KR20140126634A - Pellet boiler - Google Patents

Pellet boiler Download PDFInfo

- Publication number

- KR20140126634A KR20140126634A KR1020130045052A KR20130045052A KR20140126634A KR 20140126634 A KR20140126634 A KR 20140126634A KR 1020130045052 A KR1020130045052 A KR 1020130045052A KR 20130045052 A KR20130045052 A KR 20130045052A KR 20140126634 A KR20140126634 A KR 20140126634A

- Authority

- KR

- South Korea

- Prior art keywords

- fuel

- supply pipe

- air

- combustion chamber

- transfer device

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23B—METHODS OR APPARATUS FOR COMBUSTION USING ONLY SOLID FUEL

- F23B40/00—Combustion apparatus with driven means for feeding fuel into the combustion chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23B—METHODS OR APPARATUS FOR COMBUSTION USING ONLY SOLID FUEL

- F23B80/00—Combustion apparatus characterised by means creating a distinct flow path for flue gases or for non-combusted gases given off by the fuel

- F23B80/04—Combustion apparatus characterised by means creating a distinct flow path for flue gases or for non-combusted gases given off by the fuel by means for guiding the flow of flue gases, e.g. baffles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/22—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating

- F24H1/34—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water chamber arranged adjacent to the combustion chamber or chambers, e.g. above or at side

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/18—Arrangement or mounting of grates or heating means

- F24H9/1809—Arrangement or mounting of grates or heating means for water heaters

- F24H9/1832—Arrangement or mounting of combustion heating means, e.g. grates or burners

- F24H9/1845—Arrangement or mounting of combustion heating means, e.g. grates or burners using solid fuel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23B—METHODS OR APPARATUS FOR COMBUSTION USING ONLY SOLID FUEL

- F23B2700/00—Combustion apparatus for solid fuel

- F23B2700/003—Combustion apparatus for solid fuel adapted for use in water-tube boilers

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Solid-Fuel Combustion (AREA)

Abstract

Description

The present invention relates to a pellet boiler, and more particularly, to a pellet boiler capable of preventing failure of a fuel supply device for supplying fuel and facilitating smooth transfer of fuel.

A pellet is a product made by crushing, drying and compacting wood into small particles such as sawdust and forming it into small granules. It is small in size, homogenized and standardized, and easy to store and reprocess. There is a lot of fuel used. A pellet boiler using the same refers to a boiler that uses combustion heat generated by burning pellets for heating or hot water.

In a pellet boiler, a device for supplying pellets, that is, a fuel supply device, becomes a main constituent factor of product performance. The fuel supply device is largely divided into a top-down type, a top-down type, and a horizontal type according to the fuel supply position. 1 is a view showing a part of a conventional pellet boiler. 1, the pellet is stored in a

In the conventional pellet boiler, the

Further, the fuel supply stagnation due to the fuel tangling phenomenon, or the space of the screw conveyor and the cylinder is widened, so that the pellet powder accumulated in the space is fixed due to moisture or moisture, or the fuel supply device becomes impossible to operate However, due to the irregular size of the pellets, there is a problem that the pellets are not properly injected into the combustion chamber due to a hooking phenomenon at the fuel inlet.

SUMMARY OF THE INVENTION The present invention has been made in view of the above-mentioned problems, and it is an object of the present invention to provide a fuel supply apparatus and a fuel supply apparatus which prevent fire of a fuel storage device due to flame back- The present invention provides a pellet boiler in which malfunction of the device due to fixing of pellets can be prevented, and operation and efficiency can be improved.

According to an aspect of the present invention, there is provided a pellet boiler comprising a fuel storage device for storing fuel, a fuel transfer device for transferring the fuel provided from the fuel storage device, and a fuel conveyed from the fuel transfer device, And a fuel supply pipe guiding the fuel to the combustion chamber, wherein one end of the fuel supply pipe is connected to the combustion chamber and the other end is connected to the fuel transfer device provided apart from the combustion chamber, Is supplied to the combustion chamber through the fuel supply pipe.

The fuel supply system may further include an air supply pipe for injecting air into the fuel supply pipe, and the air supply pipe may be connected to the other end of the fuel supply pipe connected to the fuel transfer device.

The apparatus may further include an air generator for generating air to be supplied to the air supply pipe, and an air distributor for separating the flow of air supplied from the air generator and supplying the separated air to different positions.

The air distributor may further include a plurality of discharge pipes for discharging respective separated flows, one of the plurality of discharge pipes being physically connected to the air supply pipe, and air supplied from one of the plurality of discharge pipes And can be injected into the fuel supply pipe through the air supply pipe.

The other one of the plurality of discharge pipes is connected to an oil burner, and another one of the plurality of discharge pipes is connected to a flame detector for detecting a flame in the combustion chamber.

The air supply pipe may further include an air guide for guiding the flow of air injected from the air supply pipe in a specific direction to the other end of the fuel supply pipe.

According to the pellet boiler having the above-described structure, fire of the fuel storage device due to the back flame of the flame can be prevented, the fuel can be smoothly conveyed, and the device can be prevented from malfunctioning due to the fixation of the fuel pellet, Smooth operation and efficiency can be increased.

1 is a view showing the construction of a conventional pellet boiler,

2 is a view showing the construction of a

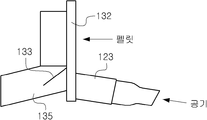

3 is an enlarged view of a connection relationship between a fuel transfer device, a fuel supply pipe, and a combustion chamber according to an embodiment of the present invention,

4 is a view showing a part of the

5 is a view illustrating a configuration of a

6 and 7 are views showing a configuration of an air distributor according to an embodiment of the present invention.

Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings.

2 is a view showing the construction of a

A hopper, which is a

At this time, the

As shown in the drawing, the

In other words, one end of the

According to the configuration of the present invention, since one end of the

The

The

Also, the first

And may further include an

Of course, the structure of the

When the pellets are supplied to the

The heat of combustion of the pellets is also used to heat

The

Meanwhile, the second

3 is an enlarged view of a connection relationship between the fuel transfer device, the fuel supply pipe, and the combustion chamber according to the embodiment of the present invention. In particular, FIG. 3 is to illustrate the connection relationship of the above-described configurations, and the configurations of the first

3, the

The

The

The

The

4 is a view showing a part of the

First, as shown in FIG. 4, a first

The connecting

5, a hole is formed in the upper portion 132-1 to which the

6 and 7 are views showing a configuration of an air distributor according to an embodiment of the present invention. Generally, a boiler is provided with a phototube for detecting a flame in a combustion chamber and an oil burner for burning fuel.

A photo tube is a cathode in which a film of sodium, potassium, or cesium is attached to the inner surface of a glass tube filled with a vacuum or a low-pressure gas, and an anode is disposed in the center of the tube. When light is emitted to the cathode, It has the function of converting the change of light into electric current and is used in the light receiving part of the flame detector. In addition, oil burners are devices for burning fuel, such as pressurized spray, rotary atomizer, and steam atomizer. In the present invention, the

As shown in FIG. 6, the

The first outlet pipe 120-1 is connected to the first

The second discharge pipe 120-2 is connected to the second

The third discharge pipe 120-3 is connected to the third

As shown in FIG. 7, the first discharge pipe 120-1, the second discharge pipe 120-2, and the third discharge pipe 120-3 have different diameters in the

While the present invention has been particularly shown and described with reference to exemplary embodiments thereof, it is evident that many alternatives, modifications, and variations will be apparent to those skilled in the art without departing from the spirit and scope of the invention. It should be interpreted as a concept. Therefore, the embodiments described in the present specification and the configurations shown in the drawings are merely the most preferred embodiments of the present invention and are not intended to represent all of the technical ideas of the present invention. Therefore, various equivalents It should be understood that there are water and modifications.

100 .............................. Boiler

110 .............................. Fuel storage device

120 .............................. Air distributor

120-1 ... First outlet

120-2 ............................ Second discharge pipe

120-3 ............................ Third discharge pipe

123 ...................... First air supply pipe

125 ...................... Second air supply pipe

127 .............................. Third air supply pipe

128 .............................. Air generation device

130 .............................. Fuel transfer device

133 .............................. Air guide

135 .............................. Fuel supply pipe

140 .............................. Combustion chamber

160 .............................. motor

165 .............................. Chain gear

Claims (6)

A fuel transfer device for transferring the fuel provided from the fuel storage device; And

And a fuel supply pipe for guiding the fuel transferred from the fuel transfer device to the combustion chamber,

Wherein the fuel supply pipe has one end connected to the combustion chamber and the other end connected to the fuel transfer device spaced apart from the combustion chamber so that the fuel transferred from the fuel transfer device is supplied to the combustion chamber through the fuel supply pipe The pellet boiler being.

And an air supply pipe for injecting air into the fuel supply pipe,

And the air supply pipe is connected to the other end of the fuel supply pipe connected to the fuel transfer device.

An air generation device for generating air to be supplied to the air supply pipe; And

Further comprising an air distributor for separating and supplying the flow of the air generated and supplied from the air generating device to different positions.

Wherein the air distributor includes a plurality of discharge pipes for discharging respective separated flows of air,

Wherein one of the plurality of discharge pipes is physically connected to the air supply pipe and air supplied from any one of the plurality of discharge pipes is injected into the fuel supply pipe via the air supply pipe.

Wherein the other one of the plurality of discharge pipes is connected to an oil burner and the other one of the plurality of discharge pipes is connected to a flame detector for detecting a flame in the combustion chamber.

And an air guide for guiding the flow of air injected from the air supply pipe in a specific direction to the other end of the fuel supply pipe provided with the air supply pipe.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020130045052A KR20140126634A (en) | 2013-04-23 | 2013-04-23 | Pellet boiler |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020130045052A KR20140126634A (en) | 2013-04-23 | 2013-04-23 | Pellet boiler |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20140126634A true KR20140126634A (en) | 2014-10-31 |

Family

ID=51995843

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020130045052A KR20140126634A (en) | 2013-04-23 | 2013-04-23 | Pellet boiler |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR20140126634A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101894374B1 (en) * | 2018-04-11 | 2018-09-04 | 강용훈 | A device for heating of vinyl house using oil indirect heating mode |

-

2013

- 2013-04-23 KR KR1020130045052A patent/KR20140126634A/en active Search and Examination

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101894374B1 (en) * | 2018-04-11 | 2018-09-04 | 강용훈 | A device for heating of vinyl house using oil indirect heating mode |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5390603B2 (en) | Fuel supply system for furnaces with a minimum output of less than 1 kW | |

| JP4766562B2 (en) | Wood pellet fired steam boiler | |

| CN101548134B (en) | Pulverized coal concentration regulator and pulverized coal combustion boiler | |

| KR101026191B1 (en) | Boiler for solid fuel and combustion apparatus | |

| PL200778B1 (en) | METHOD OF AND ARRANGEMENT for COMBUSTION OF GRANULAR, SOLID FUEL | |

| US20140150698A1 (en) | Solid fuel gravity feed combustion device, system and method | |

| US20030161694A1 (en) | Adjustable flow vectoring splitter | |

| CA2530236A1 (en) | High efficiency cyclone gasifying combustion burner to produce thermal energy and devices and method of operation | |

| JP5888726B2 (en) | Solid fuel boiler system and solid fuel burner | |

| CN203771393U (en) | Coal supply spraying opening device of circulating fluidized bed boiler | |

| JP6696790B2 (en) | Stoker incinerator | |

| US8888874B1 (en) | Mobile horizontal gasifier system | |

| JP2008032357A (en) | Wood fuel combustion device | |

| CN201344524Y (en) | Feeding device of anti-reflow biomass circulating fluidized bed boiler | |

| KR20140126634A (en) | Pellet boiler | |

| KR101170386B1 (en) | Wood pellet combustion control device | |

| WO2016014004A1 (en) | A continuous granular fuel burner | |

| JP2012078018A (en) | Pretreatment unit | |

| US3756201A (en) | Industrial boilers | |

| US10415821B2 (en) | Burner | |

| KR101269663B1 (en) | Combustion apparatus for wood pellet | |

| KR101180323B1 (en) | Combustion apparatus of pellet fuel for agriculture heater | |

| KR101557095B1 (en) | Burner fuel transfort unit | |

| KR101937619B1 (en) | The waste medium-pellet boiler of a caterpillar type | |

| WO2022151495A1 (en) | Feeding device for solid fuel combustion furnace, and combustion furnace |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AMND | Amendment | ||

| E601 | Decision to refuse application | ||

| AMND | Amendment |