JP5635205B1 - Structural member - Google Patents

Structural member Download PDFInfo

- Publication number

- JP5635205B1 JP5635205B1 JP2014047972A JP2014047972A JP5635205B1 JP 5635205 B1 JP5635205 B1 JP 5635205B1 JP 2014047972 A JP2014047972 A JP 2014047972A JP 2014047972 A JP2014047972 A JP 2014047972A JP 5635205 B1 JP5635205 B1 JP 5635205B1

- Authority

- JP

- Japan

- Prior art keywords

- structural member

- members

- bent

- section

- plate material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 claims abstract description 15

- 238000005452 bending Methods 0.000 claims abstract description 10

- 238000003466 welding Methods 0.000 claims description 2

- 238000004519 manufacturing process Methods 0.000 abstract description 3

- 238000005304 joining Methods 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 3

- 239000011810 insulating material Substances 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 239000011358 absorbing material Substances 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 2

- 230000003449 preventive effect Effects 0.000 description 2

- 229910001335 Galvanized steel Inorganic materials 0.000 description 1

- 125000002066 L-histidyl group Chemical group [H]N1C([H])=NC(C([H])([H])[C@](C(=O)[*])([H])N([H])[H])=C1[H] 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000004794 expanded polystyrene Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000008397 galvanized steel Substances 0.000 description 1

- 238000005246 galvanizing Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 1

- 229920006327 polystyrene foam Polymers 0.000 description 1

- 238000010079 rubber tapping Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Rod-Shaped Construction Members (AREA)

Abstract

【課題】部材の接合を容易にすると共に製造コストを低減し、側縁によって怪我をしたり、他部材に引っかき傷が形成されないようにする。【解決手段】細長い板材の短辺を折り曲げ加工して凹凸断面に形成した構造部材100であって、板材の両側部の先端を内側に180度折り曲げて板材面に接触させた折り曲げ縁部301が形成してあり、板材の短辺を長さ方向に平行に延びた第1〜第6の折り曲げ線101、102...106で90度折り曲げて凹凸断面に形成してあり、中央部の溝の開口方向が両脇の溝とは逆向きである。また、折り曲げ縁部301を先端に有する両側部には、折り曲げ縁部301の厚みに等しい窪み60が設けてあり、窪み60の底部には部材連結用穴61が形成してある構造部材である。【選択図】図1The present invention makes it easy to join members and reduce manufacturing costs, and prevents side edges from being injured and other members from being scratched. A structural member 100 is formed by bending a short side of an elongated plate material to form a concavo-convex cross section, and a bent edge 301 is formed by bending the front ends of both sides of the plate material 180 degrees inward and contacting the plate material surface. It is formed and formed into a concavo-convex cross-section by bending 90 degrees with first to sixth fold lines 101, 102, ... 106 extending in parallel in the length direction at the short side of the plate material, The opening direction of is opposite to the grooves on both sides. In addition, in both side portions having the bent edge portion 301 at the tip, a recess 60 equal to the thickness of the bent edge portion 301 is provided, and a member connecting hole 61 is formed in the bottom portion of the recess 60. . [Selection] Figure 1

Description

本発明は、太陽光パネルの設置用の架台等を構成する構造部材に関する。 The present invention relates to a structural member constituting a mount for installing a solar panel.

一般的な太陽光パネルの架台用の部材は鋼製であり、製造が簡単で組み立てが容易な構造のものである。また、荷重及び地震などにも耐えられるように構造的に堅固であることが求められる。 A member for a general solar panel is made of steel, and has a structure that is easy to manufacture and easy to assemble. In addition, it is required to be structurally robust so that it can withstand loads and earthquakes.

架台用等の構造部材の従来技術は、特許文献1(特開昭51−10626号公報)及び特許文献2(大韓民国登録特許第10−0634895号公報)に開示されている。

従来の架台用構造部材は、凹凸断面の構造要素を対向配置したものである。構造要素は、板材をほぼ直角に折り曲げて凹凸に形成してあり、凸部に隣接して凹部、続いて凸部と凹凸に形成されており、長さ方向に実質的に均一断面である。

Prior arts of structural members for a pedestal or the like are disclosed in Patent Document 1 (Japanese Patent Laid-Open No. 51-10626) and Patent Document 2 (Korean Registered Patent No. 10-0634895).

A conventional structural member for a gantry is a structure in which structural elements having a concavo-convex cross section are arranged to face each other. The structural element is formed in a concavo-convex shape by bending a plate material substantially at a right angle, is formed in a concave portion adjacent to the convex portion, and subsequently in the convex portion and the concave portion, and has a substantially uniform cross section in the length direction.

この構造要素を逆向きにして間隔をあけて対向配置し、一対の構造要素を溝形鋼によって接合してH型の閉じた空間を有する構造部材が形成される。この閉じた空間内には必要に応じて空間とほぼ同じ形状の充填部材が充填される。充填材としては、発泡スチロール等の断熱材、または遮音材や吸音材が挙げられる。

構造要素と溝型鋼は、リベット、ボールねじ、タッピングねじ、スクリュー釘またはボルト等の接合具、または溶接によって接合されて一体化されている。

The structural elements are arranged opposite to each other with a gap therebetween, and a pair of structural elements are joined by groove steel to form a structural member having an H-shaped closed space. The closed space is filled with a filling member having substantially the same shape as the space as necessary. Examples of the filler include a heat insulating material such as polystyrene foam, or a sound insulating material and a sound absorbing material.

The structural element and the channel steel are joined and integrated by a rivet, a ball screw, a tapping screw, a joint such as a screw nail or a bolt, or welding.

従来の構造部材の板材の厚さが2〜3mm程度で鋭利であり、組み立て接合時に側縁が他の構造要素の表面を引っかき、構造部材の亜鉛メッキ層がはがれるという問題がある。また、ソーラーパネルの架台は屋外に設置され風雨に曝されるため、側縁から腐食が始まりやすく、寿命が短くなるという問題がある。

本発明はこれらの点の解消を目的とするもので、部材の組み立て接合を容易にし、構造体の製造費用を低減するものである。また、本発明の他の目的は、構造部材の側縁が組み立て接合時に他部材を傷つけないようにするものである。

There is a problem that the thickness of the plate member of the conventional structural member is sharp at about 2 to 3 mm, and the side edges scratch the surface of other structural elements at the time of assembling and joining, and the galvanized layer of the structural member is peeled off. In addition, since the solar panel mount is installed outdoors and exposed to wind and rain, there is a problem that corrosion tends to start from the side edge and the life is shortened.

The present invention aims to eliminate these points, and facilitates the assembly and joining of members and reduces the manufacturing cost of the structure. Another object of the present invention is to prevent the side edges of the structural members from damaging other members during assembly joining.

細長い板材の短辺を折り曲げ加工して凹凸断面に形成したものであって、板材の両側部の先端を内側に180度折り曲げて板材面に接触させた折り曲げ縁部が形成してあり、板材の短辺を溝型に折り曲げて凹凸断面に形成してあり、中央部の溝が両脇とは逆向きの溝である構造部材である。

また、折り曲げ縁部を先端に有する両側部には、折り曲げ縁部厚みに等しい窪みが設けてあり、窪み内に部材連結用穴が形成してある構造部材である。

It is formed by bending the short side of an elongated plate material to form a concavo-convex cross section, and a bent edge is formed by bending the tip of both sides of the plate material 180 degrees inward and contacting the plate material surface. It is a structural member in which a short side is bent into a groove shape to form a concavo-convex cross section, and a central groove is a groove opposite to both sides.

In addition, a dent equal to the fold edge thickness is provided on both side portions having a fold edge at the tip, and a member connecting hole is formed in the dent.

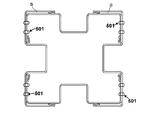

また、この構造部材4個を外側面とした閉断面部材であり、構造部材が断面四角形の4辺となるように組み立て、各部材の接合面を接合具で固定してある閉断面構造材である。 Moreover, it is a closed cross-section member with the four structural members as outer surfaces, and is a closed cross-section structural material in which the structural members are assembled so as to have four sides of a quadrangular cross-section, and the joint surfaces of each member are fixed with a joint tool. is there.

本発明の構造部材は、部材同士の接合組み立てが容易で耐久性が高く構築費用の節減効果がある。また、構造部材の接合組み立て時に部材の縁が折り曲げ縁部に形成してあるため他の部材を縁で引っかいて亜鉛メッキなどの防錆層を傷つけることがないので、傷から腐食が広がることがなく、外気に曝露された状態で使用した場合の寿命を延長することができる。また、部材の組み立て時に作業員の手などを縁で傷つけることもないので、組み立て作業を円滑に効率よく行うことができる。

また、本発明の構造部材は、接合用の穴が窪み内に設けてあるため、接合面側に先端折り曲げ縁部がある場合でもボルトやリベットなどの接合具によって部材面を密着させて接合固定することができるので、接合強度を高めることができる。

The structural member of the present invention is easy to join and assemble between members, has high durability, and has an effect of reducing construction costs. In addition, since the edge of the member is formed at the bent edge at the time of assembling the structural member, other members are not scratched by the edge and the rust preventive layer such as galvanizing is not damaged, so that corrosion spreads from the scratch. In addition, it is possible to extend the life when used in a state exposed to the outside air. Further, since the operator's hand and the like are not damaged by the edges when assembling the members, the assembling work can be performed smoothly and efficiently.

In addition, since the structural member of the present invention has a hole for joining in the recess, even if there is a bent end edge on the joint surface side, the member surface is brought into close contact with a joint such as a bolt or a rivet and fixed. Thus, the bonding strength can be increased.

図1は、本発明の構造部材100の実施例1の断面図であり、図2はその斜視図である。

亜鉛メッキ鋼板の細長い板材の両側縁が内側に180度折り曲げて先端が板材の内面に接触させて縁を丸めた折り曲げ縁部301が形成してある。

板材の縁の先端を板材に接触させてあるので、構造部材100の縁が鋭利とならず、構造部材の取り扱い時に作業員が手を傷つけたり、組み立て接合時に他の部材を引っかいて亜鉛メッキなどの防錆層に引っかき傷をつけたりすることが防止される。

板材を長手方向に延びる実質的に平行な第1折り曲げ部101、第2折り曲げ部102、第3折り曲げ部103、第4折り曲げ部104、第5折り曲げ部105及び第6折り曲げ部106において、ほぼ90度折り曲げてあり、これらの6つの折り曲げ部により第1板部201、第2板部202、第3板部203、第4板部204、第5板部205、第6板部206及び第7板部207が形成され、断面凹凸形状である。中央部の溝の開口方向は両脇の溝とは開口が反対向きとなっている。

中央部の溝の高さh2は両脇の溝の高さh1より5〜15mm程度小さくしてあり、材料を節約してコスト低減を図ることができる。

FIG. 1 is a cross-sectional view of Embodiment 1 of the

A

Since the edge of the edge of the plate material is in contact with the plate material, the edge of the

In the

The height h 2 of the groove in the central portion is Yes to about 5~15mm smaller than the height h 1 of the both sides of the groove, the cost can be reduced to save material.

図3は、本発明の実施例1の部材を組み合わせた中空の閉断面の組み立て部材400の斜視図であり、図4はその断面図である。組み立て部材400は、実施例1の構造部材100を間隔をあけて上下と左右に反対向きに配置して組み立て、各辺の中央部に溝410、420、430、440を有する四角形の閉断面部材としたものである。各部材同士が接触する部分には複数のリベット穴503が形成され、リベット501によって接合されて一体化されている。

組み立て部材400の内部には、発泡ポリスチレンなどの断熱材または吸音材を必要に応じて充填することも可能である。

FIG. 3 is a perspective view of an

The

折り曲げ縁部301が他の部材に接触する箇所においては折り曲げ縁部の厚みの分だけ空隙Sが生じ、この空隙Sの部分で部材同士を接合しても充分な接合力が得られないため、部材が一体として負荷に対して抵抗できない恐れがある。

そこで、図5に示すように、折り曲げ縁部301を有する第1板部と第7板部のほぼ中間部に折り曲げ縁部301の厚みに等しい窪み60を形成してある。窪み60は円形で底部は平面に形成してあり、底部中央にはリベットやボルトなどの接合具のための接合用穴61が形成してある。

この、窪み60を有する構造部材100を組み立てて四角形の閉断面組み立て部材とした例を図6に示す。

図4の例では折り曲げ縁部301の厚みによって空隙Sが存在したが、窪み60の深さを折り曲げ縁部の301の厚さに等しくしてあるので窪み60の底面が隣接する部材に接触し、更に接続穴61を利用してリベットやボルトなどの接合具501によって接合するため、構造部材100同士の接合が強固となり、耐荷重を増大させることができる。

図7は、構造部材100に他の構造部材100を接合する場合の断面図であり、窪み60の底面が接合する他の構造部材100に密着してボルト等の接合具で接合されており、部材同士の接合が強固となる。

Since the gap S is generated by the thickness of the bent edge at the place where the

Therefore, as shown in FIG. 5, a

FIG. 6 shows an example in which the

In the example of FIG. 4, the gap S exists depending on the thickness of the

FIG. 7 is a cross-sectional view of the case where another

本発明の構造部材100の変形例を図8及び図9に示す。

図8は、構造部材の中央部の四角形の溝の底面71の折り曲げ部を円弧状70に折り曲げて曲線状にしたものであり、図9に示す例は、溝断面を概略半円形72として円形溝としたものである。

円弧状の断面とすることによって四角形断面の溝のように折り曲げ部に応力集中が生じないので強度が増大する。

The modification of the

FIG. 8 shows a bent portion of the

By making the arc-shaped cross section, stress is not concentrated in the bent portion like the groove of the square cross section, so that the strength is increased.

100 構造部材

101〜106 第1折り曲げ部〜第6折り曲げ部

201〜207 第1板部〜第7板部

301 折り曲げ縁部

400 組み立て部材

501 リベット(接合具)

503 リベット穴

60 窪み

61 接合用穴

100 structural members

101-106 1st bending part-6th bending part 201-207 1st board part-

503

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014047972A JP5635205B1 (en) | 2014-03-11 | 2014-03-11 | Structural member |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014047972A JP5635205B1 (en) | 2014-03-11 | 2014-03-11 | Structural member |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP5635205B1 true JP5635205B1 (en) | 2014-12-03 |

| JP2015172287A JP2015172287A (en) | 2015-10-01 |

Family

ID=52139050

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014047972A Active JP5635205B1 (en) | 2014-03-11 | 2014-03-11 | Structural member |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5635205B1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109972787A (en) * | 2019-04-18 | 2019-07-05 | 安钢集团华德重工装备有限公司 | The high-strength building crossbeam of one kind and its preparation facilities |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07293959A (en) * | 1994-04-25 | 1995-11-10 | Fuji Kogyo Kk | Reinforcing structure of corner for range hood fan |

| JPH1030302A (en) * | 1996-07-17 | 1998-02-03 | Arthur Donaldson Ronald | Wall framework member, wall framework system making use thereof and assembly method of the system |

| JP2006274751A (en) * | 2005-03-30 | 2006-10-12 | Nippon Steel Corp | Brace member with shell member formed by assembling channel metal member |

| JP3898417B2 (en) * | 2000-04-12 | 2007-03-28 | 株式会社シーデーエスニュースチールホームズインターナショナル | Steel frame construction and frame articulated body |

| JP4425144B2 (en) * | 2002-12-03 | 2010-03-03 | ヘンリー テクノロジー リミテッド | Structural building elements |

| JP2013227848A (en) * | 2012-03-30 | 2013-11-07 | Joto Techno Co Ltd | Water drip for bend |

-

2014

- 2014-03-11 JP JP2014047972A patent/JP5635205B1/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07293959A (en) * | 1994-04-25 | 1995-11-10 | Fuji Kogyo Kk | Reinforcing structure of corner for range hood fan |

| JPH1030302A (en) * | 1996-07-17 | 1998-02-03 | Arthur Donaldson Ronald | Wall framework member, wall framework system making use thereof and assembly method of the system |

| JP3898417B2 (en) * | 2000-04-12 | 2007-03-28 | 株式会社シーデーエスニュースチールホームズインターナショナル | Steel frame construction and frame articulated body |

| JP4425144B2 (en) * | 2002-12-03 | 2010-03-03 | ヘンリー テクノロジー リミテッド | Structural building elements |

| JP2006274751A (en) * | 2005-03-30 | 2006-10-12 | Nippon Steel Corp | Brace member with shell member formed by assembling channel metal member |

| JP2013227848A (en) * | 2012-03-30 | 2013-11-07 | Joto Techno Co Ltd | Water drip for bend |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109972787A (en) * | 2019-04-18 | 2019-07-05 | 安钢集团华德重工装备有限公司 | The high-strength building crossbeam of one kind and its preparation facilities |

| CN109972787B (en) * | 2019-04-18 | 2023-08-01 | 安阳融达实业有限公司 | High-strength building beam and preparation device thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015172287A (en) | 2015-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5946199B2 (en) | Steel house structural members | |

| JP4938512B2 (en) | Base metal fittings and outer wall construction structure | |

| US8769908B1 (en) | Modular building panel | |

| KR101554608B1 (en) | Frame of Structure such as Steel House | |

| JP6306762B1 (en) | Light steel building structure | |

| JP5635205B1 (en) | Structural member | |

| JP6612552B2 (en) | Fireproof pillar and load bearing wall provided with the same | |

| JP6205964B2 (en) | Friction joint structure of high strength bolt | |

| JP4625528B2 (en) | Building unit structural member and floor structure using the unit structural member | |

| JP6117876B2 (en) | Insulating material holder | |

| US20230079662A1 (en) | Connecting metal | |

| JP5646102B1 (en) | Structural member for installation stand for solar panels | |

| KR101474747B1 (en) | Frame od Structure such as Steel House | |

| JP4155895B2 (en) | Lattice panel and building construction method and building | |

| JP6725126B2 (en) | Exterior louver mounting structure | |

| JP6792338B2 (en) | Wood structural material reinforcement structure | |

| JP6626640B2 (en) | Construction method of base structure and base material for joining used therefor | |

| JP6902738B2 (en) | Joining hardware and joining structure using this | |

| JP3211790U (en) | Structural reinforcement | |

| JP3927931B2 (en) | Wood corner fixing bracket | |

| JP4469300B2 (en) | Bonded hardware | |

| JP6552920B2 (en) | Panel connection structure of slope body | |

| JP5628546B2 (en) | Surface material mounting structure | |

| CN210562677U (en) | Novel aluminum alloy section plate unit with plug connector | |

| KR101147554B1 (en) | Fastener for fixing woods |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140820 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20141007 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20141015 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5635205 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |