US2639072A - Filling machine having vertically reciprocable tamping arms and plunger - Google Patents

Filling machine having vertically reciprocable tamping arms and plunger Download PDFInfo

- Publication number

- US2639072A US2639072A US52280A US5228048A US2639072A US 2639072 A US2639072 A US 2639072A US 52280 A US52280 A US 52280A US 5228048 A US5228048 A US 5228048A US 2639072 A US2639072 A US 2639072A

- Authority

- US

- United States

- Prior art keywords

- plunger

- nozzle

- hopper

- arms

- filling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 description 35

- 239000002245 particle Substances 0.000 description 5

- 229920001971 elastomer Polymers 0.000 description 4

- 239000011800 void material Substances 0.000 description 3

- 210000003813 thumb Anatomy 0.000 description 2

- 235000003301 Ceiba pentandra Nutrition 0.000 description 1

- 244000146553 Ceiba pentandra Species 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 210000000436 anus Anatomy 0.000 description 1

- 238000007596 consolidation process Methods 0.000 description 1

- 229920001821 foam rubber Polymers 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B37/00—Supplying or feeding fluent-solid, plastic, or liquid material, or loose masses of small articles, to be packaged

Definitions

- An object of this invention is to provide a conical hopper having a central nozzle for receiving a large supply of the rubber particles and to provide an elongated vertically movable plunger and two vertically and laterally movable tamping or pusher arms for pushing and kcollecting the filling material over the nozzle to permit the plunger to pack the collected material into a container secured to the lower end of the nozzle.

- Another object of this invention is to provide a funnel shaped conical hopper having inwardly tapering walls and to pivotally mount the tamping or pusher arms so that as the arms are moved downwardly in the hopper, the tapering hopper walls cause the arms to simultaneously move laterally toward the nozzle.

- Another object of this invention is to hang the tamping arms from a single horizontal crossbar and to cause the arms to move vertically in unitary relation and an equal distance.

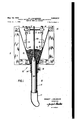

- Figure 1 is a central cross-sectional view of a fragmentary portion of the lling machine, showing tamping and packing mechanism movably mounted in a conical hopper.

- Figure 2 is a front elevation of the entire filling machine.

- Figure 3 is a front elevation of modified filling mechanism showing the lower portion of the hopper perforated and circumscribed by an inclosure and under air suction.

- Figure 4 is an enlarged cross-sectional view taken as on line 4-4 in Figure 1, with the tamping arms shown in close relation with the plunger.

- Figure 5 is a cross-sectional view taken on line 5 5 in Figure 2, showing an eccentric and pitman, the remainder parts being omitted.

- the numeral I indicates a filling machine comprising a housing I I, having a conical hopper I2 xed thereto by bolts I3.

- the hopper I2 has a nozzle I4 at its lower end.

- a nozzle extension I is mounted in the nozzle I4 and held by means of a thumb screw I6.

- a container I'I is suitably secured to the nozzle extension I5.

- the container I'I may be an arm or a leg of a doll.

- An elongated plunger rod is mounted in bearings 2I fixed to the housing II.

- yA plunger 22 is secured to the plunger rod 20 by a pin 23 and is of slightly smaller diameter than the internal diameter of the nozzle I5.

- the upper end portion of the plunger 22 tapers upwardly and is reduced in diameter to substantially that of the plunger rod 20, as indicated by the numeral 24.

- the drive mechanism for the plunger rod 20 andthe plunger 22 consists of a shaft 25 mounted in bearings 26 suitably supported at the upper elevation of the housing II.

- a gear 21 fixed to the shaft and driven in any suitable manner from a power source causes rotation of the shaft 25.

- a counterbalanced crank arm 28 Secured to the inner end of the shaft 25 is a counterbalanced crank arm 28 having one end of a link 29 pivotally connected thereto. The other end of the link 29 is pivotally connected to. a head member 30 which is vxed to the plunger rod 20.

- Rotation of the shaft 25 causes reciprocation of the plunger rod 20 and reciprocation of the plunger 22 into and out of the nozzle extension I5. It is to be noted that an annular clearance space 3

- the material 32 to be fed into the containery I1 is non-fluent and a void is formed above the nozzle on the return stroke of the plunger.

- I provide tamping arms or pusher arms 35 which are pivotally mounted on pins 36 in a horizontal cross-head 3l. The arms 35 are positioned diametrically of the conical hopper I 2.

- the cross-head 37 is guided for vertical reciprocating motion by guide rods 38 slidable in bear- Iings 39.

- An eccentric 40 mounted en the shaft' carries a pitman 4

- Rotation of the shaft 25 causes joint vertical reciprocation of the arms 35.

- the lower end portions of the arms are guided by the inclined walls of the hopper I2 for movement toward the axis of the nozzle and serve tocollect and feed the material 32 to the nozzle.

- the tamping arms 3'5 consolidate the lling material. This consolidation permits its discharge into a container through a small diameter pipe or nozzle extension I5 by the plunger 22.

- the arms have semi-circular lower portions 45, each of which is shaped like a crescent with a concave inner face 46.

- the concavity 46 permits each lower portion to closely approach the plunger 22 and feed the material 32 to the plunger 22.

- the modiiied iilling mechanism identified by the numeral 50, comprises a housing 5

- the hopper 52 has a nozzle

- 51 is mounted in the nozzle

- a container is suitably secured to the nozzle extension

- the modified filling mechanism 5c also comprises a plunger rod 201 and a plunger 221 driven by a gear 211 and a shaft 251 mounted in bearings 261, the same as shown in Figure 2.

- the modied filling mechanism 5D also comprises a cross-head and feeding arms guided by rods 381 and driven by a crank arm and by an eccentric (not shown), the saine as shown in Figure 2. y

- the hopper 52 has apertures 53 all around its lower portion while the upper portion of the hopper is intact.

- a cylindrical jacket 54 having a larger inner 4diameter than the outer diameter of the apertured lower portion of the hopper 52 is mounted in circumscribing relation with the hopper.

- the jacket 54 has upper and lower anges 55, 56 in suitably contacting relation with the hopper 52.

- a chamber 51 of annular cross-section is formed between the jacket 54 and the hopper 52.

- a tube has one end mounted in an aperture 6

- a butterfly or disk valve is mounted on a pin 66, passing diametrically through the valve 65 and through the tube 53.

- the valve 6'5 is actuated by an arm 61, secured to the pin 66.

- the free end of the arm 51 is pivotally connected Vto the lower end of a pitman B3 driven by an eccentric 89 on the shaft 251.

- Motion is intermittently and automatically communicated to the butterfly valve 65 by the pitman G8 and timed so that the valve is moved into position to close the suction tube 60, to permit a quantity of filling material to be fed into a container frictionally held on the nozzle ex- 4 the downward feeding movement of the plunger through the nozzle.

- the filling material is placed in the conical hopper having a long tubular nozzle extension at its lower end.

- a small container such as a hand or foot of a doll is attached to the lower end portion of the nozzle extension.

- the filling material is forced into the container by the vertically reciprocable plunger which is carried down within the nozzle with its lower end slightly below the nozzle extension.

- two pusher arms are positioned diametrically of the hopper and are movable vertically and laterally in the hopper in contacting relation with the sides of the hopper.

- the arms follow the sloping sides of the hopper towards the nozzle.

- the lower ends of the pusher arms are of semi-circular form adapted to partly circumscribe the plunger.

- the plunger and pusher arms move simultaneously in the saine direction for a short time.

- the plunger is moved through a large distance while the pusher arms are moved through a small distance.

- ncn-uent materials mean to include cotton, kapok, wool, latex foam rubber, etc.

- the action of the mechanism is arranged so that the pusher or tainping arms 35 first feed the iilling material down toward the opening in the bottom of the hopper and hold the material in compacted form under pressure and that the plunger 22 then comes down and pushes the already compacted material into and through the nozzle extension.

- This filling machine thus exerts a two-step feeding action, rst feeding the material toward the opening in the bottom of the hopper so as to compact the material, and second, feeding the material through the hopper and through the nozzle and into a container in timed relation.

- the pusher arms 35 have already been returned to their starting position and when the plunger is likewise returned to its starting position, the cycle is repeated.

- I may extend the hopper so as to circumscribe a portion of the nozzle extension (not shown). This will augment the suction area and increase the quantity of material that the plunger can push through the nozzle.

- a housing In a two-step feeding machine for filling containers with particles of non-fluent material, a housing, an upright conical and perforated hopper fixed to said housing and having a tubular nozzle at its lower end, a plunger reciprocally mounted on said housing for up and down movement in said hopper and through said nozzle, a cross-head slidably mounted on said housing, two tamping arms pivotally mounted on said cross-head and reciprocally mounted for up and down movements, said arms being in diametrically contacting relation with the inclined-walls of said hopper and guided by said walls for simultaneous movement to said nozzle, the lower end portions of said arms facing said nozzle being semi-circular and adapted for movement toward the axis of said nozzle for collecting and feeding said filling material to said nozzle, to permit said plunger in its downward movement to pack said collected material into said container, a drive shaft mounted transversely of said housing and having an eccentric thereon, a connecting rod mounted on said eccentric at one end and being connected to said cross-head.

- a housing for filling containers with particles of non-fluent material, a housing, an upright conical hopper xed to said housing and having a tubular nozzle at its lower ⁇ end, a plunger reciprocally mounted on said housing for up and down movement in said hopper and through said nozzle, a cross-head slid- 3 ably mounted on said housing, two tamping arms pivotally mounted on said cross-head and reciprocally mounted for up and down movements,

- said arms being in diametrically contacting relation with the inclined Walls of said hopper and guided by said walls for simultaneous movement to said nozzle, the lower end portions of said arms facing said nozzle and being semi-circular and adapted for movement toward the axis of said nozzle for collecting and feeding said filling material to said nozzle, to permit said plunger in its downward movement to pack said collected material into said container, a drive shaft mounted transversely of said housing and having an eccentric thereon, a connecting rod mounted on said eccentric at one end and being connected to said cross-head at the other end, a crank fixed at one end of said shaft, a link pivotally -secured to said crank at one end and being pivotally connected to said plunger at the other end, said plunger and said tamping arms being independently driven from said drive shaft in timed relation, whereby ⁇ the tamping arms first feed the lling material toward the opening in the bottom of the hopper and hold the material in compacted form andthe plunger then comes down and pushes the already compacted material into and through

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Basic Packing Technique (AREA)

Description

May 19 1953 A R. J. GoLDBERG .2,639,072

FILLING uAcHINE HAVING vERTIcALLY vREcIPRocALF TAMPING Amas AND YLUNGER Filed oct. 1, 1948 :s sheets-sheet 1 1 FIGJ ROBERT J. GLDBERQ lNvENToR ATTORNEY May 19, 1953 R J, G0L BERG I 2,639,072

FILLING MACHINE HAVING v 'IICALMl REcIPRocABLE v TANPING Anus AND PLUNGERy l Filed oct. 1, 1948 f :5 sheets-sheet 2 EEG-.5

ROBERT a. @01.055116A INVENTOR May 19, 1953 R. J. GQLDBERG A 2,639,072

FILLING MACHINE HVING'VERTICALLY RECIPROCABLE TAMPING'RMS AND PLUNGER lFiled oct. 1, 1948 5 sheets-sheet s ROBRT J. GOLDBERG INVENTOR 'LFIGA I ATTORNEY Patented May 19, 1953 FILLING MACHINE HAVING VERTICALLY RECIPROCABLE TAMPING ARMS AND PLUNGER Robert J. Goldberg, New York, N. Y., assigner of one-half to Max Goldberg, New York, N. Y.

Application October 1, 1948, Serial No. 52,280

2 Claims.

This invention relates to a machine for filling small containers with rubber particles or like non-fluent material.

An object of this invention is to provide a conical hopper having a central nozzle for receiving a large supply of the rubber particles and to provide an elongated vertically movable plunger and two vertically and laterally movable tamping or pusher arms for pushing and kcollecting the filling material over the nozzle to permit the plunger to pack the collected material into a container secured to the lower end of the nozzle.

Another object of this invention is to provide a funnel shaped conical hopper having inwardly tapering walls and to pivotally mount the tamping or pusher arms so that as the arms are moved downwardly in the hopper, the tapering hopper walls cause the arms to simultaneously move laterally toward the nozzle.

Another object of this invention is to hang the tamping arms from a single horizontal crossbar and to cause the arms to move vertically in unitary relation and an equal distance.

In practice it is found that downward movement of the plunger through the nozzle causes a void or empty space above the nozzle on the return stroke. This is due to the fact that rubber is a non-fluent material. The tamping arms push the particles of filling material toward the nozzle and fill the void before the plunger starts its downward stroke.

With the above and other objects in view, the invention will be hereinafter more particularly described, and the combination and arrangement of parts will be shown in the accompanying drawings and pointed out in the claims which form part of this specification.

Reference will now be had to the drawings, wherein like numerals of reference designate corresponding parts throughout the several views, in which:

Figure 1 is a central cross-sectional view of a fragmentary portion of the lling machine, showing tamping and packing mechanism movably mounted in a conical hopper.

Figure 2 is a front elevation of the entire filling machine.

Figure 3 is a front elevation of modified filling mechanism showing the lower portion of the hopper perforated and circumscribed by an inclosure and under air suction.

Figure 4 is an enlarged cross-sectional view taken as on line 4-4 in Figure 1, with the tamping arms shown in close relation with the plunger.

Figure 5 is a cross-sectional view taken on line 5 5 in Figure 2, showing an eccentric and pitman, the remainder parts being omitted.

In the illustrated embodiment of the invention, the numeral I indicates a filling machine comprising a housing I I, having a conical hopper I2 xed thereto by bolts I3.

The hopper I2 has a nozzle I4 at its lower end. A nozzle extension I is mounted in the nozzle I4 and held by means of a thumb screw I6. A container I'I is suitably secured to the nozzle extension I5. The container I'I may be an arm or a leg of a doll.

An elongated plunger rod is mounted in bearings 2I fixed to the housing II. yA plunger 22 is secured to the plunger rod 20 by a pin 23 and is of slightly smaller diameter than the internal diameter of the nozzle I5. The upper end portion of the plunger 22 tapers upwardly and is reduced in diameter to substantially that of the plunger rod 20, as indicated by the numeral 24.

The drive mechanism for the plunger rod 20 andthe plunger 22 consists of a shaft 25 mounted in bearings 26 suitably supported at the upper elevation of the housing II. A gear 21 fixed to the shaft and driven in any suitable manner from a power source causes rotation of the shaft 25.

Secured to the inner end of the shaft 25 is a counterbalanced crank arm 28 having one end of a link 29 pivotally connected thereto. The other end of the link 29 is pivotally connected to. a head member 30 which is vxed to the plunger rod 20.

Rotation of the shaft 25 causes reciprocation of the plunger rod 20 and reciprocation of the plunger 22 into and out of the nozzle extension I5. It is to be noted that an annular clearance space 3| is provided around the plunger 22 and between the outer periphery of the plunger and the inner periphery of the nozzle extension I5 to facilitate the passage of the plunger through the nozzle extension without undue jamming action.

The material 32 to be fed into the containery I1 is non-fluent and a void is formed above the nozzle on the return stroke of the plunger. For this purpose I provide tamping arms or pusher arms 35 which are pivotally mounted on pins 36 in a horizontal cross-head 3l. The arms 35 are positioned diametrically of the conical hopper I 2.

The cross-head 37 is guided for vertical reciprocating motion by guide rods 38 slidable in bear- Iings 39. An eccentric 40 mounted en the shaft' carries a pitman 4| having its lower end in operative engagement with the cross-head 31.

Rotation of the shaft 25 causes joint vertical reciprocation of the arms 35. The lower end portions of the arms are guided by the inclined walls of the hopper I2 for movement toward the axis of the nozzle and serve tocollect and feed the material 32 to the nozzle. The tamping arms 3'5 consolidate the lling material. This consolidation permits its discharge into a container through a small diameter pipe or nozzle extension I5 by the plunger 22.

The arms have semi-circular lower portions 45, each of which is shaped like a crescent with a concave inner face 46. The concavity 46 permits each lower portion to closely approach the plunger 22 and feed the material 32 to the plunger 22.

The modiiied iilling mechanism, identified by the numeral 50, comprises a housing 5| having a conical hopper 52 suitably fixed thereto. The hopper 52 has a nozzle |41. A nozzle extension |51 is mounted in the nozzle |41 and .held by thumb screw |61. A container is suitably secured to the nozzle extension |51, the same as shown in Figure l.

The modified filling mechanism 5c also comprises a plunger rod 201 and a plunger 221 driven by a gear 211 and a shaft 251 mounted in bearings 261, the same as shown in Figure 2.

The modied filling mechanism 5D also comprises a cross-head and feeding arms guided by rods 381 and driven by a crank arm and by an eccentric (not shown), the saine as shown in Figure 2. y

The hopper 52 has apertures 53 all around its lower portion while the upper portion of the hopper is intact. A cylindrical jacket 54 having a larger inner 4diameter than the outer diameter of the apertured lower portion of the hopper 52 is mounted in circumscribing relation with the hopper. The jacket 54 has upper and lower anges 55, 56 in suitably contacting relation with the hopper 52.

A chamber 51 of annular cross-section is formed between the jacket 54 and the hopper 52. A tube has one end mounted in an aperture 6| in the jacket 54. The other end of the tube ED is connected with the suction or inlet of an exhaust fan 52, well known in the art.

A butterfly or disk valve is mounted on a pin 66, passing diametrically through the valve 65 and through the tube 53. The valve 6'5 is actuated by an arm 61, secured to the pin 66. The free end of the arm 51 is pivotally connected Vto the lower end of a pitman B3 driven by an eccentric 89 on the shaft 251.

Motion is intermittently and automatically communicated to the butterfly valve 65 by the pitman G8 and timed so that the valve is moved into position to close the suction tube 60, to permit a quantity of filling material to be fed into a container frictionally held on the nozzle ex- 4 the downward feeding movement of the plunger through the nozzle.

Operation The filling material is placed in the conical hopper having a long tubular nozzle extension at its lower end. A small container such as a hand or foot of a doll is attached to the lower end portion of the nozzle extension.

The filling material is forced into the container by the vertically reciprocable plunger which is carried down within the nozzle with its lower end slightly below the nozzle extension.

In the disclosure shown, two pusher arms are positioned diametrically of the hopper and are movable vertically and laterally in the hopper in contacting relation with the sides of the hopper. The arms follow the sloping sides of the hopper towards the nozzle. The lower ends of the pusher arms are of semi-circular form adapted to partly circumscribe the plunger.

The plunger and pusher arms move simultaneously in the saine direction for a short time. The plunger is moved through a large distance while the pusher arms are moved through a small distance.

`Each stroke of the plunger forces a wad of the material .into the container, about three to fifteen reciprocations of the plunger fills a container, depending upon the size of the container.

It is to be noted that by ncn-uent materials. I mean to include cotton, kapok, wool, latex foam rubber, etc.

It is to be particularly noted that the action of the mechanism is arranged so that the pusher or tainping arms 35 first feed the iilling material down toward the opening in the bottom of the hopper and hold the material in compacted form under pressure and that the plunger 22 then comes down and pushes the already compacted material into and through the nozzle extension. This filling machine thus exerts a two-step feeding action, rst feeding the material toward the opening in the bottom of the hopper so as to compact the material, and second, feeding the material through the hopper and through the nozzle and into a container in timed relation.

The pusher arms 35 have already been returned to their starting position and when the plunger is likewise returned to its starting position, the cycle is repeated.

It is to be noted that I may extend the hopper so as to circumscribe a portion of the nozzle extension (not shown). This will augment the suction area and increase the quantity of material that the plunger can push through the nozzle.

In accordance with the patent statutes I have described and illustrated the preferred embodiment of my invention, but it will be understood that various changes and modifications can be made therein without departing from the spirit of the invention as dened by the appended claims.

I claim:

l. In a two-step feeding machine for filling containers with particles of non-fluent material, a housing, an upright conical and perforated hopper fixed to said housing and having a tubular nozzle at its lower end, a plunger reciprocally mounted on said housing for up and down movement in said hopper and through said nozzle, a cross-head slidably mounted on said housing, two tamping arms pivotally mounted on said cross-head and reciprocally mounted for up and down movements, said arms being in diametrically contacting relation with the inclined-walls of said hopper and guided by said walls for simultaneous movement to said nozzle, the lower end portions of said arms facing said nozzle being semi-circular and adapted for movement toward the axis of said nozzle for collecting and feeding said filling material to said nozzle, to permit said plunger in its downward movement to pack said collected material into said container, a drive shaft mounted transversely of said housing and having an eccentric thereon, a connecting rod mounted on said eccentric at one end and being connected to said cross-head. at the other end, a crank fixed at one end of said shaft, a link pivotally secured to said crank at one end and being pivotally connected to said plunger at the other end, said plunger and said tamping arms being independently driven from said drive shaft in timed relation, whereby the tamping arms first feed the filling material toward the Opening in the bottom of the hopper and hold the material in compacted form and the plunger then comes down and pushes the already compacted material into and through said nozzle, and air suction means communicating with said perforated hopper for removing the air from said lling material for creating an air stream in said hopper facilitating the downward movement of said material.

2. In a two-step feeding machine for filling containers with particles of non-fluent material, a housing, an upright conical hopper xed to said housing and having a tubular nozzle at its lower` end, a plunger reciprocally mounted on said housing for up and down movement in said hopper and through said nozzle, a cross-head slid- 3 ably mounted on said housing, two tamping arms pivotally mounted on said cross-head and reciprocally mounted for up and down movements,

said arms being in diametrically contacting relation with the inclined Walls of said hopper and guided by said walls for simultaneous movement to said nozzle, the lower end portions of said arms facing said nozzle and being semi-circular and adapted for movement toward the axis of said nozzle for collecting and feeding said filling material to said nozzle, to permit said plunger in its downward movement to pack said collected material into said container, a drive shaft mounted transversely of said housing and having an eccentric thereon, a connecting rod mounted on said eccentric at one end and being connected to said cross-head at the other end, a crank fixed at one end of said shaft, a link pivotally -secured to said crank at one end and being pivotally connected to said plunger at the other end, said plunger and said tamping arms being independently driven from said drive shaft in timed relation, whereby `the tamping arms first feed the lling material toward the opening in the bottom of the hopper and hold the material in compacted form andthe plunger then comes down and pushes the already compacted material into and through said nozzle.

ROBERT J. GOLDBERG.

References Cited in the ille of this patent UNITED STATES PATENTS Number Name Date 279,746 Hall June 19, 1883 691,537 Ericson Jan. 21, 1902 829,288 Patterson Aug. 21, 1906 872,161 Whitehorn Nov. 26, 1907 983,351 Colbert Feb. 7, 1911 1,255,377 Ayars Feb. 5, 1918 1,366,615 Westlund g Jan. 25, 1921

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US52280A US2639072A (en) | 1948-10-01 | 1948-10-01 | Filling machine having vertically reciprocable tamping arms and plunger |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US52280A US2639072A (en) | 1948-10-01 | 1948-10-01 | Filling machine having vertically reciprocable tamping arms and plunger |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2639072A true US2639072A (en) | 1953-05-19 |

Family

ID=21976561

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US52280A Expired - Lifetime US2639072A (en) | 1948-10-01 | 1948-10-01 | Filling machine having vertically reciprocable tamping arms and plunger |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2639072A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2981298A (en) * | 1958-07-21 | 1961-04-25 | Clarence W Vogt | Method and equipment for filling open mouth receptacles with pulverulent material |

| US3308994A (en) * | 1965-04-07 | 1967-03-14 | Baker Perkins Inc | Feeder apparatus |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US279746A (en) * | 1883-06-19 | Bran or flour packer | ||

| US691537A (en) * | 1901-07-25 | 1902-01-21 | Charles Oscar Ericson | Packing-machine. |

| US829288A (en) * | 1897-08-20 | 1906-08-21 | Rufus L Patterson | Machine for packing tobacco. |

| US872161A (en) * | 1907-04-24 | 1907-11-26 | Thomas Whitehorn | Apparatus for packing predetermined quantities in bags. |

| US983351A (en) * | 1908-02-24 | 1911-02-07 | Clarence F Colbert | Filling-machine. |

| US1255377A (en) * | 1915-12-08 | 1918-02-05 | Ayars Machine Co | Can-filling machine. |

| US1366615A (en) * | 1919-08-30 | 1921-01-25 | Prest O Lite Co Inc | Cylinder-filling machine |

-

1948

- 1948-10-01 US US52280A patent/US2639072A/en not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US279746A (en) * | 1883-06-19 | Bran or flour packer | ||

| US829288A (en) * | 1897-08-20 | 1906-08-21 | Rufus L Patterson | Machine for packing tobacco. |

| US691537A (en) * | 1901-07-25 | 1902-01-21 | Charles Oscar Ericson | Packing-machine. |

| US872161A (en) * | 1907-04-24 | 1907-11-26 | Thomas Whitehorn | Apparatus for packing predetermined quantities in bags. |

| US983351A (en) * | 1908-02-24 | 1911-02-07 | Clarence F Colbert | Filling-machine. |

| US1255377A (en) * | 1915-12-08 | 1918-02-05 | Ayars Machine Co | Can-filling machine. |

| US1366615A (en) * | 1919-08-30 | 1921-01-25 | Prest O Lite Co Inc | Cylinder-filling machine |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2981298A (en) * | 1958-07-21 | 1961-04-25 | Clarence W Vogt | Method and equipment for filling open mouth receptacles with pulverulent material |

| US3308994A (en) * | 1965-04-07 | 1967-03-14 | Baker Perkins Inc | Feeder apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2359029A (en) | Valve-controlled filling machine | |

| US2721008A (en) | Dispensing device | |

| CN205554642U (en) | Inner wrapping leisure articles sack filling device | |

| US2639072A (en) | Filling machine having vertically reciprocable tamping arms and plunger | |

| CN111892010B (en) | Automatic filling device of xiLin bottle | |

| US1777660A (en) | Machine for making concrete blocks and the like | |

| CN109436441A (en) | A kind of universal powder packing machine applied to food processing | |

| US2232180A (en) | Press for forming tablets | |

| US4565304A (en) | Dosing apparatus for viscous liquid foodstuff | |

| US1266706A (en) | Can-filling machine. | |

| GB1409402A (en) | Vibrating device | |

| US2927499A (en) | Powder consolidating press | |

| US2979086A (en) | Filling machine | |

| US691537A (en) | Packing-machine. | |

| RU186827U1 (en) | DEVICE FOR PACKING IN POLYETHYLENE | |

| US2522884A (en) | Container filling machine with pedal operated vertically swingable hopper and vertically reciprocable plunger carrying rotatable tamping fingers | |

| US2841824A (en) | Feed mechanism for injection molding machine | |

| CN213008846U (en) | Automatic filling device of xiLin bottle | |

| CN211033094U (en) | A automatic packaging machine for traditional chinese medicine granule | |

| US3332456A (en) | Tamping machine | |

| US2542739A (en) | Compressing machine | |

| US1294104A (en) | Stuffing and packing machine. | |

| CN108001742B (en) | A kind of medicine-filled pillow bag filling machine | |

| US2843294A (en) | Dispensing apparatus | |

| GB205064A (en) | Automatic machine for charging and closing pharmaceutical capsules, small boxes and the like |