KR100557490B1 - Cool air spouting hole formation structure for refrigerator - Google Patents

Cool air spouting hole formation structure for refrigerator Download PDFInfo

- Publication number

- KR100557490B1 KR100557490B1 KR1019990020216A KR19990020216A KR100557490B1 KR 100557490 B1 KR100557490 B1 KR 100557490B1 KR 1019990020216 A KR1019990020216 A KR 1019990020216A KR 19990020216 A KR19990020216 A KR 19990020216A KR 100557490 B1 KR100557490 B1 KR 100557490B1

- Authority

- KR

- South Korea

- Prior art keywords

- cold air

- duct

- air discharge

- insulating material

- discharge port

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D17/00—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces

- F25D17/04—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection

- F25D17/06—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection by forced circulation

- F25D17/08—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection by forced circulation using ducts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D17/00—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces

- F25D17/04—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection

- F25D17/06—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection by forced circulation

- F25D17/062—Arrangements for circulating cooling fluids; Arrangements for circulating gas, e.g. air, within refrigerated spaces for circulating air, e.g. by convection by forced circulation in household refrigerators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D21/00—Defrosting; Preventing frosting; Removing condensed or defrost water

- F25D21/04—Preventing the formation of frost or condensate

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/065—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the air return

- F25D2317/0653—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the air return through the mullion

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/066—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the air supply

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/067—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by air ducts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/067—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by air ducts

- F25D2317/0672—Outlet ducts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2400/00—General features of, or devices for refrigerators, cold rooms, ice-boxes, or for cooling or freezing apparatus not covered by any other subclass

- F25D2400/18—Aesthetic features

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2500/00—Problems to be solved

- F25D2500/02—Geometry problems

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Cold Air Circulating Systems And Constructional Details In Refrigerators (AREA)

- Sorption Type Refrigeration Machines (AREA)

Abstract

본 발명은 냉장고의 냉기 토출구 형성구조에 관한 것으로, 냉기 유로가 내부에 형성되고 전면에 복수개의 냉기 토출구가 형성되는 냉기 토출덕트 내부의 단열재와; 상기 냉기 토출구와 대응되는 냉기 토출구가 형성되어 단열재를 내장하는 냉기 토출덕트 외부의 덕트 사출물과; 상기 덕트 사출물의 냉기 토출구 측에서 상기 단열재의 냉기 토출구 측으로 연장하여 상기 단열재의 냉기 토출구 주위에 형성된 단턱에 억지 결합 결합됨으로써 상기 덕트 사출물과 상기 단열재의 사이뜸으로 유입되는 냉기를 차단시키는 폐쇄 리브를 포함하여 구성됨으로써, 냉기 토출덕트의 덕트 사출물과 단열재 사이의 사이뜸으로 냉기가 유입되지 않도록 냉기 토출구를 형성시킬 수 있으며, 조립후 단열재가 노출되지 않으므로 미관을 미려하게 하여 냉장고의 이미지를 고급화할 수 있게 된다.The present invention relates to a structure for forming a cold air discharge port of a refrigerator, comprising: a heat insulating material inside a cold air discharge duct in which a cold air flow path is formed and a plurality of cold air discharge holes are formed on a front surface thereof; A duct injection product external to the cold air discharge duct in which a cold air discharge port corresponding to the cold air discharge port is formed to have a heat insulating material; A closed rib extending from the cold air outlet side of the duct injection to the cold air outlet side of the heat insulator to be coupled to a step formed around the cold air outlet of the heat insulator to block cold air flowing into the duct between the duct injection and the heat insulator. In this configuration, the cold air discharge port can be formed so that cold air is not introduced into the duct between the duct injection product of the cold air discharge duct and the heat insulating material. do.

Description

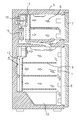

도 1은 종래의 냉장고를 나타낸 종단면도 1 is a longitudinal cross-sectional view showing a conventional refrigerator.

도 2는 도 1의 A 부분 단면 확대도 2 is an enlarged view of a portion A of FIG.

도 3은 본 발명에 따른 냉기 토출덕트가 설치된 상태를 나타낸 사시도 Figure 3 is a perspective view showing a state in which the cold air discharge duct is installed in accordance with the present invention

도 4는 도 3의 B-B선 단면도 4 is a cross-sectional view taken along the line B-B of FIG.

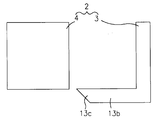

도 5a 및 도 5b는 도 4의 단열재와 덕트 사출물이 결합되기 전,후의 상태를 나타낸 단면도 5a and 5b is a cross-sectional view showing a state before and after the heat insulating material and the duct injection of FIG.

도 6은 본 발명의 다른 실시예를 나타낸 종단면도 Figure 6 is a longitudinal cross-sectional view showing another embodiment of the present invention

도 7a 및 도 7b는 도 6의 단열재와 덕트 사출물이 결합되기 전,후의 상태를 나타낸 단면도 7A and 7B are cross-sectional views showing states before and after the insulation material and the duct injection of FIG. 6 are combined.

* 도면의 주요 부분에 대한 부호의 설명 * Explanation of symbols on the main parts of the drawings

1; 냉장실 2; 냉기 토출덕트 One;

3; 덕트 사출물 3a,4a; 냉기 토출구 3;

3b,13b; 폐쇄 리브 3c,13c; 끝단부 3b, 13b; Closed

4; 단열재 4b; 단턱 4;

W; 냉기 유로 G; 사이뜸 W; Cold flow path G; Between

본 발명은 냉장고의 냉기 토출구 형성구조에 관한 것으로서, 더욱 상세하게는 냉장고의 냉장실 후벽에 설치된 냉기 토출덕트의 덕트 사출물과 스치로폴로 된 단열재 사이의 사이뜸으로 냉기가 유입되지 않도록 냉기 토출구를 형성시킬 수 있도록 한 것이다.The present invention relates to a structure for forming a cold air discharge port of a refrigerator, and more particularly, to form a cold air discharge port so that cold air does not flow into the duct between the duct injection of the cold air discharge duct installed in the rear wall of the refrigerator and the insulation made of styropole. It would be.

일반적으로, 종래의 냉장고는 도 1 및 도 2에 나타낸 바와 같이, 본체(5)내의 상부 및 하부에 각각 냉동 및 냉장 식품 등을 보관하기 위한 냉동실(6) 및 냉장실(1)이 구획되도록 형성되고, 상기 본체(5)의 상부 및 하부에는 냉동실(6) 및 냉장실(1)을 개방 및 폐쇄하기 위한 냉동실 및 냉장실 도어(7)(8)가 설치되며, 상기 냉장실(1)의 내부에는 보관 식품이나 용기를 얹어 놓기 위한 복수개의 선반(9)이 일정한 간격으로 설치되고, 상기 냉장실(1)의 하부에는 채소류나, 과일 등을 담아 보관하기 위한 야채 박스(10)가 설치된다.In general, the conventional refrigerator is formed so that the

한편, 상기 냉장실(1)의 후벽에는 냉장실(1)의 내부로 냉기를 토출시키기 위한 냉기 토출덕트(12)가 설치되는 데, 냉기 토출덕트(12)의 덕트 사출물(13)의 전면에는 복수개의 냉기 토출구(3a)가 형성되고, 상기 덕트 사출물(13) 내의 단열재(14)에는 상기 냉기 토출구(3a)와 대응되는 냉기 토출구(4a)가 형성되어 상기 냉동실(6)의 후벽에 설치된 증발기(15)에서 냉각된 냉기가 팬모터(16)의 구동에 따른 팬(17)의 회전에 의해 냉동실(6)을 거쳐 상기 냉기 토출덕트(12) 내부의 냉기 유 로(W)를 통해 유입되는 냉기를 상기 단열재(14)와 덕트 사출물(13)의 냉기 토출구(4a)(3a)를 거쳐 냉장실(1)로 냉기를 토출시키게 된다.On the other hand, a cold

그러나, 이와 같은 종래 냉기 토출덕트(12)의 냉기 토출구(3a)(4a)를 통해 나온 냉기의 일부는 냉장실(1)로 유입되지 않고 도 2에 도시된 바와 같이, 단열재(14)와 덕트 사출물(13) 사이의 약 1.5∼2㎜ 정도의 사이뜸(G)으로 냉기가 유입되어 덕트 사출물(13)을 과냉시키므로써 고내 온도(3℃)와 냉기 토출구(3a) 주위의 덕트 사출물(13) 표면 온도(-7℃)차가 크게 된다.However, a portion of the cold air discharged through the cold

따라서, 이렇게 큰 온도 차이는 고내에 고온 다습한 부하가 투입시 고내 수증기를 냉기 토출구 주변에서 과포화 상태로 만들고 덕트 사출물(13)의 표면에서 응축되어 이슬을 발생시키게 되는 데, 이 이슬은 계속 냉각될 경우 결빙을 이루게 되며, 결빙은 성장하여 때때로 냉기 토출구(3a)를 폐쇄시키는 성능상의 문제점을 일으키기도 한다. Thus, such a large temperature difference causes the high-temperature and high-pressure loads to be supersaturated around the cold air outlet when condensed and condensation on the surface of the

또한, 종래의 냉기 토출덕트(12)는 정면에서 관찰했을 때 덕트 사출물(13)의 냉기 토출구(3a) 사이로 단열재(14)가 약 1.5∼2.5㎜ 정도가 바로 노출되므로 미관상 고내 이미지를 저하시키게 되는 등의 문제점이 있었다. In addition, the conventional cold

따라서, 본 발명은 상기한 제반 문제점을 해결하기 위한 것으로서, 냉장고의 냉장실 후벽에 설치된 냉기 토출덕트의 덕트 사출물과 스치로폴로 된 단열재 사이의 사이뜸으로 냉기가 유입되지 않도록 냉기 토출구를 형성시킬 수 있도록 하여 덕트 사출물이 과냉각됨에 따른 냉기 토출구 주위에 결빙 및 결로가 발생되는 현상을 방 지할 수 있는 냉장고의 냉기 토출구 형성구조를 제공하는 데 그 목적이 있다.Accordingly, the present invention is to solve the above-mentioned problems, by forming a cold air discharge port so that the cold air does not flow into the moxibustion between the duct injection of the cold air discharge duct installed in the rear wall of the refrigerator compartment and the insulating material of the styropole. It is an object of the present invention to provide a cold air outlet forming structure of a refrigerator which can prevent freezing and condensation from occurring around the cold air outlet as the duct injection is supercooled.

본 발명의 다른 목적은 덕트 사출물과 단열재의 조립후 냉기 토출구 주변으로 단열재가 노출되지 않도록 하므로써 미관을 미려하게 하여 냉장고의 이미지를 고급화하는 데 있다.Another object of the present invention is to enhance the image of the refrigerator by making the beauty of beauty by preventing the insulation from being exposed around the cold air outlet after assembling the duct injection product and the insulation.

상기한 목적을 달성하기 위해 본 발명은 냉기 유로가 내부에 형성되고 전면에 복수개의 냉기 토출구가 형성되는 냉기 토출덕트 내부의 단열재와; 상기 냉기 토출구와 대응되는 냉기 토출구가 형성되어 단열재를 내장하는 냉기 토출덕트 외부의 덕트 사출물과; 상기 덕트 사출물의 냉기 토출구 측에서 상기 단열재의 냉기 토출구 측으로 연장하여 상기 단열재의 냉기 토출구 주위에 형성된 단턱에 억지 결합 결합됨으로써 상기 덕트 사출물과 상기 단열재의 사이뜸으로 유입되는 냉기를 차단시키는 폐쇄 리브를 포함하여 이루어진다.In order to achieve the above object, the present invention includes a heat insulating material inside the cold air discharge duct is formed therein and a plurality of cold air discharge holes formed on the front; A duct injection product external to the cold air discharge duct in which a cold air discharge port corresponding to the cold air discharge port is formed to have a heat insulating material; A closed rib extending from the cold air outlet side of the duct injection to the cold air outlet side of the heat insulator to be coupled to a step formed around the cold air outlet of the heat insulator to block cold air flowing into the duct between the duct injection and the heat insulator; It is done by

이하, 상기한 목적을 달성하기 위한 본 발명의 바람직한 실시예를 첨부된 도면을 참조하여 상세히 설명하면 다음과 같다.Hereinafter, with reference to the accompanying drawings, preferred embodiments of the present invention for achieving the above object will be described in detail.

도 3은 본 발명에 따른 냉기 토출덕트가 설치된 상태를 나타낸 사시도이고, 도 4는 도 3의 B-B선 단면도이며, 도 5a 및 도 5b는 도 4의 단열재와 덕트 사출물이 결합되기 전,후의 상태를 나타낸 단면도로서, 종래의 기술과 동일한 부분에 대해서는 동일 부호를 부여하여 본 발명을 설명한다.3 is a perspective view showing a state in which the cold air discharge duct is installed according to the present invention, Figure 4 is a cross-sectional view taken along the line BB of Figure 3, Figures 5a and 5b is a state before and after the insulation and the duct injection of Figure 4 combined As the cross-sectional view shown, the same parts as in the prior art will be denoted by the same reference numerals to describe the present invention.

본 발명은 냉장고의 냉장실(1) 후벽에 설치된 냉기 토출덕트(2)의 덕트 사출물(3)의 전면에 복수개의 냉기 토출구(3a)가 형성되고, 상기 덕트 사출물(3) 내의 스치로폴로 된 단열재(4)의 내부에는 냉기 유로(W)가 형성되며, 상기 단열재(4)에는 냉기 토출구(3a)와 대응되는 냉기 토출구(4a)가 형성되고, 상기 단열재(4)의 냉기 토출구(4a) 주위에는 단턱(4b)이 형성되며, 상기 덕트 사출물(3)의 냉기 토출구(3a) 주위에는 냉기 토출구(3a)를 향하도록 직각으로 절곡되어 상기 단턱(4b)에 억지 끼움으로 결합되어 덕트 사출물(3)과 단열재(4) 사이의 사이뜸(G)으로 유입되는 냉기를 차단시키기 위한 폐쇄 리브(3b)가 형성되고, 폐쇄 리브(3b)의 끝단부(3c)는 상기 단턱(4b)의 표면에 폐쇄 리브(3b)가 쉽게 삽입될 수 있도록 쐐기 형상으로 형성되어 구성된다.According to the present invention, a plurality of cold

상기와 같이 구성된 본 발명은 도 3 내지 도 5b에 도시한 바와 같이, 냉장고의 냉장실(1) 후벽에 설치되는 냉기 토출덕트(2)를 결합시키고자 할 때에는 먼저, 덕트 사출물(3)의 내부에 단열재(4)를 삽입시킨 상태에서 상기 덕트 사출물(3)과 단열재(4)의 냉기 토출구(3a)(4a)를 일치시킨 후, 도 5a와 같은 상태에서 상기 덕트 사출물(3)의 냉기 토출구(3a) 주위에 냉기 토출구(3a)를 향하도록 직각으로 절곡 형성된 폐쇄 리브(3b)를 상기 단열재(4)의 냉기 토출구(4a) 주위에 형성된 단턱(4b) 쪽으로 밀어줌에 따라 억지 끼움 방식으로 도 5b와 같이 용이하게 결합시킬 수 있게 된다.3 to 5b, the present invention configured as described above, in order to combine the cold air discharge duct (2) installed on the rear wall of the refrigerating chamber (1) of the refrigerator, first, inside the duct injection (3) After matching the cold

따라서, 상기 냉기 토출덕트(2)가 설치된 상태에서 도 4에 도시된 바와 같이, 냉기 토출덕트(2)를 구성하는 단열재(4) 내부의 냉기 유로(W)를 통해 유입되는 냉기를 상기 덕트 사출물(3)과 단열재(4)의 냉기 토출구(3a)(4a)를 거쳐 냉장실(1)로 냉기를 토출시킬 때, 상기 덕트 사출물(3)에 형성된 폐쇄 리브(3b)로 인해 덕트 사출물(3)과 단열재(4) 사이의 사이뜸(G)으로 냉기가 유입되는 현상을 차단시킬 수 있게 된다.Therefore, as shown in FIG. 4 in the state where the cold

또한, 상기 폐쇄 리브(3b)의 길이는 5㎜로 형성되므로 사출시 금형에서 용이하게 분리시킬 수 있고, 폐쇄 리브(3b)의 후방에 지지대를 설치하지 않아도 무방한 범위내의 최대 길이이며, 폐쇄 리브(3b)의 두께는 덕트 사출물(3)의 두께(2㎜)와 동일하게 형성시킨다.In addition, since the length of the

또한, 상기 폐쇄 리브(3b)의 끝단부(3c)는 쐐기 형상으로 형성되므로 상기 단턱(4b)의 표면에 폐쇄 리브(3b)를 쉽게 삽입시킬 수 있고, 덕트 사출물(3)과 단열재(4) 사이의 사이뜸(G)은 1.5 ± 0.5㎜의 여유를 갖도록 형성시키므로 상기 단열재(4)의 단턱(4b) 깊이에 공차가 발생하더라도 폐쇄 리브(3b)의 끝단부(3c)가 단턱(4b)을 찌르고 삽입될 수 있게 된다.In addition, since the

또한, 상기 단열재(4)에 형성된 단턱(4b)의 깊이는 고내 방향으로 3.5㎜, 두께는 폐쇄 리브(3b)의 두께와 동일하게 형성시키는 데, 상기 단턱(4b)을 형성시킨 목적은 냉기 토출덕트(2)를 통해 나온 냉기에 폐쇄 리브(3b) 두께 만큼의 덕트 사출물(3)이 바로 노출되지 않도록 하기 위함이다.In addition, the depth of the

또한, 상기 덕트 사출물(3)과 단열재(4)가 억지 끼움 방식으로 결합되면, 단열재(4)의 단턱(4b) 옆면과 폐쇄 리브(3b)의 바깥쪽면이 완전히 밀착되며, 억지 끼움을 위해 상기 단열재(4)에 폐쇄 리브(3b)를 약 0.5㎜ 정도 오버랩시키게 된다.In addition, when the

한편, 본 발명의 다른 실시예로서 도 6에 도시한 바와 같이, 냉장고의 냉장실(1) 후벽에 설치된 냉기 토출덕트(2)의 덕트 사출물(3)의 전면에 복수개의 냉 기 토출구(3a)가 형성되고, 상기 덕트 사출물(3) 내의 스치로폴로 된 단열재(4)에는 냉기 유로(W)가 형성되며, 상기 단열재(4)에는 냉기 토출구(3a)와 대응되는 냉기 토출구(4a)가 형성되고, 상기 덕트 사출물(3)의 냉기 토출구(3a) 주위에는 냉기 토출구(3a)를 향하도록 직각으로 절곡되어 상기 단열재(4)의 냉기 토출구(4a) 내측면에 억지 끼움으로 결합되어 덕트 사출물(3)과 단열재(4) 사이의 사이뜸(G)으로 유입되는 냉기를 차단시키기 위한 폐쇄 리브(13b)가 형성되며, 폐쇄 리브(13b)의 끝단부(13c)는 45°경사지게 형성되어 구성된다.On the other hand, as shown in Figure 6 as another embodiment of the present invention, a plurality of cool air discharge port (3a) is provided on the front surface of the duct injection (3) of the cold

상기와 같이 구성된 본 발명의 다른 실시예에 따른 냉장고의 냉장실(1) 후벽에 설치되는 냉기 토출덕트(2)를 결합시키고자 할 때에는 먼저, 덕트 사출물(3)의 내부에 단열재(4)를 삽입시킨 상태에서 상기 덕트 사출물(3)과 단열재(4)의 냉기 토출구(3a)(4a)를 일치시킨 후, 도 7a와 같은 상태에서 상기 덕트 사출물(3)의 냉기 토출구(3a) 주위에 냉기 토출구(3a)를 향하도록 직각으로 절곡 형성된 폐쇄 리브(13b)를 상기 단열재(4)의 냉기 토출구(4a) 쪽으로 밀어줌에 따라 냉기 토출구(4a)의 내측면과 폐쇄 리브(13b)의 바깥쪽면이 완전 밀착되므로 억지 끼움 방식으로 도 7b와 같이 손쉽게 결합시킬 수 있게 된다.In order to combine the cold air discharge duct (2) installed in the rear wall of the refrigerating chamber (1) of the refrigerator according to another embodiment of the present invention configured as described above, first, insert the heat insulating material (4) in the interior of the duct injection (3) After making the duct-

또한, 상기 폐쇄 리브(13b)의 길이는 7㎜로서 실시예의 폐쇄 리브(3b) 보다 길게 형성하여 덕트 사출물(3)과 단열재(4) 사이에 생길 수 있는 미세틈의 유로 저항을 크게 하므로써 냉기 유입량을 줄일 수 있고, 상기 폐쇄 리브(13b)의 두께는 덕트 사출물의 두께와 동일하게 형성하며, 상기 폐쇄 리브(13b)의 끝단부(13c)는 45°경사지게 형성되므로 덕트 사출물(3)과 단열재(4) 사이 사이뜸(G) 으로의 냉기 유입 이 적고 고내로 냉기 토출이 용이하게 되면서 냉기 토출덕트(2)의 유로(W)를 통해 나오는 냉기가 덕트 사출물(3)에 노출되지 않고 비스듬히 비껴가도록 할 수 있게 된다.In addition, the length of the

이상에서 상술한 바와 같이, 본 발명은 냉장고의 냉장실 후벽에 설치된 냉기 토출덕트의 덕트 사출물과 스치로폴로 된 단열재 사이의 사이뜸으로 냉기가 유입되지 않도록 냉기 토출구를 형성시킬 수 있으므로써 덕트 사출물이 과냉각됨에 따른 냉기 토출구 주위에 결빙 및 결로가 발생되는 현상을 방지할 수 있고, 덕트 사출물과 단열재의 조립시 냉기 토출구 주변으로 단열재가 노출되지 않도록 하므로써 미관을 미려하게 하여 냉장고의 이미지를 고급화시킬 수 있는 등의 많은 장점이 구비된 매우 유용한 발명이다.As described above, the present invention can form a cold air discharge port so that cold air is not introduced into the duct between the duct injection of the cold air discharge duct installed on the rear wall of the refrigerator compartment and the insulating material made of Schiropol, so that the duct injection is supercooled. It is possible to prevent the occurrence of freezing and condensation around the cold air outlet, and to enhance the image of the refrigerator by aesthetically beautiful by not exposing the heat insulating material around the cold air outlet when assembling the duct injection and the heat insulating material. It is a very useful invention with many advantages.

이상에서는 본 발명의 바람직한 실시예를 도시하고 또한 설명하였으나, 본 발명은 상기한 실시예에 의해 한정되지 않고, 이하 청구범위에서 청구하는 본 발명의 요지를 벗어남이 없이 당해 발명이 속하는 기술 분야에서 통상의 지식을 가진 자라면 누구든지 다양한 변경 실시가 가능할 것이다.

Although the preferred embodiments of the present invention have been illustrated and described above, the present invention is not limited to the above-described embodiments, and is generally defined in the technical field to which the present invention pertains without departing from the gist of the present invention as claimed in the following claims. Anyone with knowledge of the world will be able to make various changes.

Claims (4)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1019990020216A KR100557490B1 (en) | 1999-06-02 | 1999-06-02 | Cool air spouting hole formation structure for refrigerator |

| CNB001072366A CN1147692C (en) | 1999-06-02 | 2000-04-27 | Cooling air exhausting pipeline for refrigerator |

| IT2000MI000934A IT1317424B1 (en) | 1999-06-02 | 2000-04-28 | COLD AIR DISCHARGE DUCT FOR REFRIGERATOR |

| DE10023371A DE10023371C2 (en) | 1999-06-02 | 2000-05-12 | Cold air duct for a refrigerator |

| MXPA00004666A MXPA00004666A (en) | 1999-06-02 | 2000-05-12 | Cooling air exhausting pipeline for refrigerator. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1019990020216A KR100557490B1 (en) | 1999-06-02 | 1999-06-02 | Cool air spouting hole formation structure for refrigerator |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20010001166A KR20010001166A (en) | 2001-01-05 |

| KR100557490B1 true KR100557490B1 (en) | 2006-03-07 |

Family

ID=19589428

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019990020216A KR100557490B1 (en) | 1999-06-02 | 1999-06-02 | Cool air spouting hole formation structure for refrigerator |

Country Status (5)

| Country | Link |

|---|---|

| KR (1) | KR100557490B1 (en) |

| CN (1) | CN1147692C (en) |

| DE (1) | DE10023371C2 (en) |

| IT (1) | IT1317424B1 (en) |

| MX (1) | MXPA00004666A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180024279A (en) | 2016-08-29 | 2018-03-08 | 엘지전자 주식회사 | Cooling air discharge duct for refrigerator and refrigrerator having the same |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005021613A1 (en) * | 2005-05-10 | 2006-11-23 | BSH Bosch und Siemens Hausgeräte GmbH | The refrigerator |

| CN111397295A (en) * | 2020-03-30 | 2020-07-10 | 珠海格力电器股份有限公司 | Food non-freezing fresh-keeping control method, refrigeration equipment and storage medium |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0495289U (en) * | 1990-12-28 | 1992-08-18 | ||

| KR930000551Y1 (en) * | 1988-10-08 | 1993-02-10 | 대우전자 주식회사 | Duct for refrigerator |

| KR100227258B1 (en) * | 1997-10-09 | 1999-11-01 | 전주범 | A rubber and fan motor assembly for a refrigerator |

| KR19990039325U (en) * | 1998-04-09 | 1999-11-05 | 윤종용 | Cold air discharge structure of the refrigerator |

| KR200292004Y1 (en) * | 1998-09-03 | 2003-02-19 | 삼성전자 주식회사 | Refrigerator |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1110676C (en) * | 1995-10-18 | 2003-06-04 | Lg电子株式会社 | Device and method for controlling temperature of refrigerating chamber in refrigerator |

-

1999

- 1999-06-02 KR KR1019990020216A patent/KR100557490B1/en not_active IP Right Cessation

-

2000

- 2000-04-27 CN CNB001072366A patent/CN1147692C/en not_active Expired - Fee Related

- 2000-04-28 IT IT2000MI000934A patent/IT1317424B1/en active

- 2000-05-12 MX MXPA00004666A patent/MXPA00004666A/en active IP Right Grant

- 2000-05-12 DE DE10023371A patent/DE10023371C2/en not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR930000551Y1 (en) * | 1988-10-08 | 1993-02-10 | 대우전자 주식회사 | Duct for refrigerator |

| JPH0495289U (en) * | 1990-12-28 | 1992-08-18 | ||

| KR100227258B1 (en) * | 1997-10-09 | 1999-11-01 | 전주범 | A rubber and fan motor assembly for a refrigerator |

| KR19990039325U (en) * | 1998-04-09 | 1999-11-05 | 윤종용 | Cold air discharge structure of the refrigerator |

| KR200292004Y1 (en) * | 1998-09-03 | 2003-02-19 | 삼성전자 주식회사 | Refrigerator |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180024279A (en) | 2016-08-29 | 2018-03-08 | 엘지전자 주식회사 | Cooling air discharge duct for refrigerator and refrigrerator having the same |

| KR101864621B1 (en) * | 2016-08-29 | 2018-06-07 | 엘지전자 주식회사 | Refrigerator |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10023371C2 (en) | 2002-10-10 |

| ITMI20000934A0 (en) | 2000-04-28 |

| KR20010001166A (en) | 2001-01-05 |

| IT1317424B1 (en) | 2003-07-09 |

| MXPA00004666A (en) | 2002-03-08 |

| DE10023371A1 (en) | 2001-02-08 |

| ITMI20000934A1 (en) | 2001-10-29 |

| CN1147692C (en) | 2004-04-28 |

| CN1276512A (en) | 2000-12-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100187197B1 (en) | Method and apparatus for controlling the cooling air outlet | |

| KR970011047B1 (en) | Cooling equipment of refrigerators | |

| JP2002295948A (en) | Electric refrigerator | |

| KR100557490B1 (en) | Cool air spouting hole formation structure for refrigerator | |

| JP2003307382A (en) | Refrigerator | |

| JP3322495B2 (en) | Freezer refrigerator | |

| KR100557491B1 (en) | Cool air spouting way formation structure for refrigerator | |

| KR0138574Y1 (en) | Temperature sensor fastener in a refrigerator | |

| KR200164358Y1 (en) | Vegitable tray for refrigerator | |

| KR200308187Y1 (en) | Refrigerator | |

| KR19990027368U (en) | Ice trays in refrigerator | |

| KR200217744Y1 (en) | Damper Cover of Refrigerator | |

| KR100656395B1 (en) | A hot pipe mounting structure for refrigerator | |

| KR100389412B1 (en) | The structure of refrigerator | |

| KR200155507Y1 (en) | Cooling air supply device of a refrigerator | |

| KR0138575Y1 (en) | Structure of freezing room louver in a refrigerator | |

| KR100763152B1 (en) | Apparatus for supply a cool air of side-by-side type refrigerator | |

| KR200141263Y1 (en) | A refrigerator | |

| KR100474327B1 (en) | Apparatus for preventing evaporator from freezing in indirect cooling type refrigerator | |

| KR200292004Y1 (en) | Refrigerator | |

| KR200181373Y1 (en) | Thermal insulation device of a refrigerator | |

| KR910008662Y1 (en) | Duct for refrigerator | |

| JPH08233430A (en) | Freezer/refrigerator | |

| KR100547428B1 (en) | Refrigerator Door Duct | |

| KR200155506Y1 (en) | Cooling air supply device of a refirgerator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| E902 | Notification of reason for refusal | ||

| E701 | Decision to grant or registration of patent right | ||

| GRNT | Written decision to grant | ||

| FPAY | Annual fee payment |

Payment date: 20130128 Year of fee payment: 8 |

|

| FPAY | Annual fee payment |

Payment date: 20140124 Year of fee payment: 9 |

|

| FPAY | Annual fee payment |

Payment date: 20150213 Year of fee payment: 10 |

|

| FPAY | Annual fee payment |

Payment date: 20160122 Year of fee payment: 11 |

|

| FPAY | Annual fee payment |

Payment date: 20170113 Year of fee payment: 12 |

|

| FPAY | Annual fee payment |

Payment date: 20180112 Year of fee payment: 13 |

|

| FPAY | Annual fee payment |

Payment date: 20190114 Year of fee payment: 14 |

|

| EXPY | Expiration of term |