TWI681041B - Liquid crystal display device and liquid crystal composition used therefor - Google Patents

Liquid crystal display device and liquid crystal composition used therefor Download PDFInfo

- Publication number

- TWI681041B TWI681041B TW105111721A TW105111721A TWI681041B TW I681041 B TWI681041 B TW I681041B TW 105111721 A TW105111721 A TW 105111721A TW 105111721 A TW105111721 A TW 105111721A TW I681041 B TWI681041 B TW I681041B

- Authority

- TW

- Taiwan

- Prior art keywords

- liquid crystal

- formula

- crystal compound

- crystal composition

- independently

- Prior art date

Links

- 0 CCC(CC)(c(cc1)ccc1O)c1cc(NCC2(C)c3cc(N)c(*)c(N)c3)c2cc1 Chemical compound CCC(CC)(c(cc1)ccc1O)c1cc(NCC2(C)c3cc(N)c(*)c(N)c3)c2cc1 0.000 description 13

- SMTKRIXZWWEJGB-UHFFFAOYSA-N CC(C1)C(C(C=C(C2F)F)=CC2[F]C)C(F)=C(C)C1C1=CCC(C(CC2)CCC2I)C=C1[F]C Chemical compound CC(C1)C(C(C=C(C2F)F)=CC2[F]C)C(F)=C(C)C1C1=CCC(C(CC2)CCC2I)C=C1[F]C SMTKRIXZWWEJGB-UHFFFAOYSA-N 0.000 description 1

- AJQMFUYBFQQAKA-UHFFFAOYSA-N CCCC(CC1)CCC1C(CC1)CCC1c(cc1)ccc1OC(F)(F)F Chemical compound CCCC(CC1)CCC1C(CC1)CCC1c(cc1)ccc1OC(F)(F)F AJQMFUYBFQQAKA-UHFFFAOYSA-N 0.000 description 1

- DYSJQUQJVBYIOT-UHFFFAOYSA-N Cc(ccc(C)c1F)c1F Chemical compound Cc(ccc(C)c1F)c1F DYSJQUQJVBYIOT-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/06—Non-steroidal liquid crystal compounds

- C09K19/08—Non-steroidal liquid crystal compounds containing at least two non-condensed rings

- C09K19/10—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings

- C09K19/20—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings linked by a chain containing carbon and oxygen atoms as chain links, e.g. esters or ethers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/0403—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit the structure containing one or more specific, optionally substituted ring or ring systems

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/42—Mixtures of liquid crystal compounds covered by two or more of the preceding groups C09K19/06 - C09K19/40

- C09K19/44—Mixtures of liquid crystal compounds covered by two or more of the preceding groups C09K19/06 - C09K19/40 containing compounds with benzene rings directly linked

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/42—Mixtures of liquid crystal compounds covered by two or more of the preceding groups C09K19/06 - C09K19/40

- C09K19/46—Mixtures of liquid crystal compounds covered by two or more of the preceding groups C09K19/06 - C09K19/40 containing esters

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/0403—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit the structure containing one or more specific, optionally substituted ring or ring systems

- C09K2019/0407—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit the structure containing one or more specific, optionally substituted ring or ring systems containing a carbocyclic ring, e.g. dicyano-benzene, chlorofluoro-benzene or cyclohexanone

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K2019/0444—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit characterized by a linking chain between rings or ring systems, a bridging chain between extensive mesogenic moieties or an end chain group

- C09K2019/0466—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit characterized by a linking chain between rings or ring systems, a bridging chain between extensive mesogenic moieties or an end chain group the linking chain being a -CF2O- chain

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/06—Non-steroidal liquid crystal compounds

- C09K19/08—Non-steroidal liquid crystal compounds containing at least two non-condensed rings

- C09K19/10—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings

- C09K19/12—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings at least two benzene rings directly linked, e.g. biphenyls

- C09K2019/121—Compounds containing phenylene-1,4-diyl (-Ph-)

- C09K2019/122—Ph-Ph

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/06—Non-steroidal liquid crystal compounds

- C09K19/08—Non-steroidal liquid crystal compounds containing at least two non-condensed rings

- C09K19/10—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings

- C09K19/12—Non-steroidal liquid crystal compounds containing at least two non-condensed rings containing at least two benzene rings at least two benzene rings directly linked, e.g. biphenyls

- C09K2019/121—Compounds containing phenylene-1,4-diyl (-Ph-)

- C09K2019/123—Ph-Ph-Ph

Landscapes

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Nonlinear Science (AREA)

- Mathematical Physics (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Liquid Crystal Substances (AREA)

Abstract

Description

相關申請案之交互參照Cross-reference of related applications

本申請案主張在2015年04月15日向韓國智慧財產局提出之韓國專利申請號第10-2015-0053223號、以及2015年12月21日提出之第10-2015-018292號的優先權及效益,其全部內容併於本說明書作為參考。This application claims the priority and benefits of Korean Patent Application No. 10-2015-0053223 filed with the Korean Intellectual Property Office on April 15, 2015, and No. 10-2015-018292 filed on December 21, 2015 , The entire content of which is used as a reference in this manual.

本發明係關於一種液晶顯示裝置(LCD)及其所用之液晶合成物。The present invention relates to a liquid crystal display (LCD) and the liquid crystal composition used therefor.

液晶顯示裝置可包含具有複數個像素之第一基板、第二基板、及介於第一和第二基板之間的液晶層。液晶顯示裝置根據每個像素電極和共用電極之間產生的電場改變光在液晶層中之透光率,從而顯示影像。液晶顯示裝置可包含複數個像素,每個像素可包含像素電極。The liquid crystal display device may include a first substrate having a plurality of pixels, a second substrate, and a liquid crystal layer interposed between the first and second substrates. The liquid crystal display device changes the light transmittance of light in the liquid crystal layer according to the electric field generated between each pixel electrode and the common electrode, thereby displaying an image. The liquid crystal display device may include a plurality of pixels, and each pixel may include a pixel electrode.

最近,發現除了可顯示平面影像(2D)外,液晶顯示裝置還可顯示立體影像(3D),並需要更多影像資訊的解決方案提供給使用者。因此,與傳統液晶顯示裝置相比,需要具有高速度及高耐久度的液晶顯示裝置。Recently, it has been found that in addition to displaying flat images (2D), liquid crystal display devices can also display stereoscopic images (3D), and solutions that require more image information are provided to users. Therefore, compared with the conventional liquid crystal display device, a liquid crystal display device with high speed and high durability is required.

例示性實施例提供具有高介電異向性(dielectric anisotropy)及高折射率異向性(refractive index anisotropy)並具有較好的低溫安定性(LTS)的單液晶化合物、及包含其之液晶合成物。Exemplary embodiments provide a single liquid crystal compound having high dielectric anisotropy and high refractive index anisotropy and having good low temperature stability (LTS), and liquid crystal synthesis including the same Thing.

另一例示性實施例提供一種液晶顯示裝置,包含具有高介電異向性及高折射率異向性並提升低溫安定性的液晶合成物。Another exemplary embodiment provides a liquid crystal display device including a liquid crystal composition having high dielectric anisotropy and high refractive index anisotropy and improving low-temperature stability.

根據實施例,液晶顯示裝置包含第一基板、面對第一基板之第二基板、位於至少第一基板和第二基板其中之一上的電極部、以及包含液晶合成物且位於第一基板與第二基板之間的液晶層。According to an embodiment, a liquid crystal display device includes a first substrate, a second substrate facing the first substrate, an electrode portion located on at least one of the first substrate and the second substrate, and a liquid crystal composition and located on the first substrate and The liquid crystal layer between the second substrates.

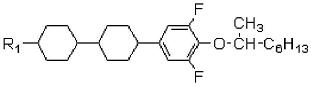

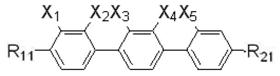

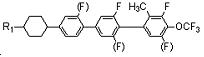

根據實施例,液晶合成物包含至少一液晶化合物,如式1所示。 式1 According to an embodiment, the liquid crystal composition includes at least one liquid crystal compound, as shown in Formula 1. Formula 1

式1中,R1 表示氫或具有1~15個碳原子的烷基,其中至少一-CH2 -基可在無氧原子彼此相連的情形下獨立被-C≡C-、-CF2 O-、-CH=CH-、-O-、-CO-O-、-O-CO-、或-O-CO-O-取代,且1~3個氫原子可被鹵素原子取代。In Formula 1, R 1 represents hydrogen or an alkyl group having 1 to 15 carbon atoms, in which at least one -CH 2 -group can be independently -C≡C-, -CF 2 O when oxygen-free atoms are connected to each other -, -CH=CH-, -O-, -CO-O-, -O-CO-, or -O-CO-O-, and 1 to 3 hydrogen atoms can be replaced by halogen atoms.

R2 表示-F、-Cl、-CF3 、-CHF2 、-CH2 F、-OCF3 、-CN、-NCS、或有1~5個碳原子經一到三個-F取代的烷基,且-CH2 -基選擇性在無兩個氧原子彼此相連的情形下獨立被氧原子取代。R 2 represents -F, -Cl, -CF 3 , -CHF 2 , -CH 2 F, -OCF 3 , -CN, -NCS, or an alkane having 1 to 5 carbon atoms substituted with one to three -F Group, and the -CH 2 -group selectivity is independently substituted by an oxygen atom without two oxygen atoms being connected to each other.

(F)表示氫原子選擇性經-F取代,A11 、A12 、A13 、A21 、及A22 各自以下結構獨立表示:、、、、、、、、、、、、、、、或。 Z11 、Z12 、Z13 、Z21 、及Z22 可各自獨立地為單鍵、-CH2 CH2 -、-CH=CH-、-CH2 O-、-OCH2 -、-C≡C-、-CH2 CF2 -、-CHFCHF-、-CF2 CH2 -、-CH2 CHF-、-CHFCH2 -、-C2 F4 -、-COO-、-OCO-、-CF2 O-、或-OCF2 -,a、b、c、d、及e係各自獨立地為0~3的整數,且a+b+c+d+e小於或等於5。(F) indicates that the hydrogen atom is selectively substituted with -F, and A 11 , A 12 , A 13 , A 21 , and A 22 are each independently represented by the following structures: , , , , , , , , , , , , , , ,or . Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 may each independently be a single bond, -CH 2 CH 2 -, -CH=CH-, -CH 2 O-, -OCH 2 -, -C≡ C-, -CH 2 CF 2 -, -CHFCHF-, -CF 2 CH 2 -, -CH 2 CHF-, -CHFCH 2 -, -C 2 F 4 -, -COO-, -OCO-, -CF 2 O-, or -OCF 2 -, a, b, c, d, and e are each independently an integer of 0 to 3, and a+b+c+d+e is less than or equal to 5.

根據實施例,至少一個Z11 、Z12 、Z13 、Z21 、及Z22 可為-CF2 O-.。According to an embodiment, at least one of Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 may be -CF 2 O-.

根據實施例,d和e為0,且R2 可為-F、-OCF3 、或-CF3 。According to an embodiment, d and e are 0, and R 2 may be -F, -OCF 3 , or -CF 3 .

根據實施例,Z13 為-CF2 O-,d和e為0,且R2 可為-F、-OCF3 、或-CF3 。According to an embodiment, Z 13 is -CF 2 O-, d and e are 0, and R 2 may be -F, -OCF 3 , or -CF 3 .

根據實施例,式1之液晶化合物可以式1-1表示。According to the embodiment, the liquid crystal compound of Formula 1 may be represented by Formula 1-1.

式1-1 Formula 1-1

R1 、R2 、A11 、A12 、 Z11 、Z12 、a、及b係與式1所定義的相同。R 1 , R 2 , A 11 , A 12 , Z 11 , Z 12 , a, and b are the same as defined in Formula 1.

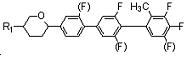

根據實施例,式1-1之液晶化合物可以式1-2表示。According to the embodiment, the liquid crystal compound of Formula 1-1 may be represented by Formula 1-2.

式1-2 Formula 1-2

R1 係與式1所定義的相同,且o為0或1。R 1 is the same as defined in Formula 1, and o is 0 or 1.

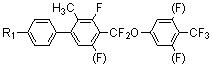

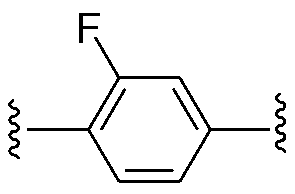

根據實施例,液晶合成物可進一步包含如式2所示之至少一液晶化合物。According to an embodiment, the liquid crystal composition may further include at least one liquid crystal compound as shown in Formula 2.

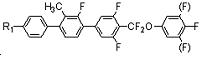

式2 Formula 2

R11 係與式1所定義的R1 相同,除了式1之R1 的定義外,R21 表示-F、-Cl、-CF3、或-OCF3 ,A3 及A4 彼此獨立地為經F-取代或未取代的1,4-伸環己基(1,4-cyclohexylene)或經F-取代或未取代的1,4-伸苯基(1,4-phenylene),且A5 表示以下結構之一:、、、、、或。 1 and the same system as defined in Formula 1 R R 11, in addition to the definition of R 1 of formula 1, R 21 represents -F, -Cl, -CF3, or -OCF 3, A 3 and A 4 independently of one another by F-substituted or unsubstituted 1,4-cyclohexylene (1,4-cyclohexylene) or F-substituted or unsubstituted 1,4-phenylene (1,4-phenylene), and A 5 represents the following One of the structures: , , , , ,or .

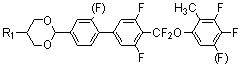

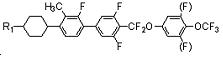

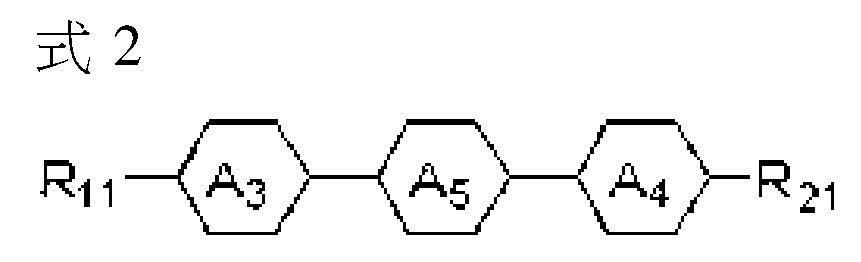

根據實施例,液晶合成物進一步包含如式3所示的液晶化合物。According to an embodiment, the liquid crystal composition further includes a liquid crystal compound represented by Formula 3.

式3 Formula 3

R11 、R12 獨立地與式1中R1 的定義相同,且A3 、A4 獨立地為經F-取代或未取代的1,4-伸環己基或經F取代或未取代的1,4-伸苯基。R 11 and R 12 are independently the same as the definition of R 1 in Formula 1, and A 3 and A 4 are independently 1,4-cyclohexyl substituted by F- or unsubstituted or 1 substituted or unsubstituted by F ,4-phenylene.

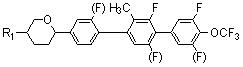

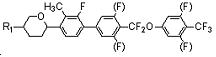

根據實施例,液晶合成物可進一步包含如式4所示之液晶化合物。According to an embodiment, the liquid crystal composition may further include a liquid crystal compound as shown in Formula 4.

式4 Formula 4

在式4中,R1 、R2 相同於式1中R1 、R2 的定義,A11 、A12 、A13 、Z11 、Z12 、Z13 及(F)同時相同於式1中A11 、A12 、A13 、Z11 、Z12 、Z13 及(F)的定義,f、g及h各自獨立地為0或1,且f+g+h為2或3。In Formula 4, R 1 and R 2 are the same as the definitions of R 1 and R 2 in Formula 1, A 11 , A 12 , A 13 , Z 11 , Z 12 , Z 13 and (F) are also the same as in Formula 1 In the definitions of A 11 , A 12 , A 13 , Z 11 , Z 12 , Z 13 and (F), f, g and h are each independently 0 or 1, and f+g+h is 2 or 3.

根據實施例,液晶合成物可進一步包含至少一液晶化合物,其為式5~7的任意其中之一。According to an embodiment, the liquid crystal composition may further include at least one liquid crystal compound, which is any one of Formulas 5-7.

式5 Formula 5

式6 Formula 6

式7 Formula 7

R1 、A11 係相同於式1中的定義,p為0或1,R3 表示氫、氧自由基、或具有的1~15個碳原子的烷基,其中至少一-CH2-基可在無兩氧原子彼此相連的情形下獨立被-C≡C-、-CF2 O-、-CH=CH-、-O-、-CO-O-、-O-CO-、或-O-CO-O-取代,且1~3個氫原子可被鹵素原子取代,n為1至12的整數,且m為0至12的整數。R 1 and A 11 are the same as defined in Formula 1, p is 0 or 1, R 3 represents hydrogen, oxygen radical, or an alkyl group having 1 to 15 carbon atoms, of which at least one -CH2- group may be In the case where no two oxygen atoms are connected to each other, they are independently -C≡C-, -CF 2 O-, -CH=CH-, -O-, -CO-O-, -O-CO-, or -O- CO-O- substitution, and 1 to 3 hydrogen atoms can be replaced by halogen atoms, n is an integer of 1 to 12, and m is an integer of 0 to 12.

根據實施例,液晶合成物進一步包含如式8所示之間距改質劑。According to an embodiment, the liquid crystal composition further includes a pitch modifier as shown in Formula 8.

式8 Formula 8

R1 係相同於式1中的定義。R 1 is the same as defined in Formula 1.

根據本發明所準備的液晶合成物,可製造具有提升LTS、高介電常數及高折射率之液晶合成物。According to the liquid crystal composition prepared by the present invention, a liquid crystal composition having improved LTS, high dielectric constant and high refractive index can be manufactured.

另外,根據本發明所準備液晶合成物,可提供為各種形式之液晶顯示裝置優化的液晶合成物,諸如扭轉向列(TN)、超扭轉向列(STN)、平面內切換(in plane switching, IPS)、邊緣電場切換(FFS)、或平面到線切換(PLS)等。In addition, the liquid crystal composition prepared according to the present invention can provide a liquid crystal composition optimized for various forms of liquid crystal display devices, such as twisted nematic (TN), super twisted nematic (STN), in-plane switching, IPS), fringe electric field switching (FFS), or plane-to-line switching (PLS), etc.

本發明可以各種變化及各種形狀實現,並在此部分配合圖式詳細說明特定實施例。另一方面,圖式非用以使本發明限於所述實施例,而係詮釋為包含所有變化、等價物、以及符合本發明精神及範疇的替代品。為了清楚顯示,在圖式中可放大層及區的大小。The present invention can be implemented in various changes and various shapes, and in this section, a specific embodiment will be described in detail with reference to the drawings. On the other hand, the drawings are not intended to limit the present invention to the described embodiments, but are interpreted to include all changes, equivalents, and alternatives that conform to the spirit and scope of the present invention. For clarity, the size of layers and regions can be enlarged in the drawings.

雖然本文可使用「第一」、「第二」等詞來說明各種元件,這些元件不應受限於這些詞。該些詞可用以區分一元件與另一元件。因此,在本發明書中所謂的第一元件可命名為第二元件而不背離本一或多個實施例之教義。作為「第一」元件的元件說明可不需要或暗示第二元件或其他元件的存在。也可使用「第一」、「第二」等詞來區別不同的類別或元件組。為便於說明,「第一」、「第二」等詞可分別表示例如「第一類(或第一組)」、「第二類(或第二組)」等。Although the words "first", "second", etc. may be used herein to describe various elements, these elements should not be limited to these words. These words can be used to distinguish one element from another. Therefore, the so-called first element in the present invention may be named as the second element without departing from the teachings of the one or more embodiments. The description of an element as a "first" element may not require or imply the presence of a second element or other elements. You can also use words such as "first" and "second" to distinguish between different categories or component groups. For ease of description, the words "first", "second", etc. may mean "first type (or first group)", "second type (or second group)", etc., respectively.

當提到第一元件係位於第二元件「上」、「連接」或「耦接」第二元件,該第一元件可直接位於第二元件上、直接連接或耦接第二元件、或可存在一或多個中間元件。相反地,當提到第一元件係「直接」位於第二元件「上」、「直接連接」或「直接耦接」第二元件,第一元件與第二元件之間不存在中間元件。當元件A位於其他二元件B與C「之間」時,元件A可直接位於元件B上及直接位於元件C上,或可能有其他中間層在A與B之間、A與C之間、或A與B及A與C之間。在整篇說明書中,相同的元件符號可表示相同的元件。詞「及/或」包含一或多個關聯項目之任意及所有組合。「或」表示「及/或」。When it is mentioned that the first element is located "on", "connected" or "coupled" to the second element, the first element may be directly located on the second element, directly connected or coupled to the second element, or may There are one or more intermediate elements. Conversely, when it is mentioned that the first component is "directly" located "on", "directly connected" or "directly coupled" to the second component, there is no intermediate component between the first component and the second component. When element A is "between" the other two elements B and C, element A may be directly on element B and directly on element C, or there may be other intermediate layers between A and B, A and C, Or between A and B and A and C. Throughout the specification, the same symbol may indicate the same element. The word "and/or" includes any and all combinations of one or more related items. "Or" means "and/or".

本文可使用如「之下」、「下方」、「以下」、「上方」、「以上」等空間相對詞以便於說明圖式中所示之一元件或特徵和另一元件或特徵的關係。空間相對詞係除了解釋在圖式中所繪示的面向外,將涵蓋所用或運作中裝置的不同面向。例如,若圖示中裝置被翻轉時,所謂其他元件或特徵「之下」、「下方」的元件則將定向為其他元件或特徵「上方」。This text may use spatial relative terms such as "below", "below", "below", "above", "above", etc. in order to explain the relationship between one element or feature and another element or feature shown in the drawings. In addition to explaining the orientations depicted in the drawings, spatial relative word systems will cover different orientations of the devices used or in operation. For example, if the device shown in the figure is turned over, the so-called "below" or "below" other elements or features will be oriented "above" the other elements or features.

在本文中所用之詞彙僅具描述特定實施例而不具限制性之目的。在整篇說明書中,除非另有清楚說明,單數式「一」、「該」意在同時包含複數式。將被進一步瞭解的是,當詞「包含」及/或「包括」用於本文時,其指名所列特徵、整數、步驟、操作、元件、及/或構件的存在,但不排除一或多個其他特徵、整數、步驟、操作、元件、構件、及/或以上組合的存在。The vocabulary used herein is for the purpose of describing particular embodiments only and is not limiting. Throughout the specification, unless clearly stated otherwise, the singular expression "a" and "the" are intended to include both the plural expressions. It will be further understood that when the words "include" and/or "include" are used in this document, they refer to the existence of listed features, integers, steps, operations, elements, and/or components, but do not exclude one or more There are other features, integers, steps, operations, elements, components, and/or combinations of the above.

本文參照實施例(及中間結構)之截面圖來說明實施例。因此,例如製造技術及/或公差之差異預期將導致示意圖形狀不同。又,實施例不應被解釋成限於本文所繪示特定區塊的形狀,但應包含例如製造造成的形狀變形。舉例而言,繪示為矩形的植入區之邊緣可具有圓角或彎角特徵及/或植入濃度梯度,而不僅是植入到非植入區的二元變化。相同的,以植入法形成的嵌入區可穿過植入發生地點導致植入作用在植入與表面之間的區塊。因此,圖式中所示區塊為原則性示意圖,且該形狀不意在說明裝置區塊的實際形狀,更不意在限制實施例之範疇。This document describes the embodiments with reference to the cross-sectional views of the embodiments (and intermediate structures). Therefore, for example, differences in manufacturing techniques and/or tolerances are expected to result in different schematic shapes. Also, the embodiments should not be construed as being limited to the shapes of specific blocks depicted herein, but should include, for example, shape distortions caused by manufacturing. For example, the edges of the implanted area depicted as a rectangle may have rounded or curved features and/or implant concentration gradients, not just the binary changes implanted into the non-implanted area. Similarly, the embedding area formed by the implantation method can pass through the place where the implantation occurs to cause the implantation to act on the block between the implantation and the surface. Therefore, the blocks shown in the drawings are schematic diagrams, and the shape is not intended to illustrate the actual shape of the device block, nor to limit the scope of the embodiments.

考慮有關測量及相關特定數量(即,測量系統的限制)之測量的誤差,本文所用「約」或「近似」應包含所列數值,且表示在所屬領域之通常知識者決定的特定數值之可接受偏差範圍內。例如,「約」可表示在一或多個標準差內,或在所列數值±30%、±20%、±10%、或±5%內。Considering the measurement errors related to the measurement and the related specific quantity (ie, the limitation of the measurement system), "approximately" or "approximately" as used herein shall include the listed values and represent the specific values determined by those of ordinary knowledge in the field. Accept the deviation. For example, "about" may mean within one or more standard deviations, or within ±30%, ±20%, ±10%, or ±5% of the listed values.

如本文所用,「烷基」表示直鏈或支鏈、飽和、具有特定數量碳原子的單價烴基(如,甲基或己基)。As used herein, "alkyl" refers to a linear or branched, saturated, monovalent hydrocarbon group (eg, methyl or hexyl) having a specific number of carbon atoms.

除非另有定義,用於本文之所有用詞(包含技術及科學用詞)具有的意思和本發明所屬領域之通常知識者所理解的一樣。如同字典中一般定義的,這些用詞將被進一步理解而解釋成具有與相關領域之文獻一致的意義,且不應被解釋成過度理想化或形式化的意義,除非本文有另外定義。Unless otherwise defined, all terms (including technical and scientific terms) used in this text have the same meaning as those of ordinary knowledge in the field to which the present invention belongs. As generally defined in dictionaries, these terms will be further understood and interpreted to have a meaning consistent with the literature in the relevant field, and should not be interpreted as an over-ideal or formal meaning unless otherwise defined herein.

以下內容,將更詳細地解釋較佳實施例。The following will explain the preferred embodiment in more detail.

本發明係關於一種用液晶化合物作為材料的液晶顯示裝置,以及包含該液晶化合物的合成物。The present invention relates to a liquid crystal display device using a liquid crystal compound as a material, and a composition containing the liquid crystal compound.

構成液晶產物的單液晶化合物可為200~600 g/mol分子量的有機物並具有長鍵分子結構。液晶分子結構可分成維持直鏈特徵的核心基、具有可撓性的末端基、及特定用途的連鎖基。不受理論束縛,一或兩端的末端基具有易彎的鏈形成(烷基、烷氧基、烯基等)以維持可撓性,並在另一端插入極性基(-F、-CN、-OCF3 )以調整液晶如介電常數之物理特性。The single liquid crystal compound constituting the liquid crystal product may be an organic substance with a molecular weight of 200 to 600 g/mol and has a long bond molecular structure. The liquid crystal molecular structure can be divided into a core group that maintains a straight-chain characteristic, a flexible end group, and a special-purpose chain group. Without being bound by theory, the terminal groups at one or both ends have flexible chain formation (alkyl, alkoxy, alkenyl, etc.) to maintain flexibility, and polar groups (-F, -CN,-are inserted at the other end) OCF 3 ) to adjust the physical characteristics of liquid crystal such as dielectric constant.

根據液晶顯示面板(LCD)的特性和應用方式,LCD可具有各種模式,如扭轉向列(TN)、超扭轉向列(STN)、平面內切換(in plane switching, IPS)、邊緣電場切換(FFS)等。在這些不同的液晶顯示裝置中,僅用一或兩個液晶化合物難以達到產品要求,像是澄清點(Clearing Point, Tc)溫度、介電異向性、折射率異向性、旋轉黏度(rotational viscosity)等,因此可混合7~20種單液晶化合物來製造液晶合成物。According to the characteristics and application methods of the liquid crystal display panel (LCD), the LCD can have various modes, such as twisted nematic (TN), super twisted nematic (STN), in-plane switching (IPS), and fringe electric field switching ( FFS) etc. In these different liquid crystal display devices, it is difficult to meet the product requirements with only one or two liquid crystal compounds, such as clearing point (Clearing Point, Tc) temperature, dielectric anisotropy, refractive index anisotropy, rotational viscosity (rotational viscosity), etc., so 7 to 20 kinds of single liquid crystal compounds can be mixed to make liquid crystal composites.

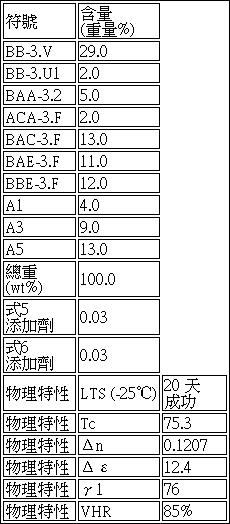

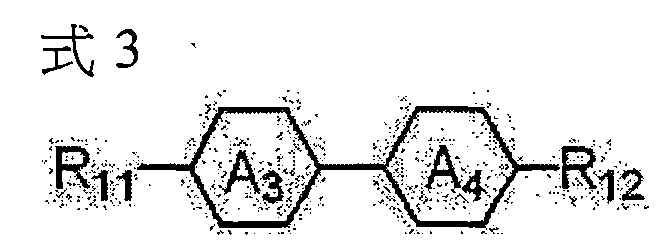

將液晶合成物所需的主要元件之一般特性列在表1中。 表1

如表1所示,無論LCD面板之應用方式,低旋轉黏度較佳,且折射率異向性較佳為大於或等於0.07,雖然其最佳值會根據LCD的晶隙變化。同時,主動陣列液晶顯示器(active matrix-LCD, AM-LCD)所需的特定電阻大於或等於1013 Ωm。需要製造一種混和物可滿足這些特性,且即使在小於或等於-25℃的低溫下能夠運作LCD。As shown in Table 1, regardless of the application method of the LCD panel, low rotational viscosity is preferred, and the refractive index anisotropy is preferably greater than or equal to 0.07, although its optimal value will vary according to the crystal gap of the LCD. At the same time, the specific resistance required for an active matrix liquid crystal display (AM-LCD) is greater than or equal to 10 13 Ωm. There is a need to manufacture a mixture that meets these characteristics and can operate LCDs even at low temperatures of -25°C or less.

當混合不少於10種單液晶化合物時,雖然大部份共晶點(eutectic point)都不高於-20℃,因高熔點的單液晶化合物在混和物長期被置於低溫下而可能發生再結晶。因此,為了避免此再結晶,適當混合具不同烷基衍生物的烷基同系物。另一方面,單液晶化合物傾向具有長烷基鏈以提升折射率異向性或介電異向性,且該長烷基鏈可增加旋轉黏度並減少彈性模數。所增加的旋轉黏度及所減少的彈性模數可增加反應時間。When mixing no less than 10 single liquid crystal compounds, although most of the eutectic points are not higher than -20℃, high melting point single liquid crystal compounds may occur when the mixture is kept at a low temperature for a long time re-crystallize. Therefore, in order to avoid this recrystallization, it is appropriate to mix alkyl homologues with different alkyl derivatives. On the other hand, single liquid crystal compounds tend to have long alkyl chains to increase refractive index anisotropy or dielectric anisotropy, and the long alkyl chains can increase rotational viscosity and reduce elastic modulus. The increased rotational viscosity and reduced elastic modulus can increase the reaction time.

例如,如表2所示,比1號化合物多兩個亞甲基單元(亞甲基,-CH2

-)的2號化合物具有低熔點,使其具有較佳LTS;然而,旋轉黏度(γ1)增加20 mPas以上,使LCD的反應時間增加(Hiraoka, H,(2009), Mol. Cryst. Liq. Cryst., Vol 509, pp 89

)。 表2

因此,期望具高介電異向性、高折射率異向性、低旋轉黏度、及低熔點的單液晶化合物,且本發明提供的單液晶化合物具高介電異向性及高折射率異向性,還有低旋轉黏度和低熔點。Therefore, a single liquid crystal compound having high dielectric anisotropy, high refractive index anisotropy, low rotational viscosity, and low melting point is desired, and the single liquid crystal compound provided by the present invention has high dielectric anisotropy and high refractive index anisotropy Anisotropy, low rotational viscosity and low melting point.

根據實施例的液晶化合物係表示如式1。The liquid crystal compound system according to the embodiment is represented as Formula 1.

式1 Formula 1

式1中,R1 表示氫或具有1~15個碳原子的烷基,其中至少一-CH2 -基可在無兩氧原子彼此相連的情形下獨立被-C≡C-、-CF2 O-、-CH=CH-、-O-、-CO-O-、-O-CO-、或-O-CO-O-取代,且1~3個氫原子可被鹵原子取代。In Formula 1, R 1 represents hydrogen or an alkyl group having 1 to 15 carbon atoms, wherein at least one -CH 2 -group can be independently -C≡C-, -CF 2 without two oxygen atoms connected to each other O-, -CH=CH-, -O-, -CO-O-, -O-CO-, or -O-CO-O-, and 1 to 3 hydrogen atoms can be replaced by halogen atoms.

同時,對於R1 ,當具偶數個碳原子的R1 中至少一-CH2 -基被雙鍵取代時,雙鍵可被插入雙數碳之端點。例如,當雙鍵被插入R1 時,其可為CH2 =CH-或CH2 =CH-CH2 -CH2 -。當R1 的碳原子為奇數個且大於或等於3時,雙鍵可插在從末端數來之雙數碳與其旁邊的單數碳之間。例如,當雙鍵被插入R1 時,其可為CH3 -CH=CH-或CH3 -CH=CH-CH2 -CH2 -。不受理論束縛,藉由插入雙鍵於R1 中,可減少旋轉黏度、增加澄清點、並控制彈性模數。R2 可為極性基,-F、-Cl、-CF3 、-CHF2 、-CH2 F、-OCF3 、-CN、-NCS、或被一到三個-F取代的烷基,其-CH2 -基在無兩氧原子彼此相連的情形下獨立被氧原子取代。根據實施例,R2 可為-F、-Cl、-CF3 、或-OCF3 。Meanwhile, for R 1 , when at least one -CH 2 -group in R 1 having an even number of carbon atoms is substituted with a double bond, the double bond may be inserted into the end of the double carbon. For example, when a double bond is inserted into R 1 , it may be CH 2 =CH- or CH 2 =CH-CH 2 -CH 2 -. When the number of carbon atoms of R 1 is odd and greater than or equal to 3, the double bond can be inserted between the double-numbered carbon counted from the terminal and the single-numbered carbon next to it. For example, when a double bond is inserted into R 1 , it can be CH 3 -CH=CH- or CH 3 -CH=CH-CH 2 -CH 2 -. Without being bound by theory, by inserting a double bond in R 1 , the rotational viscosity can be reduced, the clarification point can be increased, and the elastic modulus can be controlled. R 2 may be a polar group, -F, -Cl, -CF 3 , -CHF 2 , -CH 2 F, -OCF 3 , -CN, -NCS, or an alkyl group substituted with one to three -F, which The -CH 2 -group is independently replaced by an oxygen atom without two oxygen atoms being connected to each other. According to an embodiment, R 2 may be -F, -Cl, -CF 3 , or -OCF 3 .

(F)表示氫原子被選擇性以-F取代,且A11 、A12 、A13 、A21 、及A22 各獨立以下結構表示:、、、、、、、、、、、、、、、或。(F) indicates that the hydrogen atom is selectively substituted with -F, and A 11 , A 12 , A 13 , A 21 , and A 22 are each independently represented by the following structures: , , , , , , , , , , , , , , ,or .

根據實施例且不受理論束縛,1,4-伸苯基可用於A11 、A12 、A13 、A21 、及A22 作高折射率異向性,且包含氟或氧之環結構可用以提升介電異向性。According to the embodiments and not being bound by theory, 1,4-phenylene can be used for A 11 , A 12 , A 13 , A 21 , and A 22 for high refractive index anisotropy, and ring structures containing fluorine or oxygen are available To improve the dielectric anisotropy.

Z11 、Z12 、Z13 、Z21 、及Z22 彼此獨立為單鍵、-CH2 CH2 -、-CH=CH-、-CH2 O-、-OCH2 -、-C≡C-、-CH2 CF2 -、-CHFCHF-、-CF2 CH2 -、-CH2 CHF-、-CHFCH2-、-C2 F4 -、-COO-、-OCO-、-CF2 O-、或-OCF2 -。Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 are independently a single bond, -CH 2 CH 2 -, -CH=CH-, -CH 2 O-, -OCH 2 -, -C≡C- , -CH 2 CF 2 -, -CHFCHF-, -CF 2 CH 2 -, -CH 2 CHF-, -CHFCH2-, -C 2 F 4 -, -COO-, -OCO-, -CF 2 O-, Or -OCF 2 -.

考慮到介電異向性、旋轉黏度、折射率異向性等,可選擇性組合Z11 、Z12 、Z13 、Z21 、及Z22 。根據實施例,至少一Z11 、Z12 、Z13 、Z21 、及Z22 可為-CF2 O-。當至少一Z11 、Z12 、Z13 、Z21 、及Z22 為-CF2 O-時,液晶化合物可具有高介電異向性。特別是,當Z13 為-CF2 O-時,可提升介電異向性並最小化液晶化合物之澄清點的下降。根據實施例,Z11 、Z12 、Z13 、Z21 、及Z22 分別可為單鍵,且在此案例中,化合物可具有低旋轉黏度。In consideration of dielectric anisotropy, rotational viscosity, refractive index anisotropy, etc., Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 can be selectively combined. According to an embodiment, at least one of Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 may be -CF 2 O-. When at least one of Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 is -CF 2 O-, the liquid crystal compound may have high dielectric anisotropy. In particular, when Z 13 is -CF 2 O-, the dielectric anisotropy can be improved and the decrease in the clear point of the liquid crystal compound can be minimized. According to an embodiment, Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 may each be a single bond, and in this case, the compound may have a low rotational viscosity.

a、b、c、d、及e分別獨立代表數值0至3,且a+b+c+d+e小於或等於5。a, b, c, d, and e independently represent the values 0 to 3, and a+b+c+d+e is less than or equal to 5.

式1之液晶化合物比起其他類型的液晶可具有較高的介電常數,且考慮在高介電常數下其旋轉黏度可相對較低。同時,式1之液晶化合物比起對應分子量之其他類型的液晶化合物可具有相對較低的熔點。The liquid crystal compound of Formula 1 may have a higher dielectric constant than other types of liquid crystal, and it is considered that the rotational viscosity may be relatively low under a high dielectric constant. Meanwhile, the liquid crystal compound of Formula 1 may have a relatively lower melting point than other types of liquid crystal compounds corresponding to molecular weight.

在實施例中,當多環間的環被甲基取代時,該甲基取代的環增加多環間的角度。不受理論所束縛,當多環間角度因為該甲基取代的環而增加時,液晶分子之間的堆積密度降低,且熔點下降。在式1中,1,4-伸苯基的第三位置被甲基取代,並因此減少式1之液晶化合物的堆積密度且降低熔點。不受理論限制,當具2個碳原子的二或多個烷基存在於多環之間時,液晶分子之長軸及短軸之間的比率降低,且澄清點大幅下降。同時,當多環間的環被氟取代時,該環本質上的表現相同於甲基取代的環。另一方面,由於氟降低了正介電異向性,難以獲得預期數量的高介電異向性。為了增加正介電異向性,氟基可被插在環的第二及第六位置中。In an embodiment, when the ring between multiple rings is substituted with a methyl group, the methyl substituted ring increases the angle between the multiple rings. Without being bound by theory, when the angle between multiple rings increases due to the methyl-substituted ring, the packing density between liquid crystal molecules decreases and the melting point decreases. In Formula 1, the third position of 1,4-phenylene is substituted with a methyl group, and thus the bulk density of the liquid crystal compound of Formula 1 is reduced and the melting point is lowered. Without being limited by theory, when two or more alkyl groups having 2 carbon atoms exist between the polycyclic rings, the ratio between the long axis and the short axis of the liquid crystal molecule decreases, and the clearing point decreases greatly. At the same time, when the ring between multiple rings is substituted with fluorine, the ring behaves essentially the same as the methyl-substituted ring. On the other hand, since fluorine reduces the positive dielectric anisotropy, it is difficult to obtain the expected amount of high dielectric anisotropy. In order to increase the positive dielectric anisotropy, fluorine groups can be inserted in the second and sixth positions of the ring.

式1之液晶化合物可包含結構以式1A表示的化合物,且在式1A中,R1 與式1的相同。The liquid crystal compound of Formula 1 may include a compound represented by Formula 1A, and in Formula 1A, R 1 is the same as Formula 1.

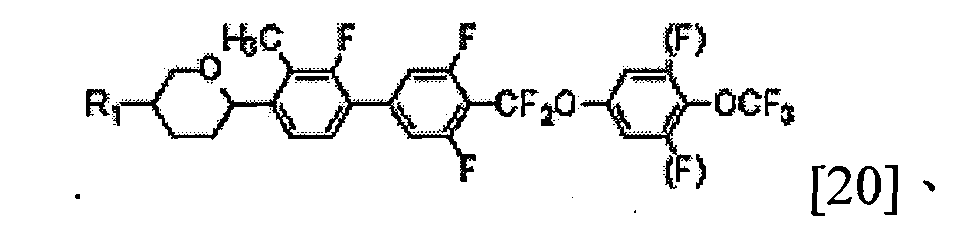

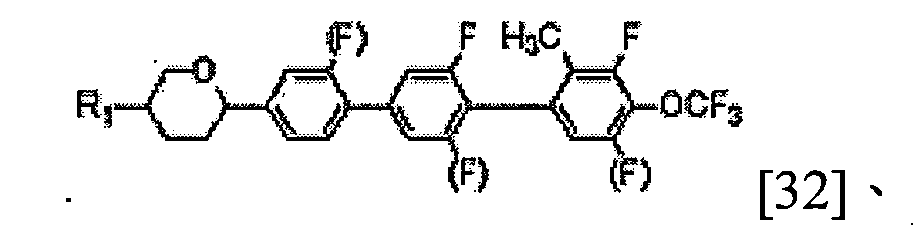

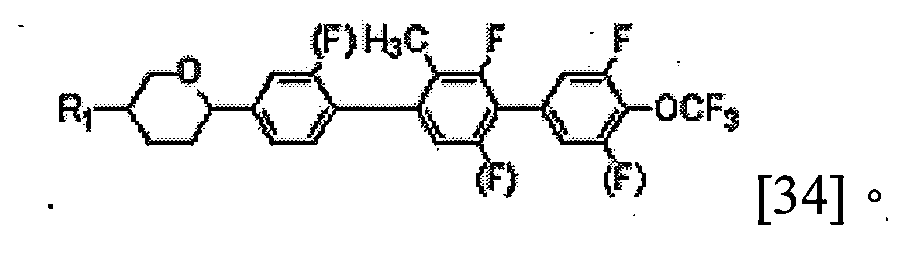

式1A[1]、[2]、[3]、[4]、[5]、[6]、[7]、[8]、[9]、[10]、[11]、[12]、[13]、[14]、[15]、[16]、[17]、[18]、[19]、[20]、[21]、[22]、[23]、[24]、[25]、[26]、[27]、[28]、[29]、[30]、[31]、[32]、[33]、[34]。Formula 1A [1], [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [twenty one], [twenty two], [twenty three], [twenty four], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34].

例如,在一些實施例中,液晶化合物可為式1表示的液晶化合物,其中至少一Z11 、Z12 、Z13 、Z21 、及Z22 為-CF2 O-。根據另一實施例,液晶化合物可為d及e為0的液晶化合物,且R2 為-F、-OCF3 、或-CF3 。根據另一實施例,液晶化合物可為Z13 為-CF2 O-、d及e為0、且R2 為-F、-OCF3 、或-CF3 的液晶化合物。For example, in some embodiments, the liquid crystal compound may be a liquid crystal compound represented by Formula 1, wherein at least one of Z 11 , Z 12 , Z 13 , Z 21 , and Z 22 is -CF 2 O-. According to another embodiment, the liquid crystal compound may be a liquid crystal compound in which d and e are 0, and R 2 is -F, -OCF 3 , or -CF 3 . According to another embodiment, the liquid crystal compound may be a liquid crystal compound in which Z 13 is -CF 2 O-, d and e are 0, and R 2 is -F, -OCF 3 , or -CF 3 .

更特別地,根據實施例,式1之液晶化合物可為式1-1所示之結構化合物的其中之一。More specifically, according to the embodiment, the liquid crystal compound of Formula 1 may be one of the structural compounds represented by Formula 1-1.

式1-1 Formula 1-1

R1 、R2 、A11 、A12 、 Z11 、Z12 、(F)、a、及b係與式1所定義的相同。R 1 , R 2 , A 11 , A 12 , Z 11 , Z 12 , (F), a, and b are the same as defined in Formula 1.

根據實施例,式1之液晶化合物可為式1-2所表示的結構化合物的至少其中之一。According to an embodiment, the liquid crystal compound of Formula 1 may be at least one of the structural compounds represented by Formula 1-2.

式1-2 Formula 1-2

其中o為0或1Where o is 0 or 1

R1 係與式1相同。式1-2之液晶化合物可為式1-2-1、1-2-2、及1-2-3表示的結構化合物的至少其中之一。R 1 is the same as Formula 1. The liquid crystal compound of Formula 1-2 may be at least one of the structural compounds represented by Formula 1-2-1, 1-2-2, and 1-2-3.

式1-2-1 Formula 1-2-1

式1-2-2 Formula 1-2-2

式1-2-3 Formula 1-2-3

在另一實施例中,液晶組成物包含或以式1之液晶化合物組成。In another embodiment, the liquid crystal composition includes or consists of the liquid crystal compound of Formula 1.

如根據實施例的液晶合成物,式1之液晶化合物對應液晶合成物的全部重量係包含1%或更大的重量百分比(wt%)。As in the liquid crystal composition according to the embodiment, the liquid crystal compound of Formula 1 contains 1% or more by weight (wt%) corresponding to the total weight of the liquid crystal composition.

根據實施例的液晶合成物可包含式1之液晶化合物,其重量百分比為1%或更高、或在1~40%區間內、或在1~30%區間內。當式1之液晶化合物的重量百分比低於1%時,難以取得高介電常數及保證LTS,而當重量百分比高於40%時,例如顯示裝置之耐久度會因低直流電(DC)產生於顯示裝置中而劣化。The liquid crystal composition according to the embodiment may include the liquid crystal compound of Formula 1 in a weight percentage of 1% or more, or in the range of 1-40%, or in the range of 1-30%. When the weight percentage of the liquid crystal compound of Formula 1 is less than 1%, it is difficult to obtain a high dielectric constant and ensure LTS, and when the weight percentage is higher than 40%, for example, the durability of the display device may be caused by low direct current (DC) Degraded in the display device.

根據實施例之液晶合成物較佳可包含一或二或多個式1-2之結構的液晶化合物,且在此情況下,可維持長時間的LTS。The liquid crystal composition according to the embodiment may preferably include one or two or more liquid crystal compounds of the structure of Formula 1-2, and in this case, LTS can be maintained for a long time.

特別地,根據實施例之液晶合成物可包含式1-2-1之液晶化合物。對於式1-2-1,其為具20之介電異向性及114 mPas之旋轉黏度的材料。因此,當液晶合成物之介電異向性約為3~6時,為有效獲得低旋轉黏度的液晶合成物,可包含重量百分比約3~7%的式1-2-1之液晶化合物。在具有介電異向性為10或更高的液晶合成物之案例中,當具介電異向性為30或更高的式1-2-2及/或1-2-3之單一物質材料的重量百分比約10%或更高時,可輕易地調整介電異向性。In particular, the liquid crystal composition according to the embodiment may include the liquid crystal compound of Formula 1-2-1. For Formula 1-2-1, it is a material with a dielectric anisotropy of 20 and a rotational viscosity of 114 mPas. Therefore, when the dielectric anisotropy of the liquid crystal composition is about 3~6, in order to effectively obtain a liquid crystal composition with low rotational viscosity, the liquid crystal compound of Formula 1-2-1 may be included in a weight percentage of about 3~7%. In the case of a liquid crystal composition with a dielectric anisotropy of 10 or higher, when a single substance of formula 1-2-2 and/or 1-2-3 with a dielectric anisotropy of 30 or higher When the weight percentage of the material is about 10% or higher, the dielectric anisotropy can be easily adjusted.

根據實施例,除了式1之液晶化合物外,混合以下一或多個額外之液晶化合物的液晶合成物可提升LTS、高介電異向性、及低旋轉黏度。According to an embodiment, in addition to the liquid crystal compound of Formula 1, a liquid crystal composition mixed with one or more of the following additional liquid crystal compounds can improve LTS, high dielectric anisotropy, and low rotational viscosity.

在根據實施例之液晶合成物中,液晶合成物可進一步包含至少一個式2之液晶化合物。In the liquid crystal composition according to the embodiment, the liquid crystal composition may further include at least one liquid crystal compound of Formula 2.

式2 Formula 2

R11 與式1所定義的R1 相同,除了式1之R1 的定義外,R21 表示-F、-Cl、-CF3 、或-OCF3 ,A3 及A4 彼此獨立地為經F-取代或未取代的1,4-伸環己基、或經F-取代或未取代的1,4-伸苯基,且A5 可以具有以下表示結構的:、、、、、。The same as R 11 defined in Formula 1 R 1, in addition to the definition of R 11 in the formula, R 21 represents -F, -Cl, -CF 3, or -OCF 3, A 3 and A 4 independently of one another by F-substituted or unsubstituted 1,4-cyclohexyl, or F-substituted or unsubstituted 1,4-phenylene, and A 5 may have the following structure: , , , , , .

根據實施例,式2之液晶化合物為具式2-1所示結構的化合物。According to the embodiment, the liquid crystal compound of Formula 2 is a compound having the structure shown in Formula 2-1.

式2-1 Formula 2-1

R11 、R21 、及A5 和式2中的相同。式2-1之液晶化合物可在比式1之液晶化合物更高的溫度中使用,且當結合式1之化合物及式2-1之化合物時,可補償高溫安定性及低旋轉黏度。當式2-1之化合物與式1之化合物混合時,式2-1之液晶化合物之較佳重量百分比為5~35%。當式2-1之液晶化合物的重量百分比不大於5%時,可減少澄清點上升效應,而當其重量大於35%時,可發展出層列液晶相(smectic phase)而減低LTS。R 11 , R 21 , and A 5 are the same as in Formula 2. The liquid crystal compound of Formula 2-1 can be used at a higher temperature than the liquid crystal compound of Formula 1, and when the compound of Formula 1 and the compound of Formula 2-1 are combined, high-temperature stability and low rotational viscosity can be compensated. When the compound of Formula 2-1 and the compound of Formula 1 are mixed, the preferred weight percentage of the liquid crystal compound of Formula 2-1 is 5 to 35%. When the weight percentage of the liquid crystal compound of Formula 2-1 is not more than 5%, the clearing point rise effect can be reduced, and when its weight is more than 35%, a smectic liquid phase can be developed to reduce LTS.

式2-1之液晶化合物可為如式2-1-1a或式2-1-1b所示的結構。The liquid crystal compound of Formula 2-1 may have a structure as shown in Formula 2-1-1a or Formula 2-1-1b.

式2-1-1a Formula 2-1-1a

式2-1-1b Formula 2-1-1b

R11 、R21 與式2中的相同。R 11 and R 21 are the same as in Formula 2.

式2-1-1a或式2-1-1b之液晶化合物可為式2-1-1-1及/或式2-1-1-2所示結構的至少一化合物。The liquid crystal compound of Formula 2-1-1a or Formula 2-1-1b may be at least one compound of the structure represented by Formula 2-1-1-1 and/or Formula 2-1-1-2.

式2-1-1-1 Formula 2-1-1

式2-1-1-2 Formula 2-1-1-2

根據實施例,式2之液晶化合物可為如式2-2所示結構的化合物。According to an embodiment, the liquid crystal compound of Formula 2 may be a compound of the structure shown in Formula 2-2.

式2-2 Formula 2-2

R11 、R21 和式2中定義的相同,X1 ~ X5 獨立地為-H或-F,且至少一X3 或X4 為-F。R 11 and R 21 are the same as defined in Formula 2, X 1 to X 5 are independently -H or -F, and at least one X 3 or X 4 is -F.

式2-2之液晶化合物比起式1之液晶化合物具有較高的折射率異向性及較高的澄清點。因此,當結合式1之液晶合成物時,式2-2之液晶化合物可補償液晶合成物之折射率異向性及低澄清點。當混合式1及式2-2之化合物時,相對整體合成物可包含重量百分比1~20%的式2-2之液晶化合物。當包含重量百分比20%或以上的式2-2之液晶化合物時,折射率異向性可變得太高而無法用於液晶顯示裝置。另外,當其重量百分比低於1%時,可難以在合成物中控制折射率異向性。The liquid crystal compound of Formula 2-2 has higher refractive index anisotropy and higher clear point than the liquid crystal compound of Formula 1. Therefore, when combining the liquid crystal composition of Formula 1, the liquid crystal compound of Formula 2-2 can compensate for the refractive index anisotropy and low clearing point of the liquid crystal composition. When the compounds of Formula 1 and Formula 2-2 are mixed, the liquid crystal compound of Formula 2-2 may be included in the total composition by 1 to 20% by weight. When 20% by weight or more of the liquid crystal compound of Formula 2-2 is included, the refractive index anisotropy may become too high to be used in a liquid crystal display device. In addition, when the weight percentage is less than 1%, it may be difficult to control the refractive index anisotropy in the composition.

式2-2之液晶化合物可為具式2-2-1至少一結構之液晶化合物。The liquid crystal compound of Formula 2-2 may be a liquid crystal compound having at least one structure of Formula 2-2-1.

式2-2-1、。Formula 2-2-1 , .

R11 、R21 與式2中相同。式2-2-1之液晶化合物可具有式2-2-1-1之結構如下: 式2-2-1-1 R 11 and R 21 are the same as in Formula 2. The liquid crystal compound of Formula 2-2-1 may have the structure of Formula 2-2-1-1 as follows: Formula 2-2-1-1

在根據實施例之液晶合成物中,液晶合成物可進一步包含式3之液晶化合物的至少一化合物。In the liquid crystal composition according to the embodiment, the liquid crystal composition may further include at least one compound of the liquid crystal compound of Formula 3.

式3 Formula 3

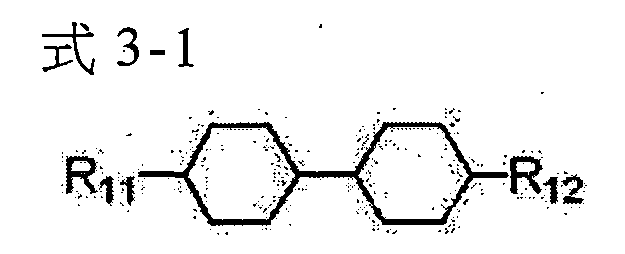

R11 、R12 獨立地相同於式1中R1 的定義,且A3 、A4 獨立地為經F-取代或未取代的1,4-伸環己基、或經F-取代或未取代的1,4-伸苯基。根據實施例,式3之液晶化合物為式3-1或3-2所示結構的化合物。R 11 and R 12 are independently the same as the definition of R 1 in Formula 1, and A 3 and A 4 are independently 1,4-cyclohexyl substituted or unsubstituted by F- or substituted or unsubstituted by F- 1,4-phenylene. According to the embodiment, the liquid crystal compound of Formula 3 is a compound of the structure shown in Formula 3-1 or 3-2.

式3-1 Formula 3-1

式3-2 Formula 3-2

R11 、R12 與式3中的相同。R 11 and R 12 are the same as in Formula 3.

式3-1之液晶化合物可具有式3-1-1或式3-1-2之結構如下:The liquid crystal compound of Formula 3-1 may have the structure of Formula 3-1-1 or Formula 3-1-2 as follows:

式3-1-1 Formula 3-1-1

式3-1-2 Formula 3-1-2

如式3所示液晶化合物,特別是式3-1-1,具有的旋轉黏度低於式1之液晶化合物。因此,當與式1之液晶化合物結合時可補償液晶合成物之旋轉黏度。特別是,當式1之液晶化合物與式3-1-1之液晶化合物混合時,式3-1-1之液晶化合物可對應整體液晶合成物占15~45%的重量百分比。當式3-1-1之液晶化合物的重量百分比低於15%時,難以為動態影像取得具有低旋轉濃度的液晶合成物。但,當其重量百分比高於45%時,係過量使用單一物質,並可減少LTS。The liquid crystal compound shown in Formula 3, especially Formula 3-1-1, has a rotational viscosity lower than that of Formula 1. Therefore, when combined with the liquid crystal compound of Formula 1, the rotational viscosity of the liquid crystal composition can be compensated. In particular, when the liquid crystal compound of Formula 1 is mixed with the liquid crystal compound of Formula 3-1-1, the liquid crystal compound of Formula 3-1-1 may correspond to 15 to 45% by weight of the entire liquid crystal composition. When the weight percentage of the liquid crystal compound of Formula 3-1-1 is less than 15%, it is difficult to obtain a liquid crystal composition having a low rotation density for dynamic images. However, when its weight percentage is higher than 45%, it is excessive use of a single substance and can reduce LTS.

在根據實施例之液晶合成物中,液晶合成物包含至少一式1之液晶化合物、至少一式2之液晶化合物、及至少一式3之液晶化合物。In the liquid crystal composition according to the embodiment, the liquid crystal composition includes at least one liquid crystal compound of Formula 1, at least one liquid crystal compound of Formula 2, and at least one liquid crystal compound of Formula 3.

在根據實施例之液晶合成物中,液晶合成物可進一步包含至少一式4之液晶化合物。In the liquid crystal composition according to the embodiment, the liquid crystal composition may further include at least a liquid crystal compound of Formula 4.

式4 Formula 4

在式4中,R1 、R2 獨立地相同於式1中R1 、R2 的定義,A11 、A12 、A13 、Z11 、Z12 、Z13 及(F)也相同於式1中A11 、A12 、A13 、Z11 、Z12 、Z13 及(F)的定義,f、g、h各自獨立地為0或1,且f+g+h為2或3。In Formula 4, R 1 and R 2 are independently the same as the definitions of R 1 and R 2 in Formula 1, and A 11 , A 12 , A 13 , Z 11 , Z 12 , Z 13 and (F) are also the same as the formula In the definitions of A 11 , A 12 , A 13 , Z 11 , Z 12 , Z 13 and (F) in 1, f, g and h are each independently 0 or 1, and f+g+h is 2 or 3.

式4之液晶合成物可包含至少一式4-1所示結構的液晶化合物,且在式4-1中R1 、R2 、及(F)之定義與他們在式1中的定義相同。The liquid crystal composition of Formula 4 may include at least one liquid crystal compound of the structure shown in Formula 4-1, and the definitions of R 1 , R 2 , and (F) in Formula 4-1 are the same as their definitions in Formula 1.

式4-1、、、、、、、、、、、、、、、、、。Formula 4-1 , , , , , , , , , , , , , , , , , .

根據實施例,式4-1之液晶化合物包含至少一式4-1-1及4-1-2所示結構的液晶化合物。According to an embodiment, the liquid crystal compound of Formula 4-1 includes at least one liquid crystal compound of the structure represented by Formula 4-1-1 and 4-1-2.

式4-1-1 Formula 4-1-1

式4-1-2 Formula 4-1-2

A表示以下結構之一:、、、、、或。A represents one of the following structures: , , , , ,or .

式4所示液晶化合物係用以最佳化液晶顯示裝置之液晶合成物的物理特性,且特別是式4-1-1之化合物,可同時提升液晶之澄清點和介電常數。又,當包含式1的液晶合成物具有不大於6的低介電異向性時,可降低LTS;然而,當式4-1-1之化合物相對全部液晶合成物的重量百分比為1~10%時,可提升LTS。The liquid crystal compound shown in Formula 4 is used to optimize the physical properties of the liquid crystal composition of the liquid crystal display device, and especially the compound of Formula 4-1-1 can simultaneously increase the clear point and dielectric constant of the liquid crystal. Also, when the liquid crystal composition including Formula 1 has a low dielectric anisotropy not greater than 6, LTS can be reduced; however, when the weight percentage of the compound of Formula 4-1-1 relative to the total liquid crystal composition is 1 to 10 %, can increase LTS.

如式4-1-1所示的液晶化合物可具有式4-1-1-1之結構。The liquid crystal compound represented by Formula 4-1-1 may have a structure of Formula 4-1-1-1.

式4-1-1-1 Formula 4-1-1-1

同時,液晶合成物實施例可進一步包含各種添加物,例如抗氧化劑及/或紫外線(UV)穩定劑。Meanwhile, the liquid crystal composition embodiment may further include various additives, such as antioxidants and/or ultraviolet (UV) stabilizers.

液晶合成物可進一步包含從式5~7所選之一或多個化合物作為抗氧化劑或UV穩定劑。The liquid crystal composition may further include one or more compounds selected from Formulae 5 to 7 as antioxidants or UV stabilizers.

式5 Formula 5

R1 、A11 係相同於式1中的定義,且p為0或1。R 1 and A 11 are the same as defined in Formula 1, and p is 0 or 1.

式6 Formula 6

式7 Formula 7

在式6、7中,R3 表示氫、氧自由基、或具有的1~15個碳原子的烷基,其中至少一-CH2-基可在無兩氧原子彼此相連的情形下獨立被-C≡C-、-CF2 O-、-CH=CH-、-O-、-CO-O-、-O-CO-、或-O-CO-O-取代,且1~3個氫原子可被鹵原子取代,n為1~12的整數,且m為0~12的整數。In formulas 6 and 7, R 3 represents hydrogen, an oxygen radical, or an alkyl group having 1 to 15 carbon atoms, in which at least one -CH2- group can be independently-without two oxygen atoms connected to each other- C≡C-, -CF 2 O-, -CH=CH-, -O-, -CO-O-, -O-CO-, or -O-CO-O-, and 1 to 3 hydrogen atoms It can be substituted by halogen atom, n is an integer from 1 to 12, and m is an integer from 0 to 12.

從式5~7所選之化合物的含量可約為1~2000 ppm,並根據合成物全部重量較佳為200~500 ppm。The content of the compound selected from formulas 5 to 7 may be about 1 to 2000 ppm, and preferably 200 to 500 ppm based on the total weight of the composition.

式5之化合物可捕捉在液晶合成物內因UV產生的雜質,例如離子、自由基等。The compound of Formula 5 can capture impurities generated by UV in the liquid crystal composition, such as ions and free radicals.

式5之化合物可為式5-1之化合物。The compound of Formula 5 may be the compound of Formula 5-1.

式5-1 Formula 5-1

其中(O)為O或CH2 。Where (O) is O or CH 2 .

式6、7之化合物可捕捉在液晶合成物內因熱能產生的雜質,例如離子、自由基等。根據實施例之液晶合成物包含至少一式1之液晶化合物及至少一式5~7之化合物,並在此案例中,利用包含至少一式5~7之化合物來提升液晶合成物之熱安定性及UV安定性。The compounds of formulas 6 and 7 can capture impurities such as ions and free radicals generated in the liquid crystal composition due to thermal energy. The liquid crystal composition according to the embodiment includes at least one liquid crystal compound of Formula 1 and at least one compound of Formula 5-7, and in this case, the compound containing at least one Formula 5-7 is used to improve the thermal stability and UV stability of the liquid crystal composition Sex.

同時,在根據實施例之液晶合成物中,液晶合成物進一步包含式8之間距改質化合物。R1 與式1中的定義相同。Meanwhile, in the liquid crystal composition according to the embodiment, the liquid crystal composition further includes the distance modification compound of Formula 8. R 1 has the same definition as in Formula 1.

式8 Formula 8

當液晶具有扭曲螺旋結構,間距表示液晶導向體(director)在螺旋結構內旋轉360度內所走的距離。可根據間距改質劑之合成物比率調整間距值。When the liquid crystal has a twisted spiral structure, the pitch indicates the distance traveled by the liquid crystal director within 360 degrees of rotation in the spiral structure. The spacing value can be adjusted according to the composition ratio of the spacing modifier.

當相對重量百分比100%之液晶合成物包含重量約0.01~5%之式8所示化合物時,可較容易獲得期望間距。When the liquid crystal composition with a relative weight percentage of 100% contains the compound represented by Formula 8 in an amount of about 0.01 to 5% by weight, the desired pitch can be obtained more easily.

根據實施例,液晶合成物包含式1~4之液晶化合物之一、及/或式5~8之化合物之一的各種組成。According to an embodiment, the liquid crystal composition includes various compositions of one of the liquid crystal compounds of formulae 1 to 4 and/or one of the compounds of formulae 5 to 8.

例如,根據實施例之液晶合成物可包含式1-2之液晶化合物及式2-1之液晶化合物。For example, the liquid crystal composition according to the embodiment may include the liquid crystal compound of Formula 1-2 and the liquid crystal compound of Formula 2-1.

根據另一實施例之液晶合成物包含式1-2之液晶化合物及式2-2之液晶化合物。The liquid crystal composition according to another embodiment includes the liquid crystal compound of Formula 1-2 and the liquid crystal compound of Formula 2-2.

根據再一實施例之液晶合成物包含式1-2之液晶化合物及式4-1之液晶化合物。The liquid crystal composition according to still another embodiment includes the liquid crystal compound of Formula 1-2 and the liquid crystal compound of Formula 4-1.

根據又一實施例之液晶合成物額外包含式3之液晶化合物。例如,根據實施例之液晶合成物可包含式1-2之液晶化合物、式2-2之液晶化合物、及式3之液晶化合物。The liquid crystal composition according to still another embodiment additionally includes the liquid crystal compound of Formula 3. For example, the liquid crystal composition according to the embodiment may include the liquid crystal compound of Formula 1-2, the liquid crystal compound of Formula 2-2, and the liquid crystal compound of Formula 3.

根據再一實施例之液晶合成物額外包含式4之液晶化合物。The liquid crystal composition according to still another embodiment additionally includes the liquid crystal compound of Formula 4.

根據又一實施例之液晶合成物額外包含至少一式5~7之液晶化合物。例如,根據實施例之液晶合成物可包含式1-2之液晶化合物及式5~7之添加物。The liquid crystal composition according to still another embodiment additionally includes at least one liquid crystal compound of formula 5-7. For example, the liquid crystal composition according to the embodiment may include the liquid crystal compound of Formula 1-2 and the additives of Formula 5-7.

根據再一實施例之液晶合成物進一步包含式8之化合物。The liquid crystal composition according to still another embodiment further includes the compound of formula 8.

根據實施例,液晶合成物可具有各種合成比例而不違背本發明的概念。According to the embodiment, the liquid crystal composition may have various synthesis ratios without violating the concept of the present invention.

根據實施例,液晶合成物包含式1-2之液晶化合物、式3-1-1之液晶化合物、及式5之化合物。According to an embodiment, the liquid crystal composition includes a liquid crystal compound of Formula 1-2, a liquid crystal compound of Formula 3-1-1, and a compound of Formula 5.

例如,根據實施例之液晶合成物可包含3~35重量份(parts by weight)如式1-2-2所示之液晶化合物、15~45重量份如式3-1-1所示之液晶化合物、及0.01~0.05重量份如式5所示之液晶化合物。For example, the liquid crystal composition according to the embodiment may include 3 to 35 parts by weight of the liquid crystal compound as shown in Formula 1-2-1, and 15 to 45 parts by weight of the liquid crystal as shown in Formula 3-1-1 The compound and 0.01 to 0.05 parts by weight of the liquid crystal compound represented by Formula 5.

同時,根據實施例之液晶合成物可包含如式1-2-2所示之液晶化合物、及如式1-2-3所示之液晶化合物,且在此情況中,式1-2-2之液晶化合物和式1-2-3之液晶化合物之間的重量比例可為1:0.5至1:2.0。Meanwhile, the liquid crystal composition according to the embodiment may include a liquid crystal compound as shown in Formula 1-2-1, and a liquid crystal compound as shown in Formula 1-2-3, and in this case, Formula 1-1-2 The weight ratio between the liquid crystal compound and the liquid crystal compound of Formula 1-2-3 may be 1:0.5 to 1:2.0.

根據實施例,液晶合成物包含式1-2之液晶化合物、式2-1-1-1之液晶化合物、式2-1-1-2之液晶化合物、及式4-1-1-1之液晶化合物。According to an embodiment, the liquid crystal composition includes a liquid crystal compound of formula 1-2, a liquid crystal compound of formula 2-1-1-1, a liquid crystal compound of formula 2-1-1-2, and a formula of 4-1-1 Liquid crystal compound.

同時,根據實施例之液晶化合物包含至少一5~20重量份之如式1-2-2所示及式2-1-1-1所示的液晶化合物、5~20重量份之如式2-1-1-2所示的液晶化合物、以及2~10重量份之如式4-1-1-1所示的液晶化合物。Meanwhile, the liquid crystal compound according to the embodiment includes at least one 5 to 20 parts by weight of the liquid crystal compound represented by Formula 1-2-1 and the formula 2-1-1-1, and 5 to 20 parts by weight of Formula 2 Liquid crystal compound represented by -1-1-2, and 2 to 10 parts by weight of the liquid crystal compound represented by Formula 4-1-1-1.

根據實施例,液晶合成物包含式1-2之液晶化合物、式3-1-1之液晶化合物、式2-2-1-1之液晶化合物、及式4-1-2之液晶化合物。According to an embodiment, the liquid crystal composition includes a liquid crystal compound of Formula 1-2, a liquid crystal compound of Formula 3-1-1, a liquid crystal compound of Formula 2-2-1-1, and a liquid crystal compound of Formula 4-1-2.

同時,根據實施例之液晶合成物包含1~40重量份之如式1-2所示的液晶化合物、15~45重量份之如式3-1-1所示的液晶化合物、2~15重量份之如式2-2-1-1所示的液晶化合物、及3~35重量份之如式4-1-2所示的液晶化合物。Meanwhile, the liquid crystal composition according to the embodiment includes 1 to 40 parts by weight of the liquid crystal compound represented by Formula 1-2, 15 to 45 parts by weight of the liquid crystal compound represented by Formula 3-1-1, and 2 to 15 parts by weight One part is a liquid crystal compound represented by Formula 2-2-1-1, and 3 to 35 parts by weight is a liquid crystal compound represented by Formula 4-1-2.

以此方式,可獲得具正介電異向性的液晶合成物,且所得之液晶合成物具2.0或更高的介電異向性、70度或更高的澄清點、及0.09或更高的折射率異向性。液晶合成物可用在液晶以做主動陣列AM-LCD或被動陣列PM-LCD。且液晶合成物可應用在垂直電場模式或水平電場模式之液晶顯示器,及更具體地應用在各種LCD模式,如扭轉向列(TN)、超扭轉向列(STN)、平面內切換(IPS)、邊緣電場切換(FFS)、平面到線切換(PLS)、先進高效能IPS(AH-IPS)、聚合物穩定配向(polymer sustained alignment, PSA)等。In this way, a liquid crystal composition with positive dielectric anisotropy can be obtained, and the resulting liquid crystal composition has a dielectric anisotropy of 2.0 or higher, a clear point of 70 degrees or higher, and 0.09 or higher The refractive index anisotropy. Liquid crystal composites can be used in liquid crystals to do active array AM-LCD or passive array PM-LCD. And the liquid crystal composition can be applied to the liquid crystal display of vertical electric field mode or horizontal electric field mode, and more specifically applied to various LCD modes, such as twisted nematic (TN), super twisted nematic (STN), in-plane switching (IPS) , Edge electric field switching (FFS), plane-to-line switching (PLS), advanced high-efficiency IPS (AH-IPS), polymer sustained alignment (PSA), etc.

應用根據實施例之液晶合成物的液晶顯示器可具有垂直電場模式或水平電場模式。液晶顯示裝置 The liquid crystal display using the liquid crystal composition according to the embodiment may have a vertical electric field mode or a horizontal electric field mode. Liquid crystal display device

第1圖係根據一例示性實施例所示之液晶顯示裝置的示意圖。FIG. 1 is a schematic diagram of a liquid crystal display device according to an exemplary embodiment.

根據實施例之液晶顯示裝置可以多種型態實現,例如扭轉向列(TN)、超扭轉向列(STN)、平面內切換(IPS)、邊緣電場切換(FFS)、平面到線切換(PLS)、先進高效能IPS(AH-IPS)、聚合物穩定配向(PSA)等。The liquid crystal display device according to the embodiment may be implemented in various types, such as twisted nematic (TN), super twisted nematic (STN), in-plane switching (IPS), fringe electric field switching (FFS), and plane-to-line switching (PLS) , Advanced high-performance IPS (AH-IPS), polymer stable alignment (PSA), etc.

在實施例中,以TN模式作為範例解釋,且根據個別模式可改變各構件之形狀及佈局。In the embodiment, the TN mode is explained as an example, and the shape and layout of each component can be changed according to the individual mode.

根據實施例,液晶顯示裝置100包含第一基板110、第二基板120、及介於第一基板110和第二基板120之間的液晶層130。在第二基板120上定義有複數個像素區,且在各像素區上設置有複數個像素。According to an embodiment, the liquid

第一基板110可包含上座基板111、光罩層112、濾光器113、上絕緣膜114、共用電極115、及上對準膜101。光罩層112形成於上座基板111上,並可包含低光傳透率(例如碳黑等)的不透光材料之色劑。The

濾光器113形成於上座基板111上,並可形成為部分重疊光罩層112或其他相鄰濾光器113。The

上絕緣膜113保護光罩層112及濾光器113,並可填補光罩層112和濾光器113產生的階差,使第一基板110之表面平坦。The upper

共用電極115可利用如氧化銦錫(ITO)或氧化銦鋅(IZO)等製成。在共用電極115上施加預設共用電壓。The

上對準膜101接觸液晶層130,使得在液晶層130內的液晶分子131沿著預設方向初步對準或傾斜。The

第二基板120包含為像素設置的複數個薄膜電晶體。更具體地,第二基板120可包含下座基板121、閘電極122、閘絕緣膜123、半導體層124a、歐姆接觸層124b、源電極125、汲電極126、保護層127、像素電極128、及下對準膜102。The

閘電極122形成於下座基板121上,並從閘線接受閘訊號(未顯示)。閘絕緣膜123包覆閘電極122。The

半導體層124a形成於閘絕緣膜123上以重疊閘電極122,且一對歐姆接觸層124b形成於半導體層124a上彼此相對。The

源電極125及汲電極126形成於歐姆接觸層124b上。將源電極125設置與汲電極126分隔,使部分半導體層124a露出。部分汲電極126通過接觸孔CH電性連接至像素電極128。The

保護層127包覆源電極125、汲電極126、及露出的半導體層124a。The

接觸孔CH形成於保護層127內,使汲電極126通過接觸孔CH電性連接至像素電極128。The contact hole CH is formed in the

像素電極128形成於保護層127上,及下對準膜102形成於像素電極128上。將汲電極126送來的預設資料電壓施加至像素電極128上。The

施加在共用電極115上的資料電壓與共用電壓之間的電壓差產生電場,並可利用該電場調整液晶分子131在液晶層130內的排列。The voltage difference between the data voltage applied to the

根據實施例,雖然光罩層和濾光器被示為形成於上座基板上,本發明係不限於此,且光罩層及/或濾光器可形成於下座基板上。According to an embodiment, although the mask layer and the filter are shown as being formed on the upper base substrate, the present invention is not limited thereto, and the mask layer and/or the filter may be formed on the lower base substrate.

同時,根據實施例,當電極部作為電極提供電場給液晶層時,即像素電極和共用電極,可以不同方式設置電極部。例如,雖然在前述實施例中,共用電極被示為形成於上座基板上,本發明係不限於此,且在其他實施例中,共用電極可形成於下座基板上。第2圖係根據另一例示性實施例所示之液晶顯示裝置的示意圖。在實施例中,共用電極115設置於下座基板121上。在實施例中,共用電極115與像素電極128位於相同層上,但不限於此。共用電極115可與像素電極128設置於不同層上,並在其他實施例中可與像素電極128重疊。Meanwhile, according to the embodiment, when the electrode portion serves as an electrode to provide an electric field to the liquid crystal layer, that is, the pixel electrode and the common electrode, the electrode portion may be provided in different ways. For example, although in the foregoing embodiments, the common electrode is shown to be formed on the upper base substrate, the present invention is not limited thereto, and in other embodiments, the common electrode may be formed on the lower base substrate. FIG. 2 is a schematic diagram of a liquid crystal display device according to another exemplary embodiment. In the embodiment, the

液晶層130包含含有式1之液晶化合物的液晶合成物,由於液晶合成物本質上與上述實施例之液晶合成物相同,不會提供進一步說明。The

為了增加視角,像素可分成複數個領域,且液晶合成物可在一像素區內沿著二或多個不同方向對準。各像素中可形成突起等,以將像素分成複數個領域,且像素電極和共用電極可包含切口部。In order to increase the viewing angle, pixels can be divided into multiple fields, and the liquid crystal composition can be aligned along two or more different directions within a pixel area. A protrusion or the like may be formed in each pixel to divide the pixel into a plurality of areas, and the pixel electrode and the common electrode may include cutouts.

根據實施例之液晶顯示裝置所應用的液晶合成物可具有多種模式,如垂直電場模式(例如TN、STN、VA等)、以及水平電場模式(例如IPS、PLS、FFS等)。The liquid crystal composition applied to the liquid crystal display device according to the embodiment may have various modes, such as a vertical electric field mode (eg, TN, STN, VA, etc.), and a horizontal electric field mode (eg, IPS, PLS, FFS, etc.).

以下,將詳細說明實施例。式 1 之液晶化合物的合成 Hereinafter, the embodiment will be described in detail. Synthesis of Liquid Crystal Compound of Formula 1

式1之液晶化合物可使用以下製備方法來合成,且對相應的製備方法相對重要的是在氟旁邊插入一甲基。The liquid crystal compound of Formula 1 can be synthesized using the following preparation method, and it is relatively important for the corresponding preparation method to insert a methyl group next to fluorine.

反應式1 Reaction 1

反應式2 Reaction 2

反應式3 Reaction 3

如反應式1所示,藉由逐漸滴入二異丙基氨基鋰(lithium diisopropylamide ,LDA)並滴定添加甲基碘化物,可移去1-溴-2-氟-4-碘苯(1-bromo-2-fluoro-4-iodobenzene)之第三位置的氫並將甲基連接到伸苯基之第三位置。欲瞭解此反應可參考文獻((a) Schlosser, M. 2001Eur. J. Org. Chem. , pp 3975; (b) Schlosser, M. (2005)Angew. Chem. Int. Ed. , vol 44, pp 376)。As shown in Equation 1, by gradually dropping lithium diisopropylamide (LDA) and titrating methyl iodide, 1-bromo-2-fluoro-4-iodobenzene (1- bromo-2-fluoro-4-iodobenzene) hydrogen at the third position and connect the methyl group to the third position of the phenylene group. For the reaction, refer to the literature ((a) Schlosser, M. 2001 Eur. J. Org. Chem. , pp 3975; (b) Schlosser, M. (2005) Angew. Chem. Int. Ed. , vol 44, pp 376).

另一方面,根據反應式3,其應用反應式1的方法於2-取代-1,3-二氟-5-碘苯而產生具有一或二個甲基取代基的化合物。由於此化合物不具有極性,無法使其分割,並因此無法獲得期望化合物。On the other hand, according to Reaction Formula 3, the method of Reaction Formula 1 is applied to 2-substituted-1,3-difluoro-5-iodobenzene to produce a compound having one or two methyl substituents. Since this compound has no polarity, it cannot be divided, and thus the desired compound cannot be obtained.

最有效率之方法,如反應式2中,醇部被保護在環結構中,接著添加丁基鋰使甲基僅插在單一位置。此醇環結構保護反應係使用已知方法實現,並根據本發明混合1.5當量之2,3-二氫吡喃(2,3-dihydropyran)與醇化物,再使用氫氯酸做催化劑以獲得醇環結構保護材料。The most efficient method, as in Equation 2, the alcohol part is protected in the ring structure, and then butyllithium is added so that the methyl group is only inserted in a single position. This alcohol ring structure protection reaction is achieved using a known method, and according to the present invention, 1.5 equivalents of 2,3-dihydropyran (2,3-dihydropyran) and alcoholate are mixed, and then hydrochloric acid is used as a catalyst to obtain alcohol Ring structure protection material.

因此,如下之液晶合成物可藉由反應式1、2製作,且反應式2、3中的R2 可為-F、-Cl、-Br。Therefore, the following liquid crystal composition can be produced by Reaction Formulas 1 and 2, and R 2 in Reaction Formulas 2 and 3 can be -F, -Cl, or -Br.

根據實施例之使用上述反應式製作的液晶合成物之詳細範例如下所示,且R1 與式1相同。[1]、[2]、[3]、[4]、[5]、[6]、[7]、[8]、[9]、[10]、[11]、[12]、[13]、[14]、[15]、[16]、[17]、[18]、[19]、[20]、[21]、[22]、[23]、[24]、[25]、[26]、[27]、[28]、[29]、[30]、[31]、[32]、[33]、[34]。A detailed example of the liquid crystal composition manufactured using the above reaction formula according to the embodiment is shown below, and R 1 is the same as Formula 1. [1], [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [twenty one], [twenty two], [twenty three], [twenty four], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34].

在下文中,將藉由詳細實施例來詳細說明本發明之功能和效益。然而,這些實施例僅僅是範例,且不會限定本發明的範疇。合成範例 1 :液晶化合物 A1 之合成 In the following, the functions and benefits of the present invention will be explained in detail through detailed embodiments. However, these embodiments are only examples and do not limit the scope of the present invention. Synthesis Example 1: Synthesis of Compound A1 of the liquid crystal

反應式4 Reaction 4

在氮氣環境下,醇化物(A1-2)(2.3g,14.2 mmol)、四丁基溴化銨(tetrabutylammonium bromide)(0.42g, 1.29 mmol)、及碳酸鉀(potassium carbonate)(3.6g, 25.9 mmol)溶解於二甲基甲醯胺(dimethylformamide)(50 ml)中,並在40°C下攪拌產物1小時。溴化物(A1-1)(5.4g,15mmol)溶解於二甲基甲醯胺(50ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A1)(4.5g,10.3mmol)。(產量73%)質譜:252、281、442[M+ ],相位轉變溫度(TCr-l ):67.3°C。合成範例 2 :液晶化合物 A2 之合成 Under a nitrogen atmosphere, alcoholate (A1-2) (2.3g, 14.2 mmol), tetrabutylammonium bromide (0.42g, 1.29 mmol), and potassium carbonate (3.6g, 25.9 mmol) was dissolved in dimethylformamide (50 ml), and the product was stirred at 40°C for 1 hour. The bromide (A1-1) (5.4 g, 15 mmol) was dissolved in dimethylformamide (50 ml), the solution was added dropwise and then the product was refluxed at 90° C. for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A1) (4.5 g, 10.3 mmol) was formed. (Yield 73%) Mass spectrum: 252, 281, 442 [M + ], phase transition temperature (T Cr-l ): 67.3°C. Synthesis Example 2: Synthesis of liquid crystal compound A2

反應式5 Reaction 5

在氮氣環境下,硼酸化合物(A2-1)(4.9g,20mmol)、溴化物(A2-2)(7.8g,20mmol)、及(PPh3 )4 Pd(0.1g)溶解於二甲氧基乙烷(100ml)中,並接著加入2M碳酸鉀溶液(30ml)。加溫至60°C,並將產物回流6小時。冷卻後,以水和二氯甲烷稀釋反應溶液使相位分離。接著,萃取出有機層,以蒸餾水清洗,並用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(正己烷:乙酸乙酯)至生成產物(A2)(4.8g,8.9 mmol)。(產量45%)質譜:360、389、536[M+ ],相位轉變溫度(TCr-l ):53.1°C。合成範例 3 :液晶化合物 A3 之合成 Under a nitrogen atmosphere, the boric acid compound (A2-1) (4.9 g, 20 mmol), bromide (A2-2) (7.8 g, 20 mmol), and (PPh 3 ) 4 Pd (0.1 g) were dissolved in dimethoxy Ethane (100ml), and then added 2M potassium carbonate solution (30ml). Warm to 60°C and reflux the product for 6 hours. After cooling, the reaction solution was diluted with water and dichloromethane to separate phases. Next, the organic layer was extracted, washed with distilled water, and dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (n-hexane: ethyl acetate) until the product (A2) (4.8 g, 8.9 mmol) was formed. (Yield 45%) Mass spectrum: 360, 389, 536 [M + ], phase transition temperature (T Cr-l ): 53.1°C. Synthesis Example 3: Synthesis of liquid crystal compound A3

反應式6 Reaction 6

在氮氣環境下,醇化物(A3-2)(4.1g, 25.6mmol)、四丁基溴化銨(0.75g, 2.3mmol)、及碳酸鉀(6.4g, 46.6mmol)溶解於二甲基甲醯胺(70ml)中,在40°C下攪拌產物1小時。溴化物(A3-1)(12.2g, 27mmol)溶解於二甲基甲醯胺(70ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A3)(9.7g, 18.1mmol)。(產量71%)質譜:346、375、536[M+ ],相位轉變溫度(TCr-N ):70.2°C,相位轉變溫度(TN-l ):126.3°C。合成範例 4 :液晶化合物 A4 之合成 Under a nitrogen atmosphere, alcoholate (A3-2) (4.1g, 25.6mmol), tetrabutylammonium bromide (0.75g, 2.3mmol), and potassium carbonate (6.4g, 46.6mmol) were dissolved in dimethyl formaldehyde In acetamide (70 ml), the product was stirred at 40°C for 1 hour. The bromide (A3-1) (12.2 g, 27 mmol) was dissolved in dimethylformamide (70 ml), the solution was dropped and then the product was refluxed at 90° C. for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A3) (9.7 g, 18.1 mmol) was formed. (Yield 71%) Mass spectrum: 346, 375, 536 [M + ], phase transition temperature (T Cr-N ): 70.2°C, phase transition temperature (T Nl ): 126.3°C. Synthesis Example 4: Synthesis of Compound A4 of the liquid crystal

反應式7 Reaction 7

在氮氣環境下,醇化物(A4-2)(3.20g, 19.7mmol)、四丁基溴化銨(0.64g, 2.0mmol)、及碳酸鉀(5.46g, 39.5mmol)溶解於二甲基甲醯胺(50ml)中,在40°C下攪拌產物1小時。溴化物(A4-1)(8.23g, 21.7mmol)溶解於二甲基甲醯胺(50ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A4)(5.91g, 12.8 mmol)。(產量65%)質譜:271、299、460[M+ ],相位轉變溫度(TCr-l ):72.2°C。合成範例 5 :液晶化合物 A5 之合成 Under a nitrogen atmosphere, alcoholate (A4-2) (3.20g, 19.7mmol), tetrabutylammonium bromide (0.64g, 2.0mmol), and potassium carbonate (5.46g, 39.5mmol) were dissolved in dimethyl formaldehyde In acetamide (50 ml), the product was stirred at 40°C for 1 hour. The bromide (A4-1) (8.23 g, 21.7 mmol) was dissolved in dimethylformamide (50 ml), the solution was added dropwise and the product was then refluxed at 90° C. for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A4) (5.91 g, 12.8 mmol) was formed. (65% yield) Mass spectrum: 271, 299, 460 [M + ], phase transition temperature (T Cr-l ): 72.2°C. Synthesis Example 5: Synthesis of liquid crystal compound A5

反應式8 Reaction 8

在氮氣環境下,醇化物(A5-2)(3.70 g, 22.8 mmol)、四丁基溴化銨(0.74 g, 2.3 mmol)、及碳酸鉀(6.31 g, 45.6 mmol)溶解於二甲基甲醯胺(50ml)中,在40°C下攪拌產物1小時。溴化物(A5-1)(11.08 g, 25.1 mmol)溶解於二甲基甲醯胺(50ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A5)(8.59 g, 16.4 mmol)。(產量72%)質譜:347、361、522[M+ ],相位轉變溫度(TCr-N ):89°C,相位轉變溫度(TN-l ):123.0°C。合成範例 6 :液晶化合物 A6 之合成 Under a nitrogen atmosphere, alcoholate (A5-2) (3.70 g, 22.8 mmol), tetrabutylammonium bromide (0.74 g, 2.3 mmol), and potassium carbonate (6.31 g, 45.6 mmol) were dissolved in dimethyl formaldehyde In acetamide (50 ml), the product was stirred at 40°C for 1 hour. The bromide (A5-1) (11.08 g, 25.1 mmol) was dissolved in dimethylformamide (50 ml), the solution was dropped and then the product was refluxed at 90°C for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A5) (8.59 g, 16.4 mmol) was formed. (Yield 72%) Mass spectrum: 347, 361, 522 [M + ], phase transition temperature (T Cr-N ): 89°C, phase transition temperature (T Nl ): 123.0°C. Synthesis Example 6: Synthesis of Compound A6 of the liquid crystal

反應式9 Reaction 9

在氮氣環境下,醇化物(A6-2)(2.27 g, 14.0 mmol)、四丁基溴化銨(0.46 g, 1.4 mmol)、及碳酸鉀(3.87g, 28.0mmol)溶解於二甲基甲醯胺(50ml)中,在40°C下攪拌產物1小時。溴化物(A6-1)(6.64 g, 15.4 mmol)溶解於二甲基甲醯胺(50 ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A6)(4.23 g, 8.3 mmol)。(產量59%)質譜:351、512[M+ ],相位轉變溫度(TCr-N ):82.4°C,相位轉變溫度(TN-l ):94.5°C。合成範例 7 :液晶化合物 A7 之合成 Under a nitrogen atmosphere, alcoholate (A6-2) (2.27 g, 14.0 mmol), tetrabutylammonium bromide (0.46 g, 1.4 mmol), and potassium carbonate (3.87 g, 28.0 mmol) were dissolved in dimethyl methyl In acetamide (50 ml), the product was stirred at 40°C for 1 hour. Bromide (A6-1) (6.64 g, 15.4 mmol) was dissolved in dimethylformamide (50 ml), the solution was added dropwise and the product was then refluxed at 90°C for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A6) (4.23 g, 8.3 mmol) was formed. (Yield 59%) Mass spectrum: 351, 512 [M + ], phase transition temperature (T Cr-N ): 82.4°C, phase transition temperature (T Nl ): 94.5°C. Synthesis Example 7: Synthesis of liquid crystal compound of A7

反應式10 Reactive 10

在氮氣環境下,醇化物(A7-2)(3.25 g, 20.0 mmol)、四丁基溴化銨(0.65 g, 2.0 mmol)、及碳酸鉀(5.54 g, 40.1 mmol)溶解於二甲基甲醯胺(50ml)中,在40°C下攪拌產物1小時。溴化物(A7-1)(9.82 g, 22.1 mmol)溶解於二甲基甲醯胺(50ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A7)(6.44 g, 12.2 mmol)。(產量61%)質譜:365、526[M+ ],相位轉變溫度(TCr-N ):65.7°C,相位轉變溫度(TN-l ):121.8°C。合成範例 8 :液晶化合物 A8 之合成 Under a nitrogen atmosphere, alcoholate (A7-2) (3.25 g, 20.0 mmol), tetrabutylammonium bromide (0.65 g, 2.0 mmol), and potassium carbonate (5.54 g, 40.1 mmol) were dissolved in dimethyl formaldehyde In acetamide (50 ml), the product was stirred at 40°C for 1 hour. The bromide (A7-1) (9.82 g, 22.1 mmol) was dissolved in dimethylformamide (50 ml), the solution was added dropwise and then the product was refluxed at 90°C for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A7) (6.44 g, 12.2 mmol) was formed. (Yield 61%) Mass spectrum: 365, 526 [M + ], phase transition temperature (T Cr-N ): 65.7°C, phase transition temperature (T Nl ): 121.8°C. Synthesis Example 8: Synthesis of liquid crystal compound A8

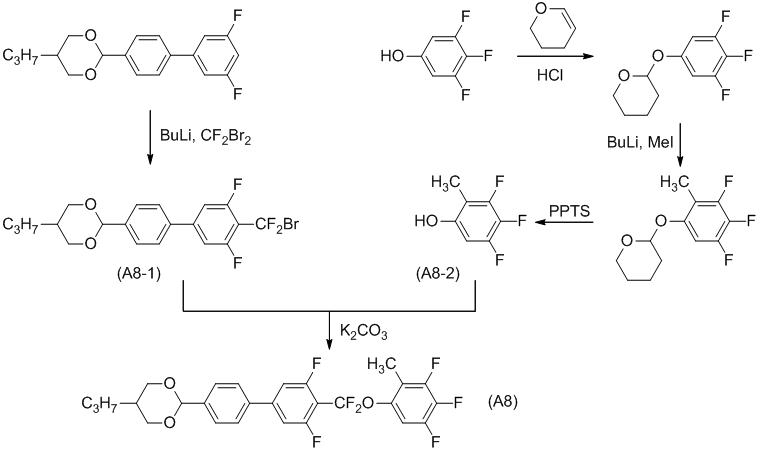

反應式11 Reaction 11

在氮氣環境下,醇化物(A8-2)(2.74 g, 16.9 mmol)、四丁基溴化銨(0.55 g, 1.7 mmol)、及碳酸鉀(4.67 g, 33.8 mmol)溶解於二甲基甲醯胺(50 ml)中,在40°C下攪拌產物1小時。溴化物(A8-1)(8.32 g, 18.6 mmol)溶解於二甲基甲醯胺(50 ml)中,滴入溶液並接著在90°C下將產物回流2小時。在反應結束後,用水和甲苯稀釋反應溶液使相位分離。萃取出有機層,以碳酸氫鈉溶液及蒸餾水清洗,接著用硫酸鎂乾燥。在矽膠柱上洗滌產物,接著再結晶(溶劑正己烷:乙酸乙酯)至生成產物(A8)(6.07 g, 11.5 mmol)。(產量68%)質譜:367、528[M+ ],相位轉變溫度(TCr-N ):67.3°C 。液晶化合物及液晶合成物的評估方法 Under a nitrogen atmosphere, alcoholate (A8-2) (2.74 g, 16.9 mmol), tetrabutylammonium bromide (0.55 g, 1.7 mmol), and potassium carbonate (4.67 g, 33.8 mmol) were dissolved in dimethyl formaldehyde In amide (50 ml), the product was stirred at 40°C for 1 hour. The bromide (A8-1) (8.32 g, 18.6 mmol) was dissolved in dimethylformamide (50 ml), the solution was added dropwise and the product was then refluxed at 90°C for 2 hours. After the reaction, the reaction solution was diluted with water and toluene to separate the phases. The organic layer was extracted, washed with sodium bicarbonate solution and distilled water, and then dried over magnesium sulfate. The product was washed on a silica gel column, and then recrystallized (solvent n-hexane: ethyl acetate) until the product (A8) (6.07 g, 11.5 mmol) was formed. (Yield 68%) Mass spectrum: 367, 528 [M + ], phase transition temperature (T Cr-N ): 67.3°C. Evaluation method of liquid crystal compound and liquid crystal compound

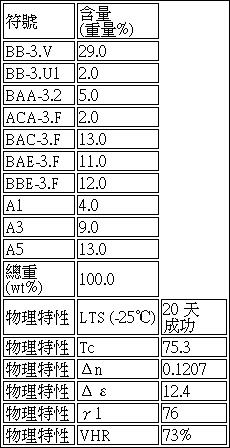

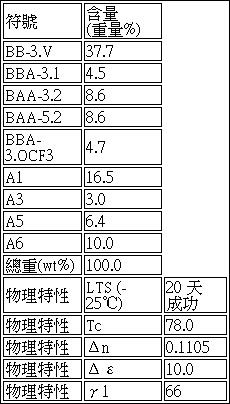

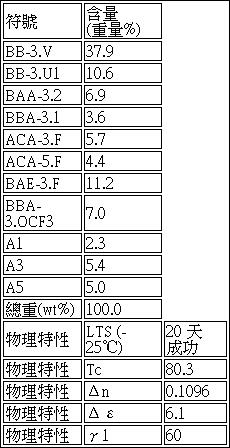

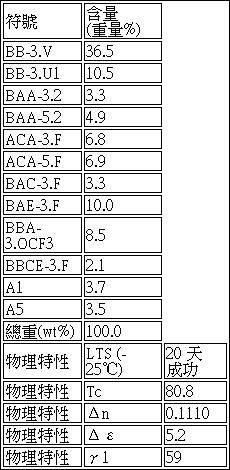

根據以下方法評估LTS及液晶化合物和液晶合成物的物理特性: (1) LTSEvaluate the physical properties of LTS, liquid crystal compounds and liquid crystal compounds according to the following methods: (1) LTS