JP7542917B2 - ウエーハの生成方法 - Google Patents

ウエーハの生成方法 Download PDFInfo

- Publication number

- JP7542917B2 JP7542917B2 JP2020186938A JP2020186938A JP7542917B2 JP 7542917 B2 JP7542917 B2 JP 7542917B2 JP 2020186938 A JP2020186938 A JP 2020186938A JP 2020186938 A JP2020186938 A JP 2020186938A JP 7542917 B2 JP7542917 B2 JP 7542917B2

- Authority

- JP

- Japan

- Prior art keywords

- workpiece

- wafer

- laser beam

- peeling

- peeling layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 32

- 230000002093 peripheral effect Effects 0.000 claims description 68

- 239000013078 crystal Substances 0.000 claims description 16

- 238000000034 method Methods 0.000 claims description 15

- 238000003384 imaging method Methods 0.000 claims description 13

- 238000003708 edge detection Methods 0.000 claims description 7

- 230000001678 irradiating effect Effects 0.000 claims description 6

- 235000012431 wafers Nutrition 0.000 description 106

- 230000003287 optical effect Effects 0.000 description 18

- 230000015572 biosynthetic process Effects 0.000 description 14

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 14

- 229910010271 silicon carbide Inorganic materials 0.000 description 14

- 239000007788 liquid Substances 0.000 description 13

- 238000010586 diagram Methods 0.000 description 9

- 238000000926 separation method Methods 0.000 description 9

- 239000004065 semiconductor Substances 0.000 description 7

- 238000002679 ablation Methods 0.000 description 6

- 238000005498 polishing Methods 0.000 description 5

- 238000010521 absorption reaction Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000009966 trimming Methods 0.000 description 2

- 230000000295 complement effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

- H01L21/3043—Making grooves, e.g. cutting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/03—Observing, e.g. monitoring, the workpiece

- B23K26/032—Observing, e.g. monitoring, the workpiece using optical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/352—Working by laser beam, e.g. welding, cutting or boring for surface treatment

- B23K26/3568—Modifying rugosity

- B23K26/3576—Diminishing rugosity, e.g. grinding; Polishing; Smoothing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/362—Laser etching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/38—Removing material by boring or cutting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/50—Working by transmitting the laser beam through or within the workpiece

- B23K26/53—Working by transmitting the laser beam through or within the workpiece for modifying or reforming the material inside the workpiece, e.g. for producing break initiation cracks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02002—Preparing wafers

- H01L21/02005—Preparing bulk and homogeneous wafers

- H01L21/02008—Multistep processes

- H01L21/0201—Specific process step

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02002—Preparing wafers

- H01L21/02005—Preparing bulk and homogeneous wafers

- H01L21/02008—Multistep processes

- H01L21/0201—Specific process step

- H01L21/02013—Grinding, lapping

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02002—Preparing wafers

- H01L21/02005—Preparing bulk and homogeneous wafers

- H01L21/02008—Multistep processes

- H01L21/0201—Specific process step

- H01L21/02021—Edge treatment, chamfering

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/0445—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising crystalline silicon carbide

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67092—Apparatus for mechanical treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/36—Electric or electronic devices

- B23K2101/40—Semiconductor devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/50—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Crystallography & Structural Chemistry (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Laser Beam Processing (AREA)

Description

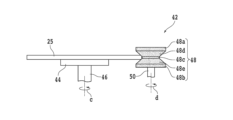

概ね径が等しい円盤状の上部48a及び下部48bと、上部48a及び下部48bより径が小さい円盤状の中央部48cと、上部48a及び中央部48cを接続するように上部48a及び中央部48cの間に設けられた円錐台状の上方面取り部48dと、下部48b及び中央部48cを接続するように下部48b及び中央部48cの間に設けられた円錐台状の下方面取り部48eとを有する。

3 :レーザービーム

5 :光軸

11 :被加工物

11a:表面

11b:裏面

11c:c軸

11d:垂線

11e:c面

13 :一次オリエンテーションフラット

15 :二次オリエンテーションフラット

17a:外周領域

17b:中央領域

19 :改質部

21 :クラック

23 :剥離層

25 :ウエーハ

25a:剥離面

2 :レーザー照射装置

4 :チャックテーブル

6 :レーザービーム照射ユニット

8 :ヘッド

10 :連結部

12 :撮像ユニット

14 :分離装置

16 :液体

18 :液槽

20 :載置テーブル

22 :超音波照射ユニット

24 :研削装置

26 :チャックテーブル

28 :研削ユニット

30 :スピンドル

32 :ホイールマウント

34 :ボルト

36 :研削ホイール

38 :基台

40 :研削砥石

42 :面取り装置

44 :チャックテーブル

46 :スピンドル

48 :研削砥石

48a:上部

48b:下部

48c:中央部

48d:上方面取り部

48e:下方面取り部

50 :スピンドル

Claims (4)

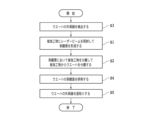

- 第一の面と該第一の面の裏面である第二の面とを有する単結晶SiCインゴット又は単結晶SiCウエーハである被加工物から該第一の面と該第二の面との間隔未満の厚さを有するウエーハを生成するウエーハの生成方法であって、

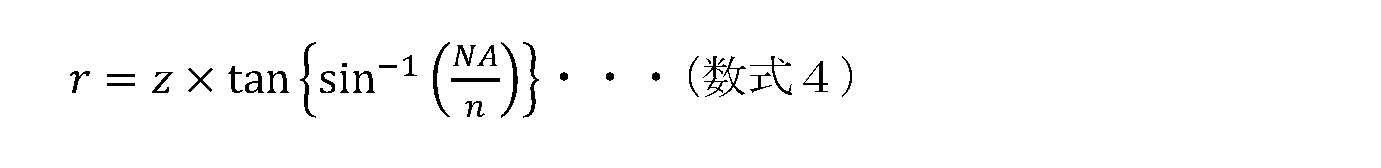

該被加工物を透過する波長のレーザービームの集光点を該被加工物の内部に位置付けるとともに、該被加工物のc面に平行な面と該第一の面とが交差する交差線に沿って、該被加工物と該集光点とを相対的に移動させながら該レーザービームを照射して、改質部と該改質部から該c面に沿って伸展するクラックとを含む剥離層を形成する剥離層形成ステップと、

該剥離層において該被加工物を分離して該被加工物から該ウエーハを剥離するウエーハ剥離ステップと、

を含み、

該剥離層形成ステップでは、該被加工物の外周縁から所定距離内側までの外周領域を除く該被加工物の中央領域に該集光点が位置付けられた状態でのみ該レーザービームを照射し、

該剥離ステップでは、該被加工物に超音波振動を付与して該クラックを該中央領域のみならず該外周領域にも伸展させることによって該被加工物を分離して該被加工物から該ウエーハを剥離することを特徴とする、ウエーハの生成方法。 - 該剥離層形成ステップの前に、撮像ユニットにより該被加工物の該第一の面側を撮像することで該被加工物の外周縁を検出する外周縁検出ステップを含む、請求項1に記載のウエーハの生成方法。

- 該ウエーハ剥離ステップの後に、該被加工物から該ウエーハが剥離されたことによって露出する該ウエーハの剥離面を研削する研削ステップを含む、請求項1または2に記載のウエーハの生成方法。

- 該ウエーハ剥離ステップの後に、該ウエーハの外周縁を面取りする面取りステップを含む、請求項1乃至3のいずれかに記載のウエーハの生成方法。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020186938A JP7542917B2 (ja) | 2020-11-10 | 2020-11-10 | ウエーハの生成方法 |

| US17/451,682 US12106967B2 (en) | 2020-11-10 | 2021-10-21 | Wafer producing method |

| TW110139862A TW202220047A (zh) | 2020-11-10 | 2021-10-27 | 晶圓的生成方法 |

| CN202111292261.1A CN114535815A (zh) | 2020-11-10 | 2021-11-03 | 晶片的生成方法 |

| DE102021212374.0A DE102021212374A1 (de) | 2020-11-10 | 2021-11-03 | Waferherstellungsverfahren |

| KR1020210150597A KR20220063734A (ko) | 2020-11-10 | 2021-11-04 | 웨이퍼의 생성 방법 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020186938A JP7542917B2 (ja) | 2020-11-10 | 2020-11-10 | ウエーハの生成方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022076543A JP2022076543A (ja) | 2022-05-20 |

| JP7542917B2 true JP7542917B2 (ja) | 2024-09-02 |

Family

ID=81256046

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020186938A Active JP7542917B2 (ja) | 2020-11-10 | 2020-11-10 | ウエーハの生成方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US12106967B2 (ja) |

| JP (1) | JP7542917B2 (ja) |

| KR (1) | KR20220063734A (ja) |

| CN (1) | CN114535815A (ja) |

| DE (1) | DE102021212374A1 (ja) |

| TW (1) | TW202220047A (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024139560A1 (zh) * | 2022-12-30 | 2024-07-04 | 山东天岳先进科技股份有限公司 | 一种基于激光致裂的碳化硅剥离片及加工方法和激光剥离系统 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20180185957A1 (en) | 2015-06-23 | 2018-07-05 | Siltectra Gmbh | Method for guiding a crack in the peripheral region of a donor substrate |

| JP2019102676A (ja) | 2017-12-05 | 2019-06-24 | 株式会社ディスコ | 剥離装置 |

| JP2020017627A (ja) | 2018-07-25 | 2020-01-30 | 株式会社デンソー | SiCウェハ及びSiCウェハの製造方法 |

| JP2020113664A (ja) | 2019-01-15 | 2020-07-27 | 株式会社ディスコ | ウエーハ、及びウエーハの生成方法 |

| JP2020145418A (ja) | 2019-02-05 | 2020-09-10 | 株式会社ディスコ | 基板を製造する方法、及び基板の製造用システム |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000094221A (ja) | 1998-09-24 | 2000-04-04 | Toyo Advanced Technologies Co Ltd | 放電式ワイヤソー |

| JP6399913B2 (ja) | 2014-12-04 | 2018-10-03 | 株式会社ディスコ | ウエーハの生成方法 |

| JP7330695B2 (ja) | 2018-12-21 | 2023-08-22 | 浜松ホトニクス株式会社 | レーザ加工方法、及び、半導体デバイス製造方法 |

-

2020

- 2020-11-10 JP JP2020186938A patent/JP7542917B2/ja active Active

-

2021

- 2021-10-21 US US17/451,682 patent/US12106967B2/en active Active

- 2021-10-27 TW TW110139862A patent/TW202220047A/zh unknown

- 2021-11-03 CN CN202111292261.1A patent/CN114535815A/zh active Pending

- 2021-11-03 DE DE102021212374.0A patent/DE102021212374A1/de active Pending

- 2021-11-04 KR KR1020210150597A patent/KR20220063734A/ko active Search and Examination

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20180185957A1 (en) | 2015-06-23 | 2018-07-05 | Siltectra Gmbh | Method for guiding a crack in the peripheral region of a donor substrate |

| JP2019102676A (ja) | 2017-12-05 | 2019-06-24 | 株式会社ディスコ | 剥離装置 |

| JP2020017627A (ja) | 2018-07-25 | 2020-01-30 | 株式会社デンソー | SiCウェハ及びSiCウェハの製造方法 |

| JP2020113664A (ja) | 2019-01-15 | 2020-07-27 | 株式会社ディスコ | ウエーハ、及びウエーハの生成方法 |

| JP2020145418A (ja) | 2019-02-05 | 2020-09-10 | 株式会社ディスコ | 基板を製造する方法、及び基板の製造用システム |

Also Published As

| Publication number | Publication date |

|---|---|

| TW202220047A (zh) | 2022-05-16 |

| US20220148881A1 (en) | 2022-05-12 |

| KR20220063734A (ko) | 2022-05-17 |

| JP2022076543A (ja) | 2022-05-20 |

| CN114535815A (zh) | 2022-05-27 |

| US12106967B2 (en) | 2024-10-01 |

| DE102021212374A1 (de) | 2022-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6482425B2 (ja) | ウエーハの薄化方法 | |

| TWI706454B (zh) | 碳化矽(SiC)基板的分離方法 | |

| JP6773506B2 (ja) | ウエーハ生成方法 | |

| JP6506520B2 (ja) | SiCのスライス方法 | |

| CN110047746B (zh) | 平坦化方法 | |

| JP5875122B2 (ja) | 単結晶基板製造方法および内部改質層形成単結晶部材 | |

| US20170301549A1 (en) | METHOD OF PROCESSING SiC WAFER | |

| JP6180223B2 (ja) | ウェーハの製造方法 | |

| JP6004339B2 (ja) | 内部応力層形成単結晶部材および単結晶基板製造方法 | |

| US11094523B2 (en) | Processing method for wafer | |

| US11018059B2 (en) | SiC substrate processing method | |

| JP6324796B2 (ja) | 単結晶基板の加工方法 | |

| JP7542917B2 (ja) | ウエーハの生成方法 | |

| JP2015037172A (ja) | ウェーハの加工方法 | |

| JP6202695B2 (ja) | 単結晶基板製造方法 | |

| WO2023106017A1 (ja) | ウェハ製造方法 | |

| JP6576782B2 (ja) | ウエーハの加工方法 | |

| WO2023106018A1 (ja) | ウェハ製造方法 | |

| US11901231B2 (en) | Separation method of wafer | |

| JP2023085188A (ja) | ウェハ製造方法 | |

| JP2023085189A (ja) | ウェハ製造方法 | |

| CN118402043A (zh) | 晶圆制造方法 | |

| JP2023071253A (ja) | 加工方法 | |

| JP2024009647A (ja) | ウエーハの生成方法 | |

| JP2017076713A (ja) | ウエーハの加工方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20230925 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240613 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240618 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240628 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20240820 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20240820 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7542917 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |