US20070225088A1 - Durable Golf Tee Construction - Google Patents

Durable Golf Tee Construction Download PDFInfo

- Publication number

- US20070225088A1 US20070225088A1 US11/756,399 US75639907A US2007225088A1 US 20070225088 A1 US20070225088 A1 US 20070225088A1 US 75639907 A US75639907 A US 75639907A US 2007225088 A1 US2007225088 A1 US 2007225088A1

- Authority

- US

- United States

- Prior art keywords

- ring portion

- middle ring

- ball seat

- golf tee

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B57/00—Golfing accessories

- A63B57/10—Golf tees

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B57/00—Golfing accessories

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B57/00—Golfing accessories

- A63B57/10—Golf tees

- A63B57/12—Golf tees attached to straps

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B57/00—Golfing accessories

- A63B57/10—Golf tees

- A63B57/13—Golf tees foldable or separable

Definitions

- the present invention relates generally to design and construction of durable and reusable golf tees.

- the main advantage of present invention helps to reduce the loss of or damages to the golf tee, and therefore, has great environmental value.

- tees traditionally are simply a wood stick with a widened seat on top for the ball to be placed. Although tees are relatively inexpensive and golfers usually carry a package of them in the golf bags, golfers sometimes run into problems when these one-time-use tees are used up in a game.

- Present invention provides a durable golf tee that allows golf players to carry only ONE tee of present invention and do not need to worry about buying a bunch of tees again and again.

- present invention also has high environmental value in reducing wasted material.

- Present invention has a unique construction for a first tee having separable ball seat portion, so that the tee will not be damaged by golf swings.

- a string is utilized to connect the first separable tee to a second tee, so that even when the first tee is hit up in the air, the string along with the second tee actually pull back and stop the first tee from flying out and disappear into any long grassy area on or around the tee-off box in the golf course.

- the string used to connect the separable first tee and the second tee also helps to create a line for golfers to visualize and provides a good guidance for improving golf games.

- the ball seat of the first tee is separable from, but connected to the middle ring portion and base by a combination of a wire and spring, creating the desired structure to withstand hitting and quick restoration to original shape.

- said Lee 470 Patent uses a clevis pin ( 8 ) to connect the ball seat to the base; often times these hard pins tend to break.

- said Lee 470 Patent is a two-piece construction, whereas present invention is a three-piece construction, allowing the better string attachment and more durable tee than Lee 470 Patent.

- said Lee 470 Patent provides no bevel angle at the junction of top ball seat and the base, so that there is more resistance for break-away action (at time of club head impacting the tee) and the restoration (from the break-away ball seat back to the base) requires more alignment effort.

- FIG. 1 shows the durable golf tee having a first tee and a second tee connected by a string.

- FIG. 2 a shows the assembled profile view of first tee.

- FIG. 2 b shows the exploded view of first tee.

- FIG. 3 a shows the position of the ball seat being slanted, upon striking by golf clubs.

- FIG. 3 b shows the wire being secured to the base by a end-clamp fitted to a cave slot on top of the base; and also shows the bevel angle made to the protruding of the middle ring portion.

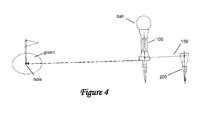

- FIG. 4 shows the present golf tee construction can be used to help line up golfer's swing to the target by keeping the string tight and lined up to the target.

- FIG. 5 shows the existence of extended circumference on the middle ring portion, for ease of human handling.

- Present invention uses the prevalent rubber or plastic material as the main ingredient for the production of the middle ring portion.

- These materials include, but are not limited to, PE, PVC, PU, etc., and help to enhance the durability of present invention.

- the technique of plastic/rubber injection to form the middle ring portion, as well as the making of said plastic/rubber, are commonly found practices and need no disclosure herein.

- FIG. 1 shows a first tee 100 , connected to a second tee 200 , by a string 150 .

- a string 150 By using this pair of tees connect by a string 150 , golfers will be able to locate the tee after striking the ball (sitting on top of the tee), because the tee being struck upon (whether it's tee 100 or tee 200 , depending on the use), the other tee will pull back the “flying out” action of the tee being struck upon.

- the string 150 can be made of bright color and thus helping to locate the tee construction.

- FIGS. 2 a and 2 b show the breakable/separable construction of first tee 100 .

- First tee 100 is further made up of 3 main parts: ball seat 80 , middle ring portion 50 and base 20 .

- Ball seat 80 has an inner hollowed out space to receive a spring 86 and a wire 83 .

- Middle ring portion 50 has an upright protruding 51 that is sized to snugly receive the opening of the inner hollowed out space of the ball seat 80 , easily aligning the ball seat 80 to the middle portion 50 and the base 20 , as shown in the assembled view of FIG. 2 a.

- An upper end-clamp 839 and a lower end-clamp 831 are used to secure said wire 83 in place, so that the upper end of wire 83 will pull and compress said spring 86 towards the base, at time of impact from a golf swing.

- Lower end claim 831 of wire 83 is attached, through a hole in the middle ring portion 50 , directly to the base top 28 .

- This arrangement of wire 83 connection produces more durable breakable ball seat 80 movements, than otherwise is the case, as achieved by other prior art disclosure, such as the Lee 470 patent.

- FIG. 3 a shows the separable ball seat 80 of first tee 100 can be slanted and swayed as struck upon by golf clubs.

- the ball seat 80 will be momentarily slanted, wire 83 pulls back the spring 86 , so that the spring 86 will be in a state of compression, exerting force to restore to the spring's original uncompressed state.

- Such a construction allows the first tee 100 to absorb the impact of a golf swing and hit by breaking away, yet remains connected by the wire 83 and then quickly restore its previous state due to the spring's 86 resilient force.

- FIG. 3 b shows that first end-clamp 831 further has a groove G, to mesh with the cave slot 28 on top of said base.

- first end-clamp 831 is “grabbed into” said cave slot 28 nice and tightly.

- the connection of end-clamp 831 to cave slot 28 is made really strong and durable.

- Said cave slot 28 and said base 20 is made from a same metal piece via precise lathing process, so that when plastic (or rubber, depending on implementation choice) material is injected over the clamped together combo of cave slot 28 and first end-claim 831 , it forms an extremely strong holding power to retain the wire 83 .

- said protruding 51 is made to have a bevel angle BA, so that there is less resistance at the time of ball seat 80 break-away (when clubhead is impacting the golf ball) and the automatic restoration of ball seat 80 to the protruding 51 is made easier, due to the bevel angle BA.

- This bevel angle BA is an advantage of Lee 470 patent, where the base of said two-piece construction contains a 90-degree protrusion for insertion into ball seat, for purpose of breakaway and restoration.

- FIG. 4 shows the string 150 can be used to help line up golfer's swing, creating more utility for present invention.

- golfers can switch the two tees and use the second tee 200 as the ball-striking tee, so that the ball sits lower and closer to the ground, creating better hitting surface more akin to using iron shot than a driver (using woods).

- FIG. 5 shows the middle ring portion 50 has extended outer circumferential edge (as marked by letters a and b) to allow better and convenient handling by human figures.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Physical Education & Sports Medicine (AREA)

- Golf Clubs (AREA)

Abstract

A durable golf tee construction to prevent the loss of or damage to golf tees, allowing golf players to play many rounds of golf using only one golf tee. The first tee of the duo-tee construction contains a wire connected to the base top and the separable ball seat, through a center hole in the middle ring portion, so that the whole structure becomes more durable and thus environmental friendly than other prior art disclosure's teaching.

Description

- This application is a Continuation-In-Part (CIP) application, under 37 CFR 1.53(b), of a prior parent application Ser. No. 10/907,580, by the same inventors, to supplement the disclosure re the matter related to “Durable Golf Tee Construction”. Present CIP application claims priority of the filing date of Apr. 6, 2005 for the content already disclosed in the prior application, per the requirements of 35 U.S.C. § 120 and 37 C.F.R. 1.78.

- The present invention relates generally to design and construction of durable and reusable golf tees. The main advantage of present invention helps to reduce the loss of or damages to the golf tee, and therefore, has great environmental value.

- Golf tees traditionally are simply a wood stick with a widened seat on top for the ball to be placed. Although tees are relatively inexpensive and golfers usually carry a package of them in the golf bags, golfers sometimes run into problems when these one-time-use tees are used up in a game.

- Present invention provides a durable golf tee that allows golf players to carry only ONE tee of present invention and do not need to worry about buying a bunch of tees again and again.

- Because golfers need not repeatedly buy those one-time golf tees, present invention also has high environmental value in reducing wasted material.

- Present invention has a unique construction for a first tee having separable ball seat portion, so that the tee will not be damaged by golf swings.

- Furthermore, a string is utilized to connect the first separable tee to a second tee, so that even when the first tee is hit up in the air, the string along with the second tee actually pull back and stop the first tee from flying out and disappear into any long grassy area on or around the tee-off box in the golf course.

- The string used to connect the separable first tee and the second tee also helps to create a line for golfers to visualize and provides a good guidance for improving golf games.

- The ball seat of the first tee is separable from, but connected to the middle ring portion and base by a combination of a wire and spring, creating the desired structure to withstand hitting and quick restoration to original shape.

- Present invention has great advantage over prior art patent by inventor Hyung Choon Lee, U.S. Pat. No. 6,783,470 (Lee 470 Patent) in that:

- (1) said Lee 470 Patent uses a clevis pin (8) to connect the ball seat to the base; often times these hard pins tend to break.

- (2) said Lee 470 Patent is a two-piece construction, whereas present invention is a three-piece construction, allowing the better string attachment and more durable tee than Lee 470 Patent.

- (3) said Lee 470 Patent provides no bevel angle at the junction of top ball seat and the base, so that there is more resistance for break-away action (at time of club head impacting the tee) and the restoration (from the break-away ball seat back to the base) requires more alignment effort.

- (4) said tee of Lee 470 Patent could become lost in the grass, just like other regular tees, lacking the string/second tee pulling of present invention, which ensures golfers will always be able to locate the tee.

- The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate the preferred embodiment of the invention and together with the description, serve to explain the principles of the invention.

- A brief description of the drawings is as follows:

-

FIG. 1 shows the durable golf tee having a first tee and a second tee connected by a string. -

FIG. 2 a shows the assembled profile view of first tee. -

FIG. 2 b shows the exploded view of first tee. -

FIG. 3 a shows the position of the ball seat being slanted, upon striking by golf clubs. -

FIG. 3 b shows the wire being secured to the base by a end-clamp fitted to a cave slot on top of the base; and also shows the bevel angle made to the protruding of the middle ring portion. -

FIG. 4 shows the present golf tee construction can be used to help line up golfer's swing to the target by keeping the string tight and lined up to the target. -

FIG. 5 shows the existence of extended circumference on the middle ring portion, for ease of human handling. - Present invention uses the prevalent rubber or plastic material as the main ingredient for the production of the middle ring portion. These materials include, but are not limited to, PE, PVC, PU, etc., and help to enhance the durability of present invention. The technique of plastic/rubber injection to form the middle ring portion, as well as the making of said plastic/rubber, are commonly found practices and need no disclosure herein.

-

FIG. 1 shows afirst tee 100, connected to asecond tee 200, by astring 150. By using this pair of tees connect by astring 150, golfers will be able to locate the tee after striking the ball (sitting on top of the tee), because the tee being struck upon (whether it's tee 100 ortee 200, depending on the use), the other tee will pull back the “flying out” action of the tee being struck upon. Thestring 150 can be made of bright color and thus helping to locate the tee construction. -

FIGS. 2 a and 2 b show the breakable/separable construction offirst tee 100.First tee 100 is further made up of 3 main parts:ball seat 80,middle ring portion 50 andbase 20.Ball seat 80 has an inner hollowed out space to receive aspring 86 and awire 83. -

Middle ring portion 50 has an upright protruding 51 that is sized to snugly receive the opening of the inner hollowed out space of theball seat 80, easily aligning theball seat 80 to themiddle portion 50 and thebase 20, as shown in the assembled view ofFIG. 2 a. - An upper end-

clamp 839 and a lower end-clamp 831 are used to secure saidwire 83 in place, so that the upper end ofwire 83 will pull and compress saidspring 86 towards the base, at time of impact from a golf swing. -

Lower end claim 831 ofwire 83 is attached, through a hole in themiddle ring portion 50, directly to thebase top 28. This arrangement ofwire 83 connection produces more durablebreakable ball seat 80 movements, than otherwise is the case, as achieved by other prior art disclosure, such as the Lee 470 patent. -

FIG. 3 a shows theseparable ball seat 80 offirst tee 100 can be slanted and swayed as struck upon by golf clubs. When a golf player hits the ball, theball seat 80 will be momentarily slanted,wire 83 pulls back thespring 86, so that thespring 86 will be in a state of compression, exerting force to restore to the spring's original uncompressed state. Such a construction allows thefirst tee 100 to absorb the impact of a golf swing and hit by breaking away, yet remains connected by thewire 83 and then quickly restore its previous state due to the spring's 86 resilient force. -

FIG. 3 b shows that first end-clamp 831 further has a groove G, to mesh with thecave slot 28 on top of said base. - As shown in

FIGS. 3 b(1) and 3 b(2), first end-clamp 831 is “grabbed into” saidcave slot 28 nice and tightly. After the plastic (or rubber) injection process, to form themiddle ring portion 50, the connection of end-clamp 831 tocave slot 28 is made really strong and durable. - Said

cave slot 28 and saidbase 20 is made from a same metal piece via precise lathing process, so that when plastic (or rubber, depending on implementation choice) material is injected over the clamped together combo ofcave slot 28 and first end-claim 831, it forms an extremely strong holding power to retain thewire 83. - Furthermore, as shown in

FIG. 3 b (3), said protruding 51 is made to have a bevel angle BA, so that there is less resistance at the time ofball seat 80 break-away (when clubhead is impacting the golf ball) and the automatic restoration ofball seat 80 to the protruding 51 is made easier, due to the bevel angle BA. - This bevel angle BA is an advantage of Lee 470 patent, where the base of said two-piece construction contains a 90-degree protrusion for insertion into ball seat, for purpose of breakaway and restoration.

-

FIG. 4 shows thestring 150 can be used to help line up golfer's swing, creating more utility for present invention. Depending on preference, golfers can switch the two tees and use thesecond tee 200 as the ball-striking tee, so that the ball sits lower and closer to the ground, creating better hitting surface more akin to using iron shot than a driver (using woods). -

FIG. 5 shows themiddle ring portion 50 has extended outer circumferential edge (as marked by letters a and b) to allow better and convenient handling by human figures.

Claims (14)

1. A durable golf tee construction, comprising:

a. A first golf tee having a base, a middle ring portion, a separable ball seat connected to said base by a wire placed through the center of said middle ring portion, said wire further having a first end-clamp attached to a cave slot on top of said base and a second end-clamp wedged on top of a resilient means located inside said separable ball seat;

b. A second golf tee; and,

c. A string connecting said first and second tee.

2. The golf tee of claim 1 , wherein said resilient means inside said separable ball seat of the first golf tee is a spring located inside a coaxially hollowed out inner space to house said spring and said wire, so as to allow said spring to move slidably inside the coaxial hollowed space of said ball seat, so that said ball seat may be temporarily separated from said middle ring portion, but remain connected to said middle ring portion by said wire, and so that said spring, in its compressed state, will exert force on said ball seat to resume its original state of being connected and fitted to said middle ring portion and said base.

3. The golf tee of claim 2 , wherein said cave slot is made from the same integral metal work piece forming the base.

4. The golf tee of claim 3 , wherein said middle ring portion is made of plastic material by plastic injection means to pressingly match said first end-clamp tightly with said cave slot on top of said base.

5. The golf tee of claim 4 , wherein said middle ring portion has a protruding sized to fit the diameter of the hollowed out inner space of said ball seat so that the ball seat will be easily aligned with the middle ring portion and base after temporarily separated from said middle ring portion after being struck upon by golf clubs.

6. The golf tee of claim 5 , wherein said middle ring portion has a bevel angel made to the protruding top for easier insertion to the opening of said coaxial hollowed space of said ball seat, resulting in lesser friction between the breakaway ball seat and the middle ring portion.

7. The golf tee of claim 5 , wherein said middle ring portion has extended outer circumferential edge for easy human handling.

8. A durable golf tee construction, comprising:

a base, a middle ring portion, a separable ball seat connected to said base by a wire placed through the center of said middle ring portion, said wire further having a first end-clamp attached to a cave slot on top of said base and a second end-clamp wedged on top of a resilient means located inside said separable ball seat;

9. The golf tee of claim 8 , wherein said resilient means inside said separable ball seat is a spring located inside a coaxially hollowed out inner space to house said spring and said wire, so as to allow said spring to move slidably inside the coaxial hollowed space of said ball seat, so that said ball seat may be temporarily separated from said middle ring portion, but remain connected to said middle ring portion by said wire, and so that said spring, in its compressed state, will exert force on said ball seat to resume its original state of being connected and fitted to said middle ring portion and said base.

10. The golf tee of claim 9 , wherein said cave slot is made from the same integral metal work piece forming the base.

11. The golf tee of claim 10 , wherein said middle ring portion is made of plastic or rubber material by injection means to pressingly match said first end-clamp tightly with said cave slot on top of said base.

12. The golf tee of claim 11 , wherein said middle ring portion has a protruding sized to fit the diameter of the hollowed out inner space of said ball seat so that the ball seat will be easily aligned with the middle ring portion and base after temporarily separated from said middle ring portion after being struck upon by golf clubs.

13. The golf tee of claim 12 , wherein said middle ring portion has a bevel angel made to the protruding top for easier insertion to the opening of said coaxial hollowed space of said ball seat, resulting in lesser friction between the breakaway ball seat and the middle ring portion.

14. The golf tee of claim 12 , wherein said middle ring portion has extended outer circumferential edge for easy human handling.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/756,399 US20070225088A1 (en) | 2005-04-06 | 2007-05-31 | Durable Golf Tee Construction |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/907,580 US20060229144A1 (en) | 2005-04-06 | 2005-04-06 | Durable golf tee construction |

| US11/756,399 US20070225088A1 (en) | 2005-04-06 | 2007-05-31 | Durable Golf Tee Construction |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/907,580 Continuation-In-Part US20060229144A1 (en) | 2005-04-06 | 2005-04-06 | Durable golf tee construction |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20070225088A1 true US20070225088A1 (en) | 2007-09-27 |

Family

ID=46327975

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/756,399 Abandoned US20070225088A1 (en) | 2005-04-06 | 2007-05-31 | Durable Golf Tee Construction |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US20070225088A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011123168A1 (en) * | 2010-03-17 | 2011-10-06 | Sightline Payments, Llc | Bankcard cash disbursements at casinos |

| USD850548S1 (en) * | 2017-01-11 | 2019-06-04 | William Reichert | Golf tee restraint |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2011203A (en) * | 1933-07-28 | 1935-08-13 | Nippon Trading Company | Golf tee |

| US4418916A (en) * | 1981-02-17 | 1983-12-06 | Matsura Norio | Tilt top gulf tee |

| US4524974A (en) * | 1983-02-22 | 1985-06-25 | Matsura Norio | Golf tee |

| US5242170A (en) * | 1992-05-14 | 1993-09-07 | Super Tee, Inc. | Golf tee |

| US5413348A (en) * | 1994-06-06 | 1995-05-09 | Basso; Alfonso | Golf tee anchoring system |

| US20020022538A1 (en) * | 2000-08-17 | 2002-02-21 | Kyoung-Soo Choi | Flexible golf tee |

| US20030181262A1 (en) * | 2002-03-20 | 2003-09-25 | Lee Hyung Choon | Golf tee |

| US20050143195A1 (en) * | 2003-12-24 | 2005-06-30 | Dong-Yi Syu | Golf tee |

| USD516648S1 (en) * | 2004-11-20 | 2006-03-07 | Hyung Choon Lee | Golf tee |

| US7011586B2 (en) * | 2003-02-26 | 2006-03-14 | Daiya Corporation | Golf tee |

| USD555218S1 (en) * | 2007-01-22 | 2007-11-13 | Hyung Choon Lee | Golf tee |

-

2007

- 2007-05-31 US US11/756,399 patent/US20070225088A1/en not_active Abandoned

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2011203A (en) * | 1933-07-28 | 1935-08-13 | Nippon Trading Company | Golf tee |

| US4418916A (en) * | 1981-02-17 | 1983-12-06 | Matsura Norio | Tilt top gulf tee |

| US4524974A (en) * | 1983-02-22 | 1985-06-25 | Matsura Norio | Golf tee |

| US5242170A (en) * | 1992-05-14 | 1993-09-07 | Super Tee, Inc. | Golf tee |

| US5413348A (en) * | 1994-06-06 | 1995-05-09 | Basso; Alfonso | Golf tee anchoring system |

| US20020022538A1 (en) * | 2000-08-17 | 2002-02-21 | Kyoung-Soo Choi | Flexible golf tee |

| US20030181262A1 (en) * | 2002-03-20 | 2003-09-25 | Lee Hyung Choon | Golf tee |

| US6783470B2 (en) * | 2002-03-20 | 2004-08-31 | Hyung Choon Lee | Golf tee |

| US7011586B2 (en) * | 2003-02-26 | 2006-03-14 | Daiya Corporation | Golf tee |

| US20050143195A1 (en) * | 2003-12-24 | 2005-06-30 | Dong-Yi Syu | Golf tee |

| USD516648S1 (en) * | 2004-11-20 | 2006-03-07 | Hyung Choon Lee | Golf tee |

| USD555218S1 (en) * | 2007-01-22 | 2007-11-13 | Hyung Choon Lee | Golf tee |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011123168A1 (en) * | 2010-03-17 | 2011-10-06 | Sightline Payments, Llc | Bankcard cash disbursements at casinos |

| USD850548S1 (en) * | 2017-01-11 | 2019-06-04 | William Reichert | Golf tee restraint |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20060229144A1 (en) | Durable golf tee construction | |

| US7416498B2 (en) | Device for preventing loss of golf tees | |

| TW201200210A (en) | Golf club head or other ball striking device having removable or interchangeable body member | |

| JP2007244845A (en) | Tee of golf | |

| US20130310200A1 (en) | Magnetically Attached Golf Tee | |

| US7338394B2 (en) | Golf tee | |

| US2144846A (en) | Golf club | |

| US20070225088A1 (en) | Durable Golf Tee Construction | |

| US6056651A (en) | Golf ball mounting device | |

| KR100955871B1 (en) | Golf club for both putters and chippers | |

| KR102606393B1 (en) | Golf Tee | |

| KR200442499Y1 (en) | Golf putter with indicator of direction | |

| US20140057741A1 (en) | Adjustable shape golf tee | |

| KR200327568Y1 (en) | combination golf tee | |

| KR101046427B1 (en) | A golf club for head cover which has a weight facility to swing | |

| JP3244914U (en) | golf approach practice machine | |

| KR200245110Y1 (en) | Golf Tee | |

| KR200463928Y1 (en) | Course indication tools for golf tee | |

| KR101423621B1 (en) | Folding type golf tee combined with green repair | |

| US9174105B2 (en) | Golf tee insertion tool | |

| KR200362735Y1 (en) | Means of Golf Tee | |

| KR200438865Y1 (en) | A golf club for putting | |

| KR20240101237A (en) | height adjustable golf tee | |

| KR100254777B1 (en) | Device of golf club for tee shot | |

| US20020082113A1 (en) | Head for a child's golf club |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCB | Information on status: application discontinuation |

Free format text: EXPRESSLY ABANDONED -- DURING EXAMINATION |