US1784935A - Door latch - Google Patents

Door latch Download PDFInfo

- Publication number

- US1784935A US1784935A US30875828A US1784935A US 1784935 A US1784935 A US 1784935A US 30875828 A US30875828 A US 30875828A US 1784935 A US1784935 A US 1784935A

- Authority

- US

- United States

- Prior art keywords

- casing

- latch

- door

- button

- sides

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000004888 barrier function Effects 0.000 description 10

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000010276 construction Methods 0.000 description 2

- 235000006629 Prosopis spicigera Nutrition 0.000 description 1

- 240000000037 Prosopis spicigera Species 0.000 description 1

- FHNINJWBTRXEBC-UHFFFAOYSA-N Sudan III Chemical compound OC1=CC=C2C=CC=CC2=C1N=NC(C=C1)=CC=C1N=NC1=CC=CC=C1 FHNINJWBTRXEBC-UHFFFAOYSA-N 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 210000003811 finger Anatomy 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 210000003813 thumb Anatomy 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/24—Arrangements in which the fastening members which engage one another are mounted respectively on the wing and the frame and are both movable, e.g. for release by moving either of them

- E05B63/248—Arrangements in which the fastening members which engage one another are mounted respectively on the wing and the frame and are both movable, e.g. for release by moving either of them the striker being movable for latching, and pushed back by a member on the wing for unlatching, or vice versa

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S292/00—Closure fasteners

- Y10S292/37—Push button operators

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/1043—Swinging

- Y10T292/1051—Spring projected

- Y10T292/1052—Operating means

- Y10T292/1053—Lever and push or pull rod

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/175—Bolt releasers

- Y10T292/18—Free-end-engaging means

Definitions

- the invention aims to provide aneW and improved latch for cupboard and other doors" ofsuch construetion that it may be easily ancl inexpensively manufactured, sold at small cost, easily applied andboth latehed and unlatched conveniently and easily.

- Fig. 1 is aside elevation showing the latch appliecl to a portion of adoor anda shelf toward which said door closes.

- Fig. 2 is aeentral longitudinal sectional V1ew.

- Fig. 3 is a view similar to Fig. 2 but showing the lateh released.

- Fig. 4 is a horizontal sectional view on 9 line 4-4.- 01 Fig. 2.

- Fig. 5 is a vertieal sectional view on line 5-5 of Fig. 2.

- Fig. 6 is a perspeetive view of the casing in which the latchreleasing parts are 25 mounted.

- the form of construction seleeted f01 il lustration in the present application may be eonsidered as preferred,arld while this construction will beherein specifically eX- 30 plained, it is to be understood. that within the scope of the nvention as claimed, Variations may be made.-

- a bottom plate contacts with the lower edges of the sides 7 throughout substantially the front.halves of the latter.

- the front portion of this plate projectsfor wardly beyond the flanges 9 and is bent up wardly to provide a lug 11, while therear end 0f saicl plate 10 is bent upwardly between the casing sicles 7 to form-a barrier 12.

- the lug 11 and barrier 12 are formed With rela tively large ancl small openings 13. ⁇ 14 for a pur.pose te appear. Wl1ile the plate 10 may be seeured to the casing sides 7 in ariy desired 50 manner, I prefer t0 previde said plate With to secure them together,

- Apush-button 16 passes sliclably through the opening 13 and a rod 17 is securecl to and projects earwardly from this push-button thr0ugh the opening 14.

- the 'ront end of the rod is receivecl in a socket. 3 in the rear enclof the push-button 16 and a pin 18 passes through said button and rod the ends 0 the pin projectingbeynd the push button to abt the inner side of the lug 11 and limit the forward movementof the button and r0d.

- a coiled comprssion springl9 surrounds the r0d 17 and abuts the barrier 14 and the pushbutten 16 te normally shift the latter and the 10d 17 forwrdly to the limit permitted by pinl8.

- a latch-releasinglever 20 is fulcrumecl at '30 21 in the rear portion of the casing ;formed by the parts above described this 'le"er being mountedin operativerelation with the rear end. ofthe rool 17, so that up0n rear- Ward movement of this rocl, the lever 20 will be swung to the positin shown in Fig.

- the latcl1 22 is preferably of grvity-ap. pliedform and is pivoted at 25 in a flat eas 1ng. This casingis formeel from a single metal plate bentginto channel-shape te provide.parallel sides 26 'anda bottom 27.

- the upper portions of thesicles 26 are bent laterally and apertured to provide attaehing flanges 28, and a longitudinalslot 29 is formed in the bottom 27 througlrwhich a portion of the latchmay project as shown in Fig. 2 for engagement with the casing enrl 8.

- the latch is provided with a stop lu g 30 to rest upon the bettom 27 and limit the projeetion of saicl latch attaching oonvex sides of the two disks toward each other, the securingof these disks being preferably ellected by providing disk 34 witha portion Whioh passes throughthe opening 32 and is clinched.

- the concavity of the disk 34 receives the push-button 16.

- an opening 0 is formed in the door D, the first deseribed eas ing is passed rearwardly through this opening and its flanges 9 are seeuredto the door by screwsS. Then, the plate 24 is placed around the rear portion ofthe casing -and fastened to the door bv screws .or the 1ike S.- Tlie disk 3Iis seeured to the outer side of the door by sorews or the like S and ether screws S are employed to fastei1 the flanges 28 of the latch casing to a shelf or other fixed member M towardwhieh the door D closes.

- Some of the openings throghwhich the screws S pass arepreferably of elongated form to permit proper longitudinal adjust. ment to dispose the latch 22 in proper eo.-op-

- said projecting portion of said casing havng an open side, a self-projecting lateh having means or mounting it independently of the door and having a portion receivable in said open side of the easing,andmeansin said casing for forcing said lateh from the easing when desired, said means having an operating button at-the front ol-thed0or.

- an elongated casing f0r passage thrugh a door said casing having a lateral attaching flange and a transverse lng at its front end, a transverse barrier between its ends, a rear W 11 or coaotion with a latch, and an open side to adnit the lat0h,

- said lug and barrier be1ng formed with alined relatively large and small "openings, a push.- button slidable in the opening of said lug, a rod seonred to 'said push-button andprojeetv ing rearwardly through the openingofsaid.

- a latch-releasing lever pivotally mounted in the rear portion of said casing and operatively related with said rod f0r actuation by means of the latter, a coiled' eompression spring surrounding said rod and bearing against said pushbutton and aid barrier, and means for limiting the forward movement of said push-button and rod.

- theforward move passes slidably, the peripheral edge of said diskbeingprovided with an outstandingapertured attaching flange, and aknob-forming conczwo-convex disk centrally apertured and joined to the first named disk, the convex sides of the two disks abutting each ether, sad button being received in the concavity of the second disk to be pushed by the thumb when two fingers of the band are plsiced between the convex sides of the two disks preparatory to opening the door.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Sheet Holders (AREA)

Description

Dec. 16, 193). v. E. JQHNSON 5 9 DOOR LATCH Filed Sept. 27. 1928 Patented Dec. 16, 1930 UNITED STATES PATENT OFFICE v1cmon E. JOENSON, OF ROYAL OAK, MICHIGAN, ASSIGNOR OF ONE-I-I'LTO JO1\TE E.. woncomrn, OF ROYAL DAK, IVIIOHIGAN 13003 LATCH" Applcation fi1ed September 27, 1928. Se1ia1 No. 308,758.

The invention aims to provide aneW and improved latch for cupboard and other doors" ofsuch construetion that it may be easily ancl inexpensively manufactured, sold at small cost, easily applied andboth latehed and unlatched conveniently and easily.

W ith the foregoing in view, the invention resides in the novel subject matter hereinafter described and clamed, deseription be- 10 ing accomplisheol by reference to the aceo1n panying drawing.

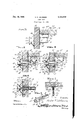

Fig. 1 is aside elevation showing the latch appliecl to a portion of adoor anda shelf toward which said door closes.

1 Fig. 2 is aeentral longitudinal sectional V1ew. Fig. 3 is a view similar to Fig. 2 but showing the lateh released.

Fig. 4 is a horizontal sectional view on 9 line 4-4.- 01 Fig. 2.

Fig. 5 is a vertieal sectional view on line 5-5 of Fig. 2. Fig. 6 is a perspeetive view of the casing in which the latchreleasing parts are 25 mounted. I The form of construction seleeted f01 il lustration in the present application, may be eonsidered as preferred,arld while this construction will beherein specifically eX- 30 plained, it is to be understood. that within the scope of the nvention as claimed, Variations may be made.-

"An elongated metal strip is bent substantially intoU-shape to provicle two parallel casing sides 7 and a rear casingend 8, the front ends of said sides 7 being apertured. and laterally bent to provide attaching flanges 9. A bottom plate contacts with the lower edges of the sides 7 throughout substantially the front.halves of the latter. The front portion of this plate projectsfor wardly beyond the flanges 9 and is bent up wardly to provide a lug 11, while therear end 0f saicl plate 10 is bent upwardly between the casing sicles 7 to form-a barrier 12. The lug 11 and barrier 12 are formed With rela tively large ancl small openings 13.\14 for a pur.pose te appear. Wl1ile the plate 10 may be seeured to the casing sides 7 in ariy desired 50 manner, I prefer t0 previde said plate With to secure them together,

Excessive movement of the upstanding longitudinal flanges 15 Which are spot Welded, soldered or otherivvise secured t0 saidsides. Apush-button 16 passes sliclably through the opening 13 and a rod 17 is securecl to and projects earwardly from this push-button thr0ugh the opening 14. Preferably the 'ront end of the rod is receivecl in a socket. 3 in the rear enclof the push-button 16 and a pin 18 passes through said button and rod the ends 0 the pin projectingbeynd the push button to abt the inner side of the lug 11 and limit the forward movementof the button and r0d. A coiled comprssion springl9 surrounds the r0d 17 and abuts the barrier 14 and the pushbutten 16 te normally shift the latter and the 10d 17 forwrdly to the limit permitted by pinl8.

A latch-releasinglever 20 is fulcrumecl at '30 21 in the rear portion of the casing ;formed by the parts above described this 'le"er being mountedin operativerelation with the rear end. ofthe rool 17, so that up0n rear- Ward movement of this rocl, the lever 20 will be swung to the positin shown in Fig. 3 for the purpose" of releasing the latch A portion of thslatch is normallyreeeved in one ofthe open sides ofthe easing aml abuts the rear casing end 8, said latch bei1ig g;Q mounted in amanner1hereinafter explainecl; latch-releasing leven 20 under the influence of the red 17, is prevented by a stop tongue 23 earried bya rectangular plate2l Which snrrounds the casing The latcl1 22 is preferably of grvity-ap. pliedform and is pivoted at 25 in a flat eas 1ng. This casingis formeel from a single metal plate bentginto channel-shape te provide.parallel sides 26 'anda bottom 27. The upper portions of thesicles 26 are bent laterally and apertured to provide attaehing flanges 28, and a longitudinalslot 29 is formed in the bottom 27 througlrwhich a portion of the latchmay project as shown in Fig. 2 for engagement with the casing enrl 8. The latch is provided with a stop lu g 30 to rest upon the bettom 27 and limit the projeetion of saicl latch attaching oonvex sides of the two disks toward each other, the securingof these disks being preferably ellected by providing disk 34 witha portion Whioh passes throughthe opening 32 and is clinched. The concavity of the disk 34 receives the push-button 16.

T0 install the device, an opening 0 is formed in the door D, the first deseribed eas ing is passed rearwardly through this opening and its flanges 9 are seeuredto the door by screwsS. Then, the plate 24 is placed around the rear portion ofthe casing -and fastened to the door bv screws .or the 1ike S.- Tlie disk 3Iis seeured to the outer side of the door by sorews or the like S and ether screws S are employed to fastei1 the flanges 28 of the latch casing to a shelf or other fixed member M towardwhieh the door D closes. Some of the openings throghwhich the screws S pass arepreferably of elongated form to permit proper longitudinal adjust. ment to dispose the latch 22 in proper eo.-op-

erative relation With the casing end8, before these serevvs are tightened and the others driven.

When the door D is closed, the casing end 8 strikes and upwardly swings thelatch 22 and when this easing end has cleared said latch, the latter falls by gravity to the ex tent permitted by the stoplug30 and abuts the inner side of said casing end 8as shown inFig. 2, thereby latehing the door closed. At this time, lever 20 underlies the lateh 22 and when the push-button 16is rearWardly foreed, rod 17 thereby upwardly foreing the latch rom engagementwith the casing end 8 and permitting outward swinging of the door. Wl1en lateh-releasing and door-opening are to be effected, the operator places two ingers between the convex sides of disk 31-34 and with his thuinlo presses npon the"pushblt ton 16. Hence, with the hand in one positien, the 1atch maybe released andthe door pulled open, the disk 34thenc0nstituting a knob.

As excellent res1ilts "are obtainable from the details discl0sed, thesedetails are preferably followed. However,ivithinthe scope of the invention as clainnd, variations may be 1 1121d625 above stated I claimr- 1. In a door latch, 'acasing for passage upwardlyjsvvings said lever,

through a door and having a portion te pro ject rearwardly beyond the door, said projecting portion of said casing havng an open side, a self-projecting lateh having means or mounting it independently of the door and having a portion receivable in said open side of the easing,andmeansin said casing for forcing said lateh from the easing when desired, said means having an operating button at-the front ol-thed0or.

-2. Ina doorlatch, an elongated casing f0r passage thrugh a door, said casing having a lateral attaching flange and a transverse lng at its front end, a transverse barrier between its ends,a rear W 11 or coaotion with a latch, and an open side to adnit the lat0h,

said lug and barrier be1ng formed with alined relatively large and small "openings, a push.- button slidable in the opening of said lug, a rod seonred to 'said push-button andprojeetv ing rearwardly through the openingofsaid.

barrier, a latch-releasing lever pivotally mounted in the rear portion of said casing and operatively related with said rod f0r actuation by means of the latter, a coiled' eompression spring surrounding said rod and bearing against said pushbutton and aid barrier, and means for limiting the forward movement of said push-button and rod.

3. In a door latch, a metal stripbent i'nto substantially U-shape to form parallel casing sides and arear casing end f-or co-action with a latch,.the front ends of sadsidesbeing bent laterally ;to provide attaching flanges, a bottom plate seoured to the Gasing sides and projecting forwardly therefrom, the front end of said plate being bent upwardly t0 forma lug, therear. end of said plate being bent upwardly between said easing sides to provide a barrier which is located in. advance of said rear casing.endsaidlug and barrier being formed.with alined relatively largeand small openings, a push-buttonslidable in the opening of 'said lug, a rod secured to said push-button and projecting rearward 1y throgh the opening of said barrier, a lateh-releasing lever pivotally mounted in the rear portioi1of tsaid casing andoperativelyrelated with said rod. for aetuationjbjy means of thelatter,wa coiled compresSion spring surrounding saidrod and=bearing against sad push-button jand saidbarrier, a1id means ment ofsaid push-button and rod.-

4. In a latch, a metal plate bent nto.cl1aii-v nel shape to provide casmg sides and a casng bottom, the latter having a longitudnal slot,

the upper portions of said sides being bent laterally and apertured to form attaehing flanges, and a-latch loosely pivoted between said casing sides and having a portionprojecting through said s lt, said 1atch having a 1ug Co-operable with said easingbottom to limit the projection of saidlateh through said slot.

for limit-ng theforward move passes slidably, the peripheral edge of said diskbeingprovided with an outstandingapertured attaching flange, and aknob-forming conczwo-convex disk centrally apertured and joined to the first named disk, the convex sides of the two disks abutting each ether, sad button being received in the concavity of the second disk to be pushed by the thumb when two fingers of the band are plsiced between the convex sides of the two disks preparatory to opening the door.

In testimony whereof I have hereunto aflixed my signature.

VICTOR E. JOHNSON.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US30875828 US1784935A (en) | 1928-09-27 | 1928-09-27 | Door latch |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US30875828 US1784935A (en) | 1928-09-27 | 1928-09-27 | Door latch |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1784935A true US1784935A (en) | 1930-12-16 |

Family

ID=23195271

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US30875828 Expired - Lifetime US1784935A (en) | 1928-09-27 | 1928-09-27 | Door latch |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1784935A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2606783A (en) * | 1950-05-15 | 1952-08-12 | Roethel Engineering Corp | Door handle assembly |

| US3039804A (en) * | 1961-08-04 | 1962-06-19 | Ideal Brass Works Inc | Door latch mechanism |

| US3838877A (en) * | 1973-10-29 | 1974-10-01 | W Hanson | Overhead door latch |

| US3973794A (en) * | 1975-04-30 | 1976-08-10 | Leonard Green | Interior door latch assembly |

| US4341409A (en) * | 1978-12-11 | 1982-07-27 | Sharp Kabushiki Kaisha | Door latching assembly |

| US4943695A (en) * | 1988-01-05 | 1990-07-24 | Gannett Co., Inc. | Method of and apparatus for protecting a push button on a newspaper vending machine |

| US4986585A (en) * | 1990-03-01 | 1991-01-22 | Panter Scott C | Anti-theft guard for wing window latch safety button |

| US6318134B1 (en) * | 1998-07-14 | 2001-11-20 | Mossberg Safe Systems, Inc. | Safe locking mechanism |

| US9534422B1 (en) * | 2015-07-21 | 2017-01-03 | Safe and Care Ltd. | Latch fitting tool |

| US20180274270A1 (en) * | 2017-03-27 | 2018-09-27 | Ford Global Technologies, Llc | Bezel-less release button |

-

1928

- 1928-09-27 US US30875828 patent/US1784935A/en not_active Expired - Lifetime

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2606783A (en) * | 1950-05-15 | 1952-08-12 | Roethel Engineering Corp | Door handle assembly |

| US3039804A (en) * | 1961-08-04 | 1962-06-19 | Ideal Brass Works Inc | Door latch mechanism |

| US3838877A (en) * | 1973-10-29 | 1974-10-01 | W Hanson | Overhead door latch |

| US3973794A (en) * | 1975-04-30 | 1976-08-10 | Leonard Green | Interior door latch assembly |

| US4341409A (en) * | 1978-12-11 | 1982-07-27 | Sharp Kabushiki Kaisha | Door latching assembly |

| US4943695A (en) * | 1988-01-05 | 1990-07-24 | Gannett Co., Inc. | Method of and apparatus for protecting a push button on a newspaper vending machine |

| US4986585A (en) * | 1990-03-01 | 1991-01-22 | Panter Scott C | Anti-theft guard for wing window latch safety button |

| US6318134B1 (en) * | 1998-07-14 | 2001-11-20 | Mossberg Safe Systems, Inc. | Safe locking mechanism |

| US9534422B1 (en) * | 2015-07-21 | 2017-01-03 | Safe and Care Ltd. | Latch fitting tool |

| US20180274270A1 (en) * | 2017-03-27 | 2018-09-27 | Ford Global Technologies, Llc | Bezel-less release button |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1784935A (en) | Door latch | |

| US2047401A (en) | Door latch and opening mechanism | |

| US1619031A (en) | And paul ostrosky | |

| US2812204A (en) | Door lock | |

| US1244910A (en) | Door-opener. | |

| US3364621A (en) | Pedal-type door opener | |

| US983647A (en) | Latch. | |

| US2186795A (en) | Latch | |

| US2233278A (en) | Catch | |

| US3450453A (en) | Drawer latch device for filing cabinets | |

| US2558233A (en) | Latch | |

| US1075367A (en) | Sliding-door latch. | |

| US1548530A (en) | Sash lock | |

| US1940537A (en) | Latch mechanism | |

| US3168239A (en) | Signaling device for mail box and the like | |

| US2790665A (en) | Refrigerator latch | |

| US1321514A (en) | of aurora | |

| US2410347A (en) | Door latch | |

| US1955439A (en) | Overhead doorlock | |

| US2776157A (en) | Screen door latch | |

| US2488794A (en) | Door latch | |

| US1654729A (en) | Latch | |

| US1880876A (en) | A corpobation of mich | |

| US1854768A (en) | Electric door opener | |

| US2459190A (en) | Refrigerator latch |