US20060289318A1 - Closable package for retaining multiple discs in pouch-type holders or disc-receiving trays - Google Patents

Closable package for retaining multiple discs in pouch-type holders or disc-receiving trays Download PDFInfo

- Publication number

- US20060289318A1 US20060289318A1 US11/424,820 US42482006A US2006289318A1 US 20060289318 A1 US20060289318 A1 US 20060289318A1 US 42482006 A US42482006 A US 42482006A US 2006289318 A1 US2006289318 A1 US 2006289318A1

- Authority

- US

- United States

- Prior art keywords

- disc

- base portion

- receiving area

- tray

- pouch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B33/00—Constructional parts, details or accessories not provided for in the other groups of this subclass

- G11B33/02—Cabinets; Cases; Stands; Disposition of apparatus therein or thereon

- G11B33/04—Cabinets; Cases; Stands; Disposition of apparatus therein or thereon modified to store record carriers

- G11B33/0405—Cabinets; Cases; Stands; Disposition of apparatus therein or thereon modified to store record carriers for storing discs

- G11B33/0433—Multiple disc containers

- G11B33/0444—Multiple disc containers for discs without cartridge

Definitions

- the present invention relates generally to a package for storing multiple disc-like recording media and, more particularly, to a closable package comprising at least one plastic tray supporting multiple discs, optionally in pouch-type holders and locking means for retaining the discs in the tray(s).

- planar discs are in use at the present time to record and store information which is to be retrieved by various means, such as by optical or magnetic means.

- Typical of such discs are compact discs in which information is digitally recorded by use of a laser beam and then read optically by a laser beam.

- Such discs are used to record audio information, such as musical renditions, video information such as visual images and digital information for use as read only and other memories for use in various applications, such as computer applications.

- audio information such as musical renditions

- video information such as visual images and digital information for use as read only and other memories for use in various applications, such as computer applications.

- such discs are sold with information already recorded thereon.

- such discs are sold in blank form and are used by the customer to record information thereon.

- optical discs are sold for use as computer storage media and are used in hard disc storage systems.

- the term compact disc, CD or disc is intended to encompass all such discs and disc-shaped packaging, e.g., for pharmaceuticals or cosmetics, whatever their size

- Compact discs containing laser recorded information are typically packaged in injection molded plastic enclosures designed to hold one or more CDs for protecting the discs during storage and shipment.

- Enclosures commonly used at the present time comprise a three piece assembly consisting of a base or bottom element, an insert or tray in the base/bottom element for positioning and supporting the disc in the base/bottom element, e.g., by a center projection (commonly referred to as a “rosette”) which engages the periphery of the aperture in the center of the disc, and a lid or cover which is hinged to the base/bottom element and is closed thereon after the disc is mounted therein on the tray.

- a center projection commonly referred to as a “rosette”

- enclosures utilize only two pieces, omit the tray, and position and support the disc via the center projection directly on the base/bottom element.

- the enclosure is, typically, at least partially transparent and graphics relating to the disc and containing trademark and sales promotional information are usually inserted in such a manner as to be visible through the enclosure.

- U.S. Pat. No. 4,709,812 discloses a compact disc package formed from a prescored, preprinted unitary blank and at least one injection molded plastic compact disc holder or tray adhesively adhered to one segment of the blank, the blank being adapted to fold along fold lines to position a blank segment over the top of the disc holder to sandwich it, in book style, between the segment to which it is adhered and the overlying segment.

- FIG. 1 is a top perspective view, of an improved tray of a CD package of the present invention, with disc-receiving pouches not shown.

- FIG. 2 is a perspective view of the improved tray of FIG. 1 taken along a vertical plane passing longitudinally through the tray.

- FIG. 3 is a top perspective view of the improved tray of FIG. 1 showing two disc-receiving pouches pivoted to form acute angles with the floor of the tray.

- FIG. 4 is a top perspective view of the improved tray of FIG. 1 with two disc-containing pouches lying in their rest positions in the tray.

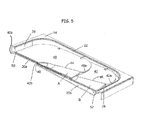

- FIG. 5 is another perspective view of the improved tray of FIG. 1 , including two disc-containing pouches lying in their rest positions in the tray, taken along a vertical plane passing longitudinally through the tray.

- FIG. 6 is top perspective view of the tray of FIG. 1 , with two pouches pivoted to form acute angles with the floor of the tray, one pouch containing a disc and the other having a disc ready for insertion therein.

- FIG. 7 is a top perspective view of the tray of FIG. 1 containing four disc-receiving pouches, three of which have been pivoted from their rest positions.

- FIG. 8 is a perspective view of the tray of FIG. 7 taken along a vertical plane passing longitudinally through the tray.

- FIG. 9 is another top perspective view of the tray of FIG. 7 containing four disc-containing pouches.

- FIG. 10 is still another top perspective view of the tray of FIG. 7 containing four disc-containing pouches, the uppermost of which is pivoted to form an acute angle with the floor of the tray.

- FIG. 11 is yet another top perspective view of the tray of FIG. 7 containing four disc-containing pouches.

- FIG. 12 is a perspective view of the improved tray of FIG. 1 mounted on one panel of a book-like package.

- FIG. 13 is a top perspective view of another embodiment of the tray of the present invention.

- FIG. 14 is another top perspective view of the tray of FIG. 13 including disc separator sheets.

- FIG. 15 is another top perspective view of the tray of FIG. 13 containing three discs arranged spaced apart in the longitudinal direction and overlapping.

- FIG. 16 is another top perspective view of the tray of FIG. 13 containing two discs arranged spaced apart in the longitudinal direction and overlapping.

- FIG. 17 is a perspective view of the improved tray of FIG. 13 taken along a vertical plane passing longitudinally through the tray.

- FIG. 18 is a perspective view of the improved tray of FIG. 13 mounted on one panel of a book-like package.

- FIG. 19 is a top perspective view of another embodiment of the improved tray of FIG. 13 which utilizes pivotable latching wings to prevent unwanted axial movement of the discs out of the tray.

- FIG. 20 is a top perspective view of an improved tray of another package of the present invention.

- FIG. 21 is a bottom perspective view of the improved tray of FIG. 20 .

- FIG. 22 is a top perspective view of the tray of FIG. 20 having discs A, B and C stored therein.

- FIG. 23 is another perspective view of the improved tray of FIG. 20 .

- FIG. 24 is a bottom perspective view of the sheet separators forming part of the pouch-type disc holders of the tray shown in FIG. 21 .

- FIG. 25 is a bottom perspective view of the tray of the sheet separators shown in FIG. 24 interleaved between discs A, B and C.

- FIG. 26 is a partial perspective view of the tray of FIG. 20 taken along a vertical plane passing longitudinally through the tray.

- FIG. 27 is a perspective view of a package of the present invention with the cover panel open and three discs stored in the tray of FIG. 20 and showing one form of cover locking means for the discs in the tray.

- FIG. 28 is a perspective view of a package of the present invention with the cover panel open and three discs stored in the tray of FIG. 20 and showing another form of cover locking means for the discs in the tray.

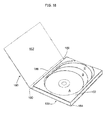

- FIG. 29 is a perspective view of the package of FIG. 28 in the closed position taken along the longitudinal center line of the tray.

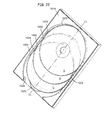

- FIG. 30 is a top perspective view of the package of FIG. 28 taken along a vertical plane passing longitudinally through the package.

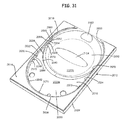

- FIG. 31 is a top perspective view of an improved tray of another package of the present invention.

- FIG. 32 is a bottom perspective view of the improved tray of FIG. 31 .

- FIG. 33 is a top perspective view of the tray of FIG. 31 taken along a vertical plane passing longitudinally through the tray.

- FIG. 34 is a top plan view of the tray of FIG. 31 .

- FIG. 35 is a perspective view of a package of the present invention in the closed position, comprising a stack of the improved trays of FIG. 31 enclosed on three sides by paperboard cover and base panels connected by a spine panel.

- FIG. 36 is a top perspective view of the package of FIG. 34 with the cover panel open and two discs stored in the uppermost tray and showing one form of cover locking means for the discs in the top tray.

- FIG. 37 is a perspective view of the package of FIG. 36 with the cover panel and the trays fanned out showing discs mounted in the trays.

- FIG. 38 is a perspective view of the package of FIG. 36 showing the undersides of two of the trays.

- FIG. 39 is a perspective view of the package of FIG. 36 taken along a vertical plane passing longitudinally through the package.

- FIG. 40 is an enlarged perspective view of one side of the package as viewed in FIG. 39 .

- FIG. 41 is a top perspective view of the package of FIG. 34 with the cover panel open and two discs stored in the uppermost tray and showing another form of cover locking means for the discs in the top tray.

- FIG. 42 is a sectional view through the centerline of a single tray embodiment of the package of the present invention.

- FIG. 43 is an enlarged sectional view of one side of the package as viewed in FIG. 42 .

- FIG. 44 is a top perspective view of a single tray embodiment of the package of the present invention taken along a vertical plane passing longitudinally through the package.

- FIG. 45 is a perspective view showing how a disc may be inserted or removed from one tray within the package of FIG. 36 .

- FIGS. 1-11 A preferred embodiment of the present invention is illustrated in FIGS. 1-11 , in which there is shown a tray for an improved CD package 10 for housing two or more discs.

- the package comprises a planar tray 12 which is generally rectangular, elongate and flat and includes an upper planar surface 14 having an elongate, generally rectangular-shaped recess 16 formed therein along substantially its entire width and length.

- the recess 16 defines a disc receiving housing which has a peripheral wall 18 extending between a housing floor 20 a , 20 b and the upper planar surface 14 of the tray 12 .

- the housing peripheral wall 18 comprises two elongate, longitudinally extending walls 22 , 24 and two transverse walls 26 , 28 connecting with the longitudinal walls.

- circular discs A, B are supported in their rest positions in respective oblique planes relative to the housing floor 20 a , 20 b in each of two receiving areas 30 , 32 with disc A partially overlapping disc B and aligned along the longitudinal direction of the tray to form a row.

- Tray 12 has a first disc receiving area 30 formed therein extending from one transverse peripheral wall 26 toward the median portion of the tray 12 , including floor portion 20 a , and a second disc receiving area 32 which is depressed from the first disc receiving area 30 by virtue of a transversely extending downward step 34 in the floor positioned between and generally parallel to the transverse peripheral walls 26 , 28 .

- the length of floor 20 b between the step 34 and the opposite transverse peripheral wall 28 represents the second disc receiving area 32 and is approximately the diameter of a disc.

- each disc is received within a pouch 40 , 42 , preferably formed of transparent plastic material, which comprises two generally rectangular plastic sheets sealed along three sides and open only at one transverse end 40 a , 42 a .

- a V-shaped notch 44 , 46 is formed in the upper sheet of each plastic pouch 40 , 42 communicating with the open transverse end 40 a , 42 a to facilitate grasping a disc which is in the pouch for purposes of removal.

- Each disc A, B is housed within a pouch 40 , 42 and, as can be seen in FIG.

- one lower peripheral edge 42 b of the pouch 42 containing disc B is hingedly connected in the corner 48 defined between the step 34 and the floor 20 b , and extends obliquely upward, relative to the floor 20 b , in the longitudinal direction with its upper peripheral edge substantially flush with the upper planar surface 14 of the tray 12 and adjacent the opposite transverse wall 28 .

- Disc A rests upon the previous disc B and is spaced longitudinally therefrom along the housing with the lower peripheral edge 40 b of its pouch 40 hingedly connected in the corner 50 defined between the one transverse peripheral wall 26 and the floor 20 a and the upper peripheral edge of the pouch resting on the previous disc B.

- disc A is supported obliquely above its underlying floor element 20 a , and the discs are not parallel.

- a support means is provided to maintain disc B in an oblique position.

- the support means comprises a relatively short wall portion 52 , which may be inclined downwardly from the top of the opposite peripheral transverse wall 28 into the recess 16 .

- disc B is supported in an oblique plane above floor portion 20 b between the upper peripheral edge of the wall portion and the corner 48 defined between the step 34 and the floor portion 20 b .

- the disc A partially overlaps and rests upon the immediately preceding disc B. The extent of the overlap between adjacent discs depends on the number of discs spaced along the housing and the length of the housing.

- the lower peripheral edges 40 b , 42 b of the pouches are hingedly connected to the corners 48 , 50 in which they rest to allow the pouches to pivot about the corner to facilitate disc removal.

- Tabs 54 extend into the recess 16 from the longitudinal peripheral walls 22 , 24 into contact with the edges of the discs A, B at positions between the center of each disc and the edge thereof nearest the pouch opening 40 a , 42 a to prevent longitudinal sliding motion of the discs A, B when the pouches 40 , 42 lie in their rest positions within the tray 12 .

- Notches 56 are formed in the pouch walls 40 c , 40 d , 42 c , 42 d to accommodate the tabs 54 .

- the pouch In order to remove a disc from a pouch, the pouch is pivoted upwardly about its lower peripheral edge 40 b , 42 b until the disc is sufficiently raised from the immediately preceding disc and sufficiently out of tray 12 that it can be easily grasped at the V-notch and slid out of the pouch in a direction parallel to the pouch walls 40 c , 40 d , 42 c , 42 d.

- tray 12 In a four-disc embodiment, shown in FIGS. 7-11 , the structure of tray 12 remains the same as in the two-disc embodiment. Therefore, like parts are represented by like reference numerals. The only difference is that in the four-disc embodiment, there are two pouches 40 , 41 and 42 , 43 hingedly connected along their lower peripheral edges 40 b , 41 b and 42 b , 43 b within each of the corners 48 , 50 , respectively. In this configuration, the discs A, C in each of the pouches 40 , 41 and the discs B, D in each of the pouches 42 , 43 are coaxial with one another when the pouches lie in their rest positions in tray 12 .

- coaxial discs A, C partially overlie coaxial discs B, D when the pouches lie in their rest positions in tray 12 .

- each is two-sided and can hold two discs arranged coaxially with respect to each other.

- Each disc is received on one side of the two sided plastic pouch, which comprises, in one form, three generally rectangular plastic sheets sealed along three sides and open only at the upper transverse side. Discs are inserted into the two openings along the upper peripheral edge of each of the pouches on either side or both sides of the center sheet.

- a V-shaped notch is formed in each of the outer sheets of each plastic pouch, communicating with the open transverse side, to facilitate grasping a disc in the pouch for purposes of its removal from the pouch.

- the four-disc embodiment of this invention can be used for storing three discs as well, e.g., by omitting one of the pouches in the four pouch embodiment or by leaving one pouch pocket empty in the two-sided pouch embodiment.

- the paper board 80 of FIG. 12 comprises a plurality of paper panels which are desirably formed from a presized, pre-printed unitary blank.

- the blank includes two panels 82 , 84 onto either of which the plastic tray 12 is adhesively or mechanically attached, separated by a spine panel 86 .

- Fold lines 88 , 90 separate panels 82 , 84 , respectively, from spine panel 86 and allow the panels to be pivoted between package open and package closed positions.

- the panels may be single ply although, in some instances, it may be desirable for one or both of these panels to be two or multiple ply.

- FIGS. 13-18 Another embodiment of the present invention is illustrated in FIGS. 13-18 , in which there is shown another improved CD package 100 for housing two or more discs.

- the package comprises a planar tray 102 which is generally rectangular, elongate and flat and includes an upper planar surface 104 having an elongate, generally rectangular-shaped, with arcuate end portions, recess 106 formed therein along substantially its entire width and length.

- the recess defines a disc receiving housing which has a peripheral wall 108 extending between a housing floor 110 a , 110 b , 100 c and the upper planar surface 104 of the tray 102 .

- the housing peripheral wall 108 comprises two elongate, longitudinally extending walls 112 , 114 and two arcuate end walls 116 , 118 connecting with the longitudinal walls.

- the arcuate end walls are generally semi-circular and have a diameter slightly larger than the diameter of a disc.

- circular discs A, B, C are supported in their rest positions in respective oblique planes relative to the housing floor 110 a , 110 b , 110 c in each of three receiving areas 120 , 122 , 124 with disc A partially overlapping disc B and disc B partially overlapping disc C, with the discs aligned along the longitudinal direction of the tray to form a row.

- Tray 102 has a first disc receiving area 120 formed therein extending from one arcuate end wall 116 toward the median portion of the tray 102 , including floor portion 110 a , a second disc receiving area 122 which is depressed from the first disc receiving area 120 by virtue of an arcuate semi-circular downward step 126 in the floor positioned between the arcuate end walls 116 , 118 , and generally parallel to arcuate end wall 116 , including floor portion 110 b , and a third disc receiving area 124 which is depressed from the second disc receiving area 122 by virtue of an arcuate semi-circular downward step 128 in the floor positioned between step 126 and arcuate end wall 118 , and generally parallel to arcuate end wall 116 , including floor portion 110 c .

- the length of floor 110 c between the step 128 and the opposite arcuate end wall 118 represents the third disc receiving area 124 and is approximately the diameter of a disc.

- the discs are supported within the tray 102 in a uniformly spaced apart in the longitudinal direction arrangement.

- Each disc A, B, C is received within its respective disc receiving area 120 , 122 , 124 with the lower peripheral edge of the disc supported, respectively, in one of the corner 130 between the arcuate end wall 116 and floor portion 110 a and corners 131 and 133 , between the steps 126 , 128 and floor portions 110 b , 110 c , respectively.

- the discs extend obliquely upward, relative to the floor portions 110 a , 110 b , 110 c , in the longitudinal direction with their upper peripheral edges substantially flush with the upper planar surface 104 of the tray 102 .

- Disc C has its lower peripheral edge supported in corner 133 and its upper peripheral edge supported along the upper peripheral edge of arcuate wall portion 118 .

- a support means is provided to maintain disc C in an oblique position.

- the support means comprises a relatively short wall portion 117 , which, desirably, is inclined downwardly from the top of the arcuate end wall 118 into the recess 106 .

- Disc B has its lower peripheral edge supported in corner 131 and its upper peripheral edge rests upon the previous disc C, with disc B spaced longitudinally from disc C along the housing.

- Disc A has its lower peripheral edge supported in the corner 130 defined between the arcuate end wall 116 and floor portion 110 a and its upper peripheral edge resting on the previous disc B, with disc A spaced longitudinally from disc B along the housing.

- each of discs A, B, C is supported obliquely above its underlying floor element 110 a , 110 b , 110 c , and the discs are not parallel.

- the extent of the overlap between adjacent discs depends on the number of discs spaced along the housing and the length of the housing.

- Plastic separator sheets 132 , 134 are affixed, desirably with adhesive, to the upper surfaces of floor portions 110 a , 110 b and extend therefrom toward arcuate end wall 118 a sufficient distance to completely separate disc B from disc C and disc A from disc B.

- the separator sheets are generally circular in shape and approximate the dimensions of a disc in order that separator sheets 132 , 134 are coextensive with discs B and C in tray 102 .

- Separator sheet 132 defines with the underlying floor portion 110 c a pouch-like enclosure for receiving disc C therein.

- separator sheet 134 defines with separator sheet 132 a pouch-like enclosure for receiving disc B therein.

- Disc A overlies separator sheet 134 .

- the discs are insertable into and removable from tray 102 by sliding in the oblique direction corresponding with their rest positions in the tray.

- disc C may be removed by sliding it over inclined wall portion 117 , which desirably is inclined at substantially the same oblique angle as disc C in the tray, in a direction toward arcuate end wall 118 .

- disc C may be slid from its oblique rest position out from under separation sheet 132 by exerting an obliquely-directed removal force to the disc without lifting the disc.

- disc B may be slid out from between separator sheet 132 , 134 and disc A may be slid out from on top of separator sheet 134 . It is noteworthy that the discs must be slid out of their respective pouch-like enclosures (discs B, C) or along separator sheet 134 (disc A) before they can be moved axially.

- three side wall detents 136 extend into the recess 106 from each of the longitudinal peripheral walls 112 , 114 into contact with the edges of the discs A, B, C at positions between the center of each disc and the edge thereof nearest arcuate end wall 118 .

- Each of the detents 136 comprises a tab 138 projecting into the recess 106 from an adjacent segment 140 of the peripheral longitudinal wall 112 , 114 .

- the wall segment 140 is defined by a pair of longitudinally spaced apart vertical slits 142 in the peripheral wall which extend from the floor 110 a , 110 b , 110 c upwardly toward the planar surface 104 .

- the slits 142 separate the segment 140 from the remainder of the peripheral wall, allowing the segment 140 to flex toward and away from the recess 106 independent of the remainder of the peripheral wall.

- the pressure of the disc against the tab 138 is insufficient to cause the wall segment 140 to flex inwardly away from the recess 106 and the discs are positively retained against sliding movement.

- the force of the disc against tab 138 causes wall segment 140 to deflect away from the recess 106 , allowing the disc to be slidingly removed from tray 102 .

- circumferentially spaced apart horizontal projections 144 extend from the arcuate end wall 116 inwardly into recess 106 . Desirably, the projections are positioned a small distance above floor portion 110 a and are equally spaced about the arcuate end wall 116 .

- the projections 144 bear against the upper surface of disc A around its periphery in order to retain disc A and any disc(s) underlying disc A against axial movement in the tray 102 .

- inadvertent sliding movement of the discs out of tray 102 can be prevented without use of sidewall detents 136 , by enlarging each of separator sheets 132 , 134 and including a pair of raised yieldable dimples on each sheet positioned longitudinally to contact the edges of discs A and B between the center of each disc and the edge thereof nearest arcuate end wall 118 .

- the dimples are positioned transversely such that one dimple contacts each disc edge on opposite sides of the longitudinal axis A-A of tray 102 .

- the paper board 180 illustrated in FIG. 18 comprises a plurality of paper panels which are desirably formed from a presized, pre-printed unitary blank.

- the blank includes two panels 182 , 184 onto either of which the plastic tray 102 is adhesively or mechanically attached, separated by a spine panel 186 .

- Fold lines 188 , 190 separate panels 182 , 184 , respectively, from spine panel 186 and allow the panels to be pivoted between package open and package closed positions.

- the panels may be single ply although, in some instances, it may be desirable for one or both of these panels to be two or multiple ply.

- FIG. 19 there is illustrated another embodiment of the improved tray of FIG. 13 . Therefore, like parts are represented by like reference numerals.

- inadvertent sliding movement of the discs in the tray 202 is avoided by extending the arcuate semi-circular downward steps 126 , 128 upward into the longitudinal peripheral walls to form arcuately stepped longitudinal peripheral walls 204 , 206 .

- the intersection of the arcuate end wall 116 and the upward extension of arcuate step 126 defines a step 208 which extends inwardly from each of the peripheral longitudinal walls 204 , 206 into recess 106 .

- step 210 which extends inwardly from each of the peripheral longitudinal walls 204 , 206 into recess 106 .

- each locking wing 212 includes one longitudinal edge 212 a which is pivotably supported by tray 102 and an opposite longitudinal edge 212 b which overlies the discs in tray 202 to prevent axial movement thereof.

- each locking wing 212 comprises a flap formed from the longitudinally extending planar surface portion 214 , which flap desirably pivots about the outer longitudinal peripheral edge of longitudinally extending planar surface portion 214 , for example, via a living hinge 216 .

- the top surfaces 218 of the locking wings 212 are substantially flush with the planar surface 204 and the free longitudinal edge 212 b of the locking wings, opposite to the living hinge edge 212 a , overlies the discs A, B, C, preventing their axial movement.

- the surfaces 220 of the locking wings 212 which face the discs in the closed position include a pair of male protrusions 222 which positively engage female apertures 224 , as by a snap engagement, formed in the recessed upwardly facing surface 226 of the longitudinally extending planar surface portion 214 from which the flap was formed. Additionally, a flange 228 profiled to correspond to the profile of the longitudinal peripheral walls projects from surfaces 220 into the recess 106 . In instances where the longitudinal peripheral walls are not profiled to prevent sliding movement of the discs, the profiled flange, in the closed position, will seat in the recess between the longitudinal peripheral walls and the disc edges with the steps on the flange profile contacting the disc edges to prevent sliding movement of the discs.

- FIGS. 20-30 Further embodiments of the present invention are illustrated in FIGS. 20-30 , in which there is shown an improved CD package 1010 for housing three discs.

- the package comprises a planar tray 1012 which is generally rectangular, elongate and flat and includes an upper planar surface 1014 having an elongate, generally rectangular-shaped, with arcuate end portions, recess 1016 formed therein along substantially its entire width and length.

- the recess defines a disc receiving housing which has a peripheral wall 1018 extending between a housing floor 1020 a , 1020 b , 1020 c and the upper planar surface 1014 of the tray 1012 .

- the housing peripheral wall 1018 comprises two elongate, longitudinally extending walls 1022 , 1024 and two arcuate end walls 1026 , 1028 connecting with the longitudinal walls.

- the arcuate end walls are generally semi-circular and have a diameter slightly larger than the diameter of a disc.

- circular discs A, B, C are supported in their rest positions in respective oblique planes relative to the housing floor 1020 a , 1020 b , 1020 c in each of three receiving areas 1030 , 1032 , 1034 with disc A partially overlapping disc B and disc B partially overlapping disc C, with the discs aligned along the longitudinal direction of the tray to form a row.

- Tray 1012 has a first disc receiving area 1030 formed therein extending from one arcuate end wall 1026 toward the median portion of the tray 1012 , including floor portion 1020 a , a second disc receiving area 1032 which is depressed from the first disc receiving area 1030 by virtue of an arcuate semi-circular downward step 1036 in the floor positioned between the arcuate end walls 1026 , 1028 , and generally parallel to arcuate end wall 1026 , including floor portion 1020 b , and a third disc receiving area 1034 which is depressed from the second disc receiving area 1032 by virtue of an arcuate semi-circular downward step 1038 in the floor positioned between step 1036 and arcuate end wall 1028 , and generally parallel to arcuate end wall 1026 , including floor portion 1020 c .

- the length of floor 1020 c between the step 1038 and the opposite arcuate end wall 1028 represents the third disc receiving area 1034 and is approximately the diameter of a disc.

- Each of the floor portions 1020 a , 1020 b , 1020 c defines a generally triangularly shaped aperture 1027 therein which is bisected by the longitudinal centerline of the tray CL-CL, includes two legs extending generally along arcuate wall portion 1026 or arcuate steps 1036 , 1038 , respectively, and a base extending perpendicular to the centerline of the tray and interconnecting the ends of the legs.

- the discs are supported within the tray 1012 in a uniformly spaced apart in the longitudinal direction arrangement.

- Each disc A, B, C is received within its respective disc receiving area 1030 , 1032 , 1034 with the lower peripheral edge of the disc supported, respectively, in one of the corner 1040 between the arcuate end wall 1026 and floor portion 1020 a and corners 1041 and 1043 , between the steps 1036 , 1038 and floor portions 1020 b , 1020 c , respectively.

- the discs extend obliquely upward, relative to the floor portions 1020 a , 1020 b , 1020 c , in the longitudinal direction.

- Disc C has its lower peripheral edge supported in corner 1043 and its upper peripheral edge supported along the upper peripheral edge of arcuate wall portion 1028 .

- a support means is provided to maintain disc C in an oblique position.

- the support means comprises a relatively short wall portion 1029 , which, desirably, is inclined downwardly from the top of the arcuate end wall 1028 into the recess 1016 .

- Disc B has its lower peripheral edge supported in corner 1041 and its upper peripheral edge rests upon the previous disc C, with disc B spaced longitudinally from disc C along the tray.

- Disc A has its lower peripheral edge supported in the corner 1040 defined between the arcuate end wall 1026 and floor portion 1020 a and its upper peripheral edge resting on the previous disc B, with disc A spaced longitudinally from disc B along the tray.

- each of discs A, B, C is supported obliquely above its underlying floor element 1020 a , 1020 b , 1020 c , and the discs are not parallel.

- the extent of the overlap between adjacent discs depends on the number of discs spaced along the housing and the length of the housing.

- Separator sheets 1042 , 1044 (see FIGS. 24 and 25 ), which are preferably formed from plastic but may also be formed from paper, extend from arcuate end wall 1026 and from step 1036 , respectively, toward arcuate end wall 1028 a sufficient distance to completely separate disc A from disc B and disc B from disc C, respectively.

- the separator sheets are generally circular in shape, approximately the diameter of a disc but are longer than the diameter of a disc by the length of floor 1020 a and 1020 b , which are desirably the same length.

- separator sheets 1042 , 1044 have an arcuate upper peripheral edge corresponding to arcuate end wall 1026 and arcuate step 1036 .

- separator sheet 1042 to be positioned in tray 1012 on floor portion 1020 a with one end adjacent arcuate end wall 1026 , yet be of sufficient length to be coextensive with disc B.

- separator sheet 1044 is positioned in tray 1012 on floor portion 1020 b with one end adjacent step 1036 , yet is of sufficient length to be coextensive with disc C in tray 1012 .

- Each of separator sheets 1042 , 1044 includes an arcuate cut-out 1045 formed in its upper periphery 1042 a , 1044 a , which is adjacent arcuate end wall 1026 and step 1036 , respectively, when the sheets are positioned on floor portions 1020 a , 1020 b .

- the separator sheets 1042 , 1044 each also include a pair of sideways extending ears 1052 , desirably, positioned on opposite sides of cut out 1045 and at equiangular distances of about 20° to 90° therefrom.

- Ears 1052 extend through slots 1054 in arcuate end wall 1026 and step 1036 and include an undercut portion 1056 to engage a wall at the end of each slot 1054 for mechanically locking the separator sheets 1042 , 1044 in position on floors 1020 a , 1020 b .

- Each separator sheet 1042 , 1044 has an opening flap feature 1046 , 1048 incorporated therein.

- a desirable opening flap feature 1046 , 1048 is formed by cutting through the separator sheet along a semi circle to define a generally arcuate flap 1050 (or through the separator sheet along three perpendicular sides to define a generally rectangular flap) such that a flap is formed in the sheets which is pivotable about a fold line 1053 .

- Flap 1050 is formed in separator sheets 1042 , 1044 at a position which corresponds with apertures 1027 in floor portions 1020 b , 1020 c so that, with the separator sheets in position against respective end wall 1026 and step 1034 , flap 1050 on each sheet extends downwardly into and through apertures 1027 .

- flap 1050 includes an intermediate fold line 1055 parallel to fold line 1053 and spaced between fold line 1053 and the free end 1058 of flap 1050 to permit flap 1050 to be folded along fold line 1055 so that the portion of flap 1050 between fold line 1055 and its free end 1058 generally underlies the floor of tray 1012 with the free end 1058 pointed generally toward arcuate end wall 1028 .

- the distance between fold lines 1053 , 1055 must be at least as long as the height of steps 1036 , 1038 .

- separator sheet 1044 defines with the underlying floor portion 1020 c a pouch-like enclosure for receiving disc C therein with the lower peripheral edge of disc C in contact with flap 1050 .

- separator sheet 1042 defines with separator sheet 1044 a pouch-like enclosure for receiving disc B therein with the lower peripheral edge of disc B in contact with flap 1050 .

- Disc A overlies separator sheet 1042 .

- Separator sheet arcuate cut outs 1045 in a lower separator sheet, for example separator sheet 1044 allows flap 1050 of upper separator sheet 1042 to be pressed through aperture 1027 in floor portion 1020 b without interference from separator sheet 1044 .

- discs are insertable into and removable from tray 1012 by sliding in the oblique direction corresponding with their rest positions in the tray.

- disc C may be removed by sliding it over inclined wall portion 1029 , which desirably is inclined at substantially the same oblique angle as disc C in the tray, in a direction toward arcuate end wall 1028 .

- disc C may be slid from its oblique rest position out from under separation sheet 1044 by exerting an obliquely-directed removal force to the disc without lifting the disc.

- disc B may be slid out from between separator sheet 1042 , 1044 and disc A may be slid out from on top of separator sheet 1042 .

- discs B, C must be slid out of their respective pouch-like enclosures (discs B, C) or along separator sheet 1134 (disc A) at least about 10 mm before they can be moved axially. Flaps 1050 prevent discs B, C from inadvertently sliding over floor portions 1020 a , 1020 b , respectively.

- a side wall detents 1060 extends into the recess 1016 from each of the opposite longitudinal peripheral walls 1022 , 1024 in each of disc receiving areas 1030 , 1032 , 1034 .

- the detents 1060 contact the edges of the discs A, B, C at longitudinal positions between the center of each disc and the peripheral edge thereof nearest arcuate end wall 1028 .

- Each of the detents 1060 comprises a tab 1062 projecting into the recess 1016 into contact with discs A, B, C from an adjacent depending segment 1064 of the peripheral longitudinal wall 1022 , 1024 .

- the wall segment 1064 is defined by a pair of longitudinally spaced apart vertical slits 1066 in the peripheral wall which extend from the floor 1020 a , 1020 b upwardly toward the planar surface 1014 and a horizontal slit 1068 separating the wall segment 1064 from floor 1020 a , 1020 b .

- the slits 1066 separate the segment 1064 from the remainder of the peripheral wall and, together with the slit 1068 , allow the depending segment 1064 to flex toward and away from the recess 1016 independent of the remainder of the peripheral wall.

- circumferentially spaced apart horizontal projections 1070 overlie and bear against the upper surface of disc A at its peripheral edges.

- three horizontal projections 1070 overlie and bear against the upper surface of disc A at its peripheral edges and extend from the arcuate end wall 1026 inwardly into recess 1016 .

- the projections 1070 are positioned a small distance above floor portion 1020 a and are equally spaced, preferably at approximately 90° intervals, about the arcuate end wall 1026 .

- end wall projection 1070 is positioned at the intersection of arcuate end wall 1026 and the centerline CL-CL of tray 1012 and the side wall projections 1070 are positioned at equal circumferential distances on either side of end wall projection 1070 and angularly spaced about 90° therefrom.

- disc A When disc A is inserted into tray 1012 , its lower peripheral edge and adjacent side edges are positioned in corner 1040 below the projections 1070 and its upper peripheral edge rests on disc B.

- the projections 1070 bear against the upper surface of disc A around its periphery in order to retain disc A against axial movement in the tray 1012 . Since disc A is the uppermost disc, retaining it against axial movement also prevents axial movement of discs B, C, which underlie disc A.

- the discs are insertable into and removable from tray 1012 by sliding in the oblique direction corresponding with their orientations in the tray.

- disc C may be removed by sliding it over inclined wall portion 1029 of arcuate end wall 1028 , which desirably is inclined at substantially the same oblique angle as disc C in the tray, in a direction toward arcuate end wall 1028 .

- Disc C may be slid from its oblique position in tray 1012 by exerting an obliquely-directed removal force to the disc without lifting the disc.

- discs A, B may be slid out from their position in tray 1012 . It is noteworthy that the discs must be slid at least 10 mm out of tray 1012 before they can be moved axially. It will be apparent that any of discs A, B, C can be slidably removed from tray 1012 without need for removing the other of the discs.

- the package enclosure 1080 of FIGS. 27-30 which preferably is formed from paper board but also may be formed from plastic, comprises a plurality of paper panels which are desirably formed from a presized, pre-printed unitary blank.

- the blank includes two panels 1082 , 1084 onto either of which a plastic tray 1012 is adhesively or mechanically attached separated by a spine panel 1086 .

- Fold lines 1088 , 1090 separate panels 1082 , 1084 , respectively, from spine panel 1086 and allow the panels to be pivoted between package open ( FIG. 27, 28 ) and package closed ( FIG. 29, 30 ) positions.

- the panels, if paper, may be single ply although, in some instances, it may be desirable for one or both of these panels to be two or multiple ply.

- Appropriate latching means (not shown), which are well known in the field, may be used if it is desired to latch the package 1010 in the closed position.

- discs A ,B, C are positioned in tray 1012 such that their upper peripheral edges are at substantially the same height and trays 1012 are dimensioned in such a manner that the upper peripheral edges of discs A, B, C project a small distance above planar surface 1014 . This facilitates locking the discs in the tray during storage, shipping and handling.

- cover 1082 of paperboard 1080 locks discs A, B in the tray 1012 by providing three vertically spaced apart pockets 1100 , 1102 , 1104 in the inward facing panel 1083 of cover 1082 , which pockets 1100 , 1102 , 1104 are positioned and oriented to receive the upper peripheral edges of discs A, B, C respectively, protruding above the planar surface 1014 of tray 1012 .

- discs A, B, C are locked between the corners 1040 , 1041 , 1043 supporting the lower peripheral edges of the discs and pockets 1100 , 1102 , 1104 in cover panel 1083 supporting the upper peripheral edges of the discs.

- trays 1012 are dimensioned in such a manner that the upper peripheral edges of discs A and B are substantially flush with planar surface 1014 .

- cover 1082 of paperboard 1080 locks discs A, B, C in the tray 1012 by providing cover mounted features which project from panel 1083 of cover 1082 into recess 1016 proximate the upper peripheral edges of discs A, B, C.

- cover mounted features may be three vertically spaced apart ribs 1106 , 1108 , 1110 positioned and oriented to abut or proximately abut the upper peripheral edges of discs A, B, C or other cover mounted or cover embossed features which project from panel 1083 into recess 1016 to lock discs A, B, C in tray 1012 .

- the discs A, B, C in a single tray 1012 are locked in place when cover 1082 is closed.

- the opening of the cover 1082 releases the discs in tray 1012 .

- the reverse is true when closing package 1010 .

- the discs in the tray 1012 are once again locked in position.

- the discs are securely held in the tray 1012 , but not locked therein, when the user can directly view and touch the discs in a facing tray.

- FIGS. 31-45 Still additional preferred embodiments of the present invention are illustrated in FIGS. 31-45 , in which there is shown an improved CD package 2010 for housing two discs.

- the package comprises a planar tray 2012 which is generally rectangular, elongate and flat and includes an upper planar surface 2014 having an elongate, generally rectangular-shaped, with arcuate end portions, recess 2016 formed therein along substantially its entire width and length.

- the recess 2016 defines a disc receiving housing which has a peripheral wall 2018 extending between a housing floor 2020 a , 2020 b and the upper planar surface 2014 of the tray 2012 .

- the housing peripheral wall 2018 comprises two elongate, longitudinally extending walls 2022 , 2024 and two arcuate end walls 2026 , 2028 connecting with the longitudinal walls.

- the arcuate end walls are generally semi-circular and have a diameter slightly larger than the diameter of a disc.

- a flange or skirt 2029 depends from the periphery of planar surface 2014 with the lower edges of skirt 2029 generally flush with the lowermost floor 2020 b.

- circular discs A, B are supported in their rest positions in respective oblique planes relative to the housing floor 2020 a , 2020 b in each of two receiving areas 2030 , 2032 with disc A partially overlapping disc B and aligned along the longitudinal direction of the tray to form a row.

- Tray 2012 has a first disc receiving area 2030 formed therein extending from one peripheral arcuate end wall 2026 toward the median portion of the tray 2012 , including floor portion 2020 a , and a second disc receiving area 2032 which is depressed from the first disc receiving area 2030 by virtue of an arcuate semi-circular downward step 2034 in the floor positioned between the arcuate end walls 2026 , 2028 , and generally parallel to arcuate end wall 2026 .

- the length of floor 2020 b between the step 2034 and the opposite peripheral arcuate end wall 2028 represents the second disc receiving area 2032 and is approximately the diameter of a disc.

- the discs are supported within the tray 2012 in a uniformly spaced apart in the longitudinal direction arrangement.

- one lower peripheral edge of disc B is supported in the corner 2040 defined between the step 2034 and the floor 2020 b , and extends obliquely upward, relative to the floor 2020 b , in the longitudinal direction with its upper peripheral edge adjacent the opposite transverse wall 2028 .

- the lower peripheral edge of disc B rests on nub 2044 which protrudes upwardly from floor 2020 b and into recess 2016 from a location on step 2034 where step 2034 intersects the centerline CL-CL of tray 2012 .

- nubs 2046 which protrude upwardly from floor 2020 b and into recess 2016 from locations on the peripheral wall which are, desirably, equiangularly spaced on either side of nub 2044 , preferably by about 90°.

- nub 2044 protrudes a smaller distance above floor 2020 b than do nubs 2046 , which desirably are the same height.

- Disc A is, desirably, supported generally parallel to disc B and is spaced longitudinally therefrom along the housing with the lower peripheral edge of disc A supported in the corner 2042 defined between the one peripheral arcuate end wall 2026 and the floor 2020 a .

- nubs 2048 which protrude upwardly from floor 2020 a and into recess 2016 from locations on the peripheral wall, which are equiangularly spaced, desirably by about 90°, from nubs 2050 .

- Nubs 2050 protrude upwardly from floor 2020 a and into recess 2016 from locations on arcuate end wall 2026 and are spaced apart on opposite sides of end projection 2070 , as will be described more fully hereinafter.

- nubs 2050 which are the same height, protrude a smaller distance above floor 2020 a than do nubs 2046 , which desirably are the same height.

- disc A is supported obliquely above its underlying floor element 2020 a , the discs are generally parallel and disc A partially overlaps disc B with the extent of the overlap between adjacent discs depending on the number of discs spaced along the housing and the length of the housing.

- two side wall detents 2060 extend into the recess 2016 from each of the opposite longitudinal peripheral walls 2022 , 2024 in each of disc receiving areas 2030 , 2032 .

- the detents 2060 contact the edges of the discs A, B at longitudinal positions between the center of each disc and the peripheral edge thereof nearest arcuate end wall 2028 .

- Each of the detents 2060 comprises a tab 2062 projecting into the recess 2016 into contact with discs A, B from an adjacent depending segment 2064 of the peripheral longitudinal wall 2022 , 2024 .

- the wall segment 2064 is defined by a pair of longitudinally spaced apart vertical slits 2066 in the peripheral wall which extend from the floor 2020 a , 2020 b upwardly toward the planar surface 2014 and a horizontal slit 2068 separating the wall segment 2064 from floor 2020 a , 2020 b .

- the slits 2066 separate the segment 2064 from the remainder of the peripheral wall and, together with the slit 2068 , allow the depending segment 2064 to flex toward and away from the recess 2016 independent of the remainder of the peripheral wall.

- circumferentially spaced apart horizontal projections 2070 overlie and bear against the upper surface of discs A, B at their peripheral edges. Desirably, three horizontal projections 2070 overlie and bear against the upper surface of disc A at its peripheral edges and extend from the arcuate end wall 2026 inwardly into recess 2016 .

- the projections 2070 are positioned a small distance above floor portion 2020 a and are equally spaced, preferably at approximately 90° intervals, about the arcuate end wall 2026 .

- end wall projection 2070 is positioned at the intersection of arcuate end wall 2026 and the centerline CL-CL of tray 2012 and the side wall projections 2070 are positioned at equal circumferential distances on either side of end wall projection 2070 and angularly spaced about 90° therefrom.

- disc A When disc A is inserted into tray 2012 , its lower peripheral edge and adjacent side edges are positioned in corner 2042 on nubs 2050 below the projections 2070 and its side edges rest on nubs 2048 to space disc A from disc B and orient it generally parallel thereto.

- the projections 2070 bear against the upper surface of disc A around its periphery in order to retain disc A against axial movement in the tray 2012 .

- two horizontal projections 2070 desirably overlie and bear against the upper surface of disc B at its peripheral edges and extend from opposite longitudinal walls 2022 , 2024 inwardly into recess 2016 .

- disc B When disc B is inserted into tray 2012 , its lower peripheral edge is positioned in corner 2040 on nub 2044 with its side edges resting on nubs 2046 and below the projections 2070 .

- the projections 2070 bear against the upper surface of disc B at its side edges in order to retain disc B against axial movement in the tray 2012 .

- the discs are insertable into and removable from tray 2012 by sliding in the oblique direction corresponding with their orientations in the tray.

- disc B may be removed by sliding it over inclined wall portion 2052 of arcuate end wall 2028 , which desirably is inclined at substantially the same oblique angle as disc B in the tray, in a direction toward arcuate end wall 2028 .

- Disc B may be slid from its oblique position in tray 2012 by exerting an obliquely-directed removal force to the disc without lifting the disc.

- disc A may be slid out from its position in tray 2012 .

- discs must be slid at least 5 mm, preferably at least 10 mm, out of tray 2012 to clear overlying projections 2070 before they can be moved axially. It will be apparent that either of discs A, B can be slidably removed from tray 2012 without need for removing the other of the discs.

- the paper board 2080 of FIGS. 35-45 comprises a plurality of paper panels which are desirably formed from a presized, pre-printed unitary blank.

- the blank includes two panels 2082 , 2084 onto either of which a plastic tray 2012 (with, optionally, additional plastic trays stacked thereon, as will be described more fully hereinafter), is adhesively or mechanically attached, separated by a spine panel 2086 .

- Fold lines 2088 , 2090 separate panels 2082 , 2084 , respectively, from spine panel 2086 and allow the panels to be pivoted between package open ( FIG. 36 ) and package closed ( FIG. 35 ) positions.

- the panels may be single ply although, in some instances, it may be desirable for one or both of these panels to be two or multiple ply.

- Appropriate latching means (not shown), which are well known in the field, may be used if it is desired to latch the package 2010 in the closed position.

- the trays 2012 may be used singly or arranged in a stack together with the paperboard 2080 to form the package of the present invention. Most preferably, a single tray 2012 or bottom tray of a stack of trays 2012 is adhesively adhered to panels 2084 serving as the base panel with the other panel 2082 serving as the cover panel. As shown in FIGS. 35-41 , when the trays are arranged in a stack, they are hinged to each other by a flexible hinge member 2092 that is affixed to one side of the stack of trays, such as along one of the longitudinal edges.

- the hinged member 2092 may be fabricated, as is well known, from a suitable material, such as a styrene-based film or tape, polyethylene, polypropylene, or the like.

- the hinge member 2092 may be fabricated from a strip of commercially available poly tape.

- the hinge member 2092 must be flexible enough to allow the stack of trays to be opened and closed freely, as by pivoting the upper tray, and each succeeding tray, in order, about the flexible hinge.

- the hinge member 2092 must be strong enough to prevent premature failure of the hinge member or separation of the hinge member from trays in the stack.

- the hinge member 2092 may be affixed to the trays using an adhesive, or using a mechanical technique, including techniques using ultrasound or heat.

- discs A and B are positioned in tray 2012 such that their upper peripheral edges are at substantially the same height and trays 2012 are dimensioned in such a manner that the upper peripheral edges of discs A and B project a small distance above planar surface 2014 .

- cover 2082 of paperboard 2080 locks discs A, B in the single tray or uppermost tray in a stack by providing a pair of pockets 2100 , 2102 in the inward facing panel 2083 of cover 2082 , which pockets 2100 , 2102 are positioned and oriented to receive the upper peripheral edges of discs A, B, respectively, protruding above the planar surface 2014 of tray 2012 .

- discs A, B are locked between the corners 2040 , 2042 supporting the lower peripheral edges of the discs and pockets 2100 , 2102 in cover panel 2083 supporting the upper peripheral edges of the discs.

- trays 2012 are dimensioned in such a manner that the upper peripheral edges of discs A and B are substantially flush with planar surface 2014 .

- cover 2082 of paperboard 2080 locks discs A, B in the single tray or uppermost tray in a stack by providing cover mounted features which project from panel 2083 of cover 2082 into recess 2016 proximate the upper peripheral edges of discs A, B.

- cover mounted features may be ribs 2108 , 2110 positioned and oriented to abut or proximately abut the upper peripheral edges of discs A, B, or other cover mounted or cover embossed features which project from panel 2083 into recess 2016 to lock discs A, B in tray 2012 .

- each tray 2012 includes a transversely elongate, desirably, generally oval shaped, aperture 2104 extending through floor 2020 b .

- the aperture 2104 is positioned and oriented in floor 2020 b to receive the upper peripheral edge of disc A which protrudes above the planar surface of the immediately lower tray in the stack.

- each tray 2012 includes a rib 2106 (see FIG. 32 ) which depends from the underside of floor 2020 b of the tray at about the area of inclined wall portion 2052 and is adjacent peripheral skirt 2029 .

- discs A, B in a tray 2012 are locked in position between the corners 2040 , 2042 supporting the lower peripheral edges of the discs and aperture 2104 and rib 2106 , respectively, constraining the upper peripheral edges of the discs.

- the discs A, B in a single tray or the top tray in a stack are locked in place when cover 2082 is closed.

- Discs A, B in other than the top tray in a stack of trays are locked in place when the package 2010 is in the closed position with each tray in a stack adjacent to the trays above and below it.

- the opening of the cover 2082 releases the discs in the top tray and pivoting the trays in the stack about hinge member 2092 releases, in turn, the discs in each tray.

- the reverse is true when closing package 2010 .

- the discs in the trays are once again locked in position.

- the discs are securely held in the tray 2012 , but not locked therein, when the user can directly view and touch the discs in a facing tray.

Landscapes

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Packaging For Recording Disks (AREA)

Abstract

Packages are disclosed for storing multiple disc-like recording media in trays having optional pouch-type holders, and with means for retaining the media within the trays.

Description

- This application claims the benefit of priority under 35 U.S.C. § 119(e) of provisional application Ser. Nos. 60/691,356, filed on Jun. 17, 2005, 60/693,563, filed on Jun. 24, 2005, and 60/694,421, filed on Jun. 27, 2005.

- 1. Field of the Invention

- The present invention relates generally to a package for storing multiple disc-like recording media and, more particularly, to a closable package comprising at least one plastic tray supporting multiple discs, optionally in pouch-type holders and locking means for retaining the discs in the tray(s).

- 2. Description of the Prior Art

- Various types of planar discs are in use at the present time to record and store information which is to be retrieved by various means, such as by optical or magnetic means. Typical of such discs are compact discs in which information is digitally recorded by use of a laser beam and then read optically by a laser beam. Such discs are used to record audio information, such as musical renditions, video information such as visual images and digital information for use as read only and other memories for use in various applications, such as computer applications. In most instances, at the present time, such discs are sold with information already recorded thereon. In other applications, such discs are sold in blank form and are used by the customer to record information thereon. In the latter case, for example, optical discs are sold for use as computer storage media and are used in hard disc storage systems. As used herein, the term compact disc, CD or disc is intended to encompass all such discs and disc-shaped packaging, e.g., for pharmaceuticals or cosmetics, whatever their size, for all known or proposed uses.

- Compact discs containing laser recorded information are typically packaged in injection molded plastic enclosures designed to hold one or more CDs for protecting the discs during storage and shipment. Enclosures commonly used at the present time, such as the well known “jewel box,” comprise a three piece assembly consisting of a base or bottom element, an insert or tray in the base/bottom element for positioning and supporting the disc in the base/bottom element, e.g., by a center projection (commonly referred to as a “rosette”) which engages the periphery of the aperture in the center of the disc, and a lid or cover which is hinged to the base/bottom element and is closed thereon after the disc is mounted therein on the tray. Other enclosures utilize only two pieces, omit the tray, and position and support the disc via the center projection directly on the base/bottom element. The enclosure is, typically, at least partially transparent and graphics relating to the disc and containing trademark and sales promotional information are usually inserted in such a manner as to be visible through the enclosure.

- Except for the printed matter inserted therein, the “jewel box” is entirely plastic. For this reason, as well as because the typical jewel box requires three separately injection molded elements which must be manually assembled, the use of this type of enclosure is relatively expensive. Moreover, the use of such an enclosure is believed to be ecologically unacceptable by many because the plastic is non-biodegradable and, in view of the huge volume of such enclosures in use today, the disposal of these enclosures poses either a real or potential environmental problem. One solution to both of these problems has been the development of hybrid packages comprising both paper board and plastic components. These hybrid packages provide a CD package which is suitable and attractive for display, sale and storage of compact discs, yet which is both simple and inexpensive to manufacture.

- For example, U.S. Pat. No. 4,709,812—Kosterka discloses a compact disc package formed from a prescored, preprinted unitary blank and at least one injection molded plastic compact disc holder or tray adhesively adhered to one segment of the blank, the blank being adapted to fold along fold lines to position a blank segment over the top of the disc holder to sandwich it, in book style, between the segment to which it is adhered and the overlying segment.

- When it is desired to have a disc package house multiple discs, it has become common to form a book like package having opposite panels connected by a spine panel and to adhesively or mechanically adhere an injection molded plastic disc holder or tray to each of the facing panels. In this manner, when the book is closed, the trays seat upon one another in face-to-face relationship. Typically the height of upstanding peripheral rims around at least a portion of at least one of the trays limits the thickness of the book when the book is in the closed position to assure that the discs on the panels do not contact each other. The problem with this sort of arrangement is that the thickness of each tray doubles the thickness of the package as compared to a package containing only a single disc holder. Such a double thickness package occupies more retail space than is desirable and is wasteful of plastic material. More recently, only a single plastic tray has been used which is capable of receiving a plurality of discs. This type of package is illustrated in U.S. Pat. No. 5,743,390—Pozzoli, which discloses a plastic tray having first and second accommodation regions, each region capable of receiving up to two discs.

- Efforts to date directed at plastic trays used in hybrid packaging which are capable of receiving more than two discs suffer from one or more shortcomings which make the resulting CD packaging unsatisfactory. This is because prior art hybrid packaging is, typically, either uneconomical to manufacture and/or is expensive to transport, store and display in retail stores. Accordingly, there remains a need for a simple, inexpensive to manufacture, inexpensive to ship and display multiple-disc hybrid CD package which is reliable for use over the long term.

-

FIG. 1 is a top perspective view, of an improved tray of a CD package of the present invention, with disc-receiving pouches not shown. -

FIG. 2 is a perspective view of the improved tray ofFIG. 1 taken along a vertical plane passing longitudinally through the tray. -

FIG. 3 is a top perspective view of the improved tray ofFIG. 1 showing two disc-receiving pouches pivoted to form acute angles with the floor of the tray. -

FIG. 4 is a top perspective view of the improved tray ofFIG. 1 with two disc-containing pouches lying in their rest positions in the tray. -

FIG. 5 is another perspective view of the improved tray ofFIG. 1 , including two disc-containing pouches lying in their rest positions in the tray, taken along a vertical plane passing longitudinally through the tray. -

FIG. 6 is top perspective view of the tray ofFIG. 1 , with two pouches pivoted to form acute angles with the floor of the tray, one pouch containing a disc and the other having a disc ready for insertion therein. -

FIG. 7 is a top perspective view of the tray ofFIG. 1 containing four disc-receiving pouches, three of which have been pivoted from their rest positions. -

FIG. 8 is a perspective view of the tray ofFIG. 7 taken along a vertical plane passing longitudinally through the tray. -

FIG. 9 is another top perspective view of the tray ofFIG. 7 containing four disc-containing pouches. -

FIG. 10 is still another top perspective view of the tray ofFIG. 7 containing four disc-containing pouches, the uppermost of which is pivoted to form an acute angle with the floor of the tray. -

FIG. 11 is yet another top perspective view of the tray ofFIG. 7 containing four disc-containing pouches. -

FIG. 12 is a perspective view of the improved tray ofFIG. 1 mounted on one panel of a book-like package. -

FIG. 13 is a top perspective view of another embodiment of the tray of the present invention. -

FIG. 14 is another top perspective view of the tray ofFIG. 13 including disc separator sheets. -

FIG. 15 is another top perspective view of the tray ofFIG. 13 containing three discs arranged spaced apart in the longitudinal direction and overlapping. -

FIG. 16 is another top perspective view of the tray ofFIG. 13 containing two discs arranged spaced apart in the longitudinal direction and overlapping. -

FIG. 17 is a perspective view of the improved tray ofFIG. 13 taken along a vertical plane passing longitudinally through the tray. -

FIG. 18 is a perspective view of the improved tray ofFIG. 13 mounted on one panel of a book-like package. -

FIG. 19 is a top perspective view of another embodiment of the improved tray ofFIG. 13 which utilizes pivotable latching wings to prevent unwanted axial movement of the discs out of the tray. -

FIG. 20 is a top perspective view of an improved tray of another package of the present invention. -

FIG. 21 is a bottom perspective view of the improved tray ofFIG. 20 . -

FIG. 22 is a top perspective view of the tray ofFIG. 20 having discs A, B and C stored therein. -

FIG. 23 is another perspective view of the improved tray ofFIG. 20 . -

FIG. 24 is a bottom perspective view of the sheet separators forming part of the pouch-type disc holders of the tray shown inFIG. 21 . -

FIG. 25 is a bottom perspective view of the tray of the sheet separators shown inFIG. 24 interleaved between discs A, B and C. -

FIG. 26 is a partial perspective view of the tray ofFIG. 20 taken along a vertical plane passing longitudinally through the tray. -

FIG. 27 is a perspective view of a package of the present invention with the cover panel open and three discs stored in the tray ofFIG. 20 and showing one form of cover locking means for the discs in the tray. -

FIG. 28 is a perspective view of a package of the present invention with the cover panel open and three discs stored in the tray ofFIG. 20 and showing another form of cover locking means for the discs in the tray. -

FIG. 29 is a perspective view of the package ofFIG. 28 in the closed position taken along the longitudinal center line of the tray. -

FIG. 30 is a top perspective view of the package ofFIG. 28 taken along a vertical plane passing longitudinally through the package. -

FIG. 31 is a top perspective view of an improved tray of another package of the present invention. -

FIG. 32 is a bottom perspective view of the improved tray ofFIG. 31 . -

FIG. 33 is a top perspective view of the tray ofFIG. 31 taken along a vertical plane passing longitudinally through the tray. -

FIG. 34 is a top plan view of the tray ofFIG. 31 . -

FIG. 35 is a perspective view of a package of the present invention in the closed position, comprising a stack of the improved trays ofFIG. 31 enclosed on three sides by paperboard cover and base panels connected by a spine panel. -

FIG. 36 is a top perspective view of the package ofFIG. 34 with the cover panel open and two discs stored in the uppermost tray and showing one form of cover locking means for the discs in the top tray. -

FIG. 37 is a perspective view of the package ofFIG. 36 with the cover panel and the trays fanned out showing discs mounted in the trays. -

FIG. 38 is a perspective view of the package ofFIG. 36 showing the undersides of two of the trays. -

FIG. 39 is a perspective view of the package ofFIG. 36 taken along a vertical plane passing longitudinally through the package. -

FIG. 40 is an enlarged perspective view of one side of the package as viewed inFIG. 39 . -

FIG. 41 is a top perspective view of the package ofFIG. 34 with the cover panel open and two discs stored in the uppermost tray and showing another form of cover locking means for the discs in the top tray. -

FIG. 42 is a sectional view through the centerline of a single tray embodiment of the package of the present invention. -

FIG. 43 is an enlarged sectional view of one side of the package as viewed inFIG. 42 . -

FIG. 44 is a top perspective view of a single tray embodiment of the package of the present invention taken along a vertical plane passing longitudinally through the package. -

FIG. 45 is a perspective view showing how a disc may be inserted or removed from one tray within the package ofFIG. 36 . - A preferred embodiment of the present invention is illustrated in

FIGS. 1-11 , in which there is shown a tray for animproved CD package 10 for housing two or more discs. The package comprises aplanar tray 12 which is generally rectangular, elongate and flat and includes an upperplanar surface 14 having an elongate, generally rectangular-shapedrecess 16 formed therein along substantially its entire width and length. Therecess 16 defines a disc receiving housing which has aperipheral wall 18 extending between ahousing floor planar surface 14 of thetray 12. The housingperipheral wall 18 comprises two elongate, longitudinally extendingwalls transverse walls FIGS. 1-6 , circular discs A, B are supported in their rest positions in respective oblique planes relative to thehousing floor areas Tray 12 has a firstdisc receiving area 30 formed therein extending from one transverseperipheral wall 26 toward the median portion of thetray 12, includingfloor portion 20 a, and a seconddisc receiving area 32 which is depressed from the firstdisc receiving area 30 by virtue of a transversely extendingdownward step 34 in the floor positioned between and generally parallel to the transverseperipheral walls floor 20 b between thestep 34 and the opposite transverseperipheral wall 28 represents the seconddisc receiving area 32 and is approximately the diameter of a disc. - The discs are supported within the

tray 12 in a uniformly spaced apart in the longitudinal direction arrangement. As can be seen inFIG. 3 , each disc is received within apouch transverse end notch plastic pouch transverse end pouch FIG. 5 , one lowerperipheral edge 42 b of thepouch 42 containing disc B is hingedly connected in thecorner 48 defined between thestep 34 and thefloor 20 b, and extends obliquely upward, relative to thefloor 20 b, in the longitudinal direction with its upper peripheral edge substantially flush with the upperplanar surface 14 of thetray 12 and adjacent the oppositetransverse wall 28. Disc A rests upon the previous disc B and is spaced longitudinally therefrom along the housing with the lowerperipheral edge 40 b of itspouch 40 hingedly connected in thecorner 50 defined between the one transverseperipheral wall 26 and thefloor 20 a and the upper peripheral edge of the pouch resting on the previous disc B. Thus, disc A is supported obliquely above itsunderlying floor element 20 a, and the discs are not parallel. - A support means is provided to maintain disc B in an oblique position. The support means comprises a relatively

short wall portion 52, which may be inclined downwardly from the top of the opposite peripheraltransverse wall 28 into therecess 16. Thus disc B is supported in an oblique plane abovefloor portion 20 b between the upper peripheral edge of the wall portion and thecorner 48 defined between thestep 34 and thefloor portion 20 b. The disc A partially overlaps and rests upon the immediately preceding disc B. The extent of the overlap between adjacent discs depends on the number of discs spaced along the housing and the length of the housing. - The lower

peripheral edges corners Tabs 54 extend into therecess 16 from the longitudinalperipheral walls pouches tray 12.Notches 56 are formed in thepouch walls tabs 54. In order to remove a disc from a pouch, the pouch is pivoted upwardly about its lowerperipheral edge tray 12 that it can be easily grasped at the V-notch and slid out of the pouch in a direction parallel to thepouch walls - In a four-disc embodiment, shown in

FIGS. 7-11 , the structure oftray 12 remains the same as in the two-disc embodiment. Therefore, like parts are represented by like reference numerals. The only difference is that in the four-disc embodiment, there are twopouches peripheral edges corners pouches pouches tray 12. At the same time, coaxial discs A, C partially overlie coaxial discs B, D when the pouches lie in their rest positions intray 12. In an alternative form of the invention, not shown, only two pouches are needed and each is two-sided and can hold two discs arranged coaxially with respect to each other. Each disc is received on one side of the two sided plastic pouch, which comprises, in one form, three generally rectangular plastic sheets sealed along three sides and open only at the upper transverse side. Discs are inserted into the two openings along the upper peripheral edge of each of the pouches on either side or both sides of the center sheet. Desirably, a V-shaped notch is formed in each of the outer sheets of each plastic pouch, communicating with the open transverse side, to facilitate grasping a disc in the pouch for purposes of its removal from the pouch. It will, of course, be appreciated, that the four-disc embodiment of this invention can be used for storing three discs as well, e.g., by omitting one of the pouches in the four pouch embodiment or by leaving one pouch pocket empty in the two-sided pouch embodiment. - The

paper board 80 ofFIG. 12 comprises a plurality of paper panels which are desirably formed from a presized, pre-printed unitary blank. In one embodiment of the invention, the blank includes twopanels plastic tray 12 is adhesively or mechanically attached, separated by aspine panel 86. Foldlines separate panels spine panel 86 and allow the panels to be pivoted between package open and package closed positions. The panels may be single ply although, in some instances, it may be desirable for one or both of these panels to be two or multiple ply. - Another embodiment of the present invention is illustrated in

FIGS. 13-18 , in which there is shown anotherimproved CD package 100 for housing two or more discs. The package comprises aplanar tray 102 which is generally rectangular, elongate and flat and includes an upperplanar surface 104 having an elongate, generally rectangular-shaped, with arcuate end portions,recess 106 formed therein along substantially its entire width and length. The recess defines a disc receiving housing which has aperipheral wall 108 extending between ahousing floor planar surface 104 of thetray 102. The housingperipheral wall 108 comprises two elongate, longitudinally extendingwalls arcuate end walls housing floor areas -

Tray 102 has a firstdisc receiving area 120 formed therein extending from onearcuate end wall 116 toward the median portion of thetray 102, includingfloor portion 110 a, a seconddisc receiving area 122 which is depressed from the firstdisc receiving area 120 by virtue of an arcuate semi-circulardownward step 126 in the floor positioned between thearcuate end walls arcuate end wall 116, includingfloor portion 110 b, and a thirddisc receiving area 124 which is depressed from the seconddisc receiving area 122 by virtue of an arcuate semi-circulardownward step 128 in the floor positioned betweenstep 126 andarcuate end wall 118, and generally parallel toarcuate end wall 116, includingfloor portion 110 c. The length offloor 110 c between thestep 128 and the oppositearcuate end wall 118 represents the thirddisc receiving area 124 and is approximately the diameter of a disc. - The discs are supported within the

tray 102 in a uniformly spaced apart in the longitudinal direction arrangement. Each disc A, B, C is received within its respectivedisc receiving area corner 130 between thearcuate end wall 116 andfloor portion 110 a andcorners steps floor portions floor portions planar surface 104 of thetray 102. Disc C has its lower peripheral edge supported incorner 133 and its upper peripheral edge supported along the upper peripheral edge ofarcuate wall portion 118. A support means is provided to maintain disc C in an oblique position. The support means comprises a relativelyshort wall portion 117, which, desirably, is inclined downwardly from the top of thearcuate end wall 118 into therecess 106. Disc B has its lower peripheral edge supported incorner 131 and its upper peripheral edge rests upon the previous disc C, with disc B spaced longitudinally from disc C along the housing. Disc A has its lower peripheral edge supported in thecorner 130 defined between thearcuate end wall 116 andfloor portion 110 a and its upper peripheral edge resting on the previous disc B, with disc A spaced longitudinally from disc B along the housing. Thus, each of discs A, B, C is supported obliquely above itsunderlying floor element -