JP7154033B2 - discharge tool - Google Patents

discharge tool Download PDFInfo

- Publication number

- JP7154033B2 JP7154033B2 JP2018082608A JP2018082608A JP7154033B2 JP 7154033 B2 JP7154033 B2 JP 7154033B2 JP 2018082608 A JP2018082608 A JP 2018082608A JP 2018082608 A JP2018082608 A JP 2018082608A JP 7154033 B2 JP7154033 B2 JP 7154033B2

- Authority

- JP

- Japan

- Prior art keywords

- plug

- discharge

- metering

- contents

- stroke

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Closures For Containers (AREA)

Description

本発明は、吐出栓の引上げ操作に次いで容器本体を倒立させることにより、容器本体の内容物を一定量だけ計量し、当該吐出栓の押下げ操作により、内容物を小出しして吐出可能にする吐出具に関する。 According to the present invention, by inverting the container main body after pulling up the discharge plug, the contents of the container main body are measured by a predetermined amount, and the contents can be dispensed and discharged by pushing down the discharge plug. Regarding the discharge tool.

従来、容器本体に取付けられてその内容物を計量して吐出可能にする吐出具として、特許文献1に記載の如く、容器本体の口部の外側に筒状部材(特許文献1ではシェル部材という)が装着され、筒状部材の内側には中栓が配置され、可動栓の先端部が筒状部材の先端筒状部を通って外界に露出してなるものがある。キャップの取外しに伴って可動栓を、中栓の仕切り壁から起立するシャフト部に沿って引上げる操作で、当該可動栓の筒状周壁に貫設される連通孔を筒状部材の筒状部で閉じるとともに中栓の供給孔を開いて筒状部材の内側に内容物を供給する一方、当該可動栓を押下げる操作で、供給孔を閉じるとともに上記連通孔を筒状部材の筒状部から開くことで筒状部材内の内容物を可動栓の先端吐出口から吐出させる。 Conventionally, as a discharge tool attached to a container body to measure and discharge the contents thereof, as described in Patent Document 1, a cylindrical member (called a shell member in Patent Document 1) is provided on the outside of the mouth of the container body. ) is attached, an inner plug is disposed inside the tubular member, and the tip of the movable plug is exposed to the outside through the tip tubular portion of the tubular member. When the cap is removed, the movable plug is pulled up along the shaft portion rising from the partition wall of the inner plug, and the communication hole penetrating through the cylindrical peripheral wall of the movable plug is moved to the tubular portion of the tubular member. and open the supply hole of the inner plug to supply the contents to the inside of the tubular member. By opening the cylindrical member, the content inside the cylindrical member is discharged from the distal end discharge port of the movable plug.

この吐出具では、中栓のシャフト部の先端に、可動栓を押下げたときに、先端吐出口を流路から開閉可能に封止する弾性弁を一体に設けていて、可動栓と弾性弁とが筒状部材における先端筒状部の内側で該筒状部材の径方向に並び、弾性弁が可動栓の先端吐出口から外方に突出するように配置されている。 In this discharge tool, an elastic valve is integrally provided at the tip of the shaft portion of the inner plug to open and close the discharge port at the tip from the flow path when the movable plug is pushed down. are arranged in the radial direction of the cylindrical member inside the distal end cylindrical portion of the cylindrical member, and the elastic valve is arranged to protrude outward from the distal end discharge port of the movable plug.

吐出具は、可動栓を引上げた後、容器本体を倒立させることにより、容器本体の内容物を中栓の供給孔から筒状部材の内側の計量空間に供給可能にする。次いで、可動栓を被塗布面に当てる等して押込めば、可動栓は中栓の供給孔を閉じ、筒状部材の計量空間に一定量の内容物が計量される。そして、可動栓から突出する弾性弁の弁体を被塗布面に押し当てて押し込めば、可動栓の先端吐出口が開かれて、計量済の内容物を小出しして吐出できる。 After the movable plug is pulled up, the discharge tool inverts the container body so that the contents of the container body can be supplied from the supply hole of the inner plug to the measuring space inside the cylindrical member. Next, when the movable plug is pressed against the surface to be coated, the movable plug closes the supply hole of the inner plug, and a certain amount of the content is weighed into the measuring space of the cylindrical member. When the valve body of the elastic valve protruding from the movable plug is pressed against the surface to be coated, the discharge port at the tip of the movable plug is opened, and the weighed content can be dispensed.

特許文献1に記載の吐出具では、可動栓と弾性弁とが筒状部材における先端筒状部の内側で該筒状部材の径方向に並び、弾性弁が可動栓の先端吐出口から外方に突出するように配置されている。従って、筒状部材の設計における先端筒状部の小径化に困難があり、吐出具の小型化を困難にする。 In the discharge tool described in Patent Document 1, the movable plug and the elastic valve are aligned in the radial direction of the cylindrical member inside the distal end cylindrical portion of the cylindrical member, and the elastic valve extends outward from the distal end discharge port of the movable plug. are arranged so as to protrude into the Therefore, it is difficult to reduce the diameter of the tip cylindrical portion in the design of the cylindrical member, which makes it difficult to reduce the size of the discharge tool.

また、特許文献1に記載の吐出具では、弾性弁の弁体が可動栓の先端吐出口から外方に突出するように配置されている。従って、可動栓の押込みと同時に弾性弁の弁体が押込まれ、可動栓が閉じられる前に弾性弁の弁体が開いてしまうおそれがある。従って、筒状部材の計量空間に一定量の内容物が供給されたとき、可動栓が未だ閉じられていないにもかかわらず、弾性弁の弁体が開いて計量中に内容物を吐出させてしまい、一定量の内容物を正しく計量できないおそれがある。 Further, in the discharge tool described in Patent Document 1, the valve body of the elastic valve is arranged so as to protrude outward from the distal end discharge port of the movable plug. Therefore, there is a possibility that the valve body of the elastic valve is pushed in at the same time as the movable plug is pushed in, and the valve body of the elastic valve is opened before the movable plug is closed. Therefore, when a certain amount of content is supplied to the measuring space of the cylindrical member, the valve element of the elastic valve opens to discharge the content during measurement even though the movable plug is not yet closed. It may not be possible to measure a certain amount of contents correctly.

本発明の課題は、吐出具において、吐出栓が設けられる筒状部材の小径化を図ることにある。 An object of the present invention is to reduce the diameter of a cylindrical member on which a discharge plug is provided in a discharge tool.

本発明の他の課題は、吐出具において、一定量の内容物を正しく計量して吐出可能にすることにある。 Another object of the present invention is to enable a discharge tool to correctly measure and discharge a fixed amount of contents.

請求項1に係る発明は、容器本体に取付けられてその内容物を計量して吐出可能にする吐出具であって、容器本体の口部に取付けられる筒状部を備えるとともに、該筒状部の軸方向に沿う一端に開口部が形成された筒状部材と、筒状部材における筒状部の軸方向に沿う他端に容器本体の口部を仕切る仕切り壁を備え、容器本体の倒立によって該容器本体の内容物を該筒状部の内側に供給する供給孔が該仕切り壁に形成された中栓と、筒状部材における筒状部の内側からその開口部を通って外界に露出し、該開口部の内周との間に内容物の吐出経路を形成可能にするとともに、該筒状部の内側から該筒状部の軸方向に沿う一端方向に移動されることにより引上げられて該内容物の吐出経路を閉じる吐出シール位置と、該筒状部の内側に押込まれて該内容物の吐出経路を開く吐出可能位置との間で移動可能にされる吐出栓と、筒状部材の内側に配置され、吐出栓の移動に連動して移動可能になるように該吐出栓と連結され、中栓の仕切り壁から離間して該仕切り壁の供給孔からの内容物の供給を可能にする計量可能位置と、該仕切り壁に近接して該仕切り壁の供給孔からの内容物の供給を不能にする計量シール位置との間で移動可能にされる計量栓と、筒状部材の内側で吐出栓と計量栓との間に介装されるばね部を有し、それらの吐出栓、計量栓及びばね部が該筒状部材における筒状部の軸方向に沿って直列配置され、吐出栓がその栓本体部における計量栓寄り端部の周方向複数位置から垂れ下がる複数枚のばね片からなるばね部を一体に設け、計量栓がその栓本体部の吐出栓寄り端部に係合部を設け、各ばね片は、筒状部材における筒状部の軸方向で、計量栓の係合部を抜け止め可能に抱持するとともに、該計量栓の栓本体部を上記軸方向に押圧可能となっており、前記内容物を吐出する際において、吐出栓の引上げによって、該吐出栓が吐出シール位置に設定されるとともに、計量栓が該吐出栓の引上げ力を受けて計量可能位置に設定されることにより、筒状部材における筒状部の内側に容器本体の内容物が供給可能にされて一定量の内容物が計量可能にされ、吐出栓の引上げ後、該吐出栓の押込みによって、計量栓が該吐出栓の押込み力を受けて計量シール位置に設定された後、該吐出栓の更なる押込み力を受けたばね部が撓んで該吐出栓が吐出可能位置に設定されることにより、筒状部材における筒状部に計量されていた内容物が吐出可能にされるようにしたものである。 The invention according to claim 1 is a discharge tool that is attached to a container body and that measures and discharges the contents of the container body, comprising a cylindrical part that is attached to the mouth of the container body, and the cylindrical part A tubular member having an opening formed at one end along the axial direction of the tubular member, and a partition wall partitioning the mouth of the container body at the other axial end of the tubular portion of the tubular member. A supply hole for supplying the contents of the container body to the inside of the tubular portion is exposed to the outside through an inner plug formed in the partition wall and an opening of the tubular portion of the tubular member from the inside of the tubular portion. , a discharge path for the contents can be formed between itself and the inner periphery of the opening, and the container is pulled up by moving from the inside of the tubular portion toward one end along the axial direction of the tubular portion. a discharge plug movable between a discharge sealing position that closes the discharge path for the contents and a dischargeable position that is pushed into the tubular part to open the discharge path for the contents; a cylindrical member; and is connected to the discharge plug so as to be movable in conjunction with the movement of the discharge plug, and is separated from the partition wall of the inner plug so that the contents can be supplied from the supply hole of the partition wall. and a metering seal position proximate to the partition wall and disabling the supply of contents from the supply port of the partition wall; a spring portion interposed between the discharge plug and the metering plug inside, the discharge plug, the metering plug, and the spring section being arranged in series along the axial direction of the tubular portion of the tubular member; The discharge plug is integrally provided with a spring portion consisting of a plurality of spring pieces hanging down from a plurality of positions in the circumferential direction of the end of the plug main body near the metering plug, and the metering plug engages the end of the plug main body near the discharge plug. Each spring piece holds the engaging portion of the metering plug in the axial direction of the tubular member so as to prevent it from coming off, and presses the plug main body of the metering plug in the axial direction. When the contents are to be discharged, the discharge plug is pulled up to set the discharge plug to the discharge sealing position, and the metering plug receives the lifting force of the discharge plug to move to the meterable position. By setting, the contents of the container body can be supplied to the inside of the cylindrical portion of the cylindrical member, and a fixed amount of contents can be measured . , after the metering plug receives the pressing force of the discharge plug and is set at the metering seal position, the spring portion receives a further pushing force of the discharge plug and bends to set the discharge plug to the dischargeable position. , which is metered into the tubular portion of the tubular member It is designed to allow the contents to be discharged .

本発明によれば、吐出具において、吐出栓が設けられる筒状部材の小径化を図ることができる。 According to the present invention, it is possible to reduce the diameter of the tubular member on which the discharge plug is provided in the discharge tool.

また、本発明によれば、吐出具において、一定量の内容物を正しく計量して吐出させることができる。 In addition, according to the present invention, it is possible to correctly measure and discharge a fixed amount of contents in the discharge tool.

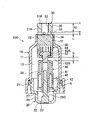

図1、図2は、吐出具100を容器本体201に取付けて構成された吐出容器200を示し、容器本体201に収容してある育毛剤、美容液、化粧液等の内容物を計量して頭皮、顔面等の被塗布面に吐出可能にする。尚、吐出容器200の容器本体201には吐出具100を被覆可能にする不図示のキャップが着脱される。

FIGS. 1 and 2 show a

尚、本明細書では、吐出具100が取付けられた容器本体201を机上等に載置した吐出容器200の正立状態において、該吐出容器200の中心軸に沿う方向で吐出具100の側を「上」、容器本体201の側を「下」と称するものとする。

In this specification, when the container

吐出具100は、筒状部材10、中栓20、吐出栓30、計量栓40、及びばね部50を有して構成される。

The

筒状部材10は、ポリプロピレン等のプラスチック成形体であり、図8に示す如くの両端開口の筒状体からなり、図2に示す如く、容器本体201の口部202に被着されて取付けられる筒状部11を備えるとともに、該筒状部11の軸方向に沿う一端である上端に開口部12が形成される。開口部12には吐出栓30の後述する栓本体部31が上下動可能に装填される。

The

筒状部材10の筒状部11は、図2、図8等に示す容器本体201における口部202の外周部に液密(液体の流通を封止する)に打込まれ(又は螺着されて)取付けられる大径筒状部11Aと、大径筒状部11Aの上端部から上方に延在して計量空間13を内側に形成する中径筒状部11Bと、中径筒状部11Bの上端部から上方に延在する小径筒状部11Cを有する。大径筒状部11Aの下端側内周部には容器本体201との打込み部(又は螺着部)14を備える。大径筒状部11A、中径筒状部11B、小径筒状部11Cはそれらの外径を順に小径とする関係にある。

The

筒状部材10は、大径筒状部11Aと小径筒状部11Bとの連結部の内側から下方に延在する環状壁部15を備え、大径筒状部11Aと環状壁部15との間に環状溝部16を形成して備える。環状壁部15、環状溝部16には、中栓20の後述する環状壁部25、環状凸部24が係着される。

The

中栓20は、ポリプロピレン等のプラスチック成形体であり、図9に示す如く、一端開口の有底筒状体からなり、筒状部材10における環状壁部15、環状溝部16に後述する如くに取付けられ、容器本体201の開口部202に嵌着される取付筒部21を有し、筒状部材10における筒状部11の軸方向に沿う他端である取付筒部21の下端側に容器本体201の開口部202を仕切る仕切り壁22を備え、容器本体201の倒立によって該容器本体201の内容物を該筒状部11の内側の計量空間13に供給する複数個(例えば3個)の供給孔23が該仕切り壁22に形成される。中栓20における取付筒部21の上端部には、筒状部材10の環状溝部16に液密に差込まれる環状凸部24と、環状凸部24の内周側に環状隙間を介するように設けられて筒状部材10における環状壁部15の内周面に液密に嵌合する環状壁部25が突設される。

The

中栓20は、取付筒部21の下端部に連結されて仕切り壁22の外縁部にまで延びる、該取付筒部21より小径の嵌合筒部26を備える。嵌合筒部26の内周面は、仕切り壁22に形成した供給孔23の周囲において、図3に示す如く、計量栓40の後述する栓本体部41が液密に嵌合する嵌合シール部27を形成する。

The

中栓20は、複数個の供給孔23によって囲まれる仕切り壁22の中央部にガイドポスト28を立設して備える。ガイドポスト28は、計量栓40の上下移動のガイドになる。ガイドポスト28は、仕切り壁22に固定される大径基部28Aと、大径基部28Aの側から徐々に細径をなして延びる小径ガイド部28Bを備える。大径基部28Aと小径ガイド部28Bとの境界にそれらの外径差によって形成される環状段差面28Cは、計量シール位置にまで移動した計量栓40の栓本体部41が後述する如くに衝合するように形成されており、該計量栓40の計量シール側への移動限(移動限界位置)を規制する。

The

吐出栓30は、ポリプロピレン等のプラスチック成形体であり、図3に示す如く、筒状部材10における筒状部11の開口部12内に上下に移動可能に支持され、該筒状部11の内側からその開口部12を通って外界に突出可能に露出し、容器本体201の倒立によって該筒状部11の内側の計量空間13を外界に連通可能にする内容物の吐出経路L(図7参照)を該開口部12の内周面との間に形成可能にする概ね棒状の栓本体部31を有する。栓本体部31は、外周面における上端側の一定範囲を筒状部11の開口部12よりわずかに小径のくびれ状面31Aとし、このくびれ状面31Aが筒状部材10の開口部12の内周との間に形成する環状隙間を上述の吐出経路Lとする。

The

吐出栓30は、筒状部材10における筒状部11の軸方向に沿う栓本体部31の中心軸上に吐出孔32を形成し、該栓本体部31において筒状部11の開口部12から外界に突出する端面31Pに該吐出孔32を開口させて備えるとともに、該栓本体部31の軸方向中間部の周方向複数位置(例えば4つの位置)に該吐出孔32から径方向に延在して該栓本体部31のくびれ状面31Aに開口する連通孔33を備える。そして、吐出栓30は、栓本体部31の外周面において、連通孔33が開口するくびれ状面31Aを筒状部11の軸方向に沿う両側から挟む内方側と外方側の2位置のそれぞれに、該栓本体部31の外周面の全周に渡って径方向に膨出して筒状部11における開口部12の内周面に液密に摺動可能に嵌合される内方側と外方側の2個の環状シール部34、35を備える。

The

吐出栓30は、筒状部材10における筒状部11の内側から該筒状部11の軸方向に沿う一端方向である上端方向に引上げられ、栓本体部31の内方側環状シール部34が該筒状部11における開口部12の内周面と液密に嵌合することになる吐出シール位置に設定されたとき、該筒状部11の内側の計量空間13と吐出経路Lとの導通を閉じるものになる

The

他方、吐出栓30は、筒状部材10における筒状部11の内側に押込まれ、吐出栓30の内方側環状シール部34が該筒状部11における開口部12の内周面との液密の嵌合を解かれる吐出可能位置に設定されたとき、該筒状部11の内側の計量空間13と吐出経路Lとを導通するものになる。このようにして吐出栓30が吐出可能位置に設定され、内方側環状シール部34が開口部12の内周面との液密の嵌合を解かれたとき、外方側環状シール35が開口部12の内周面と液密に嵌合し、栓本体部31のくびれ状面31Aが開口部12の内周面との間に形成する環状隙間を外界に対して閉じる。これにより、筒状部11の内側の内容物は、容器本体201の倒立によって吐出経路Lから必ず連通孔33経由で栓本体部31の中心軸上に形成されている吐出孔32の狭い吐出面積の範囲から被塗布面に向けて吐出されるものになる。

On the other hand, the

吐出栓30は、上述の吐出シール位置と吐出可能位置との間で移動可能にされる。尚、吐出シール位置は、1つの定点でなく、吐出可能位置以外の一定の範囲にある全ての点を含む概念である。尚、吐出可能位置も1つの定点でなくて良い。

The

計量栓40は、図13、図14に示す如く、ポリプロピレン等のプラスチック成形体であり、筒状部材10の内側に配置され、概ね有天スカート状の栓本体部41を有し、吐出栓30の上述の引上げ/押込みの移動に連動して上下に移動可能になるように該吐出栓30と連結されている。

As shown in FIGS. 13 and 14, the

計量栓40は、吐出栓30の引上げに連動する移動により、中栓20の仕切り壁22から離間して該仕切り壁22との間に内容物の流入経路Rを形成し、容器本体201の内容物を仕切り壁22の供給孔23から計量空間13へ供給可能にする計量可能位置に設定される。

When the

他方、計量栓40は、吐出栓30の押込みに連動する移動により中栓20の仕切り壁22に近接し、仕切り壁22の供給孔23からの内容物の供給を不能にする計量シール位置に設定される。

On the other hand, the

このとき、中栓20は、前述した如く、仕切り壁22に形成した供給孔23の周囲に嵌合シール部27を形成しており、上述の計量シール位置に設定される計量栓40は、その栓本体部41の天面部41Aの外周部から垂設されるスカート状シール部42の先端部を上記嵌合シール部27の内周部の全周に渡って液密に嵌合し、該仕切り壁22の供給孔23からの内容物の供給を不能にする。

At this time, as described above, the

計量栓40は、図14(A)に示す如く、栓本体部41における天面部41Aの下面に、スカート状シール部42に囲まれて該スカート状シール部42と同芯をなすガイド筒43を垂設して備える。計量栓40は、中栓20が備えるガイドポスト28の小径ガイド部28Bまわりにガイド筒43を遊挿して上下に移動可能にされ、ガイド筒43の内面を小径ガイド部28Bの外面に沿わせることによってその上下移動をガイドされるとともに、計量シール位置にまで移動したガイド筒43の先端面を中栓20の環状段差面28Cに衝合させてその移動限が規制される(図3)。

As shown in FIG. 14A, the

尚、計量栓40は、栓本体部41における天面部41Aの上面の中央部から上方に突出する係合部44を備える。係合部44は、天面部41Aから延びる軸部44Aと、軸部44Aの上端部に設けられる膨出部44Bとから構成され、ばね部50と後述する如くに係合可能にされる。

The

ばね部50は、図3乃至図7に示す如く、筒状部材10の内側で吐出栓30と計量栓40との間に介装される。吐出栓30、計量栓40及びばね部50は筒状部材10における筒状部11の軸方向に沿って直列配置される。

The

ここで、本実施形態においては、吐出栓30は、図10乃至図12に示す如く、その栓本体部31における計量栓40寄り端部にばね部50を一体に設ける。そして、このばね部50は、吐出栓30と一体成形されたポリプロピレン等のプラスチック成形体であり、該吐出栓30の栓本体部31の外周面と概ね同一外径をなす環状部51を該栓本体部31における計量栓40寄り端部に設け、環状部51の周方向に間隔をおいた複数位置から該栓本体部31の軸方向に垂れ下がる複数枚のばね片52を備えて構成される。各ばね片52は、吐出栓30における栓本体部31の外周面に沿って下方に延びる縦片部52Aと、縦片部52Aの下端部から該栓本体部31の径方向中心側に延びる横片部52Bとを備え、縦片部52Aと横片部52BはL字状をなす。

Here, in the present embodiment, as shown in FIGS. 10 to 12, the

ばね部50の各ばね片52を形成する縦片部52Aと横片部52Bは、計量栓40の前述した係合部44を構成している膨出部44Bを外側から囲んで、抜け止め可能に抱持する。そして、各ばね片52は、計量栓40が計量シール位置に設定された状態下で、筒状部材10における筒状部11の内側に押込まれる吐出栓30の押込力を受けるとき、その横片部52Bを計量栓40の栓本体部41における天面部41Aの上面に当接し、該栓本体部41を軸方向に押圧可能にするとともに、その縦片部52Aを圧縮されて弾性撓み変形する。

The

このとき、計量栓40が計量シール位置に設定された状態下で、吐出栓30における栓本体部31の端部に設けたばね部50の各ばね片52が上述の如くに弾性撓み変形可能にするため、図6に示す如く、栓本体部31の上記端部の下面(容器本体201側の面)と計量栓40の係合部44における膨出部44Bの上面との間には縦片部52Aの圧縮分の隙間δが確保される必要がある。

At this time, under the condition that the

尚、吐出容器200は、容器本体201に着脱可能に取付けられるキャップ(不図示)を有する。キャップは、容器本体201に取付けられた状態で、該容器本体201に取付けられている吐出具10における筒状部材10に筒状部11から外界に突出している吐出栓30の先端突出部30P(図2)と係合せしめられる。これにより、吐出栓30は、容器本体201からのキャップの取外しに連動し、筒状部材10における筒状部11の内側から引上げ可能にされる。その後、キャップは、吐出栓30の先端突出部30Pから離れて容器本体201及び吐出具100から取外し除去される。

The

従って、吐出具100によれば、吐出栓30の引上げによって、該吐出栓30が吐出シール位置に設定されるとともに、計量栓40が該吐出栓30の引上げ力を受けて計量可能位置に設定可能にされることにより、容器本体201の倒立によって筒状部材10における筒状部11の内側の計量空間13に容器本体201の内容物が供給可能にされて一定量の内容物が計量可能にされる。他方、吐出栓30の押込みによって、計量栓40が該吐出栓30の押込み力を受けて計量シール位置に設定される一方、該吐出栓30の押込み力を受けたばね部50の各ばね片52が撓んで該吐出栓30が吐出可能位置に設定されることにより、筒状部材10における筒状部11の内側の計量空間13に計量されていた内容物が吐出栓30の吐出孔32から吐出可能にされる。

Therefore, according to the

しかるに、吐出具100にあっては、吐出栓30の押込みによって、計量栓40が該吐出栓30の押込み力を受けて計量シール位置に設定された後、該吐出栓30の更なる押込み力を受けたばね部50の各ばね片52が撓んで該吐出栓30が吐出可能位置に設定されることにより、筒状部材10における筒状部11の内側の計量空間13に計量されていた内容物が吐出可能にされる。

However, in the

このとき、ばね部50の各ばね片52のばね力は、計量栓40が計量シール位置に設定されてその栓本体部41を中栓20の嵌合シール部27に嵌合する嵌合力よりも大きくなるように設定されている。上記ばね力は上記嵌合力よりも小さいと、計量栓40による計量シールが不完全のままに、吐出栓30による吐出シールが開になってしまい、完全に計量シールできない。

At this time, the spring force of each

即ち、吐出容器200を構成する吐出具100は、吐出栓30を、計量可能状態(図4)における最大引上げストローク端Cと、吐出実行状態(図7)における最大押込みストローク端Eとの間で移動可能にされ、以下の如くに、計量吐出動作を行なう。

That is, the

(1)待機状態(図3)

吐出容器200がキャップ(不図示)を取付けられている保管中で、吐出具100が待機状態にあるとき、吐出具100は計量も吐出もできない。吐出栓30は、栓本体部31の端面31Pを筒状部材10の筒状部11における開口部12の端面Aから外界に一定長さhだけ突出させた待機位置Bに設定される。このとき、吐出栓30は、栓本体部31の内方側環状シール部34が筒状部材10の筒状部11における開口部12の内周面と液密に嵌合する吐出シール位置に設定され(図3)、吐出孔32からの内容物の吐出を停止されている。

(1) Standby state (Fig. 3)

When the dispensing

このとき、計量栓40は、栓本体部41のスカート状シール部42が中栓20の嵌合シール部27に液密に嵌合する計量シール位置に設定され(図3)、容器本体201の内容物が仕切り壁22の供給孔23から筒状部材10の計量空間13へ流入することを不能にしている。

At this time, the

(2)計量可能状態(図4)

吐出容器200のキャップ(不図示)が容器本体201から取外されるのに連動して、吐出栓30の端面31Pが上述(1)の待機位置Bから一定の引上げストローク分S0だけ引上げられて最大引上げストローク端Cに設定されると(図4)、吐出栓30は未だ吐出シール位置に維持され(図4)、吐出孔32からの内容物の吐出は停止されている。

(2) Weighable state (Fig. 4)

As the cap (not shown) of the

このとき、計量栓40は、吐出栓30に一体に設けてあるばね部50の各ばね片52が該計量栓40の係合部44を抱持していることに基づき、該吐出栓30の上述の引上げ力を受けて該吐出栓30の引上げに連動し、該計量栓40のスカート状シール部42の先端部が中栓20の嵌合シール部27から離れる計量可能位置(図4)に設定される。尚、計量栓40における栓本体部41の天面部41Aは、栓本体部41の係合部44を構成する膨出部44Bがばね部50における各ばね片52の横片部52Bに対して有する軸方向の遊び分の隙間G(図4)を介するように、各ばね片52の横片部52Bから離隔する。吐出具100にあっては、G=0であっても良い。

At this time, the

これにより、計量栓40は、栓本体部41のスカート状シール部42が中栓20の嵌合シール部27から離間し、中栓20との間に内容物の流入経路Rを形成し、容器本体201の内容物を仕切り壁22の供給孔23から筒状部材10の計量空間13へ供給することを可能にする。但し、容器本体201が転倒されない限り、筒状部材10の計量空間13への上述の内容物の供給は実行されない。

As a result, the skirt-shaped

(3)計量実行状態(図5)

上述(2)の計量可能状態に設定された容器本体201を倒立する(図5)。これにより、容器本体201の内容物は、仕切り壁22の供給孔23、中栓20と計量栓40との間の流入経路R(図5の矢印)を経て、筒状部材10における筒状部11の内側の計量空間13に供給される。このとき、吐出栓30は吐出シール位置に維持されている。

(3) Weighing execution state (Fig. 5)

The

尚、計量栓40は、容器本体201の倒立と、計量空間13への内容物の流入によって該計量空間13内で下降し、上述(2)で栓本体部41の天面部41Aが各ばね片52の横片部52Bに対して生じていた遊び分の隙間Gを解消する。

In addition, the measuring

(4)計量完了状態(図6)

上述(3)で筒状部材10における筒状部11の内側の計量空間13に内容物が供給された吐出具100において、該筒状部11の開口部12から外界に突出している吐出栓30における栓本体部31の端面31Pを頭皮等の被塗布面Fに押し当てる。この押し当て外力によって、吐出栓30の端面31Pが上述(2)、(3)の最大引上げストローク端Cから第1の押込みストローク分S1だけ押込まれてストローク中間点Dに設定されると(図6)、吐出栓30は未だ栓本体部31の内方側環状シール部34が筒状部材10の筒状部11における開口部12の内周面と液密に嵌合する吐出シール位置に維持される。そして、計量栓40は吐出栓30の上述の第1の押込みストローク分S1の押込み力を受けて該吐出栓30の押込みに連動し、栓本体部41のスカート状シール部42が中栓20の嵌合シール部27に液密に嵌合する計量シール位置に設定替えされる(図6)。この吐出栓30の押込みストロークは、計量栓40におけるガイド筒43の先端面が前述した如くに中栓20の環状段差面28Cに衝合し、計量栓40がその移動限に付勢されるに伴ない、そのストローク中間点Dで一端停止される。

(4) Weighing completed state (Fig. 6)

In the

これにより、容器本体201の内容物を中栓22の供給孔23から筒状部材10の計量空間13へ供給することが不能になり、該計量空間13への一定量の内容物の計量が完了する。

As a result, the contents of the

このとき、吐出栓30は吐出シール位置にあり、計量空間13に計量済の内容物が吐出栓30の吐出孔32から不意に吐出することはない。

At this time, the

(5)吐出実行状態(図7)

上述(4)で計量完了した吐出具100において、吐出栓30における栓本体部31の端面31Pを頭皮等の被塗布面Fに更に押し当てると、この更なる押し当て外力によって、吐出栓30の端面31Pが上述(4)のストローク中間点Dから第2の押込みストローク分S2だけ押込まれて最大押込みストローク端E(最大押込みストローク端Eは、筒状部11における開口部12の端面Aと同レベル、又は該端面Aよりわずかに突出するレベルに位置する)に設定されると(図7)、該吐出栓30の更なる押込み力を受けたばね部50の各ばね片52は撓む。そして、吐出栓30は、栓本体部31の内方側環状シール部34が計量空間13に計量済の内容物を吐出孔32の側に吐出可能にするように、吐出経路Lを開く吐出可能位置に設定替えされる(図7)。

(5) Discharge execution state (Fig. 7)

When the

これにより、計量空間13に計量済の内容物が、吐出経路L、吐出栓30の連通孔33を経由して吐出孔32から吐出され、頭皮等の被塗布面Fに塗布される。

As a result, the content weighed into the weighing

このとき、計量栓40は上述(4)に計量シール位置に維持されており、計量空間13への新たな内容物の供給はない。

At this time, the

(6)吐出中断状態(図6の計量完了状態と同じ状態になる)

上述(5)で計量実行中の吐出具100において、吐出栓30における栓本体部31の端面31Pを頭皮等の被塗布面Fから離すと、ばね部50の各ばね片52が押し当て外力の消失による撓みの復元力を吐出栓30に及ぼす。吐出栓30は、この復元力を受けて最大押込みストローク端Eから上述の第2の押込みストローク分S2だけ押し出されて、上述(4)のストローク中間点D又はその近傍に復帰せしめられ、吐出シール位置に設定替えされる(図6)。尚、復元力を受けた吐出栓30と一体のばね部50は、その復元力によって計量栓40から軸方向に弾発的に移動したとき、前述(2)で各ばね片52の横片部52Bと計量栓40における栓本体部41の天面部41Aとの間に生じていた軸方向の遊び分の隙間Gを再び形成し得る。

(6) Dispensing interrupted state (same state as metering completion state in Fig. 6)

When the

これにより、吐出栓30の吐出孔32からの内容物の吐出は中断される。上述(5)、(6)の繰り返しにより、計量空間13に計量した内容物を吐出孔32から小出しできる。

As a result, the discharge of the contents from the

従って、本実施形態によれば以下の作用効果を奏する。

(a)吐出具100は、筒状部材10の内側で吐出栓30と計量栓40との間に介装されるばね部50を有し、それらの吐出栓30、計量栓40及びばね部50が該筒状部材10における筒状部11の軸方向に沿って直列配置される。従って、吐出栓30と計量栓40とばね部50とが筒状部材10における筒状部11の内側で該筒状部材10の設計における筒状部11の小径化を容易にし、吐出具100の小型化を図ることができる。

Therefore, according to this embodiment, the following effects are obtained.

(a) The

(b)吐出具100は、吐出栓30の押込みによって、計量栓40が該吐出栓30の押込み力を受けて計量シール位置に設定された後、該吐出栓30の更なる押込み力を受けたばね部50が撓んで該吐出栓30が吐出可能位置に設定されることにより、筒状部材10における筒状部11に計量されていた内容物が吐出可能にされる。即ち、計量栓40が計量シール位置に完全に設定される前に、吐出栓30が吐出可能位置に設定されるおそれはない。従って、筒状部材10の計量空間13に一定量の内容物が供給されたとき、計量栓40が未だ閉じられていないにもかかわらず、吐出栓30が開いて計量済の内容物を吐出させてしまうことがなく、一定量の内容物を正しく計量できる。また、一定量以上の内容物が筒状部材10の計量空間13に供給されることもなく、この内容物を過剰に使用することとなるおそれもない。

(b) After the

(c)吐出具100は、計量栓40がその栓本体部41を中栓20の嵌合シール部27に嵌合する嵌合力よりも、ばね部50のばね力を大きく設定している。これにより、吐出栓30の押込みによってまず先に、計量栓40の栓本体部41が中栓20の嵌合シール部27に嵌合して計量シール位置に設定される。続いて、吐出栓30の更なる押込み力がばね部50のばね力を越えたときに、ばね部50が撓んで吐出栓30が吐出可能位置に設定されるものになる。これにより、吐出具100による上述(b)の計量吐出動作の確実を図ることができる。

(c) In the

(d)吐出具100は、吐出栓30が最大引上げストローク端Cと最大押込みストローク端Eとの間で移動可能にされる。そして、吐出栓30が最大引上げストローク端Cにあるときに、吐出栓30は吐出シール位置に設定され、計量栓40は計量可能位置に設定され、吐出栓30が外力によって最大引上げストローク端Cから第1の押込みストローク分だけ押込まれてストローク中間点Dに設定されたときに、吐出栓30は未だ吐出シール位置に維持され、計量栓40は該吐出栓30の押込み力を受けて計量シール位置に設定替えされ、吐出栓30が更なる外力によってストローク中間点Dから第2の押込みストローク分だけ押込まれて最大押込みストローク端Eに設定されたときに、該吐出栓30の更なる押込み力を受けたばね部50が撓んで該吐出栓30が吐出可能位置に設定替えされ、計量栓40は未だ計量シール位置に維持され、吐出栓30が外力の消失によるばね部50の撓みの復元力を受けたときに、吐出栓30は最大押込みストローク端Eからストローク中間点Dに復帰せしめられ、吐出栓30は吐出シール位置に設定される。これにより、吐出具100による上述(b)の計量吐出動作の確実を図ることができる。

(d)

(e)吐出具100は、吐出栓30がその栓本体部31における計量栓40寄り端部の周方向複数位置から垂れ下がる複数枚のばね片52からなるばね部50を一体に設け、各ばね片52は、筒状部材10における筒状部11の軸方向で、計量栓40の係合部44を抜け止め可能に抱持するとともに、計量栓40の栓本体部41を上記軸方向に押圧可能にする。これにより、上述(a)のばね部50を簡易に備えることができる。

(e) In the

(f)容器本体201に着脱可能に取付けられるキャップを有する。そして、吐出具100の使用に際し、キャップの容器本体201からの取外しに連動して吐出栓30が引上げ可能にされ、該吐出栓30を容易に最大引上げストローク端Cに設定し、吐出具100を使用開始できる。

(f) has a cap detachably attached to the

本発明の吐出具において、吐出具は吐出栓31に吐出孔32、連通孔33を形成させず、栓本体部31の外周面に外方側環状シール部35を備えないものでも良い。このとき、吐出具100は、上述した吐出実行状態(図7)において、筒状部材10における筒状部11の内側の内容物が吐出経路L経由で栓本体部31の外周まわりから環状をなす吐出形態をなして直に外界に向けて吐出される。

In the discharge tool of the present invention, the

本発明によれば、吐出具において、吐出栓が設けられる筒状部材の小径化を図ることができる。 According to the present invention, it is possible to reduce the diameter of the tubular member on which the discharge plug is provided in the discharge tool.

また、本発明によれば、吐出具において、一定量の内容物を正しく計量して吐出させることができる。 In addition, according to the present invention, it is possible to correctly measure and discharge a fixed amount of contents in the discharge tool.

100 吐出具

200 吐出容器

201 容器本体

202 口部

10 筒状部材

11 筒状部

12 開口部

13 計量空間

20 中栓

22 仕切り壁

23 供給孔

27 嵌合シール部

30 吐出栓

31 栓本体部

32 吐出孔

40 計量栓

41 栓本体部

44 係合部

50 ばね部

52 ばね片

100

Claims (4)

容器本体の口部に取付けられる筒状部を備えるとともに、該筒状部の軸方向に沿う一端に開口部が形成された筒状部材と、

筒状部材における筒状部の軸方向に沿う他端に容器本体の口部を仕切る仕切り壁を備え、容器本体の倒立によって該容器本体の内容物を該筒状部の内側に供給する供給孔が該仕切り壁に形成された中栓と、

筒状部材における筒状部の内側からその開口部を通って外界に露出し、該開口部の内周との間に内容物の吐出経路を形成可能にするとともに、該筒状部の内側から該筒状部の軸方向に沿う一端方向に移動されることにより引上げられて該内容物の吐出経路を閉じる吐出シール位置と、該筒状部の内側に押込まれて該内容物の吐出経路を開く吐出可能位置との間で移動可能にされる吐出栓と、

筒状部材の内側に配置され、吐出栓の移動に連動して移動可能になるように該吐出栓と連結され、中栓の仕切り壁から離間して該仕切り壁の供給孔からの内容物の供給を可能にする計量可能位置と、該仕切り壁に近接して該仕切り壁の供給孔からの内容物の供給を不能にする計量シール位置との間で移動可能にされる計量栓と、

筒状部材の内側で吐出栓と計量栓との間に介装されるばね部を有し、それらの吐出栓、計量栓及びばね部が該筒状部材における筒状部の軸方向に沿って直列配置され、

吐出栓がその栓本体部における計量栓寄り端部の周方向複数位置から垂れ下がる複数枚のばね片からなるばね部を一体に設け、

計量栓がその栓本体部の吐出栓寄り端部に係合部を設け、

各ばね片は、筒状部材における筒状部の軸方向で、計量栓の係合部を抜け止め可能に抱持するとともに、該計量栓の栓本体部を上記軸方向に押圧可能となっており、

前記内容物を吐出する際において、吐出栓の引上げによって、該吐出栓が吐出シール位置に設定されるとともに、計量栓が該吐出栓の引上げ力を受けて計量可能位置に設定されることにより、筒状部材における筒状部の内側に容器本体の内容物が供給可能にされて一定量の内容物が計量可能にされ、

吐出栓の引上げ後、該吐出栓の押込みによって、計量栓が該吐出栓の押込み力を受けて計量シール位置に設定された後、該吐出栓の更なる押込み力を受けたばね部が撓んで該吐出栓が吐出可能位置に設定されることにより、筒状部材における筒状部に計量されていた内容物が吐出可能にされる吐出具。 A discharge tool attached to a container body to measure and discharge the contents thereof,

a tubular member having a tubular portion attached to the mouth portion of the container body and having an opening formed at one end along the axial direction of the tubular portion;

The other end of the tubular member along the axial direction of the tubular portion is provided with a partition wall for partitioning the mouth portion of the container body, and a supply hole for supplying the contents of the container body to the inside of the tubular portion when the container body is inverted. is formed on the partition wall; and

It is exposed to the outside world through the opening from the inside of the tubular portion of the tubular member so that a discharge path for the contents can be formed between the opening and the inner circumference of the opening, and from the inside of the tubular portion. A discharge seal position that closes the discharge path of the contents by being pulled up by being moved in one end direction along the axial direction of the cylindrical part, and a discharge seal position that is pushed into the inside of the cylindrical part to close the discharge path of the contents. a spigot movable between an open spigot position;

It is arranged inside the cylindrical member, is connected to the discharge plug so as to be movable in conjunction with the movement of the discharge plug, and is spaced apart from the partition wall of the inner plug to allow the contents from the supply hole of the partition wall to flow. a metering tap movable between a meterable position that allows dispensing and a metering seal position that is proximate to the partition wall and disables dispensing of contents from the dispensing hole in the partition wall;

A spring portion is interposed between the discharge plug and the metering plug inside the tubular member, and the discharge plug, the metering plug, and the spring section extend along the axial direction of the tubular portion of the tubular member. arranged in series,

The discharge plug is integrally provided with a spring portion composed of a plurality of spring pieces hanging down from a plurality of positions in the circumferential direction of the end of the plug main body near the metering plug,

The metering plug is provided with an engaging portion at an end portion of the plug main body near the discharge plug,

Each spring piece holds the engagement portion of the metering plug in the axial direction of the tubular portion of the tubular member so as to prevent it from slipping out, and is capable of pressing the plug main body of the metering plug in the axial direction. cage,

When the contents are discharged, the discharge plug is pulled up to set the discharge plug to the discharge seal position, and the metering plug receives the lifting force of the discharge plug and is set to the meterable position, The content of the container body can be supplied to the inside of the tubular portion of the tubular member so that a certain amount of the content can be measured,

After the discharge plug is pulled up and pushed in, the metering plug receives the pushing force of the discharge plug and is set at the metering seal position. A discharge tool capable of discharging contents weighed in a cylindrical portion of a cylindrical member by setting the discharge plug to a dischargeable position .

計量栓がその栓本体部を中栓の嵌合シール部に嵌合する嵌合力よりも、ばね部のばね力が大きい請求項1に記載の吐出具。 A fitting seal portion is formed around the supply hole formed in the partition wall by the inner plug, and the metering plug set at the metering seal position fits its plug main body portion into the fitting seal portion to fit the partition wall. configured to disable delivery of contents from the feed hole of the

2. The discharge tool according to claim 1 , wherein the spring force of the spring portion is greater than the fitting force for fitting the body portion of the measuring plug to the fitting seal portion of the inner plug.

吐出栓が最大引上げストローク端にあるときに、該吐出栓は吐出シール位置に設定され、計量栓は計量可能位置に設定され、

吐出栓が外力によって最大引上げストローク端から第1の押込みストローク分だけ押込まれてストローク中間点に設定されたときに、該吐出栓は未だ吐出シール位置に維持され、計量栓は該吐出栓の押込み力を受けて計量シール位置に設定替えされ、

吐出栓が更なる外力によってストローク中間点から第2の押込みストローク分だけ押込まれて最大押込みストローク端に設定されたときに、該吐出栓の更なる押込み力を受けたばね部が撓んで該吐出栓が吐出可能位置に設定替えされ、計量栓は未だ計量シール位置に維持され、

吐出栓が外力の消失によるばね部の撓みの復元力を受けたときに、該吐出栓は最大押込みストローク端からストローク中間点に復帰せしめられ、該吐出栓は吐出シール位置に設定される請求項1又は2に記載の吐出具。 said outlet plug is movable between a maximum pull-up stroke end and a maximum push-in stroke end;

when the discharge tap is at the end of the maximum withdrawal stroke, the discharge tap is set in the discharge seal position and the metering tap is set in the meterable position;

When the discharge plug is pushed by the first push stroke from the end of the maximum lifting stroke by an external force and set to the stroke midpoint, the discharge plug is still maintained at the discharge sealing position, and the metering plug is pushed in. It is set to the weighing seal position by receiving force,

When the discharge plug is pushed by a second pushing stroke from the stroke midpoint by a further external force and set at the maximum pushing stroke end, the spring portion receiving the further pushing force of the discharge plug bends to close the discharge plug. is set to the dischargeable position, the metering plug is still maintained in the metering seal position,

When the discharge plug receives the restoring force of the deflection of the spring portion due to the disappearance of the external force, the discharge plug is returned from the end of the maximum pushing stroke to the midpoint of the stroke, and the discharge plug is set at the discharge sealing position. 3. The discharge tool according to 1 or 2 .

吐出栓は、キャップの容器本体からの取外しに連動して引上げられる請求項1乃至3のいずれかに記載の吐出具。 Having a cap detachably attached to the container body,

4. The discharge tool according to any one of claims 1 to 3, wherein the discharge plug is lifted in conjunction with removal of the cap from the container body.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018082608A JP7154033B2 (en) | 2018-04-23 | 2018-04-23 | discharge tool |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018082608A JP7154033B2 (en) | 2018-04-23 | 2018-04-23 | discharge tool |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019189266A JP2019189266A (en) | 2019-10-31 |

| JP7154033B2 true JP7154033B2 (en) | 2022-10-17 |

Family

ID=68389022

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018082608A Active JP7154033B2 (en) | 2018-04-23 | 2018-04-23 | discharge tool |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP7154033B2 (en) |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007008551A (en) | 2005-06-30 | 2007-01-18 | Yoshino Kogyosho Co Ltd | Quantitative coating container |

| JP2009292507A (en) | 2008-06-05 | 2009-12-17 | Hoyu Co Ltd | Dispensing container |

| JP2013067436A (en) | 2013-01-25 | 2013-04-18 | Taisho Pharmaceutical Co Ltd | Measurement spout container |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4739227Y1 (en) * | 1969-09-26 | 1972-11-28 | ||

| JPS5130147Y2 (en) * | 1972-02-10 | 1976-07-29 | ||

| JPH1018675A (en) * | 1996-06-28 | 1998-01-20 | Tadao Takagi | Pivot shaft for revolving door |

-

2018

- 2018-04-23 JP JP2018082608A patent/JP7154033B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007008551A (en) | 2005-06-30 | 2007-01-18 | Yoshino Kogyosho Co Ltd | Quantitative coating container |

| JP2009292507A (en) | 2008-06-05 | 2009-12-17 | Hoyu Co Ltd | Dispensing container |

| JP2013067436A (en) | 2013-01-25 | 2013-04-18 | Taisho Pharmaceutical Co Ltd | Measurement spout container |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019189266A (en) | 2019-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3313249B1 (en) | Measured dose dispenser | |

| JP6076863B2 (en) | Weighing container | |

| KR101635810B1 (en) | Cosmetic vessel having mixed two-type materials | |

| JP6496655B2 (en) | Metering dispensing container | |

| TW201446615A (en) | Metered dose squeeze dispenser | |

| JP2006036317A (en) | Metering dispenser | |

| JP2010260581A (en) | Metering and applying plug | |

| MX2011001336A (en) | Closure device comprising a measuring cap, intended to be connected to a flexible container. | |

| KR100569770B1 (en) | Constant-volume dispensing coating container | |

| JP7033683B2 (en) | Fixed-quantity discharge container | |

| JP7154033B2 (en) | discharge tool | |

| JP6639322B2 (en) | Metering container | |

| JP6053120B2 (en) | Metered discharge container | |

| JP6679168B2 (en) | Fixed volume dispensing container | |

| JP6679167B2 (en) | Fixed volume dispensing container | |

| JP2011046438A (en) | Measuring spout device and measuring spout container including the same | |

| JP2008074459A (en) | Constant volume application container | |

| JP6215117B2 (en) | Double container | |

| JP7355530B2 (en) | Pour spout, container with spout | |

| JP6482300B2 (en) | Application container | |

| JP5707300B2 (en) | Metering dispenser | |

| JP6671734B2 (en) | Metering dispensing application container | |

| JP2017074958A (en) | Measurement cap | |

| JP6295174B2 (en) | Metering dispenser | |

| JP2005212851A (en) | Container for quantitative coating |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20210302 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20220107 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20220125 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20220310 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20220512 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20220913 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20221004 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 7154033 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |