US2223792A - Hydraulic apparatus for operating machine tools and the like - Google Patents

Hydraulic apparatus for operating machine tools and the like Download PDFInfo

- Publication number

- US2223792A US2223792A US201576A US20157638A US2223792A US 2223792 A US2223792 A US 2223792A US 201576 A US201576 A US 201576A US 20157638 A US20157638 A US 20157638A US 2223792 A US2223792 A US 2223792A

- Authority

- US

- United States

- Prior art keywords

- valve

- pressure

- port

- cylinder

- working

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q5/00—Driving or feeding mechanisms; Control arrangements therefor

- B23Q5/22—Feeding members carrying tools or work

- B23Q5/26—Fluid-pressure drives

- B23Q5/266—Fluid-pressure drives with means to control the feed rate by controlling the fluid flow

- B23Q5/268—Fluid-pressure drives with means to control the feed rate by controlling the fluid flow depending upon the position of the tool or work

Definitions

- This invention relates to hydraulic apparatus for operating machine tools and the like.

- the said apparatus is characterized by a novel mode of operation which comprises applying pressure to move the tool in a given direction;

- the working pressure moves the tool against an opposing hydraulic pressure which is automatically increased When the tool has travelled a predetermined distance.

- This increase of pressure opposing movement of the tool causes a corresponding increase of working pressure which is utilized, as previously explained, to effect either immediate or delayed reversal of the direction of movement of the tool.

- the increase of pressure opposing movement of the tool by the working pressure merely serves to cushion the movement of the tool toward the end of its stroke and to cause the necessary increase of working pressure.

- the increase of pressure opposing movement of the tool is utilized to prevent operation of the reversing valve by the increased working pressure until such time as the tool actually engages the stop.

- a characteristic feature common to several forms of apparatus disclosed herein is the application of hydraulic pressure to move a tool against a mechanical stop which, in addition to halting the tool after it has travelled a predetermined distance, also serves, by its resistance to further movement of the tool, to promote establishment of pressure conditions resulting in hydraulic reversal of the tool.

- This employment of a mechanical stop controlling both the working stroke and the reversal of the tool enables the point to which the tool is advanced at the end of the working stroke to be predetermined within sufficiently close limits to meet the demands of any operating conditions likely to arise.

- apparatus provided in accordance with this invention may be designed so that the travel and reversal of the tool during a working stroke is closely regulated by a mechanical stop, as previously explained, while the reversal of the tool at the end of a return stroke is controlled solely by an increase of the pressure then acting to move the tool.

- the reig'ersal of the tool after it has travelled a predetermined distance in either direction may be 'made dependent solely on an automatic increase of the pressure which is then acting on the tool.

- ythe latter may be operated against a stop at each end of its travel so that the resistance of the stop serves, as previously explained, to control both the stroke and the reversal of the tool within very close limits.

- Figures 2 to 4 inclusive are views similar to Fig. 1 but showing other positions to which the valves and other component parts are shifted during operation of the apparatus.

- Figure 5 is a vertical sectional view along the line 5-5 of Fig. 2.

- Figure 6 is a vertical sectional view along the line 6-6 of Fig. 2.

- Figure '1 is a view similar to Fig. 1 but showing a modified form of apparatus.

- 5 represents a work table such as the table of a planer or milling machine.

- This table is rigidly secured, as indicated at 6, to the piston rods 1 and 8 of pistons 9a and 9b working in cylinder I8.

- the left hand end of cylinder I0 communicates with a port I I which is alternately connected to fluid pressure supply passage I2 and exhaust passage I3 through the agency of a reversing valve I4.

- the right hand end of cylinder I0 communicates with a port I5 which is alternately connected to passages I2 and I3 by the valve I4.

- ⁇ Passage I2 is connected to a pump or other source of pressure duid by pipe I6.

- Cylinder port is connected, through throttle valve I1 and check valve I9, to valve port 2

- Cylinder port I5 is connected, through throttle valve I8 and check valve 20, to valve port 22 also leading to reversing valve I4.

- Check valves I9 and 20 are spring loaded to close against the valve seats I9' and 20'. These valves open when the flow is from the valve ports 2

- Throttle valves I1 and I8 are normally biased to open position by valve springs I1'v and I 8 acting, respectively, against suitable abutments I1a and I8a carried by the outer ends of the valve stems IIb and

- an arm 28 acts against the outer end of stem

- Arm 28 is carried by a pin or shaft 28a rotatably mounted in a suitable bracket 29. This pin or shaft 28a is connected, by arm and vertical link 3

- Link 32 is provided with a cam lug or projection 34 disposed in the path of an operating cam carried by table 5.

- the throttle valve I8 is moved inwardly or to the left by an arm 28b xed to a pin or shaft 28c journalled in bracket 29a.

- This pin or shaft 28c is connected, by arm 30a and vertical link 3

- Link 32a is provided with a lug 34a disposed in the path of an operating cam 35a carried by the table.

- Reversing valve I4 is slidably mounted in a suitably ported valve liner 31 arranged in passage 31a intersecting the main cylinder ports 2

- the ends of this valve are formed to provide operating pistons 38 and 39 working in cylinders 40 and 4I.

- the body portion of valve I4 is provided with annular ports 42, 43, 44 and 45.

- Port 43 is the port through which main cylinder port II is alternately connected to exhaust port I3 or to branch

- the port 44 is the one through which main cylinder port I5 is alternately connected to exhaust port I3 or to branch I2b of pressure supply port I2 through valves I8 and 20 and port 22.

- reversing valve I4 is controlled by a 'cylindrical pilot valve 41 slidably mounted in pilot valve cylinder 48.

- This cylinder is connected through port 50, valve 5

- Valve 5I is normally biased to closed position by a spring 53 and is automatically opened when uid'pressure in supply port I2 exceeds a predetermined value.

- the closing pressure applied through spring 53 is regulated by adjusting screw 54.

- the ends of pilot valve cylinder 48 are also connected to the main working cylinder ports II and I5 by suitable pipes 56 and 51.

- Reversing valve cylinders 40 and 4I are also connected to pilot valve cylinder 48 by pipes 59 and 60 and passages 6I and 62, said passages opening into cylinder 48 at points between the ends of the cylinder and the central port 50.

- a port 64 communicating with the extreme left hand end of cylinder 48, is connected through a valve controlled bypass to a port 65 formed in the cylinder wall below and som-ewhat to the left of the cylinder end of passage 6

- Cylinder 48 is also provided with additional ports indicated at 61 and 68, the former communicating with the extreme right hand end of the cylinder and the latter being located below and slightly to the right of the adjacent end of passage 62.

- Ports 64 and 55 are connected together by a threeway valve 8U so arranged that when the valve lever is turned to the right as shown, port 64 is blocked and port 65 is open through valve 80 to atmosphere.

- Ports 61 and 68 are similarly connected by valve 8

- port I of Working-cylinder Il is connected to branch I2a of fluid pressure supply port I2 through annular port 43 of reversing valve I4 and valves I1 and I9.

- the remaining working-cylinder port I5 is connected to exhaust passage I3 through annular port 44 of valve I4 and valve I8, valve 20 being closed by its spring.

- Reversing valve I4 is being held in the position shown in Figure 1 partly by pump pressure acting through branch I2b and valve port 45 against the annulus X and partly by exhaust pressure acting against the outer face Y of piston 39.

- cam 35a acting through links 32a, 3Ia and arm 28h serves to partially close throttle valve I8 as shown in Fig. 2.

- the increased pressure thus established in passage I2 is sufiicient to open valve 5I (Fig. 2) so that port 58 ls placed in communication with port 52.

- valve I4 When valve I4 reaches to the extreme right hand position shown in Fig. 4 pressure fluid is supplied tothe right hand end of cylinder I8 through ports I2, 44, 22, I5, and valve 28 and is exhausted from the left hand endof said cylinder through ports II, 2

- valve I4 valve 5I closes and the right hand end of pilot valve cylinder 48 is connected to port I2 through port 61, pipe 51 and ports I5, 22 and 44.

- the left hand end of pilot cylinder 48 is simultaneously connected to exhaust port I3 through port 64, pipe 56, port II, valve I1, and ports 2

- Pump pressure is thus established in the right hand end of cylinder 48 and acts to shift valve 41 to the left. (Fig. 4.) This disrupts the communication previously established between pilot valve cylinder ports 58 and 6I through piston port 41a and places port 50 in communication with port 62 through piston port 41h as shown more particularlyin Fig..4.

- valve I2 ⁇ As ⁇ pistons 9a and 9b near the end of their ⁇ return stroke cam 35 engages lug 34 and operates link 32 to shift cushioning valve I'I to the right, thus throttling the exhaust through port Il.

- the resulting rise in pump pressure in port I2 opens valve 5

- table 5 operates against mechanical stop 5a at the end of the working stroke and against a hydraulic cushion at the end of the return stroke.

- the pressure conditions necessary for operating the reversing valve are established partly by the increased pump pressure due to choking of the exhaust near the end of the working stroke and partly by the drop in exhaust pressure which occurs in part of the system as the piston is halted by the stop 5a.

- This arrangement enables the reversal of table 5 at the end of the working stroke to be predetermined within very ne limits.

- valve I1 On the return stroke the reversal is timed solely bythe throttling action of valve I1 which, in addition to providing a hydraulic cushion against which the table 5 operates, also causes the rise in pump pressure which acts against piston 39 to reverse valve I4.

- This method of effecting reversal of the table at the end of the return stroke is satisfactory where it is not necessary for the table to work to a ne clearance at both ends of its travel. It will be understood, however, that the return stroke of table 5 may be adjusted, within limits, by changing the position of the cam 35.

- valve 80 in the position shown in Fig. l and reversing valve 8

- Fig. 7 shows a modification in which provision is made for operating two tool slides alternately.

- cylinder ports II and I5 are -through ports I2, I

- cylinders 14 and 15 respectively connected to the outer ends of cylinders 14 and 15. These cylinders contain the working pistons 16 and 11 to which the tool slides 18 and 1 9 are rigidly fastened as indicated at 80.

- the ports II 4and- I5 are alternately placed in communication with pressure supply passage I2 and exhaust passage I3 through the agency of the main reversing valve I4 and pilot valve 48. In this instance the cushioning valve I1 is omitted from passage II.

- Fig. '7 pipe 82 represents a push back pressure supply leading from the accumulator 82a.

- This pipe is provided with branches 83 and 84 communicating with pressure chambers 85 and 86 formed in the cylinder heads 14a and 15a of cylinders 14 and 15.

- Chamber 85 is in constant communication with cylinder 14 through the port 81 and bore 88 of a hollow stop pin 89.

- This pin is slidably mounted in cylinder head 14a. so that its inner end projects into the inner end of cylinder 14.

- Chamber 85 and cylinder 14 are also connected by a bypass 90 provided with a check valve 9

- Chamber 86 is in constant communication with cylinder I5 through the port 93 and bore 94 of a hollow stop pin 95 slidably mounted in cylinder head 15a so that its inner end extends into said cylinder. Chamber 86 and cylinder 15 are also connected by a bypass 96 provided with a check valve 91.

- each stop pin is adjusted by means of an adjusting screw in threaded engagement with the wall of the pin bore, said screw being keyed to a worm wheel

- pins 89 and 95 are also provided with lateral slots 89a and 95a which serve to maintain restricted communication between the bores of the pins and the inner ends of cylinders 14 and 15 when the pistons 16 and 11 are at the ends of their working strokes. These slots are tapered so that they decrease in width toward the inner ends of the pins.

- pilot valve cylinder ports 66 and 68 are respectively connected to the inner ends of cylinders 14 and 15 by pipes

- the remaining pilot valve cylinder ports are connected in the same way as described in connection with Fig. 1, with the exception that ports 64 and 69 are both plugged as indicated at

- piston 11 is shown at the end of its working stroke, the outer end of cylinder 15 being .connected to the iluid pressure supply passage I2 through cylinder port I5 and reversing valve port 44.

- the pump pressure in passage I2 rises and opens valve I so that reversing valve cylinder 4I is placed in communication with port I2 through ports 52, 50, 41b and 62 and pipe 60. Pump pressure is thus established in cylinder 4

- Valve I4 does not reverse at this time because the pressure in cylinder 4

- 08 is through the bore of pin 85 and is choked or throttled as the inner end of this pin enters the piston recess 11a.

- piston 95 comes to rest the extreme inner end of the pin port v95a is still uncovered by the piston and provides restricted communication between annulus

- bypass 91 The purpose of the bypass 91 is to speed up the return stroke of the piston by permitting a more rapid flow of the push back pressure into the cylinder 15 than would be possible if all the push back pressure had to enter the cylinder through pin 95. I'he bypass 91 is not essential and may be ⁇ omitted where speeding up of the return stroke is unimportant.

- valve I4 When valve I4 is reversed to connect cylinder port I5 to exhaust passage I3, the cylinder port II is connected to receive pressure fluid from port I2 through reversing valve port 43.

- the connections at the reversing valve ends of pilot valve passages 56 and 51 are reversed so that passage 56 is now connected to fluid pressure supply port I2 through cylinder port II and reversing valve port 43 while passage 51 is connected to exhaust passage I3 through cylinder port I5 and reversing valve port 44.

- Pump pressure is thus established in the left hand end of pilot valve cylinder 41 to shift pilot valve 48 to the right.

- This shifting of valve 48 disrupts communication between pipe

- the reversal of valve 48 also disrupts the communication previously established between pilot valve ports 50 and 62 and places port 50 in communication with pilot valve port 6

- piston 16 With cylinder port I5 connected to exhaust port I3 and cylinder port II connected to pressure fluid supply port I2 by the described reversal of valve I4 the piston 16 will make a working stroke under pump pressure supplied through passage II as the piston 11 makes its return stroke under push-back pressure supplied from accumulator 82a through pipes 82 and 84, chamber 86, pin 95 and valve 91, such push-back pressure acting against piston 11 being increased to some extent by the discharge from cylinder 14 into the push-back pressure system.

- the return speed of piston 11 depends on the resistance offered by the work to the tool carried by toolslide 19. When piston 16 nears the end of its working stroke the escape of the push back pressure ⁇ through pin 89 is choked as the inner end of the pin enters the piston recess 16a.

- Apparatus for operating a machine tool or other translatable element by fluid pressure comprising means for applying working fluid pressure to move said element in a given direction against an opposing fluid pressure, means for increasing the opposing pressure to effect a corresponding increase of the working pressure when the element has travelled a predetermined distance, and means for reversing the direction of travel of the element in response to the increase of the working pressure.

- Apparatus for operating a machine tool or other translatable element by fluid pressure comprising a mechanical stop, means for applying fluid working pressure to move said element toward said stop against the resistance of an opposing fluid pressure, means for automatically increasing said opposing pressure to effect a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, means for reversing the direction of travel of the element in response to said increase of working pressure, and means for preventing operation of said last mentioned means until the element is halted by said stop.

- Apparatus for operating a machine tool or other element by fluid pressure comprising means for applying working pressure to move said element in a given direction against an opposing pressure, means for increasing the opposing pressure to cause a corresponding increase ofthe working pressure when the element has travelled a predetermined distance, means for reversing the direction of travel of the element in response to the increase of working pressure and means for utilizing said opposing pressure to prevent operation of the reversing means until the element has travelled to a predetermined point beyond the point at which the pressure increase occurs.

- Apparatus for operating a machine tool or other translatable element by fluid pressure comprising a mechanical stop, means for applying fluid pressure to move said element into engagement with said stop against the resistance of an opposing iluid pressure, means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, means for reversing the direction of.

- Apparatus for operating a machine tool or other element by iluid pressure comprising a mechanical stop.

- means for applying working pressure to move said element into engagement with said stop against the resistance of an opposing fluid pressure means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, a reversing valve arranged to operate in response to the increase of working pressure to establish connections resulting in reversal ⁇ oi! the direction of travel of said element and means for utilizing said opposing pressure to prevent the aforesaid operation of the reversing valve until the element is halted by engagement with said stop.

- Apparatus for operating a machine tool or other element by lluid pressure comprising means for applying working fluid pressure to move said element in a given direction against an opposing uid pressure, means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance and a reversing valve arranged to operate in response to the said increase of working pressure to establish connections resulting in reversal of the direction of travel of the tool.

- Apparatus for operating a machine tool or other element by fluid pressure comprising means for applying working fluid pressure to move said element in a given direction, means for increasing said pressure when the element has travelledv a predetermined distance, a reversing valve, means functioning in response to the said increase of working pressure for opening a normally closed passage through which said pressure is applied directly to the reversing valve to operate the latter to a position establishing connections resulting in reversal of the direction of travel of said element and means for preventing the aforesaid operation of the reversing valve in response to the opening of said passage until said element has travelled a predetermined distance beyond the point at which the pressure increase occurs.

- Apparatus for operating a machine tool or other element by fluid pressure comprising a cylinder, a piston working in the cylinder and connected to said tool or other element, a reversing valve through which fluid working pressure is applied to one side of the piston to move the tool or other element on a working stroke against an opposing fluid pressure acting against the opposite side of the piston, a valve through which said opposing fluid pressure is discharged from the cylinder during the aforesaid movement oi' the piston, means for operating said valve to throttle the discharge of said opposing pressure from said cylinder when the tool has been moved a predetermined distance on its working stroke, said operation of the valve serving to increase effect a return movement of the tool at the endof the working stroke and a valve normally closing said passage and arranged to be opened automatically by the working pressure when the latter is increased to a predetermined value by the aforesaid increase of the opposing fluid pressure.

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Fluid-Pressure Circuits (AREA)

Description

Dec. 3, 1940. W P, MUER 2,223,792

HYDRAULIC APPARATUS FOR OPERATING MACHINE TOOLS AND THE LIKE Filed April l2, 1938 5 Sheets-Sheet l i W.P.MUIR Y .QMWM

ATT() RNEY Dec. 3, 1940. W P. Mum 2,223,792

HYDRAULIC APPARATUS FOR OPERATING MACHINE TOOLS AND THE LIKE Filed April l2, 1938 5 Sheets-Sheet 2 INVENTOR WRMUIR AT TORNEY W. P. MUIR Dec. 3, 1940.

HYDRAULIC APPARATUS FOR OPERATING MACHINE TOOLS AND THE LIKE Filed April 12, 1938 5 Sheets-Sheet 3 INVENTOR wan/lum ATTOB/NEY Dec, 3, 1940. W. P .MUIR 2,223,792

HYDRAULIC APPARTUS FOR OPERATING MACHINE TOOLS AND THE LIKE Filed April l2, 1938 5 Sheets-Sheet 4 L5.. n 5i in ll $1 9D @l 2 M. s $4 'l fil *2Q l I I? EB FH Q 1, :f 4| v )Il Il o I oo b4 @g a @a f il O l 1 O s' CD ,It @im n r 'l :a

| du mr ,I

vINvEN'roR WP.MUR

BY @M ATTORNEY WQP. MUIR 2,223,792

HYDRAULIC APPARATUS FOR OPERATING MACHINE TOOLS ND THE LIKE Dec. 3, 1940.

Filed April l2, 193B 5 Sheets-Sheet 5 @OA w@ l NVENTOR W13. MUR

ATTORNE Patented Dec. 3, 1940 UNITED STATES PATENT OFFICE HYDRAULIC APPARATUS FOR OPERATING MACHINE TOOLS AND THE LIKE Application April 12, 1938, Serial N0. 201,576

8 Claims. (Cl. 121-45) This invention relates to hydraulic apparatus for operating machine tools and the like.

The said apparatus is characterized by a novel mode of operation which comprises applying pressure to move the tool in a given direction;

increasing said pressure when the tool has travelled a predetermined distance, and utilizing the increased pressure to reverse the direction of travel of the tool. This method may be applied lo to effect either immediate or delayed reversal of the tool in response to the rise of working pressure acting thereon. In the case of immediate reversal the increased pressure is preferably utilized to open a normally closed passage leading I5 to a reversing valve which then operates in direct response to such pressure to establish hydraulic connections resulting in reversal of the direction of travel of the tool. In the case of delayed reversal, operation of the reversing valve by the 0 increased Working pressure is prevented by an opposing hydraulic pressure until the travel of the tool is halted by a mechanical stop. When this occurs fthe opposing pressure is released or decreased suiciently to permit operation of the 2r, reversing valve by the working pressure acting thereon.

Hereto the movement of tables on machine tools actuated by hydraulic means has been limited by the inability of the hydraulic system to :m control the movements up to a predetermined point in the travel with absolute accuracy. The control of reversal of travel of the table was by means of cams reversing the main control valve directly or through a pilot valve, and it has been 3,-, found impractcable to use a definite mechanical stop for the table travel with the positive assurance that the table will contact this stop every time and not reverse its motion until it does so.

40 With the system described herein, definite assurance that the table will come to some positive l accurate stop so that it will be possible to mill, plane or grind right up to a shoulder or radius Without leaving a relief or undercut for the tool to work into and thereby eliminating the extra operation to machine this relief or undercut and the weakness to the piece entailed by theundercut.

Several samples of apparatus, illustrating dif- 50 ferent Ways of effecting hydraulic operation of machine tools or tables in accordance with the novel principles of this invention, are shown and described in the present application. It will be understood, however, that the principles involved 65 may be embodied in various other forms of apparatus for operating machine tools, tables or any other movable elements to which the invention is usefully applicable.

' In the preferred embodiment of the invention, the working pressure moves the tool against an opposing hydraulic pressure which is automatically increased When the tool has travelled a predetermined distance. This increase of pressure opposing movement of the tool causes a corresponding increase of working pressure which is utilized, as previously explained, to effect either immediate or delayed reversal of the direction of movement of the tool. When the increased working pressure is to be utilized for eilecting immediate operation of the reversing valve the increase of pressure opposing movement of the tool by the working pressure merely serves to cushion the movement of the tool toward the end of its stroke and to cause the necessary increase of working pressure. When reversal of the tool is to be delayed until the tool is halted by a mechanical stop the increase of pressure opposing movement of the tool is utilized to prevent operation of the reversing valve by the increased working pressure until such time as the tool actually engages the stop.

A characteristic feature common to several forms of apparatus disclosed herein is the application of hydraulic pressure to move a tool against a mechanical stop which, in addition to halting the tool after it has travelled a predetermined distance, also serves, by its resistance to further movement of the tool, to promote establishment of pressure conditions resulting in hydraulic reversal of the tool. This employment of a mechanical stop controlling both the working stroke and the reversal of the tool enables the point to which the tool is advanced at the end of the working stroke to be predetermined within sufficiently close limits to meet the demands of any operating conditions likely to arise.

As a general rule it is not necessary that the return stroke of a hydraulically actuated tool becontrolled and predetermined within the same close limits as the working stroke. Consequently, apparatus provided in accordance with this invention may be designed so that the travel and reversal of the tool during a working stroke is closely regulated by a mechanical stop, as previously explained, while the reversal of the tool at the end of a return stroke is controlled solely by an increase of the pressure then acting to move the tool. In other cases, where the limits within which both the working and return strokes must bepredetermined are fairly wide, the reig'ersal of the tool after it has travelled a predetermined distance in either direction may be 'made dependent solely on an automatic increase of the pressure which is then acting on the tool. In still other cases, where extreme accuracy is required in respect to controlling both the Working and return strokes of the tool, ythe latter may be operated against a stop at each end of its travel so that the resistance of the stop serves, as previously explained, to control both the stroke and the reversal of the tool within very close limits.

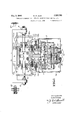

Proceeding now to a more detailed description reference will be had to the accompanying drawings in which- Figure 1 is a view, mainly in vertical section, of one form of apparatus by which the invention may be reduced to practice.

Figures 2 to 4 inclusive are views similar to Fig. 1 but showing other positions to which the valves and other component parts are shifted during operation of the apparatus.

Figure 5 is a vertical sectional view along the line 5-5 of Fig. 2.

' Figure 6 is a vertical sectional view along the line 6-6 of Fig. 2.

Figure '1 is a view similar to Fig. 1 but showing a modified form of apparatus.

In the construction shown in Figs. 1 to 6 inclusive, 5 represents a work table such as the table of a planer or milling machine. This table is rigidly secured, as indicated at 6, to the piston rods 1 and 8 of pistons 9a and 9b working in cylinder I8. The left hand end of cylinder I0 communicates with a port I I which is alternately connected to fluid pressure supply passage I2 and exhaust passage I3 through the agency of a reversing valve I4. The right hand end of cylinder I0 communicates with a port I5 which is alternately connected to passages I2 and I3 by the valve I4. `Passage I2 is connected to a pump or other source of pressure duid by pipe I6.

Cylinder port is connected, through throttle valve I1 and check valve I9, to valve port 2| leading to reversing valve I4. Cylinder port I5 is connected, through throttle valve I8 and check valve 20, to valve port 22 also leading to reversing valve I4. Check valves I9 and 20 are spring loaded to close against the valve seats I9' and 20'. These valves open when the flow is from the valve ports 2| and 22 to the cylinder ports II and I5 respectively, but close when the direction of flow through the cylinder and valve ports is reversed. Throttle valves I1 and I8 are normally biased to open position by valve springs I1'v and I 8 acting, respectively, against suitable abutments I1a and I8a carried by the outer ends of the valve stems IIb and |8b.r When table 5 approaches the end of its stroke in one direction, an arm 28 acts against the outer end of stem |1b to shift the throttle valve I1 to the right from the lopen position shown in Figure l. Arm 28 is carried by a pin or shaft 28a rotatably mounted in a suitable bracket 29. This pin or shaft 28a is connected, by arm and vertical link 3|, to one end of a horizontal link 32 having its opposite end pivoted to a bracket 33. Link 32 is provided with a cam lug or projection 34 disposed in the path of an operating cam carried by table 5. When the table 5 approaches the end of its stroke in the opposite direction the throttle valve I8 is moved inwardly or to the left by an arm 28b xed to a pin or shaft 28c journalled in bracket 29a. This pin or shaft 28c is connected, by arm 30a and vertical link 3|a, to the outer end of a horizontal link 32a having its opposite end pivoted to a bracket 33a. Link 32a is provided with a lug 34a disposed in the path of an operating cam 35a carried by the table.

Reversing valve I4 is slidably mounted in a suitably ported valve liner 31 arranged in passage 31a intersecting the main cylinder ports 2| and 22; exhaust port I3; and branches |2a and I2b of fluid pressure supply port I2. The ends of this valve are formed to provide operating pistons 38 and 39 working in cylinders 40 and 4I. The body portion of valve I4 is provided with annular ports 42, 43, 44 and 45. Port 43 is the port through which main cylinder port II is alternately connected to exhaust port I3 or to branch |2a of fluid pressure supply port I2 through valves |1 and I9 and port 2|. The port 44 is the one through which main cylinder port I5 is alternately connected to exhaust port I3 or to branch I2b of pressure supply port I2 through valves I8 and 20 and port 22.

The positioning of reversing valve I4 is controlled by a 'cylindrical pilot valve 41 slidably mounted in pilot valve cylinder 48. This cylinder is connected through port 50, valve 5| and port 52 to the uid pressure supply port I2. Valve 5I is normally biased to closed position by a spring 53 and is automatically opened when uid'pressure in supply port I2 exceeds a predetermined value. The closing pressure applied through spring 53 is regulated by adjusting screw 54. The ends of pilot valve cylinder 48 are also connected to the main working cylinder ports II and I5 by suitable pipes 56 and 51. Reversing valve cylinders 40 and 4I are also connected to pilot valve cylinder 48 by pipes 59 and 60 and passages 6I and 62, said passages opening into cylinder 48 at points between the ends of the cylinder and the central port 50. A port 64, communicating with the extreme left hand end of cylinder 48, is connected through a valve controlled bypass to a port 65 formed in the cylinder wall below and som-ewhat to the left of the cylinder end of passage 6|. Cylinder 48 is also provided with additional ports indicated at 61 and 68, the former communicating with the extreme right hand end of the cylinder and the latter being located below and slightly to the right of the adjacent end of passage 62. Ports 64 and 55 are connected together by a threeway valve 8U so arranged that when the valve lever is turned to the right as shown, port 64 is blocked and port 65 is open through valve 80 to atmosphere. Ports 61 and 68 are similarly connected by valve 8| except that valve 8|, as shown with the valve lever turned to the right, affords direct communication between said ports 61 and 68.

In describing the operation it Will be assumed that table 5 and pistons 9a and 9b are making a working stroke to the right as indicated by arrow 1I. In this case port I of Working-cylinder Il is connected to branch I2a of fluid pressure supply port I2 through annular port 43 of reversing valve I4 and valves I1 and I9. The remaining working-cylinder port I5 is connected to exhaust passage I3 through annular port 44 of valve I4 and valve I8, valve 20 being closed by its spring.

Reversing valve I4 is being held in the position shown in Figure 1 partly by pump pressure acting through branch I2b and valve port 45 against the annulus X and partly by exhaust pressure acting against the outer face Y of piston 39. In

this connection it will be noted that exhaust pressure in cylinder port I5 is transmitted to the outer end of reversing valve cylinder 4I through pipe 51, valve 8|, port 68, passage 82 and pipe 68. Since valve 5I is closed there is no pressure in cylinder 40 of reversing valve I4. Pilot valve 41 is provided with ports 41a and 41b and is held in the position shown in Fig. 1 by pump pressure admitted to the left hand end of pilot valve cylinder 48 by way of port II, pipe 58 and port 84.

As the table 5 nears the end of its stroke in the direction indicated by the arrow 1I, cam 35a acting through links 32a, 3Ia and arm 28h serves to partially close throttle valve I8 as shown in Fig. 2. This restricts the flow from port I5 to port 22 and causes an immediate rise in pressure in port lI and in the left hand end of cylinder I0 by the pump.v There is a corresponding rise of exhaust pressure in port I5 and the right hand end of cylinder I0. The increased pressure thus established in passage I2 is sufiicient to open valve 5I (Fig. 2) so that port 58 ls placed in communication with port 52. This permits the pressure in passage I2 to be' transmitted through ports 52, 58, and 41a, passage 6I and pipe 59 to reversing valve cylinder 40 where it acts against the outer face Z of piston 38. There is no reversal of valve I4 at this time since the pressure acting against the face Z of piston 38 is less than the sum of the opposing pressures acting against annulus X and face Y of piston 39, due to the rise in exhaust pressure in port I5, pipe 51, valve BI, ports 68, 41h and 62 and pipe 60.

As piston 9b reaches the end of its stroke (Fig. 3) and is held against further movement by engagement of table 5 with the right hand table stop 5a, the pressure in port I5 and reversing valve cylinder 4I drops to the point where the pump pressure acting against the face Z of piston 38 overcomes the pump pressure acting on annulus X and becomes effective to shift valve I4 to the right as indicated in Fig. 3. In `this connection it will be noted that the pressure receiving area Z is larger than the area X. It may be noted here that when piston 9a reaches the position shown in Fig. 3 valve I8 is fully closed so that port I5 is isolated from port 22.

When valve I4 reaches to the extreme right hand position shown in Fig. 4 pressure fluid is supplied tothe right hand end of cylinder I8 through ports I2, 44, 22, I5, and valve 28 and is exhausted from the left hand endof said cylinder through ports II, 2|, 43 and I3 and valve I1. As cam 35a moves away from link 32a on the return stroke of piston 9 cushioning valve I8 resumes its open position as shown in Fig. 4.

During the aforesaid reversal of valve I4 valve 5I closes and the right hand end of pilot valve cylinder 48 is connected to port I2 through port 61, pipe 51 and ports I5, 22 and 44. The left hand end of pilot cylinder 48 is simultaneously connected to exhaust port I3 through port 64, pipe 56, port II, valve I1, and ports 2| and 43. Pump pressure is thus established in the right hand end of cylinder 48 and acts to shift valve 41 to the left. (Fig. 4.) This disrupts the communication previously established between pilot valve cylinder ports 58 and 6I through piston port 41a and places port 50 in communication with port 62 through piston port 41h as shown more particularlyin Fig..4.

`As` pistons 9a and 9b near the end of their `return stroke cam 35 engages lug 34 and operates link 32 to shift cushioning valve I'I to the right, thus throttling the exhaust through port Il. The resulting rise in pump pressure in port I2 opens valve 5| so that port 50 is connected to port I2 through port 52. Since pilot valve 41 is now in the position shown in Fig. 4', port 50 is also connected to port 62 through piston port 41h so that pump pressure is established in cylinder 4I and acts against the face Y of piston 39 to shift reversing valve I4 to the left. Since valve cuts off port 84 and exhausts ports B5 and 6I through port 41a there is no exhaust pressure acting against piston 38 in opposition to the pump pressure acting against piston 39. Consequently, valve I4 will reverse as soon as the pump pressure in port I2 is increased by the exhaust throttling action of valve I1.

From the foregoing it will be seen that table 5 operates against mechanical stop 5a at the end of the working stroke and against a hydraulic cushion at the end of the return stroke. On the Working stroke the pressure conditions necessary for operating the reversing valve are established partly by the increased pump pressure due to choking of the exhaust near the end of the working stroke and partly by the drop in exhaust pressure which occurs in part of the system as the piston is halted by the stop 5a. This arrangement enables the reversal of table 5 at the end of the working stroke to be predetermined within very ne limits. On the return stroke the reversal is timed solely bythe throttling action of valve I1 which, in addition to providing a hydraulic cushion against which the table 5 operates, also causes the rise in pump pressure which acts against piston 39 to reverse valve I4. This method of effecting reversal of the table at the end of the return stroke is satisfactory where it is not necessary for the table to work to a ne clearance at both ends of its travel. It will be understood, however, that the return stroke of table 5 may be adjusted, within limits, by changing the position of the cam 35.

If it is desired to have table 5 operate against a mechanical stop at each end of its travel this may be accomplished by providing the left hand table stop 5b and reversing the position of valve 80 to provide a communicating passage between ports 64 and 65, valve 8l being left in the position shown in the drawings. In this case throttling of port II by valve I'I does not result in immediate reversal of valve I4 from the position shown in Fig. 4. On the` contrary, exhaust pressure transmitted to the face Z of piston 38, through pipe 56, valve 80, ports 41a and 6I and pipe 59 serves, in conjunction with the pump pressure acting against annulus X' (Fig. 4) to hold valve I4 against reversal until table 5 encounters stop 5b. When this occurs the resulting drop in exhaust pressure acting against face Z permits the pump pressure acting against face Y of piston 39 to overcome the pump pressure acting against annulus X' and thus effect reversal of valve I4. i

If it is desired to provide for instant reversal of the table at both ends of travel without the use of the mechanical stops 5a and 5b this may be accomplished by leaving valve 80 in the position shown in Fig. l and reversing valve 8| to a position blocking port 61 and venting port 88 to atmosphere. This prevents exhaust pressure being established in either of the cylinders 40 and 4I. Thus any degree of accuracy in either direction may be had at the will of the operator.

Fig. 7 shows a modification in which provision is made for operating two tool slides alternately. In this case cylinder ports II and I5 are -through ports I2, I| and I5.

respectively connected to the outer ends of cylinders 14 and 15. These cylinders contain the working pistons 16 and 11 to which the tool slides 18 and 1 9 are rigidly fastened as indicated at 80. The ports II 4and- I5 are alternately placed in communication with pressure supply passage I2 and exhaust passage I3 through the agency of the main reversing valve I4 and pilot valve 48. In this instance the cushioning valve I1 is omitted from passage II.

The pistons 16 and 11 are operated on their inward or working strokes by high pressure uid pumped to the outer end of cylinders 14 and 15 On their return stroke the pistons are operated by a relatively low, constant, push-back pressure obtained from a separate source such as an air loaded accumulator connected to the inner ends of cylinders 14 and 15. In Fig. '7 pipe 82 represents a push back pressure supply leading from the accumulator 82a. This pipe is provided with branches 83 and 84 communicating with pressure chambers 85 and 86 formed in the cylinder heads 14a and 15a of cylinders 14 and 15. Chamber 85 is in constant communication with cylinder 14 through the port 81 and bore 88 of a hollow stop pin 89. This pin is slidably mounted in cylinder head 14a. so that its inner end projects into the inner end of cylinder 14. Chamber 85 and cylinder 14 are also connected by a bypass 90 provided with a check valve 9|.

Chamber 86 is in constant communication with cylinder I5 through the port 93 and bore 94 of a hollow stop pin 95 slidably mounted in cylinder head 15a so that its inner end extends into said cylinder. Chamber 86 and cylinder 15 are also connected by a bypass 96 provided with a check valve 91.

The outer ends of pins 89 and 95 serve as piston stops which t into the piston recesses 16a and 11a as the pistons 15 and 16 complete their working strokes, the length of which may be accurately predetermined by lengthwise adjustment of the pins 89 and 95 with reference to cylinders 14 and 15. In the present instance each stop pin is adjusted by means of an adjusting screw in threaded engagement with the wall of the pin bore, said screw being keyed to a worm wheel |02 which is held against longitudinal movement in a gear casing |03 and is operated by a suitable worm |04. The outer ends of pins 89 and 95 are also provided with lateral slots 89a and 95a which serve to maintain restricted communication between the bores of the pins and the inner ends of cylinders 14 and 15 when the pistons 16 and 11 are at the ends of their working strokes. These slots are tapered so that they decrease in width toward the inner ends of the pins.

The pilot valve cylinder ports 66 and 68 are respectively connected to the inner ends of cylinders 14 and 15 by pipes |04 and |05. The remaining pilot valve cylinder ports are connected in the same way as described in connection with Fig. 1, with the exception that ports 64 and 69 are both plugged as indicated at |08'.

In Fig. 7, piston 11 is shown at the end of its working stroke, the outer end of cylinder 15 being .connected to the iluid pressure supply passage I2 through cylinder port I5 and reversing valve port 44. As the piston is stopped by pin 95 the pump pressure in passage I2 rises and opens valve I so that reversing valve cylinder 4I is placed in communication with port I2 through ports 52, 50, 41b and 62 and pipe 60. Pump pressure is thus established in cylinder 4| and acts against the face Y of reversing valve piston 89.

Valve I4 does not reverse at this time because the pressure in cylinder 4| ls insufilcient to overcome the corresponding increase ot the opposing push back pressure which is-transmitted from the push back annulus |08 of cylinder 15 to reversing valve cylinder 40 through pipe |05, pilot valve ports 41a and 8| and pipe 59. In this connection it may be explained that the escape of push back pressure from annulus |08 is through the bore of pin 85 and is choked or throttled as the inner end of this pin enters the piston recess 11a. When piston 95 comes to rest the extreme inner end of the pin port v95a is still uncovered by the piston and provides restricted communication between annulus |05 and the bore oi pin 85. By virtue of this communication, the push back pressure in annulus |08 drops to normal as soon as the piston is halted by pin 95 and this drop is sulcient to permit reversal of valve I4 by the pump pressure acting against face Y of reversing valve piston 39. When valve I4 is reversed iiuid pressure is exhausted from the outer end of cylinder 15 through cylinder port I5, reversing valve port 44 and exhaust passage I3. This permits the piston 11 to be operated on its return stroke by push back pressure supplied to the inner end of cylinder 15 through pin 95 and bypass 91. The purpose of the bypass 91 is to speed up the return stroke of the piston by permitting a more rapid flow of the push back pressure into the cylinder 15 than would be possible if all the push back pressure had to enter the cylinder through pin 95. I'he bypass 91 is not essential and may be `omitted where speeding up of the return stroke is unimportant.

When valve I4 is reversed to connect cylinder port I5 to exhaust passage I3, the cylinder port II is connected to receive pressure fluid from port I2 through reversing valve port 43. At the same time the connections at the reversing valve ends of pilot valve passages 56 and 51 are reversed so that passage 56 is now connected to fluid pressure supply port I2 through cylinder port II and reversing valve port 43 while passage 51 is connected to exhaust passage I3 through cylinder port I5 and reversing valve port 44. Pump pressure is thus established in the left hand end of pilot valve cylinder 41 to shift pilot valve 48 to the right. This shifting of valve 48 disrupts communication between pipe |05 and pilot Valve port 6I and establishes communication between pilot valve port 62 and the pipe |04 which is connected to the inner end of cylinder 14. The reversal of valve 48 also disrupts the communication previously established between pilot valve ports 50 and 62 and places port 50 in communication with pilot valve port 6| which is connected to reversing valve cylinder 40 as previously described.

With cylinder port I5 connected to exhaust port I3 and cylinder port II connected to pressure fluid supply port I2 by the described reversal of valve I4 the piston 16 will make a working stroke under pump pressure supplied through passage II as the piston 11 makes its return stroke under push-back pressure supplied from accumulator 82a through pipes 82 and 84, chamber 86, pin 95 and valve 91, such push-back pressure acting against piston 11 being increased to some extent by the discharge from cylinder 14 into the push-back pressure system. The return speed of piston 11 depends on the resistance offered by the work to the tool carried by toolslide 19. When piston 16 nears the end of its working stroke the escape of the push back pressure` through pin 89 is choked as the inner end of the pin enters the piston recess 16a. The working stroke of piston 16 is thus cushioned and slowed/ down so that there is an immediate rise in both the pump pressure and the push back pressure in cylinder 14. The rise of pump pressure in port I2 issufficient to open valve 5| so that port is placed in communication with reversing valve cylinder 40 through ports 52, 50, 41a, 6| and pipe 59, it being remembered that pilot valve 48 is now in the opposite position to that shown in Fig. 7. The pump pressure thus established in reversing valve cylinder 40 becomes effective to shift valve |4 to the right when the opposing push back pressure in reversing valve cylinder 4| drops to normal as occurs when piston 16 is halted by pin 89. In this connection it will be noted that When pilot valve 48 is in the opposite position to that shown in Fig. '1 the push back pressure in annulus of cylinder 16 is transmitted to reversing valve cylinder 4| through pipe |04, pilot valve ports 66, 41h and 62 and pipe 60. When valve |4 is reversed to resume the position shown in Fig. 7 the pilot valve 48 is also returned to the position shown in this ligure by pump pressure acting through passage 51.

Having thus described my invention, what I claim is:

1. Apparatus for operating a machine tool or other translatable element by fluid pressure comprising means for applying working fluid pressure to move said element in a given direction against an opposing fluid pressure, means for increasing the opposing pressure to effect a corresponding increase of the working pressure when the element has travelled a predetermined distance, and means for reversing the direction of travel of the element in response to the increase of the working pressure.

2. Apparatus for operating a machine tool or other translatable element by fluid pressure comprising a mechanical stop, means for applying fluid working pressure to move said element toward said stop against the resistance of an opposing fluid pressure, means for automatically increasing said opposing pressure to effect a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, means for reversing the direction of travel of the element in response to said increase of working pressure, and means for preventing operation of said last mentioned means until the element is halted by said stop.

3. Apparatus for operating a machine tool or other element by fluid pressure comprising means for applying working pressure to move said element in a given direction against an opposing pressure, means for increasing the opposing pressure to cause a corresponding increase ofthe working pressure when the element has travelled a predetermined distance, means for reversing the direction of travel of the element in response to the increase of working pressure and means for utilizing said opposing pressure to prevent operation of the reversing means until the element has travelled to a predetermined point beyond the point at which the pressure increase occurs.

4. Apparatus for operating a machine tool or other translatable element by fluid pressure comprising a mechanical stop, means for applying fluid pressure to move said element into engagement with said stop against the resistance of an opposing iluid pressure, means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, means for reversing the direction of.

travel of the element in response to the said increase of working pressure and means for utilizing said opposing pressure to prevent operation of the reversing means until the element is halted by engagement with said stop.

5. Apparatus for operating a machine tool or other element by iluid pressure comprising a mechanical stop. means for applying working pressure to move said element into engagement with said stop against the resistance of an opposing fluid pressure, means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance toward said stop, a reversing valve arranged to operate in response to the increase of working pressure to establish connections resulting in reversal `oi! the direction of travel of said element and means for utilizing said opposing pressure to prevent the aforesaid operation of the reversing valve until the element is halted by engagement with said stop.

6. Apparatus for operating a machine tool or other element by lluid pressure comprising means for applying working fluid pressure to move said element in a given direction against an opposing uid pressure, means for increasing the opposing pressure to cause a corresponding increase of the working pressure when the element has travelled a predetermined distance and a reversing valve arranged to operate in response to the said increase of working pressure to establish connections resulting in reversal of the direction of travel of the tool.

7. Apparatus for operating a machine tool or other element by fluid pressure comprising means for applying working fluid pressure to move said element in a given direction, means for increasing said pressure when the element has travelledv a predetermined distance, a reversing valve, means functioning in response to the said increase of working pressure for opening a normally closed passage through which said pressure is applied directly to the reversing valve to operate the latter to a position establishing connections resulting in reversal of the direction of travel of said element and means for preventing the aforesaid operation of the reversing valve in response to the opening of said passage until said element has travelled a predetermined distance beyond the point at which the pressure increase occurs.

8. Apparatus for operating a machine tool or other element by fluid pressure comprising a cylinder, a piston working in the cylinder and connected to said tool or other element, a reversing valve through which fluid working pressure is applied to one side of the piston to move the tool or other element on a working stroke against an opposing fluid pressure acting against the opposite side of the piston, a valve through which said opposing fluid pressure is discharged from the cylinder during the aforesaid movement oi' the piston, means for operating said valve to throttle the discharge of said opposing pressure from said cylinder when the tool has been moved a predetermined distance on its working stroke, said operation of the valve serving to increase effect a return movement of the tool at the endof the working stroke and a valve normally closing said passage and arranged to be opened automatically by the working pressure when the latter is increased to a predetermined value by the aforesaid increase of the opposing fluid pressure.

WILLIAM P. MUIR.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201576A US2223792A (en) | 1938-04-12 | 1938-04-12 | Hydraulic apparatus for operating machine tools and the like |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201576A US2223792A (en) | 1938-04-12 | 1938-04-12 | Hydraulic apparatus for operating machine tools and the like |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2223792A true US2223792A (en) | 1940-12-03 |

Family

ID=22746388

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US201576A Expired - Lifetime US2223792A (en) | 1938-04-12 | 1938-04-12 | Hydraulic apparatus for operating machine tools and the like |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2223792A (en) |

Cited By (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2427970A (en) * | 1943-01-25 | 1947-09-23 | Ex Cell O Corp | Hydraulic control system for machine tools and the like |

| US2437109A (en) * | 1941-02-25 | 1948-03-02 | Black Rock Mfg Company | Dipping machine |

| US2454235A (en) * | 1943-10-19 | 1948-11-16 | Connectieut Tool & Engineering | Drilling machine |

| US2516594A (en) * | 1944-04-07 | 1950-07-25 | Kearfott Company Inc | Windshield wiper |

| US2517243A (en) * | 1944-02-26 | 1950-08-01 | Alco Valve Co | Pressure controlled pump operating valve mechanism |

| US2523572A (en) * | 1944-03-18 | 1950-09-26 | Allis Chalmers Mfg Co | Control for a plurality of fluid pressure motors |

| US2537680A (en) * | 1949-06-29 | 1951-01-09 | Air Associates Inc | Pressure actuated distributing valve means for motors |

| US2563068A (en) * | 1945-01-29 | 1951-08-07 | Trico Products Corp | Windshield cleaner |

| US2569213A (en) * | 1947-03-12 | 1951-09-25 | Denison Eng Co | Hydraulic motor control apparatus |

| US2603952A (en) * | 1948-07-03 | 1952-07-22 | Adiel Y Dodge | Wheel cylinder for hydraulic brake mechanism |

| US2606414A (en) * | 1947-08-16 | 1952-08-12 | Int Harvester Co | Stop mechanism for implement adjusting cylinders |

| US2614537A (en) * | 1950-06-28 | 1952-10-21 | John Deere Van Brunt Co | Means for regulating stroke of fluid-pressure apparatus |

| US2646074A (en) * | 1948-07-28 | 1953-07-21 | R S Products Corp | Variable stroke cushioned valve |

| US2678638A (en) * | 1948-11-01 | 1954-05-18 | Cecil W Bopp | Fluid stop for fluid motors |

| US2680952A (en) * | 1949-11-21 | 1954-06-15 | Mcdonnell Aircraft Corp | Electrically powered hydraulic linear wingfold actuator |

| US2688314A (en) * | 1953-05-01 | 1954-09-07 | Smallpeice Ltd | Arrangement of control valves |

| US2689548A (en) * | 1953-05-01 | 1954-09-21 | Smallpeice Ltd | Arrangement of control valves |

| US2698517A (en) * | 1952-05-21 | 1955-01-04 | Kenneth F Witt | Automatic means to control and reverse fluid-operated cylinder-and-piston units |

| US2735404A (en) * | 1956-02-21 | L- komph | ||

| US2761424A (en) * | 1948-07-28 | 1956-09-04 | R S Products Corp | Variable stroke cushioned valves |

| DE1035513B (en) * | 1952-01-24 | 1958-07-31 | Diskus Werke Frankfurt Main Ag | Hydraulic piston drive for reciprocating parts of machine tools, e.g. B. for grinding slide |

| US2976851A (en) * | 1957-02-28 | 1961-03-28 | Werkzeugmaschinenfabrik Veb | Automatic hydraulic positioning device for machine parts |

| US2996045A (en) * | 1959-07-16 | 1961-08-15 | Honeywell Regulator Co | Time modulated hydraulic servo valve |

| US3046951A (en) * | 1961-03-27 | 1962-07-31 | Honeywell Regulator Co | Hydraulic control valve |

| US3082749A (en) * | 1960-12-05 | 1963-03-26 | Kobe Inc | Fluid operated pump control system |

| US3800665A (en) * | 1972-07-27 | 1974-04-02 | Von Ruden Mfg Co | Fluid pressure operated reciprocatory motor |

| US3834521A (en) * | 1972-05-15 | 1974-09-10 | Cpe Ind Inc | Air drive for conveyor |

| US5044254A (en) * | 1991-02-01 | 1991-09-03 | Coltene/Whaldent, Inc. | Reciprocating air motor |

| US5079988A (en) * | 1989-12-26 | 1992-01-14 | Raymond Robert E | Hydraulic sensor and transducing apparatus |

| US20060260465A1 (en) * | 2005-05-17 | 2006-11-23 | Trestain Dennis A | Bi-directional pneumatic motor |

| US9803660B1 (en) * | 2014-02-04 | 2017-10-31 | Danfoss Power Solutions Inc. | Low friction compact servo piston assembly |

-

1938

- 1938-04-12 US US201576A patent/US2223792A/en not_active Expired - Lifetime

Cited By (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2735404A (en) * | 1956-02-21 | L- komph | ||

| US2437109A (en) * | 1941-02-25 | 1948-03-02 | Black Rock Mfg Company | Dipping machine |

| US2427970A (en) * | 1943-01-25 | 1947-09-23 | Ex Cell O Corp | Hydraulic control system for machine tools and the like |

| US2454235A (en) * | 1943-10-19 | 1948-11-16 | Connectieut Tool & Engineering | Drilling machine |

| US2517243A (en) * | 1944-02-26 | 1950-08-01 | Alco Valve Co | Pressure controlled pump operating valve mechanism |

| US2523572A (en) * | 1944-03-18 | 1950-09-26 | Allis Chalmers Mfg Co | Control for a plurality of fluid pressure motors |

| US2516594A (en) * | 1944-04-07 | 1950-07-25 | Kearfott Company Inc | Windshield wiper |

| US2563068A (en) * | 1945-01-29 | 1951-08-07 | Trico Products Corp | Windshield cleaner |

| US2569213A (en) * | 1947-03-12 | 1951-09-25 | Denison Eng Co | Hydraulic motor control apparatus |

| US2606414A (en) * | 1947-08-16 | 1952-08-12 | Int Harvester Co | Stop mechanism for implement adjusting cylinders |

| US2603952A (en) * | 1948-07-03 | 1952-07-22 | Adiel Y Dodge | Wheel cylinder for hydraulic brake mechanism |

| US2646074A (en) * | 1948-07-28 | 1953-07-21 | R S Products Corp | Variable stroke cushioned valve |

| US2761424A (en) * | 1948-07-28 | 1956-09-04 | R S Products Corp | Variable stroke cushioned valves |

| US2678638A (en) * | 1948-11-01 | 1954-05-18 | Cecil W Bopp | Fluid stop for fluid motors |

| US2537680A (en) * | 1949-06-29 | 1951-01-09 | Air Associates Inc | Pressure actuated distributing valve means for motors |

| US2680952A (en) * | 1949-11-21 | 1954-06-15 | Mcdonnell Aircraft Corp | Electrically powered hydraulic linear wingfold actuator |

| US2614537A (en) * | 1950-06-28 | 1952-10-21 | John Deere Van Brunt Co | Means for regulating stroke of fluid-pressure apparatus |

| DE1035513B (en) * | 1952-01-24 | 1958-07-31 | Diskus Werke Frankfurt Main Ag | Hydraulic piston drive for reciprocating parts of machine tools, e.g. B. for grinding slide |

| US2698517A (en) * | 1952-05-21 | 1955-01-04 | Kenneth F Witt | Automatic means to control and reverse fluid-operated cylinder-and-piston units |

| US2689548A (en) * | 1953-05-01 | 1954-09-21 | Smallpeice Ltd | Arrangement of control valves |

| US2688314A (en) * | 1953-05-01 | 1954-09-07 | Smallpeice Ltd | Arrangement of control valves |

| US2976851A (en) * | 1957-02-28 | 1961-03-28 | Werkzeugmaschinenfabrik Veb | Automatic hydraulic positioning device for machine parts |

| US2996045A (en) * | 1959-07-16 | 1961-08-15 | Honeywell Regulator Co | Time modulated hydraulic servo valve |

| US3082749A (en) * | 1960-12-05 | 1963-03-26 | Kobe Inc | Fluid operated pump control system |

| US3046951A (en) * | 1961-03-27 | 1962-07-31 | Honeywell Regulator Co | Hydraulic control valve |

| US3834521A (en) * | 1972-05-15 | 1974-09-10 | Cpe Ind Inc | Air drive for conveyor |

| US3800665A (en) * | 1972-07-27 | 1974-04-02 | Von Ruden Mfg Co | Fluid pressure operated reciprocatory motor |

| US5079988A (en) * | 1989-12-26 | 1992-01-14 | Raymond Robert E | Hydraulic sensor and transducing apparatus |

| US5044254A (en) * | 1991-02-01 | 1991-09-03 | Coltene/Whaldent, Inc. | Reciprocating air motor |

| WO1992014041A1 (en) * | 1991-02-01 | 1992-08-20 | Coltene/Whaledent, Inc. | Reciprocating air motor |

| US20060260465A1 (en) * | 2005-05-17 | 2006-11-23 | Trestain Dennis A | Bi-directional pneumatic motor |

| US7225725B2 (en) * | 2005-05-17 | 2007-06-05 | Trestain Dennis A | Bi-directional pneumatic motor |

| US9803660B1 (en) * | 2014-02-04 | 2017-10-31 | Danfoss Power Solutions Inc. | Low friction compact servo piston assembly |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2223792A (en) | Hydraulic apparatus for operating machine tools and the like | |

| US3488953A (en) | Control apparatus for fluid operated vehicles | |

| US3129645A (en) | Electrically modulated fluid valve | |

| US2804883A (en) | Open-center follow-up control valve | |

| US3269416A (en) | Control valve mechanism with means for reducing hydraulic shock | |

| US3216448A (en) | Spool valve assembly | |

| US3596566A (en) | Hydraulic valve | |

| US2593039A (en) | Valve for sequential operation of hydraulic motors | |

| US2454551A (en) | Servo unit | |

| US2310100A (en) | Power transmission | |

| US2613650A (en) | Hydraulic servomotor | |

| US3722541A (en) | Control valve | |

| US2777426A (en) | Hydraulic speed control valve | |

| US3054384A (en) | Piston velocity governor | |

| GB1527255A (en) | Hydraulic control valves | |

| US2859735A (en) | Shiftable mechanism with momentarily actuated control | |

| US2879745A (en) | Dual throttling motor control circuit | |

| US2958339A (en) | Pilot-type selector valve for hydraulic motors | |

| US3358711A (en) | Valve | |

| US3628557A (en) | Variable preferential flow control valve | |

| US3513877A (en) | Control valve with counter-balancing and direction controlling valve element | |

| US2464626A (en) | Pilot operated servo valve | |

| GB1033109A (en) | Control valves for fluid-pressure-operated mechanisms | |

| US3730219A (en) | Control valve means for fluid motors | |

| US2974642A (en) | Control valve |