US20090249743A1 - Stud with lengthwise indented grooves, and with intervening planar surfaces, and method - Google Patents

Stud with lengthwise indented grooves, and with intervening planar surfaces, and method Download PDFInfo

- Publication number

- US20090249743A1 US20090249743A1 US12/457,339 US45733909A US2009249743A1 US 20090249743 A1 US20090249743 A1 US 20090249743A1 US 45733909 A US45733909 A US 45733909A US 2009249743 A1 US2009249743 A1 US 2009249743A1

- Authority

- US

- United States

- Prior art keywords

- web

- indented

- sheet metal

- grooves

- flanges

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C3/08—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal with apertured web, e.g. with a web consisting of bar-like components; Honeycomb girders

- E04C3/09—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal with apertured web, e.g. with a web consisting of bar-like components; Honeycomb girders at least partly of bent or otherwise deformed strip- or sheet-like material

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C2003/0404—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects

- E04C2003/0443—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by substantial shape of the cross-section

- E04C2003/0473—U- or C-shaped

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49616—Structural member making

- Y10T29/49623—Static structure, e.g., a building component

- Y10T29/49631—Columnar member

Definitions

- the invention relates to steel studs or structural members formed with edge formations, with planar edge flanges and indents located between planar portions of the edge flanges.

- the stud indents may be grooves or dimpled surfaces.

- the studs are formed with web main openings and edge formations along at least one side of the openings formed with at least two indented parallel spaced apart grooves in each said edge flange.

- Such studs usually were formed as a C-section, i.e. there was a central web, and the opposite side edges of the web were formed into edge flanges. Several such bends were sometime incorporated in an effort to get greater strength, while using thinner gauge metal. However this did not overcome the heat transfer problem. Accordingly metal studs have been proposed with reduced heat transfer properties. These studs were formed with generally triangular or trapezoidal openings, in the web, while the two edges were bent over as flanges or legs at 90 degrees, as before. Heat losses were thus reduced since there was less metal through which the heat could pass.

- Rounded openings in the studs avoid the problems caused by the corners of the triangular or trapezoidal openings and splitting of metal, and greatly facilitate high speed manufacture of such studs because there is less stud length lost in the cut to length process.

- Corrugations do not provide a surface suitable for attachment of structure such as wall panels. There are no “flats” between the folds. If a panel is set against such folds the panel will make point contact with the peak of every alternate fold. If screws are secured through the panel into the metal the screws may penetrate the metal in a random fashion, and cause unequal pressure points in the panel, and may damage the panel.

- a more serious problem with corrugations in a stud is that the manufacturing process by which corrugations are folded into the sheet metal, causes the metal to be drawn from the edges in towards the centre of the strip. Essentially the strip “shrinks” across its width.

- the load bearing capacity of a given stud of a given gauge can be increased substantially, by forming indented grooves, which are formed from the outside surface in to the inside surface, of the eventual stud.

- the process of indenting the grooves is carried out while at the same time clamping the metal strip along its edges, so as to prevent any reduction in the width of the metal strip.

- the indenting of the grooves causes a slight stretching of the medial portion of the strip, between the grooves, where the strip is not subject to any clamping action. Between the grooves the strip remains flat and planar. This facilitates the attachment of material such as dry wall.

- the actual stretching action is scarcely noticeable, in the overall width of the stud, but it is significant in that it holds the width of the finished stud stable, and maintains specifications for the product.

- the invention comprises a steel member for use in supporting structures and having a web defining edges and an axis, and the web defining an inner planar surface on one side, and an outer planar surface on the other side an edge flange formed on at least one web edge, the flange and the web defining inside surfaces and outside surfaces, and being characterized by indented grooves formed along said at least one flange, parallel to said web axis, the indentations being formed. from said mounting surfaces into said inside surfaces, and leaving planar surfaces along the flange on either side of each said groove.

- the stud may also have longitudinal indented grooves formed along its web.

- the invention further seeks to provide a steel member as described including openings formed in said web at spaced intervals, and flanges formed around said openings, being indented from said outside to said inside surfaces.

- the invention further provides a steel member as described, which is particularly suited for embedment in concrete, and has a further edge flange which is formed as embedment edge.

- the invention further seeks to provide a steel member as described, which is particularly suited for use in the supporting of dry wall partitions, and may incorporate a cross brace with a snap-in engagement.

- This type of stud does not have the problem of heat transfer since the partition walls are usually erected inside the building, dividing up the space into separate rooms. They will not necessarily use the complex web openings and ribs of the other embodiments.

- Such studs may be made of ultra light weight, thin gauge steel. For this purpouse the studs have flanges which are formed with numerous point-like depressions or dimple-like indentations. These add stiffness and also provide pints for easy secure insertion of screw fastenings.

- the invention further provides a steel member for use in supporting structures and having reduced heat transfer characteristics as compared with solid web studs, and having a web defining side edges and an axis, a flange on at least one side edge, openings through said web at spaced intervals therealong, of predetermined size and profile, at least a side portion of said web displaced from said opening from said outside to said inside surfaces and remaining attached integrally to said web, a first bend formed in said side portion, a second bend formed in said side portion spaced from said first bend, said first and second bends being formed along axes parallel to said web axis, and thus defining three-sided channel shaped reinforcements.

- the invention further seeks to provide a steel member as described with diagonal ribs between the web openings, and with depressions formed in the web at each end of each rib, indented from said outside to said inside surfaces and, rib openings formed in the depressions to reduce heat transfer.

- the invention further seeks to provide a steel member as described wherein said openings are shaped with opposed linear side edges, side portions of said web integral with said linear side edges being formed into said channel shapes along said inside surfaces.

- the invention further seeks to provide a steel member as described wherein a further flange is formed on a second edge of said web, said further flange being angled at an angle to said web and an embedment lip formed along said further flange for embedment in a concrete panel.

- the invention also provides a method of making a steel member having a web and side edges, and an edge flange along at least one said side edge, and longitudinal indented grooves in said web and said edge flange, being characterized by the steps of, clamping the strip along both side edges of the strip, and forming a strip of sheet metal with longitudinal indented grooves in a web portion and in at least one edge flange portion, and by bending the edge flange portion relative to said web portion, so as to form inside and outside surfaces, and bending a lip on said edge flange portion.

- the forming of the grooves causes a small degree of stretching of the strip.

- the actual amount of stretching is small, and is spread over almost the entire width of the strip, and therefor has little or no effect on the end product.

- FIG. 1 is a perspective illustration of a stud illustrating one embodiment of the invention, with narrow longitudinal indented grooves;

- FIG. 2 is a side elevation of the stud of FIG. 1 ;

- FIG. 3 is a section along line 3 - 3 of FIG. 2 ;

- FIG. 4 is a perspective of a further embodiment of stud illustrating another embodiment of the invention for embedment in concrete in which are numerous, narrow, longitudinal indented grooves; and an embedment edge for embedment in concrete;

- FIG. 5 is a side elevation of the stud of FIG. 4 ;

- FIG. 6 is a section along line 6 - 6 of FIG. 5 ;

- FIG. 7 is a perspective of a further embodiment of stud for use in reinforcing concrete panels

- FIG. 8 is a side elevation of the stud of FIG. 7 ;

- FIG. 9 is a section along 9 - 9 of FIG. 8 ;

- FIG. 10 is a section of a modification similar to FIG. 1 ;

- FIG. 11 is a perspective of a further embodiment, and incorporating x-shaped transverse indented grooves, as well as longitudinal indented grooves;

- FIG. 12 is a side elevation of FIG. 11 ;

- FIG. 13 is a section along the line 13 - 13 of FIG. 12 ;

- FIG. 14 is a section of a modification similar to FIG. 3 ;

- FIG. 15 is a perspective of a further embodiment of a stud particularly suitable for the erection of dry wall partitions

- FIG. 16 is an enlarged perspective of portion of FIG. 15 ;

- FIG. 17 is a perspective illustration illustrating a cross bracing member adapted to extend transversely between two studs

- FIG. 18 is a perspective illustration of a further embodiment of a dry wall stud

- FIG. 19 is a illustration of a further embodiment of a dry wall stud

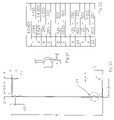

- FIG. 20 is a schematic section illustrating the ranges of dimensions of the various indented grooves and flanges and webs of the studs;

- FIG. 21 is an enlarged detail of the detail 21 of FIG. 20 ;

- FIG. 22 is a table of the ranges of dimensions, which may be used for various modified forms of studs

- FIG. 23 is an illustration of an indenting roll forming tool, suitable for indenting grooves according to the invention into the metal webs used manufacture of these studs;

- FIG. 24 is a schematic section of a roll forming line showing the forming of the grooves by indenting parallel grooves from one side only of the web;

- FIG. 25 is a schematic section of a roll forming line showing the forming of grooves by indenting parallel grooves from one side only of the web, while clamping the side edges of the strip to resist shrinking across its width;

- FIG. 26 is schematic section corresponding to FIG. 25 showing further grooves being indented, and the edge flanges bent inwards;

- FIG. 27 is a perspective of a further embodiment of stud showing grooves spaced lengthwise at intervals.

- FIG. 28 is a top plan of the stud of FIG. 27 .

- the invention provides sheet metal structural members referred to herein generically as studs, suitable for use in erecting various structures, walls, floors, roofs, and the like and also internal partition walls.

- the invention also provides sheet metal studs suitable for use in reinforcement of thin-shell concrete panels which are widely used in completing walls, in particular.

- Such thin-shell structures can also form floors, roofs and the like, and can also serve as shuttering or form work for pouring concrete, such as columns and beams, and even flooring and concrete partitions.

- Such thin-shell panels, when used as shuttering may be left in place, thus avoiding the need for removing and repositioning shuttering or form work, many times over.

- the invention also provides a method of making such studs.

- the invention is there illustrated in the form of a stud ( 10 ), formed of sheet metal, in this case steel.

- the stud ( 10 ) has a web ( 12 ) which is essentially planar, and edge flanges, or “legs”, ( 14 ) and ( 16 ) along each side edge of the web ( 12 ).

- Each of the flanges ( 14 ) ( 16 ) is formed by bending side edges of the web ( 12 ) at right angles. Lips ( 18 ) are formed on each edge flange ( 14 - 16 ) again at right angles.

- the flanges, and the web define a generally C-shape in section, having “inside” surfaces, around the inside of the C-shape, and outer “mounting” surfaces, around the outside of the C-shape, to which other structure can be attached.

- These outer surfaces are planar surfaces, such that for example, dry wall panels or the like can be placed against them and secured in position.

- Longitudinal indented flange grooves ( 20 ) are formed by indenting two spaced apart grooves along each edge flange ( 14 - 16 ) for greater load bearing capacity. Between grooves ( 20 ) there are planar flange portions ( 21 ), ( FIG. 3 ), for supporting other structure such as wall panels or the like. Longitudinal indented web grooves ( 22 ) are also formed by indenting grooves inwardly along web ( 12 ). Alongside each of the web grooves ( 22 ) there are further planar surfaces ( 23 ). The longitudinal indented flange grooves ( 20 ), and web grooves ( 22 ) are indented from the outward surfaces inwardly into the inside surfaces. In this way the outward mounting surfaces ( 21 ) and ( 23 ) are left clear for the attachment of other structure, which may be any form of wall material, such as outer sheathing, or for example, drywall panels, not shown.

- the grooves are formed during the roll forming of the stud, in a manner to be described below.

- This stud may be intended for external or internal use, typically in the erecting of walls or partitions between spaces in a commercial or office building, for example. Studs of larger dimensions can be used for floor, ceilings, roofs and any structure requiring greater load capacity.

- This stud may also be made for embedment in a thin-shell concrete panel, and would then have an embedment flange ( 16 A) ( FIG. 4 ) in place of flange ( 16 ).

- embedment flange ( 16 A) FIG. 4

- These two features of longitudinal flange grooves ( 20 ) (and in larger studs web grooves ( 22 )) enable the studs to be made of a reduced thickness or gauge of sheet metal, without sacrificing anything in the load bearing capacity of rigidity or firmness.

- Web openings ( 24 ) are formed through the web at regular spaced intervals. Between the web openings ( 24 ), portions of the web define transverse struts ( 26 ). This form of construction substantially reduces the heat transfer from one side edge of the web to the other.

- transverse grooves ( 32 ) formed across the web at each end of the member.

- These transverse grooves ( 32 ) may simply be straight grooves running at right angles to the web axis. Diagonal grooves can also be provided, as described below.

- the spacing between, and alongside, the grooves ( 20 ), defines the planar surfaces ( 21 ) and enables the secure attachment of structure, by for example screws (S) FIG. 23 , secured in grooves ( 20 ).

- screws (S) FIG. 23 When tightened down the screws will pull a structure such as a panel firmly up against the planar surfaces ( 21 ), without distorting the flanges or studs, and without damaging the panel itself.

- a further form of stud is shown in FIGS. 4 , 5 and 6 . In these Figures, similar components as in FIGS. 1 , 2 & 3 have the same numbers.

- the web openings ( 24 ) are trapezoidal, defining opposite linear sides, parallel to the longitudinal axis of the stud.

- the struts ( 26 ) are diagonal.

- Reinforcing side portions ( 25 ) integral with the web ( 12 ), are bent over at right angles and thus form three sided channel-shaped reinforcements on opposite linear sides of the web openings. Depressions ( 28 ) have circular holes in place of slots.

- the flange ( 16 ) of the FIG. 1 embodiment is replaced by the flange ( 16 A).

- the flange ( 16 A) is formed with an embedment edge ( 34 ), and a locking strip ( 36 ).

- the embedment edge ( 34 ) will be formed with a series of through openings punched out.

- the purpose of the embedment edge and the locking strip is that they can be embedded in poured concrete, when forming a composite concrete wall panel, so as to provide a secure anchoring of the concrete to the frame work of studs, all of which is known in the art.

- This stud may also have the flange ( 16 ) of FIG. 1 where the embedment edge is not required.

- FIGS. 7 , 8 and 9 illustrate a stud similar to the FIG. 4 embodiment, that is to say, this particular stud is designed for concrete embedment and reinforcement, in the same way as at the FIG. 4 embodiment.

- FIG. 1 It has essentially the same features as the FIG. 1 and the FIG. 4 embodiments, and has the same modified flange ( 16 A) with embedment edge ( 34 ) and locking strip ( 36 ) in the same way as the FIG. 4 embodiment. In this case, however, additional longitudinal indented web grooves ( 22 ) are shown, extending along the web longitudinally. These web grooves add significantly to the load bearing capacity of the stud.

- the web openings ( 24 ) are of somewhat different shape than the web openings ( 24 ) in the FIGS. 1 and 4 embodiments, and by virtue of their different shape, the transverse struts ( 26 ) between the openings are somewhat wider and are arranged in alternating diagonal fashion.

- the other modification in this embodiment is that the end transverse grooves ( 38 ) are somewhat diagonal, rather than being simply transverse to the axis of the stud, at right angles.

- FIG. 10 illustrates the stud of FIGS. 7 , 8 and 9 , with the right angle edge flange ( 16 ) in place of the embedment flange ( 16 A).

- FIGS. 11 , 12 , 13 and 14 is a further modification of the FIG. 7 embodiment, of still greater load bearing capacity.

- the stud has all of the same essential features as shown in FIGS. 1 , 4 and 7 .

- the transverse grooves ( 42 ) are now arranged the form a letter X. Grooves ( 42 ) are placed in pairs along the ribs between each web opening ( 24 ).

- Depressions ( 28 ) are formed with holes ( 44 ) rather than the slots ( 30 ) of the FIGS. 1 though 7 embodiments.

- the embodiment also uses the feature of the internal reinforcement channel ( 46 ) (also shown in FIG. 4 ). These are formed by turning a portion of the web ( 12 ), which has been struck out from the web openings ( 24 ), inwardly around two right angle bends ( FIG. 13 ) so as to form three sided reinforcement channels along opposite linear sides of the web openings ( 24 ).

- FIG. 14 shows a modification of this embodiment of FIG. 11 , having an embedment flange ( 16 A), with an embedment edge ( 34 ) and a locking strip ( 36 ) in the same manner as the embodiment of FIG. 7 .

- FIG. 15 is a front perspectives of a dry wall stud indicated generally as ( 50 ).

- This dry wall stud is usually formed of thinner gauge material than the heavier duty studs of FIGS. 1 through 14 .

- the stud ( 50 ) has a web ( 52 ), and flanges ( 54 ) ( 56 ) with lips ( 58 ).

- this embodiment has numerous separate point depressions ( 60 ) indented into the outer surfaces of flanges ( 54 - 56 )

- Similar separate point shaped depressions ( 62 ) are indented in the web ( 52 ). Openings ( 64 ) are formed through the web, and are preferably surrounded by depressions ( 66 ).

- L-shaped corner grooves ( 68 ) extend transversely of the web and the flanges ( 54 ) and ( 56 ) respectively. These are indented at spaced intervals along the stud so as to add further rigidity to the flanges ( 54 ) and ( 56 ). This will materially assist in the insertion of dry wall screws when dry wall panels are secured.

- FIG. 16 shows the surface of part of one flange ( 54 ), and part of the web, greatly enlarged. It will be seen that the depressions ( 60 ), and formed in an essentially four-sided pyramid shape, indented down from the outer surface into the interior surface of the stud. Between each depression ( 60 ) there are lengthwise and transverses ridges ( 61 ).

- the ridges ( 61 ) define what is the planar outside surface of the stud. Thus the ridges ( 61 ) will provide contact and support for any other structure such as dry wall, which may be secured to the stud.

- the depressions ( 60 ) give the stud significantly greater strength and rigidity. This greatly assists in the attachment of material such as dry wall, using self tapping screws.

- the tip or drill point of a screw will seat down in one of the depressions ( 60 ). When the installer applies pressure to the screw, to make it bite into the strip material, the strip will not deflect as readily. In addition the screw will penetrate more surely into the metal.

- each depression ( 60 ) already has side surfaces which converge downwardly below the planar outer surface of the metal.

- the metal will extrude along the length of the screw and the threads will form along the length of the screw threads and form or extrude a tube of sheet metal around the screw. This will ensure that the screw holds securely, when tightened down, and does not gradually becomes loose.

- transverse bracing When erecting dry wall framing in particular, it is desirable to incorporate some form of transverse cross braces between adjacent upright studs.

- a transverse bracing is illustrated in FIG. 17 .

- the stud of FIG. 15 is shown, connected with a transverse bracing member ( 70 ).

- This bracing member is a simple right-angular L shaped section, formed with a series of generally L shaped slots ( 72 ).

- the L shaped slots ( 72 ) define flexible tongues ( 74 ), which are deflected slightly out of the plane of the material.

- the bracing members ( 70 ) can simply be flexed slightly, and inserted through the openings ( 64 ) in the stud ( 50 ).

- the tongues ( 74 ) will flex slightly and allow the bracing members to spring outwardly into the original position.

- the slots ( 72 ) and tongues ( 74 ) will lock and capture the edges of the web ( 52 ) around the opening ( 64 ), in the manner shown in FIG. 17 .

- FIGS. 18 and 19 illustrate further minor modifications for a dry wall stud.

- the dry wall stud is indicated as ( 80 ) having a web ( 82 ) and flanges ( 84 ) and ( 86 ).

- Multiple separate indents or dimples ( 88 ) similar to FIG. 16 are formed in the flanges.

- Web grooves ( 90 ) arranged in a generally diagonal fashion extending across the web ( 82 ).

- the web grooves may simply either be alternating diagonal defining V shapes, or may define Y shapes.

- corner bracing grooves ( 92 ) are formed to assist in bracing the flanges against flexing, during insertion of the dry wall screws.

- FIG. 20 illustrates a schematic section of a typical stud with indented grooves such as the stud of FIG. 7 or FIG. 11 , for example.

- the dimensions of the studs may vary in terms of web width illustrated as A and in terms of flange width illustrated as B, and in terms of lip height illustrated as C.

- the groove width is shown as D ( FIG. 21 ).

- the groove spacing in the flanges is shown as X-X, between which is the planar section of the flange. These variations may be within the range of the variations indicated in the table of FIG. 22 .

- the dimensions will assist materially in the erection of dry wall.

- the thickness or gauge of the sheet material may vary according to the table of FIG. 22 .

- the depth and width of the longitudinal indented grooves is indicated as D and E in FIG. 21 and their variations are illustrated in Table of FIG. 22 .

- the spacing between the longitudinal indented grooves in the flanges and when used, in the web, may vary within the range indicated in FIG. 22 , by the letters X, XX, Y, Z and ZZ.

- FIG. 20 illustrates a schematic section of a typical stud with indented grooves such as the stud of FIG. 7 or FIG. 11 , for example.

- the dimensions of the studs may vary in terms of web width illustrated as A and in terms of flange width illustrated as B, and in terms of lip height illustrated as C.

- the groove width is shown as D ( FIG. 21 ).

- the groove spacing in the flanges is shown as X-X, between which is the planar section of the flange. These variations may be within the range of the variations indicated in the table of FIG. 22 .

- the dimensions will assist materially in the erection of dry wall.

- the thickness or gauge of the sheet material may vary according to the table of FIG. 22 .

- the depth and width of the longitudinal indented grooves is indicated as D and E in FIG. 21 and their variations are illustrated in Table of FIG. 22 .

- the spacing between the longitudinal indented grooves in the flanges and when used, in the web, may vary within the range indicated in FIG. 22 , by the letters X, XX, Y, Z and ZZ.

- the grooves may be indented into the material by using pairs of rolls indicated schematically in FIG. 23 , and in more detail in FIGS. 24 , 25 , and 26 .

- an upper clamp roll ( 100 ) and lower clamp roll ( 104 ) holds the sheet metal.

- sheet metal material of a wide variety of thicknesses or gauge may be advantageously formed with indented grooves, the effect of the rolls varying somewhat depending on the thickness of the gauge of the material.

- These studs enable the use of a reduction in thickness or gauge of sheet metal. It is anticipated that a reduction of at least one gauge and probably two gauges can be achieved while still providing adequate support to a wall or a concrete panel. This will reduce the cost of the walls or panels. It will also reduce the heat transfer through the panel and stud, since the reduction in gauge reduces the actual mass of metal available to provide a heat transfer path.

- the erecting of interior partitions is commonly completed by erecting a frame work of metal studs. Studs are erected usually on 16 inch centres. Top and bottom channels provide a means of anchoring the tops and bottoms of the vertical studs. In order to reduce the metal required in such studs, the thickness or gauge of the steel is reduced to a minimum, compatible with providing a reasonably firm wall or partition. Reduction of metal also reduces the weight loading per floor on a building, which can also result in substantial saving in the construction of the building fabric. Such walls usually involve the completion of each side of the wall by panels of gypsum wall board, so-called dry wall.

- these panels are secured to the studs by screws having chisel points, which will drill through the metal of the stud and are self-tapping. It is well known, however, that the insertion of such screws can be hindered, if the metal forming the stud is made too thin. In this case, the stud flanges will simply bend when the pressure of the screw point is applied to it, and the screw will slip off.

- the present invention utilizes narrow longitudinal indented grooves in the edge flanges of the stud and also in the web of larger studs. These narrow longitudinal indented grooves substantially increase the rigidity of the edge flanges which facilitate the insertion of self-tapping screws.

- the longitudinal indented grooves provide narrow grooves for anchoring the tip of the screw so that it will not slip when pressure is applied to it to provide the drilling and self-tapping action.

- the use of the multiple separate indented dimples ( 60 ) also has the same result, locating and holding the screw point while it bites into the sheet metal.

- Manufacture of the studs of the invention would typically proceed by passing a continuous strip of flat sheet metal through a series of narrowly spaced apart web clamping roller dies ( 100 - 104 ).

- the studs may be the FIGS. 1 and 7 embodiments, in which case they will have been formed with web openings and channels, prior to the forming of the indentations.

- the grooves are formed by recess dies ( 106 ) and male indenting dies ( 108 ). These dies are mounted on a series of separate shafts spaced apart along the roll forming production line, as shown in more detail in FIGS. 24 , 25 , and 26 .

- FIGS. 24 , 25 , and 26 the indenting dies are shown in pairs, so that they indent two spaced apart grooves ( 102 ) simultaneously.

- FIG. 24 shows the indenting of two grooves ( 102 a - 102 b ), side by side.

- FIG. 25 show the next stage in which a further groove ( 102 c ) is indented.

- a bend ( 110 ) is being formed between groove ( 102 a ) and groove ( 102 b ) to form the lip on the edge flange.

- FIG. 26 shows the indenting of two further grooves ( 102 d - 102 e ), in the actual web portion of the stud.

- a bend ( 112 ) is being formed between groove ( 102 c ) and groove ( 102 d ), which will thus form the edge flange of the stud.

- the clamping dies ( 100 - 104 ) function to grip the sheet metal on either side.

- the indenting dies ( 106 - 108 ) form the grooves in the sheet metal.

- the clamping dies hold the sheet metal on either side of the indenting dies so as to prevent the sheet metal from being drawn inwardly from either edge.

- the studs so formed will maintain their uniform preset width, which is required for the job for which they are intended.

- the effect of passing the flat strip through these groove roller dies will be to form narrow longitudinal indented grooves, in the portions of the strip which will eventually form the edge flanges and the lips of the stud, and in some cases, will form the web as well.

- the studs will, of course, be cut to suitable length in a mechanism of which several types are well known in the art.

- the multiple separate indents or dimples ( 60 ) of FIG. 16 may be formed by using toothed indent rolls (not shown) similar to indent rolls ( 108 ), but having a plurality of separate point shaped tooth formations (similar to gear teeth for example). As the metal passes between such rolls the teeth will form separate individual indents, as shown in FIG. 16 , in the sheet metal.

- Cutting to length will normally be performed upstream of the roller dies, where the strip sheet is still flat and unformed. In this way each piece of sheet metal passing through the various punching and forming and roll forming sequences is already precut to the exact length required for the finished stud.

- Suitable controls which form no part of the invention are incorporated in the rotary press so that the rotary press is timed to operate exactly where required on each stud. Where openings are not required, at each end of each stud, the controls disable the rotary press so that leading and trailing ends of the sheet metal pass through unpunched and unformed.

- indented as used herein is intended to define the effect of forming the lengthwise grooves, or multiple indented dimples.

- the grooves or dimples are deflected inwardly towards the space enclosed with the shape of the C section of the stud. This leaves the exterior surface of the two edge flanges planar (flat) and thus available to receive wall finishing panels such as dry wall or similar panels.

- FIGS. 27 and 28 A further embodiment of stud ( 120 ) is shown in FIGS. 27 and 28 .

- edge flanges ( 122 ) are formed with a series of separate indented grooves ( 124 ), which are spaced apart lengthwise along the edge flanges. Two rows of such grooves ( 124 ) are shown, with the grooves in one row being offset with relation to the grooves in the other row. The ends of grooves in one row overlap the ends of grooves in the other, adjacent row thus providing for continuity of reinforcement along the stud.

- depressions ( 126 ) of irregular triangle shape are formed in the web at each end of each diagonal rib, and openings ( 128 ) are formed in the depressions.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Load-Bearing And Curtain Walls (AREA)

Abstract

A steel stud member for use in supporting structures and having reduced thickness as compared with conventional studs, and having a web having side edges, flanges on the side edges, formed at angles to the web, the web and the flanges enclosing inside surfaces, and having outside surfaces for mounting structure, and plurality of narrow indented longitudinal grooves formed in the flanges, and in the web, indented inwardly from the outside to the inside of the flanges, providing greater load bearing capacity for a given gauge of steel. Also disclosed is a method of making such a steel member.

In another embodiment the flanges are indented with a plurality of separate dimples

Description

- This application is a Continuation in Part of application Ser. No. 11/652,073 filed, Jan. 11 2007, Title, STUD WITH LENGTHWISE INDENTED RIBS AND METHOD, Inventor Ernest R Bodnar, which turn claimed priority of U.S. Provisional Application Ser. No. 60/759,068 Filed Jan. 11 2006 Title STUD WITH LENGTHWISE INDENTED RIBS AND METHOD, inventor Ernest R Bodnar.

- The invention relates to steel studs or structural members formed with edge formations, with planar edge flanges and indents located between planar portions of the edge flanges. The stud indents may be grooves or dimpled surfaces. In a particular preferred form the studs are formed with web main openings and edge formations along at least one side of the openings formed with at least two indented parallel spaced apart grooves in each said edge flange.

- Steel studs of a wide variety have been proposed for erecting structures. Usually such studs are used to replace wooden studs. Wood is a relatively poor heat transfer medium. Heat loss through wooden studs has not been a significant problem in the past. Metal studs having solid webs however, do create a heat loss transfer path through the exterior wall or other structure. This results in cold patches along the lines of the studs. Condensation, known as “ghosting” appears along these lines.

- Such studs usually were formed as a C-section, i.e. there was a central web, and the opposite side edges of the web were formed into edge flanges. Several such bends were sometime incorporated in an effort to get greater strength, while using thinner gauge metal. However this did not overcome the heat transfer problem. Accordingly metal studs have been proposed with reduced heat transfer properties. These studs were formed with generally triangular or trapezoidal openings, in the web, while the two edges were bent over as flanges or legs at 90 degrees, as before. Heat losses were thus reduced since there was less metal through which the heat could pass.

- The shape of these openings tended to restrict the size of the conduits which could be passed through the studs.

- Rounded openings in the studs avoid the problems caused by the corners of the triangular or trapezoidal openings and splitting of metal, and greatly facilitate high speed manufacture of such studs because there is less stud length lost in the cut to length process.

- Proposals have been suggested to form studs with corrugations in the flanges or even in the webs themselves. Corrugations involve essentially folding the sheet metal first in one direction and then in the other. The end result looks, in section, like a kind of sine wave shape. The folds are continuous, ie they fold back and forth without any spacing between them. An example is shown in U.S. Pat. No. 6,092,349 Trenerry, issued Jul. 25, 2000. The folds are similar to what is known as “corrugated iron”, which has been used for simple roofing purpouses form very many years.

- This proposal has many disadvantages. Corrugations do not provide a surface suitable for attachment of structure such as wall panels. There are no “flats” between the folds. If a panel is set against such folds the panel will make point contact with the peak of every alternate fold. If screws are secured through the panel into the metal the screws may penetrate the metal in a random fashion, and cause unequal pressure points in the panel, and may damage the panel. A more serious problem with corrugations in a stud, is that the manufacturing process by which corrugations are folded into the sheet metal, causes the metal to be drawn from the edges in towards the centre of the strip. Essentially the strip “shrinks” across its width.

- This means that it is difficult to produce a stud as an end product, which has a definite preset width. Also the stud so produced will use a greater quantity of steel, making it more costly.

- It is now found that the load bearing capacity of a given stud of a given gauge can be increased substantially, by forming indented grooves, which are formed from the outside surface in to the inside surface, of the eventual stud. The process of indenting the grooves is carried out while at the same time clamping the metal strip along its edges, so as to prevent any reduction in the width of the metal strip. In effect the indenting of the grooves causes a slight stretching of the medial portion of the strip, between the grooves, where the strip is not subject to any clamping action. Between the grooves the strip remains flat and planar. This facilitates the attachment of material such as dry wall.

- This can be achieved by forming the stud with planar surfaces, in the edge flanges along each edge of the web, and forming narrow, longitudinal indented grooves, spaced apart by planar surfaces formed in the edge flanges, and also by forming narrow longitudinal indented grooves spaced apart by planar surfaces in the web, while holding the two edges of the strip clamped so that the edges cannot be drawn inwardly.

- The actual stretching action is scarcely noticeable, in the overall width of the stud, but it is significant in that it holds the width of the finished stud stable, and maintains specifications for the product.

- Another use of such studs is in concrete panels. Concrete panels of reduced thickness are now reinforced by a framework of metal studs partially embedded in the concrete. The studs provide great strength to the panels, and also facilitate erection and attachment of the panels to the structure.

- These novel studs with longitudinal indented grooves can be made with edge formations for embedment in concrete.

- With a view to achieving the foregoing and other objectives the invention comprises a steel member for use in supporting structures and having a web defining edges and an axis, and the web defining an inner planar surface on one side, and an outer planar surface on the other side an edge flange formed on at least one web edge, the flange and the web defining inside surfaces and outside surfaces, and being characterized by indented grooves formed along said at least one flange, parallel to said web axis, the indentations being formed. from said mounting surfaces into said inside surfaces, and leaving planar surfaces along the flange on either side of each said groove.

- The stud may also have longitudinal indented grooves formed along its web. The invention further seeks to provide a steel member as described including openings formed in said web at spaced intervals, and flanges formed around said openings, being indented from said outside to said inside surfaces.

- The invention further provides a steel member as described, which is particularly suited for embedment in concrete, and has a further edge flange which is formed as embedment edge.

- The invention further seeks to provide a steel member as described, which is particularly suited for use in the supporting of dry wall partitions, and may incorporate a cross brace with a snap-in engagement. This type of stud does not have the problem of heat transfer since the partition walls are usually erected inside the building, dividing up the space into separate rooms. They will not necessarily use the complex web openings and ribs of the other embodiments. Such studs may be made of ultra light weight, thin gauge steel. For this purpouse the studs have flanges which are formed with numerous point-like depressions or dimple-like indentations. These add stiffness and also provide pints for easy secure insertion of screw fastenings.

- The invention further provides a steel member for use in supporting structures and having reduced heat transfer characteristics as compared with solid web studs, and having a web defining side edges and an axis, a flange on at least one side edge, openings through said web at spaced intervals therealong, of predetermined size and profile, at least a side portion of said web displaced from said opening from said outside to said inside surfaces and remaining attached integrally to said web, a first bend formed in said side portion, a second bend formed in said side portion spaced from said first bend, said first and second bends being formed along axes parallel to said web axis, and thus defining three-sided channel shaped reinforcements.

- The invention further seeks to provide a steel member as described with diagonal ribs between the web openings, and with depressions formed in the web at each end of each rib, indented from said outside to said inside surfaces and, rib openings formed in the depressions to reduce heat transfer.

- The invention further seeks to provide a steel member as described wherein said openings are shaped with opposed linear side edges, side portions of said web integral with said linear side edges being formed into said channel shapes along said inside surfaces.

- The invention further seeks to provide a steel member as described wherein a further flange is formed on a second edge of said web, said further flange being angled at an angle to said web and an embedment lip formed along said further flange for embedment in a concrete panel.

- The invention also provides a method of making a steel member having a web and side edges, and an edge flange along at least one said side edge, and longitudinal indented grooves in said web and said edge flange, being characterized by the steps of, clamping the strip along both side edges of the strip, and forming a strip of sheet metal with longitudinal indented grooves in a web portion and in at least one edge flange portion, and by bending the edge flange portion relative to said web portion, so as to form inside and outside surfaces, and bending a lip on said edge flange portion.

- Since the foregoing steps are carried out while continuing the clamping of the strip along both side edges, to maintain a predetermined width, the forming of the grooves causes a small degree of stretching of the strip. The actual amount of stretching is small, and is spread over almost the entire width of the strip, and therefor has little or no effect on the end product.

- The various features of novelty which characterize the invention are pointed out with more particularity in the claims annexed to and forming a part of this disclosure. For a better understanding of the invention, its operating advantages and specific objects attained by its use, reference should be made to the accompanying drawings and descriptive matter in which there are illustrated and described preferred embodiments of the invention.

-

FIG. 1 is a perspective illustration of a stud illustrating one embodiment of the invention, with narrow longitudinal indented grooves; -

FIG. 2 is a side elevation of the stud ofFIG. 1 ; -

FIG. 3 is a section along line 3-3 ofFIG. 2 ; -

FIG. 4 is a perspective of a further embodiment of stud illustrating another embodiment of the invention for embedment in concrete in which are numerous, narrow, longitudinal indented grooves; and an embedment edge for embedment in concrete; -

FIG. 5 is a side elevation of the stud ofFIG. 4 ; -

FIG. 6 is a section along line 6-6 ofFIG. 5 ; -

FIG. 7 is a perspective of a further embodiment of stud for use in reinforcing concrete panels; -

FIG. 8 is a side elevation of the stud ofFIG. 7 ; -

FIG. 9 is a section along 9-9 ofFIG. 8 ; -

FIG. 10 is a section of a modification similar toFIG. 1 ; -

FIG. 11 is a perspective of a further embodiment, and incorporating x-shaped transverse indented grooves, as well as longitudinal indented grooves; -

FIG. 12 is a side elevation ofFIG. 11 ; -

FIG. 13 is a section along the line 13-13 ofFIG. 12 ; -

FIG. 14 is a section of a modification similar toFIG. 3 ; -

FIG. 15 is a perspective of a further embodiment of a stud particularly suitable for the erection of dry wall partitions; -

FIG. 16 is an enlarged perspective of portion ofFIG. 15 ; -

FIG. 17 is a perspective illustration illustrating a cross bracing member adapted to extend transversely between two studs; -

FIG. 18 is a perspective illustration of a further embodiment of a dry wall stud; -

FIG. 19 is a illustration of a further embodiment of a dry wall stud; -

FIG. 20 is a schematic section illustrating the ranges of dimensions of the various indented grooves and flanges and webs of the studs; -

FIG. 21 is an enlarged detail of thedetail 21 ofFIG. 20 ; -

FIG. 22 is a table of the ranges of dimensions, which may be used for various modified forms of studs; -

FIG. 23 is an illustration of an indenting roll forming tool, suitable for indenting grooves according to the invention into the metal webs used manufacture of these studs; -

FIG. 24 is a schematic section of a roll forming line showing the forming of the grooves by indenting parallel grooves from one side only of the web; -

FIG. 25 is a schematic section of a roll forming line showing the forming of grooves by indenting parallel grooves from one side only of the web, while clamping the side edges of the strip to resist shrinking across its width; -

FIG. 26 is schematic section corresponding toFIG. 25 showing further grooves being indented, and the edge flanges bent inwards; -

FIG. 27 is a perspective of a further embodiment of stud showing grooves spaced lengthwise at intervals; and, -

FIG. 28 is a top plan of the stud ofFIG. 27 . - As already described the invention provides sheet metal structural members referred to herein generically as studs, suitable for use in erecting various structures, walls, floors, roofs, and the like and also internal partition walls. The invention also provides sheet metal studs suitable for use in reinforcement of thin-shell concrete panels which are widely used in completing walls, in particular. Such thin-shell structures can also form floors, roofs and the like, and can also serve as shuttering or form work for pouring concrete, such as columns and beams, and even flooring and concrete partitions. Such thin-shell panels, when used as shuttering, may be left in place, thus avoiding the need for removing and repositioning shuttering or form work, many times over. The invention also provides a method of making such studs.

- Referring to

FIG. 1 it will be seen that the invention is there illustrated in the form of a stud (10), formed of sheet metal, in this case steel. The stud (10) has a web (12) which is essentially planar, and edge flanges, or “legs”, (14) and (16) along each side edge of the web (12). Each of the flanges (14) (16) is formed by bending side edges of the web (12) at right angles. Lips (18) are formed on each edge flange (14-16) again at right angles. - The flanges, and the web define a generally C-shape in section, having “inside” surfaces, around the inside of the C-shape, and outer “mounting” surfaces, around the outside of the C-shape, to which other structure can be attached. These outer surfaces are planar surfaces, such that for example, dry wall panels or the like can be placed against them and secured in position.

- Longitudinal indented flange grooves (20) are formed by indenting two spaced apart grooves along each edge flange (14-16) for greater load bearing capacity. Between grooves (20) there are planar flange portions (21), (

FIG. 3 ), for supporting other structure such as wall panels or the like. Longitudinal indented web grooves (22) are also formed by indenting grooves inwardly along web (12). Alongside each of the web grooves (22) there are further planar surfaces (23). The longitudinal indented flange grooves (20), and web grooves (22) are indented from the outward surfaces inwardly into the inside surfaces. In this way the outward mounting surfaces (21) and (23) are left clear for the attachment of other structure, which may be any form of wall material, such as outer sheathing, or for example, drywall panels, not shown. - It also assists in the insertion of fastenings for such structure, as will be explained below.

- The grooves are formed during the roll forming of the stud, in a manner to be described below.

- This stud may be intended for external or internal use, typically in the erecting of walls or partitions between spaces in a commercial or office building, for example. Studs of larger dimensions can be used for floor, ceilings, roofs and any structure requiring greater load capacity.

- This stud may also be made for embedment in a thin-shell concrete panel, and would then have an embedment flange (16A) (

FIG. 4 ) in place of flange (16). These two features of longitudinal flange grooves (20) (and in larger studs web grooves (22)) enable the studs to be made of a reduced thickness or gauge of sheet metal, without sacrificing anything in the load bearing capacity of rigidity or firmness. - Web openings (24) are formed through the web at regular spaced intervals. Between the web openings (24), portions of the web define transverse struts (26). This form of construction substantially reduces the heat transfer from one side edge of the web to the other.

- Depressions (28), which in this case are generally circular, are formed at each end of struts (26), and strut openings, such as slots (30) are formed in depressions (28). This further restricts heat transfer across the stud.

- The rigidity of such studs can be further increased by transverse grooves (32) formed across the web at each end of the member. These transverse grooves (32) may simply be straight grooves running at right angles to the web axis. Diagonal grooves can also be provided, as described below.

- The spacing between, and alongside, the grooves (20), defines the planar surfaces (21) and enables the secure attachment of structure, by for example screws (S)

FIG. 23 , secured in grooves (20). When tightened down the screws will pull a structure such as a panel firmly up against the planar surfaces (21), without distorting the flanges or studs, and without damaging the panel itself. A further form of stud is shown inFIGS. 4 , 5 and 6. In these Figures, similar components as inFIGS. 1 , 2 & 3 have the same numbers. The web openings (24) are trapezoidal, defining opposite linear sides, parallel to the longitudinal axis of the stud. The struts (26) are diagonal. Reinforcing side portions (25) integral with the web (12), are bent over at right angles and thus form three sided channel-shaped reinforcements on opposite linear sides of the web openings. Depressions (28) have circular holes in place of slots. However, the flange (16) of theFIG. 1 embodiment is replaced by the flange (16A). The flange (16A) is formed with an embedment edge (34), and a locking strip (36). Typically, the embedment edge (34) will be formed with a series of through openings punched out. The purpose of the embedment edge and the locking strip is that they can be embedded in poured concrete, when forming a composite concrete wall panel, so as to provide a secure anchoring of the concrete to the frame work of studs, all of which is known in the art. This stud may also have the flange (16) ofFIG. 1 where the embedment edge is not required. -

FIGS. 7 , 8 and 9 illustrate a stud similar to theFIG. 4 embodiment, that is to say, this particular stud is designed for concrete embedment and reinforcement, in the same way as at theFIG. 4 embodiment. - It has essentially the same features as the

FIG. 1 and theFIG. 4 embodiments, and has the same modified flange (16A) with embedment edge (34) and locking strip (36) in the same way as theFIG. 4 embodiment. In this case, however, additional longitudinal indented web grooves (22) are shown, extending along the web longitudinally. These web grooves add significantly to the load bearing capacity of the stud. - In this embodiment, the web openings (24) are of somewhat different shape than the web openings (24) in the

FIGS. 1 and 4 embodiments, and by virtue of their different shape, the transverse struts (26) between the openings are somewhat wider and are arranged in alternating diagonal fashion. - The other modification in this embodiment is that the end transverse grooves (38) are somewhat diagonal, rather than being simply transverse to the axis of the stud, at right angles.

-

FIG. 10 illustrates the stud ofFIGS. 7 , 8 and 9, with the right angle edge flange (16) in place of the embedment flange (16A). - The embodiment of

FIGS. 11 , 12, 13 and 14 is a further modification of theFIG. 7 embodiment, of still greater load bearing capacity. In this case, the stud has all of the same essential features as shown inFIGS. 1 , 4 and 7. However, in this case, there are lip grooves (40) indented in the lips (18). In addition, the transverse grooves (42) are now arranged the form a letter X. Grooves (42) are placed in pairs along the ribs between each web opening (24). - Depressions (28) are formed with holes (44) rather than the slots (30) of the

FIGS. 1 though 7 embodiments. - The embodiment also uses the feature of the internal reinforcement channel (46) (also shown in

FIG. 4 ). These are formed by turning a portion of the web (12), which has been struck out from the web openings (24), inwardly around two right angle bends (FIG. 13 ) so as to form three sided reinforcement channels along opposite linear sides of the web openings (24). -

FIG. 14 shows a modification of this embodiment ofFIG. 11 , having an embedment flange (16A), with an embedment edge (34) and a locking strip (36) in the same manner as the embodiment ofFIG. 7 . -

FIG. 15 is a front perspectives of a dry wall stud indicated generally as (50). This dry wall stud is usually formed of thinner gauge material than the heavier duty studs ofFIGS. 1 through 14 . In this case, the stud (50) has a web (52), and flanges (54) (56) with lips (58). In place of the flange grooves ofFIGS. 1 to 14 , this embodiment has numerous separate point depressions (60) indented into the outer surfaces of flanges (54-56) - Similar separate point shaped depressions (62) are indented in the web (52). Openings (64) are formed through the web, and are preferably surrounded by depressions (66).

- L-shaped corner grooves (68) extend transversely of the web and the flanges (54) and (56) respectively. These are indented at spaced intervals along the stud so as to add further rigidity to the flanges (54) and (56). This will materially assist in the insertion of dry wall screws when dry wall panels are secured.

-

FIG. 16 shows the surface of part of one flange (54), and part of the web, greatly enlarged. It will be seen that the depressions (60), and formed in an essentially four-sided pyramid shape, indented down from the outer surface into the interior surface of the stud. Between each depression (60) there are lengthwise and transverses ridges (61). - The ridges (61) define what is the planar outside surface of the stud. Thus the ridges (61) will provide contact and support for any other structure such as dry wall, which may be secured to the stud.

- The depressions (60) give the stud significantly greater strength and rigidity. This greatly assists in the attachment of material such as dry wall, using self tapping screws. The tip or drill point of a screw will seat down in one of the depressions (60). When the installer applies pressure to the screw, to make it bite into the strip material, the strip will not deflect as readily. In addition the screw will penetrate more surely into the metal.

- Also it is significant that each depression (60) already has side surfaces which converge downwardly below the planar outer surface of the metal. When the screw does penetrate and create screw threads, the metal will extrude along the length of the screw and the threads will form along the length of the screw threads and form or extrude a tube of sheet metal around the screw. This will ensure that the screw holds securely, when tightened down, and does not gradually becomes loose.

- When erecting dry wall framing in particular, it is desirable to incorporate some form of transverse cross braces between adjacent upright studs. Such a transverse bracing is illustrated in

FIG. 17 . In this case, the stud ofFIG. 15 is shown, connected with a transverse bracing member (70). This bracing member is a simple right-angular L shaped section, formed with a series of generally L shaped slots (72). The L shaped slots (72) define flexible tongues (74), which are deflected slightly out of the plane of the material. - The bracing members (70) can simply be flexed slightly, and inserted through the openings (64) in the stud (50). The tongues (74) will flex slightly and allow the bracing members to spring outwardly into the original position. The slots (72) and tongues (74) will lock and capture the edges of the web (52) around the opening (64), in the manner shown in

FIG. 17 . -

FIGS. 18 and 19 illustrate further minor modifications for a dry wall stud. In this case, the dry wall stud is indicated as (80) having a web (82) and flanges (84) and (86). Multiple separate indents or dimples (88) similar toFIG. 16 , are formed in the flanges. Web grooves (90) arranged in a generally diagonal fashion extending across the web (82). The web grooves may simply either be alternating diagonal defining V shapes, or may define Y shapes. Preferably, corner bracing grooves (92) are formed to assist in bracing the flanges against flexing, during insertion of the dry wall screws. -

FIG. 20 illustrates a schematic section of a typical stud with indented grooves such as the stud ofFIG. 7 orFIG. 11 , for example. The dimensions of the studs may vary in terms of web width illustrated as A and in terms of flange width illustrated as B, and in terms of lip height illustrated as C. The groove width is shown as D (FIG. 21 ). The groove spacing in the flanges is shown as X-X, between which is the planar section of the flange. These variations may be within the range of the variations indicated in the table ofFIG. 22 . The dimensions will assist materially in the erection of dry wall. By locating the two flange grooves spaced apart, with a planar section between them, it is possible for dry wall panels to be installed, with the edges of two dry wall panels (not shown) abutting each other and overlying the one stud. The installer will then insert screws along each panel edge, and the screws will seat into their respective grooves, which are in the correct locations to receive them. - The thickness or gauge of the sheet material, shown as T, may vary according to the table of

FIG. 22 . - The depth and width of the longitudinal indented grooves is indicated as D and E in

FIG. 21 and their variations are illustrated in Table ofFIG. 22 . - The spacing between the longitudinal indented grooves in the flanges and when used, in the web, may vary within the range indicated in

FIG. 22 , by the letters X, XX, Y, Z and ZZ. - Within these ranges it is found that the longitudinal indented grooves provide significant increases in load bearing capacity.

-

FIG. 20 illustrates a schematic section of a typical stud with indented grooves such as the stud ofFIG. 7 orFIG. 11 , for example. The dimensions of the studs may vary in terms of web width illustrated as A and in terms of flange width illustrated as B, and in terms of lip height illustrated as C. The groove width is shown as D (FIG. 21 ). The groove spacing in the flanges is shown as X-X, between which is the planar section of the flange. These variations may be within the range of the variations indicated in the table ofFIG. 22 . The dimensions will assist materially in the erection of dry wall. By locating the two flange grooves spaced apart, with a planar section between them, it is possible for dry wall panels to be installed, with the edges of two dry wall panels (not shown) abutting each other and overlying the one stud. The installer will then insert screws along each panel edge, and the screws will seat into their respective grooves, which are in the correct locations to receive them. - The thickness or gauge of the sheet material, shown as T, may vary according to the table of

FIG. 22 . - The depth and width of the longitudinal indented grooves is indicated as D and E in

FIG. 21 and their variations are illustrated in Table ofFIG. 22 . - The spacing between the longitudinal indented grooves in the flanges and when used, in the web, may vary within the range indicated in

FIG. 22 , by the letters X, XX, Y, Z and ZZ. - Within these ranges it is found that the longitudinal indented grooves provide significant increases in load bearing capacity.

- The grooves may be indented into the material by using pairs of rolls indicated schematically in

FIG. 23 , and in more detail inFIGS. 24 , 25, and 26. - In this case an upper clamp roll (100) and lower clamp roll (104) holds the sheet metal.

- A groove recess roll (106), and groove indent roll (108) indent the groove (102). Within the rolls, sheet metal material of a wide variety of thicknesses or gauge may be advantageously formed with indented grooves, the effect of the rolls varying somewhat depending on the thickness of the gauge of the material. These studs enable the use of a reduction in thickness or gauge of sheet metal. It is anticipated that a reduction of at least one gauge and probably two gauges can be achieved while still providing adequate support to a wall or a concrete panel. This will reduce the cost of the walls or panels. It will also reduce the heat transfer through the panel and stud, since the reduction in gauge reduces the actual mass of metal available to provide a heat transfer path.

- The erecting of interior partitions is commonly completed by erecting a frame work of metal studs. Studs are erected usually on 16 inch centres. Top and bottom channels provide a means of anchoring the tops and bottoms of the vertical studs. In order to reduce the metal required in such studs, the thickness or gauge of the steel is reduced to a minimum, compatible with providing a reasonably firm wall or partition. Reduction of metal also reduces the weight loading per floor on a building, which can also result in substantial saving in the construction of the building fabric. Such walls usually involve the completion of each side of the wall by panels of gypsum wall board, so-called dry wall. Usually, these panels are secured to the studs by screws having chisel points, which will drill through the metal of the stud and are self-tapping. It is well known, however, that the insertion of such screws can be hindered, if the metal forming the stud is made too thin. In this case, the stud flanges will simply bend when the pressure of the screw point is applied to it, and the screw will slip off. The present invention utilizes narrow longitudinal indented grooves in the edge flanges of the stud and also in the web of larger studs. These narrow longitudinal indented grooves substantially increase the rigidity of the edge flanges which facilitate the insertion of self-tapping screws. In addition, the longitudinal indented grooves provide narrow grooves for anchoring the tip of the screw so that it will not slip when pressure is applied to it to provide the drilling and self-tapping action. The use of the multiple separate indented dimples (60) also has the same result, locating and holding the screw point while it bites into the sheet metal.

- Manufacture of the studs of the invention, would typically proceed by passing a continuous strip of flat sheet metal through a series of narrowly spaced apart web clamping roller dies (100-104). The studs may be the

FIGS. 1 and 7 embodiments, in which case they will have been formed with web openings and channels, prior to the forming of the indentations. - The grooves are formed by recess dies (106) and male indenting dies (108). These dies are mounted on a series of separate shafts spaced apart along the roll forming production line, as shown in more detail in

FIGS. 24 , 25, and 26. - In

FIGS. 24 , 25, and 26 the indenting dies are shown in pairs, so that they indent two spaced apart grooves (102) simultaneously.FIG. 24 shows the indenting of two grooves (102 a-102 b), side by side.FIG. 25 show the next stage in which a further groove (102 c) is indented. A bend (110) is being formed between groove (102 a) and groove (102 b) to form the lip on the edge flange. -

FIG. 26 shows the indenting of two further grooves (102 d-102 e), in the actual web portion of the stud. - A bend (112) is being formed between groove (102 c) and groove (102 d), which will thus form the edge flange of the stud.

- The clamping dies (100-104) function to grip the sheet metal on either side.

- The indenting dies (106-108) form the grooves in the sheet metal.

- The clamping dies hold the sheet metal on either side of the indenting dies so as to prevent the sheet metal from being drawn inwardly from either edge.

- The studs so formed will maintain their uniform preset width, which is required for the job for which they are intended.

- The effect of passing the flat strip through these groove roller dies will be to form narrow longitudinal indented grooves, in the portions of the strip which will eventually form the edge flanges and the lips of the stud, and in some cases, will form the web as well. The studs will, of course, be cut to suitable length in a mechanism of which several types are well known in the art.

- The multiple separate indents or dimples (60) of

FIG. 16 , may be formed by using toothed indent rolls (not shown) similar to indent rolls (108), but having a plurality of separate point shaped tooth formations (similar to gear teeth for example). As the metal passes between such rolls the teeth will form separate individual indents, as shown inFIG. 16 , in the sheet metal. - In the event that it is required to form any additional formations in the web, or transverse grooves openings or the like, then typically these will be formed in a rotary die machine, which will be located downstream of the longitudinal groove dies, but before the bending dies. Such rotary die machines are known in the art. Alternatively, however, in some cases it is possible that flying die systems may be used, although these would require a slower production speed.

- Cutting to length will normally be performed upstream of the roller dies, where the strip sheet is still flat and unformed. In this way each piece of sheet metal passing through the various punching and forming and roll forming sequences is already precut to the exact length required for the finished stud.

- It also possible to cut to length downstream of the roller dies, in some cases. It must be remembered that in cutting to length, provision must be left at each end of each stud to leave end portions of the stud free of openings, so that it can be placed in an eventual structure, with all of the openings in each stud aligned with one another across the structure. This will greatly facilitate the installation of services through the openings.

- Suitable controls which form no part of the invention are incorporated in the rotary press so that the rotary press is timed to operate exactly where required on each stud. Where openings are not required, at each end of each stud, the controls disable the rotary press so that leading and trailing ends of the sheet metal pass through unpunched and unformed.

- The term “indented” as used herein is intended to define the effect of forming the lengthwise grooves, or multiple indented dimples. The grooves or dimples are deflected inwardly towards the space enclosed with the shape of the C section of the stud. This leaves the exterior surface of the two edge flanges planar (flat) and thus available to receive wall finishing panels such as dry wall or similar panels.

- In these illustrations, studs which are shown for explanation only, are relatively short. Clearly in most cases the studs would be longer, as required by the particular structure for which they are required.

- A further embodiment of stud (120) is shown in

FIGS. 27 and 28 . - In this case the edge flanges (122) are formed with a series of separate indented grooves (124), which are spaced apart lengthwise along the edge flanges. Two rows of such grooves (124) are shown, with the grooves in one row being offset with relation to the grooves in the other row. The ends of grooves in one row overlap the ends of grooves in the other, adjacent row thus providing for continuity of reinforcement along the stud. In this stud depressions (126) of irregular triangle shape are formed in the web at each end of each diagonal rib, and openings (128) are formed in the depressions.

- The foregoing is a description of a preferred embodiment of the invention which is given here by way of example only. The invention is not to be taken as limited to any of the specific features as described, but comprehends all such variations thereof as come within the scope of the appended claims.

Claims (20)

1. A reinforced indented sheet metal stud for use in construction

and having a web defining side edges and an axis, a first flange along one side edge, and a second flange along the other side edge, said web and said flanges defining inside surfaces and outside mounting surfaces on opposite surfaces of said sheet metal, and comprising;

longitudinal indented grooves formed along at least one of said first and second flanges, parallel to said web axis wherein said indented grooves in said flanges are formed as depressions from said outside mounting surface extending into said inside surface; and,

planar surface spaces on the outside mounting surface of said at least one flange between said indented grooves.

2. A reinforced indented sheet metal stud as claimed in claim 1 , including two said flanges bent at right angles to said web and longitudinal indented grooves in both said flanges, and planar surfaces spaces between said grooves on each said flange.

3. A reinforced indented sheet metal stud as claimed in claim 1 including depressions formed in said web at spaced intervals, and openings formed in said depressions.

4. A reinforced indented sheet metal stud as claimed in claim 1 having an embedment edge formed along one said flange, for embedment in concrete.

5. A reinforced indented sheet metal stud as claimed in claim 1 including openings through said web at spaced intervals therealong, of predetermined size and profile, at least a side portion of said web displaced from said opening remaining attached integrally to said web, a first bend formed in said side portion, a second bend formed in said side portion spaced from said first bend, said first and second bends being formed along axes parallel to said web axis to define reinforcing channels.

6. A reinforced indented sheet metal stud as claimed in claim 5 including a cross brace member having fastenings with a snap-in engagement for insertion into said web openings.

7. A reinforced indented sheet metal stud as claimed in claim 5 including depressions formed in said web at spaced intervals and, openings formed in said depressions to reduce heat transfer.

8. A reinforced indented sheet metal stud as claimed in claim 5 and having openings shaped with opposed linear side edges, side portions of said web integral with said linear side edges being formed into said channel shapes.

9. A reinforced indented sheet metal stud as claimed in claim 1 and having an embedment edge on a said flange being angled at an angle to said web and a locking strip formed along said embedment edge for embedment in a concrete panel.

10. A reinforced indented sheet metal stud as claimed in claim 9 and having openings through said web at spaced intervals therealong, of predetermined size and profile, at least a side portion of said web displaced from said opening remaining attached integrally to said web, a first bend formed in said side portion, a second bend formed in said side portion spaced from said first bend, said first and second bends being formed along axes parallel to said web axis to define reinforcing channels.

11. A reinforced indented sheet metal stud as claimed in claim 1 and being formed of sheet metal having a gauge between 0.149 inch and 0.1196 inch, and a web width of between 3.625 and 14.00 inch, and flange width of between 1.25 and 3.0 inch, and wherein the indented grooves have a depth of between 0.125 and 50 inch and a groove width of between 0.0625 and 0.50 inch, and having a planar spacing between said indented grooves in said web of between 0.50 and 1.25 inch.

12. A reinforced indented sheet metal stud as claimed in claim 9 being further characterized by being formed of sheet metal having a gauge between 0.149 inch and 1.196 inch, and a web width of between 3.625 and 14.00 inch, and flange width of between 1.25 and 3.0 inch, and wherein the indented grooves have a depth of between 0.125 and 0.50 inch and a groove width of between 0.0625 and 0.50 inch and a spacing between said indented grooves in said web of between 0.50 and 1.25 inch.

13. A reinforced indented sheet metal stud for use in construction and having a web defining side edges and an axis, a first flange along one side edge, and a second flange along the other side edge, said web and said flanges defining inside surfaces and outside mounting surfaces on opposite surfaces of said sheet metal, and comprising;

multiple separate dimples indented in each of said first and second flanges, forming depressions from said outside mounting surface extending into said inside surface; and,

longitudinal and transverses ridges on the outside mounting surface of each said flange between said dimples.

14. A reinforced indented sheet metal stud for use in construction as claimed in claim 13 and including transverse indented L-shaped corner grooves, formed in said web and in each said flange, located at spaced apart intervals therealong.

15. A reinforced indented sheet metal stud for use in construction as claimed in claim 14 wherein said dimples are generally of pyramid shape.

16. A reinforced indented sheet metal stud for use in construction as claimed in claim 15 , and including web openings formed in said web at spaced intervals therealong.

17. A reinforced indented sheet metal stud for use in construction as claimed in claim 13 , and including grooves indented across said web, generally from one flange to the other.

18. A method of making a reinforced indented sheet metal stud

and comprising the steps of;

forming a sheet metal strip having a web with side edges;

forming longitudinal indented grooves in said flanges, said grooves being spaced apart and defining planar web portions between said grooves;

forming flanges along each said side edge, said flanges having lips on said flanges;

bending said flanges relative to said web whereby to define an outer mounting surface and an inside surface of said stud, said grooves being formed as depressions indented from said outer mounting surface into said inside surface; and,

forming longitudinal indented grooves in said web.

19. A method of making a reinforced indented sheet metal stud as claimed in claim 18 and further comprising the steps of;

forming main web openings in said sheet metal strip at spaced intervals,

subsequently forming edge flanges around said openings and,

prior to forming said indented grooves.