JP7382657B2 - Gear material holding device and gear material attachment method - Google Patents

Gear material holding device and gear material attachment method Download PDFInfo

- Publication number

- JP7382657B2 JP7382657B2 JP2021505041A JP2021505041A JP7382657B2 JP 7382657 B2 JP7382657 B2 JP 7382657B2 JP 2021505041 A JP2021505041 A JP 2021505041A JP 2021505041 A JP2021505041 A JP 2021505041A JP 7382657 B2 JP7382657 B2 JP 7382657B2

- Authority

- JP

- Japan

- Prior art keywords

- holding member

- gear material

- machine tool

- circular hole

- pull rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 title claims description 117

- 238000000034 method Methods 0.000 title claims description 23

- 229910000831 Steel Inorganic materials 0.000 claims description 5

- 239000010959 steel Substances 0.000 claims description 5

- 238000003825 pressing Methods 0.000 claims description 4

- VNTLIPZTSJSULJ-UHFFFAOYSA-N chromium molybdenum Chemical compound [Cr].[Mo] VNTLIPZTSJSULJ-UHFFFAOYSA-N 0.000 claims description 2

- 238000003754 machining Methods 0.000 description 7

- 238000005520 cutting process Methods 0.000 description 5

- 238000007781 pre-processing Methods 0.000 description 4

- 101100008050 Caenorhabditis elegans cut-6 gene Proteins 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 210000000078 claw Anatomy 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 229910000851 Alloy steel Inorganic materials 0.000 description 1

- 238000005255 carburizing Methods 0.000 description 1

- 230000012447 hatching Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B31/00—Chucks; Expansion mandrels; Adaptations thereof for remote control

- B23B31/02—Chucks

- B23B31/10—Chucks characterised by the retaining or gripping devices or their immediate operating means

- B23B31/12—Chucks with simultaneously-acting jaws, whether or not also individually adjustable

- B23B31/20—Longitudinally-split sleeves, e.g. collet chucks

- B23B31/201—Characterized by features relating primarily to remote control of the gripping means

- B23B31/207—Characterized by features relating primarily to remote control of the gripping means using mechanical transmission through the spindle

- B23B31/2073—Axially fixed cam, moving jaws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23F—MAKING GEARS OR TOOTHED RACKS

- B23F23/00—Accessories or equipment combined with or arranged in, or specially designed to form part of, gear-cutting machines

- B23F23/02—Loading, unloading or chucking arrangements for workpieces

- B23F23/06—Chucking arrangements

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Gripping On Spindles (AREA)

- Gear Processing (AREA)

- Gears, Cams (AREA)

Description

この発明は、歯車を製造する際に、歯車の材料を工作機械に取り付けるための保持装置に関する。 The present invention relates to a holding device for attaching gear material to a machine tool when manufacturing gears.

歯車を製造するためには、中心部に孔を有する円盤状の部材に、様々な加工を行う。例えば、前加工としては円盤状の粗部材の外表面を切削して精密な形状に仕上げたり、かさ歯車のための円錐状の外形を形成するなどの他に、歯切りと呼ばれる工程などがある。これらの工程では、いずれも旋盤などの工作機械の回転部に歯車用材料を取り付け、歯車を回転させながら必要な加工を行う。 In order to manufacture gears, various processes are performed on a disc-shaped member with a hole in the center. For example, pre-processing includes cutting the outer surface of a rough disk-shaped member to give it a precise shape, forming a conical outer shape for a bevel gear, and a process called gear cutting. . In all of these processes, gear material is attached to the rotating part of a machine tool such as a lathe, and the necessary processing is performed while rotating the gear.

歯車用材料を工作機械に取り付けるためには、通常は特許文献1のように複数の爪によって外側から歯車用材料を把持するチャックが使用される。また、特許文献2や特許文献3には、歯車用材料の上面および下面に接する部材で挟み付けることによって歯車用材料を工作機械に取り付けることが記載されている。

In order to attach gear material to a machine tool, a chuck that grips the gear material from the outside with a plurality of claws is usually used, as disclosed in

従来のようにチャックで歯車用材料の外側面を把持すると、そのチャックが接している部分やその付近ではバイトなどを当てることができず、加工することができない。したがって、外側面の全周に渡って加工する場合は、爪の位置をずらしてチャックをやり直しながら、チャックで隠れていない部分を順次加工しなければならない。また、はすば歯車やねじ歯車のように軸方向に対して傾いた歯すじの場合、1本の歯すじがチャックの間に収まらない場合は、そもそも歯すじを形成できない。 If the outer surface of the gear material is gripped with a chuck as in the past, it is impossible to apply a tool or the like to the area in contact with the chuck or its vicinity, making it impossible to process the material. Therefore, when machining the entire circumference of the outer surface, it is necessary to shift the position of the claws and re-chuck, and sequentially process the parts that are not hidden by the chuck. Further, in the case of a tooth trace inclined with respect to the axial direction, such as a helical gear or a screw gear, if one tooth trace cannot fit between the chucks, the tooth trace cannot be formed in the first place.

特許文献2や特許文献3の発明では、歯車用材料の上面および下面に接する部材で挟み付けるので、歯車用材料の側面は開放されている。しかし、これらは非常に複雑な構造であり、高価である。作成しようとする歯車も種類が多ければ、それに合わせて多種の装置が必要となり、コストが上昇する。また、歯車用材料の着脱のためには、歯車用材料の上面に接する部材も着脱せねばならず、作業に時間がかかる。スパイラルベベルギアなどのように円錐台状の形状を有する歯車の場合は、上下から挟み込むことが難しく、挟み込むことができても円錐台の部分の加工が困難となる。

In the inventions of

さらに、特許文献1~3の発明では、歯車用材料の中心軸を正確に合わせることが難しい。特に初期の工程においては歯車用材料の中央部の孔の中心位置と外周の位置が正確に一致していない場合もある。この場合、特許文献1のように外側面を把持して回転させながら加工すれば、仕上がった製品の軸中心は外周の中心位置からずれたままになる。

Furthermore, in the inventions of

この発明は、歯車用材料の中央部の孔の中心位置に工作機械の回転軸を正確に合わせて取り付けることができ、しかも着脱が容易な歯車用材料保持装置および歯車用材料取り付け方法を提供することを目的とする。 The present invention provides a gear material holding device and a gear material mounting method that can be mounted while accurately aligning the rotating shaft of a machine tool with the center position of a hole in the center of the gear material, and that can be easily attached and detached. The purpose is to

上記の課題を解決するために、この発明の歯車用材料保持装置は、中央部に円形穴を有する歯車用材料を工作機械に回転可能に保持するための装置であり、歯車用材料の円形穴の側壁に接する中空円筒状部を有する保持部材と、保持部材の中空円筒状部に挿入される引っ張り棒とを有し、保持部材の中空円筒状部の端部には長さ方向に沿った複数の切り込みによって分割された分割部が形成されており、

引っ張り棒の端部には、先端に向かって外径が大きくなるようなテーパ部が形成されており、保持部材は工作機械に対して着脱自在に取り付けられるようになっており、引っ張り棒は保持部材に対して長さ方向に沿って前後動できるようになっており、引っ張り棒のテーパ部が保持部材の分割部に進入することによって保持部材の分割部が拡大して歯車用材料の円形穴の側壁に押し当てられるようになっている。あるいは、中央部に円形穴を有する歯車用材料を保持するための装置であり、工作機械に接続される工作機械接続部材と、歯車用材料の円形穴の側壁に接する中空円筒状部を有する保持部材と、保持部材の中空円筒状部に挿入される引っ張り棒とを有し、保持部材の中空円筒状部の端部には長さ方向に沿った複数の切り込みによって分割された分割部が形成されており、引っ張り棒の端部には、先端に向かって外径が大きくなるようなテーパ部が形成されており、保持部材は工作機械接続部材に対して着脱自在に取り付けられるようになっており、引っ張り棒は保持部材に対して長さ方向に沿って前後動できるようになっており、引っ張り棒のテーパ部が保持部材の分割部に進入することによって保持部材の分割部が拡大して歯車用材料の円形穴の側壁に押し当てられるようになっている。In order to solve the above problems, the gear material holding device of the present invention is a device for rotatably holding gear material having a circular hole in the center in a machine tool, and the gear material holding device has a circular hole in the gear material. a holding member having a hollow cylindrical portion in contact with the side wall of the holding member; a pull rod inserted into the hollow cylindrical portion of the holding member; A divided section is formed by multiple cuts,

A tapered part is formed at the end of the pull rod so that the outer diameter increases toward the tip, and the holding member can be detachably attached to the machine tool. It is designed to be able to move back and forth along the length of the member, and when the tapered part of the pull rod enters the divided part of the holding member, the divided part of the holding member expands and the circular hole in the gear material is expanded. It is designed to be pressed against the side wall of the Alternatively, it is a device for holding a gear material having a circular hole in the center, and includes a machine tool connecting member connected to a machine tool and a hollow cylindrical part that contacts the side wall of the circular hole of the gear material. a member and a pull rod inserted into a hollow cylindrical portion of the holding member, and an end portion of the hollow cylindrical portion of the holding member is formed with a divided portion divided by a plurality of notches along the length direction. A tapered part is formed at the end of the pull rod so that the outer diameter increases toward the tip, and the holding member can be detachably attached to the machine tool connecting member. The pull rod is capable of moving back and forth along its length with respect to the holding member, and the tapered portion of the draw rod enters the divided portion of the holding member, thereby expanding the divided portion of the holding member. It is pressed against the side wall of the circular hole in the gear material.

この発明の歯車用材料取り付け方法は、上述の歯車用材料保持装置を工作機械に設置し、歯車用材料の円形穴を歯車用材料の中空円筒状部にはめ込み、引っ張り棒を保持部材に対して長さ方向に移動させて引っ張り棒のテーパ部を保持部材の分割部に進入させ、分割部を拡大させて歯車用材料の円形穴の側壁に押し当てることによって、歯車用材料を工作機械に取り付ける。 The gear material attachment method of the present invention includes installing the gear material holding device described above in a machine tool, fitting the circular hole of the gear material into the hollow cylindrical part of the gear material, and moving the pull rod against the holding member. Attach the gear material to the machine tool by moving the pull rod lengthwise so that the tapered portion of the drawbar enters the split portion of the holding member, expanding the split portion and pressing it against the side wall of the circular hole in the gear material. .

この発明の歯車用材料保持装置および歯車用材料取り付け方法は、歯車用材料を工作機械に簡単に着脱でき、しかも、歯車用材料の中央部の孔の中心位置に工作機械の回転軸を正確に合わせて取り付け、精密な加工を実現することができる。 The gear material holding device and gear material attaching method of the present invention allow the gear material to be easily attached to and removed from the machine tool, and moreover, the rotating shaft of the machine tool can be accurately positioned at the center of the hole in the center of the gear material. They can be installed together to achieve precision machining.

本発明を実施するための形態について、図面に基づいて詳細に説明する。図1は歯車用材料保持装置を示す断面図である。歯車用材料保持装置1は、中央部に円形穴x1を有する歯車用材料xを保持するための装置である。工作機械yに接続される工作機械接続部材2と、保持部材3と、引っ張り棒4とを有する。車用材料保持装置1はさまざまな形状の歯車用の材料に適用でき、たとえば平歯車用の円筒状のもの以外にも、傘歯車用の材料のように円錐台状の形状を有するものなどにも適用できる。本例では、スパイラルベベルギア用の歯車用材料を示す。このような形状では、最大径の側面部分が小さく、従来のチャックで外から把持することは難しく、また、上下から挟み込むと上部の円錐台状の部分の加工ができなくなる。

Embodiments for carrying out the present invention will be described in detail based on the drawings. FIG. 1 is a sectional view showing a gear material holding device. The gear

図2は工作機械接続部材を示す断面図、図3は同平面図である。本発明において使用する工作機械は、歯車の製造や前処理に使用される各種の一般的な工作機械が対象になり得る。これらの工作機械は、モータなどの駆動源(図示せず)によって駆動されて回転運動する部材yを有し、チャックなど歯車用材料を保持する部材を取り付ける部分が設けられている。本例であれば、上向きに開いた円錐台形状の窪みが形成されており、ここに工作機械接続部材2を固定する。工作機械自体にこのような適切な形状の回転部がない時は、適宜作成して元の工作機械の回転部と置き換えてもよい。

FIG. 2 is a sectional view showing the machine tool connecting member, and FIG. 3 is a plan view thereof. The machine tool used in the present invention can be any of various general machine tools used for manufacturing or pre-processing gears. These machine tools have a member y that rotates by being driven by a drive source (not shown) such as a motor, and are provided with a portion to which a member such as a chuck for holding gear material is attached. In this example, a truncated cone-shaped depression that opens upward is formed, and the machine

工作機械接続部材2の外形は工作機械の回転部に装着できる形状に形成されている。外側側面にはテーパ状になった部分があり、この面が工作機械の円錐台形状の窪みの面に接する。また、この工作機械接続部材2の中央部は中心軸に沿って中空部が形成されている。特に上端部付近において中空部は、上向きに開いた円錐状の窪みになっている。そして、外側側面のテーパ状の面および中央部の円錐状の窪みの面は、全面に渡って研磨仕上げを行うことが好ましい。研磨仕上げを行うことによって、工作機械および後述の保持部材との接続が良好になり、加工のために工作機械を回転させたときにバックラッシュが少なくなる。こうして、より精密な加工が実現できる。

The outer shape of the machine

次に、保持部材3について説明する。図4は保持部材を示す断面図、図5は同正面図、図6は同平面図である。保持部材3も中心部が中空になった形状である。基部は、外形が概ね円錐台の形状であり、工作機械接続部材2の窪み部に係合するテーパ面になっている。本例では、挿入を容易にするために下端部の外周により強いテーパ角が形成されている。

Next, the holding

保持部材3の上部には、中空円筒状部5が形成されている。その外形は保持しようとする対象の歯車用材料の円形穴の形に対応するが、それよりも若干小さくなっている。そして、中空円筒状部5の少なくとも先端部には長さ方向に沿った複数の切り込み6によって分割された分割部が形成されている。切り込みの数、すなわち分割数は3以上6以下であることが好ましく、特に図6に示すように4つの切り込み6によって4等分することが好ましい。また、切り込み6の深さは、引っ張り棒4の先端部が下降した時に、適切なたわみが生じるように、すなわち、分割部が外向きに開くようにたわむことで歯車用材料の円形穴の内壁面に接し、しかも、十分な強さで内壁面に押し付けられるように設定されていればよい。この条件が満たされるなら、切り込み6は中空円筒状部5の上端部付近のみでもよいが、本例では中空円筒状部5の全長に渡って設けられている。

A hollow

中空円筒状部5の上端部の内壁面には、上に向いて肉厚が薄くなるようなテーパ面が形成されている。

The inner wall surface of the upper end of the hollow

図7は引っ張り棒を示す正面図、図8は同平面図である。引っ張り棒4は下部が丸棒状の部材であり、その部分の外径は保持部材3の中空穴の径よりも小さくなっていて、保持部材3の中空穴の中に挿入しても、保持部材3の内壁との間に隙間が生じるようになっている。

FIG. 7 is a front view showing the pull rod, and FIG. 8 is a plan view thereof. The lower part of the

引っ張り棒4の上部は、先端に向かって外径が大きくなるようなテーパ部が形成されている。このテーパ角は中空円筒状部5の上端部の内壁面のテーパ角と概ね一致している。後述の通り、このテーパ部があることによって、引っ張り棒4が下降した時に中空円筒状部5の分割部を押し広げる。ここでは、少ない移動量によって分割部を大きく広げることができるようにするために、大きなテーパ角を設けており、たとえば、軸方向に対して75°に設定されている。また、上端面では径は中空円筒状部5の内径よりも大きくなっている。

The upper part of the

引っ張り棒4の下端部にはおねじ部が形成されている。また、上面にはドライバーや六角レンチなどの締結工具の先端が挿入される工具挿入穴7が形成されている。本例では、プラスドライバー用の十字穴が設けられている。

The lower end of the

引っ張り棒4の下方には棒状の連結部材8が設けられている。連結部材8の上端部の中心にはめねじ部が設けられている。このめねじ部に引っ張り棒4のおねじ部を係合させるとことによって、連結部材8と引っ張り棒4が連結される。このとき、連結部材8の上端と保持部材の下端の間には隙間が形成されている。

A rod-shaped connecting

さらに連結部材8の下端部にもおねじ部のような係合部が形成されていて、駆動部材9と連結できるようになっている。ここで、駆動部材9は油圧装置などの駆動源によって、引っ張り棒4や連結部材8を軸方向に沿って前後動させる部材であり、さらに、工作機械の本体に対して引っ張り棒4や連結部材8を回転自在に支持する。このような駆動部材9は多くの工作機械に装備されていることが多く、その場合はそれを使用すればよい。また、適当な駆動部材が備わっていない場合は、別途作成して取り付けてもいよい。また、連結部材8は少し短めに設定し、駆動部材9との間に隙間ができるようにし、接続時にはワッシャ状のスペーサー10で調整するようにしてもよい。

Furthermore, an engaging portion such as a male thread is formed at the lower end of the connecting

歯車用材料保持装置1の主要な部材である工作機械接続部材、保持部材および引っ張り棒は、強度のある素材で作られる。金属材料のうちでも、強度が高く、しかも入手性の良い鋼材が好ましい。特に、保持部材3および引っ張り棒4には、クロムモリブデン鋼が適している。本例では、JIS G4053 機械構造用合金鋼鋼材においてSCM415で分類されているものを使用している。これは、焼き入れを行うのに適した素材であり、本例では浸炭焼き入れを施している。

The main members of the gear

そして、工作機械接続部材2、保持部材3や引っ張り棒4には、焼き入れを施すことが好ましい。図10は、焼き入れを行う箇所を示している。

引っ張り棒4のテーパ部Q1および中空円筒状部5のテーパ面Q2に焼き入れを施すことは、特に好ましい。この部分は、強い力で相互に押し当てられるので、摩耗が進行しやすい。焼き入れを施すことによって、摩耗を抑制し、長期の寿命を実現でき、また、形状の精度が保たれることによって、歯車用材料を正確に保持できる。

また、分割部5では、先端のテーパ面Q2以外の部分も全て焼き入れを施してもよい。この場合、まず円筒状の部材を作成してから、焼き入れを施し、その後に長さ方向に沿った切り込みを行うことが好ましい。円筒の形状の時に焼き入れを施すことによって、焼き入れにおける変形を小さくし、正確な形状を得ることができる。この焼き入れによって、分割部5の強度と剛性が向上し、耐久性が増すとともに、引っ張り棒4の上下動による分割部5の開閉により適した弾性も得られる。

保持部材3の中空円筒状部5の外面Q3およびこれに続く基部Q4の面にも焼き入れを施すことが好ましい。この部分を強化することによって、正確な形状を維持し、歯車用材料を正確に固定できる。

保持部材3の基部で、テーパ状になった部分Q5、および、これと係合する工作機械接続部材2の中空部の円錐状の窪みの部分Q6にも焼き入れを行うことが好ましい。この部分も相互に接触するので、強化して摩耗を抑制するとともに、正確な位置関係と係合が保たれる。

なお、保持部材3と工作機械接続部材2のはめあい公差は、JISのH8以上とすることが好ましい。これによって、工作時において振れの小さい正確な回転を歯車用材料に与えることができ、精度の高い歯車を得ることができる。

また、保持部材3の基部で、テーパ状になった部分Q5の上には、円柱側面の形状となる部分3aを形成することが好ましい。工作機械接続部材2、あるいは後述するように工作機械の回転部に着脱するときに、この部分3aを把持することができる。The machine

It is particularly preferable to harden the tapered portion Q1 of the

Further, in the divided

It is preferable that the outer surface Q3 of the hollow

It is preferable that the tapered portion Q5 at the base of the holding

In addition, it is preferable that the fitting tolerance between the holding

Further, it is preferable that a portion 3a having a cylindrical side surface shape is formed on the tapered portion Q5 at the base of the holding

ついで、歯車用材料保持装置の作用と歯車用材料取り付け方法について説明する。まず、歯車用材料保持装置1を組み立てる。歯車用材料保持装置1は工作機械接続部材2、保持部材3、引っ張り棒4の部分に分かれており、本例ではさらに連結部材8も含んでいる。保持部材3は使用対象となりうる歯車用材料xの形状、特に円形穴x1の内径や深さなどに対応して、複数の種類のものを用意しておき、その中からそのときの歯車用材料xにあった保持部材を選択することができる。また、引っ張り棒4や連結部材8も同様に複数の種類のものを用意しておくことができる。このように、それぞれの部分の部材を組み合わせることによって、歯車用材料保持装置1の全てを交換することなく、一部のみを交換することによって多種の歯車を製造することができる。

Next, the function of the gear material holding device and the method of attaching gear material will be explained. First, the gear

歯車用材料保持装置1を工作機械の回転部yに取り付け、連結部材8を駆動部材9に接続する。そして、歯車用材料xを保持部材に取り付ける。図9は保持部材の中空円筒状部を示す拡大断面図である。図9(a)に示すように引っ張り棒4を上側の位置にする。このとき、引っ張り棒4の上端部は中空円筒状部5の上端部から離れているか、あるいは弱く接している状態である。中空円筒状部5の分割部は拡張されておらず、歯車用材料xの円形穴x1を中空円筒状部5にはめ込むことができる。

The gear

ついで、駆動部材9を作動させて引っ張り棒4を下向きに引き下げる。図9(b)に示すように引っ張り棒4の上端部は下降し、これにより中空円筒状部5の分割部の上端部に外向きの力を加える。分割部の上端部は外向きにたわみながら押し広げられ、歯車用材料xの円形穴x1の内側面x2に押し当てられる。こうして、歯車用材料xは保持部材3に強固に固定される。このとき、円形穴x1の中心位置は保持部材3の中心軸の位置に正確に合う。また、引っ張り棒4の上端部は引っ張り棒4の上端部に対して下向きの力も加える。これによって、歯車用材料保持装置1は工作機械の回転部yに強固に固定される。

Then, the

以上、歯車用材料xの取り付けは歯車用材料xの円形穴x1を中空円筒状部5にはめ込み、駆動部材9で引っ張り棒4を引き下げるだけで実施できる。歯車用材料xの取り付けが完了すれば、工作機械の回転部yを回転させ、前加工や歯切りなど必要な加工処理を行うことができる。歯車用材料xの外周は完全に開放されており、加工作業を妨げるものはない。本例のスパイラルベベルギア用の歯車用材料など複雑な形状を持つ場合でも、簡単かつ確実に固定でき、全ての外表面を自由に加工できる。円形穴x1の内径が中空円筒状部5の外形に対応していれば、どのような外形状の歯車用材料でも保持できる。

As described above, the gear material x can be attached by simply fitting the circular hole x1 of the gear material x into the hollow

前加工を行う場合、歯車用材料xの外形の仕上がりは粗く、外周の中心位置と円形穴の中心位置が一致していない場合も考えられる。この発明の歯車用材料保持装置および歯車用材料取り付け方法によれば、工作機械の回転部yの回転中心は円形穴x1の中心位置に一致する。したがって、最終製品となる歯車は、歯面が中心軸を中心に正確に回転する。 When pre-processing is performed, the finished outer shape of the gear material x may be rough, and the center position of the outer periphery may not match the center position of the circular hole. According to the gear material holding device and the gear material attaching method of the present invention, the rotation center of the rotating portion y of the machine tool coincides with the center position of the circular hole x1. Therefore, the tooth surfaces of the final gear rotate accurately around the central axis.

必要な加工処理が終われば工作機械の回転部yの回転を停止する。駆動部材9を作動させて引っ張り棒4を上向きに移動させ、図9(a)に示す状態に戻す。分割部の上端部は縮小し、歯車用材料xの円形穴x1の内側面x2から離れる。こうして、加工処理後の歯車用材料xは簡単に取り外すことができる。

When the necessary processing is completed, the rotation of the rotating part y of the machine tool is stopped. The

以上、駆動部材9の作動による引っ張り棒4の上下動により、保持部材は工作機械接続部材に対して着脱できる。ドライバーやスパナなどの工具を使う必要もない。

As described above, the holding member can be attached to and detached from the machine tool connecting member by vertical movement of the

コンピュータ制御の工作機械では、駆動部材9の作動も自動制御できるようになっている。したがって、駆動部材9の上下動を自動制御することにより、歯車用材料xの取り付けおよび取り外しも自動化でき、作業を自動化・高速化でき、安全性も向上できる。

In a computer-controlled machine tool, the operation of the

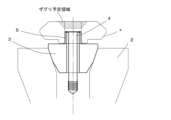

図11は、歯車用材料取り付け方法の例を示す断面図である。歯車用材料によっては、中心穴の内部にも加工を行うことがある。特に、中心部に外に向て開いた形状のザグリ加工を施す場合がある。この場合、切削刃を中心部に進入させながら、ザグリ加工を行う。図11では、ザグリを行うべき部分をハッチングで示している。本例では、引っ張り棒の先端部および保持部材の空円筒状部の先端は、そのザグリ深さよりも深い所に位置するように、その形状が設定されている。この位置で、歯車用材料を保持する。これによって、引っ張り棒や保持部材は切削刃と干渉しないので、ザグリ加工を安全かつ容易に行うことができる。 FIG. 11 is a sectional view showing an example of a method for attaching gear material. Depending on the gear material, the inside of the center hole may also be machined. In particular, there are cases in which a counterboring process is applied to the center part in a shape that opens outward. In this case, counterboring is performed while the cutting blade enters the center. In FIG. 11, the portions to be counterbored are indicated by hatching. In this example, the shapes of the tip of the pull rod and the tip of the empty cylindrical portion of the holding member are set so that they are located deeper than the depth of the counterbore. Hold the gear material in this position. As a result, the pull rod and the holding member do not interfere with the cutting blade, so counterboring can be performed safely and easily.

図12は、歯車用材料保持装置の第2の例を示す断面図である。本例では、図1に示す例と異なって、保持部材3は工作機械の回転部yに直接取り付けられる。工作機械によっては、図1に示すような工作機械接続部材2を接続するのに適した回転部yを備えていないものもある。このような場合、図1に示すような回転部yを作成して、元の回転部と置き換えることも考えられるが、本例では図12に示すように、保持部材3を取り付けるための中空部が、中央部おいて中心軸に沿って形成されていて、その上端部付近において中空部は、上向きに開いた円錐状の窪みになっている。これは、図1の例の工作機械接続部材2の中央部に設けられている円錐状の窪みに相当する。この円錐状の窪みに保持部材3を装着することによって、保持部材3を工作機械に対して回転可能に取り付けることができる。保持部材3のテーパ部は、上側については大きい範囲に設けてもよく、この場合、工作機械の回転部yの中空部の円錐状の窪みの上側に保持部材3のテーパ部の一部が出た状態になる。

FIG. 12 is a sectional view showing a second example of a gear material holding device. In this example, unlike the example shown in FIG. 1, the holding

保持部材3の基部で、テーパ状になった部分Q5、および、これと係合する工作機械の回転部yの中空部の円錐状の窪みの部分Q6にも焼き入れを行うことが好ましい。さらに、窪みの部分Q6には研磨も行うことが好ましい。この部分も相互に接触するので、強化して摩耗を抑制するとともに、正確な位置関係と係合が保たれる。これによって、工作時において振れの小さい正確な回転を歯車用材料に与えることができ、精度の高い歯車を得ることができる。

It is preferable to harden the tapered portion Q5 at the base of the holding

1.歯車用材料保持装置

2.工作機械接続部材

3.保持部材

4.引っ張り棒

5.中空円筒状部

6.切り込み

8.連結部材

9.駆動部材

x.歯車用材料

x1.円形穴

x2.円形穴の内壁

y.工作機械の回転部1. Gear

Claims (5)

歯車用材料の円形穴の側壁に接する中空円筒状部を有する保持部材と、

保持部材の中空円筒状部に挿入される引っ張り棒とを有し、

保持部材の中空円筒状部の端部には長さ方向に沿った複数の切り込みによって分割された分割部が形成されており、

引っ張り棒の端部には、先端に向かって外径が大きくなるようなテーパ部が形成されており、

保持部材は工作機械に対して着脱自在に取り付けられるようになっており、

引っ張り棒は保持部材に対して長さ方向に沿って前後動できるようになっており、

引っ張り棒のテーパ部が保持部材の分割部に進入することによって保持部材の分割部が拡大して歯車用材料の円形穴の側壁に押し当てられるようにした歯車用材料保持装置を工作機械に設置し、

歯車用材料の円形穴を保持部材の中空円筒状部にはめ込み、

引っ張り棒を保持部材に対して長さ方向に移動させて引っ張り棒のテーパ部が保持部材の分割部に進入させ、分割部を拡大させて歯車用材料の円形穴の側壁に押し当てることによって、歯車用材料を工作機械に取り付ける歯車用材料取り付け方法であり、

歯車用材料は中心部にザグリ加工を施すものであり、そのザグリ深さよりも深い円形穴の内部の所に引っ張り棒の先端部および保持部材の空円筒状部の先端が位置して歯車用材料を保持する歯車用材料取り付け方法。 A device for rotatably holding gear material with a circular hole in the center on a machine tool,

a holding member having a hollow cylindrical portion in contact with the side wall of the circular hole of the gear material;

a pull rod inserted into the hollow cylindrical portion of the holding member;

A divided portion is formed at the end of the hollow cylindrical portion of the holding member by a plurality of notches along the length,

The end of the pull rod has a tapered part that increases in outer diameter toward the tip.

The holding member can be detachably attached to the machine tool,

The draw rod is capable of moving back and forth along its length with respect to the holding member;

A gear material holding device is installed on a machine tool in which the tapered part of the pull rod enters the divided part of the holding member, thereby expanding the divided part of the holding member and pressing it against the side wall of the circular hole in the gear material. death,

Insert the circular hole of the gear material into the hollow cylindrical part of the holding member,

by moving the drawbar longitudinally relative to the retaining member such that the tapered portion of the drawbar enters the split in the retaining member, enlarging the split and pressing against the side wall of the circular hole in the gear material; A gear material attachment method for attaching gear material to a machine tool,

The material for gears has a counterbore in the center, and the tip of the pull rod and the tip of the empty cylindrical part of the holding member are located inside the circular hole deeper than the depth of the counterbore, and the material for gears is processed by counterbore processing. Material attachment method for gears that hold.

工作機械に接続される工作機械接続部材と、

歯車用材料の円形穴の側壁に接する中空円筒状部を有する保持部材と、

保持部材の中空円筒状部に挿入される引っ張り棒とを有し、

保持部材の中空円筒状部の端部には長さ方向に沿った複数の切り込みによって分割された分割部が形成されており、

引っ張り棒の端部には、先端に向かって外径が大きくなるようなテーパ部が形成されており、

保持部材は工作機械接続部材に対して着脱自在に取り付けられるようになっており、

引っ張り棒は保持部材に対して長さ方向に沿って前後動できるようになっており、

引っ張り棒のテーパ部が保持部材の分割部に進入することによって保持部材の分割部が拡大して歯車用材料の円形穴の側壁に押し当てられるようになした歯車用材料保持装置を工作機械に設置し、

歯車用材料の円形穴を保持部材の中空円筒状部にはめ込み、

引っ張り棒を保持部材に対して長さ方向に移動させて引っ張り棒のテーパ部が保持部材の分割部に進入させ、分割部を拡大させて歯車用材料の円形穴の側壁に押し当てることによって、歯車用材料を工作機械に取り付ける歯車用材料取り付け方法であり、

歯車用材料は中心部にザグリ加工を施すものであり、そのザグリ深さよりも深い円形穴の内部の所に引っ張り棒の先端部および保持部材の空円筒状部の先端が位置して歯車用材料を保持する歯車用材料取り付け方法。 A device for holding gear material with a circular hole in the center,

a machine tool connecting member connected to the machine tool;

a holding member having a hollow cylindrical portion in contact with the side wall of the circular hole of the gear material;

a pull rod inserted into the hollow cylindrical portion of the holding member;

A divided portion is formed at the end of the hollow cylindrical portion of the holding member by a plurality of notches along the length,

The end of the pull rod has a tapered part that increases in outer diameter toward the tip.

The holding member can be detachably attached to the machine tool connecting member,

The draw rod is capable of moving back and forth along its length with respect to the holding member;

A gear material holding device for a machine tool is provided in which the tapered part of the pull rod enters the divided part of the holding member so that the divided part of the holding member expands and is pressed against the side wall of a circular hole in the gear material. installed,

Insert the circular hole of the gear material into the hollow cylindrical part of the holding member,

by moving the drawbar longitudinally relative to the retaining member such that the tapered portion of the drawbar enters the split in the retaining member, enlarging the split and pressing against the side wall of the circular hole in the gear material; A gear material attachment method for attaching gear material to a machine tool,

The material for gears has a counterbore in the center, and the tip of the pull rod and the tip of the empty cylindrical part of the holding member are located inside the circular hole deeper than the depth of the counterbore, and the material for gears is processed by counterbore processing. How to attach material for gears to hold.

工作機械の回転部は鋼材を素材としており、工作機械の回転部の中央部は中心軸に沿って中空部が形成されていて、その上端部付近において中空部は上向きに開いた円錐状の窪みになっていて、

保持部材の基部には取り付け部材の円錐状の窪みに係合する形状のテーパ面が設けられており、

工作機械の回転部の円錐状の窪みの表面には焼き入れが施されている請求項1に記載の歯車用材料取り付け方法。 The holding member can be detachably attached to the rotating part of the machine tool.

The rotating part of the machine tool is made of steel, and the center of the rotating part of the machine tool has a hollow part formed along the central axis, and near the upper end, the hollow part is a conical depression that opens upward. It has become,

The base of the holding member is provided with a tapered surface shaped to engage with the conical recess of the mounting member,

2. The method for attaching gear material according to claim 1, wherein the surface of the conical recess of the rotating part of the machine tool is hardened.

5. The method for attaching gear materials according to claim 3, wherein the holding member and the pull rod are made of chromium molybdenum steel and are carburized and hardened.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2023185236A JP2023184611A (en) | 2019-03-14 | 2023-10-30 | Holding device for material for gear and attaching method for material for gear |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019047377A JP6853926B2 (en) | 2019-03-14 | 2019-03-14 | Material holding device for gears and material mounting method for gears |

| PCT/JP2020/009793 WO2020184465A1 (en) | 2019-03-14 | 2020-03-06 | Gear-material holding device and gear-material attachment method |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2023185236A Division JP2023184611A (en) | 2019-03-14 | 2023-10-30 | Holding device for material for gear and attaching method for material for gear |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPWO2020184465A1 JPWO2020184465A1 (en) | 2020-09-17 |

| JPWO2020184465A5 JPWO2020184465A5 (en) | 2023-01-30 |

| JP7382657B2 true JP7382657B2 (en) | 2023-11-17 |

Family

ID=72427488

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019047377A Active JP6853926B2 (en) | 2019-03-14 | 2019-03-14 | Material holding device for gears and material mounting method for gears |

| JP2021505041A Active JP7382657B2 (en) | 2019-03-14 | 2020-03-06 | Gear material holding device and gear material attachment method |

| JP2023185236A Pending JP2023184611A (en) | 2019-03-14 | 2023-10-30 | Holding device for material for gear and attaching method for material for gear |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019047377A Active JP6853926B2 (en) | 2019-03-14 | 2019-03-14 | Material holding device for gears and material mounting method for gears |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2023185236A Pending JP2023184611A (en) | 2019-03-14 | 2023-10-30 | Holding device for material for gear and attaching method for material for gear |

Country Status (2)

| Country | Link |

|---|---|

| JP (3) | JP6853926B2 (en) |

| WO (1) | WO2020184465A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113416824B (en) * | 2021-06-02 | 2022-09-13 | 重庆南雁实业集团龙剑机械制造有限公司 | Gearbox gear shaft quenching tool |

| CN114102275B (en) * | 2021-11-19 | 2023-03-21 | 南京航空航天大学 | Device suitable for gear ultrasonic vibration auxiliary grinding and operation process thereof |

| CN116000386B (en) * | 2022-10-27 | 2024-07-02 | 湘潭大学 | Variable diameter gear prestressing force applys device |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5837099B2 (en) * | 1978-03-10 | 1983-08-13 | 株式会社綱島機械製作所 | Workpiece mounting device |

| JPS59183707U (en) * | 1983-05-23 | 1984-12-07 | 株式会社 大隈鉄工所 | collect jig |

| JPH1110420A (en) * | 1997-06-23 | 1999-01-19 | Ntn Corp | Static pressure air bearing spindle |

| JP4358460B2 (en) * | 2001-06-11 | 2009-11-04 | 日産ディーゼル工業株式会社 | Clamping device for milling |

| JP5735086B2 (en) * | 2013-12-04 | 2015-06-17 | 富士機械製造株式会社 | Hybrid chuck |

-

2019

- 2019-03-14 JP JP2019047377A patent/JP6853926B2/en active Active

-

2020

- 2020-03-06 WO PCT/JP2020/009793 patent/WO2020184465A1/en active Application Filing

- 2020-03-06 JP JP2021505041A patent/JP7382657B2/en active Active

-

2023

- 2023-10-30 JP JP2023185236A patent/JP2023184611A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JP6853926B2 (en) | 2021-04-07 |

| WO2020184465A1 (en) | 2020-09-17 |

| JP2023184611A (en) | 2023-12-28 |

| JP2020146809A (en) | 2020-09-17 |

| JPWO2020184465A1 (en) | 2020-09-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2023184611A (en) | Holding device for material for gear and attaching method for material for gear | |

| US3100333A (en) | Method of making compound gear | |

| US9555460B2 (en) | Method for manufacturing a split link for use in a flexible tube bending mandrel | |

| US5074731A (en) | Radially insertable screw nut | |

| US20040035000A1 (en) | Inner spline member and manufacturing method thereof | |

| JP5609291B2 (en) | Mandrel for manufacturing internal gear and method and apparatus for manufacturing internal gear using the mandrel | |

| US4768268A (en) | Method for manufacturing a single-piece type valve sleeve | |

| CN113785129B (en) | Blind rivet nut, blind rivet nut assembly and installation method | |

| JP4117659B2 (en) | Positioning mechanism, positioning jig and positioning method | |

| US20160076576A1 (en) | Disposable aligner for self-tapping threaded insert | |

| JPH05263815A (en) | Long point drill screw and method of manufacture thereof | |

| JP5768969B2 (en) | Broaching tool with protrusion-type front guide | |

| KR101515358B1 (en) | Swaging apparatus and method for manufacturing the long bit socket | |

| JP6467184B2 (en) | Screw manufacturing method and screw | |

| JP5303336B2 (en) | Inclined gear forging device | |

| JP5375987B2 (en) | Sheet surface processing method | |

| JPH11333542A (en) | Method for rolling outer peripheral surface of cylinder and working jig | |

| JP3480455B2 (en) | Manufacturing method and watch | |

| JP3735362B1 (en) | Positioning jig | |

| KR100672864B1 (en) | Method of manufacturing a bolt and maching tool for being used in the method | |

| CN214185589U (en) | Unsettled lever cover gear grinding anchor clamps that rise | |

| JP4663991B2 (en) | Method for forming screw holes | |

| WO2006090985A1 (en) | Method of manufacturing pinion shaft and mold thereof | |

| JP2009083071A (en) | Sheet surface machining tool and method, and manufacturing method of injector using the same sheet surface machining tool | |

| KR20240007982A (en) | A method for manufacturing a sleeve for a power transmission device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20230118 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20230118 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20231003 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20231030 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7382657 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |