US20110030804A1 - Fluid redistribution device for containers having a working fluid - Google Patents

Fluid redistribution device for containers having a working fluid Download PDFInfo

- Publication number

- US20110030804A1 US20110030804A1 US12/852,911 US85291110A US2011030804A1 US 20110030804 A1 US20110030804 A1 US 20110030804A1 US 85291110 A US85291110 A US 85291110A US 2011030804 A1 US2011030804 A1 US 2011030804A1

- Authority

- US

- United States

- Prior art keywords

- rapid prototyping

- fluid

- opening

- liquid

- pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/124—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/0318—Processes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/85978—With pump

- Y10T137/86035—Combined with fluid receiver

Definitions

- the present invention generally relates to devices used in free form fabrication of components, and more particularly, but not exclusively, to devices used to redistribute freeform fabricating fluid.

- Mitigating inhomogeneous areas within a freeform fabricating fluid remains an area of interest.

- Some existing systems have various shortcomings relative to certain applications. Accordingly, there remains a need for further contributions in this area of technology.

- One embodiment of the present invention is a unique redistributing device.

- Other embodiments include apparatuses, systems, devices, hardware, methods, and combinations for redistributing a working fluid. Further embodiments, forms, features, aspects, benefits, and advantages of the present application shall become apparent from the description and figures provided herewith.

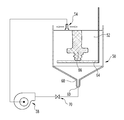

- FIG. 1 depicts one embodiment of the present application.

- FIG. 2 depicts one embodiment of the present application.

- the working fluid 52 includes a mixture of particles suspended in a binder that can be processed into a hardened shape.

- the particles can take the form of ceramic particles, but other types of particles are also contemplated.

- the binder can be a photosensitive substance capable of being hardened upon activation by a device such as, but not limited to, a laser.

- Other types of binders having a variety of compositions and capable of being activated by other devices is also contemplated herein.

- the working fluid 52 can be a non-Newtonian fluid.

- the working fluid 52 can be used to, among other things, build molds for use in investment casting operations. Such operations can be used to build among other things aircraft gas turbine engine components such a blades and vanes.

- aircraft includes, but is not limited to, helicopters, airplanes, unmanned space vehicles, fixed wing vehicles, variable wing vehicles, rotary wing vehicles, unmanned combat aerial vehicles, tailless aircraft, hover crafts, and other airborne and/or extraterrestrial (spacecraft) vehicles.

- the present inventions are contemplated for utilization in other applications that may not be coupled with an aircraft such as, for example, industrial applications, power generation, pumping sets, naval propulsion, weapon systems, security systems, perimeter defense/security systems, and the like known to one of ordinary skill in the art.

- a distributing member 54 and a fluid moving device 58 are in fluid communication with the container 50 .

- the working fluid 52 can pass from one portion of the container 50 to another after passing between the distributing member 54 and the fluid moving device 58 .

- the distributing member 54 includes an orifice 56 and moves relative to a surface of the working fluid 52 .

- the orifice 56 can either withdraw working fluid 52 from the container 50 or it can supply the working fluid 52 to the container, depending on the direction of flow of working fluid 52 .

- the orifice 56 is a scanned intake orifice.

- the distributing member 54 can move along the surface of the working fluid such that the working fluid 52 is withdrawn from the surface or is deposited on the surface, again depending on the direction of flow of the working fluid.

- the orifice 56 can have a front portion at a different height than a back portion. A variety of sizes, shapes, numbers, orientations, and configurations of the orifice 56 are contemplated.

- the fluid moving device 58 can take the form of a pump and can provide for a variety of flow rates of the working fluid 52 .

- the pump can be a continuous flow pump or a discontinuous flow pump and can be capable of providing motive force to the working fluid 52 at a variety of flow rates.

- a speed characteristic of the pump may be matched with the speed of the distributing member 54 .

- the velocity that the working fluid 52 flows into or out of the distributing member 54 is set equal to the speed at which the orifice 56 is travelling which can result in an essentially turbulence free material redistribution when working fluid 52 is moved from the bottom of the container 50 to the top.

- matching a pumping characteristic to a motion of the distributing member 54 can result in more uniform fluid flow at the surface of the working fluid 52 and consequently can be used to reduce mounding over previously exposed areas.

- the container 50 includes an opening 60 through which the working fluid 52 can pass.

- the working fluid enters the container 50 through the opening 60 , while in another the working fluid 52 is withdrawn from the container 50 through the opening 60 .

- the opening 60 can include multiple openings or more than one aperture through which the working fluid 52 passes.

- the opening 60 can be placed at various locations around the container 50 . In just one non-limiting embodiment, the opening 60 is placed at the bottom of the container 50 .

- a shear mixer 62 can be included in the flow circuit between the container 50 , distributing member 54 , and fluid moving device 58 to promote mixing of the working fluid 52 .

- the operation of the distributing member 54 in conjunction with the fluid moving device 58 can be used to redistribute the working fluid.

- the working fluid 52 is prone to some level of separation (e.g. lighter materials migrating toward the surface) then the distributing member 54 can be used to circulate a portion of the working fluid in a top to bottom, bottom to top, or both, fashion.

- the working fluid 52 can be moved between the opening 60 in the container 50 and the distributing member 54 .

- a portion of the working fluid 52 can either be removed and conveyed to the container 50 through the opening 60 , or the portion of working fluid 52 can be conveyed from the container 50 through the opening 60 and distributed to the surface.

- the working fluid redistributing device can be used with a layered build process such as free form fabrication.

- the distributing member 54 can be moved across the surface of the working fluid 52 after each successive layer is built.

- the distributing member 54 can also be used to continuously dispense or receive the working fluid 52 .

- FIG. 2 one embodiment of a working fluid redistributing device is depicted.

- the container 50 is shown having a quantity of working fluid 52 disposed therein.

- a build platform 64 capable of being moved within the container 50 .

- the build platform 64 can be lowered into the container during a build process of a device such as a mold 66 .

- the mold 66 can be produced in layers using free form fabrication techniques, among potential others.

- the distributing member 54 is moved across the surface of the working fluid 52 .

- the orifice 56 of the distributing member 54 is in fluid communication with the working fluid 52 and the fluid moving device 58 .

- the fluid moving device 58 is capable of causing the working fluid 52 to flow through a conduit and to the distributing member 54 where it is added near the surface. In another form of operation the fluid moving device 58 is capable of causing the working fluid 52 to be pulled through the distributing member 54 and be delivered to an area 68 in the container 50 .

- the area 68 is a relatively low point in the container 50 , but in other embodiments the working fluid 52 can be delivered to other areas whether or not at a relatively low point in the container 50 .

- a valve 70 can be incorporated in a fluid passage that conveys the working fluid 52 and used to close off and/or regulate the flow rate of the working fluid 52 .

- the valve 70 is disposed between the fluid moving device 58 and the container 50 , but other embodiments can locate the valve 70 elsewhere.

- a filter can also be used in a passage in which working fluid 52 is flowed.

- a filter could be disposed in the passage leading between the container 50 and the fluid moving device 58 .

- Such a filter can be used to remove and/or prevent objects of a certain size from pass either to or from the fluid moving device 58 .

- the filter could be used to remove a relatively large mass from the working fluid 52 as it moves from the container 50 to the fluid moving device 58 .

- Such a filter, or filters, could be placed elsewhere in the working fluid redistributing device.

- One aspect of the present application provides an apparatus comprising a vat having an upper portion and a lower portion and containing a rapid prototyping liquid that can be operated upon to produce a solid body, a movable device having an opening located near a surface of the rapid prototyping liquid and disposed within the vat through which a portion of the rapid prototyping liquid is conveyed when the movable device is moved, and wherein the rapid prototyping liquid is circulated through the opening between the surface and a location disposed toward the lower portion of the vat.

- the present application further includes pump in fluid communication with the opening and the location toward the lower portion of the vat.

- the present application provides wherein the opening of the moveable device is a scanned opening.

- Still another refinement of the present application provides wherein the speed of the rapid prototyping liquid through the opening is matched with a speed of the opening relative to the surface to mitigate a turbulence behind the moveable device.

- a still further refinement of the present application provides wherein a front and a back of the opening are at different heights relative to the surface.

- a yet still further refinement of the present application provides wherein the rapid prototyping liquid can be conveyed in two directions.

- a further refinement of the present application provides wherein the rapid prototyping liquid can be conveyed toward the surface from the location disposed toward the lower portion of the vat.

- a further still refinement of the present application provides wherein the rapid prototyping liquid can be conveyed away from the surface and toward the location disposed toward the lower portion of the vat.

- a yet another refinement of the present application provides wherein the rapid prototyping liquid can be conveyed toward the surface from the location disposed toward the lower portion of the vat or away from the surface and toward the location disposed toward the lower portion of the vat.

- Another refinement of the present application further includes a fluid shearing device in flow communication with the movable device.

- a refinement of the present application provides wherein the pump conveys the portion from the opening in the vessel to the surface of the rapid prototyping multi-component fluid.

- Another refinement of the present application provides wherein the pump conveys the portion from the surface of the rapid prototyping multi-component fluid to the opening in the vessel.

- Still another refinement of the present application provides wherein the pump is operable to provide work that conveys the rapid prototyping multi-component from a relatively deeper part of the vessel to the surface.

- a yet further refinement of the present application provides wherein the speed between the moveable device relative to the surface and a rate of the rapid prototyping multi-component fluid through the orifice is different

- a still further refinement of the present application provides wherein the rapid prototyping multi-component fluid is a non-Newtonian fluid.

- a yet still further refinement of the present application further includes a fluid shearing device in communication with the pump.

- Still another aspect of the present application provides an apparatus comprising a vat of rapid prototyping fluid, a pump for conveying the rapid prototyping fluid, and means for distributing the rapid prototyping fluid.

- Yet still another aspect of the present application provides a method comprising filling a vessel with a rapid prototyping liquid, scanning an orifice across a surface of the rapid prototyping liquid, and circulating the rapid prototyping fluid between the surface and a relatively deeper part of the vessel.

- a further aspect of the present application provides a method comprising filling a vessel with a rapid prototyping liquid, moving an orifice across a surface of the rapid prototyping liquid, and circulating the rapid prototyping fluid between the surface and a relatively deeper part of the vessel.

- a refinement of the present application further includes powering a pump to drive the circulating.

- Another refinement of the present application further includes mixing a relatively lower density portion of the rapid prototyping liquid with a relatively higher density portion of the rapid prototyping liquid.

- a still another refinement of the present application further includes building a layer of a freeform fabricated object from the rapid prototyping liquid.

- a further refinement of the present application further includes scanning the orifice after the building.

- a still further refinement of the present application further includes shear mixing the rapid prototyping liquid.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Optics & Photonics (AREA)

Abstract

A container having a working fluid that can be used to build freeform fabricated components is disclosed. A distributing member and a fluid moving device are used in conjunction with the container. The fluid moving device can take the form of a pump and the distributing member is moveable across a surface of the working fluid to either deposit working fluid or withdraw working fluid from the surface. The distributing member is in fluid communication with the fluid moving device, which is in fluid communication with an opening in the container.

Description

- The present application claims the benefit of U.S. Provisional Patent Application 61/232,445, filed Aug. 9, 2009, and is incorporated herein by reference.

- The present invention generally relates to devices used in free form fabrication of components, and more particularly, but not exclusively, to devices used to redistribute freeform fabricating fluid.

- Mitigating inhomogeneous areas within a freeform fabricating fluid remains an area of interest. Some existing systems have various shortcomings relative to certain applications. Accordingly, there remains a need for further contributions in this area of technology.

- One embodiment of the present invention is a unique redistributing device. Other embodiments include apparatuses, systems, devices, hardware, methods, and combinations for redistributing a working fluid. Further embodiments, forms, features, aspects, benefits, and advantages of the present application shall become apparent from the description and figures provided herewith.

-

FIG. 1 depicts one embodiment of the present application. -

FIG. 2 depicts one embodiment of the present application. - For the purposes of promoting an understanding of the principles of the invention, reference will now be made to the embodiments illustrated in the drawings and specific language will be used to describe the same. It will nevertheless be understood that no limitation of the scope of the invention is thereby intended. Any alterations and further modifications in the described embodiments, and any further applications of the principles of the invention as described herein are contemplated as would normally occur to one skilled in the art to which the invention relates.

- With reference to

FIG. 1 , acontainer 50 having a quantity of workingfluid 52 useful in building free-form fabricated components is shown. The workingfluid 52 includes a mixture of particles suspended in a binder that can be processed into a hardened shape. The particles can take the form of ceramic particles, but other types of particles are also contemplated. Furthermore, the binder can be a photosensitive substance capable of being hardened upon activation by a device such as, but not limited to, a laser. Other types of binders having a variety of compositions and capable of being activated by other devices is also contemplated herein. In one non-limiting form the workingfluid 52 can be a non-Newtonian fluid. - The working

fluid 52 can be used to, among other things, build molds for use in investment casting operations. Such operations can be used to build among other things aircraft gas turbine engine components such a blades and vanes. As used herein, the term “aircraft” includes, but is not limited to, helicopters, airplanes, unmanned space vehicles, fixed wing vehicles, variable wing vehicles, rotary wing vehicles, unmanned combat aerial vehicles, tailless aircraft, hover crafts, and other airborne and/or extraterrestrial (spacecraft) vehicles. Further, the present inventions are contemplated for utilization in other applications that may not be coupled with an aircraft such as, for example, industrial applications, power generation, pumping sets, naval propulsion, weapon systems, security systems, perimeter defense/security systems, and the like known to one of ordinary skill in the art. - A distributing

member 54 and afluid moving device 58 are in fluid communication with thecontainer 50. During operation the workingfluid 52 can pass from one portion of thecontainer 50 to another after passing between the distributingmember 54 and thefluid moving device 58. The distributingmember 54 includes anorifice 56 and moves relative to a surface of the workingfluid 52. Theorifice 56 can either withdraw workingfluid 52 from thecontainer 50 or it can supply the workingfluid 52 to the container, depending on the direction of flow of workingfluid 52. In one form theorifice 56 is a scanned intake orifice. The distributingmember 54 can move along the surface of the working fluid such that the workingfluid 52 is withdrawn from the surface or is deposited on the surface, again depending on the direction of flow of the working fluid. Theorifice 56 can have a front portion at a different height than a back portion. A variety of sizes, shapes, numbers, orientations, and configurations of theorifice 56 are contemplated. - The

fluid moving device 58 can take the form of a pump and can provide for a variety of flow rates of the workingfluid 52. The pump can be a continuous flow pump or a discontinuous flow pump and can be capable of providing motive force to the workingfluid 52 at a variety of flow rates. In one application a speed characteristic of the pump may be matched with the speed of the distributingmember 54. In one non-limiting example, the velocity that the workingfluid 52 flows into or out of the distributingmember 54 is set equal to the speed at which theorifice 56 is travelling which can result in an essentially turbulence free material redistribution when workingfluid 52 is moved from the bottom of thecontainer 50 to the top. When the workingfluid 52 is moved from the top to the bottom, matching a pumping characteristic to a motion of the distributingmember 54 can result in more uniform fluid flow at the surface of the workingfluid 52 and consequently can be used to reduce mounding over previously exposed areas. - The

container 50 includes an opening 60 through which the workingfluid 52 can pass. In one form of operation the working fluid enters thecontainer 50 through the opening 60, while in another the workingfluid 52 is withdrawn from thecontainer 50 through the opening 60. In some embodiments the opening 60 can include multiple openings or more than one aperture through which the workingfluid 52 passes. Furthermore, the opening 60 can be placed at various locations around thecontainer 50. In just one non-limiting embodiment, the opening 60 is placed at the bottom of thecontainer 50. - A

shear mixer 62 can be included in the flow circuit between thecontainer 50, distributingmember 54, andfluid moving device 58 to promote mixing of the workingfluid 52. - In one form of operation the operation of the distributing

member 54 in conjunction with thefluid moving device 58 can be used to redistribute the working fluid. For example, if the workingfluid 52 is prone to some level of separation (e.g. lighter materials migrating toward the surface) then the distributingmember 54 can be used to circulate a portion of the working fluid in a top to bottom, bottom to top, or both, fashion. The workingfluid 52 can be moved between the opening 60 in thecontainer 50 and the distributingmember 54. As the distributingmember 54 moves along the surface, a portion of the workingfluid 52 can either be removed and conveyed to thecontainer 50 through theopening 60, or the portion of workingfluid 52 can be conveyed from thecontainer 50 through theopening 60 and distributed to the surface. - In one form of operation the working fluid redistributing device can be used with a layered build process such as free form fabrication. The distributing

member 54 can be moved across the surface of the workingfluid 52 after each successive layer is built. The distributingmember 54 can also be used to continuously dispense or receive the workingfluid 52. - Turning now to

FIG. 2 , one embodiment of a working fluid redistributing device is depicted. Thecontainer 50 is shown having a quantity of workingfluid 52 disposed therein. Also disposed in thecontainer 50 is abuild platform 64 capable of being moved within thecontainer 50. In one non-limiting form thebuild platform 64 can be lowered into the container during a build process of a device such as amold 66. Themold 66 can be produced in layers using free form fabrication techniques, among potential others. In the illustrative embodiment the distributingmember 54 is moved across the surface of the workingfluid 52. Theorifice 56 of the distributingmember 54 is in fluid communication with the workingfluid 52 and thefluid moving device 58. In one form of operation thefluid moving device 58 is capable of causing the workingfluid 52 to flow through a conduit and to the distributingmember 54 where it is added near the surface. In another form of operation thefluid moving device 58 is capable of causing the workingfluid 52 to be pulled through the distributingmember 54 and be delivered to anarea 68 in thecontainer 50. In the illustrative embodiment thearea 68 is a relatively low point in thecontainer 50, but in other embodiments the workingfluid 52 can be delivered to other areas whether or not at a relatively low point in thecontainer 50. - Other devices can also be used with the embodiment of the working fluid redistributing device depicted in

FIG. 2 . Avalve 70 can be incorporated in a fluid passage that conveys the workingfluid 52 and used to close off and/or regulate the flow rate of the workingfluid 52. In the illustrative embodiment thevalve 70 is disposed between the fluid movingdevice 58 and thecontainer 50, but other embodiments can locate thevalve 70 elsewhere. In some applications a filter can also be used in a passage in which workingfluid 52 is flowed. For example, in the illustrative embodiment a filter could be disposed in the passage leading between thecontainer 50 and the fluid movingdevice 58. Such a filter can be used to remove and/or prevent objects of a certain size from pass either to or from the fluid movingdevice 58. In one non-limiting example the filter could be used to remove a relatively large mass from the workingfluid 52 as it moves from thecontainer 50 to the fluid movingdevice 58. Such a filter, or filters, could be placed elsewhere in the working fluid redistributing device. - One aspect of the present application provides an apparatus comprising a vat having an upper portion and a lower portion and containing a rapid prototyping liquid that can be operated upon to produce a solid body, a movable device having an opening located near a surface of the rapid prototyping liquid and disposed within the vat through which a portion of the rapid prototyping liquid is conveyed when the movable device is moved, and wherein the rapid prototyping liquid is circulated through the opening between the surface and a location disposed toward the lower portion of the vat.

- In one refinement the present application further includes pump in fluid communication with the opening and the location toward the lower portion of the vat.

- In another refinement the present application provides wherein the opening of the moveable device is a scanned opening.

- Still another refinement of the present application provides wherein the speed of the rapid prototyping liquid through the opening is matched with a speed of the opening relative to the surface to mitigate a turbulence behind the moveable device.

- Yet still refinement of the present application provides wherein a speed characteristic of the pump is matched with the speed of the opening relative to the surface.

- A still further refinement of the present application provides wherein a front and a back of the opening are at different heights relative to the surface.

- A yet still further refinement of the present application provides wherein the rapid prototyping liquid can be conveyed in two directions.

- A further refinement of the present application provides wherein the rapid prototyping liquid can be conveyed toward the surface from the location disposed toward the lower portion of the vat.

- A further still refinement of the present application provides wherein the rapid prototyping liquid can be conveyed away from the surface and toward the location disposed toward the lower portion of the vat.

- A yet another refinement of the present application provides wherein the rapid prototyping liquid can be conveyed toward the surface from the location disposed toward the lower portion of the vat or away from the surface and toward the location disposed toward the lower portion of the vat.

- Another refinement of the present application further includes a fluid shearing device in flow communication with the movable device.

- Another aspect of the present application provides an apparatus comprising a vessel having a rapid prototyping multi-component fluid that can be formed into a solid object, the vessel having an opening located beneath a surface of the rapid prototyping multi-component fluid, a pump for conveying the rapid prototyping multi-component, the pump in fluid communication with the opening in the vessel, and a moving orifice having an orifice opening located near the surface of the rapid prototyping multi-component fluid and operable to pass a portion of the rapid prototyping multi-component fluid, the pump operable to provide work to convey the portion between the surface and the opening of the vessel.

- A refinement of the present application provides wherein the pump conveys the portion from the opening in the vessel to the surface of the rapid prototyping multi-component fluid.

- Another refinement of the present application provides wherein the pump conveys the portion from the surface of the rapid prototyping multi-component fluid to the opening in the vessel.

- Still another refinement of the present application provides wherein the pump is operable to provide work that conveys the rapid prototyping multi-component from a relatively deeper part of the vessel to the surface.

- A yet further refinement of the present application provides wherein the speed between the moveable device relative to the surface and a rate of the rapid prototyping multi-component fluid through the orifice is different

- A still further refinement of the present application provides wherein the rapid prototyping multi-component fluid is a non-Newtonian fluid.

- A yet still further refinement of the present application further includes a fluid shearing device in communication with the pump.

- Still another aspect of the present application provides an apparatus comprising a vat of rapid prototyping fluid, a pump for conveying the rapid prototyping fluid, and means for distributing the rapid prototyping fluid.

- Yet still another aspect of the present application provides a method comprising filling a vessel with a rapid prototyping liquid, scanning an orifice across a surface of the rapid prototyping liquid, and circulating the rapid prototyping fluid between the surface and a relatively deeper part of the vessel.

- A further aspect of the present application provides a method comprising filling a vessel with a rapid prototyping liquid, moving an orifice across a surface of the rapid prototyping liquid, and circulating the rapid prototyping fluid between the surface and a relatively deeper part of the vessel.

- A refinement of the present application further includes powering a pump to drive the circulating.

- Another refinement of the present application further includes mixing a relatively lower density portion of the rapid prototyping liquid with a relatively higher density portion of the rapid prototyping liquid.

- A still another refinement of the present application further includes building a layer of a freeform fabricated object from the rapid prototyping liquid.

- A further refinement of the present application further includes scanning the orifice after the building.

- A still further refinement of the present application further includes shear mixing the rapid prototyping liquid.

- While the invention has been illustrated and described in detail in the drawings and foregoing description, the same is to be considered as illustrative and not restrictive in character, it being understood that only the preferred embodiments have been shown and described and that all changes and modifications that come within the spirit of the inventions are desired to be protected. It should be understood that while the use of words such as preferable, preferably, preferred or more preferred utilized in the description above indicate that the feature so described may be more desirable, it nonetheless may not be necessary and embodiments lacking the same may be contemplated as within the scope of the invention, the scope being defined by the claims that follow. In reading the claims, it is intended that when words such as “a,” “an,” “at least one,” or “at least one portion” are used there is no intention to limit the claim to only one item unless specifically stated to the contrary in the claim. When the language “at least a portion” and/or “a portion” is used the item can include a portion and/or the entire item unless specifically stated to the contrary.

Claims (20)

1. An apparatus comprising:

a vat having an upper portion and a lower portion and containing a rapid prototyping liquid that can be operated upon to produce a solid body;

a movable device having an opening located near a surface of the rapid prototyping liquid and disposed within the vat through which a portion of the rapid prototyping liquid is conveyed when the movable device is moved; and

wherein the rapid prototyping liquid is circulated through the opening between the surface and a location disposed toward the lower portion of the vat.

2. The apparatus of claim 1 , which further includes pump in fluid communication with the opening and the location toward the lower portion of the vat.

3. The apparatus of claim 1 , wherein the opening of the moveable device is a scanned opening.

4. The apparatus of claim 2 , wherein the speed of the rapid prototyping liquid through the opening is matched with a speed of the opening relative to the surface to mitigate a turbulence behind the moveable device.

5. The apparatus of claim 1 , wherein a front and a back of the opening are at different heights relative to the surface.

6. The apparatus of claim 1 , wherein the rapid prototyping liquid can be conveyed toward the surface from the location disposed toward the lower portion of the vat or away from the surface and toward the location disposed toward the lower portion of the vat.

7. The apparatus of claim 7 , which further includes a fluid shearing device in flow communication with the movable device.

8. An apparatus comprising:

a vessel having a rapid prototyping multi-component fluid that can be formed into a solid object, the vessel having an opening located beneath a surface of the rapid prototyping multi-component fluid;

a pump for conveying the rapid prototyping multi-component, the pump in fluid communication with the opening in the vessel; and

a moving orifice having an orifice opening located near the surface of the rapid prototyping multi-component fluid and operable to pass a portion of the rapid prototyping multi-component fluid, the pump operable to provide work to convey the portion between the surface and the opening of the vessel.

9. The apparatus of claim 8 , wherein the pump conveys the portion from the opening in the vessel to the surface of the rapid prototyping multi-component fluid.

10. The apparatus of claim 8 , wherein the pump conveys the portion from the surface of the rapid prototyping multi-component fluid to the opening in the vessel.

11. The apparatus of claim 8 , wherein the speed between the moveable device relative to the surface and a rate of the rapid prototyping multi-component fluid through the orifice is different

12. The apparatus of claim 8 , wherein the rapid prototyping multi-component fluid is a non-newtonian fluid.

13. The apparatus of claim 8 , which further includes a fluid shearing device in communication with the pump.

14. An apparatus comprising:

a vat of rapid prototyping fluid;

a pump for conveying the rapid prototyping fluid; and

means for distributing the rapid prototyping fluid.

15. A method comprising:

filling a vessel with a rapid prototyping liquid;

moving an orifice across a surface of the rapid prototyping liquid; and

circulating the rapid prototyping fluid between the surface and a relatively deeper part of the vessel.

16. The method of claim 15 , which further includes powering a pump to drive the circulating.

17. The method of claim 19 , which further includes mixing a relatively lower density portion of the rapid prototyping liquid with a relatively higher density portion of the rapid prototyping liquid.

18. The method of claim 15 , which further includes building a layer of a freeform fabricated object from the rapid prototyping liquid.

19. The method of claim 18 , which further includes scanning the orifice after the building.

20. The method of claim 15 , which further includes shear mixing the rapid prototyping liquid.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/852,911 US20110030804A1 (en) | 2009-08-09 | 2010-08-09 | Fluid redistribution device for containers having a working fluid |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US23244509P | 2009-08-09 | 2009-08-09 | |

| US12/852,911 US20110030804A1 (en) | 2009-08-09 | 2010-08-09 | Fluid redistribution device for containers having a working fluid |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20110030804A1 true US20110030804A1 (en) | 2011-02-10 |

Family

ID=43533881

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US12/852,911 Abandoned US20110030804A1 (en) | 2009-08-09 | 2010-08-09 | Fluid redistribution device for containers having a working fluid |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US20110030804A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL2015169B1 (en) * | 2015-07-15 | 2017-02-01 | Admatec Europe B V | Additive manufacturing device for manufacturing a three dimensional object. |

| US11141909B2 (en) | 2015-07-15 | 2021-10-12 | Admatec Europe B.V. | Additive manufacturing device for manufacturing a three dimensional object |

Citations (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5071337A (en) * | 1990-02-15 | 1991-12-10 | Quadrax Corporation | Apparatus for forming a solid three-dimensional article from a liquid medium |

| US5171490A (en) * | 1988-11-29 | 1992-12-15 | Fudim Efrem V | Method and apparatus for production of three-dimensional objects by irradiation of photopolymers |

| US5236812A (en) * | 1989-12-29 | 1993-08-17 | E. I. Du Pont De Nemours And Company | Solid imaging method and apparatus |

| US5248249A (en) * | 1990-07-27 | 1993-09-28 | Sony Corporation | Three-dimensional structure forming apparatus provided with a liquid-level control system for a main resin tank |

| US5358673A (en) * | 1990-02-15 | 1994-10-25 | 3D Systems, Inc. | Applicator device and method for dispensing a liquid medium in a laser modeling machine |

| US5512162A (en) * | 1992-08-13 | 1996-04-30 | Massachusetts Institute Of Technology | Method for photo-forming small shaped metal containing articles from porous precursors |

| US5525051A (en) * | 1993-03-22 | 1996-06-11 | Sony Corporation | Optical molding apparatus |

| US5573721A (en) * | 1995-02-16 | 1996-11-12 | Hercules Incorporated | Use of a support liquid to manufacture three-dimensional objects |

| US5902537A (en) * | 1995-02-01 | 1999-05-11 | 3D Systems, Inc. | Rapid recoating of three-dimensional objects formed on a cross-sectional basis |

| US5922364A (en) * | 1997-03-03 | 1999-07-13 | Young, Jr.; Albert C. | Stereolithography layering control system |

| US5976448A (en) * | 1996-05-29 | 1999-11-02 | Dsm N.V. | Optical forming apparatus for forming three-dimensional objects |

| US6391245B1 (en) * | 1999-04-13 | 2002-05-21 | Eom Technologies, L.L.C. | Method for creating three-dimensional objects by cross-sectional lithography |

| US6438998B1 (en) * | 1999-08-31 | 2002-08-27 | Samsung Electronics, Co., Ltd. | Ultrasonic dispersion apparatus for silica sol |

| US6519500B1 (en) * | 1999-09-16 | 2003-02-11 | Solidica, Inc. | Ultrasonic object consolidation |

| US20040012112A1 (en) * | 1996-12-20 | 2004-01-22 | Z Corporation | Three-dimensional printer |

| US20040084814A1 (en) * | 2002-10-31 | 2004-05-06 | Boyd Melissa D. | Powder removal system for three-dimensional object fabricator |

| US20040159967A1 (en) * | 2002-11-11 | 2004-08-19 | Farnworth Warren M. | Bubble elimination system for use with stereolithography apparatus and bubble elimination methods |

| US6837856B2 (en) * | 2001-09-19 | 2005-01-04 | Matsushita Electric Industrial Co., Ltd. | Ultrasonic search unit and method for producing the same |

| US6881607B2 (en) * | 2000-08-08 | 2005-04-19 | Micron Technology, Inc. | Underfill and encapsulation of carrier substrate-mounted flip-chip components using stereolithography |

| US6902246B2 (en) * | 2001-10-03 | 2005-06-07 | 3D Systems, Inc. | Quantized feed system for solid freeform fabrication |

| US6955783B2 (en) * | 2000-08-29 | 2005-10-18 | Micron Technology, Inc. | Layer thickness control for stereolithography utilizing variable liquid elevation and laser focal length |

| US20060022379A1 (en) * | 2004-07-30 | 2006-02-02 | Board Of Regents, The University Of Texas System | Multi-material stereolithography |

| US20060192312A1 (en) * | 2005-02-28 | 2006-08-31 | 3D Systems, Inc. | Multiple vat leveling system |

| US20070075461A1 (en) * | 2005-09-30 | 2007-04-05 | 3D Systems, Inc. | Rapid prototyping and manufacturing system and method |

| US7329379B2 (en) * | 2003-11-04 | 2008-02-12 | Hewlett-Packard Development Company, Lp. | Method for solid freeform fabrication of a three-dimensional object |

| US7790074B2 (en) * | 2003-07-30 | 2010-09-07 | Houston-Packard Development Company, L.P. | Stereolithographic method for forming three-dimensional structure |

-

2010

- 2010-08-09 US US12/852,911 patent/US20110030804A1/en not_active Abandoned

Patent Citations (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5171490A (en) * | 1988-11-29 | 1992-12-15 | Fudim Efrem V | Method and apparatus for production of three-dimensional objects by irradiation of photopolymers |

| US5236812A (en) * | 1989-12-29 | 1993-08-17 | E. I. Du Pont De Nemours And Company | Solid imaging method and apparatus |

| US5071337A (en) * | 1990-02-15 | 1991-12-10 | Quadrax Corporation | Apparatus for forming a solid three-dimensional article from a liquid medium |

| US5358673A (en) * | 1990-02-15 | 1994-10-25 | 3D Systems, Inc. | Applicator device and method for dispensing a liquid medium in a laser modeling machine |

| US5248249A (en) * | 1990-07-27 | 1993-09-28 | Sony Corporation | Three-dimensional structure forming apparatus provided with a liquid-level control system for a main resin tank |

| US5512162A (en) * | 1992-08-13 | 1996-04-30 | Massachusetts Institute Of Technology | Method for photo-forming small shaped metal containing articles from porous precursors |

| US5525051A (en) * | 1993-03-22 | 1996-06-11 | Sony Corporation | Optical molding apparatus |

| US5609814A (en) * | 1993-03-22 | 1997-03-11 | Sony Corporation | Optical molding process |

| US5902537A (en) * | 1995-02-01 | 1999-05-11 | 3D Systems, Inc. | Rapid recoating of three-dimensional objects formed on a cross-sectional basis |

| US5573721A (en) * | 1995-02-16 | 1996-11-12 | Hercules Incorporated | Use of a support liquid to manufacture three-dimensional objects |

| US5976448A (en) * | 1996-05-29 | 1999-11-02 | Dsm N.V. | Optical forming apparatus for forming three-dimensional objects |

| US20040012112A1 (en) * | 1996-12-20 | 2004-01-22 | Z Corporation | Three-dimensional printer |

| US5922364A (en) * | 1997-03-03 | 1999-07-13 | Young, Jr.; Albert C. | Stereolithography layering control system |

| US6391245B1 (en) * | 1999-04-13 | 2002-05-21 | Eom Technologies, L.L.C. | Method for creating three-dimensional objects by cross-sectional lithography |

| US6438998B1 (en) * | 1999-08-31 | 2002-08-27 | Samsung Electronics, Co., Ltd. | Ultrasonic dispersion apparatus for silica sol |

| US6519500B1 (en) * | 1999-09-16 | 2003-02-11 | Solidica, Inc. | Ultrasonic object consolidation |

| US6881607B2 (en) * | 2000-08-08 | 2005-04-19 | Micron Technology, Inc. | Underfill and encapsulation of carrier substrate-mounted flip-chip components using stereolithography |

| US6955783B2 (en) * | 2000-08-29 | 2005-10-18 | Micron Technology, Inc. | Layer thickness control for stereolithography utilizing variable liquid elevation and laser focal length |

| US6837856B2 (en) * | 2001-09-19 | 2005-01-04 | Matsushita Electric Industrial Co., Ltd. | Ultrasonic search unit and method for producing the same |

| US6902246B2 (en) * | 2001-10-03 | 2005-06-07 | 3D Systems, Inc. | Quantized feed system for solid freeform fabrication |

| US20040084814A1 (en) * | 2002-10-31 | 2004-05-06 | Boyd Melissa D. | Powder removal system for three-dimensional object fabricator |

| US20040164461A1 (en) * | 2002-11-11 | 2004-08-26 | Ahmad Syed Sajid | Programmed material consolidation systems including multiple fabrication sites and associated methods |

| US20040159967A1 (en) * | 2002-11-11 | 2004-08-19 | Farnworth Warren M. | Bubble elimination system for use with stereolithography apparatus and bubble elimination methods |

| US7790074B2 (en) * | 2003-07-30 | 2010-09-07 | Houston-Packard Development Company, L.P. | Stereolithographic method for forming three-dimensional structure |

| US7329379B2 (en) * | 2003-11-04 | 2008-02-12 | Hewlett-Packard Development Company, Lp. | Method for solid freeform fabrication of a three-dimensional object |

| US20060022379A1 (en) * | 2004-07-30 | 2006-02-02 | Board Of Regents, The University Of Texas System | Multi-material stereolithography |

| US20090179355A1 (en) * | 2004-07-30 | 2009-07-16 | Ryan Wicker | Methods for multi-material stereolithography |

| US20060192312A1 (en) * | 2005-02-28 | 2006-08-31 | 3D Systems, Inc. | Multiple vat leveling system |

| US20070075461A1 (en) * | 2005-09-30 | 2007-04-05 | 3D Systems, Inc. | Rapid prototyping and manufacturing system and method |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL2015169B1 (en) * | 2015-07-15 | 2017-02-01 | Admatec Europe B V | Additive manufacturing device for manufacturing a three dimensional object. |

| US11141909B2 (en) | 2015-07-15 | 2021-10-12 | Admatec Europe B.V. | Additive manufacturing device for manufacturing a three dimensional object |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12005643B2 (en) | Device for the generative manufacturing of three-dimensional components | |

| US20190224670A1 (en) | Microfluidic chip and control method thereof, droplet generation device, and microsphere preparation device | |

| KR101731778B1 (en) | Method for stabilizing a powder bed by means of vacuum for additive manufacturing | |

| US11980943B2 (en) | Device and a method for fabricating a three-dimensional part by selectively melting a powder bed | |

| US11192277B2 (en) | 3D ceramic printer and a method using the same | |

| JP6930743B2 (en) | Ejector and airfoil shape | |

| US11565314B2 (en) | Three-dimensional shaped article production method | |

| EP3094411B1 (en) | Particle separator for an additive manufacturing system and method of operation | |

| EP3086921B1 (en) | Methods and systems for three-dimensional printing utilizing a jetted-particle binder fluid | |

| CN107418872A (en) | Prepare the device of microballoon and prepare the method for microballoon | |

| US20150042018A1 (en) | Method and device for producing three-dimensional models | |

| AU2016371246A1 (en) | Apparatus and method for fabricating an object | |

| CA3010954A1 (en) | Method and apparatus for fluid cavitation abrasive surface finishing | |

| CN101561674A (en) | Molding method of components of heterogeneous materials | |

| CN106827527A (en) | The manufacture method of three-D moulding object | |

| US11759859B2 (en) | Techniques for depowdering additively fabricated parts through fluid immersion and related systems and methods | |

| US10259158B2 (en) | Method and apparatus for fabricating ceramic and metal components via additive manufacturing with uniform layered radiation drying | |

| US20110030804A1 (en) | Fluid redistribution device for containers having a working fluid | |

| WO2021108304A1 (en) | Abrasive suspension jet cutting system having reduced system wear and process materials reclamation | |

| EP3180171B1 (en) | Deposition of clay structures | |

| CN113442258A (en) | 3D printer and method for digitally manufacturing composite ceramic functional gradient material | |

| CN103350498B (en) | Method and equipment for manufacturing heterogeneous solid model | |

| CN111086210A (en) | 3D printing-based equipment and method for processing net-shaped multilayer structure composite material | |

| US11117295B2 (en) | Systems for manufacturing a particulate-binder composite article | |

| EP3463810B1 (en) | Additive manufacturing system fluid ejector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: ROLLS-ROYCE CORPORATION, INDIANA Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:SCHLIENGER, MAX ERIC;REEL/FRAME:025043/0368 Effective date: 20100825 |

|

| STCB | Information on status: application discontinuation |

Free format text: ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |