JP7555071B2 - Equipment shared cable rack - Google Patents

Equipment shared cable rack Download PDFInfo

- Publication number

- JP7555071B2 JP7555071B2 JP2020201952A JP2020201952A JP7555071B2 JP 7555071 B2 JP7555071 B2 JP 7555071B2 JP 2020201952 A JP2020201952 A JP 2020201952A JP 2020201952 A JP2020201952 A JP 2020201952A JP 7555071 B2 JP7555071 B2 JP 7555071B2

- Authority

- JP

- Japan

- Prior art keywords

- connector

- mounting

- parent

- lighting device

- plate portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003780 insertion Methods 0.000 claims description 10

- 230000037431 insertion Effects 0.000 claims description 10

- 238000009434 installation Methods 0.000 description 23

- 238000000034 method Methods 0.000 description 18

- 238000010586 diagram Methods 0.000 description 16

- 230000002265 prevention Effects 0.000 description 10

- 239000002184 metal Substances 0.000 description 5

- 239000011347 resin Substances 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000000463 material Substances 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Landscapes

- Details Of Indoor Wiring (AREA)

- Laying Of Electric Cables Or Lines Outside (AREA)

Description

本発明は、トンネル内に敷設され、各種ケーブルを保持する器具共架型ケーブルラックに関する。 The present invention relates to a cable rack that is installed inside a tunnel and holds various cables.

特許文献1には、親桁を左右両側に対向配置し、親桁の長手方向に間隔をあけた複数個所において左右の親桁間を子桁で連結した鋼製はしご形のケーブルラックが開示してある。

また、特許文献2には、ケーブルラックをトンネル内に敷設する態様が開示してある。当該ケーブルラックは、電源ケーブルや調光ケーブル等の各種ケーブルを保持するラック本体を備えており、ラック本体は、トンネル内の車両進行方向に沿って延びる一対の親桁と、親桁の間に略等間隔に複数架設された子桁とを備えている。ラック本体を支持する支持部材は、トンネルの側壁に設けられたアンカーボルトが挿通される取付孔を有する取付部と、取付部から屈曲して延びる載置部(設置部)とを備えている。 Patent document 2 also discloses a method for laying a cable rack inside a tunnel. The cable rack includes a rack body that holds various cables such as power cables and light control cables, and the rack body includes a pair of parent girders that extend along the vehicle travel direction inside the tunnel, and multiple child girders that are installed at approximately equal intervals between the parent girders. The support member that supports the rack body includes a mounting section that has mounting holes through which anchor bolts provided on the side wall of the tunnel are inserted, and a placement section (installation section) that extends and bends from the mounting section.

ラック本体は、車両進行方向に沿って延びるように当該設置部上に複数設けられている。設置部には、先端が逆U字状に湾曲するボルトが備えてあり、ボルトの先端部を親桁に係合させて締結することにより、ラック本体を支持部材に固定している。 Multiple rack bodies are provided on the installation section so as to extend along the vehicle travel direction. The installation section is equipped with a bolt whose tip is curved into an inverted U-shape, and the rack body is fixed to the support member by engaging and fastening the tip of the bolt to the parent girder.

親桁は、車両進行方向に沿って延びるように設置部上に複数設けてあり、それぞれの端部どうしをボルトや連結板を介して連結していた。例えば親桁どうしの連結をボルトによって行う場合は、通常、一対の親桁における片側の親桁につき2本のボルトで連結していた。即ち、一対の親桁どうしを連結する際には4本のボルトを使用することとなる。また、この場合、ボルトに応じた数のナットやワッシャを使用することとなる。トンネル内で親桁どうしの連結をボルトで行う施工時には、1本ずつボルトを締結する作業を行うため、煩雑であった。 Multiple parent girders were installed on the installation section so as to extend in the direction of vehicle travel, and their ends were connected together via bolts or connecting plates. For example, when parent girders were connected together with bolts, typically two bolts were used for each parent girder in a pair of parent girders. In other words, four bolts are used to connect a pair of parent girders. In this case, the same number of nuts and washers are used as the bolts. When connecting parent girders together inside a tunnel with bolts, the bolts must be tightened one by one, which was cumbersome.

従って、本発明の目的は、簡便な構造で施工性が向上するケーブルラックを提供することにある。 Therefore, the object of the present invention is to provide a cable rack with a simple structure and improved workability.

上記目的を達成するための本発明に係るケーブルラックの第一特徴構成は、トンネル内に敷設され、長尺状の一本の親桁と、当該親桁の長手方向に間隔をあけた複数個所に配設してケーブルを保持可能な子桁と、を備え、前記親桁は、前記親桁の長手方向に直交する断面視において、前記子桁を載置する上面載置部と、当該上面載置部の両端から下垂する一対の側方部と、当該側方部の下端部から内側に屈曲し、間隔を開けて互いに対向するように設けられた一対の下フランジ部と、を備えるように構成した点にある。 The first characteristic configuration of the cable rack of the present invention for achieving the above-mentioned object is that it comprises a single long parent girder laid inside a tunnel, and child girders arranged at multiple locations spaced apart along the longitudinal direction of the parent girder and capable of holding cables, and the parent girder is configured to comprise, in a cross-sectional view perpendicular to the longitudinal direction of the parent girder, an upper surface mounting portion on which the child girders are placed, a pair of side portions hanging down from both ends of the upper surface mounting portion, and a pair of lower flange portions bent inward from the lower ends of the side portions and arranged opposite each other with a gap between them .

本構成によれば、親桁が一本だけで構成してあるため、簡便な構造のケーブルラックとすることができる。また、親桁が一本だけで構成してあるため、親桁どうしを連結する際には、一本の親桁だけを連結すればよいため、施工性が向上する。

また、本構成によれば、一対の下フランジ部をレール状に構成することができるため、例えば後述の固定具等の部材を一対の下フランジ部に沿ってスライド移動させることができる。

According to this configuration, since the cable rack is made up of only one parent girder, it is possible to provide a cable rack with a simple structure. Also, since the cable rack is made up of only one parent girder, when connecting parent girders to each other, it is only necessary to connect one parent girder, which improves workability.

Furthermore, according to this configuration, the pair of lower flange portions can be configured in a rail shape, so that members such as a fixing tool described below can be slid along the pair of lower flange portions.

本発明に係るケーブルラックの第二特徴構成は、前記ケーブルラックを設置する設置部と前記ケーブルラックとを固定する固定具を備え、前記固定具は、一対の前記下フランジ部の間をスライド移動可能な固定具板状部材と、当該固定具板状部材を貫通する固定具ボルト部材と、当該固定具ボルト部材に螺合する固定具ナット部材と、を備えた点にある。 A second characteristic configuration of the cable rack according to the present invention is that it comprises a fixing device that fixes the cable rack to an installation portion for installing the cable rack, and the fixing device comprises a fixing device plate member that can slide between a pair of lower flange portions, a fixing device bolt member that passes through the fixing device plate member, and a fixing device nut member that screws into the fixing device bolt member.

本構成によれば、1つの固定具を使用すればケーブルラックを設置部に固定することができるため、施工性が向上する。 With this configuration, the cable rack can be fixed to the installation section using a single fastener, improving workability.

本発明に係るケーブルラックの第三特徴構成は、隣接する親桁どうしを接続する接続具を備え、前記接続具は、一方の親桁の端部および他方の親桁の端部を包持する接続具本体と、一方の親桁の端部および接続具本体を貫通し、或いは他方の親桁の端部および接続具本体を貫通する少なくとも二本の接続具ボルト部材と、当該接続具ボルト部材に螺合する少なくとも二つの接続具ナット部材と、を備えた点にある。 A third characteristic configuration of the cable rack of the present invention is that it comprises a connector for connecting adjacent parent girders, the connector comprising a connector main body that embraces an end of one parent girder and an end of the other parent girder, at least two connector bolt members that penetrate the end of one parent girder and the connector main body or that penetrate the end of the other parent girder and the connector main body, and at least two connector nut members that screw into the connector bolt members.

本構成によれば、1つの接続具を使用すれば隣接する親桁どうしを接続することができるため、施工性が向上する。 With this configuration, adjacent parent girders can be connected using a single connector, improving workability.

本発明に係るケーブルラックの第四特徴構成は、隣接する親桁どうしを接続する接続具を備え、前記接続具は、前記下フランジ部を挟持する二枚の接続具板状部材と、前記二枚の接続具板状部材を貫通する接続具ボルト部材と、当該接続具ボルト部材に螺合する接続具ナット部材と、を備えた点にある。 A fourth characteristic configuration of the cable rack of the present invention is that it is equipped with a connector for connecting adjacent parent girders, and the connector comprises two connector plate members that clamp the lower flange portion, a connector bolt member that penetrates the two connector plate members, and a connector nut member that screws into the connector bolt member.

本構成によれば、1つの接続具を使用すれば隣接する親桁どうしを接続することができるため、施工性が向上する。 With this configuration, adjacent parent girders can be connected using a single connector, improving workability.

本発明に係るケーブルラックの第五特徴構成は、照明装置を取り付ける照明装置取付具を備え、前記照明装置取付具は、前記一対の下フランジ部の間から前記親桁の内部空間に侵入させることができ、かつ前記照明装置取付具を前記侵入のときとは異なる姿勢に変更することで前記一対の下フランジ部によって係止可能な係止板部と、前記照明装置を取り付ける取付部を有する取付板部と、前記係止板部および前記取付板部を角度をつけて接続する屈曲部と、を備えた点にある。 A fifth characteristic configuration of the cable rack of the present invention is that it comprises a lighting device mounting fixture for mounting a lighting device, the lighting device mounting fixture comprising a locking plate portion that can be inserted into the internal space of the parent girder from between the pair of lower flange portions and can be engaged by the pair of lower flange portions by changing the lighting device mounting fixture to a posture different from that at the time of the insertion, a mounting plate portion having a mounting portion for mounting the lighting device, and a bent portion that connects the locking plate portion and the mounting plate portion at an angle.

本構成によれば、照明装置取付具を親桁に取り付ける際に、照明装置取付具の姿勢を変更するだけで係止板部を一対の下フランジ部に係止させて取り付けることができるため、施工性が向上する。 With this configuration, when attaching the lighting device fixture to the parent beam, the locking plate portion can be engaged with the pair of lower flange portions by simply changing the position of the lighting device fixture, improving workability.

本発明に係るケーブルラックの第六特徴構成は、照明装置を取り付ける照明装置取付具を備え、前記照明装置取付具は、前記一対の下フランジ部の間から前記親桁の内部空間に侵入させることができ、かつ前記侵入後に所定の角度だけ回転させることで前記一対の下フランジ部によって係止可能な係止板部と、前記照明装置を取り付ける取付部を有する取付板部と、前記係止板部および前記取付板部を貫通して前記係止板部および前記取付板部を接続する接続ボルト部材と、前記接続ボルト部材に螺合する接続ナット部材と、を備えた点にある。

A sixth characteristic configuration of the cable rack of the present invention is that it comprises a lighting device mounting fixture for mounting a lighting device, the lighting device mounting fixture comprising a locking plate portion that can be inserted into the internal space of the parent girder from between the pair of lower flange portions and can be engaged by the pair of lower flange portions by rotating it by a predetermined angle after the insertion, a mounting plate portion having a mounting portion for mounting the lighting device, a connecting bolt member that passes through the locking plate portion and the mounting plate portion to connect the locking plate portion and the mounting plate portion, and a connecting nut member that screws into the connecting bolt member.

本構成によれば、照明装置取付具を親桁に取り付ける際に、係止板部を所定の角度だけ回転させるだけで係止板部を一対の下フランジ部に係止させて取り付けることができるため、施工性が向上する。 With this configuration, when attaching the lighting device fixture to the parent beam, the locking plate can be attached to the pair of lower flanges by simply rotating the locking plate by a specified angle, improving workability.

以下、本発明の実施形態を図面に基づいて説明する。

本発明のケーブルラックは、トンネル内に敷設され、各種ケーブルを保持する。

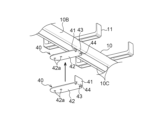

図1に示したように、本発明のケーブルラックXは、長尺状の一本の親桁10と、当該親桁10の長手方向に間隔をあけた複数個所に配設してケーブルを保持可能な子桁11と、を備える。

Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

The cable rack of the present invention is laid inside a tunnel to hold various cables.

As shown in Figure 1, the cable rack X of the present invention comprises a single

親桁10および子桁11において、材質は何れも金属製とすればよいがこれに限定されるものではなく、樹脂等を使用してもよい。親桁10は、例えば角柱状の態様とし、親桁10の上面に短寸の子桁11を略等間隔で配設した場合について説明するが、このような態様に限定されるものではない。子桁11はケーブルを保持可能な態様であればその形状は特に限定されるものではない。本実施形態では、子桁11の両端にケーブルの落下を防止するケーブル止め部11aを設けて断面がコ字状を呈する態様とした場合について説明する。本実施形態では、当該子桁11は、親桁10にボルト61で固定する場合について説明するが、この態様に限定されるものではない。当該ボルトは例えば六角ボルトや、皿ボルト等を使用するとよい。

The

本構成によれば、親桁10が一本だけで構成してあるため、簡便な構造のケーブルラックXとすることができる。また、親桁10が一本だけで構成してあるため、親桁10どうしを連結する際には、一本の親桁10だけを連結すればよいため、施工性が向上する。

According to this configuration, the cable rack X can be made of a simple structure because it is made up of only one

親桁10は、親桁10の長手方向に直交する断面視において、子桁11を載置する上面載置部10Aと、当該上面載置部10Aの両端から下垂する一対の側方部10Bと、当該側方部10Bの下端部から内側に屈曲し、間隔を開けて互いに対向するように設けられた一対の下フランジ部10Cと、を備えるように構成してある。

In a cross-sectional view perpendicular to the longitudinal direction of the

親桁10は、トンネル内の車両進行方向に沿って延びるように、ケーブルラックXを設置する設置部1上に複数設けてある。当該設置部1は、トンネルの側壁にて車両進行方向に沿って略等間隔に複数設けられた支持部材2に亘って、ケーブルラックXを略水平な状態で設置できるようにしてある。本発明のケーブルラックXは、設置部1とケーブルラックXとを固定する固定具20を備える(図2~4)。

固定具20は、一対の下フランジ部10Cの間をスライド移動可能な固定具板状部材21と、当該固定具板状部材21を貫通する固定具ボルト部材22と、当該固定具ボルト部材22に螺合する固定具ナット部材23と、を備える。

The

固定具ボルト部材22は、固定具板状部材21に形成したボルト穴21aを貫通している。固定具板状部材21において、材質は金属製とすればよいがこれに限定されるものではなく、樹脂等を使用してもよい。本実施形態では、固定具板状部材21において、設置部1の位置ズレを防止する設置部位置ズレ防止部21bと、親桁10の位置ズレを防止する親桁位置ズレ防止部21cと、を備えた場合について説明する。設置部位置ズレ防止部21bは固定具板状部材21に対して下側に折り曲げた状態の一対のフランジ部とし、親桁位置ズレ防止部21cは固定具板状部材21に対して上側に折り曲げた状態の一対のフランジ部とするのがよいが、このような態様に限定されるものではない。

The fixing

固定具20によってケーブルラックXと設置部1とを固定する手順は以下の通りである。まず、固定具20を、親桁10の端部から一対の下フランジ部10Cの間をスライドさせるようにして親桁10の内部空間に侵入させる(図2~3)。このとき、固定具板状部材21の下面の一部が下フランジ部10Cの上面をスライドすることとなる。設置部1に形成してあるL字状の溝1aに固定具ボルト部材22を係入し、設置部位置ズレ防止部21bである一対のフランジ部によって設置部1を挟持する(図4(a))。このとき、親桁位置ズレ防止部21cである一対のフランジ部は、親桁10の側方部10Bの内側に近接或いは当接した状態となっている(図4(b))。この状態で固定具ボルト部材22に対して固定具ナット部材23を螺入させると、固定具板状部材21の下面の一部と下フランジ部10Cの上面とが密接し、かつ下フランジ部10Cの下面と設置部1の上面とが密接し、さらに固定具ナット部材23によって設置部1の下面を締め上げることとなる(図4(b))。このようにボルトを締結することで、1つの固定具20によって設置部1とケーブルラックXとを固定することができる。

The procedure for fixing the cable rack X and the

固定具ボルト部材22の先端は固定具ナット部材23が螺合した状態で潰した状態としてもよい。固定具ボルト部材22の先端を潰すことで当該先端の直径を大きくする等の変形を施すことができ、固定具ナット部材23がトンネル内の振動等で緩んだとしてもこの変形部分が固定具ナット部材23の抜け止めとなり、固定具ナット部材23が固定具ボルト部材22から抜け落ちるのを未然に防止することができる。

The tip of the fixing

本発明のケーブルラックXは、隣接する親桁10どうしを接続する接続具30を備える(図5~7)。当該接続具30は、一方の親桁10の端部および他方の親桁10’の端部を包持する接続具本体30Aと、一方の親桁10の端部および接続具本体30Aを貫通し、或いは他方の親桁10’の端部および接続具本体30Aを貫通する少なくとも二本の接続具ボルト部材33と、当該接続具ボルト部材33に螺合する少なくとも二つの接続具ナット部材34と、を備える。

The cable rack X of the present invention includes a

接続具ボルト部材33は、一方の親桁10の端部および接続具本体30Aを貫通する少なくとも一本の接続具ボルト部材33と、他方の親桁10’の端部および接続具本体30Aを貫通する少なくとも一本の接続具ボルト部材33とを設けるようにすればよい。そのため、接続具ボルト部材33の数は二本以上であればよい。接続具ナット部材34の数は接続具ボルト部材33の数に合わせればよい。

The

接続具本体30Aは、親桁10の上面載置部10Aと対面する接続具本体上面部30aと、親桁10の側方部10Bと対面する一対の接続具本体側面部30bと、親桁10の下フランジ部10Cと対面する一対の接続具本体下フランジ部30cと、を備えるように構成してある。このように接続具本体30Aは、親桁10を包むように親桁10を保持して隣接する親桁どうしを接続することができる態様となっている。

The

接続具本体30Aは金属製とすればよいがこれに限定されるものではなく、樹脂等を使用してもよい。接続具ボルト部材33は、親桁10および接続具本体30Aのそれぞれに形成したボルト穴10α,30αを貫通している。本実施形態では、2本の接続具ボルト部材33を使用する態様について説明するが、この態様に限定されるものではない。

The

接続具30によって隣接する親桁10どうしを接続する手順は以下の通りである。まず、接続具本体30Aの一方の端部に一方の親桁10の端部を侵入させ、接続具本体30Aの他方の端部に他方の親桁10’の端部を侵入させる(図5~6)。一方の親桁10の端部と他方の親桁10’の端部とを当接させ、接続具本体30Aが一方の親桁10の端部および他方の親桁10’の端部を包持した状態で、ボルト穴10α,30αに接続具ボルト部材33を貫通させる(図7)。当該接続具ボルト部材33に対して接続具ナット部材34を螺入させると、接続具本体30Aの下面と一方の親桁10の上面とが密接し、かつ接続具本体30Aの下面と他方の親桁10’の上面とが密接し、さらに接続具ナット部材34によって一方の親桁10の下面および他方の親桁10’の下面を締め上げる。このようにボルトを締結することで、1つの接続具30によって隣接する親桁10どうしを接続することができる。

The procedure for connecting

接続具ボルト部材33の先端は接続具ナット部材34が螺合した状態で潰した状態としてもよい。接続具ボルト部材33の先端を潰すことで当該先端の直径を大きくする等の変形を施すことができ、接続具ナット部材34がトンネル内の振動等で緩んだとしても、この変形部分が接続具ナット部材34の抜け止めとなり、接続具ナット部材34が接続具ボルト部材33から抜け落ちるのを未然に防止することができる。

The tip of the

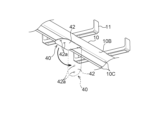

本発明のケーブルラックXは、照明装置50を取り付ける照明装置取付具40を備える(図8~11)。当該照明装置取付具40は、一対の下フランジ部10Cの間から親桁10の内部空間に侵入させることができ、かつ照明装置取付具40を前記侵入のときとは異なる姿勢に変更することで一対の下フランジ部10Cによって係止可能な係止板部41と、照明装置50を取り付ける取付部42aを有する取付板部42と、係止板部41および取付板部42を角度をつけて接続する屈曲部43と、を備える。

The cable rack X of the present invention includes a lighting

本実施形態では、一対の照明装置取付具40のそれぞれを照明装置50の両端のそれぞれに取り付ける態様について説明する。照明装置50の両端には、照明装置接続部材50Aを取り付けてある。当該照明装置接続部材50Aは、照明装置取付具40と面接触する接続板状部50aを備える。当該接続板状部50aは、照明装置50の端部と対面するように備えることができるが、このような態様に限定されるものではない。係止板部41は、一対の下フランジ部10Cの間から親桁10の内部空間に侵入させることができ、当該侵入のときとは異なる姿勢に変更することで一対の下フランジ部10Cによって係止可能な態様であれば、その形状は特に限定されるものではない。本実施形態の係止板部41は矩形を呈する板状の態様とし、係止板部41の長寸が一対の下フランジ部10Cの間の寸法より長く、係止板部41の短寸が一対の下フランジ部10Cの間の寸法より短くなるように係止板部41の寸法を設定する場合について説明する。係止板部41をこのように構成すれば、照明装置取付具40を前記侵入のときとは異なる姿勢に変更したときに、係止板部41の長寸側の両端を一対の下フランジ部10Cに係止させることができるため、係止板部41を一対の下フランジ部10Cによって係止することができる。

In this embodiment, a mode in which a pair of lighting

取付板部42は、照明装置50を取り付ける取付部42aを有する態様であれば、その形状は特に限定されるものではない。本実施形態の取付板部42は、取付部42aを2つの取り付け穴とした板状の態様とした場合について説明する。

The shape of the mounting

係止板部41および取付板部42は屈曲部43を介して接続してあるが、係止板部41および取付板部42の間には切欠部44を形成して屈曲部43と接続してもよい。係止板部41、取付板部42および屈曲部43において、材質は何れも金属製とすればよいがこれに限定されるものではなく、樹脂等を使用してもよい。係止板部41および取付板部42を角度をつけて接続する屈曲部43について、当該角度αは90°以下、例えば80~85°程度とするのがよい(図11(b))。当該角度αをこのように設定すると、取付板部42に照明装置50を取り付けたときに、係止板部41および取付板部42の角度が広がるように(例えば90°となるように)調整すれば、屈曲部43が変形した(広げられた)分だけ係止板部41が下フランジ部10Cを押圧する力が大きくなる。これにより、照明装置取付具40を下フランジ部10Cに係止する力が大きくなって照明装置取付具40を下フランジ部10Cに確実に固定することができる。

The locking

照明装置取付具40によって照明装置50を取り付ける手順は以下の通りである。まず、一対の照明装置取付具40を親桁10に取り付ける。照明装置取付具40における係止板部41を垂直にした状態(取付板部42を水平にした状態)で、係止板部41を一対の下フランジ部10Cの間から親桁10の内部空間に侵入させる(図9)。係止板部41を侵入させた状態で水平方向に約90°回転させ、さらに、取付板部42を垂直に姿勢変更することで、係止板部41の長寸側の両端を一対の下フランジ部10Cに係止させる(図10)。このようにして一対の照明装置取付具40を親桁10に取り付けた状態で、照明装置50をボルト51によって照明装置取付具40に取り付ける(図8,11)。

The procedure for mounting the

〔別実施の形態1〕

上述した照明装置取付具40に替えて照明装置取付具は以下のように構成してもよい。

即ち、図12~14に示したように、本形態の照明装置取付具40’は、一対の下フランジ部10Cの間から親桁10の内部空間に侵入させることができ、かつ前記侵入後に所定の角度だけ回転させることで一対の下フランジ部10Cによって係止可能な係止板部41’と、照明装置50を取り付ける取付部42aを有する取付板部42’と、係止板部41’および取付板部42’を貫通して係止板部41’および取付板部42’を接続する接続ボルト部材45と、接続ボルト部材45に螺合する接続ナット部材46と、を備える。

[Another embodiment 1]

Instead of the

That is, as shown in Figures 12 to 14, the lighting

係止板部41’は、一対の下フランジ部10Cの間から親桁10の内部空間に侵入させることができ、当該侵入後に所定の角度だけ回転させることで一対の下フランジ部10Cによって係止可能な態様であれば、その形状は特に限定されるものではない。係止板部41’は、接続ボルト部材45を軸芯として単独で回転可能に構成してある。係止板部41’をこのように構成すれば、係止板部41’を前記侵入後に所定の角度(例えば90°)だけ回転させることで係止板部41’の両端を一対の下フランジ部10Cに係止させることができるため、係止板部41’を一対の下フランジ部10Cによって係止することができる。係止板部41’を一対の下フランジ部10Cに係止させた後、接続ボルト部材45に対して接続ナット部材46を螺入させると、係止板部41’の下面と下フランジ部10Cの上面とが密接する。このようにボルトを締結することで、照明装置取付具40’を親桁10に取り付けることができる。

The shape of the locking plate portion 41' is not particularly limited as long as it can be inserted into the internal space of the

〔別実施の形態2〕

上述した実施形態では、子桁11を親桁10にボルト61で固定する場合について説明した。しかし、このような態様に限定されるものではなく、図15に示したように、各子桁を例えば2つのリベット62で固定してもよい。リベット62の数は限定されるものではない。

[Another embodiment 2]

In the above-described embodiment, the

〔別実施の形態3〕

上述した実施形態では、隣接する親桁10どうしを接続する接続具30として、接続具本体30Aと、接続具ボルト部材33と、接続具ナット部材34と、を備えた態様について説明した。しかし、このような態様に限定されるものではなく、図16~18に示したように、接続具30として、下フランジ部10Cを挟持する二枚の接続具板状部材31,32と、二枚の接続具板状部材31,32を貫通する接続具ボルト部材33と、当該接続具ボルト部材33に螺合する接続具ナット部材34と、を備える態様としてもよい。

[Another embodiment 3]

In the above-described embodiment, the

二枚の接続具板状部材31,32は、上側接続具板状部材31と下側接続具板状部材32を重ねた態様とする。二枚の接続具板状部材31,32において、材質は何れも金属製とすればよいがこれに限定されるものではなく、樹脂等を使用してもよい。接続具ボルト部材33は、接続具板状部材31,32のそれぞれに形成したボルト穴31a,32aを貫通している。本実施形態では、2本の接続具ボルト部材33を使用する態様について説明するが、この態様に限定されるものではない。また、本実施形態では、二枚の接続具板状部材31,32のそれぞれに親桁10の位置ズレを防止する接続具親桁位置ズレ防止部31b,32bを備えた場合について説明する。接続具親桁位置ズレ防止部31b,32bは、何れも上側に折り曲げた状態の一対のフランジ部とするのがよいが、このような態様に限定されるものではない。

The two

接続具30によって隣接する親桁10どうしを接続する手順は以下の通りである。まず、二枚の接続具板状部材31,32の間隔を少し開けて(下フランジ部10Cを挟持することができる程度の間隔)重ねた状態とした接続具30の一方の端部を、一方の親桁10の端部に侵入させる(図16)。このとき、二枚の接続具板状部材31,32によって下フランジ部10Cを挟持するように接続具30を親桁10の端部に侵入させる(図17(a))。接続具親桁位置ズレ防止部31bである一対のフランジ部は、親桁10の側方部10Bの内側に近接あるいは当接した状態となっており、接続具親桁位置ズレ防止部32bである一対のフランジ部は、親桁10の側方部10Bの外側に近接あるいは当接した状態となっている(図17(b))。この状態で接続具30の他方の端部を、他方の親桁10’の端部に侵入させる(図17~18)。一方の親桁10の端部と他方の親桁10’の端部とを当接させた状態で、接続具ボルト部材33に対して接続具ナット部材34を螺入させると、上側接続具板状部材31の下面と下フランジ部10Cの上面とが密接し、かつ下フランジ部10Cの下面と下側接続具板状部材32の上面とが密接し、さらに接続具ナット部材34によって下側接続具板状部材32の下面を締め上げることとなる。このようにボルトを締結することで、1つの接続具30によって隣接する親桁10どうしを接続することができる。

The procedure for connecting

接続具ボルト部材33の先端は接続具ナット部材34が螺合した状態で潰した状態としてもよい。接続具ボルト部材33の先端を潰すことで当該先端の直径を大きくする等の変形を施すことができ、接続具ナット部材34がトンネル内の振動等で緩んだとしても、この変形部分が接続具ナット部材34の抜け止めとなり、接続具ナット部材34が接続具ボルト部材33から抜け落ちるのを未然に防止することができる。

The tip of the

〔別実施の形態4〕

上述した実施形態では、照明装置50の両端に照明装置接続部材50Aを取り付け、照明装置接続部材50Aには、接続板状部50aを照明装置50の端部と対面するように備えてある態様について説明した。しかし、このような態様に限定されるものではなく、図19に示したように、接続板状部50aを照明装置50の端部と対面しないように備えてもよい。このように構成することで、照明装置50が親桁10より離間する距離を上記の実施形態に比べて大きくすることができる。

[Another embodiment 4]

In the above-described embodiment, the lighting

本発明は、トンネル内に敷設され、各種ケーブルを保持する器具共架型ケーブルラックに利用できる。 This invention can be used for equipment-mounted cable racks that are installed inside tunnels and hold various cables.

X ケーブルラック

1 設置部

10 親桁

10A 上面載置部

10B 側方部

10C 下フランジ部

11 子桁

20 固定具

21 固定具板状部材

22 固定具ボルト部材

23 固定具ナット部材

30 接続具

30A 接続具本体

33 接続具ボルト部材

34 接続具ナット部材

40、40’ 照明装置取付具

41、41’ 係止板部

42、42’ 取付板部

42a 取付部

43 屈曲部

45 接続ボルト部材

46 接続ナット部材

50 照明装置

Claims (6)

前記親桁は、前記親桁の長手方向に直交する断面視において、前記子桁を載置する上面載置部と、当該上面載置部の両端から下垂する一対の側方部と、当該側方部の下端部から内側に屈曲し、間隔を開けて互いに対向するように設けられた一対の下フランジ部と、を備えるように構成したケーブルラック。 The system is provided with a single long parent girder laid in a tunnel, and child girders arranged at intervals in a longitudinal direction of the parent girder and capable of holding cables ,

The cable rack is configured so that, in a cross-sectional view perpendicular to the longitudinal direction of the parent girder, the parent girder comprises an upper surface mounting portion on which the child girder is placed, a pair of side portions hanging down from both ends of the upper surface mounting portion, and a pair of lower flange portions bent inward from the lower ends of the side portions and arranged opposite each other with a gap between them .

前記固定具は、一対の前記下フランジ部の間をスライド移動可能な固定具板状部材と、当該固定具板状部材を貫通する固定具ボルト部材と、当該固定具ボルト部材に螺合する固定具ナット部材と、を備えた請求項1に記載のケーブルラック。 a mounting unit for mounting the cable rack and a fixing device for fixing the cable rack;

The cable rack of claim 1, wherein the fixing device comprises a fixing plate member that can slide between a pair of the lower flange portions, a fixing bolt member that passes through the fixing plate member, and a fixing nut member that screws into the fixing bolt member.

前記接続具は、一方の親桁の端部および他方の親桁の端部を包持する接続具本体と、一方の親桁の端部および接続具本体を貫通し、或いは他方の親桁の端部および接続具本体を貫通する少なくとも二本の接続具ボルト部材と、当該接続具ボルト部材に螺合する少なくとも二つの接続具ナット部材と、を備えた請求項1に記載のケーブルラック。 A connector is provided for connecting adjacent parent girders,

The cable rack of claim 1, wherein the connector comprises a connector body that holds an end of one parent girder and an end of the other parent girder, at least two connector bolt members that penetrate the end of one parent girder and the connector body or the end of the other parent girder and the connector body, and at least two connector nut members that screw into the connector bolt members .

前記接続具は、前記下フランジ部を挟持する二枚の接続具板状部材と、前記二枚の接続具板状部材を貫通する接続具ボルト部材と、当該接続具ボルト部材に螺合する接続具ナット部材と、を備えた請求項1に記載のケーブルラック。 A connector is provided for connecting adjacent parent girders,

The cable rack of claim 1, wherein the connector comprises two connector plate members that sandwich the lower flange portion, a connector bolt member that passes through the two connector plate members, and a connector nut member that screws into the connector bolt member.

前記一対の下フランジ部の間から前記親桁の内部空間に侵入させることができ、かつ前記照明装置取付具を前記侵入のときとは異なる姿勢に変更することで前記一対の下フランジ部によって係止可能な係止板部と、

前記照明装置を取り付ける取付部を有する取付板部と、

前記係止板部および前記取付板部を角度をつけて接続する屈曲部と、を備えた請求項1に記載のケーブルラック。 A lighting device mounting fixture for mounting a lighting device is provided, the lighting device mounting fixture comprising:

a locking plate portion that can be inserted into the internal space of the parent girder from between the pair of lower flange portions and can be locked by the pair of lower flange portions by changing the posture of the lighting device mounting fixture to a different posture from that at the time of the insertion;

a mounting plate portion having a mounting portion for mounting the lighting device;

The cable rack according to claim 1 , further comprising a bent portion that connects the locking plate portion and the mounting plate portion at an angle.

前記一対の下フランジ部の間から前記親桁の内部空間に侵入させることができ、かつ前記侵入後に所定の角度だけ回転させることで前記一対の下フランジ部によって係止可能な係止板部と、

前記照明装置を取り付ける取付部を有する取付板部と、

前記係止板部および前記取付板部を貫通して前記係止板部および前記取付板部を接続する接続ボルト部材と、

前記接続ボルト部材に螺合する接続ナット部材と、を備えた請求項1に記載のケーブルラック。 A lighting device mounting fixture for mounting a lighting device is provided, the lighting device mounting fixture comprising:

a locking plate portion that can be inserted into an internal space of the parent girder from between the pair of lower flange portions and can be locked by the pair of lower flange portions by rotating the locking plate portion by a predetermined angle after the insertion;

a mounting plate portion having a mounting portion for mounting the lighting device;

a connecting bolt member that penetrates the locking plate portion and the mounting plate portion to connect the locking plate portion and the mounting plate portion;

The cable rack according to claim 1 , further comprising: a connection nut member that is screwed onto the connection bolt member.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020201952A JP7555071B2 (en) | 2020-12-04 | 2020-12-04 | Equipment shared cable rack |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020201952A JP7555071B2 (en) | 2020-12-04 | 2020-12-04 | Equipment shared cable rack |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022089512A JP2022089512A (en) | 2022-06-16 |

| JP7555071B2 true JP7555071B2 (en) | 2024-09-24 |

Family

ID=81989445

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020201952A Active JP7555071B2 (en) | 2020-12-04 | 2020-12-04 | Equipment shared cable rack |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP7555071B2 (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000059949A (en) | 1998-08-05 | 2000-02-25 | Masanori Nishino | Wiring jig for electric cable |

| JP2001025131A (en) | 1999-07-08 | 2001-01-26 | Mirai Ind Co Ltd | Bracket for wiring and piping member |

| JP2009254023A (en) | 2008-04-01 | 2009-10-29 | East Nippon Expressway Co Ltd | Cable rack and method for installing cable rack on tunnel wall surface |

| JP2011160513A (en) | 2010-01-29 | 2011-08-18 | Chugoku Electric Power Co Inc:The | Cable support fitting |

-

2020

- 2020-12-04 JP JP2020201952A patent/JP7555071B2/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000059949A (en) | 1998-08-05 | 2000-02-25 | Masanori Nishino | Wiring jig for electric cable |

| JP2001025131A (en) | 1999-07-08 | 2001-01-26 | Mirai Ind Co Ltd | Bracket for wiring and piping member |

| JP2009254023A (en) | 2008-04-01 | 2009-10-29 | East Nippon Expressway Co Ltd | Cable rack and method for installing cable rack on tunnel wall surface |

| JP2011160513A (en) | 2010-01-29 | 2011-08-18 | Chugoku Electric Power Co Inc:The | Cable support fitting |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2022089512A (en) | 2022-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7468491B2 (en) | Accessory for lifting and bonding wire cable trays | |

| TW201107611A (en) | Snap-on structural connector | |

| US9909692B2 (en) | Conduit spacing and mounting system and method | |

| RU2274771C2 (en) | Mounting bus butt-joint unit connector | |

| JP7555071B2 (en) | Equipment shared cable rack | |

| US20120012715A1 (en) | Systems, methods, and apparatus for providing a metal clad cable clamp | |

| US20050173363A1 (en) | Mounting fastening | |

| RU2702710C1 (en) | Car exhaust pipe mounting fastener | |

| JP3616614B2 (en) | Suspension bolt support device | |

| DK202200535A1 (en) | Solar Panel Mounting System and Method for Mounting Solar Pan el Plates to a Solar Panel | |

| JP4693894B2 (en) | Bus duct support system and bus duct support device | |

| KR20140014758A (en) | Celling louver | |

| CN108867208B (en) | Raceway arrangement | |

| JP2018186440A (en) | Supporting metal fitting for antenna installation | |

| JP7062257B1 (en) | Bolt support bracket | |

| JP4558990B2 (en) | Bus duct support device | |

| JP2009044959A5 (en) | ||

| JP4404669B2 (en) | Bus duct support device | |

| JP3734748B2 (en) | Mounting device | |

| JP2847505B2 (en) | Duct support | |

| JP4466318B2 (en) | Fasteners | |

| JP2023033046A (en) | Anti-vibration metal fixture for channel steel | |

| JP3295348B2 (en) | Mounting tools such as pipes, control panels, boxes, cables, etc. that can be attached to the building, beams, haze, etc. | |

| JP4242092B2 (en) | Bus duct support system and bus duct support device | |

| WO2020240721A1 (en) | Guide rail bracket and guide rail mount method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20231110 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240617 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240618 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240806 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20240820 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20240902 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7555071 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |