JP4573557B2 - Case for two-component reactive adhesive - Google Patents

Case for two-component reactive adhesive Download PDFInfo

- Publication number

- JP4573557B2 JP4573557B2 JP2004108612A JP2004108612A JP4573557B2 JP 4573557 B2 JP4573557 B2 JP 4573557B2 JP 2004108612 A JP2004108612 A JP 2004108612A JP 2004108612 A JP2004108612 A JP 2004108612A JP 4573557 B2 JP4573557 B2 JP 4573557B2

- Authority

- JP

- Japan

- Prior art keywords

- case

- adhesive

- cylinder

- component reactive

- piston

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Package Specialized In Special Use (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Tubes (AREA)

Description

本発明は、2液性反応型接着剤用ケースに関し、更に詳しくは、包袋状のフィルムに充填された2液性反応型の接着剤を装填して、繰り返し使用する2液性反応型接着剤用ケースに関するものである。 The present invention relates to a case for a two-component reactive adhesive, and more specifically, a two-component reactive adhesive that is repeatedly used by loading a two-component reactive adhesive filled in a bag-like film. It is related with the case for medicine.

従来より、接着剤として多種にわたる有機系物質や無機系物質が使用されており、製品形態も使用後の廃棄物量の削減や環境への配慮のために、複合フィルムより成るフォイルパックや金属製の折り畳み可能なチューブ等が使用されている。このような可とう性を有する貯蔵形態の接着剤は、場合によっては、専用のケースに装填して、コーキングガン等のディスペンサーによって接着剤を吐出し、使用されている。 Conventionally, a wide variety of organic and inorganic materials have been used as adhesives, and the product form is also made of foil packs made of composite film or metal to reduce the amount of waste after use and to give consideration to the environment. A foldable tube or the like is used. In some cases, such a storage-type adhesive having flexibility is loaded in a special case and discharged by a dispenser such as a caulking gun.

2液性反応型の接着剤に関しても、特開昭63-232830号公報(特許文献1)に記載のように、2成分、即ち、主剤と硬化剤を所定の容量比で貯蔵し、使用時には主剤と硬化剤を吐出せしめ、混合させるためのフォイルパックやケース、ディスペンサー、吐出口に取り付けるスタティックミキサー等が既に実用化されている。 As for a two-component reactive adhesive, as described in JP-A-63-232830 (Patent Document 1), two components, that is, a main agent and a curing agent are stored at a predetermined volume ratio, and when used, Foil packs, cases, dispensers, static mixers attached to discharge ports, etc. for discharging and mixing the main agent and curing agent have already been put into practical use.

特に、建築、土木関係の用途に関しては、従来の2液性の接着剤を予め混合、撹拌することなく、人体への付着や接触等による悪影響を低減化出来るものとして、注目されている。 In particular, for applications related to construction and civil engineering, it has been attracting attention because it can reduce adverse effects due to adhesion and contact with the human body without mixing and stirring a conventional two-component adhesive in advance.

この2液性反応型用のフォイルパックやケースは、主剤と硬化剤を分離した状態で貯蔵、輸送される。接着剤の使用時にはディスペンサーのプランジャーが、ケースに装填されたピストンを押すことにより、2液をそれぞれ吐出口まで独立、分離した状態で押し出し、スタティックミキサーにて均一に混合することによって硬化反応が起きる。 The foil pack and case for the two-component reaction type are stored and transported with the main agent and the curing agent separated. When the adhesive is used, the plunger of the dispenser pushes the piston loaded in the case to extrude the two liquids to the discharge port independently and separately, and mixes them uniformly with a static mixer. Get up.

接着剤の種類としては、有機系としてエポキシ樹脂やビニルエステル樹脂、シリコン変性樹脂、ウレタン変性樹脂、フェノール樹脂、メラミン樹脂、ユリア樹脂、キシレン樹脂、アルキッド樹脂、不飽和ポリエステル樹脂、アクリル樹脂、ポリイミド樹脂、フラン樹脂、シアノアクリレート樹脂等があり、無機系としてはセメントモルタル、モルタル、エポキシモルタル等があり、それぞれ被着体の種類や用途によって使い分けられている。 Types of adhesives include organic epoxy resins, vinyl ester resins, silicon modified resins, urethane modified resins, phenol resins, melamine resins, urea resins, xylene resins, alkyd resins, unsaturated polyester resins, acrylic resins, polyimide resins. Furan resin, cyanoacrylate resin, and the like, and inorganic types include cement mortar, mortar, epoxy mortar, and the like, which are properly used depending on the type and application of the adherend.

更に、実開平5-80563号公報(特許文献2)に記載のディスペンサーは、1液性と2液性のケースを兼用出来るという特長がある。 Furthermore, the dispenser described in Japanese Utility Model Laid-Open No. 5-80563 (Patent Document 2) has a feature that it can be used as both a one-component and two-component case.

しかしながら、前述の従来例において、特許文献1の技術では、2液性反応型の接着剤は、種類によって主剤や硬化剤の混合比が異なるため、それぞれの混合比に対応した容量比の異なるフォイルパックやケース、ディスペンサーを使用しなければならず、汎用性に欠け、接着剤の種類ごとにそれぞれに特殊なケースや高価なディスペンサーを用意しなければならないという実用上の欠点があった。

However, in the above-described conventional example, in the technique of

また、接着剤の種類が異なっていても、接着剤の内容成分を調整することで、混合比を統一させるという実例もあるが、応用範囲に乏しく、本来の接着力や硬化物の強度に悪影響を及ぼすという問題があった。 In addition, even if the type of adhesive is different, there is an example in which the mixing ratio is unified by adjusting the content of the adhesive, but the application range is poor, and the original adhesive strength and the strength of the cured product are adversely affected. There was a problem of affecting.

また、特許文献2の技術では、2液性のケースにおいては、押し出しのロッド、即ちプランジャーのロッド間隔が固定されており、容量比の違いに対応出来ず、且つ繰り返し使用出来ないという問題があった。そのため、2液性反応型接着剤の機能を保持したままで、混合比、即ち容量比の違いへの対応が容易であり、汎用性に長け、簡便且つ繰り返し使用可能なケースの出現が切に望まれていた。

Moreover, in the technique of

本発明は前記課題を解決するものであり、その目的とするところは、2液性反応型の接着剤において、容量比の異なるフォイルパックやケースであっても、それぞれに専用のディスペンサーを用意する必要がなく、きわめて汎用的であり、簡便なディスペンサーのみで吐出、混合が出来、且つ繰り返し使用出来る2液性反応型接着剤用ケースを提供せんとするものである。 The present invention solves the above-mentioned problems, and an object of the present invention is to prepare a dedicated dispenser for each of two-pack type reactive adhesives even in foil packs and cases having different volume ratios. It is not necessary, and is intended to provide a two-component reactive adhesive case that is extremely versatile, can be discharged and mixed with only a simple dispenser, and can be used repeatedly.

前記目的を達成するための本発明に係る2液性反応型接着剤用ケースは、異なる2種類の接着剤がそれぞれ断面円形状の包袋に充填され、これら2つの包袋を2個の実質的に中空で断面円形状のシリンダーに装填して用いる2液性反応型接着剤用ケースにおいて、前記2個のシリンダーのそれぞれの内周面に複数の凹条が該シリンダーの軸方向に設けられると共に、該互いのシリンダー近傍部で該シリンダーの軸方向に該互いのシリンダー内を連通させる線条の隙間が設けられており、それぞれの包袋を押し潰し該包袋内に収容された接着剤を吐出させるための断面円形状の2つのピストンが、該隙間を介して共に連結されると共に、該ピストンのそれぞれの外周面に前記シリンダーのそれぞれの内周面に設けられた複数の凹条に摺動自在に係合し得る複数の凸条が該ピストンの軸方向に設けられており、一方のピストンを押すことにより、他方のピストンが連動して前記シリンダー内を摺動することを特徴とする。 In order to achieve the above object, the two-component reactive adhesive case according to the present invention is filled with two different types of adhesives in a circular cross-sectional wrapping bag. In a case for a two-component reactive adhesive case that is used by being loaded into a hollow cylinder having a circular cross section , a plurality of concave stripes are provided in the axial direction of each of the two cylinders. In addition, a gap between the cylinders is provided in the vicinity of each cylinder in the axial direction of the cylinder so that the inside of the cylinder communicates with each other. circular cross section of the two pistons for ejecting is, linked together via the gap Rutotomoni, the plurality of concave stripes provided in each of the inner circumferential surface of the cylinder, each of the outer peripheral surface of the piston Slidable A plurality of ridges may engage is provided in the axial direction of the piston, by pressing one of the piston, in conjunction the other piston, characterized in that slides within the cylinder.

また、前記線条の隙間の幅が0.1mm以上、且つ3mm以下であることを特徴とする。 The width of the gap between the filaments is 0.1 mm or more and 3 mm or less.

また、前記ピストンが概略円筒状であり、該ピストンの長さと直径との比が0.5以上、且つ2以下であることを特徴とする。 The piston is substantially cylindrical, and the ratio of the length and the diameter of the piston is 0.5 or more and 2 or less.

本発明は、上述の如き構成と作用とを有するので、混合比の異なる接着剤ごとに、それぞれ専用の高価なディスペンサーを用意する必要がなく、しかも繰り返し使用出来るため、経済的に大きなコストダウンが図れる。また、1つのディスペンサーのみで1液性の接着剤や2液性の接着剤が使用出来る。 Since the present invention has the above-described configuration and operation, it is not necessary to prepare a dedicated expensive dispenser for each adhesive having a different mixing ratio, and can be used repeatedly. I can plan. In addition, a one-part adhesive or a two-part adhesive can be used with only one dispenser.

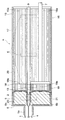

図により本発明に係る2液性反応型接着剤用ケースの一実施形態を具体的に説明する。図1は本発明に係る2液性反応型接着剤ケースに接着剤が充填された包袋をセットした様子を示す全体の断面図、図2は図1の状態から、市販の1液性コーキングガンによって包袋を押し潰した後の全体の断面図、図3は本発明に係る2液性反応型接着剤用ケースの吐出口を示す側面からの断面図、図4は本発明に係る2液性反応型接着剤用ケースの吐出口に接着剤が充填された包袋を密着させた側面からの断面図である。 An embodiment of the case for a two-component reactive adhesive according to the present invention will be specifically described with reference to the drawings. FIG. 1 is an overall cross-sectional view showing a state in which a wrapping bag filled with an adhesive is set in a two-component reactive adhesive case according to the present invention, and FIG. 2 is a commercially available one-component coking from the state of FIG. FIG. 3 is a sectional view from the side showing a discharge port of a two-component reactive adhesive case according to the present invention, and FIG. 4 is a sectional view according to the present invention. It is sectional drawing from the side surface which made the adhesive bag filled the adhesive bag closely_contact | adhere to the discharge outlet of the case for liquid reaction type adhesive agents.

また、図5は本発明に係る2液性反応型接着剤用ケースの吐出口の吐出側から見た正面図、図6は本発明に係る2液性反応型接着剤ケースのシリンダーとピストンを示す斜視説明図、図7は本発明に係る2液性反応型接着剤用ケースのシリンダーを側面から見た断面図、図8は本発明に係る2液性反応型接着剤ケースのシリンダーを正面から見た断面図、図9は本発明に係る2液性反応型接着剤ケースに装填する互いに連結した2つのピストンを側面から見た断面図、図10は本発明に係る2液性反応型接着剤ケースに装填する互いに連結した2つのピストンを吐出方向から見た正面図である。 FIG. 5 is a front view of the two-component reactive adhesive case according to the present invention as seen from the discharge side, and FIG. 6 shows the cylinder and piston of the two-component reactive adhesive case according to the present invention. FIG. 7 is a cross-sectional view of the cylinder of the two-component reactive adhesive case according to the present invention as viewed from the side, and FIG. 8 is a front view of the cylinder of the two-component reactive adhesive case according to the present invention. FIG. 9 is a sectional view of two pistons connected to each other to be loaded in a two-component reactive adhesive case according to the present invention, and FIG. 10 is a sectional view of the two-component reactive type according to the present invention. It is the front view which looked at two pistons mutually connected with which it loads in an adhesive agent case from the discharge direction.

本発明における2液性反応型接着剤用ケースAは、図1、図2、図6及び図7に示すように、大小径の異なる2個の実質的に中空のシリンダー15,16がその軸方向が互いに平行になるように一体的に並設され、全体が断面8の字形状に形成されたシリンダー部材17を有しており、シリンダー15,16はリブ状の補強板6により補強されている。またシリンダー部材17の2個のシリンダー15,16の近傍部の長手方向には線条の隙間9が形成されている。線条の隙間9の幅は0.1mm以上、且つ3mm以下に設定される。

As shown in FIGS. 1, 2, 6 and 7, the two-component reactive adhesive case A in the present invention has two substantially

シリンダー部材17の各シリンダー15,16の内部には、該シリンダー15,16内で往復移動が可能なピストン18,19がその軸方向が平行になるように連結部13に連結されている(図9及び図10参照)。ピストン18,19は概略円筒状であり、該ピストン18,19の長さと直径との比は0.5以上、且つ2以下に設定されている。

Inside the

シリンダー15,16の内周面にはその軸方向に線条で複数の凹条15a,16aが形成されており、ピストン18,19の外周面にはその軸方向に線条で前記凹条15a,16aに摺動自在に係合する複数の凸条18a,19aが形成されている。

A plurality of

そして、ピストン18,19の凸条18a,19aをシリンダー15,16の凹条15a,16aに係合すると共に連結部13を隙間9に挿通させることで、ピストン18,19がシリンダー15,16内で往復移動出来るように構成される。そして、図1及び図2に示すように、隙間9を介して共に連結された2つのピストン18,19の一方をプランジャー7により押すことにより他方が連動して各シリンダー15,16内を摺動することが出来る。

Then, the

シリンダー部材17の先端部には各シリンダー15,16内に装填された異なる2種類の接着剤を混合して吐出するための図示しないノズルを装着するためのノズルキャップ8が着脱可能に装着されている。

A

ノズルキャップ8とシリンダー15,16の先端嵌合部とは着脱可能なように、例えばノズルキャップ8をシリンダー15,16の先端円周内部に嵌め込むような形式を取っても良いし、ノズルキャップ8とシリンダー15,16の先端嵌合部を互いに凹凸の形状として結合させる方式でも構わない。この際、容易にお互いが脱落しないように、かつ着脱が容易なように摩擦抵抗を持たせることが重要である。

For example, the

シリンダー部材17内に接着剤を充填した包袋20,21を装填する場合には、図1に示すようにプランジャー7を引いてピストン18,19をシリンダー部材17の後端部まで後退させた状態でノズルキャップ8をシリンダー部材17から脱離し、図3及び図4に示すように、ノズルキャップ8の各隔室8a,8bに各包袋20,21の先端部を装着した状態で該包袋20,21の後端部をシリンダー15,16内に装填し、ノズルキャップ8をシリンダー部材17に装着する。

When loading the

ピストン18,19の包袋20,21側には、図9及び図10に示すように各包袋20,21の後端部を押すためのパラボラ状の円盤からなる押当部材18b,19bが設けられており、該押当部材18b,19bには放射状に溝18b1,19b1が形成されている。

As shown in FIGS. 9 and 10, pressing

ピストン18,19はシリンダー15,16に設けられた線条の隙間9を介して連結部13により互いに連結しており、図2に示すように、片方のピストン(例えばピストン19)をディスペンサーのプランジャー7で押すことにより、他方のピストン(例えばピストン18)が連動し、2つのピストン18,19がそれぞれの包袋20,21を押し潰して該包袋20,21内に収容された接着剤を吐出させることが出来、且つ繰り返し使用出来る。

The

このような構成により、2液性反応型接着剤であっても、1つのプランジャー7により接着剤の吐出と混合が可能であり、言い換えれば1液性のコーキングガンのようなディスペンサーであっても2液性反応型接着剤の吐出と混合が可能である。 With this configuration, even a two-component reactive adhesive can be discharged and mixed with a single plunger 7, in other words, a dispenser such as a one-component caulking gun. Can be discharged and mixed.

これにより、混合比の異なる2液性反応型接着剤ごとに、専用且つ特殊なディスペンサーを用意する必要がなくなり、飛躍的に汎用性が高くなる。即ち、混合比の異なる2液性反応型接着剤でも同一のディスペンサーが使用可能となる。この際、混合比、即ち容量比の異なるシリンダーを形成する際に、片方のシリンダーの外径を1液性接着剤用のディスペンサーに装填可能となるように統一させておくことが重要である。 Thereby, it is not necessary to prepare a dedicated and special dispenser for each two-component reactive adhesive having a different mixing ratio, and the versatility is dramatically improved. That is, the same dispenser can be used even with a two-component reactive adhesive having a different mixing ratio. At this time, when forming cylinders having different mixing ratios, that is, volume ratios, it is important to unify the outer diameters of one of the cylinders so that they can be loaded into a one-component adhesive dispenser.

1液性接着剤用のディスペンサーが使用可能となるため、一般的に普及している標準的なタイプが使用出来、コストを最小限に抑えることが可能である。 Since a dispenser for a one-component adhesive can be used, a standard type that is widely used can be used, and the cost can be minimized.

また、2液性の反応型接着剤の混合比としては1:1のものから200:1近辺の種類が存在するが、1:1を除いて、ディスペンサーのプランジャー7で押すピストン18,19は、摩擦抵抗を低減化させるために、外径の大きい方を選択した方が好ましい。摺動性を高めるために、略円筒状である各ピストン18,19の長さ/直径の比は0.5以上、且つ2以下の付近が好ましいが、事実上、プランジャー7で包袋20,21を押し潰せるようであれば構わず、特に制約を受けるものではない。しかしながら、あまりにもピストン18,19の長さ/直径の比が大きくなると、シリンダー15,16内に装填される接着剤入りの包袋20,21の体積が少なくなるため、作業効率が悪くなる。

In addition, the mixing ratio of the two-component reactive adhesive ranges from 1: 1 to around 200: 1. Except for 1: 1,

本発明における2液性反応型接着剤用ケースAは、1液性のディスペンサーで接着剤の吐出が可能であるが、2液性のディスペンサーでも吐出が可能である。この際、ディスペンサーの2個のプランジャー7は、ピストン18,19を押す中心位置が外れていても該ピストン18,19の外径内に収まっていることが重要である。

The case A for a two-component reactive adhesive in the present invention can be discharged with a one-component dispenser, but can be discharged with a two-component dispenser. At this time, it is important that the two plungers 7 of the dispenser are within the outer diameters of the

本発明における2液性反応型接着剤用ケースAの吐出口であるノズルキャップ8に取り付けるスタティックミキサーは、何ら制約を受けることはなく、市販にあるものが使用可能である。ただし嵌合部からの漏れの無いものを使用することが重要である。

The static mixer attached to the

本発明における2液性反応型接着剤用ケースAの各シリンダー15,16の間に設けられた線条の隙間9は小さいほど良く、大きくなるとフィルムからなる包袋20,21の噛み込みによる接着剤の吐出不良を招きやすい。この隙間9の幅は好ましくは0.1mm以上、且つ3mm以下、更に好ましくは0.2mm以上、且つ1mm以下で、0.4mm以上、且つ0.6mm以下が最適である。隙間9は各シリンダー15,16の近傍部に設けられることが望ましく、再接近部に設けることが最適な条件となる。

In the present invention, the

シリンダー15,16同士を固定する方法としては、あらゆる方法で可能であるが、2液性反応型接着剤用ケースAの強度や剛性、材料のコストから鑑みて、リブ状の補強板6を取り付ける方法が好ましい。この2液性反応型接着剤用ケースAの材質としては、金属、プラスティック、繊維補強プラスティック、セラミック等が挙げられるが、経済性を考慮して補強プラスティックが好ましく、炭素繊維入りの射出成形プラスティックが最適である。

Any method can be used to fix the

シリンダー15,16の内周面やピストン18,19の外周面は、本実施形態に何ら限定される必要はなく、シリンダー15,16の内周面やピストン18,19の外周面が平滑な表面であっても良く、シリンダー15,16の内周面やピストン18,19の外周面の長手方向に線条に溝が設けられたものを使用しても構わない。

The inner peripheral surfaces of the

また、プランジャー7でピストン18,19を押して接着剤入りの包袋20,21を押し潰す際の抵抗を極力抑えるために本実施形態ではシリンダー15,16の内周面に凹条15a,16aを設けた一例について説明したが、シリンダー15,16の内周面の表面をエンボス加工したり、梨地処理を施すことも可能である。

Further, in this embodiment, in order to suppress the resistance when the

シリンダー部材17は、ノズルキャップ8や図示しないノズル等の吐出部と一体化していても構わないが、本実施形態のように分割出来るように部品化していた方が、メンテナンスや接着剤の逆流による樹脂のシリンダー15,16内への汚染を避けるのに適している。

The

この際、吐出部と接着剤が充填された包袋20,21はOリング等で逆流を食い止めるか、接着剤で包袋20,21と吐出部を密着させて、完全に樹脂が洩れないような施策が好ましい。また、吐出部には、接着剤の充填された包袋20,21がピストン18,19からの圧力で容易に破れるように、適度な突起部を設けておくことも可能である。

At this time, the wrapping

2つのピストン18,19を連結する方法として各種の方法が考えられるが、形状や剛性、強度を考えると、薄い板状の連結部13を採用することが好ましく、材質としては金属製が好ましい良い。ピストン18,19の材質としては、前述のシリンダー15,16と同様である。

Various methods are conceivable as a method of connecting the two

また、前述のシリンダー15,16の内周面を長手方向に線条に溝を設けた場合には、この溝に沿うようにピストン18,19の外周面に突起部を設けることも好適である。また、該ピストン18,19には、フィルムからなる包袋20,21の噛み込みを防止するために、放射状に溝18b1,19b1の設けられたパラボラ状の円盤からなる押当部材18b,19bを取り付け、シリンダー15,16の内壁との密着性を高めることも出来る。

Further, when a groove is provided on the inner peripheral surface of the

また、2個のシリンダー15,16の先端部に包袋20,21内に収容された接着剤が吐出されるノズルキャップ8を着脱可能に装着したことで、ノズルキャップ8を脱離して接着剤が充填された包袋20,21をシリンダー15,16内に容易に装填することが出来、使用済みの包袋20,21を容易に取り外すことが出来る。また、ノズルキャップ8が詰まった場合には容易に交換することが出来、2液性反応型接着剤用ケースAを繰り返し使用することが出来る。

In addition, the

本実施例では、主剤と硬化剤の混合比が2:1の場合の2液性反応型接着剤用ケースAについて図1〜図10を用いて説明する。図3は2液性反応型接着剤用ケースAの吐出部の側面の断面図であり、ノズルキャップ8の先端部の吐出口1の外周面に設けられたネジ部1aに図示しないスタティックミキサーのネジ部を螺合締着して取り付ける。図中2は、吐出部の剛性を高め、強度を確保するためのリブ部である。

In this example, a case A for a two-component reactive adhesive when the mixing ratio of the main agent and the curing agent is 2: 1 will be described with reference to FIGS. FIG. 3 is a side sectional view of the discharge part of the case A for a two-component reactive adhesive. A static mixer (not shown) is attached to the

図4及び図5に示すように、2液性反応型接着剤用ケースAの吐出口1を繰り返し使用する場合は、吐出部の口型3は2液反応型接着剤の混入を避けるため図5に示すように2液の間隔を適度に設けておくための隔壁4を設けることが好ましい。

As shown in FIGS. 4 and 5, when the

また、本実施形態では、各包袋20,21と吐出部となるノズルキャップ8の隔室8a,8bとの隙間5は熱可塑性の接着剤で密着してある。この際、適度に接着力を下げるか、もしくは接着性の相性の悪い材質をノズルキャップ8に選択することによって、密着している包袋20,21がノズルキャップ8と剥離し易くなり、ノズルキャップ8の再利用が簡便となる。

Moreover, in this embodiment, the

図4及び図5に示すように、本実施例ではシリンダー部材17のコストを抑えるためにシリンダー15,16にリブ状の補強板6が設けられている。これにより、シリンダー部材17全体の強度や剛性が高まり、ディスペンサーのプランジャー7からの力で、接着剤の充填された包袋20,21が膨らむ力に耐えることが出来、シリンダー部材17の変形を防ぐことが出来る。

As shown in FIGS. 4 and 5, in this embodiment, the

また、本実施例では、各シリンダー15,16の内周面の長手方向に線条の凹条15a,16aを設けてあり、更に内周面の表面を梨地処理している。これらによりピストン18,19の面圧を低くすることが出来、ピストン18,19が摺動する際の摩擦による抵抗を軽減することが出来る。更に、本発明における2液性反応型接着剤用ケースAは互いのシリンダー15,16の近傍付近に長手方向に線条の隙間9があることが必須である。

Further, in this embodiment,

図9及び図10に示すように、シリンダー15,16の内周面に設けられた凹条15a,16aに沿うようにピストン18,19の外周面に凸条18a,19aが設けられており、フィルムからなる包袋20,21の噛み込みを防止する措置として、放射状に溝18b1,19b1が設けられたパラボラ状の円盤からなる押当部材18b,19bが設けられている。

As shown in FIGS. 9 and 10,

使用していないときの接着剤の逆流を防ぐために、このピストン18,19とシリンダー15,16が嵌合する際のクリアランスは0mm〜0.3mmに設定してある。ただし、ピストン18,19の外周面の凸条18a,19aとシリンダー15,16の内周面の凹条15a,16aとの間のクリアランスは0.1mm〜0.5mmと大きめにとってあり、且つ、シリンダー15,16の内表面は梨地処理してあるので、ピストン18,19の摺動抵抗はきわめて小さく抑えられている。

In order to prevent back flow of the adhesive when not in use, the clearance when the

本発明における2液性反応型接着剤用ケースAに装填された2つのピストン18,19は互いに連結していることが必須であり、本実施形態では連結部13によりピストン18,19が連結されている。この連結部13は、どのような方法や材料で接合しても構わないが、本実施例では0.5mmの金属板をインサート成形で作成した。

It is essential that the two

図1及び図2に示すように、シリンダー15,16内を連結されたピストン18,19が摺動して包袋20,21が押し潰され、接着剤が吐出口1から吐出する。本実施形態の2液性反応型接着剤用ケースAは、汎用的な1液性のディスペンサーであっても、接着剤の吐出と混合が可能であり、且つ繰り返し使用出来るので、従来では専用且つ特殊なディスペンサーでしか吐出と混合が出来なかった2液性の接着剤の吐出を、経済的にコストを低減出来、且つ、きわめて汎用的なものとして実現可能となった。

As shown in FIGS. 1 and 2, the

本発明に係る2液性反応型接着剤用ケースは、建築、土木、医療、エレクトロニクス、機械工業、粉体工業、金属加工等、あらゆる分野において、種々の2液性反応型接着剤をディスペンサーを利用して吐出、混合する場合に好適に利用出来る。 The case for two-component reactive adhesives according to the present invention can be dispensed with various two-component reactive adhesives in various fields such as architecture, civil engineering, medicine, electronics, machine industry, powder industry, metal processing, etc. It can be suitably used when discharging and mixing.

A…2液性反応型接着剤用ケース

1…吐出口

1a…ネジ部

2…リブ部

3…口型

4…隔壁

5…隙間

6…補強板

7…プランジャー

8…ノズルキャップ

8a,8b…隔室

9…隙間

13…連結部

15,16…シリンダー

15a,16a…凹条

17…シリンダー部材

18,19…ピストン

18a,19a…凸条

18b,19b…押当部材

18b1,19b1…溝

20,21…包袋

A ... Case for two-component

13 ... Connecting part

15, 16 ... Cylinder

15a, 16a ... concave

17 ... Cylinder material

18, 19 ... piston

18a, 19a ... convex

18b, 19b ... Pushing member

18b1, 19b1 ... groove

20, 21 ...

Claims (3)

前記2個のシリンダーのそれぞれの内周面に複数の凹条が該シリンダーの軸方向に設けられると共に、該互いのシリンダー近傍部で該シリンダーの軸方向に該互いのシリンダー内を連通させる線条の隙間が設けられており、それぞれの包袋を押し潰し該包袋内に収容された接着剤を吐出させるための断面円形状の2つのピストンが、該隙間を介して共に連結されると共に、該ピストンのそれぞれの外周面に前記シリンダーのそれぞれの内周面に設けられた複数の凹条に摺動自在に係合し得る複数の凸条が該ピストンの軸方向に設けられており、一方のピストンを押すことにより、他方のピストンが連動して前記シリンダー内を摺動することを特徴とする2液性反応型接着剤用ケース。 For two-component reactive adhesives, two different types of adhesives are filled in a circular cross-section wrapping bag, and these two wrapping bags are loaded into two substantially hollow circular cross-section cylinders. In case

Wherein with two of the plurality of concave stripes each of the inner peripheral surface of the cylinder is provided in the axial direction of the cylinder, to communicate the cylinder of該互physician in the axial direction of the cylinder at the cylinder vicinity of physicians該互 striatum a gap of is provided, a circular cross section of the two pistons for ejecting adhesive contained within該包bag crushed each wrapper can be linked together via the gap Rutotomoni, A plurality of ridges that can be slidably engaged with a plurality of recesses provided on each inner peripheral surface of the cylinder are provided on the outer peripheral surface of the piston in the axial direction of the piston , The two-component reactive adhesive case is characterized in that the other piston is slid in the cylinder by pushing the piston.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004108612A JP4573557B2 (en) | 2004-04-01 | 2004-04-01 | Case for two-component reactive adhesive |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004108612A JP4573557B2 (en) | 2004-04-01 | 2004-04-01 | Case for two-component reactive adhesive |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005289470A JP2005289470A (en) | 2005-10-20 |

| JP4573557B2 true JP4573557B2 (en) | 2010-11-04 |

Family

ID=35322878

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004108612A Expired - Fee Related JP4573557B2 (en) | 2004-04-01 | 2004-04-01 | Case for two-component reactive adhesive |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4573557B2 (en) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4944493B2 (en) * | 2006-05-19 | 2012-05-30 | 三洋子 藤田 | Liquid take-out device |

| DE102008041984A1 (en) * | 2008-09-11 | 2010-03-18 | Hilti Aktiengesellschaft | Cassette for multicomponent masses |

| DE102010019222B4 (en) | 2010-05-04 | 2013-11-07 | Heraeus Medical Gmbh | Discharge device for cartridges |

| DE102010019217B4 (en) | 2010-05-04 | 2014-01-16 | Heraeus Medical Gmbh | cartridge system |

| DE102010019224B3 (en) | 2010-05-04 | 2011-10-13 | Heraeus Medical Gmbh | Discharge device for pasty masses |

| DE102010019219B4 (en) | 2010-05-04 | 2013-12-12 | Heraeus Medical Gmbh | Cartridge closure and cartridge with such a closure |

| DE102010019220B4 (en) | 2010-05-04 | 2015-03-26 | Heraeus Medical Gmbh | Cartridge system with connected delivery pistons |

| DE102010019223B4 (en) | 2010-05-04 | 2012-02-16 | Heraeus Medical Gmbh | Cartridge system with compressed gas cartridge |

| US8544683B2 (en) * | 2010-10-29 | 2013-10-01 | Nordson Corporation | Multiple component dispensing cartridge and method with side-by-side fluid chambers |

| US9757763B2 (en) | 2013-10-31 | 2017-09-12 | Nordson Corporation | Side by side cartridge assemblies and related methods |

| KR101786383B1 (en) * | 2016-09-02 | 2017-10-17 | 주식회사 포스코 | Mud gun with multiple structure |

| US10968031B2 (en) * | 2017-12-27 | 2021-04-06 | Sulzer Mixpac Ag | Piston for a collapsible cartridge |

| CN109502190B (en) * | 2018-11-05 | 2023-07-07 | 浙江正庄实业有限公司 | Ultraviolet-proof low-density double-tube vacuum bottle and preparation method thereof |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6022962A (en) * | 1983-07-15 | 1985-02-05 | Masago Sangyo Kk | Method for injecting adhesive agent and vessel for adhesive agent for injection |

| JP2002145360A (en) * | 2000-11-02 | 2002-05-22 | Sankyo Yakuhin Kk | Container for product of material formed from a plurality of constituents |

-

2004

- 2004-04-01 JP JP2004108612A patent/JP4573557B2/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6022962A (en) * | 1983-07-15 | 1985-02-05 | Masago Sangyo Kk | Method for injecting adhesive agent and vessel for adhesive agent for injection |

| JP2002145360A (en) * | 2000-11-02 | 2002-05-22 | Sankyo Yakuhin Kk | Container for product of material formed from a plurality of constituents |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005289470A (en) | 2005-10-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4573557B2 (en) | Case for two-component reactive adhesive | |

| US5667102A (en) | Cartridge with an exchangeable content package | |

| US9238544B2 (en) | Article and method for sealing a collapsible container | |

| US10525500B2 (en) | Component delivery system utilizing film bags | |

| US5566860A (en) | Dual component cartridge | |

| US5875928A (en) | Device for mixing and discharging a molding composition | |

| US8544683B2 (en) | Multiple component dispensing cartridge and method with side-by-side fluid chambers | |

| CN101035737B (en) | Dual fluid cartridge for storing and dispensing fluids in unequal ratios | |

| CN101175687B (en) | Dual fluid cartridge with reduced fluid waste | |

| EP0666823B1 (en) | Multiple component metering and relative proportioning device with collapsible cartridge | |

| JP6178021B2 (en) | Cartridge and cartridge manufacturing method | |

| JP4078309B2 (en) | Device for storing, mixing, and dispensing flowable materials | |

| US20140203023A1 (en) | Cartridge and multicomponent cartridge | |

| KR102014232B1 (en) | Set of multicomponent cartridges | |

| JP2015501263A (en) | Cartridge, manufacturing method thereof, and multi-component cartridge | |

| JP5000083B2 (en) | Formulation cartridge | |

| CA2665335A1 (en) | Foil container with foil bags arranged next to one another | |

| US20060144854A1 (en) | Cartridge delivery system utilizing film bags | |

| CN1332690A (en) | Collapsible dispensing system | |

| US20240149283A1 (en) | Common head having an offset partition for use with multi-component dispensing tools and a tubular liner arranged for locating within the common head | |

| JP5745756B2 (en) | Cassette for multi-component substances | |

| JP3177471U (en) | Two-component mixing container | |

| CN215138721U (en) | Multi-component colloid static mixing connecting piece and injection mechanism thereof | |

| EP4234104A1 (en) | Cartridge assembly for insertion into a dispenser and dispenser for dispensing materials | |

| JP4522136B2 (en) | Adhesive case |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070326 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20080130 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100104 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100615 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100723 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100817 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100817 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130827 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |