US1765398A - Sprayer - Google Patents

Sprayer Download PDFInfo

- Publication number

- US1765398A US1765398A US158189A US15818926A US1765398A US 1765398 A US1765398 A US 1765398A US 158189 A US158189 A US 158189A US 15818926 A US15818926 A US 15818926A US 1765398 A US1765398 A US 1765398A

- Authority

- US

- United States

- Prior art keywords

- pressure

- pot

- valve

- air

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/24—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device

- B05B7/2489—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device an atomising fluid, e.g. a gas, being supplied to the discharge device

- B05B7/2494—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device an atomising fluid, e.g. a gas, being supplied to the discharge device a liquid being supplied from a pressurized or compressible container to the discharge device

Definitions

- This invention relates to painting equipment; and, with regard to certain more specific features, to palnt spraying EQUIP- ment actuated by. a compressed gas such as.

- the invention accordingly comprises the elements and combination of elements, features of construction, and ⁇ arrangements of parts which will be exemplified 1n the structure hereinafter described, and the scope of the application of which will in the following claims.

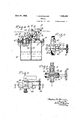

- Fig. 1 is a diagrammatic side elevation be indicated of the improved construction, shown assembled and ready for use; V I

- Fig. .3 is a vertical section of said pot

- Fig. ,4 is a plan view of a volumecontrol valve

- Fig. 5 is an enlarged horizontal section taken along line 5-5 of Fig. 6'and shows certain cut-oil ports adapted to control the volume of material;

- Fig. 6 isa front end view'of Fig. 1.

- a conventional air supply tank wh1ch wh1ch,'in the present embodiment, carr es a substantially constant pressure of air, of the order of one hundred V stant.

- the outlet of the tank 1 is equipped with a stop-cock 11 from which leads a main air'supply hose 13. Y

- the main air supply hose 13 leads to a second stop cock 15, located on the lid 17 of a paintpot 19.

- the cock 15 is in communication with aregulator valve 21, also located on said'lid 17; but the regulator 'valve 21 does not communicate with the interior of the pot 19, Rather, the outlet 23 of the regulator 21 communicates with a manifold 25 which in turn has outlet stop cocks 27, to at least one of which, is connected an air hose 29 which leads to an, air inlet nipple 81 of a spray gun33.

- the gun 33 is of the general type illustrated and describedin my patent application for spray gun,Serial No. 135,113, filed September-l3, 1926, now Patent No. 1,729,- 759 of Oct. 1, 1929, wherein a stream of painting material and air meet atla nozzle 35 to form an atomized spray 37. A new of both air and paint through the gun33 may be controlled from a trigger 89. Inasmuch as the gun per se doesnot constitute the presentinvention, a further description of it will not be given. It is to be noted that the manifold 25 carries a pressure sight gage '26 whereby the result of any adjustment at the regulator 21 may be visually noted. The purpose of the plurality of 1 valve ⁇ 11.

- cocks 27 is to accommodate more than one gun to a pot, if desired.

- cock 15 is also in communication with a non-adjustable pressure reducing This communication is made by way of pipes l3 and a small manifold 415.

- the reducing' valve 41 receives its air supply directly from the stop cock 15, without substantial loss of pressure, and not by Way of the regulator 21 after said regulator has reduced the air pressure.

- the main air supply coming through the stop cock 15' branches into two directions, in one direction through the regulator or adjustable pressure reducer 21 and in the other position, provided a substantially constant pressure is had in the tank 1.

- the non-ad ustable reducing valve 41 1S in communication with the interior of the pot 19 by way of a line 19 which leads to a blind-hole 51 adapted to prevent painting material from getting into the valve.

- a conventional outlet cock 53 communicates with the interior of the pot 19 by means-of another line 55 leading to another blind hole 57.

- a conventional safety valve 59 is also provided onsaid pot.

- the lid 17 is removably sealed to the pot 19 by thumb screws 61.

- the manifold 63 is provided with an outlet cook 67 on the outside of said lid 17. It is evident that when pressure is applied to the interior of the pot 19 in the manner described, that there will be a tendency to force paint therefrom by way of the line 65, manifold 63 and cook 67, A plurality of cocks 67 may be used if a plurality of guns 33 are to be used, as in the case of the cocks 27.

- a volume control valve 69 illustrated more particularly in Figs. 1 to 6. taken in combination with its application, is a salient" feature of this invention and will thereforebe described in particular.

- the volume control valve 69 comprises a body extension 71 from the cook 67 through which is formed a longitudinal opening or passage 73, said opening passing directly through the cock 67 and adapted to be opened and closed thereby,

- a cross-passage intersects the opening 73 and is adapted to. slidably receive a valve stem 77, the said stem 77 and the passage 75 being packed against leakage at the ends thereof by means of stuffing glands 79.

- the in the present embodiment made by a number forty drill.

- the large diameters of the other four ports are made by the same number forty drill, but the small effective diameters of said other four ports are made by drills numbered 58, 6'2, 65 and '68 I respectively.

- the five ports 81 are of variable effective diameters and will therefore be adapted to control the volume of paint passing from the pot 19, if a means is provided for placingthe respective ports in line with the passage 73. This is done by providing a control piece 83 on the end of the stem 77, whereby the'move ment of they said stem 77 may be controlled- Extending from the piece ,83 parallel" to the stem 77 is an indicator rod '85 which I

- the operation of the invention is as follows:

- the predetermined pressure (say one hundred pounds per square inch), as governed by the unloader 9, is maintainedin the7 tank 1 by the compressing system 3, o

- the stop cocks 11 and 15 are opened.

- air at one hundred pounds pressure is supplied to the regulating valve 21 and to the nonadjustable reducing valve 4.1.

- the non-adjustable reducing valve ll causes a predetermined pressure to be. maintained on the material within the pot, this pressure depending upon the original manufactured characteristics of the valve and being thirty pounds in the present embodiment. This pressure cannot be changed by the operator.

- the proper cocks 27 and 67 are opened.

- the operator sets the volume control valve 69, such that the desired port is in position to give the required paint flow adapted to maintain a given rate of work for the particular operator.

- the operator also adjusts the regulator 21 to get the desired aspirating effect on his air.

- the only remaining operation is topull the trigger 39 to put the gun 33 into operation. 1

- One of the advantages of this invention comprises the ease with which control may be had.

- the control of the paint supply was had by changing the pressure on said paint supply, which necessitated a resetting of the valve ll which was adapted to be adjusted by the operator; and it also necessitated a troublesome resetting ofthe valve 21 to meet the conditions of the new pressure on the ma terial at the gun.

- the operator cannot change the pressure on the material supply, because the reducing valve 41 is not adjustable and the unloader 9 is not under control of the operator in his remote working position.

- the unloader 9 is set primarily with regard to the requirements of safety at the tank- 1 and is not reset at the operator at the regulator21. If theoperator desires more or less material to accommodate moreor'lessspeed of operation he sets the.

- volume controlvalve 69 does not necessitate. as many resettings at the valve 21 as was the case when the pressure of the material; was initially regulated, instead of the volume of the material as. herein described.

- Another advantage comprises the fact that thehose 89 does not carry full. pot pressure 7 during the spraying operation or when paint is. flowing due to other causes; but only when the system'is idle for a period.

- a'liquid sprayer ama-in air supply tank, a pressure tight pot for liquid, a communicating line between said tank and said pot including therein a non-adjustablepressure reducer, a branch from said line on the high pressure side of said reducer to an adjustable pressure reducer, an outlet from said pot adapted to have liquid forced therefrom by means of the fixed pressure within said pot, said outlet communicating with a volume control valve, a spray gun including means for atomizing liquid by means of air under pressure, communicating means from said adjustable reducer to the air inlet of the spray gun and communicating means from said volume control valve to the liquid inlet of said spray gun, said volume control valve comprising a body having a passage, a movable closing stem intersecting said passage and having openings of various sizes therein adapted to control the volume of'fiuid going through said passage when the stem is moved.

- a main air supply tank under substantially constant pressure, a pressure tight pot for liquid, a communicating line between said tank and said pot including therein a fixed pressure reducer,

- a liquid-carrying pot means for supplying a positively constant pressure to said liquid-carrying pot comprising compressing means and a fixed pressure reducer, a spray gun having an air inlet and a liquid inlet, means for supplying an adjustable pressure of air to said air inlet comprising said compressing means and an adjustable pressure reducer, a volume control valve, said pot having a liquid outlet communicating with said volume control valve, and volume control valve having a communication with the liquid inlet of said gun, said volume control valve comprising means for adjustably inserting in the liquid outlet from said pot a member having various orifices and means for holding said last-named member in predetermined position without attention from an operator.

Landscapes

- Nozzles (AREA)

Description

.T. BIRKENMAIER S PRAYER June .24, 1930.

Filed Dec. 31, 1926 2 Sheets-Sheet 1 June 24, 1930.

A/o N-A DJus TA Wi/Qa T. BIRKENMAIER SPRAYEB Filed Dec. 5]., 1926 ADJLASTABL s,

INN

"law."

2 sheets-sheet 2 Patented June 24, 1930 UNITED STATES aoFFiacE v THEODORE'BIRKENMAIER, OFjS'I. LOUIS, MISSOURI, ASSIGNOR TO W' N. MATTHEWS CORPORATION, OF ST. LOUIS, MISSOURI, A CORPORATION OF MISSOURI .SPRAYER Application filed December 31, .1926. ,Serial No. 158,189.

This invention relates to painting equipment; and, with regard to certain more specific features, to palnt spraying EQUIP- ment actuated by. a compressed gas such as.

air.

Among the several objects of the invention may be noted the provision of means for bringing together streams of painting material. and air, both under pressure, whereby the former is projected as a spray by the latter; the provision of means of the class described in which certain air, taken from a main air supply may have its pressure adjustably regulated for purposes of atomization of painting material; the provisionof said means in. whichlthematerial supply is under a constant pressure obtained from said main air supply;.the provision of means whereby said material supply may have its Volume of flowvariedand controlled without substantially affecting the pressure of said material supply, which pressure is maintained constant, asxdescribed; the provision of a device of the class described which is compact in construction and readily operable without the necessity for involved or intricate adjustments and the provision of a device of the classdescribed which is subject to less disastrous, accidental discharges at the nozzle thereof. Other objects will be in part obvious and in part pointed out hereinafter.

The invention accordingly comprises the elements and combination of elements, features of construction, and {arrangements of parts which will be exemplified 1n the structure hereinafter described, and the scope of the application of which will in the following claims.

In the accompanying drawings, in which is illustrated one of various possible .embodiments vof the invention.

Fig. 1 is a diagrammatic side elevation be indicated of the improved construction, shown assembled and ready for use; V I

2 is .a top plan view of a paintlpo t; Fig. .3 is a vertical section of said pot; Fig. ,4 is a plan view of a volumecontrol valve;

Fig. 5 is an enlarged horizontal section taken along line 5-5 of Fig. 6'and shows certain cut-oil ports adapted to control the volume of material; and,

Fig. 6 isa front end view'of Fig. 1.

Similar reference characters indicate corresponding parts throughout the several views of the drawings.

Referring now more particularly toFig. 1

there is illustrated at numeral 1 a conventional air supply tank wh1ch,'in the present embodiment, carr es a substantially constant pressure of air, of the order of one hundred V stant. The outlet of the tank 1 is equipped with a stop-cock 11 from which leads a main air'supply hose 13. Y

The main air supply hose 13 leads to a second stop cock 15, located on the lid 17 of a paintpot 19. The cock 15 is in communication with aregulator valve 21, also located on said'lid 17; but the regulator 'valve 21 does not communicate with the interior of the pot 19, Rather, the outlet 23 of the regulator 21 communicates with a manifold 25 which in turn has outlet stop cocks 27, to at least one of which, is connected an air hose 29 which leads to an, air inlet nipple 81 of a spray gun33.

The gun 33 is of the general type illustrated and describedin my patent application for spray gun,Serial No. 135,113, filed September-l3, 1926, now Patent No. 1,729,- 759 of Oct. 1, 1929, wherein a stream of painting material and air meet atla nozzle 35 to form an atomized spray 37. A new of both air and paint through the gun33 may be controlled from a trigger 89. Inasmuch as the gun per se doesnot constitute the presentinvention, a further description of it will not be given. It is to be noted that the manifold 25 carries a pressure sight gage '26 whereby the result of any adjustment at the regulator 21 may be visually noted. The purpose of the plurality of 1 valve {11.

Referring again to Figs. 2 and 3, it is evident that the cock 15 is also in communication with a non-adjustable pressure reducing This communication is made by way of pipes l3 and a small manifold 415.

It is to be understood that thereducing' valve 41 receives its air supply directly from the stop cock 15, without substantial loss of pressure, and not by Way of the regulator 21 after said regulator has reduced the air pressure. In other words,the main air supply coming through the stop cock 15'branches into two directions, in one direction through the regulator or adjustable pressure reducer 21 and in the other position, provided a substantially constant pressure is had in the tank 1.

The non-ad ustable reducing valve 41 1S in communication with the interior of the pot 19 by way of a line 19 which leads to a blind-hole 51 adapted to prevent painting material from getting into the valve. The

purpose and description of the type of blind-hole construction is given more par.- ticularly in my patent application for painting apparatus, SerialNo. 7%,335, filed October 18, 1924, now Patent No. 1,691,37 l of Nov. 13, 1928. It does not comprise the present invention per se and will therefore not be further detailed here.

It is evident from the above, that the nonadjustable reducing valve 411 1s adapted to' maintain a substantially constant pressure within the pot 19, in so far as a fairly constant pressure is maintained within the main air supply tank. No means is provided for regulating the reduction of pressure at the non-adjustable valve 41. The result is that the liquid painting material which is carried in the pot 19 is kept at a constant pressure, say thirty pounds per square inch gage. V g

A conventional outlet cock 53 communicates with the interior of the pot 19 by means-of another line 55 leading to another blind hole 57. A conventional safety valve 59 is also provided onsaid pot. The lid 17 is removably sealed to the pot 19 by thumb screws 61.

Depending from an outlet manifold 63 in the lid 17 is an outlet line 65 reaching almost to the bottom of the pot 19. The manifold 63 is provided with an outlet cook 67 on the outside of said lid 17. It is evident that when pressure is applied to the interior of the pot 19 in the manner described, that there will be a tendency to force paint therefrom by way of the line 65, manifold 63 and cook 67, A plurality of cocks 67 may be used if a plurality of guns 33 are to be used, as in the case of the cocks 27.

The outlet side of said cock 67 is integrallyformed with a volume control valve 69, illustrated more particularly in Figs. 1 to 6. taken in combination with its application, is a salient" feature of this invention and will thereforebe described in particular.

The volume control valve 69 comprises a body extension 71 from the cook 67 through which is formed a longitudinal opening or passage 73, said opening passing directly through the cock 67 and adapted to be opened and closed thereby,

A cross-passage intersects the opening 73 and is adapted to. slidably receive a valve stem 77, the said stem 77 and the passage 75 being packed against leakage at the ends thereof by means of stuffing glands 79.

Formed laterally across the stem 77 and longitudinally of the opening 73 are cut-01f or volume control ports or orifices 81. Four of these ports 81 are smaller at one end than the other and the small end is set toward the cook 67, that is, against the flow of ma terial.v The purpose of this is to prevent flocculent material or other foreign matter from wedging and remaining in the ports. The fifth and largest port is astraight bore The construction'of the valve 69,

in the present embodiment made by a number forty drill. The large diameters of the other four ports are made by the same number forty drill, but the small effective diameters of said other four ports are made by drills numbered 58, 6'2, 65 and '68 I respectively.

7 It is evident from the drawings that the five ports 81, are of variable effective diameters and will therefore be adapted to control the volume of paint passing from the pot 19, if a means is provided for placingthe respective ports in line with the passage 73. This is done by providing a control piece 83 on the end of the stem 77, whereby the'move ment of they said stem 77 may be controlled- Extending from the piece ,83 parallel" to the stem 77 is an indicator rod '85 which I The operation of the invention is as follows:

The predetermined pressure (say one hundred pounds per square inch), as governed by the unloader 9, is maintainedin the7 tank 1 by the compressing system 3, o

1 In order to provide painting material and atomizing air at the gun 33, the stop cocks 11 and 15 are opened. By this means, air at one hundred pounds pressure is supplied to the regulating valve 21 and to the nonadjustable reducing valve 4.1. The non-adjustable reducing valve ll causes a predetermined pressure to be. maintained on the material within the pot, this pressure depending upon the original manufactured characteristics of the valve and being thirty pounds in the present embodiment. This pressure cannot be changed by the operator.

On the other hand, that air which passes to the regulating valve 21 is reduced in pressure by said valve 21 an amount depending upon the setting of the adjusting screw 47 which is controllable by'said operator. other words, the pressure of the atomizing air is under control of the operator. The pressure is indicated at the gage 26. The adjusted or regulated air pressure is maintained in the manifold 25.

In order to bring air and material to the gun 33, the proper cocks 27 and 67 are opened. The operator sets the volume control valve 69, such that the desired port is in position to give the required paint flow adapted to maintain a given rate of work for the particular operator. The operator also adjusts the regulator 21 to get the desired aspirating effect on his air.

The only remaining operation is topull the trigger 39 to put the gun 33 into operation. 1

One of the advantages of this invention comprises the ease with which control may be had. For each pressure on a supply of paint there is usually a definite atomizing air pressure required; or at least only a rather limited range of such atomizing-air pressures. In the systems previously used the control of the paint supply was had by changing the pressure on said paint supply, which necessitated a resetting of the valve ll which was adapted to be adjusted by the operator; and it also necessitated a troublesome resetting ofthe valve 21 to meet the conditions of the new pressure on the ma terial at the gun.

In the present invention the operator cannot change the pressure on the material supply, because the reducing valve 41 is not adjustable and the unloader 9 is not under control of the operator in his remote working position. The unloader 9 is set primarily with regard to the requirements of safety at the tank- 1 and is not reset at the operator at the regulator21. If theoperator desires more or less material to accommodate moreor'lessspeed of operation he sets the.

It is to be understood that there is some inherent pressure drop through the material passages from. the pot to the gun; but the resulting variation in pressure at the nozzle, is not ottheorder of the pressure variation at thenczzle which was had by manually regulating pressure from the reducer alto change the paint flow. Therefore the required. settings are simplified. The above statements hold for the system while spraymg.

Another advantagecomprises the fact that thehose 89 does not carry full. pot pressure 7 during the spraying operation or when paint is. flowing due to other causes; but only when the system'is idle for a period. and

. pressure has had a chance to build up in the line 89. 'Hence, a break in'the line or a nozzle which isv stuck and opento theflow of material does not result in. an excessive outrushing of paint with consequent loss and da1nage,"as has been the case hereto;

fore, where the line. 91. had. no volume, 0011- trolbetween it the pot under pressure. In the present invention the material line is restricted, againstany abnormal rushof fluid, therethrough. The loss of. paint and resulting.v damage, -due to accidentswhich happen frequently in thisindustry, are-thus greatly reducedby means of the presentinvention. It. istobe noted in this connection, that some time isrequired toireach the cocks27, 69'from an operators positionat the gun 33, which may. be at the end. of a long length of hose. The outrush of fluid may therefore be more disastrous. if not checked, as by. the volume control.

In view of. the above, it will be seen that the several objects. of the invention 7 are achieved. and other advantageous. results attained. j

Asmanychangescouldbe made in carry ing out the above constructions without de parting from the scopefo'fthe invention, it is intendedthat.allmatter contained in the above description or. shown in the accompanyingdrawings shall be interpreted asillustrative and not in alimiting sense.

I claim:-

1. In a'liquid sprayer, ama-in air supply tank, a pressure tight pot for liquid, a communicating line between said tank and said pot including therein a non-adjustablepressure reducer, a branch from said line on the high pressure side of said reducer to an adjustable pressure reducer, an outlet from said pot adapted to have liquid forced therefrom by means of the fixed pressure within said pot, said outlet communicating with a volume control valve, a spray gun including means for atomizing liquid by means of air under pressure, communicating means from said adjustable reducer to the air inlet of the spray gun and communicating means from said volume control valve to the liquid inlet of said spray gun, said volume control valve comprising a body having a passage, a movable closing stem intersecting said passage and having openings of various sizes therein adapted to control the volume of'fiuid going through said passage when the stem is moved. r

2. In a liquid sprayer, a main air supply tank, under substantially constant pressure, a pressure tight pot for liquid, a communicating line between said tank and said pot including therein a fixed pressure reducer,

a branch from said line on the high pressure side of said reducer to an adjustable pressure reducer, an outlet from said pot adapted to have liquid forced therefrom by means of the fixed pressure within said pot, said out-let communicating with a volume control valve, a spray gun including means for atomiz ing liquid by means of air under pressure, communicating means from said adjustable reducer to the air. inlet: of the spray gun and communicating means from said volume control valve to the" liquid inlet of said spray gun, said volume control valve comprising a passage intersected by a mov- 40 able member having various sized openings.

3. In a sprayer, a liquid-carrying pot, means for supplying a positively constant pressure to said liquid-carrying pot comprising compressing means and a fixed pressure reducer, a spray gun having an air inlet and a liquid inlet, means for supplying an adjustable pressure of air to said air inlet comprising said compressing means and an adjustable pressure reducer, a volume control valve, said pot having a liquid outlet communicating with said volume control valve, and volume control valve having a communication with the liquid inlet of said gun, said volume control valve comprising means for adjustably inserting in the liquid outlet from said pot a member having various orifices and means for holding said last-named member in predetermined position without attention from an operator.

In testimony whereof, I have signed my name to this specification this 29th day of December, 1926.

THEODORE BIRKENMAIER.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US158189A US1765398A (en) | 1926-12-31 | 1926-12-31 | Sprayer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US158189A US1765398A (en) | 1926-12-31 | 1926-12-31 | Sprayer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1765398A true US1765398A (en) | 1930-06-24 |

Family

ID=22567021

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US158189A Expired - Lifetime US1765398A (en) | 1926-12-31 | 1926-12-31 | Sprayer |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1765398A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2687739A (en) * | 1950-10-05 | 1954-08-31 | Shelburne Augustine | Control mechanism for spraying apparatus |

| US3762411A (en) * | 1971-09-20 | 1973-10-02 | Aqua Fem Inc | Power aerated douche |

| US5415352A (en) * | 1993-05-20 | 1995-05-16 | May; Michael W. | Spray system manifold apparatus and method |

| US5611485A (en) * | 1994-08-12 | 1997-03-18 | William W. Gibbs | Method and apparatus for dispensing a substance |

| US6769628B1 (en) * | 2001-03-26 | 2004-08-03 | Lauren Jay Vaage | Transportable texture applicator |

-

1926

- 1926-12-31 US US158189A patent/US1765398A/en not_active Expired - Lifetime

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2687739A (en) * | 1950-10-05 | 1954-08-31 | Shelburne Augustine | Control mechanism for spraying apparatus |

| US3762411A (en) * | 1971-09-20 | 1973-10-02 | Aqua Fem Inc | Power aerated douche |

| US5415352A (en) * | 1993-05-20 | 1995-05-16 | May; Michael W. | Spray system manifold apparatus and method |

| US5611485A (en) * | 1994-08-12 | 1997-03-18 | William W. Gibbs | Method and apparatus for dispensing a substance |

| US6769628B1 (en) * | 2001-03-26 | 2004-08-03 | Lauren Jay Vaage | Transportable texture applicator |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2380827A (en) | Multiple spraying device | |

| US3482781A (en) | Spray gun with pressure gauge feature | |

| US2513081A (en) | Multichromatic spraying apparatus | |

| US5221026A (en) | Apparatus for dispensing mixtures of liquids and pressurized gas | |

| US3871553A (en) | Dispensing gun for semi-liquid material | |

| US4537357A (en) | Spray guns | |

| US3622078A (en) | Spraying device for pastelike material with shutoff valve means for the material | |

| US4123005A (en) | Acoustical texture applicator | |

| CA1192737A (en) | Paint color change and flow control system | |

| US2259215A (en) | Spray gun | |

| US1982055A (en) | Apparatus for applying paint | |

| US1643969A (en) | Means for controlling the distribution of liquids | |

| EP0061342A1 (en) | Combination spray gun and pressure regulator | |

| GB923475A (en) | Improvements in or relating to the production of spatter finish coatings | |

| US1765398A (en) | Sprayer | |

| US1806784A (en) | Spbayeb | |

| DE917357C (en) | Spray gun for spraying more or less viscous materials | |

| US3087682A (en) | Multi-liquid spray gun | |

| US3131869A (en) | Coolant device for machine tools | |

| US2199110A (en) | Dilution of liquid chemical compounds | |

| US3907205A (en) | Spray gun with auxiliary spray attachment | |

| US2550888A (en) | Spray gun | |

| DE69009201D1 (en) | High flow low pressure air spray gun. | |

| US2112546A (en) | Spray gun | |

| US1855457A (en) | Spraying apparatus and method |