamber.

The core 25 of the helix in the inlet conduit 2B is of increasing diameter in the direction of flow through conduit 20 to provide a progressively decreasing cross sectional flow area through the inletconduit and thus to effect acceleration of the rate of flow of the incoming stock. Below this tapered portion of core 25 is a cylindrical portion which extends downwardly below vane 26 and completely through the interior of the discharge gap 3l) into the upper end of the outlet conduit I5. For example, with the conduits and casing II of the above dimensions, satisfactory results have been obtained with this cylindrical portion of the core approximately four inches in diameter and with the lower end thereof extending from seven to eight inches below the upper end of outlet conduit I5, and this downwardly projecting end portion of the core is shown as tapered to a rounded end of small radius to minimize turbulence. In additionyit will be noted that the lower end of the Vhelical vane 26 is shown as terminating at a point substantially above the lower end of the inlet conduit 20, for example approximately eight inches above the lower end of conduit 2d when the other dimensions of the device are as stated above.

The base I includes a tapered throat portion 35 which provides the bottom for separating chamber I2, to receive reject material settling in the chamber, and a cylindrical passage 35 extends horizontally through the base below and in com- 35. A screw conveyor All is mounted in the passage 3d for removing reject material settling therein, and it is lconnected through a exibie coupling 4I with a drive motor l2 mounted in the back of the base by means of a housing d3. The forward end of the passage 36 is provided with an outlet 44 which-extends forwardly beyond the end of screw 40, and a closure door i5 :or'this outlet is pivoted at the top of the outlet casting and provided with one or morecounterweights t@ for normally holding the door l5 in sealing position on the outer end of the outlet de. Provision is made for introducing a flow of clean water to the separating chamber I2 above the throat an l annular distributing passage 50 formed between thev bottom ilange I3 oi casing is and the upper portion of the base l, and a valve 5I is provided for controlling the admission of water to this passage from outside the casing. If it 'is desired to draw off liquid from the lower end of the chamber to supplement the reject removing action of the conveyor 8, this may be done by way of valve 5I instead of adding clean water Vas described.

reason of the progressively decreasing effective flowarea of the inlet conduit resulting from the tapered construction of the core 25. Also, with the vane 26 terminating above the lower end of the conduit as disclosed, the whirling motion of the stock is uniformly distributed around the core 25before the stock reaches the separating chamber,thus suppressing the tendency towards a jetlike discharge which occurs if the vane continues to the separating chamber and causes undesirable turbulence at the discharge gap.

Since the stock is thus whirling with a helical motion when it reaches the upper end of the chamber l2, and since the core 25 extends completely through the discharge gap 3!) into the outlet conduit, all ofthe stock will be subjected to this whirling motion as it flows towards the outlet conduit, this action being represented in Fig. l by the solid line arrows 55.v The centrifugal force resulting from this motion of the stock causes heavy particles therein to be concentrated in the outer part of the whirling mass of stock, and accordingly when this mass reaches the gap 30, the heavy particles will be thrown radially through this gap into the surrounding upper portion of the annular space 33. The clean stock will continue to whirl as it travels downwardly across inwardly of gap 3U and along the core 25 into the upper end of the outlet conduit i5, and with gap 30 of substantial length as shown, effective discharge of the heavy particles will take place while the stock traverses the lengthof the gap. In this connection, it should be noted that the length of ga'p 30 should vbe sufficient to provide adequate opportunity for the effective centrifugal force to overcome the forces of through flow and gravity tending to hold the heavy particles in the line of flow, while at the same time the gap should not be so long as to provide opportunity for remixing of the separated particles with the clean stock. Satisfactory results from both of these standpoints have been obtained with this gap of the dimensions given above and with the stock flowing through the device at a rate of the order of 1000 gallons Iper minute at a consistency of approximately 0.8% and an inlet pressure of approximately 20 pounds.

The heavy particles which are discharged into the space 33 will also whirl but in a larger spiral as indicated by the stippled arrows 55, thus effectively concentrating the reject material along the outer wall of chamber l2 as settling thereof takes place downwardly inthe chamber towards the conveyor 40, and it will thus be seen that the conditions set up within the chamber l2 all contribute to effective separation of heavymaterial andto prevention of remixing of the separated material with the clean stock. Since all of the stock is forced to whirl as it traverses the inlet conduit and the discharge passage,there is no relatively stagnant central portion such as might exist if the core 25 were not present, and at the same time the construction of the device as shown effectively prevents shortcircuiting of the stock of a high pressure inlet to a low pressure outlet. The arrangement with the outlet conduit located centrally within the annular space 33 is also of assistance in maintaining continued separation of the reject once it has been discharged through passage 3D. Not only does the whirling of the reject in itself tend to prevent remixing, but since the space 33 continuesbelow the level of gap 30 to the lower portion of chamber I2, gravity also acts on the separated material and causes it to settle until it reaches the conveyor 40.

Effective separation is aided by the inward flow of clean liquid fromV the passage 5U; which is maintained at a low volumetric rate approximately the volumetric rate atV which the reject material is removed, for example approximately two gallons per minute under the operating conditions described above. This clean' liquid replaces the reject in the flow of clean stock into the outlet conduit, and it provides a back pressure across thev discharge gap which tends to maintain the clean stock on its desired course and is particularly useful in thecase of paper stock since it aids in preventing discharge of fiber with the heavy particles. In fact, if bits of fiber should initially be discharged through gap 3|] by clinging to heavy particles, the upward flow of the clean water through the space 33 tends to wash off this ber and carry it back into the outgoing stream of the clean stock. It will also be seen that this back pressure provided by the added flow of clean liquid can be readily predetermined and controlled as desired to regulate the discharge through gap 30. A further aid to effective separating action an the prevention of remixing of reject material with the clean stock is provided by the arrangement of the core 25 with its lower end extending a substantial distance into the outlet conduit and then terminating. The presence of the core in the upper end of the outlet conduit aids in maintaining the -desired whirling motion of all of the stock until after it has entered the discharge conduit, since it maintains the effective flow area of this portion of the outlet conduit substantially equal to that of the discharge end of the inlet conduit. In addition, the termination of the core at a position as shown within the outlet conduit increases the effective flow area of the outlet conduit beyond that point and thus produces a corresponding deceleration of the rate of ilow of the clean stock, Iwhich is desirable in effectuating the proper separation of the reject material since the resulting reduced rate of flow of the clean stock materially reduces its carrying capacity for heavy particles. Also with the device substantially free of restricted passages or orifices and provided with liberal open areas around all parts as shown, both reject material and fiber are prevented from accumulating at `any point in such manner as to cause possible change in the flow vrelatively solid slug between the end of the conveyor and the door 45. Then as additional reject accumulates and is forced against this slug, the door 45 will be opened'against its counterweights 46` to effect gradual `discharge of the reject as indicated bythe stippled arrows 5l in Fig. 2. When this occurs, however, there still remains a substantial slug of reject within the outlet 44 which acts effectively as a seal against free discharge of Vliquid through the out# let. As a result, it is found in practice that the discharge of reject takes place in the form of a damp sludge containing practically no more liquid than adheres to the individual particles 7 in this sludge, giving it a consistency roughly comparable to wet sand. This sludge is accordingly easy to handle for disposal by shovels Yor in any other convenient Way and without also den change inthe pressure within the unit such as may result from intermittent cleaning or the opening and closing of a continuously operated port type valve, and the pressure within the unit Y therefore remains constant with no peaks and valleys in the resulting efficiency curve.

Reference is made to copending application of Joseph Baxter, Jr., Serial No. 163,151, filed of even date herewith and assigned to the same assignee as this application.

. While the form` of apparatus herein described constitutes a preferred embodiment of the invention, it is Yto be understood that the invention is not limited to this precise formV of apparatus, and that changes may be made therein Without departing from the scope of the invention which is defined in the appended claims.

What is claimed is:

l. A vortex separator ior separating heavy particles from a liquid slurry stock comprising a casing forming a chamber adapted to be filied with liquid, a cylindrical inlet conduit adapted to deliver stock Vinto said chamber in substantially vertical flow, a cylindrical outlet conduit from said chamber aligned with said inlet conduit to receive said stock directly from said inlet conduit, means maintaining the adjacent ends of said conduits in axially spaced relation within said chamber to provide a circumferential dis charge gap therebetween for radial discharge of particles out of the line of flow therebetween into said chamber, said inlet and outlet conduits being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said vstock through said inlet conduit with a whirling helical motion to cause solid particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said annular space continuing downwardly in said chamber below said gap to receive said discharged particles settling downwardly vfrom said gap, means forming a core in said inlet conduit extending through the interior of said discharge gap into the interior ci said outlet'conduit to cause all of said stock to Vflow with said whirling helical motion while passing from said inlet to said outlet, said core terminating at a position spaced within said outlet conduit from said gap to cause deceleration of the rate of flow of said stock through said outlet conduit, and means in said casing below said gap for receiving said particles settling through said annular Y space.

outlet conduit from said chamber including a portion of substantial length arranged within said chamber in position to receive said stock directly from said inlet conduit, meansrmaintaining said conduits with their adjacent ends in axially spaced relation within said chamber to Vprovide a circumferential discharge gapbetween said conduits for radial discharge of particles out of the line of flow therebetweenA into the interior of said chamber, the portion of said discharge conduit within said chamber and the adjacent end of said inlet conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said stock through said inlet with a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit tosaid outlet conduit, said annular space continuing downwardly in said chamber below said gap to Vreceive said discharged particles settling downwardly from said gap, and means forming a core extending axially through the interior of said inlet conduit and said discharge gap into the interior of said discharge conduit to cause all of said stock to iiow with said whirling helical motion while passing from said inlet to said outlet, and means in said casing below said gap for receiving solid particles settling through said annular space.

3. A vortex separator for separating heavy particles from a liquid slurry stock, comprising a casing forming a chamber adapted to be lled with liquid, an inlet conduit openingY into the upper end of said chamber and extending generally vertically with respect to said casing, an outlet conduit including a portion within said chamber in axially spaced alignment with said inlet conduit providing a circumferential discharge gap between said conduits within said chamber, the portion of said discharge conduit within said chamber and the adjacent end of said inlet conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, means for delivering said stock through said-inlet with a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said annular space continuing downwardly in said chamber below said gap to receive said discharged particles settling downwardly from said gap, and means forming a core extending axially through the interior of said inlet conduit and said discharge gap into the interior of said outlet'conduit to Y of the rate of flow of said stock through said Y outlet conduit.

4. A vortex separator for separating heavy particles from a liquid slurry stock, comprising a base, a cylindrical casing mounted on said base 1n substantially upright position to define a sepi 9 arating chamber adapted to be filled with liquid, an inlet conduit extending upwardly from the top of said casing in coaxial relationV with said chamber, an outlet conduit extending through Said casing adjacent ,the lower end thereof and projecting upwardly within said casing in alignment with said inlet conduit, said outlet conduit terminating in axially spaced relation with said inlet conduit to provide a circumferential discharge gap therebetween within said chamber, said outlet conduit and the lower end of said inlet conduit being of smaller diameter than said casing to define therewith an annular space surrounding said gap and extending downwardly therefrom within said chamber to said base a helix mounted within said inlet conduit for causing stock to be delivered through said conduit with a `whirling helical motion for effecting radial discharge of heavy particles therein through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said helix including a cylindrical core extending axially through said discharge gap and into the upper end of said outlet conduit for causing all of said stock to flow with said whirling helical motion while passing from said inlet to said outlet and means in said base for collecting and discharging particles settling through said annular space.

5. A vortex separator for separating heavy particles from a liquid slurry stock, comprising a base, a cylindrical casing mounted on said base in substantially upright position to define aseparating chamber adapted to be lled with liquid, an inlet conduit Vextending upwardly from the top of said casing in coaxial relation tov said chamber,l an outlet conduit extending through said casing adjacent the lower end thereof and projecting upwardly within said casing` in alignment with said inlet conduit, said outlet conduit terminating in axially spaced relation with said inlet conduit toV provide a circumferential discharge gap therebetween within said chamber, said outlet conduit and the lower endof said inlet conduit being of smaller diameter than said casing to define therewith an annular space surrounding said gap and extending rdownwardly therefrom within said chamber to said base, a helix mounted within said inlet conduit for causing stock to be delivered through said conduit with a whirling helical motion for effecting radial discharge of heavy particles therein through said gap into said surrounding annular space as said stock passes from said inlet conduit to said outlet conduit, said helix including a cylindrical core extending axially through said discharge gap and into the vupper end of said outlet conduit for causing al1 of said stock to flow with said whirling helical motion while passing from said inlet to Said outlet, the lower end of Said helix being positioned within said inlet conduit and spaced substantially above the lower end of said inlet conduit to effect substantially uniform distribution of said whirling mo.

tion of said stock around said core prior to delivery of said stock from said inlet conduit, and means in said base for collecting and discharging particles settling through said annular space.

6. A vortex separator for separating heavy particles from a liquid slurry stock, comprising a casing forming a chamber adapted vto be filled.`

with liquid, an inlet adapted to deliver stock into said chamber, an outlet from said chamber i aligned with said inlet to receive said stock directly from said inlet, means supporting said inlet` and said outlet with their adjacent ends spaced in the directionvof flow therebetween by a substantialv distanceto form within said chamber a circumferential gap of substantial axial length for radial` discharge of particles into the interior of said chamber from the line of liow fromsaid inlet to said outlet, saidinlet and outlet being of smaller diameter than said chamber to provide-an annular Space within said chamber surrounding `said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent -end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock to said chamber with a whirling helical motion to cause heavy particles therein to be -discharged radially outwardly `through said gap into said surrounding annular spaceas said stock passes from said inlet to said outlet, said annular space being circumferentially unobstructed and continuing downwardly in said chamber below said gap to cause said discharged particles to continue to whirl therein in a helical path of greater radius than said stock within said gap for effective concentration of said particles along'the `outer Wall of said chamber while settling downwardly fromV said gap, and means in said casing below said gap for receiving said particles settling through said annular space.

'7. A vortex separator for separating heavy particles from a liquid Vslurry stock, comprising a casing forming a chamber of substantial verof said chambera circumferential gap of sub- ,stantial axial extent for radial discharge of particles into said chamber from the line of flow from said inlet to said outlet, a substantial portion of one of said conduits extending downwardly within said chamber below said gap from the end thereof adjacent the other said conduit, said conduit portion and the adjacent end of the other conduit being of smaller diameter than said chamber to provide an annular space within said chamber surrounding said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock. to said chamber with a whirling helical motion to cause heavy particles therein to be discharged radially outwardly int'o said surrounding annular space through said gap as said stock passes from said inlet conduit to said outlet conduit, said annular space continuing downwardly in said chamber below said gap to receive said discharged particles settling downwardly from said gap, and means for receiving and discharging from said casing particles settling downwardly through said annular space. Y

8. A vortex separator for separating heavy particles from a liquid slurry stock, comprising a casing forming a chamber adapted to be filled with liquid, an inlet adapted to deliver stock into said chamber, an outlet from said chamber aligned with said' inlet to receive said stock digeiser@ `ber Vto provide ail-annular space within said chamber surrounding said gap, said inlet including an elongated conduit extending in coaxial relation with said gap and said adjacent end of said outlet, means including a vane and a central core within said inlet conduit for effecting delivery of said stock to said chamber with -a whirling helical motion to cause heavy particles therein to be discharged radially outwardly through said gap into said surroundingA annular space-as said stock passes from said inlet to said outlet, said core extending within said gap from within said inlet conduit to said outlet to cause all of said stock passing from said inlet conduit to said voutlet t'o flow with said helical motion, said annular space being circumferentially unobstructed and continuing downwardly 'in said chamber be- Y low said gap to cause said discharge particles t'o continue to whirltherein in .a helical path of greater radius than said stock vwithin said gap for effective concentration of said particles along the outer wall of said chamber while settling downwardly from said gap, and means in said casing below said g-ap for receiving said particles settling through said annular space, Y

9. A Vortex separator forvfseparating Yheavy particles from Va liquid slurry stock, comprising -a casing forming a chamber-of substantial verytical extent adapted to be filled with liquid, an

inlet'conduit opening into the upper end of said chamber and including an elongated portionextending generally upwardly from said casing, an

-outlet conduit from said -chamber including a portion of substantial length arranged within Asaid casing incoaxi'al relation with said linlet conduit to receive said Stock directly from said inlet conduit, the adjacent ends of -said conduits 12 terminating in spaced relation in the direction of Ilow` therebetween by a substantial distance to form within the upper portion of said chamber a circumferential gap of substantial axial extent, said Vportion of said discharge conduitV within said chamber being of materially smaller diameter than said chamber to provide an annular space within said chamberY surrounding said gap, means including a vane and a central core within said inlet conduit for effecting deliverir of said stock to said chamber with a whirling helical motion to cause heavy particles therein t'o be discharged radially outwardly through said gap into said surrounding annular space as said stock passes from Vsaid inlet conduit to said outlet conduit, said annular space being circumferentially unobstructed and continuing downwardly in said chamber below said gap to causeV said `discharged particles to continue to whirl therein ina helical path of greater radius than said stock within said ygap for effective concentration of said .particles along the outer wall of vsaid chamber while settling downwardly from said gap, and means in said casing below said gap for receiving said particles settling through said annular space. Y

, .STEPHEN A. STAEGE.

ALBERT G. GIBSON.

References Cited in the -le of this lpatent UNITED STATES PATENTS France Jan; .271, 1942

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE501981D BE501981A (en) | 1950-05-20 | ||

| US4788A US2645397A (en) | 1948-01-28 | 1948-01-28 | Counting and packing machine |

| US163151A US2645347A (en) | 1950-05-20 | 1950-05-20 | Vortex separator for pulp |

| US163112A US2645346A (en) | 1950-05-20 | 1950-05-20 | Paper machinery |

| FR1041620D FR1041620A (en) | 1950-05-20 | 1951-02-16 | Improvements to vortex separators |

| GB4098/51A GB684896A (en) | 1950-05-20 | 1951-02-20 | Improvements in or relating to a vortex separator |

| DEB14076A DE851160C (en) | 1950-05-20 | 1951-03-08 | Vortex separator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US163112A US2645346A (en) | 1950-05-20 | 1950-05-20 | Paper machinery |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2645346A true US2645346A (en) | 1953-07-14 |

Family

ID=22588536

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US163112A Expired - Lifetime US2645346A (en) | 1948-01-28 | 1950-05-20 | Paper machinery |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US2645346A (en) |

| BE (1) | BE501981A (en) |

| DE (1) | DE851160C (en) |

| FR (1) | FR1041620A (en) |

| GB (1) | GB684896A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2740523A (en) * | 1953-02-02 | 1956-04-03 | Daniel J Winters | Spiral concentrator |

| US3288286A (en) * | 1964-02-18 | 1966-11-29 | Prins Klaas | Centrifugal type separator |

| US3372532A (en) * | 1965-08-17 | 1968-03-12 | Centrifix Corp | Dry separator |

| US4564443A (en) * | 1983-07-14 | 1986-01-14 | The Black Clawson Company | Reverse centrifugal cleaning of paper making stock |

| US5149341A (en) * | 1991-08-23 | 1992-09-22 | Taylor John A | Paper coater skip prevention and deaeration apparatus and method |

| US5514206A (en) * | 1994-04-15 | 1996-05-07 | Consolidated Papers, Inc. | Air/gas separator device |

| WO2002000352A1 (en) * | 2000-06-26 | 2002-01-03 | Ecomin Srl | Feeding method and apparatus for dynamic separators |

| WO2012101466A1 (en) * | 2011-01-27 | 2012-08-02 | Bohorquez John | System for transforming plastic polymer films and paper with or without adhesives and silicones into plastic compounds by means of a vortex device |

| CN106902998A (en) * | 2017-03-22 | 2017-06-30 | 佛山市恒学科技服务有限公司 | A kind of self-tipping type cyclone dust collectors |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1170766B (en) * | 1952-04-25 | 1964-05-21 | Voith Gmbh J M | Device for the constant separation of specifically heavy impurities from fiber suspension |

| DE3005518A1 (en) * | 1979-02-16 | 1980-09-04 | Beloit Walmsley Ltd | FABRIC SEPARATOR |

| DE4219096C2 (en) * | 1992-06-11 | 1994-06-09 | Karl Friedrich Vedder | Cyclone for phase separation of a working fluid in the partial process of condensate expansion with high excess steam |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US429347A (en) * | 1890-06-03 | Dust-collector | ||

| US1701942A (en) * | 1926-07-30 | 1929-02-12 | Andrews Leonard | Vortex classifier suitable for use in the classification of powdered materials by elutriation |

| US1755790A (en) * | 1928-12-29 | 1930-04-22 | Elmer R Nevel | Hot-air-furnace attachment |

| US1825157A (en) * | 1926-12-03 | 1931-09-29 | Anthracite Separator Co | Method and apparatus for hydraulically separating materials |

| US1880185A (en) * | 1932-09-27 | Method and means fob removing sand and the like from fluids | ||

| CH190419A (en) * | 1936-03-04 | 1937-04-30 | Feifel Eugen Prof Ing Dr | Method and device for separating physical mixtures. |

| US2184248A (en) * | 1936-08-06 | 1939-12-19 | Extractol Process Ltd | Method and mechanism for continuously forming liquid-impervious plugs in extraction units |

| FR868952A (en) * | 1939-11-18 | 1942-01-21 | Voith Gmbh J M | Tubular separator for separating heavy and light materials diluted in a liquid |

| US2346005A (en) * | 1940-08-15 | 1944-04-04 | Tandy A Bryson | Vortex separator |

| US2512253A (en) * | 1947-04-10 | 1950-06-20 | Grace W R & Co | Centrifugal separator |

-

0

- BE BE501981D patent/BE501981A/xx unknown

-

1950

- 1950-05-20 US US163112A patent/US2645346A/en not_active Expired - Lifetime

-

1951

- 1951-02-16 FR FR1041620D patent/FR1041620A/en not_active Expired

- 1951-02-20 GB GB4098/51A patent/GB684896A/en not_active Expired

- 1951-03-08 DE DEB14076A patent/DE851160C/en not_active Expired

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US429347A (en) * | 1890-06-03 | Dust-collector | ||

| US1880185A (en) * | 1932-09-27 | Method and means fob removing sand and the like from fluids | ||

| US1701942A (en) * | 1926-07-30 | 1929-02-12 | Andrews Leonard | Vortex classifier suitable for use in the classification of powdered materials by elutriation |

| US1825157A (en) * | 1926-12-03 | 1931-09-29 | Anthracite Separator Co | Method and apparatus for hydraulically separating materials |

| US1755790A (en) * | 1928-12-29 | 1930-04-22 | Elmer R Nevel | Hot-air-furnace attachment |

| CH190419A (en) * | 1936-03-04 | 1937-04-30 | Feifel Eugen Prof Ing Dr | Method and device for separating physical mixtures. |

| US2184248A (en) * | 1936-08-06 | 1939-12-19 | Extractol Process Ltd | Method and mechanism for continuously forming liquid-impervious plugs in extraction units |

| FR868952A (en) * | 1939-11-18 | 1942-01-21 | Voith Gmbh J M | Tubular separator for separating heavy and light materials diluted in a liquid |

| US2346005A (en) * | 1940-08-15 | 1944-04-04 | Tandy A Bryson | Vortex separator |

| US2512253A (en) * | 1947-04-10 | 1950-06-20 | Grace W R & Co | Centrifugal separator |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2740523A (en) * | 1953-02-02 | 1956-04-03 | Daniel J Winters | Spiral concentrator |

| US3288286A (en) * | 1964-02-18 | 1966-11-29 | Prins Klaas | Centrifugal type separator |

| US3372532A (en) * | 1965-08-17 | 1968-03-12 | Centrifix Corp | Dry separator |

| US4564443A (en) * | 1983-07-14 | 1986-01-14 | The Black Clawson Company | Reverse centrifugal cleaning of paper making stock |

| US5149341A (en) * | 1991-08-23 | 1992-09-22 | Taylor John A | Paper coater skip prevention and deaeration apparatus and method |

| US5514206A (en) * | 1994-04-15 | 1996-05-07 | Consolidated Papers, Inc. | Air/gas separator device |

| WO2002000352A1 (en) * | 2000-06-26 | 2002-01-03 | Ecomin Srl | Feeding method and apparatus for dynamic separators |

| US7028848B2 (en) | 2000-06-26 | 2006-04-18 | Ecomin Srl | Feeding method and apparatus for dynamic separators |

| WO2012101466A1 (en) * | 2011-01-27 | 2012-08-02 | Bohorquez John | System for transforming plastic polymer films and paper with or without adhesives and silicones into plastic compounds by means of a vortex device |

| CN106902998A (en) * | 2017-03-22 | 2017-06-30 | 佛山市恒学科技服务有限公司 | A kind of self-tipping type cyclone dust collectors |

Also Published As

| Publication number | Publication date |

|---|---|

| GB684896A (en) | 1952-12-24 |

| FR1041620A (en) | 1953-10-26 |

| DE851160C (en) | 1952-10-02 |

| BE501981A (en) |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2645346A (en) | Paper machinery | |

| US2377524A (en) | Method of and means for separating solid particles in pulp suspensions and the like | |

| US3399773A (en) | Apparatus for separating solids from liquids | |

| US2816490A (en) | Apparatus for treating liquid mixtures for separation of solid particles and gases | |

| US2379411A (en) | Method and apparatus for purifying paper pulp | |

| GB533235A (en) | Improvements in or relating to method of and apparatus for separating undesired particles from a liquid suspension | |

| US3516551A (en) | Cyclone separator | |

| US2364405A (en) | Method and apparatus for separating foreign matter from papermaking material | |

| SU513598A3 (en) | Device for separating aqueous suspensions | |

| US4161448A (en) | Combined separator and pump with dirty phase concentrator | |

| US3612276A (en) | Vortex-type separator apparatus | |

| US2010231A (en) | Cleaner for gaseous fluids | |

| US5131544A (en) | Device for selectively separating particles in a liquid, in particular for cleaning fibrous paper suspensing | |

| US1847751A (en) | Centrifuge method and apparatus | |

| US2557629A (en) | Method and apparatus for continuous centrifugal separation | |

| US3335860A (en) | Centrifugal cleaner for paper making stock and the like | |

| US2958461A (en) | Centrifuge machine | |

| US1753502A (en) | Dust collector | |

| US2375826A (en) | Vortex separator apparatus for treating paper pulp | |

| US1930476A (en) | Line separator and grader | |

| US2645347A (en) | Vortex separator for pulp | |

| CZ285066B6 (en) | Apparatus for separating at least one substance from liquid or gaseous medium | |

| US1908181A (en) | Dust collector and separator system | |

| US3415373A (en) | Particle size classification method and apparatus | |

| US2518084A (en) | Apparatus for separating relatively heavy particles from liquid |