US1875380A - Railway truck structure - Google Patents

Railway truck structure Download PDFInfo

- Publication number

- US1875380A US1875380A US1875380DA US1875380A US 1875380 A US1875380 A US 1875380A US 1875380D A US1875380D A US 1875380DA US 1875380 A US1875380 A US 1875380A

- Authority

- US

- United States

- Prior art keywords

- integral

- frame

- truck

- reservoir

- transom

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000012530 fluid Substances 0.000 description 36

- 230000004048 modification Effects 0.000 description 10

- 238000006011 modification reaction Methods 0.000 description 10

- 238000005266 casting Methods 0.000 description 8

- 210000001847 Jaw Anatomy 0.000 description 6

- 239000000203 mixture Substances 0.000 description 6

- 238000010276 construction Methods 0.000 description 4

- 238000009432 framing Methods 0.000 description 4

- 230000003137 locomotive Effects 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000001934 delay Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- OYFJQPXVCSSHAI-QFPUQLAESA-N enalapril maleate Chemical compound OC(=O)\C=C/C(O)=O.C([C@@H](C(=O)OCC)N[C@@H](C)C(=O)N1[C@@H](CCC1)C(O)=O)CC1=CC=CC=C1 OYFJQPXVCSSHAI-QFPUQLAESA-N 0.000 description 2

- 238000005242 forging Methods 0.000 description 2

- 238000007689 inspection Methods 0.000 description 2

- 229920000136 polysorbate Polymers 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- 230000000284 resting Effects 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61H—BRAKES OR OTHER RETARDING DEVICES SPECIALLY ADAPTED FOR RAIL VEHICLES; ARRANGEMENT OR DISPOSITION THEREOF IN RAIL VEHICLES

- B61H13/00—Actuating rail vehicle brakes

- B61H13/20—Transmitting mechanisms

- B61H13/24—Transmitting mechanisms for cars with two axles or bogies with two axles and braking cylinder(s) for each bogie, the mechanisms at each side being interconnected

Definitions

- Our invention relates to railway rolling stock and consists in a novel railway truck structure and more particularly in the combination of a fluid reservoir and fluid brake cylinder with the truck frame.

- reservoirs and brake cylinders have been completed separately from the truck frame structure of the vehicle and have been provided with flanges adapted to be attached to brackets on the vehicles framing and by which the reservoirs and cylinders have been secured in place.

- This construction requires frequent and detailed inspection to see that the rivets or bolts are tight to insure the maintenance of proper assembly.

- Such construction is likely to result in unnecessary play in the brake rigging since the brake cylinder issecured to a part that moves in relation to the truck on which the brake beams and their actuating levers are mounted.

- the main objects of our invention are to secure rigidity, to decrease maintenance attention and delays and to effect certain other economies and advantages by making the reservoir integral with the side frames of the truck, and by making the brake cylinder integral with a transverse element of the truck frame and, preferably, with a longitudinal 30 member of the frame.

- the reservoir and brake cylinder elements may be formed integrally with the truck framing by casting or by any combination of the methods of casting, welding, forging, etc.

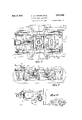

- Figure 1 is a top view of an engine truck embodying a preferred form of our invention showlng the reservoir integral with the side frames of the truck and showing the brake cylinder integral with the end sill and 1930.

- Figure 2 is in part a side view and in part a vertical section taken on the longitudinal 5 center line of Figure 1.

- Figure 3 is in part an end view and in part a vertical transverse section, taken on the line 33 of Figure 1.

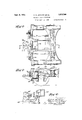

- Figure 4 is a top view of one end of a car truck embodying a modified form of our invention.

- Figure 5 is a vertical longitudinal section taken on the line 55 of Figure 4.

- Figure 6 is a half end view of the structure 55 shown in Figure 5.

- Figure 7 is a top view of the end of a car truck embodying another modification of our invention.

- Figure 8 is a vertical longitudinal section, taken on the line'88 of Figure 7.

- Figure 9 is a vertical-transverse section, taken on the line 9-9 of Figure 7

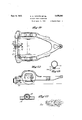

- Figure 10 is a top view of a locomotive trailer truck embodying another modified form of our invention.

- Figure 11 is a side view of the structure shown .in Figure 10.

- Figure 12 is a vertical section, taken on the line 1212 of Figure 10.

- Figure 13 is a section taken on line 1313 of Figure 1.

- the side frames of the truck are indicated at 1 and are integrally connected by end transoms 2 and 3 and center transoms 4. Between the transoms 4, is mounted the bolster 5, carrying the center plate structure '6.

- the truck frame is mounted in the conventional manner on wheels 7 by means of equalizers 50 resting on axle boxes in the pedestal jaws 8.

- the truck frame in this form of our invention has a longitudinal member 9 extending between one end transom 2 andthe 5, nearer center transom 4.

- Member 9 has one portion 10 extending horizontally to the top of transom 4 slightly below the level of the top of end transom 2 and another portionll extending downwardly and centrally to the bottom of transom 4. At the juncture of portions 10 and 11, the member 9 is continued upwardly and outwardly to merge with end transom 2.

- the reservoir member 12 which is integrally joined to the side frames 1 and is disposed transversely with respect ,to the truck.

- this reservoir is of substantially cylindrical shape, but if desirable may be made of oval, rectangular or other cross section.

- the reservoir has an opening A to facilitate casting. This opening is closed by a cap plate which is welded over the same after the casting operation is completed.

- Reservoir 12 is integrally joined to but spaced from the pedestal 'aws 8 of the side frames 1 by means of the iagonal flanges 13 at the ends of the reservoir and is spaced be tween the top and bottom levels of the frames.

- c Brake cylinder housing 14 is integral with and above the end transom 2 and longitudinal member 9, placing the cylinder above the mean top level of the truck frame.

- Nonpressure head 15 is formed integral with the cylinder housing 14.

- Integral brake hanger brackets 16 extend outwardly and downwardly from the top of the side frames 1.

- Brake rigging brackets 17 are integral with the bottom of reservoir 12.

- brackets together with projections 18 on the transverse angular member 19 are adapted to pivotally hold a portion 190.

- Member19 is integral with the pedestal jaws 8 on the opposite sides of the truck frame and also is integral with the reservoir member 12.

- Upper portion 10 of member 9 is vertically divided as shown at 20 to receive a brake rigging arm 21 which is pivotally held in position in the transom by means of pin 22 extending through the sides of the member 9.

- the brackets referred to are for the mounting of a conventional braking system.

- the cylinder housing 25 and pressure head 26 are shown integral with the channel shaped end sill 28 and the cylinder extends inwardly'therefrom, the side of the cylinder merging with the top flange 27 of the end sill.

- the end sill 28 is substantially below the level of the side frame 29, bringing the housing 25 and pressure head 26 of the brake cylinder below the level of the top of the truck frame. 5

- a brake cylinder is' shown integral with the center transom 30, the upper surface of the housing 31 of the cylinder being substantially in the plane of the top surface of the transom, while the lower' surface of the housing 31 is substantially below the level of that portion of the bottom surface of the transom at the sides of the transoms.

- the cylinder is also integral with longitudinal members32 and 33 which extend outwardly from transom 30 to the end transom 34.

- a railway truck frame including a fluid brake cylinder body and a fluid reservoir in- .tegral therewith, portions of said body and said reservoir constituting structural elements of the frame.

- An integral railway truck frame including a fluid reservoir extending transversely across the frame, and a fluid brake cylinder extending longitudinally of the frame.

- a railway truck frame including a fluid brake cylinder and a fluid reservoir being integral with the frame, said reservoir being above the mean bottom level of said frame.

- a railway truck frame including a fluid reservoir,said reservoir being integral with and below the top level of said frame.

- a railway truck frame including a fluid reservoir extending above the bottom levril of said frame and being integral therewit 13.

- a fluid reservoir disposed transversel of and integral withsaid side frames, and rackets for brake rigging integral with said reservoir.

- a fluid reservoir disposed transversely of and integral with said side frames, brackets for bmike rigging integral with said reservoir, and additional brackets for brake rigging integral with said side frames.

- a railway truck frame including a fluid 15.

- a fluid rwerframes and a longitudinal member intermediate said side frames, and a brake cylinderintegral withsaid member, a portion of the wall of said cylinder being formed by said member.

- a fluid brake cylinder having a head, said reservoir, cylinder and head all being integral with said frame.

- v 16.A railway truck frame includin an integral brake cylinder having side and end wall portions integral with frame members.

- a railway truck frame including side frames and an end transom, and a brake cylinder integral with said end transom, with the cylinders side and end wall being formed by extensions of the side and top Walls of said transom.

- transom and a longitudinal member and a said truck frame and integral with said end transom and said longitudinal member, parts of said transom and member forming at least a portion of the wall of said cylinder.

- brake cylinder disposed longitudinally of 19.

- a railway truck frame including side,

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Transmission Of Braking Force In Braking Systems (AREA)

Description

Sept. 6, 1932. K. s. HOWARD ET AL RAILWAY TRUCK STRUCTURE Filed April 21, 1930 4 Sheets-Sheet l in l/eflfor M Q/ forn Sept. 6, 1932. K. s. HOWARD ET AL RAILWAY TRUCK STRUCTURE Filed April 21, 1930 4 Sheets-Sheet 2 6M r4 fornez P 5, 1932- K. s. HOWARD ET AL RAILWAY TRUCK STRUCTURE Filed April 21, 1930 4 Sheets-Sheet 3 p 6, 1932- K. s. HOWARD ET AL 1,875,380

RAILWAY TRUCK STRUCTURE Filed April 21, 1930 4 Sheets-Sheet 4 Patented Sept. 6, 1932 UNITED STATES PATENT OFFICE KARL S. HOWARD AND -EDWIN O. JACKSON, OF ST. LOUIS, MISSOURI, ASSIGNORS TO GENERAL STEEL CASTINGS CORPORATION, OF GRANITE CITY, ILLINOIS, A GOR- IORATION OF DELAWARE RAILWAY TRUCK. STRUCTURE Application filed April 21,

Our invention relates to railway rolling stock and consists in a novel railway truck structure and more particularly in the combination of a fluid reservoir and fluid brake cylinder with the truck frame.

Customarily, reservoirs and brake cylinders have been completed separately from the truck frame structure of the vehicle and have been provided with flanges adapted to be attached to brackets on the vehicles framing and by which the reservoirs and cylinders have been secured in place. This construction requires frequent and detailed inspection to see that the rivets or bolts are tight to insure the maintenance of proper assembly. Such construction is likely to result in unnecessary play in the brake rigging since the brake cylinder issecured to a part that moves in relation to the truck on which the brake beams and their actuating levers are mounted.

The main objects of our invention are to secure rigidity, to decrease maintenance attention and delays and to effect certain other economies and advantages by making the reservoir integral with the side frames of the truck, and by making the brake cylinder integral with a transverse element of the truck frame and, preferably, with a longitudinal 30 member of the frame.

We also desire to form either the brake cylinder pressure'head or the non-pressure head or the non-pressure head and housing or pressure head and housing or housing integral with the truck frame.

Other detail objects of our invention will appear from a reading ofithe following de-- scription of the device with reference to the accompanying drawings of the same.

' The reservoir and brake cylinder elements may be formed integrally with the truck framing by casting or by any combination of the methods of casting, welding, forging, etc.

In the accompanying drawings which illustrate our invention- Figure 1 is a top view of an engine truck embodying a preferred form of our invention showlng the reservoir integral with the side frames of the truck and showing the brake cylinder integral with the end sill and 1930. Serial No. 446,124.

the longitudinal member connecting the end sill and a transverse transom of the truck frame. a

Figure 2 is in part a side view and in part a vertical section taken on the longitudinal 5 center line of Figure 1.

Figure 3 is in part an end view and in part a vertical transverse section, taken on the line 33 of Figure 1.

Figure 4 is a top view of one end of a car truck embodying a modified form of our invention.

Figure 5 is a vertical longitudinal section taken on the line 55 of Figure 4.

Figure 6 is a half end view of the structure 55 shown in Figure 5.

Figure 7 is a top view of the end of a car truck embodying another modification of our invention.

Figure 8 is a vertical longitudinal section, taken on the line'88 of Figure 7.

Figure 9 is a vertical-transverse section, taken on the line 9-9 of Figure 7 Figure 10 is a top view of a locomotive trailer truck embodying another modified form of our invention.

Figure 11 is a side view of the structure shown .in Figure 10.

Figure 12 is a vertical section, taken on the line 1212 of Figure 10.

Figure 13 is a section taken on line 1313 of Figure 1.

In the structures shown in the first three figures, the side frames of the truck are indicated at 1 and are integrally connected by end transoms 2 and 3 and center transoms 4. Between the transoms 4, is mounted the bolster 5, carrying the center plate structure '6. The truck frame is mounted in the conventional manner on wheels 7 by means of equalizers 50 resting on axle boxes in the pedestal jaws 8.

The truck frame in this form of our invention has a longitudinal member 9 extending between one end transom 2 andthe 5, nearer center transom 4. Member 9 has one portion 10 extending horizontally to the top of transom 4 slightly below the level of the top of end transom 2 and another portionll extending downwardly and centrally to the bottom of transom 4. At the juncture of portions 10 and 11, the member 9 is continued upwardly and outwardly to merge with end transom 2.

Further reinforcement is given to the truck frame by the reservoir member 12 which is integrally joined to the side frames 1 and is disposed transversely with respect ,to the truck. Preferably, this reservoir is of substantially cylindrical shape, but if desirable may be made of oval, rectangular or other cross section. The reservoir has an opening A to facilitate casting. This opening is closed by a cap plate which is welded over the same after the casting operation is completed.

This disposition of flanges 13 enables the equalizer bars 50 to extend over flanges 13 and between the ends of the reservoir 12 and pedestal jaws 8 to a point over the axle boxes 38.

c Brake cylinder housing 14 is integral with and above the end transom 2 and longitudinal member 9, placing the cylinder above the mean top level of the truck frame. Nonpressure head 15 is formed integral with the cylinder housing 14.

To further. carry out the main objects of our invention, as much of the brake rigging mounting structure as possible is made integral with the main parts of the frame. Integral brake hanger brackets 16 extend outwardly and downwardly from the top of the side frames 1. Brake rigging brackets 17 are integral with the bottom of reservoir 12.

These latter brackets together with projections 18 on the transverse angular member 19 are adapted to pivotally hold a portion 190.

of the brake rigging. Member19 is integral with the pedestal jaws 8 on the opposite sides of the truck frame and also is integral with the reservoir member 12. Upper portion 10 of member 9 is vertically divided as shown at 20 to receive a brake rigging arm 21 which is pivotally held in position in the transom by means of pin 22 extending through the sides of the member 9. The brackets referred to are for the mounting of a conventional braking system.

In the modification illustrated'in Figures 4, 5 and 6, the cylinder housing 25 and pressure head 26 are shown integral with the channel shaped end sill 28 and the cylinder extends inwardly'therefrom, the side of the cylinder merging with the top flange 27 of the end sill. The end sill 28 is substantially below the level of the side frame 29, bringing the housing 25 and pressure head 26 of the brake cylinder below the level of the top of the truck frame. 5

.In the modification illustrated in Figures 7, 8 and 9, a brake cylinder is' shown integral with the center transom 30, the upper surface of the housing 31 of the cylinder being substantially in the plane of the top surface of the transom, while the lower' surface of the housing 31 is substantially below the level of that portion of the bottom surface of the transom at the sides of the transoms. The cylinder is also integral with longitudinal members32 and 33 which extend outwardly from transom 30 to the end transom 34.

In the modification illustrated in Figures 10, 11 and 12, we show our invention applied to a trailer truck for a' locomotive 1n which brake cylinderhousing 35 and nonpressure head 36 are shown formed integral with the rear transom 37 of the truck frame.

We direct attention to our copending application, Serial Number 446,125, filed pril 21, 1930, which illustrates other truck structures having brake cylinder elements integral with the truck frame.

Some. features of our inventionmay be included in any structure in which' instead of the entire reservoir or cylinder bein integral with the frame as described a ove, suitable brackets for supporting the reservoiror cylinder are integral with the truck frame.

Other details in the structure of our invention may be modified without departing from the spirit thereof and we contemplate the exclusive use of all modifications that come within the scope of our claims.

We claim:

1. A railway truck frame including a fluid brake cylinder body and a fluid reservoir in- .tegral therewith, portions of said body and said reservoir constituting structural elements of the frame.

2. An integral railway truck frame including a fluid reservoir extending transversely across the frame, and a fluid brake cylinder extending longitudinally of the frame.

3. In combination in a railway truck, a plurality of sets of wheels, and an integral frame mounted thereon and including a fluid brake cylinder between one set of wheels and a fluid reservoir between another set of brake cylinder and a fluid reservoir integralwith the frame, portions of said cylinder and reservoir constituting structural elements of the frame and said brake, cylinder being above themean top level of said frame.

10. A railway truck frame including a fluid brake cylinder and a fluid reservoir being integral with the frame, said reservoir being above the mean bottom level of said frame.

.11. A railway truck frame including a fluid reservoir,said reservoir being integral with and below the top level of said frame.

12. A railway truck frame including a fluid reservoir extending above the bottom levril of said frame and being integral therewit 13. In a railway truck, spaced side frames, a fluid reservoir disposed transversel of and integral withsaid side frames, and rackets for brake rigging integral with said reservoir.

14. In a railway truck, spaced sideframes, a fluid reservoir disposed transversely of and integral with said side frames, brackets for bmike rigging integral with said reservoir, and additional brackets for brake rigging integral with said side frames.

9. A railway truck frame including a fluid 15. In a railway truck frame, a fluid rwerframes and a longitudinal member intermediate said side frames, and a brake cylinderintegral withsaid member, a portion of the wall of said cylinder being formed by said member. s In testimony whereof we hereunto aflix our signatures this'14th day of April, 1930.

KARL S. HOWARD. EDWIN CQJACKSON'.

voir, and a fluid brake cylinder having a head, said reservoir, cylinder and head all being integral with said frame.

v 16.A railway truck frame includin an integral brake cylinder having side and end wall portions integral with frame members.

17. A railway truck frame including side frames and an end transom, and a brake cylinder integral with said end transom, with the cylinders side and end wall being formed by extensions of the side and top Walls of said transom. Y

18. In a railway truck frame, end

transom and a longitudinal member, and a said truck frame and integral with said end transom and said longitudinal member, parts of said transom and member forming at least a portion of the wall of said cylinder. C

., brake cylinder disposed longitudinally of 19. A railway truck frame including side,

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1875380A true US1875380A (en) | 1932-09-06 |

Family

ID=3424170

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US1875380D Expired - Lifetime US1875380A (en) | Railway truck structure |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1875380A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2811114A (en) * | 1951-04-30 | 1957-10-29 | Gen Steel Castings Corp | Railway truck structue |

| US4046080A (en) * | 1973-06-08 | 1977-09-06 | Wegmann & Co. | Motorized swiveling streetcar trucks |

| US4362109A (en) * | 1979-05-24 | 1982-12-07 | Centro Ricerche Fiat S.P.A. | Railway vehicle trucks |

| US20150321681A1 (en) * | 2014-05-06 | 2015-11-12 | Amsted Rail-Faiveley, LLC | Braking system for a railway car |

| US20160082986A1 (en) * | 2013-05-02 | 2016-03-24 | Siemens Ag Österreich | Wheelset Bearing for the Wheelset of a Rail Vehicle Having an Internally Mounted Truck |

-

0

- US US1875380D patent/US1875380A/en not_active Expired - Lifetime

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2811114A (en) * | 1951-04-30 | 1957-10-29 | Gen Steel Castings Corp | Railway truck structue |

| US4046080A (en) * | 1973-06-08 | 1977-09-06 | Wegmann & Co. | Motorized swiveling streetcar trucks |

| US4362109A (en) * | 1979-05-24 | 1982-12-07 | Centro Ricerche Fiat S.P.A. | Railway vehicle trucks |

| US20160082986A1 (en) * | 2013-05-02 | 2016-03-24 | Siemens Ag Österreich | Wheelset Bearing for the Wheelset of a Rail Vehicle Having an Internally Mounted Truck |

| US9776646B2 (en) * | 2013-05-02 | 2017-10-03 | Siemens Ag Österreich | Wheelset bearing for the wheelset of a rail vehicle having an internally mounted truck |

| US20150321681A1 (en) * | 2014-05-06 | 2015-11-12 | Amsted Rail-Faiveley, LLC | Braking system for a railway car |

| US9540020B2 (en) * | 2014-05-06 | 2017-01-10 | Amsted Rail-Faiveley, LLC | Braking system for a railway car |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1875380A (en) | Railway truck structure | |

| US2199360A (en) | Spring plankless truck | |

| US2494280A (en) | Brake | |

| US2119505A (en) | Car truck brake mechanism | |

| US970128A (en) | Underframe for railway-cars. | |

| US1459250A (en) | Articulated car | |

| US1988729A (en) | Car underframe structure | |

| US1825476A (en) | Railway car structure | |

| US1663036A (en) | Railway vehicle structure | |

| US2197443A (en) | Railway hopper car | |

| US2132233A (en) | Cast railway car body bolster | |

| US1810876A (en) | Railway car | |

| US1736292A (en) | Railway-car construction | |

| US2065200A (en) | Car truck with brake mechanism | |

| US1754634A (en) | Body bolster | |

| US2086840A (en) | Clasp brake | |

| US1955915A (en) | Railway truck structure | |

| US2297748A (en) | Side frame | |

| US1735239A (en) | Freight-car truck or tender truck | |

| US1856338A (en) | Railway vehicle underframe | |

| US1936897A (en) | Clasp brake for motor trucks | |

| US1875594A (en) | Railway tank car underframe | |

| US2084859A (en) | Railway car underframe | |

| US1779599A (en) | Locomotive structure | |

| US1833466A (en) | Locomotive tender |