US2280867A - Abrading and blackboard cleaning machine - Google Patents

Abrading and blackboard cleaning machine Download PDFInfo

- Publication number

- US2280867A US2280867A US301994A US30199439A US2280867A US 2280867 A US2280867 A US 2280867A US 301994 A US301994 A US 301994A US 30199439 A US30199439 A US 30199439A US 2280867 A US2280867 A US 2280867A

- Authority

- US

- United States

- Prior art keywords

- casing

- pulleys

- belt

- abrading

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B23/00—Portable grinding machines, e.g. hand-guided; Accessories therefor

- B24B23/06—Portable grinding machines, e.g. hand-guided; Accessories therefor with abrasive belts, e.g. with endless travelling belts; Accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B43—WRITING OR DRAWING IMPLEMENTS; BUREAU ACCESSORIES

- B43L—ARTICLES FOR WRITING OR DRAWING UPON; WRITING OR DRAWING AIDS; ACCESSORIES FOR WRITING OR DRAWING

- B43L21/00—Blackboard or slate cleaning devices

- B43L21/02—Blackboard or slate cleaning devices with means for absorbing the chalk dust

Definitions

- My invention relates to an 'abrading and blackboard cleaning machine for surfacing floors or other surfaces andfor cleaning blackboards or the like and the objects of my invention are more particularly simplification and improvements upon the structure disclosed in my Letters Patent No. 2,178,865, for abrading and blackboard cleaning machine, issued November 7, 1939, and the principal objects of the simplification improvements are:

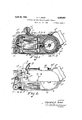

- Figure 1' is a longitudinal sectional view of my abrading and blackboard cleaning machine taken from the line l-I of Fig. 3 showing parts and portions in elevation to facilitate the illustration

- Fig. 2 is a side elevational view thereof

- Fig. 3 is a transverse sectional view taken from the line 3--3 of Fig. 1 showing parts and portions in elevation to facilitate the illustration and also showing a portion broken away and in section

- Fig. 4 is a fragmentary transverse sectional view taken from the lined-I of Fig. 2 showing parts and portions in elevation to facilitate the illustration

- Fig. 5 is a transverse sectional view taken from the line 5-5 of Fig. 1 showing parts in elevation to facilitate the illustration

- Fig. 6 is a fragmentary elevational view taken from the line, 8-4 of Fig. 4 showing by dash lines a varying position of a belt guide of the machine.

- The'main casing I is a shell like casing provided with a hollow cylindrical portion I a at its one end and is provided with a gear casing portion Ib at its other end.

- Revolubly mounted in the main casing portion la is an armature '5 which is surrounded by an armature field 5a in the conventional manner.

- the armature shaft 5b is supported at one end in the ball bearing I3a positioned in the casing member I3 and is supported at its opposite end in the ball bearing Ic positioned in the main casing I.

- Mounted on the armature shaft 5b intermediate the armature 5 and the bearing I0 is the fan.

- the bevel pinion is mounted on the end of the armature shaft 5b and is arranged to mesh with the bevel gear 1 which is mounted on the drive shaft Ia, which is substantially at a right angle to the shaft 5b, as shown best in Figs. 1 and 3 of the drawings.

- This drive shaft la is supported in the ball bearings 1b which are mounted in the bearing casing members 22 and 23.

- Mounted on opposite-ends of the drive shaft Ia are the drive pulleys 8 and 9.

- This casing and belt guard 2 Secured to the one side of the main casing I is the casing and belt guard 2 by means of the bolts 2a, as shown best in Figs. 2 and 5 of the drawings.

- This casing and belt guard 2 is provided with an angularly extending portion 2b which is arranged in spaced relation to the upper side of the main casing I permitting free passage of the abrasive belt I2 therebetween. It is also provided at its one end with a curved portion 20 which is arranged in slight spaced relation with the drive pulleys I and I and is integral with the skirt portion 21!, as shown in Fig. 2 of the drawings.

- the guide handle 4 is mounted on the upper side of the casing and belt guard 2 near its front 'portionbymeanso'ftheboltlawhichisscrew II and II by means of the upwardly extending portion 2 In of the bearing casing 2l which is held securely therein by means of bolts 2lb, as shown best in Figs. 1 and 4 of the drawings.

- This casing member I2 is secured to the flange'portion lc of the main casing I by means of bolts lie and

- the spring plate II is mounted on the upper side of the main,casing I at its end portion Ila.

- This spring plate I is resilient and is substantially the width of the belt" and tends to keep the belt l2 under tension at all times.

- a bar portion llb Secured on one end of the spring plate ll is a bar portion llb which is provided with reduced portions lie at its opposite ends which are arranged to engage the holes I511 of the spring plate latch members I! and I6 when the belt I2 is being removed or replaced.

- the spring plate latch members I! and I6 are secured to the main casing I by means of the bolt lib as shown best in Fig. 2 of the drawings.

- the belt guide members l1 and I8 are secured on opposite edges of the front portion 2! of the Y the dash line position, as indicated at A in Fig.

- the fan I being mounted on the armature shaft Ib, is adapted to circulate air around the armature I and force the air outwardly through the openings Id of the main casing I. .It will be noted that air is permitted to enter through the openings lie in the casing l3 at the forward end of the armature l-

- the bearing casing members 22 and 23 are mounted on opposite sides of the casing portion lb of the main casing l and are arranged to encase the pinion 6 and gear I and support the bearings lb on the shaft Ia.

- the operation of my abrading and blackboard cleaning machine is substantially as follows:

- the electric conductor B is connected to a power supply and the switch 20 in connection therewith is arranged to close or break the circuit in connection with the armature 5.

- the oplid in the recess portions l2b of the member' I Mounted on therear end ofthis casing and belt' -guard2bymeans ofthebrackets Ia and Ibis erator grasps the operating handle 3 in one hand and the guide handle 4 in the other hand and starts the armature .5 to revolve by means of the switch handle 200, the belt l2 being mounted on the pulleys 2, 8, II and II and the spring plate i s around said pulleys and spring plate in a'pountercloclrwise direction, as shown in Fig. 1 of the drawings.

- the lower surface of the machine is then placed on any surface which it is desired to finish and the machine may be moved accordingly by means of the handles 3 and 4.

- the belt guides l1 and I! hold the belt l2 in proper alignment with the pulleys II and lland the spring plate ll automatically compensates for any stretchingof the belt l2.

- the spring plate It is pressed inwardly toward the spring plate latch members l5 and I6 and the extending portions llc thereof engage the slotted portions lid of the latch members l5 and I 6, thereby holding the spring plate l4 in spaced relation from the belt l2.

- the thumb screw Ila is removed from the portion 2! of the casing 2 and the belt guide member I8 is shifted'to the dash line position A, as

- a hollow shell like casing a motor mounted therein at one end with its axis longitudinally thereof, a drive shaft in connection with one end of said motor extending backwardly therefrom, a bevel pinion on the extended end of said drive shaft, a bevel gearcentrally positioned in the rear portion of said casing and intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions therefrom, a drive pulley secured on each end of said shaft outwardly of said casing with the surfaces of said pulleys extending to the upper and lower sides and beyond the rear end portion of said casing, and a single endless abrasive belt positioned over said pulleys and around saidcasing and contactingwith said pulleys whereby said abrasive belt is driven by said pulleys said casing enclosing said motor and the gear driving means.

- a hollow shell like casing a motor mounted therein at one end with its axis longitudinally thereof, a drive shaft in connection with one drive shaft, a bevel gear centrally positioned in said pulleys extending to the upper end lowersides and beyond the rear end portion of said casing, a single endless abrasive belt positioned over said pulleys and around said casing and contacting with said pulleys whereby said abrasive belt is driven by said pulleys said casing enclosing said motor and the gear driving means, and a separate casing and belt guard secured in spaced relation to said abrasive belt.

- an abrading and blackboard cleaning machine of the class described the combination of an elongated hollow shell like casing with a transverse curved partition forming a circular compartment at the rear end thereof, a motor mounted in the front end thereof with its axis longitudinally of said casing, a shaft for said motor extending backwardly substantially centrally of said casing to near the front side of said circular compartment, a bevel pinion on the extended end of said shaft, a bevel gear intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions laterally of said casing centrally of said circular compartment, a pair of drive pulleys mounted on said shaft, one on each side of said bevel gear with their surfaces extending to the upper and lower sides and beyond the rear portion of said casing, and a single abrasive belt mounted tightly on said pulleys whereby said abrasive belt is driven, said belt extending around the outer side of said casing.

- a hollow shell-like casing a motor mounted therein at one end thereof with its axis longitudinally of said casins, a drive shaft in connection with one end of said motor extending therefrom, a pinion on the extending end of said drive shaft, a gear central-' ly positioned in another end portion of said casing and intermeshing'with said pinion, a shaft for said sear extending in opposite directions therefrom, a drive pulley on each end of said shaft outwardly of said casing with the surfaces of said pulleys extending to the upper and lower side and beyond the end portion of said casing and an endless abrasive belt positioned over and contacting said pulleys and positioned around said casing and shiftably removable from said pulleys at'one side of said casing whereby said 10 abrasive belt is shifted sideways from said pulleys.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Description

April 28, 1942. H. A. SWAN 2,280,867

ABRADING AND BLACKBOARD CLEANING MACHINE Filed Oct. 30, 1939 2 Sheets-Sheet 1 IN VENTOR.

BY Harold/I. 811 022 ATTORNEY.

April 28, 1942. H. A. swAN ABRADING AND BLACKBOARD CLEANING MACHINE Filed Oct. 30, 1939 2 Sheets-Sheet 2 E Z k. 8 J 4 3 0 O B. u I 2 M? M: 5 r B 2 Patented Apr. 28, 1942 UNITED STATES PATENT OFFICE ABRADING AND BLACKBOARI) CLEANING I rim-ores. Swan, Coronado, com. Application October so, 1939, semi No. 301,994

90laiml.

My invention relates to an 'abrading and blackboard cleaning machine for surfacing floors or other surfaces andfor cleaning blackboards or the like and the objects of my invention are more particularly simplification and improvements upon the structure disclosed in my Letters Patent No. 2,178,865, for abrading and blackboard cleaning machine, issued November 7, 1939, and the principal objects of the simplification improvements are:

First, to provide an abrading and blackboard cleaning machine of this class in which an endless abrasive belt is shiftably supported on only one pair of. pulleys at each end and surrounds the motor and driving means of said machine;

Second, to provide an abrading and blackboard cleaning machine of this class in which a relatively small number of parts are used in proportion to its function;

Third, to provide an abrading and blackboard cleaning machine of this class with a relatively large area contact surface in accordance with the size of the machine;

Fourth, to provide a machine of this class in which the tension of the abrasive belt is automatically adjusted;

Fifth, to provide a machine of this class in which the driving pulleys are tangent to the upper and lower side of the machine and are in direct operative relation with the operating motor thereof appear hereinafter, my invention consists of certain novel features. of construction, combination and arrangement of parts and portions as will be hereinafter described in detail and particularly set forth in the appended claims, reference being had to the accompanying drawings and to the characters of reference thereon which form a part of this application in which:

Figure 1' is a longitudinal sectional view of my abrading and blackboard cleaning machine taken from the line l-I of Fig. 3 showing parts and portions in elevation to facilitate the illustration; Fig. 2 is a side elevational view thereof; Fig. 3 is a transverse sectional view taken from the line 3--3 of Fig. 1 showing parts and portions in elevation to facilitate the illustration and also showing a portion broken away and in section; Fig. 4 is a fragmentary transverse sectional view taken from the lined-I of Fig. 2 showing parts and portions in elevation to facilitate the illustration; Fig. 5 is a transverse sectional view taken from the line 5-5 of Fig. 1 showing parts in elevation to facilitate the illustration; and Fig. 6 is a fragmentary elevational view taken from the line, 8-4 of Fig. 4 showing by dash lines a varying position of a belt guide of the machine. a v

Similar characters of reference refer to similar parts and portions throughout the several views of the drawings:

The main casing I, casing and belt guard 2, operating handle 3, guide handle 4., armature -5, bevel pinion 6, bevel gear I, drive pulleys 8 and 9, front pulleys I0 and II, abrasive belt I2, casing member I3, spring plate I4, spring plate latch members I5 and I6, belt guide members I1 and I8, fan l9, switch 20, bearing casing 2| and the bearing casing members 22 and 23 constitutethe principal parts. and portions of my abrading and blackboard cleaning machine.

The'main casing I is a shell like casing provided with a hollow cylindrical portion I a at its one end and is provided with a gear casing portion Ib at its other end. Revolubly mounted in the main casing portion la is an armature '5 which is surrounded by an armature field 5a in the conventional manner. The armature shaft 5b is supported at one end in the ball bearing I3a positioned in the casing member I3 and is supported at its opposite end in the ball bearing Ic positioned in the main casing I. Mounted on the armature shaft 5b intermediate the armature 5 and the bearing I0 is the fan. I 9. The bevel pinion is mounted on the end of the armature shaft 5b and is arranged to mesh with the bevel gear 1 which is mounted on the drive shaft Ia, which is substantially at a right angle to the shaft 5b, as shown best in Figs. 1 and 3 of the drawings. This drive shaft la is supported in the ball bearings 1b which are mounted in the bearing casing members 22 and 23. Mounted on opposite-ends of the drive shaft Ia are the drive pulleys 8 and 9.

Secured to the one side of the main casing I is the casing and belt guard 2 by means of the bolts 2a, as shown best in Figs. 2 and 5 of the drawings. This casing and belt guard 2 is provided with an angularly extending portion 2b which is arranged in spaced relation to the upper side of the main casing I permitting free passage of the abrasive belt I2 therebetween. It is also provided at its one end with a curved portion 20 which is arranged in slight spaced relation with the drive pulleys I and I and is integral with the skirt portion 21!, as shown in Fig. 2 of the drawings.

the operating handle 8.

The guide handle 4 is mounted on the upper side of the casing and belt guard 2 near its front 'portionbymeanso'ftheboltlawhichisscrew II and II by means of the upwardly extending portion 2 In of the bearing casing 2l which is held securely therein by means of bolts 2lb, as shown best in Figs. 1 and 4 of the drawings. This casing member I2 is secured to the flange'portion lc of the main casing I by means of bolts lie and The spring plate II is mounted on the upper side of the main,casing I at its end portion Ila. This spring plate I is resilient and is substantially the width of the belt" and tends to keep the belt l2 under tension at all times.

Secured on one end of the spring plate ll is a bar portion llb which is provided with reduced portions lie at its opposite ends which are arranged to engage the holes I511 of the spring plate latch members I! and I6 when the belt I2 is being removed or replaced.

The spring plate latch members I! and I6 are secured to the main casing I by means of the bolt lib as shown best in Fig. 2 of the drawings.

The belt guide members l1 and I8 are secured on opposite edges of the front portion 2! of the Y the dash line position, as indicated at A in Fig.

6 of the drawings, the detent portion l8b being forced over the edge of the portion II when shifted to said position A.

The fan I, being mounted on the armature shaft Ib, is adapted to circulate air around the armature I and force the air outwardly through the openings Id of the main casing I. .It will be noted that air is permitted to enter through the openings lie in the casing l3 at the forward end of the armature l- The bearing casing members 22 and 23 are mounted on opposite sides of the casing portion lb of the main casing l and are arranged to encase the pinion 6 and gear I and support the bearings lb on the shaft Ia. u

The operation of my abrading and blackboard cleaning machine is substantially as follows: The electric conductor B is connected to a power supply and the switch 20 in connection therewith is arranged to close or break the circuit in connection with the armature 5. when it is desired to operate my abrading machine, the oplid in the recess portions l2b of the member' I Mounted on therear end ofthis casing and belt' -guard2bymeans ofthebrackets Ia and Ibis erator grasps the operating handle 3 in one hand and the guide handle 4 in the other hand and starts the armature .5 to revolve by means of the switch handle 200, the belt l2 being mounted on the pulleys 2, 8, II and II and the spring plate i s around said pulleys and spring plate in a'pountercloclrwise direction, as shown in Fig. 1 of the drawings. The lower surface of the machine is then placed on any surface which it is desired to finish and the machine may be moved accordingly by means of the handles 3 and 4.

It will be noted that the ratio derived from the pinion 6 and gear I provides sufficient power on the drive pulleys I and I to permit the use of considerable pressure on the machine when abrading surfaces. v

The belt guides l1 and I! hold the belt l2 in proper alignment with the pulleys II and lland the spring plate ll automatically compensates for any stretchingof the belt l2.

when it is desired to remove the belt l2 from the machine, the spring plate It is pressed inwardly toward the spring plate latch members l5 and I6 and the extending portions llc thereof engage the slotted portions lid of the latch members l5 and I 6, thereby holding the spring plate l4 in spaced relation from the belt l2. The thumb screw Ila is removed from the portion 2! of the casing 2 and the belt guide member I8 is shifted'to the dash line position A, as

shown in Fig. 6 of the drawings. The belt is then readily removed from one side of the ma-- chine C as indicated in Fig. 3 of the drawings.

Though I have shown and described a particular construction, combination and arrangement of parts and portions, I do not wish to be limited to this particular construction, combi-- nation and arrangement, but desire to include in the scope of my invention the construction, combination and arrangement substantially as set forth in the appended claims.

Having thus described my invention, what I claim as new and desire to secure by Letters Patent is:

1. In an abrading and blackboard cleaning machine of the class described, the combinationof a hollow shell like casing, a motor mounted therein at one end with its axis longitudinally thereof, a drive shaft in connection with one end of said motor extending backwardly therefrom, a bevel pinion on the extended end of said drive shaft, a bevel gearcentrally positioned in the rear portion of said casing and intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions therefrom, a drive pulley secured on each end of said shaft outwardly of said casing with the surfaces of said pulleys extending to the upper and lower sides and beyond the rear end portion of said casing, and a single endless abrasive belt positioned over said pulleys and around saidcasing and contactingwith said pulleys whereby said abrasive belt is driven by said pulleys said casing enclosing said motor and the gear driving means.

2. In an abrading and blackboard cleaning machine of the class described, the combination of a hollow shell like casing, a motor mounted therein at one end with its axis longitudinally thereof, a drive shaft in connection with one drive shaft, a bevel gear centrally positioned in said pulleys extending to the upper end lowersides and beyond the rear end portion of said casing, a single endless abrasive belt positioned over said pulleys and around said casing and contacting with said pulleys whereby said abrasive belt is driven by said pulleys said casing enclosing said motor and the gear driving means, and a separate casing and belt guard secured in spaced relation to said abrasive belt.

3. In an abrading and blackboard cleaning machine of the class described, the combination of a hollow shell like casing, a motor mounted therein at the front portion with its axis longitudinally thereof, a drive shaft in connection with one end of said motor extending backwardly therefrom, a bevel pinion on the extended end of said drive shaft; a bevel gear centrally positioned in the rear portion of said casing and intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions therefrom, a drive pulley secured on each end of said shaft with the surfaces of said pulleys extending to the upper and lower sides and beyond the rear end portion of said casing, a single abrasive belt positioned over said pulleys and around said casing and contacting with said pulleys whereby said abrasive belt is driven by said pulleys, a separate casing and belt guard secured in spaced relation to said abrasive belt, and automatic tension means in engagement with the upper front side of said abrasive belt supported by said casing.

4. In an abrading and blackboard cleaning machine of the class described, the combination of a hollow shell like casing, a motor mounted therein at the front portion with its axis longitudinally thereof, a drive shaft in connection with one end of said motor extending backwardly therefrom, a bevel pinion on the extendedend of said drive shaft, a bevel gear centrally positioned in the rear portion of said casing and intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions therefrom, a drive pulley secured on each end of said shaft with the surfaces of said pulleys extending to the upper and lower sides and beyond the rear end portion of said casing, a single abrasive belt positioned over said pulleys and around said casing and contacting with said pulleys whereby said abrasive belt is driven by said pulleys, a separate casing and belt guard secured in spaced relation to said abrasive belt, automatic tension means in engagement with the upper front side of said abrasive belt supported by said casing, and means for guiding the side edges of said belt on said spring tension means.

5. In an abrading and blackboard cleaning machine of the class described, the combination of an elongated hollow shell like casing with a transverse curved partition forming a circular compartment at the rear end thereof, a motor mounted in the front end thereof with its axis longitudinally of said casing, a shaft for said motor extending backwardly substantially centrally of said casing to near the front side of said circular compartment, a bevel pinion on the extended end of said shaft, a bevel gear intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions laterally of said casing centrally of said circular compartment, a pair of drive pulleys mounted on said shaft, one on each side of said bevel gear with their surfaces extending to the upper and lower sides and beyond the rear portion of said casing, and a single abrasive belt mounted tightly on said pulleys whereby said abrasive belt is driven, said belt extending around the outer side of said casing.

6. In an abrading and blackboard cleaning machine of the class described, the combination of an elongated hollow shell like casing with a transverse curved partition forming a circular compartment at the rear end thereof, a motor mounted in the front end thereof with its axis longitudinally of said casing, a shaft for said motor extending backwardly substantially centrally of said casing to near the front side of said circular compartment, a bevel pinion on the extended end of said shaft, a bevel gear intermeshing with said bevel pinion, a shaftfor said bevel gear extending in opposite directions laterally of said casing centrally of said circular compartment, a pair of drive pulleys mounted on said shaft, one on each side of said bevel gear with their surfaces extending to the upper and lower sides and beyond the rearportion of said casing, a single abrasive belt mounted tightly on said pulleys whereby said abrasive belt is driven, said belt extending around the outer side of said casing, and a separate casing and belt guard secured in spaced relation to said abrasive belt at its upper and rear side, said rear side being wholly arcuate.

7. In an abrading andblackboard cleaning machine of the class described, the combination of an elongated hollow shell like casing with a transverse curved partition forming a circular compartment at the rear end thereof, a motor mounted in the front end thereof with its axis longitudinally of said casing, a shaft for said motor extending backwardly substantially centrally of said casing to near the front side of said circular compartment, a bevel pinion on the extended end of said shaft, a bevel gear intermeshing with said bevel pinion, a shaft for said bevel gear extending in opposite directions laterally of said casing centrally of said circular compartment, a pair of drive pulleys mounted on said shaft, one on each side of said bevel gear with their surfaces extending to the upper and lower sides and beyond the rear portion of said casing, a single abrasive belt mounted tightly on said pulleys whereby said abrasive belt is driven, said belt extending around the outer side of said casing, a separate casing and belt guard secured in spaced relation to said abrasive belt at its upper and rear side, said rear side being wholly arcuate, and means secured to opposite sides of said casing for guiding said belt.

8. In an abrading and blackboard cleaning machine of the class described, the combination of a hollow shell like casing, a motor mounted therein at one end with its axis longitudinally thereof, a drive shaft in connection with one end of said motor extending therefrom, a pinion on the extended end of said drive shaft, a gear centrally positioned in anotherend portion of said casing and intermeshing with said pinion, a shaft for said gear extending in opposite directions therefrom, a drive pulley secured on each end of said shaft outwardly of said casing with the surfaces of said pulleys extending to the upper and lower sides and beyond the end portion of said casing and an endless abrasive belt positioned over said pulleys and around said casing and contacting with said pulleys whereby said abrasive belt is driven by said pulleys, said cas-- in: enclosing said motor and the gear-driving means. 7 v

9. Infan abrading machine of the class described, the combination of a hollow shell-like casing, a motor mounted therein at one end thereof with its axis longitudinally of said casins, a drive shaft in connection with one end of said motor extending therefrom, a pinion on the extending end of said drive shaft, a gear central-' ly positioned in another end portion of said casing and intermeshing'with said pinion, a shaft for said sear extending in opposite directions therefrom, a drive pulley on each end of said shaft outwardly of said casing with the surfaces of said pulleys extending to the upper and lower side and beyond the end portion of said casing and an endless abrasive belt positioned over and contacting said pulleys and positioned around said casing and shiftably removable from said pulleys at'one side of said casing whereby said 10 abrasive belt is shifted sideways from said pulleys.

HAROLD A. SWAE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US301994A US2280867A (en) | 1939-10-30 | 1939-10-30 | Abrading and blackboard cleaning machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US301994A US2280867A (en) | 1939-10-30 | 1939-10-30 | Abrading and blackboard cleaning machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2280867A true US2280867A (en) | 1942-04-28 |

Family

ID=23165801

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US301994A Expired - Lifetime US2280867A (en) | 1939-10-30 | 1939-10-30 | Abrading and blackboard cleaning machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2280867A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2718735A (en) * | 1952-07-07 | 1955-09-27 | William P Hamilton | Sander |

| US20040082598A1 (en) * | 2000-12-01 | 2004-04-29 | Osi Pharmaceuticals, Inc. | Compounds specific to adenosine A, receptors and uses thereof |

| US20050272357A1 (en) * | 2004-06-07 | 2005-12-08 | Andrew Walker | Sanding apparatus |

| US20050272356A1 (en) * | 2004-06-07 | 2005-12-08 | Andrew Walker | Sanding apparatus |

-

1939

- 1939-10-30 US US301994A patent/US2280867A/en not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2718735A (en) * | 1952-07-07 | 1955-09-27 | William P Hamilton | Sander |

| US20040082598A1 (en) * | 2000-12-01 | 2004-04-29 | Osi Pharmaceuticals, Inc. | Compounds specific to adenosine A, receptors and uses thereof |

| US20050272357A1 (en) * | 2004-06-07 | 2005-12-08 | Andrew Walker | Sanding apparatus |

| US20050272356A1 (en) * | 2004-06-07 | 2005-12-08 | Andrew Walker | Sanding apparatus |

| US7018280B2 (en) | 2004-06-07 | 2006-03-28 | Black & Decker Inc. | Sanding apparatus |

| US7226346B2 (en) | 2004-06-07 | 2007-06-05 | Black & Decker Inc. | Sanding apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2976436A (en) | Multi-speed drill | |

| US2280867A (en) | Abrading and blackboard cleaning machine | |

| US3251086A (en) | Power handle assembly | |

| US3164932A (en) | Ice skate sharpener | |

| US2649871A (en) | Saw attachment for drills and the like | |

| US2178865A (en) | Abrading and blackboard cleaning machine | |

| US1465285A (en) | Suction cleaner | |

| US2079356A (en) | Apparatus for erasing | |

| US2018046A (en) | Vibrator | |

| US1939579A (en) | Vacuum cleaner | |

| US3336703A (en) | Portable power tool | |

| US2033939A (en) | Portable electric cutting machine | |

| US2341068A (en) | Grinder | |

| US2472161A (en) | Vacuum-actuated abrading device | |

| US1588744A (en) | Hand power saw | |

| US2544810A (en) | Sanding and polishing attachment for electric handsaw supporting and driving units | |

| US1950824A (en) | Dental-instrument grinding device | |

| US2918685A (en) | Machine for removing hardened paint | |

| US2750610A (en) | Butcher's accessory | |

| US1660134A (en) | Scraping device | |

| US2601749A (en) | Spring tension grinding machine | |

| US2774198A (en) | Portable belt sanding machine | |

| US2562832A (en) | Planer attachment for portable power sources | |

| US2897637A (en) | Electric knife sharpener | |

| US1951964A (en) | Tool for sanding, rubbing, or polishing surfaces |