US1784302A - Process for conditioning electric switches - Google Patents

Process for conditioning electric switches Download PDFInfo

- Publication number

- US1784302A US1784302A US148418A US14841826A US1784302A US 1784302 A US1784302 A US 1784302A US 148418 A US148418 A US 148418A US 14841826 A US14841826 A US 14841826A US 1784302 A US1784302 A US 1784302A

- Authority

- US

- United States

- Prior art keywords

- switch

- electrodes

- contacts

- vacuum

- gases

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H33/00—High-tension or heavy-current switches with arc-extinguishing or arc-preventing means

- H01H33/60—Switches wherein the means for extinguishing or preventing the arc do not include separate means for obtaining or increasing flow of arc-extinguishing fluid

- H01H33/66—Vacuum switches

Definitions

- This invention relates to a process for con ditioning electrical switches and refers par-- ticularly to switches adapted for use on high tension or high voltage transmission lines or v for linesintended to handle high power.

- An. object of'the present invention is to provide a process for. producing a switch which will be small in size, inexpensive to manufacture, and which can be used for high voltage or high power transmission lines without the dangers encountered in the use of the' present switches employed for like purao poses.

- the present invention ap'prehends that extremely high vacuums are the best known means of insulation and if employed as an in sulation for an electricalswitch will permit a relatively short separationv of the contact blades of the switch to break the current without causing arcing thereof.-

- high vacuum for insulating purposes was gener- 0 ally known, including even the value of such vacuum as in insulation in purely disconnect switches, it was-generally believed that electrical currents could not be opened by the separation of contacts in a vacuum chamber because the are formed at that separation would in its very operation vaporize some of the contact material and change the insulating vacuum to a conducting vacuum.

- the vacuum necessary to be employed must not contain any mercury, mercury vapor, 'or vapors from other metal or gas ordinaril occluded in metals and other materials 0 construction.

- contacts of copper, tungsten, or other suitable material properly conditioned for high vacuum-switch operation are enclosed in an insulating vacuum and thoroughly out-gassed.

- the out-gassing process consists of heating ()0 the materials within the vacuum chamber and exhausting the gases as they are'driven ofl.

- the preliminary heating may be done by external heat applied to the vacuum container, by heating the parts to be gassed, or by induction of electrical currents in them, these currents being induced by placing a primary winding in which an alternating current is flowing aroundthe Vacuum chamber, the final outgassing is performed by connecting the switch'in an electric circuit and allowing a charge of electric current to flow through the switch contacts and opening the contacts in such a way as to maintain for a short interval of time 'an are between the contacts.

- the gases must be pumped out of the switch chamber by means of .a high vacuum pump capable of producing a vacuum of at least 10- cm. of mer'cury'according to a McLeod gage.

- charcoal made absorbent for gases.

- some refrigerating agent such as cooling brine or liquid air.

- the moving contact or contacts of the switch must be entirely sealed within the vacuum switch inasmuch as no present-day known form of stufling box which could be used for running an operating rod for such contact through the chamber walls, while at the same time sufliciently tightly closing the chamber asto maintain the necessary extremely high vacuum.

- a metal vacuum-ti ht accordion or bellows-like device one end of which is sealed to the vacuum chamber and the other end of which is sealed to a movable operating link or rod used in transmitting motion from mechanism outside the vacuum chamber to the movmg contact parts contained within the vacuum chamber.

- the accordion or bellows-like device permits, by its flexibility, the required motion without loss of vacuum due to leaks, such as would occur if the rod were brought through a stufling box.

- the moving content may be loosely mounted within the vacuum chamber and operated to and from the contacting position by avity throu h tippin g or turning the sw-itc body as a w ole.

- the moving contacts of the switch may be loosely mounted within the vacuum chamber and connected with a plunger likewise located within the vacuum chamber but positioned to be actuated by a solenoid outside the vacuum chamber for, forcing the contacts to and from the contacting position.

- Another feature of the present invention is the provision of means by which the slight disintegration of the contacts of the switch at the breaking of the switch is prevented from coating the nmer walls of the vacuum chamber and eventually making said vacuum chamber conductive.

- the present invention includes a shield for preventing metal thrown from the contacts from depodting and accumulating upon the chamber walls.

- the switch comprises a chamber housing 2 of insulatin material, such as glass.

- 3 indicates a fixe conthe inner end cored out as at 5 to assist in centering the fixed and moving contacts of the switch and secure adequate contact. 6

- Said moving contact 6 indicates a moving contactfor the switchadapted to make contact with the fixed con-' tact 3 when the switch is closed, as illustrated in Figure 1.

- Said moving contact 6 has an annular recess 7 atits end for engaging the annular endof the stationary contact, thus centering the two contacts in the contacting position and securing a firm, intimate contact.

- the moving contact 6 is indicated'as connected with a rod 8 which extends without the housing 2 so that the upper end may be connected with a mechanical mechanism (not shown) by which the switch may be operated.

- a mechanical mechanism (not shown) by which the switch may be operated.

- the rod 8 of the moving contact is likewise sealed to the housing of the switch.

- the'housing 2 includes an accor ion or bellows 9 enclosing the rod 8.

- One end of said accordion or bellows 9 is sealed to the glass portion of the hoilsing as indicated at 10 and the other end of the accordion or bellows 9 is sealed to the rod 8', as indicated at 11.

- the switch is'inguide bars or standards l7 and 18. Said.

- guide bars mount a bar 19 engaging the switch housing 2' for holding the same in vertical position and also a bar 20 slidably secured to the rod 8 for guiding said rod in its vertical motion.

- 30 indicates stops on rod 8 to limit the motion of said rod, thereby preve'ntin excessive strains being placed on the accor ion.

- shield 21 secured to one of the contacts or otherwise mounted within the vessel or "vacuumjcham her 2 is rovidcd a shield 21 indicated as surroundlng the contacts and spaced between the contacts and the chamber walls. Said shield 21 revents the metallic ions or atoms thrown o from the contacts in opening'the switch from being deposited upon the walls of the chamber 2 and'hence prevents said walls from being built up with metal and rendered conductive to electrical currents.

- the chamber formed by the housing 35 and their rods. .Said out-gassing prelimi- 2 must be evacuated to an extremely low pressure. Preferably this evacuation is as thorough as possible.

- a suitable vacuum pump isconnected with the vessel housing 2. This pump connection is not shown inasmuch as the connection is fused together after the conditioning of the switch herein described. In other forms of the invention, the vacuum pump may, as before described, be left attached to the switch for operation continuously or intermittently to maintain the necessary high vacuum.

- vacuum chamber of the switch must be reduced in pressure to nearly a complete vacuum. This degree of evacuation must be beyond the vacuum in which rarefied gas is a conductor for electricity.

- the degree of vacuum required' is at least approximately 10" cm. mercury.

- the present invention is to be distinguished by the use of such exceptionall high vacuums. It is to be understood t at in evacuating. the vessel, the gases within the vessel first become more conductive to electricity and finally a. point is reached where the ionized gases are reduced to such an extent as to cause a decrease in the conductivity to electricity. This point of evacuation must be passed for operation of the switch of the resent invention.

- the switch After securing t e desired vacuum on the switch the switch then should be conditioned by out-gassing the switch.

- This step is employed for thoroughly removing all gases adsorbed within the metals of the contacts narily may be carried out in any of the ways greviouslypointed out but preferably it is nallyaccomplished by placing the switch in a high poweredline and opening the contacts are heated and the gases driven-out of the metals and removed by the vacuum pump.

- connection with t e vacuum pump may be sealed andthe vacuum pump removed, and the switch will thereafter op erate satisfactorily.

- the switch is illustrated as modified to provide a plurality of breaks-on opening the switch, the switch having a stationary contact 3 and another stationary contact 3b.

- the moving contact 6b is adapted for bridging said fixed contacts -3 andv 3b.

- Said moving contact 6?) is also indicated as provided with the pivoted arm 86 and the rod 23.

- the bellows9 for said rod areindicated as extending without the remainder of the housing 2.

- the switch is constructed in a form to give a snap or quick motion in breaking the contacts.

- the stationary contact 3 is engaged by the moving contact 60 which is provided with two spring arms 24 and 25, which are adapted to be forced outwardly in assuming the contacting position by the toggle connection 26 with the moving rod 80.

- Said rod 80 is sealed to the outside bellows 9.

- This form of the invention produces a rapid motion of the moving" contacts away from the stationary contacts in openin the switch.

- Each of the switches of the modified forms the instantaneous establishment of an arc.

- the action of the switch in establishing an are for that moment in which the current-is passing to the point of zero value is of great current from bein interrupted instantaneously at a time of 11 value. If the current enefit to the switch in that it' prevents the were interrupted instantaneously at a time of full value, a current surge would be placed on the line which would be ruinous to electrical apparatus thereon. For successful operation of the switch of the ty of the present invention, it is essential t at after the current passes to the point of zero value, the arc will not be maintained or re-estab- I lished.

- the occluded gases can be removed sufiiciently so that sustained arcing does not take place.

- the occluded gases of the contacts can be removed therefrom by establishing an arc discharge between the. electrodes at the potentials at which the switch is to be operated. Thereafter when the switch is operated at such potential an arc will be established for a fractional cycle only and will 'not be maintained and will not re-establish itself after the current has passed through the point of zero value.

- a process of producing "an electrical switch which comprises mounting contacts within a gas-tight chamber, exhausting the chamber to a pressure lower than the pressure at which gases are conductive, imposing an electrical potential on the contacts, opening the contacts to establish an arc therebetween, and exhausing from the chamber exber, which includes establishing an are be-.

- a process of conditioning an electrical switch for operation in breakin power circuits'carrying high power, whic 1 comprises, removing the gases from around the electrodes to such an extent that the gases present contain insuflicient ions to'establish an are, applying a potential between the con-.

- a process of conditioning a switch for operation in interrupting power circuits carrying high power which comprises removing from the field of the electrodes, the gases so that there I are insuflicient io'ns around the electrodes to sustain an arc, subjecting the electrodes to 'a preliminary outgassing treatment by heating the electrodes and removing the expelled gases from the field of the electrodes, then applyingpotential between the electrodes and opening the electrodes so as to effect an electrical discharge between the electrodes in. both directions, sufiicient to expel additional occluded gases from the contacts, removing suchroceluded gases from the field of the electrodes, and continuing the operation until the electrodes may be repeatedly separated without the development of a sustained arc therebetween.

- a process of conditioning an electrical swltch for operation of interrupting power transmission of distribution circuits which comprises, removing the gases around the electrodes to such an extent that a vacuum ambient is provided for the electrodes containing insuflicient gas to itself establish an are when the electrodes are separated, applying a potential between the electrodes, and opening the electrodes to establish a discharge therebetween to free theielectrodes of occluded gases or gas-evolving material, removing gases from the electrode ambient, and continuing the operation until the electrodes may be used for breaking power circuits without sufficient occluded material being drawn from the electrodes to establish an alternating current arc.

- a process of conditioning an electrical switch for operation in interrupting power circuits which comprises,'removing the gases around the electrodes to form an ambient therefor containing insuflicient gas to itself establish an are when the electrodes are separating, establishing an alternating current are between the electrodes for removing occluded gases therefrom, removing the expelled occluded gases from the electrode am bient, and continuing the operation until the electrodes have been denuded of gas-forming material to such a depth that an alternating current are will not be established when the electrodes are separating.

- a process of conditioning an electrical switch for operation in interrupting power circuits which comprises, removing the gases around the electrodes to such an extent that the electrode ambient contains insuflicient gases to itself establish an are when the electrodes separate, removing gas and gas-evolv- 1 ing materials from the electrodes, by establishing an arc therebetween, to such a depth that the electrodes are capable of emitting vapors of the material of the electrode only on separating, and will establish an'arc for a fractional cycle only.

- a process of conditioning an electrical switch for operation of interrupting power transmission or distribution circuits which comprises, removing the gases around the electrodes to such an extent that a vacuum ambient is provided for the electrodes containing insuflicient gas to itself establish an are when the electrodes are separated. applV ing a potential between -the electrodes and opening the electrodes to establish a discharge therebetween to free the electrodes of the occluded gases or gas-evolving material, removing gass from the electrode ambient. and repeating the discharge operations until the electrodes have been denuded of gas-forming material to such a depth that thev may be separated without the potential of the circuit establishing an alternating current arc.

- a process of conditioning a switch for operation in interrupting power circuits which comprises removing from the electrode ambient the gases so'thatthere is insuflicient material around the electrodes to establish an are when the electrodes separate, sending an electric-current through the switch and then opening the electrodes so as toeffect a discharge between the electrodes, removing the gases expelled from the electrodes. applving an increased potential to the switch circuit and effecting a further discharge between the electrodes, and repeating the operations until the electrodes may be repeatedly separated without the development of an alternating current are therebetween.

Landscapes

- High-Tension Arc-Extinguishing Switches Without Spraying Means (AREA)

Description

Dec. 9, 1930. R. A. MILLIKAN ET AL PROCESS FORCONDITIONING ELECTRIC SWITCHES Filed-Nov- 1926 2 Sheets-Sheet gwuwntov.

Filed Nov. 15,

R. A. MlLLlKAN ET AL PROCESS OR CONDITIONING ELECTRIC SWITCHES III?! 111511 1111.

Dec. 9, 1930.

PatentgedDe. 9, 1 930 UNITED STATES PATENT OFFICE ROBERT A. MILLIKAN AND ROYAL W. SORENSEN, OF PASADENA, CALIFORNIA, AS-

SIGNORS TO CALIFORNIA INSTITUTE OF TECHNOLOGY, 01

v CORPORATION OF CALIFORNIA rnocnss non connrrronme ELECTRIC swrronn's Application filed November 15, 1926. Serial No. 148,418.

This invention relates to a process for con ditioning electrical switches and refers par-- ticularly to switches adapted for use on high tension or high voltage transmission lines or v for linesintended to handle high power.

With the development in the transmission of electrical energy whereby voltages around 200,000 volts or over are frequently employed, the present types of electrical o switches'have proven extremely unsatisfactory for switching such high tension or high power lines. 7

An. object of'the present invention is to provide a process for. producing a switch which will be small in size, inexpensive to manufacture, and which can be used for high voltage or high power transmission lines without the dangers encountered in the use of the' present switches employed for like purao poses. p v a The present invention ap'prehends that extremely high vacuums are the best known means of insulation and if employed as an in sulation for an electricalswitch will permit a relatively short separationv of the contact blades of the switch to break the current without causing arcing thereof.- Before the present invention, while the value of high vacuum for insulating purposes was gener- 0 ally known, including even the value of such vacuum as in insulation in purely disconnect switches, it was-generally believed that electrical currents could not be opened by the separation of contacts in a vacuum chamber because the are formed at that separation would in its very operation vaporize some of the contact material and change the insulating vacuum to a conducting vacuum. The vacuum necessary to be employed must not contain any mercury, mercury vapor, 'or vapors from other metal or gas ordinaril occluded in metals and other materials 0 construction.

In accordance with the present invention, contacts of copper, tungsten, or other suitable material properly conditioned for high vacuum-switch operation are enclosed in an insulating vacuum and thoroughly out-gassed. -The out-gassing process consists of heating ()0 the materials within the vacuum chamber and exhausting the gases as they are'driven ofl. The preliminary heating may be done by external heat applied to the vacuum container, by heating the parts to be gassed, or by induction of electrical currents in them, these currents being induced by placing a primary winding in which an alternating current is flowing aroundthe Vacuum chamber, the final outgassing is performed by connecting the switch'in an electric circuit and allowing a charge of electric current to flow through the switch contacts and opening the contacts in such a way as to maintain for a short interval of time 'an are between the contacts. During all these out-gassing processes, the gases must be pumped out of the switch chamber by means of .a high vacuum pump capable of producing a vacuum of at least 10- cm. of mer'cury'according to a McLeod gage.

After the switch has been conditioned by this out-gassing r'ocess, the required vacuum PASADENA, CALIFORNIA,

may thereafter e maintained on the switch 7 in operation by tightly sealing the vacuum chamber or the switch may be left connected,

to a vacuum pump which is operatedmascre- 'quired to maintain such vacuum or there may be sealed to the vacuum chamber a pocket'com taining charcoal made absorbent for gases. When charcoal is used, its absorbing power is increased by cooling with some refrigerating agent, such as cooling brine or liquid air.

The moving contact or contacts of the switch must be entirely sealed within the vacuum switch inasmuch as no present-day known form of stufling box which could be used for running an operating rod for such contact through the chamber walls, while at the same time sufliciently tightly closing the chamber asto maintain the necessary extremely high vacuum. Inasmuch as for accomplished in the present invention by using a metal vacuum-ti ht accordion or bellows-like device, one end of which is sealed to the vacuum chamber and the other end of which is sealed to a movable operating link or rod used in transmitting motion from mechanism outside the vacuum chamber to the movmg contact parts contained within the vacuum chamber. When-so used, the accordion or bellows-like device permits, by its flexibility, the required motion without loss of vacuum due to leaks, such as would occur if the rod were brought through a stufling box.

While the use of such accordion or bellowslike device for connecting the moving contacts of the switch and with outside mecha nism is of extreme value for a commercial use of the switch, it is possible to substitute therefor other means for operating the moving contacts without leaks into the vacuum chamber. For example, the moving content may be loosely mounted within the vacuum chamber and operated to and from the contacting position by avity throu h tippin g or turning the sw-itc body as a w ole. Also the moving contacts of the switch may be loosely mounted within the vacuum chamber and connected with a plunger likewise located within the vacuum chamber but positioned to be actuated by a solenoid outside the vacuum chamber for, forcing the contacts to and from the contacting position.

Another feature of the present invention is the provision of means by which the slight disintegration of the contacts of the switch at the breaking of the switch is prevented from coating the nmer walls of the vacuum chamber and eventually making said vacuum chamber conductive. In the operation of a switch of this type, each time the switch is o ned a certain amount of material is t own of the contacts and after repeated operation, said material will build up and coat the vacuum chamber walls, rendering the same conductive if means are not provided 'for preventing this action. Accordingly the present invention includes a shield for preventing metal thrown from the contacts from depodting and accumulating upon the chamber walls.

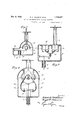

7 Various further objects and advantages of the present invention will be understood from a description of an example of a preferred switch and process of producing the same embodying t e present invention. For this I purpose, we have illustrated a switch embodyinvention. .Such Switch is in the present g the accompanying drawings illustrated in wherein Figure 1 discloses the switch in elevation and partially in vertical section, and

Figures 2, 3, and 4 indicate modified forms of the switch likewise in elevation and mainly in vertical section. v I

Referring to the drawings, the switch comprises a chamber housing 2 of insulatin material, such as glass. 3 indicates a fixe conthe inner end cored out as at 5 to assist in centering the fixed and moving contacts of the switch and secure adequate contact. 6

indicates a moving contactfor the switchadapted to make contact with the fixed con-' tact 3 when the switch is closed, as illustrated in Figure 1. Said moving contact 6 has an annular recess 7 atits end for engaging the annular endof the stationary contact, thus centering the two contacts in the contacting position and securing a firm, intimate contact.

The moving contact 6 is indicated'as connected with a rod 8 which extends without the housing 2 so that the upper end may be connected with a mechanical mechanism (not shown) by which the switch may be operated. To connect the switch in a circuit, one conduc'tor is attached to the end of the rod 3 which extends through the housing 2 and another conductor is attached to the rod 8 without the housing 2. The rod 8 of the moving contact is likewise sealed to the housing of the switch. In order to accomplish this while 'still permitting the rod 8 to be moved for opening and closin the switch, the'housing 2 includes an accor ion or bellows 9 enclosing the rod 8. One end of said accordion or bellows 9 is sealed to the glass portion of the hoilsing as indicated at 10 and the other end of the accordion or bellows 9 is sealed to the rod 8', as indicated at 11.

For mounting the switch, the switch is'inguide bars or standards l7 and 18. Said.

,guide bars mount a bar 19 engaging the switch housing 2' for holding the same in vertical position and also a bar 20 slidably secured to the rod 8 for guiding said rod in its vertical motion. 30 indicates stops on rod 8 to limit the motion of said rod, thereby preve'ntin excessive strains being placed on the accor ion.

Secured to one of the contacts or otherwise mounted within the vessel or "vacuumjcham her 2 is rovidcd a shield 21 indicated as surroundlng the contacts and spaced between the contacts and the chamber walls. Said shield 21 revents the metallic ions or atoms thrown o from the contacts in opening'the switch from being deposited upon the walls of the chamber 2 and'hence prevents said walls from being built up with metal and rendered conductive to electrical currents.

In constructing and in operating the switch, the chamber formed by the housing 35 and their rods. .Said out-gassing prelimi- 2 must be evacuated to an extremely low pressure. Preferably this evacuation is as thorough as possible. In the construction of theswitch, it is understood that a suitable vacuum pump isconnected with the vessel housing 2. This pump connection is not shown inasmuch as the connection is fused together after the conditioning of the switch herein described. In other forms of the invention, the vacuum pump may, as before described, be left attached to the switch for operation continuously or intermittently to maintain the necessary high vacuum. The

vacuum chamber of the switch must be reduced in pressure to nearly a complete vacuum. This degree of evacuation must be beyond the vacuum in which rarefied gas is a conductor for electricity. The degree of vacuum required' is at least approximately 10" cm. mercury. The present invention is to be distinguished by the use of such exceptionall high vacuums. It is to be understood t at in evacuating. the vessel, the gases within the vessel first become more conductive to electricity and finally a. point is reached where the ionized gases are reduced to such an extent as to cause a decrease in the conductivity to electricity. This point of evacuation must be passed for operation of the switch of the resent invention.

' After securing t e desired vacuum on the switch the switch then should be conditioned by out-gassing the switch. This step is employed for thoroughly removing all gases adsorbed within the metals of the contacts narily may be carried out in any of the ways greviouslypointed out but preferably it is nallyaccomplished by placing the switch in a high poweredline and opening the contacts are heated and the gases driven-out of the metals and removed by the vacuum pump. After the completion of this 0 eration, if

desired, the connection with t e vacuum pump may be sealed andthe vacuum pump removed, and the switch will thereafter op erate satisfactorily.

. In Figures 2, 3, and 4, the switch is illustrated' as slightly modified in form or shape, the similar elements of the switch being designated in these figures by similar nume'rals. In Figure 2, the movingcontactfi.

" 'is indicated as mounted upon a plvot-arm 8a as at 22and connect- 23 which extends outside the vessel 2 through an accordion 9. In this case, the accordion!) is indicated as positioned within the balance of the housing.

pivoted to the housing In Figure 3, the switch is illustrated as modified to provide a plurality of breaks-on opening the switch, the switch having a stationary contact 3 and another stationary contact 3b. The moving contact 6b is adapted for bridging said fixed contacts -3 andv 3b.

Said moving contact 6?) is also indicated as provided with the pivoted arm 86 and the rod 23. The bellows9 for said rod areindicated as extending without the remainder of the housing 2.

In Figure 4, the switch is constructed in a form to give a snap or quick motion in breaking the contacts. In this case, the stationary contact 3 is engaged by the moving contact 60 which is provided with two spring arms 24 and 25, which are adapted to be forced outwardly in assuming the contacting position by the toggle connection 26 with the moving rod 80. Said rod 80 is sealed to the outside bellows 9. This form of the invention produces a rapid motion of the moving" contacts away from the stationary contacts in openin the switch.

Each of the switches of the modified forms the instantaneous establishment of an arc.

It appears that even perfectly conditioned electrodes in a perfect vacuum will generate an are at the instant of separation This follows from the reason that the electrode surfaces are neverv absolutely flat and there is always alast infinitesimal point of separation. AtL-the instant of separation there is concentrated upon this infinitesimal point, for an. infinitesimal distance of separation, the entire voltage between the electrodes. These conditions cause electronstobe actually pulled from the, cold electrodes or contacts and also due to heating of the point of'separation, result in the formation of an ionized vapor which will establish an are. This are maintains itself for the balance of the current tacts, if any remain 'occlu edtherein, operat-- ing comparatively deeply into the contacts for such gases. If even comparatively deeply wburied occluded--gases exist ixf'the contacts during this instantaneous.establishment of the arc, they will be drawn into the arcfield and when insuflicient amount will furnish'a' means for re establishingfoigmaintaining the are after the current has passed through the pointof zero value.

The action of the switch in establishing an are for that moment in which the current-is passing to the point of zero value is of great current from bein interrupted instantaneously at a time of 11 value. If the current enefit to the switch in that it' prevents the were interrupted instantaneously at a time of full value, a current surge would be placed on the line which would be ruinous to electrical apparatus thereon. For successful operation of the switch of the ty of the present invention, it is essential t at after the current passes to the point of zero value, the arc will not be maintained or re-estab- I lished. The fact that electrodes, when separated on high potential lines in a perfect vacuum, produce an arc, however, causes switches of this type to extract occluded gases from the contacts which are not removed by ordinary methods of removing occluded gases and has led the art in previous experiments with vacuum switches to come to the conclusion that switching in vacuum without persistentarcing was lmpossible. By following the procedure of removing occluded gases herein described it has been found, however,

that the occluded gases can be removed sufiiciently so that sustained arcing does not take place. The occluded gases of the contacts can be removed therefrom by establishing an arc discharge between the. electrodes at the potentials at which the switch is to be operated. Thereafter when the switch is operated at such potential an arc will be established for a fractional cycle only and will 'not be maintained and will not re-establish itself after the current has passed through the point of zero value. While the process of conditioning or out- -gassing the switches, herein described, is well adaptedto carry out the objects of the invention, it is understood that the invention includes all such changes and modifications as come within the scope of the appended claims.

We claim:

1. A process of producing "an electrical switch, which comprises mounting contacts within a gas-tight chamber, exhausting the chamber to a pressure lower than the pressure at which gases are conductive, imposing an electrical potential on the contacts, opening the contacts to establish an arc therebetween, and exhausing from the chamber exber, which includes establishing an are be-.

tween the parts and exhausting the expelled gases until the arc is extinguished.

4. A process of conditioning an electrical switch for operation in breakin power circuits'carrying high power, whic 1 comprises, removing the gases from around the electrodes to such an extent that the gases present contain insuflicient ions to'establish an are, applying a potential between the con-.

tacts, and. opening the contacts to effect an electronic discharge in both directions operative for pulling occluded gases from the contacts, removing such ases from the electrode field, and continuing the operation until the electrodes may be separatm. under the potential without arcing after the current passes to the point of zero value.

5. A process of conditioning a switch for operation in interrupting power circuits carrying high power, which comprises removing from the field of the electrodes, the gases so that there I are insuflicient io'ns around the electrodes to sustain an arc, subjecting the electrodes to 'a preliminary outgassing treatment by heating the electrodes and removing the expelled gases from the field of the electrodes, then applyingpotential between the electrodes and opening the electrodes so as to effect an electrical discharge between the electrodes in. both directions, sufiicient to expel additional occluded gases from the contacts, removing suchroceluded gases from the field of the electrodes, and continuing the operation until the electrodes may be repeatedly separated without the development of a sustained arc therebetween.

6. A process of conditioning an electrical swltch for operation of interrupting power transmission of distribution circuits which comprises, removing the gases around the electrodes to such an extent that a vacuum ambient is provided for the electrodes containing insuflicient gas to itself establish an are when the electrodes are separated, applying a potential between the electrodes, and opening the electrodes to establish a discharge therebetween to free theielectrodes of occluded gases or gas-evolving material, removing gases from the electrode ambient, and continuing the operation until the electrodes may be used for breaking power circuits without sufficient occluded material being drawn from the electrodes to establish an alternating current arc.

7. A process of conditioning an electrical switch for operation in interrupting power circuits which comprises,'removing the gases around the electrodes to form an ambient therefor containing insuflicient gas to itself establish an are when the electrodes are separating, establishing an alternating current are between the electrodes for removing occluded gases therefrom, removing the expelled occluded gases from the electrode am bient, and continuing the operation until the electrodes have been denuded of gas-forming material to such a depth that an alternating current are will not be established when the electrodes are separating.

8. A process of conditioning an electrical switch for operation in interrupting power circuits which comprises, removing the gases around the electrodes to such an extent that the electrode ambient contains insuflicient gases to itself establish an are when the electrodes separate, removing gas and gas-evolv- 1 ing materials from the electrodes, by establishing an arc therebetween, to such a depth that the electrodes are capable of emitting vapors of the material of the electrode only on separating, and will establish an'arc for a fractional cycle only.

9. A process of conditioning an electrical switch for operation of interrupting power transmission or distribution circuits which comprises, removing the gases around the electrodes to such an extent that a vacuum ambient is provided for the electrodes containing insuflicient gas to itself establish an are when the electrodes are separated. applV ing a potential between -the electrodes and opening the electrodes to establish a discharge therebetween to free the electrodes of the occluded gases or gas-evolving material, removing gass from the electrode ambient. and repeating the discharge operations until the electrodes have been denuded of gas-forming material to such a depth that thev may be separated without the potential of the circuit establishing an alternating current arc.

10. A process of conditioning a switch for operation in interrupting power circuits which comprises removing from the electrode ambient the gases so'thatthere is insuflicient material around the electrodes to establish an are when the electrodes separate, sending an electric-current through the switch and then opening the electrodes so as toeffect a discharge between the electrodes, removing the gases expelled from the electrodes. applving an increased potential to the switch circuit and effecting a further discharge between the electrodes, and repeating the operations until the electrodes may be repeatedly separated without the development of an alternating current are therebetween.

Signed at Los Angeles, Calif., this 30th day of October, 1926.

' ROBERT A. MILLIKAN.

ROYAL -W. SORENSEN.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US148418A US1784302A (en) | 1926-11-15 | 1926-11-15 | Process for conditioning electric switches |

| DEM97403D DE539812C (en) | 1926-11-15 | 1926-12-14 | Procedure for degassing the contacts of high-voltage vacuum switches |

| FR626633D FR626633A (en) | 1926-11-15 | 1926-12-22 | Electrical switches |

| US199580A US1996304A (en) | 1926-11-15 | 1927-06-17 | Electric switch |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US148418A US1784302A (en) | 1926-11-15 | 1926-11-15 | Process for conditioning electric switches |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1784302A true US1784302A (en) | 1930-12-09 |

Family

ID=22525676

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US148418A Expired - Lifetime US1784302A (en) | 1926-11-15 | 1926-11-15 | Process for conditioning electric switches |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1784302A (en) |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2658120A (en) * | 1948-05-25 | 1953-11-03 | Bendix Aviat Corp | Pressure responsive switch |

| US2740869A (en) * | 1953-07-20 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2740867A (en) * | 1952-10-28 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2740868A (en) * | 1953-03-02 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2794101A (en) * | 1955-08-29 | 1957-05-28 | Jennings Radio Mfg Corp | Vacuum switch |

| US2794885A (en) * | 1954-12-13 | 1957-06-04 | Jennings Radio Mfg Corp | Vacuum switch |

| US2979588A (en) * | 1958-12-09 | 1961-04-11 | Jennings Radio Mfg Corp | Vacuum switch |

| US3014106A (en) * | 1958-03-03 | 1961-12-19 | Jennings Radio Mfg Corp | Vacuum switch |

| US3021408A (en) * | 1959-05-18 | 1962-02-13 | Jennings Radio Mfg Corp | Coaxial switch |

| US3026394A (en) * | 1959-11-10 | 1962-03-20 | Jennings Radio Mfg Corp | Vacuumized electric switch |

| US3036180A (en) * | 1959-05-11 | 1962-05-22 | Gen Electric | Contact structure for a vacuum-type circuit interrupter |

| US3065321A (en) * | 1959-11-06 | 1962-11-20 | Allis Chalmers Mfg Co | Vacuum switch actuated by fluid pressure impulse means |

| US3079481A (en) * | 1961-05-19 | 1963-02-26 | Jennings Radio Mfg Corp | Multiple position vacuum switch |

| US3177323A (en) * | 1960-12-19 | 1965-04-06 | Ite Circuit Breaker Ltd | Gas deflecting plate and operating rod |

| US3270172A (en) * | 1961-06-30 | 1966-08-30 | English Electric Co Ltd | Switch having an arc stabilizing electrode |

| US3446926A (en) * | 1965-11-22 | 1969-05-27 | Jennings Radio Mfg Corp | Vacuum relay having a pivotally mounted armature |

| US3482070A (en) * | 1965-12-03 | 1969-12-02 | Asea Ab | Vacuum d.c. breaker with relative contact movement interposing a non-conductor to extinguish arc |

-

1926

- 1926-11-15 US US148418A patent/US1784302A/en not_active Expired - Lifetime

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2658120A (en) * | 1948-05-25 | 1953-11-03 | Bendix Aviat Corp | Pressure responsive switch |

| US2740867A (en) * | 1952-10-28 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2740868A (en) * | 1953-03-02 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2740869A (en) * | 1953-07-20 | 1956-04-03 | Jennings Radio Mfg Corp | Vacuum switch |

| US2794885A (en) * | 1954-12-13 | 1957-06-04 | Jennings Radio Mfg Corp | Vacuum switch |

| US2794101A (en) * | 1955-08-29 | 1957-05-28 | Jennings Radio Mfg Corp | Vacuum switch |

| US3014106A (en) * | 1958-03-03 | 1961-12-19 | Jennings Radio Mfg Corp | Vacuum switch |

| US2979588A (en) * | 1958-12-09 | 1961-04-11 | Jennings Radio Mfg Corp | Vacuum switch |

| US3036180A (en) * | 1959-05-11 | 1962-05-22 | Gen Electric | Contact structure for a vacuum-type circuit interrupter |

| US3021408A (en) * | 1959-05-18 | 1962-02-13 | Jennings Radio Mfg Corp | Coaxial switch |

| US3065321A (en) * | 1959-11-06 | 1962-11-20 | Allis Chalmers Mfg Co | Vacuum switch actuated by fluid pressure impulse means |

| US3026394A (en) * | 1959-11-10 | 1962-03-20 | Jennings Radio Mfg Corp | Vacuumized electric switch |

| US3177323A (en) * | 1960-12-19 | 1965-04-06 | Ite Circuit Breaker Ltd | Gas deflecting plate and operating rod |

| US3079481A (en) * | 1961-05-19 | 1963-02-26 | Jennings Radio Mfg Corp | Multiple position vacuum switch |

| US3270172A (en) * | 1961-06-30 | 1966-08-30 | English Electric Co Ltd | Switch having an arc stabilizing electrode |

| US3446926A (en) * | 1965-11-22 | 1969-05-27 | Jennings Radio Mfg Corp | Vacuum relay having a pivotally mounted armature |

| US3482070A (en) * | 1965-12-03 | 1969-12-02 | Asea Ab | Vacuum d.c. breaker with relative contact movement interposing a non-conductor to extinguish arc |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1784302A (en) | Process for conditioning electric switches | |

| US3462573A (en) | Vacuum-type circuit interrupters using gallium or gallium alloys as bridging conducting material | |

| US1814851A (en) | Circuit controlling apparatus | |

| US1963963A (en) | Discharge apparatus and method | |

| US1784303A (en) | Alternating-power-current interrupter | |

| US2347715A (en) | Arc starting device | |

| US2286800A (en) | Time relay for fluorescent lamps | |

| US2972032A (en) | Vacuum interrupter | |

| US1961749A (en) | Gaseous electric discharge device | |

| US2859309A (en) | Arc free multiple break circuit interrupting and isolating means | |

| US2332809A (en) | Glow switch | |

| US2246171A (en) | Method of and apparatus for interrupting electric arcs | |

| US1996304A (en) | Electric switch | |

| US1948687A (en) | Electric contact | |

| US2107742A (en) | Mercury contact interrupter | |

| US1901639A (en) | Vacuum circuit breaker | |

| GB1114613A (en) | Cross-blast circuit breakers | |

| US2146656A (en) | Electric circuit interrupter | |

| US1789556A (en) | Method of manufacturing gas-filled envelopes | |

| GB1229036A (en) | ||

| US1922245A (en) | Manufacture of gaseous conduction devices | |

| US2522062A (en) | Vacuum tube seal | |

| US1437607A (en) | Electron tube | |

| US2528033A (en) | Power rectifier tube | |

| US1879131A (en) | Method of degassing vacuum apparatus |