US20040007296A1 - Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization - Google Patents

Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization Download PDFInfo

- Publication number

- US20040007296A1 US20040007296A1 US10/618,054 US61805403A US2004007296A1 US 20040007296 A1 US20040007296 A1 US 20040007296A1 US 61805403 A US61805403 A US 61805403A US 2004007296 A1 US2004007296 A1 US 2004007296A1

- Authority

- US

- United States

- Prior art keywords

- single crystal

- superalloy

- casting

- weight

- cast

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

- C22C19/05—Alloys based on nickel or cobalt based on nickel with chromium

- C22C19/051—Alloys based on nickel or cobalt based on nickel with chromium and Mo or W

- C22C19/057—Alloys based on nickel or cobalt based on nickel with chromium and Mo or W with the maximum Cr content being less 10%

Definitions

- the present invention relates to nickel base superalloy castings and, more particularly, to a method of making single crystal superalloy castings in a manner to reduce deleterious as-cast eutectic/secondary phase scale and extraneous grain recrystallization during heat treatment.

- U.S. Pat. No. 4,643,782 describes single crystal castings made from a nickel base superalloy having a composition consisting essentially of, in weight %, of 6.4% to 6.8% Cr, 9.3% to 10.0% Co, 0.5% to 0.7% Mo, 6.2% to 6.6% W, 6.3% to 6.7% Ta, 5.45% to 5.75% Al, 0.8% to 1.2% Ti, 2.8% to 3.2% Re, 0.07 to 0.12% Hf and balance essentially nickel. Carbon is held to 60 ppm maximum in the patented alloy.

- U.S. Pat. No. 5,759,301 describes single crystal castings made from a nickel base superalloy having a composition consisting essentially of, in weight %, of 6.0% to 6.8% Cr, 8.0% to 10.0% Co, 0.5% to 0.7% Mo, 6.2% to 6.6% W, 6.3% to 7.0% Ta, 5.4% to 5.8% Al, 0.6% to 1.2% Ti, 2.7% to 3.2% Re, 0.15% to 0.3% Hf, 0.02% to 0.04% C, 40 ppm to 100 ppm B, 15 ppm to 50 ppm Mg and balance essentially nickel wherein the alloying elements C, B, Hf, and Mg are said to have a beneficial effect on small angle grain boundaries.

- U.S. Pat. No. 5,549,765 describes addition of carbon to a nickel base superalloy including the alloy of the first-discussed patent above to reduce the amount of non-metallic inclusions (e.g. oxide inclusions) in the microstructure of single crystal investment castings produced therefrom.

- non-metallic inclusions e.g. oxide inclusions

- the scale was extensively present on the as-cast airfoil surfaces of the single crystal castings, occurring over as much as 80% of the airfoil surface.

- the presence of the scale rendered the castings unacceptable for use and required a post-cast abrasive belt or other mechanical finishing operation to remove the scale.

- the present invention provides a method of making of superalloy single crystal airfoil castings, such as gas turbine engine single crystal blades and vanes, that suffer from the problem of solidification-driven scale formation in the as-cast condition and extraneous recrystallized grains in the heat treated condition.

- the present invention involves the further discovery that the problem of formation of such surface scale on surfaces of as-cast single crystal nickel base superalloy castings can be reduced or prevented by increasing the carbon concentration of the superalloy beyond the specified alloy carbon level to this end.

- the present invention involves the additional discovery that the problem of formation of recrystallized grains after heat treatment of the single crystal castings also can be reduced or prevented by increasing the carbon concentration of the superalloy beyond the specified alloy carbon level to this end.

- the carbon concentration of the superalloy is increased to an amount effective to substantially reduce or eliminate (1) formation of the solidification-driven non-oxide scale on the surfaces of single crystal castings in the as-cast condition and (2) recrystallized grains in the heat treated condition.

- FIGS. 1A, 1B and 1 C are photographs of the airfoil regions of cast single crystal nickel base superalloy turbine blades after removal of a ceramic shell mold showing the effect of carbon level of the nickel base superalloy on the amount of metallic surface scale present on the airfoil surfaces after mold removal.

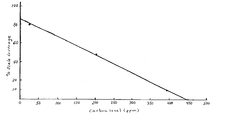

- FIG. 2 is a graph of the relationship of percent scale coverage of the casting surfaces versus carbon concentration of the nickel base superalloy.

- the present invention involves increasing the carbon concentration of nickel base superalloys formulated for single crystal casting in an amount discovered to unexpectedly and surprisingly substantially reduce or eliminate formation of the solidification-driven metallic as-cast scale discovered to be formed on the surfaces of single crystal castings of the superalloys under single crystal casting conditions and to unexpectedly and surprisingly eliminate recrystallized grains after heat treatment of the castings to develop mechanical properties.

- the present invention can be practiced with nickel base superalloys that are formulated for single crystal casting and include W, Ta, Mo, Co, Al and Cr as important alloying elements as well as optionally including Ti, Re, Hf, Y, one or more rare earth elements such as La, B, Mg and other intentional alloying elements and that suffer from the problem of solidification-driven scale formation in the as-cast condition and extraneous recrystallized grains in th heat treated condition.

- Particular nickel base superalloys which can be modified pursuant to the present invention to have increased carbon to this end include, but are not limited to, those described in U.S. Pat. Nos. 4,643,782, 5,759,301 and 5,366,695, the teachings of which are incorporated herein by reference with respect to particular alloy compositions.

- a particular nickel base superalloy casting composition modified in accordance with the present invention offered for purposes of illustration and not limitation consists essentially of, in weight %, of about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.05% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, balance essentially Ni and, C and castable to provide a single crystal microstructure, especially for gas turbine engine blades and vanes (i.e. airfoils).

- One embodiment includes about 0.05 to about 0.12 weight % Hf in the alloy composition, while another embodiment includes higher hafnium from about 0.15 to about 0.30 weight % Hf.

- the carbon concentration of the alloy composition is controlled to reduce or eliminate solidification-driven metallic scale formation in the as-cast condition and recrystallized grains after heat treatment of the castings to develop mechanical properties.

- These nickel base superalloys are modified in accordance with the invention to include increased carbon concentrations of greater than 0.04 weight %, more preferably from 0.04% to 0.1 weight % C.

- a high-Re nickel base superalloy which can be modified to benefit from practice of the invention consists essentially of, in weight %, about 1.5% to 5% Cr, about 1.5% to 10% Co, about 0.25% to 2% Mo, about 3.5% to 7.5% W, about 7% to 10% Ta, about 5% to 7% Al, 0 to about 1.2% Ti, about 5% to 7% Re, up to about 0.15% Hf, up to about 0.5% Nb, and balance essentially Ni and C.

- a high-Cr nickel base superalloy which can be modified to benefit from practice of the invention consists essentially of, in weight %, about 11% to 16% Cr, about 2% to 8% Co, about 0.2% to 2% Mo, about 3.5% to 7.5% W, about 4% to 6% Ta, about 3% to 6% Al, about 2 to about 5% Ti, up to about 0.5% Nb and balance essentially Ni and C.

- one such alloy has a nominal composition, in weight %, of 7% Cr, 8% Co, 2% Mo, 5% W, 7% Ta, 3% Re, 6.2% Al, 0.2% Hf and balance essentially Ni and C.

- Another such alloy has a nominal composition, in weight %, of 8% Cr, 5% Co, 2% Mo, 8% W, 6% Ta, 5.0% Al, 1.5% Ti, and balance essentially Ni and C. Still another such alloy has a nominal composition, in weight %, of 5% Cr, 10% Co, 2% Mo, 5% W, 3% Re, 8.5% Ta, 5.2% Al, 1.0% Ti, 0.1% Hf, and balance essentially Ni and C. Still a further such alloy has a nominal composition, in weight %, of 5% Cr, 10% Co, 2% Mo, 6% W, 3% Re, 9% Ta, 5.6% Al, 0.1% Hf and balance essentially Ni and C.

- the C concentrations of these superalloys can be intentionally increased above normal carbon impurity levels to an amount, for example only greater than 0.04 weight % C, effective to substantially reduce formation of an as-cast metallic scale when the alloy is cast as a single crystal.

- Heats #1, #2, and #3 having a nickel base superalloy composition in weight percents as set forth in Table I were prepared. TABLE I Heat Cr Co Mo W Ta Al Ti C Re Hf Ni #1 6.4 9.6 0.6 6.4 6.5 5.7 1.03 .0025 2.9 .10 balance #2 6.4 9.6 0.6 6.4 6.5 5.6 1.03 .02 2.9 .21 balance #3 6.3 9.5 0.6 6.5 6.5 5.7 1.0 .039 2.97 .10 balance

- each heat was made using conventional vacuum melting practice wherein carbon was controlled by small additions to the master alloy melt. Each heat was remelted and cast to form single crystal cored IGT blade castings having an airfoil region and a root r gion.

- the single crystal castings were produced using the conventional Bridgeman mold withdrawal directional solidification t chnique with a crystal selector passage (pigtail) to propagate a single crystal through the mold cavity. For example, each heat was melted in a crucible of a conventional casting furnace under a vacuum of less than 1 micron and superheated to 1482 degrees C. (2700 degrees F.).

- the superheated melt was poured into investment casting mold having a mold facecoat comprising zirconia backed by additional slurry/stucco layers comprising various forms of alumina and zirconia.

- Each mold cluster was preheated to 1510 degrees C. (2750 degrees F.) and mounted on a chill plate to effect unidirectional heat removal from the molten alloy in the mold.

- the melt-filled mold on the chill plate was withdrawn from the furnace into a solidification chamber of the casting furnace at a vacuum of 1 micron at a withdrawal rate of 2 to 12 inches per hour.

- the single crystal castings were cooled to room temperature and removed from the shell mold in conventional manner using a mechanical knock-out procedure, and then solution heat treated at 1310 degrees C. (2390 degrees F.) for 6 hours. After mold knock-out, the castings were observed visually for the presence of surface scale on th casting surfaces. After heat treatment, the castings were observed visually for the presence of recrystallize grains on the casting surfaces.

- FIGS. 1A, 1B, 1 C The results of casting tests with respect to scale coverage (dark areas) are illustrated in FIGS. 1A, 1B, 1 C.

- FIG. 1A wh re the alloy had a carbon level of 0.0025 w ight % C, approximately 80% of the as-cast airfoil surface of the single crystal casting after mold removal was cov red with a as-cast non-oxide scale discovered to include, among other constituents, one or more low melting point alloy eutectics and secondary alloy phases rich in one or more of such alloy elements as W, Ta, Re, Mo, Cr, Co, Ti and Hf and located predominantly at interdendritic areas of the microstructure proximate the casting surface.

- the as-cast scale included as constituents various TCP (topologically close packed) type phases including sigma phases found by TEM (transmission electron microscopy) to be rich in W, Ta, Re, Mo, Cr, Co with some to be rich in W, Ta, Re, Mo, Cr, Co, and Hf. Eutectic phases rich in titanium and tantalum also were present at some regions of the surface scale. Also present were spherical particles rich in Cr and Ni. Formation of the surface scale appeared to be solidification driven by segregation of alloying elements (solute segregation) and eutectic and phase reactions occurring during single crystal solidification.

- the as-cast eutectic/secondary phase surface scale had a widely variable thickness and was metallurgically bonded to the casting and very adherent, requiring a separate mechanical abrasive belt operation finishing to remove.

- the metallic scale is detrimental in that important alloying elements are depleted from the alloy proximate the metallic scale. Use of such mechanical methods to remove surface scale can cause rejection of castings due to the alteration of the dimensional and aerodynamic integrity of the airfoil.

- the as-cast scale can occur without or with the presence of oxide products, such as layers and/or particles, resulting from reaction between the shell mold and nickel base superalloy melt, corrosion of crucible and shell mold ceramics, and pull-out of ceramic particles from the shell mold. If the oxide products are present, they typically overlie the solidification-driven as-cast surface scale.

- the oxide products can comprise such oxides zirconium oxide, aluminum oxide and zirconium-aluminum-silicon oxide particles and layers depending upon the ceramic materials used in mold and crucible manufacture.

- FIG. 2 illustrates graphically the relationship between percent scale coverage (% of airfoil) versus the carbon content of the single crystal castings. From FIG. 2, it is apparent that carbon concentrations over 0.04 weight %, preferably from greater than 0.04 weight % to about 0.1 weight % C will eliminate or substantially reduce to less than 10% coverage of as-cast scale on the airfoil surfaces of the single crystal castings. The carbon content can be adjusted as necessary to achieve the benefits of the invention with respect to reduction or elimination of the as-cast surface scale for different nickel base superalloys.

- the higher alloy carbon concentration of Heat #3 appears to form alloy carbides, such as carbides of Ta and Ti as well as Mo, W, Hf, in th as-cast microstructure that reduce formation of the as-cast metallic scale and also reduce or localize recrystallized grains during heat treatment by virtue of pinning recrystallized grain boundaries and retarding their growth during heat treatment.

- the single crystal castings having a carbon lev 1 of 0.0025 weight % C were observed to have about 10% occurrence of recrystallized grains (i.e. 10 of the 100 single crystal castings having the carbon content of 0.0025 weight % C exhibited recrystallized grains to an extent to cause rejection of the casting pursuant to customer specifications).

- the single crystal castings having a carbon level of 0.02 weight % C were observed to have about 30% occurrence of recrystallized grains (i.e. 30 of the 100 sample single crystal castings exhibited recrystallized grains to an extent to cause rejection of the casting pursuant to customer specifications).

- alloy carbon concentration of 0.039 weight % none of the sample single crystal castings exhibited any visually observed recrystallized grains on the single crystal castings after the solution heat treatment.

- the invention envisions increasing carbon concentration of the nickel base superalloy to an amount effective to eliminate recrystallized grains on single crystal castings made therefrom.

- Alloy carbides such as carbides of Ta and Ti as well as Ni, Hf, Mo, W, are formed in the as-cast microstructure that appear to pin any recrystallized grain boundaries and retard and limit their growth during solution heat treatment.

- the present invention provides single crystal castings having carbon concentrations increased in an amount discovered to substantially reduce or eliminate formation of as-cast metallic scale on the surfaces of single crystal castings of the superalloys and recrystallized grains after solution heat treatment of the castings to develop mechanical properties.

- the present invention provides single crystal blade and vane (airfoils) castings which are substantially devoid of surface scale in the cast condition and recrystallized grains in the as solution heat treated condition.

- the present invention can be practiced in manufacture of myriad small and large sizes of airfoils, such large airfoils comprising large industrial gas turbine (IGT) blades which have a length of about 20 centimeters to about 60 centimeters and above, such as about 90 centimeters length, used throughout the stages of the turbine of stationary industrial gas turbine engines.

- IIGT industrial gas turbine

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Abstract

A single crystal casting is cast from a nickel base superalloy including Cr, Co, Mo, W, Ta, Al, Ti, Re and Hf as alloying elements with C increased effective to substantially reduce formation of a solidification-driven, as-cast eutectic/secondary phase scale metallurgically bonded to the casting when the alloy is cast as a single crystal and to reduce recrystallized grains when the casting is solution heat treated.

Description

- The present invention relates to nickel base superalloy castings and, more particularly, to a method of making single crystal superalloy castings in a manner to reduce deleterious as-cast eutectic/secondary phase scale and extraneous grain recrystallization during heat treatment.

- U.S. Pat. No. 4,643,782 describes single crystal castings made from a nickel base superalloy having a composition consisting essentially of, in weight %, of 6.4% to 6.8% Cr, 9.3% to 10.0% Co, 0.5% to 0.7% Mo, 6.2% to 6.6% W, 6.3% to 6.7% Ta, 5.45% to 5.75% Al, 0.8% to 1.2% Ti, 2.8% to 3.2% Re, 0.07 to 0.12% Hf and balance essentially nickel. Carbon is held to 60 ppm maximum in the patented alloy.

- U.S. Pat. No. 5,759,301 describes single crystal castings made from a nickel base superalloy having a composition consisting essentially of, in weight %, of 6.0% to 6.8% Cr, 8.0% to 10.0% Co, 0.5% to 0.7% Mo, 6.2% to 6.6% W, 6.3% to 7.0% Ta, 5.4% to 5.8% Al, 0.6% to 1.2% Ti, 2.7% to 3.2% Re, 0.15% to 0.3% Hf, 0.02% to 0.04% C, 40 ppm to 100 ppm B, 15 ppm to 50 ppm Mg and balance essentially nickel wherein the alloying elements C, B, Hf, and Mg are said to have a beneficial effect on small angle grain boundaries.

- U.S. Pat. No. 5,549,765 describes addition of carbon to a nickel base superalloy including the alloy of the first-discussed patent above to reduce the amount of non-metallic inclusions (e.g. oxide inclusions) in the microstructure of single crystal investment castings produced therefrom.

- In attempts to investment cast gas turbine engine single crystal blades from a nickel base superalloy of the first-discussed patent above, applicants discovered that there was formation of an as-cast metallic scale extensively over the airfoil surfaces of the single crystal cast blades and observable after the ceramic shell mold was removed from the castings. The surface scale was discovered to include, among other constituents, one or more low melting point alloy eutectics and secondary alloy phases rich in one or more of such alloy elements as W, Ta, Re, Mo, Cr, Co, Ti and Hf, with the scale being metallurgically bonded to the casting. Formation of the surface scale appeared to be solidification driven by segregation of alloying elements and eutectic and secondary phase reactions occurring during single crystal solidification. The scale was extensively present on the as-cast airfoil surfaces of the single crystal castings, occurring over as much as 80% of the airfoil surface. The presence of the scale rendered the castings unacceptable for use and required a post-cast abrasive belt or other mechanical finishing operation to remove the scale.

- Applicants also discovered that such single crystal castings were prone to develop deleterious extraneous grain nucleation and growth at the airfoil and/or root of the gas turbine engine blade during a subsequent conventional solution heat treatment that is a part of a heat treatment schedule to develop alloy mechanical properties. Such recrystallized grain regions are to be avoided and can be the cause for r jection of singl crystal castings if present beyond a preset maximum for recrystallized grains.

- The present invention provides a method of making of superalloy single crystal airfoil castings, such as gas turbine engine single crystal blades and vanes, that suffer from the problem of solidification-driven scale formation in the as-cast condition and extraneous recrystallized grains in the heat treated condition.

- The present invention involves the further discovery that the problem of formation of such surface scale on surfaces of as-cast single crystal nickel base superalloy castings can be reduced or prevented by increasing the carbon concentration of the superalloy beyond the specified alloy carbon level to this end.

- The present invention involves the additional discovery that the problem of formation of recrystallized grains after heat treatment of the single crystal castings also can be reduced or prevented by increasing the carbon concentration of the superalloy beyond the specified alloy carbon level to this end.

- In particular, the carbon concentration of the superalloy is increased to an amount effective to substantially reduce or eliminate (1) formation of the solidification-driven non-oxide scale on the surfaces of single crystal castings in the as-cast condition and (2) recrystallized grains in the heat treated condition.

- The above objects and advantages of the present invention will become more readily apparent from the following detailed description taken with the following drawings.

- FIGS. 1A, 1B and 1C are photographs of the airfoil regions of cast single crystal nickel base superalloy turbine blades after removal of a ceramic shell mold showing the effect of carbon level of the nickel base superalloy on the amount of metallic surface scale present on the airfoil surfaces after mold removal.

- FIG. 2 is a graph of the relationship of percent scale coverage of the casting surfaces versus carbon concentration of the nickel base superalloy.

- The present invention involves increasing the carbon concentration of nickel base superalloys formulated for single crystal casting in an amount discovered to unexpectedly and surprisingly substantially reduce or eliminate formation of the solidification-driven metallic as-cast scale discovered to be formed on the surfaces of single crystal castings of the superalloys under single crystal casting conditions and to unexpectedly and surprisingly eliminate recrystallized grains after heat treatment of the castings to develop mechanical properties. Generally, the present invention can be practiced with nickel base superalloys that are formulated for single crystal casting and include W, Ta, Mo, Co, Al and Cr as important alloying elements as well as optionally including Ti, Re, Hf, Y, one or more rare earth elements such as La, B, Mg and other intentional alloying elements and that suffer from the problem of solidification-driven scale formation in the as-cast condition and extraneous recrystallized grains in th heat treated condition. Particular nickel base superalloys which can be modified pursuant to the present invention to have increased carbon to this end include, but are not limited to, those described in U.S. Pat. Nos. 4,643,782, 5,759,301 and 5,366,695, the teachings of which are incorporated herein by reference with respect to particular alloy compositions.

- A particular nickel base superalloy casting composition modified in accordance with the present invention offered for purposes of illustration and not limitation consists essentially of, in weight %, of about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.05% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, balance essentially Ni and, C and castable to provide a single crystal microstructure, especially for gas turbine engine blades and vanes (i.e. airfoils). One embodiment includes about 0.05 to about 0.12 weight % Hf in the alloy composition, while another embodiment includes higher hafnium from about 0.15 to about 0.30 weight % Hf. The carbon concentration of the alloy composition is controlled to reduce or eliminate solidification-driven metallic scale formation in the as-cast condition and recrystallized grains after heat treatment of the castings to develop mechanical properties. These nickel base superalloys are modified in accordance with the invention to include increased carbon concentrations of greater than 0.04 weight %, more preferably from 0.04% to 0.1 weight % C.

- Other illustrative nickel base superalloys formulated for casting as single crystal airfoils which can be modified pursuant to the present invention to have increased carbon to this end are high-Re nickel base alloys described below and in U.S. Pat. No. 5,366,695, the teachings of which are incorporated herein by reference with respect to particular alloy compositions, and high-Cr nickel base superalloys.

- Generally, a high-Re nickel base superalloy which can be modified to benefit from practice of the invention consists essentially of, in weight %, about 1.5% to 5% Cr, about 1.5% to 10% Co, about 0.25% to 2% Mo, about 3.5% to 7.5% W, about 7% to 10% Ta, about 5% to 7% Al, 0 to about 1.2% Ti, about 5% to 7% Re, up to about 0.15% Hf, up to about 0.5% Nb, and balance essentially Ni and C. Generally, a high-Cr nickel base superalloy which can be modified to benefit from practice of the invention consists essentially of, in weight %, about 11% to 16% Cr, about 2% to 8% Co, about 0.2% to 2% Mo, about 3.5% to 7.5% W, about 4% to 6% Ta, about 3% to 6% Al, about 2 to about 5% Ti, up to about 0.5% Nb and balance essentially Ni and C. Other nickel base superalloys which can be modified to benefit from practice of the invention consists essentially of, in weight %, about 4% to 10% Cr, about 4% to 12% Co, about 1% to 4% Mo, about 4% to 10% W, about 5% to 10% Ta, about 4% to 8% Al, up to about 2% Ti, up to about 0.5% Hf, up to about 5% Re (preferably about 3% Re), and balance essentially Ni and C. For example, one such alloy has a nominal composition, in weight %, of 7% Cr, 8% Co, 2% Mo, 5% W, 7% Ta, 3% Re, 6.2% Al, 0.2% Hf and balance essentially Ni and C. Another such alloy has a nominal composition, in weight %, of 8% Cr, 5% Co, 2% Mo, 8% W, 6% Ta, 5.0% Al, 1.5% Ti, and balance essentially Ni and C. Still another such alloy has a nominal composition, in weight %, of 5% Cr, 10% Co, 2% Mo, 5% W, 3% Re, 8.5% Ta, 5.2% Al, 1.0% Ti, 0.1% Hf, and balance essentially Ni and C. Still a further such alloy has a nominal composition, in weight %, of 5% Cr, 10% Co, 2% Mo, 6% W, 3% Re, 9% Ta, 5.6% Al, 0.1% Hf and balance essentially Ni and C. The C concentrations of these superalloys can be intentionally increased above normal carbon impurity levels to an amount, for example only greater than 0.04 weight % C, effective to substantially reduce formation of an as-cast metallic scale when the alloy is cast as a single crystal.

- The following single crystal casting tests were conducted and are offered to further illustrate, but not limit, the present invention. Heats #1, #2, and #3 having a nickel base superalloy composition in weight percents as set forth in Table I were prepared.

TABLE I Heat Cr Co Mo W Ta Al Ti C Re Hf Ni #1 6.4 9.6 0.6 6.4 6.5 5.7 1.03 .0025 2.9 .10 balance #2 6.4 9.6 0.6 6.4 6.5 5.6 1.03 .02 2.9 .21 balance #3 6.3 9.5 0.6 6.5 6.5 5.7 1.0 .039 2.97 .10 balance - Each heat was made using conventional vacuum melting practice wherein carbon was controlled by small additions to the master alloy melt. Each heat was remelted and cast to form single crystal cored IGT blade castings having an airfoil region and a root r gion. The single crystal castings were produced using the conventional Bridgeman mold withdrawal directional solidification t chnique with a crystal selector passage (pigtail) to propagate a single crystal through the mold cavity. For example, each heat was melted in a crucible of a conventional casting furnace under a vacuum of less than 1 micron and superheated to 1482 degrees C. (2700 degrees F.). The superheated melt was poured into investment casting mold having a mold facecoat comprising zirconia backed by additional slurry/stucco layers comprising various forms of alumina and zirconia. Each mold cluster was preheated to 1510 degrees C. (2750 degrees F.) and mounted on a chill plate to effect unidirectional heat removal from the molten alloy in the mold. The melt-filled mold on the chill plate was withdrawn from the furnace into a solidification chamber of the casting furnace at a vacuum of 1 micron at a withdrawal rate of 2 to 12 inches per hour. The single crystal castings were cooled to room temperature and removed from the shell mold in conventional manner using a mechanical knock-out procedure, and then solution heat treated at 1310 degrees C. (2390 degrees F.) for 6 hours. After mold knock-out, the castings were observed visually for the presence of surface scale on th casting surfaces. After heat treatment, the castings were observed visually for the presence of recrystallize grains on the casting surfaces.

- The results of casting tests with respect to scale coverage (dark areas) are illustrated in FIGS. 1A, 1B, 1C. In FIG. 1A wh re the alloy had a carbon level of 0.0025 w ight % C, approximately 80% of the as-cast airfoil surface of the single crystal casting after mold removal was cov red with a as-cast non-oxide scale discovered to include, among other constituents, one or more low melting point alloy eutectics and secondary alloy phases rich in one or more of such alloy elements as W, Ta, Re, Mo, Cr, Co, Ti and Hf and located predominantly at interdendritic areas of the microstructure proximate the casting surface. For example, the as-cast scale included as constituents various TCP (topologically close packed) type phases including sigma phases found by TEM (transmission electron microscopy) to be rich in W, Ta, Re, Mo, Cr, Co with some to be rich in W, Ta, Re, Mo, Cr, Co, and Hf. Eutectic phases rich in titanium and tantalum also were present at some regions of the surface scale. Also present were spherical particles rich in Cr and Ni. Formation of the surface scale appeared to be solidification driven by segregation of alloying elements (solute segregation) and eutectic and phase reactions occurring during single crystal solidification. The as-cast eutectic/secondary phase surface scale had a widely variable thickness and was metallurgically bonded to the casting and very adherent, requiring a separate mechanical abrasive belt operation finishing to remove. The metallic scale is detrimental in that important alloying elements are depleted from the alloy proximate the metallic scale. Use of such mechanical methods to remove surface scale can cause rejection of castings due to the alteration of the dimensional and aerodynamic integrity of the airfoil.

- The as-cast scale can occur without or with the presence of oxide products, such as layers and/or particles, resulting from reaction between the shell mold and nickel base superalloy melt, corrosion of crucible and shell mold ceramics, and pull-out of ceramic particles from the shell mold. If the oxide products are present, they typically overlie the solidification-driven as-cast surface scale. The oxide products can comprise such oxides zirconium oxide, aluminum oxide and zirconium-aluminum-silicon oxide particles and layers depending upon the ceramic materials used in mold and crucible manufacture.

- In FIG. 1B where the alloy had a carbon level of 0.02 weight % C, approximately 48% of the airfoil surface of the single crystal casting was covered with the as-cast scale.

- In FIG. 1C where the alloy had a carbon level of 0.039 weight % C, approximately 10% of the airfoil surface of the single crystal casting was covered with the as-cast scale.

- FIG. 2 illustrates graphically the relationship between percent scale coverage (% of airfoil) versus the carbon content of the single crystal castings. From FIG. 2, it is apparent that carbon concentrations over 0.04 weight %, preferably from greater than 0.04 weight % to about 0.1 weight % C will eliminate or substantially reduce to less than 10% coverage of as-cast scale on the airfoil surfaces of the single crystal castings. The carbon content can be adjusted as necessary to achieve the benefits of the invention with respect to reduction or elimination of the as-cast surface scale for different nickel base superalloys. The higher alloy carbon concentration of Heat #3 appears to form alloy carbides, such as carbides of Ta and Ti as well as Mo, W, Hf, in th as-cast microstructure that reduce formation of the as-cast metallic scale and also reduce or localize recrystallized grains during heat treatment by virtue of pinning recrystallized grain boundaries and retarding their growth during heat treatment.

- From FIG. 2, it is apparent that the reduction in scale coverage with carbon concentration of the alloy can be expressed by the equation (1):

- % area fraction scale =−0.193 × carbon content in ppm +86 (1)

- The measurements of percent scale coverage were made after the ceramic shell mold was removed from the castings. Each measurement was made by overlaying a grid on photographs of the single crystal blades cast as described above and counting the boxes containing scale versus boxes without scale. A comparison was generated by averaging three photographs for three blades cast from each of the three heats.

- The results of casting and heat treatment tests with respect to extraneous recrystallized grains was made by visual rating over the surfaces of 100 single castings at the aforementioned carbon contents of 0.0025 weight % and 0.02 weight % and 12 single crystal castings at the carbon content of 0.039 weight % after the above described solution heat treatment. The single crystal castings were visually observed for presence of any extraneous recrystallized grains at the single crystal casting surface, which recrystallized grains typically form and grow during solution heat treatment as residual casting stresses at locations of the airfoil casting, e.g. at the airfoil tip or other locations, are relieved. The single crystal castings having a carbon lev 1 of 0.0025 weight % C were observed to have about 10% occurrence of recrystallized grains (i.e. 10 of the 100 single crystal castings having the carbon content of 0.0025 weight % C exhibited recrystallized grains to an extent to cause rejection of the casting pursuant to customer specifications). The single crystal castings having a carbon level of 0.02 weight % C were observed to have about 30% occurrence of recrystallized grains (i.e. 30 of the 100 sample single crystal castings exhibited recrystallized grains to an extent to cause rejection of the casting pursuant to customer specifications). However, at an alloy carbon concentration of 0.039 weight %, none of the sample single crystal castings exhibited any visually observed recrystallized grains on the single crystal castings after the solution heat treatment. Thus, the invention envisions increasing carbon concentration of the nickel base superalloy to an amount effective to eliminate recrystallized grains on single crystal castings made therefrom. Alloy carbides, such as carbides of Ta and Ti as well as Ni, Hf, Mo, W, are formed in the as-cast microstructure that appear to pin any recrystallized grain boundaries and retard and limit their growth during solution heat treatment.

- The present invention provides single crystal castings having carbon concentrations increased in an amount discovered to substantially reduce or eliminate formation of as-cast metallic scale on the surfaces of single crystal castings of the superalloys and recrystallized grains after solution heat treatment of the castings to develop mechanical properties.

- The present invention provides single crystal blade and vane (airfoils) castings which are substantially devoid of surface scale in the cast condition and recrystallized grains in the as solution heat treated condition. The present invention can be practiced in manufacture of myriad small and large sizes of airfoils, such large airfoils comprising large industrial gas turbine (IGT) blades which have a length of about 20 centimeters to about 60 centimeters and above, such as about 90 centimeters length, used throughout the stages of the turbine of stationary industrial gas turbine engines.

- While the invention has been described in terms of specific embodiments thereof, it is not intended to be limited thereto but rather only to the extent set forth in the following claims.

Claims (20)

1. A method of making a single crystal casting, comprising

providing a nickel base superalloy that includes Cr, Co, Mo, W, Ta, and Al as alloying elements and that exhibits as-cast metallic surface scale when the superalloy is cast as a single crystal casting with a C concentration effective to substantially reduce formation of said as-cast metallic surface scale, and

solidifying the superalloy in a mold to form a single crystal casting.

2. The method of claim 1 wherein said nickel base superalloy includes at least one of Ti, Re, Hf, Y, a rare earth element, Mg, and B.

3. The method of claim 1 wherein the superalloy as-cast is free of said scale.

4. The method of claim 1 including solution heat treating the casting wherein recrystallized grains are reduced after heat treatment.

5. A method of making a single crystal casting, comprising

providing a nickel base superalloy consisting essentially of, in weight %, about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.05% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, and balanc essentially Ni that exhibits as-cast metallic surface scale when the superalloy is cast as a single crystal casting, including providing said superalloy with a C concentration greater than 0.04 weight % effective to substantially reduce formation of an as-cast metallic scale when the superalloy is cast as a single crystal and

solidifying the superalloy in a mold to form a single crystal casting.

6. The method of claim 5 wherein the superalloy as-cast is free of said scale.

7. The method of claim 5 including solution heat treating the casting wherein recrystallized grains are reduced after heat treatment.

8. The method of claim 5 wherein C is included in an amount of greater than 0.04% to about 0.1% by weight.

9. A m thod of making a single crystal casting, comprising

providing a nickel base superalloy including Cr, Co, Mo, W, Ta, and Al as alloying elements that exhibits as-cast metallic surface scale when the superalloy is cast as a single crystal casting, including providing said superalloy with a C concentration controlled in accordance with the equation,

% area fraction scale =−0.193 × carbon content in ppm +86 effective to substantially reduce formation of an as-cast metallic scale when the superalloy is cast as a single crystal and

solidifying the superalloy in a mold to form a single crystal casting.

10. The method of claim 9 including heat treating the casting wherein recrystallized grains are reduced after heat treatment.

11. The method of claim 9 wherein said superalloy includes at least one of Ti, Re, Hf, Y, a rare earth element, B, Mg, and B.

12. As cast, metallic scale-free single crystal nickel base alloy casting consisting essentially of, in weight %, of about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.05% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, up to 100 ppm Y and balance essentially Ni and a C concentration greater than 0.04 weight %, said casting being substantially free of as-cast metallic scale.

13. The casting of claim 12 wherein the Hf content is from about 0.15 to about 0.30 weight %.

14. The casting of claim 12 including Re.

15. Single crystal nickel base alloy consisting essentially of, in weight %, of about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.15% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, up to 100 ppm Y and balance essentially Ni and a C concentration greater than 0.04 weight % to produce a single crystal casting substantially free of as-cast metallic scale when the alloy is cast as a single crystal.

16. The casting of claim 15 including Re.

17. A method of making a single crystal casting, comprising

providing a nickel base superalloy that includes Cr, Co, Mo, W, Ta, and Al as alloying elements and that exhibits grain recrystallization when the superalloy is solution heat treated, including providing said superalloy with a C concentration effective to substantially reduce grain recrystallization during heat treating, and

solution heat treating the superalloy.

18. The method of claim 17 wherein said nickel base superalloy includes at least one of Ti, Re, Hf, Y, a rare earth element, Mg, and B.

19. The method of claim 17 wherein said nickel base superalloy consisting essentially of, in weight %, about 6% to 6.8% Cr, about 8% to 10% Co, about 0.5% to 0.7% Mo, about 5.0% to 6.6% W, about 6.3% to 7% Ta, about 5.4% to 5.8% Al, about 0.6% to 1.2% Ti, about 0.05% to 0.3% Hf, up to about 100 ppm by weight B, up to 50 ppm by weight Mg, greater than 0.4% C, and balance essentially Ni.

20. The method of claim 17 wherein the Hf content is from about 0.15 to about 0.30 weight %.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/618,054 US20040007296A1 (en) | 1999-03-26 | 2003-07-11 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/276,858 US20020007877A1 (en) | 1999-03-26 | 1999-03-26 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

| US10/618,054 US20040007296A1 (en) | 1999-03-26 | 2003-07-11 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/276,858 Continuation US20020007877A1 (en) | 1999-03-26 | 1999-03-26 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20040007296A1 true US20040007296A1 (en) | 2004-01-15 |

Family

ID=23058365

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/276,858 Abandoned US20020007877A1 (en) | 1999-03-26 | 1999-03-26 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

| US10/618,054 Abandoned US20040007296A1 (en) | 1999-03-26 | 2003-07-11 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/276,858 Abandoned US20020007877A1 (en) | 1999-03-26 | 1999-03-26 | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US20020007877A1 (en) |

| EP (1) | EP1038983A1 (en) |

| JP (1) | JP2000312964A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100210480A1 (en) * | 2007-05-23 | 2010-08-19 | M-I Llc | Use of invert epoxy emulsions for wellbore stabilization |

| US20100276036A1 (en) * | 2006-02-22 | 2010-11-04 | General Electric Company | Carburization process for stabilizing nickel-based superalloys |

| US9551053B2 (en) | 2011-06-23 | 2017-01-24 | United Technologies Corporation | Method for limiting surface recrystallization |

| US10226814B2 (en) | 2013-03-15 | 2019-03-12 | United Technologies Corporation | Cast component having corner radius to reduce recrystallization |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002167636A (en) * | 2000-10-30 | 2002-06-11 | United Technol Corp <Utc> | Low density oxidation resistant superalloy material capable of thermal barrier coating retention without bond coat |

| US20020164263A1 (en) * | 2001-03-01 | 2002-11-07 | Kenneth Harris | Superalloy for single crystal turbine vanes |

| US7011721B2 (en) | 2001-03-01 | 2006-03-14 | Cannon-Muskegon Corporation | Superalloy for single crystal turbine vanes |

| US8241560B2 (en) * | 2003-04-28 | 2012-08-14 | Howmet Corporation | Nickel base superalloy and single crystal castings |

| US8876989B2 (en) | 2007-08-31 | 2014-11-04 | General Electric Company | Low rhenium nickel base superalloy compositions and superalloy articles |

| US20130230405A1 (en) * | 2007-08-31 | 2013-09-05 | Kevin Swayne O'Hara | Nickel base superalloy compositions being substantially free of rhenium and superalloy articles |

| FR3100144B1 (en) * | 2019-09-04 | 2021-10-01 | Safran Aircraft Engines | PROCESS FOR MANUFACTURING A METAL PART LIMITING THE APPEARANCE OF RECRISTALLIZED GRAINS IN THE SAID PART |

| CN114921706B (en) * | 2022-04-25 | 2023-08-01 | 西北工业大学 | Modified nickel-base casting superalloy and preparation method thereof |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4209348A (en) * | 1976-11-17 | 1980-06-24 | United Technologies Corporation | Heat treated superalloy single crystal article and process |

| US4371404A (en) * | 1980-01-23 | 1983-02-01 | United Technologies Corporation | Single crystal nickel superalloy |

| US4459160A (en) * | 1980-03-13 | 1984-07-10 | Rolls-Royce Limited | Single crystal castings |

| US4488915A (en) * | 1981-09-11 | 1984-12-18 | Rolls-Royce Limited | Single-crystal castings |

| US4643782A (en) * | 1984-03-19 | 1987-02-17 | Cannon Muskegon Corporation | Single crystal alloy technology |

| US4981528A (en) * | 1987-09-16 | 1991-01-01 | Rockwell International Corporation | Hot isostatic pressing of single crystal superalloy articles |

| US5100484A (en) * | 1985-10-15 | 1992-03-31 | General Electric Company | Heat treatment for nickel-base superalloys |

| US5366695A (en) * | 1992-06-29 | 1994-11-22 | Cannon-Muskegon Corporation | Single crystal nickel-based superalloy |

| US5455120A (en) * | 1992-03-05 | 1995-10-03 | General Electric Company | Nickel-base superalloy and article with high temperature strength and improved stability |

| US5549765A (en) * | 1993-03-18 | 1996-08-27 | Howmet Corporation | Clean single crystal nickel base superalloy |

| US5723800A (en) * | 1996-07-03 | 1998-03-03 | Nachi-Fujikoshi Corp. | Wear resistant cermet alloy vane for alternate flon |

| US5759301A (en) * | 1996-06-17 | 1998-06-02 | Abb Research Ltd. | Monocrystalline nickel-base superalloy with Ti, Ta, and Hf carbides |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0763604B1 (en) * | 1995-09-18 | 2007-08-22 | Howmet Corporation | Clean single crystal nickel base superalloy |

-

1999

- 1999-03-26 US US09/276,858 patent/US20020007877A1/en not_active Abandoned

-

2000

- 2000-03-22 EP EP00106211A patent/EP1038983A1/en not_active Withdrawn

- 2000-03-24 JP JP2000084436A patent/JP2000312964A/en active Pending

-

2003

- 2003-07-11 US US10/618,054 patent/US20040007296A1/en not_active Abandoned

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4209348A (en) * | 1976-11-17 | 1980-06-24 | United Technologies Corporation | Heat treated superalloy single crystal article and process |

| US4371404A (en) * | 1980-01-23 | 1983-02-01 | United Technologies Corporation | Single crystal nickel superalloy |

| US4459160A (en) * | 1980-03-13 | 1984-07-10 | Rolls-Royce Limited | Single crystal castings |

| US4488915A (en) * | 1981-09-11 | 1984-12-18 | Rolls-Royce Limited | Single-crystal castings |

| US4643782A (en) * | 1984-03-19 | 1987-02-17 | Cannon Muskegon Corporation | Single crystal alloy technology |

| US5100484A (en) * | 1985-10-15 | 1992-03-31 | General Electric Company | Heat treatment for nickel-base superalloys |

| US4981528A (en) * | 1987-09-16 | 1991-01-01 | Rockwell International Corporation | Hot isostatic pressing of single crystal superalloy articles |

| US5455120A (en) * | 1992-03-05 | 1995-10-03 | General Electric Company | Nickel-base superalloy and article with high temperature strength and improved stability |

| US5366695A (en) * | 1992-06-29 | 1994-11-22 | Cannon-Muskegon Corporation | Single crystal nickel-based superalloy |

| US5540790A (en) * | 1992-06-29 | 1996-07-30 | Cannon-Muskegon Corporation | Single crystal nickel-based superalloy |

| US5549765A (en) * | 1993-03-18 | 1996-08-27 | Howmet Corporation | Clean single crystal nickel base superalloy |

| US5759303A (en) * | 1993-03-18 | 1998-06-02 | Howmet Research Corporation | Clean single crystal nickel base superalloy |

| US5759301A (en) * | 1996-06-17 | 1998-06-02 | Abb Research Ltd. | Monocrystalline nickel-base superalloy with Ti, Ta, and Hf carbides |

| US5723800A (en) * | 1996-07-03 | 1998-03-03 | Nachi-Fujikoshi Corp. | Wear resistant cermet alloy vane for alternate flon |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100276036A1 (en) * | 2006-02-22 | 2010-11-04 | General Electric Company | Carburization process for stabilizing nickel-based superalloys |

| US8123872B2 (en) | 2006-02-22 | 2012-02-28 | General Electric Company | Carburization process for stabilizing nickel-based superalloys |

| US20100210480A1 (en) * | 2007-05-23 | 2010-08-19 | M-I Llc | Use of invert epoxy emulsions for wellbore stabilization |

| US9551053B2 (en) | 2011-06-23 | 2017-01-24 | United Technologies Corporation | Method for limiting surface recrystallization |

| US10226814B2 (en) | 2013-03-15 | 2019-03-12 | United Technologies Corporation | Cast component having corner radius to reduce recrystallization |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1038983A1 (en) | 2000-09-27 |

| US20020007877A1 (en) | 2002-01-24 |

| JP2000312964A (en) | 2000-11-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1206398A (en) | Superalloy single crystal articles | |

| US6231692B1 (en) | Nickel base superalloy with improved machinability and method of making thereof | |

| US20040011439A1 (en) | Directionally solidified casting with improved transverse stress rupture strength | |

| JP4885530B2 (en) | High strength and high ductility Ni-base superalloy, member using the same, and manufacturing method | |

| EP1431405B1 (en) | Coated article comprising a nickel base superalloy | |

| CA2586974C (en) | Nickel-base superalloy | |

| US20040007296A1 (en) | Casting of single crystal superalloy articles with reduced eutectic scale and grain recrystallization | |

| US20100071812A1 (en) | Unidirectionally-solidification process and castings formed thereby | |

| JP2000512341A (en) | Nickel-based superalloys | |

| US4765850A (en) | Single crystal nickel-base super alloy | |

| US20130022803A1 (en) | Unidirectionally-solidification process and castings formed thereby | |

| US20120152483A1 (en) | Unidirectional solidification process and apparatus and single-crystal seed therefor | |

| US20080240972A1 (en) | Low-density directionally solidified single-crystal superalloys | |

| EP2154258B1 (en) | Nickel-base superalloy, unidirectional-solidification process therefor, and castings formed therefrom | |

| JPH09272933A (en) | High strength nickel-base superalloy for directional solidification | |

| JPH02153037A (en) | Hollow casting of alloy based on nickel with columnar particle ; and alloy for production thereof and its heat treatment | |

| EP1038982A1 (en) | Single crystal superalloy articles with reduced grain recrystallization | |

| US20050000603A1 (en) | Nickel base superalloy and single crystal castings | |

| CA2503326C (en) | Heat treatment of alloys having elements for improving grain boundary strength | |

| US8241560B2 (en) | Nickel base superalloy and single crystal castings | |

| US20020007778A1 (en) | Single crystal seed alloy | |

| US20090107592A1 (en) | Heat treatment of alloys having elements for improving grain boundary strength | |

| US20060249233A1 (en) | Heat treatment of alloys having elements for improving grain boundary strength | |

| JPH10158768A (en) | Ds cast product of (low zirconium)-nickel superalloy | |

| US20080163962A1 (en) | Directionally solidified casting with improved transverse stress rupture strength |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCB | Information on status: application discontinuation |

Free format text: ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |