JP4257528B2 - Multi-cylinder internal combustion engine - Google Patents

Multi-cylinder internal combustion engine Download PDFInfo

- Publication number

- JP4257528B2 JP4257528B2 JP2004198263A JP2004198263A JP4257528B2 JP 4257528 B2 JP4257528 B2 JP 4257528B2 JP 2004198263 A JP2004198263 A JP 2004198263A JP 2004198263 A JP2004198263 A JP 2004198263A JP 4257528 B2 JP4257528 B2 JP 4257528B2

- Authority

- JP

- Japan

- Prior art keywords

- exhaust

- exhaust gas

- communication passage

- internal combustion

- combustion engine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00

- F01N13/08—Other arrangements or adaptations of exhaust conduits

- F01N13/10—Other arrangements or adaptations of exhaust conduits of exhaust manifolds

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00

- F01N13/008—Mounting or arrangement of exhaust sensors in or on exhaust apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00

- F01N13/18—Construction facilitating manufacture, assembly, or disassembly

- F01N13/1805—Fixing exhaust manifolds, exhaust pipes or pipe sections to each other, to engine or to vehicle body

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B27/00—Use of kinetic or wave energy of charge in induction systems, or of combustion residues in exhaust systems, for improving quantity of charge or for increasing removal of combustion residues

- F02B27/04—Use of kinetic or wave energy of charge in induction systems, or of combustion residues in exhaust systems, for improving quantity of charge or for increasing removal of combustion residues in exhaust systems only, e.g. for sucking-off combustion gases

- F02B27/06—Use of kinetic or wave energy of charge in induction systems, or of combustion residues in exhaust systems, for improving quantity of charge or for increasing removal of combustion residues in exhaust systems only, e.g. for sucking-off combustion gases the systems having variable, i.e. adjustable, cross-sectional areas, chambers of variable volume, or like variable means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2450/00—Methods or apparatus for fitting, inserting or repairing different elements

- F01N2450/24—Methods or apparatus for fitting, inserting or repairing different elements by bolts, screws, rivets or the like

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2560/00—Exhaust systems with means for detecting or measuring exhaust gas components or characteristics

- F01N2560/02—Exhaust systems with means for detecting or measuring exhaust gas components or characteristics the means being an exhaust gas sensor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2560/00—Exhaust systems with means for detecting or measuring exhaust gas components or characteristics

- F01N2560/02—Exhaust systems with means for detecting or measuring exhaust gas components or characteristics the means being an exhaust gas sensor

- F01N2560/025—Exhaust systems with means for detecting or measuring exhaust gas components or characteristics the means being an exhaust gas sensor for measuring or detecting O2, e.g. lambda sensors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/008—Controlling each cylinder individually

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/02—Circuit arrangements for generating control signals

- F02D41/14—Introducing closed-loop corrections

- F02D41/1438—Introducing closed-loop corrections using means for determining characteristics of the combustion gases; Sensors therefor

- F02D41/1439—Introducing closed-loop corrections using means for determining characteristics of the combustion gases; Sensors therefor characterised by the position of the sensor

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Analytical Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Exhaust Silencers (AREA)

- Exhaust Gas After Treatment (AREA)

Description

本発明は多気筒内燃機関に係り、詳しくは排気系に排ガスの空燃比を判定するための排ガスセンサを備えた多気筒内燃機関に関するものである。 The present invention relates to a multi-cylinder internal combustion engine, and more particularly to a multi-cylinder internal combustion engine provided with an exhaust gas sensor for determining an air-fuel ratio of exhaust gas in an exhaust system.

内燃機関から排出される排ガスを浄化する排気浄化装置の一つとして、内燃機関の排気通路には触媒が設けられている。触媒の性能を十分に発揮させるには触媒に流入する排ガスの空燃比をストイキ近傍に制御する必要があり、係る目的を達成するために触媒の入口近傍にはO2センサ等の排ガスセンサが設置され、この排ガスセンサにより判定された排気空燃比に基づいて内燃機関の空燃比を制御している(例えば、特許文献1参照)。尚、特許文献1に開示された多気筒内燃機関では、一対の排気通路の合流部より上流側に個別に触媒を設け、両触媒の入口近傍を連通する連通路に共通の排ガスセンサを設けている。

しかしながら、触媒の入口近傍に排ガスセンサを設けた場合、排ガスセンサより上流にはある程度の大きさの排気系容積が存在することになり、少なくともこの排気系容積に起因する輸送遅れ相当だけは排ガスセンサによる排気空燃比の判定に遅れが生じてしまう。そして、排気空燃比の判定遅れに伴って空燃比制御の応答性が低下するため、触媒への排ガス種の破過をもたらして浄化性能を悪化させるという問題が生じる。又、排ガスセンサによる排気空燃比の判定に応じて内燃機関の空燃比を制御する場合には、排気空燃比の判定遅れにより必然的に空燃比変動(空燃比自励変調)が生じ、判定遅れが大きいと空燃比変動の振幅も大きくなり、リッチ側への振幅増大による燃費悪化やリーン側への振幅増大による燃焼悪化が発生し易くなるという問題がある。 However, when an exhaust gas sensor is provided in the vicinity of the catalyst inlet, there will be a certain amount of exhaust system volume upstream from the exhaust gas sensor, and at least the exhaust delay sensor due to this exhaust system volume is at least equivalent to the exhaust gas sensor. This causes a delay in the determination of the exhaust air / fuel ratio. And since the responsiveness of the air-fuel ratio control is reduced with the delay in determining the exhaust air-fuel ratio, there arises a problem that the purification performance is deteriorated due to the breakthrough of the exhaust gas species to the catalyst. Further, when the air-fuel ratio of the internal combustion engine is controlled according to the exhaust air-fuel ratio determination by the exhaust gas sensor, the air-fuel ratio fluctuation (air-fuel ratio self-excited modulation) inevitably occurs due to the exhaust air-fuel ratio determination delay, and the determination delay If the value is large, the amplitude of the air-fuel ratio fluctuation also increases, and there is a problem that fuel consumption deterioration due to an increase in amplitude toward the rich side and combustion deterioration due to an increase in amplitude toward the lean side are likely to occur.

排気空燃比の判定遅れは、例えば排ガスセンサを内燃機関の排気ポートに取付けて、排ガスセンサの上流側の排気系容積を縮小することで改善できるが、複数気筒を有する多気筒内燃機関では各排気ポート毎に排ガスセンサを必要とするため、製造コストが高騰するという別の問題が生じてしまう。

本発明の目的は、排ガスセンサの必要数を減少させて製造コストを低減できると共に、応答性の良い排気空燃比の判定を実現することができる多気筒内燃機関を提供することにある。

The exhaust air-fuel ratio determination delay can be improved by, for example, attaching an exhaust gas sensor to the exhaust port of the internal combustion engine and reducing the exhaust system volume upstream of the exhaust gas sensor. Since an exhaust gas sensor is required for each port, another problem arises that the manufacturing cost increases.

It is an object of the present invention to provide a multi-cylinder internal combustion engine that can reduce the manufacturing cost by reducing the required number of exhaust gas sensors and can realize the exhaust air / fuel ratio determination with good responsiveness.

上記目的を達成するため、請求項1の発明は、複数の気筒を有する多気筒内燃機関において、各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、内燃機関のシリンダヘッドと排気通路とのフランジ接合箇所に内蔵され、少なくとも2つ以上の排気通路を連通する排気連通路と、排気連通路に設けられる排ガスセンサとを備え、排気ポートから排ガスセンサまでの距離を排気ポートから触媒の上流側入口までの距離より短くしたものである。 In order to achieve the above object, a first aspect of the invention relates to a multi-cylinder internal combustion engine having a plurality of cylinders, a catalyst for purifying exhaust gas provided in an exhaust passage extending from an exhaust port of each cylinder, and a cylinder of the internal combustion engine. It is built in the flange joint between the head and the exhaust passage, and has an exhaust communication passage communicating at least two exhaust passages and an exhaust gas sensor provided in the exhaust communication passage, and exhausts the distance from the exhaust port to the exhaust gas sensor. This is shorter than the distance from the port to the upstream inlet of the catalyst.

従って、各気筒の排気ポートから排出された排ガスは排気通路内を流通し、排ガスの一部が排気連通路内に取込まれて排ガスセンサに到達し、排ガスセンサにより各気筒の排ガスの空燃比が順次検出される。

そして、少なくとも2つ以上の排気通路を流通する排ガスが排気連通路を経て共通の排ガスセンサに導かれて空燃比を検出されるため、排ガスセンサの必要数は内燃機関の気筒数(換言すれば、各排気ポート毎に排ガスセンサを設けた場合)より少なくなる。一方、排気ポートから触媒の上流側入口までの距離より排気ポートから排ガスセンサまでの距離が短いため、排気ポートから排出された排ガスが排ガスセンサに到達するまでの輸送遅れが最小限に抑制されて、良好な応答性で空燃比を検出可能となる。

しかも、排気連通路がフランジ接合箇所に内蔵されているため、排気連通路内を流通する排ガスの放熱を抑制して、高い温度を保ったまま排ガスを排ガスセンサに供給可能となる。

Therefore, the exhaust gas discharged from the exhaust port of each cylinder flows through the exhaust passage, and a part of the exhaust gas is taken into the exhaust communication passage and reaches the exhaust gas sensor. The exhaust gas sensor detects the air-fuel ratio of the exhaust gas of each cylinder. Are detected sequentially.

Since the exhaust gas flowing through at least two exhaust passages is guided to the common exhaust gas sensor through the exhaust communication passage and the air-fuel ratio is detected, the required number of exhaust gas sensors is the number of cylinders of the internal combustion engine (in other words, , When an exhaust gas sensor is provided for each exhaust port). On the other hand, since the distance from the exhaust port to the exhaust gas sensor is shorter than the distance from the exhaust port to the upstream inlet of the catalyst, the transport delay until the exhaust gas discharged from the exhaust port reaches the exhaust gas sensor is minimized. The air-fuel ratio can be detected with good response.

In addition, since the exhaust communication passage is built in the flange joint portion, heat dissipation of the exhaust gas flowing through the exhaust communication passage is suppressed, and the exhaust gas can be supplied to the exhaust gas sensor while maintaining a high temperature.

請求項2の発明は、請求項1において、排気連通路が、内燃機関のシリンダヘッド側と排気通路側との少なくとも何れか一方のフランジ面に溝として形成され、フランジの接合に伴って閉塞されて通路として機能するものである。 According to a second aspect of the present invention, in the first aspect, the exhaust communication passage is formed as a groove on at least one of the flange surfaces of the cylinder head side and the exhaust passage side of the internal combustion engine, and is closed when the flange is joined. Function as a passageway .

従って、フランジ面に形成した溝がフランジ接合に伴って閉鎖されて通路として機能する。 Therefore, the grooves formed on the flange surface that acts as a path is closed with the flange connection.

好ましい態様として、請求項1,2の多気筒内燃機関において、各気筒の排気通路又は排気ポート側排気通路から排ガスセンサまでの排気連通路の容積を略等しく設定することが望ましい。このように構成すれば、各気筒の排ガスが排気連通路内を流通する際の圧力脈動が等しく影響して均等にガス交換が行われ、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現できる。

As a preferred aspect, in the multi-cylinder internal combustion engine according to

請求項3の発明は、複数の気筒を有する多気筒内燃機関において、各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、少なくとも2つ以上の排気通路を連通する排気連通路と、排気連通路に設けられる排ガスセンサと、排ガスセンサと内燃機関の吸気系とを連通し、排圧と吸気圧との圧力差により排気連通路内のガス交換を促進する吸気連通路とを備え、排ガスセンサに対する吸気連通路の接合有効断面積に比較して、排ガスセンサに対する排気連通路の接合有効断面積の総和が大きく設定されているものである。 Invention 請 Motomeko 3, in multi-cylinder internal combustion engine having a plurality of cylinders, communicates with a catalyst for purifying exhaust gas provided in an exhaust passage extending, at least two exhaust passages from the exhaust port of each cylinder An exhaust communication path, an exhaust gas sensor provided in the exhaust communication path, an exhaust gas sensor and an intake system of the internal combustion engine communicate with each other, and an intake system that promotes gas exchange in the exhaust communication path by a pressure difference between the exhaust pressure and the intake pressure. The sum of the effective joint areas of the exhaust communication passages relative to the exhaust gas sensor is set larger than the effective cross sectional area of the intake communication passages relative to the exhaust gas sensor .

従って、排ガスセンサは排気連通路を介して排気系(排気通路)と連通する一方、吸気連通路を介して吸気系とも連通し、排圧と吸気圧との圧力差により排気連通路内のガス交換が促進される。又、排ガスセンサを流れる排ガス量は排圧と吸気圧との圧力比の増加に応じて増大し、圧力比が臨界比に達して臨界状態となった時点で排ガスの流量増大は制限されるが、本発明のように断面積を設定すると、排ガスセンサの出口側(吸気連通路側)がより早期に臨界状態に達し、この箇所で排ガス流量の増大が制限されると共に、この箇所を境界として上流側には排圧が、下流側では吸気圧が作用する。よって、排ガスセンサには大気圧に近い排圧が作用し、排ガスセンサが有する圧力依存の影響を軽減して、排気空燃比の判定精度が向上する。

請求項4の発明は、複数の気筒を有する多気筒内燃機関において、各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、少なくとも2つ以上の排気通路を連通する排気連通路と、排気連通路に設けられる排ガスセンサと、排ガスセンサと内燃機関の吸気系とを連通し、排圧と吸気圧との圧力差により排気連通路内のガス交換を促進する吸気連通路とを備え、排ガスセンサに対する吸気連通路の接合有効断面積に比較して、排ガスセンサに対する排気連通路の接合有効断面積の総和が小さく設定されると共に、排ガスセンサに対する各排気連通路の接合有効断面積が相互に略均等に設定されているものである。

従って、排ガスセンサは排気連通路を介して排気系(排気通路)と連通する一方、吸気連通路を介して吸気系とも連通し、排圧と吸気圧との圧力差により排気連通路内のガス交換を促進できる。又、排ガスセンサの圧力依存への対策を実施する必要がない場合、本発明のように構成すれば、排ガスセンサの入口側(排気連通路側)がより早期に臨界状態に達し、この箇所で排ガス流量の増大が制限されるが、各排気連通路の接合有効断面積が略均等のため、各気筒の排圧変動の影響を受けず各排気連通路から排ガスセンサに流入する排ガス量が略等しくなり、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定が実現される。

Therefore, the exhaust gas sensor communicates with the exhaust system (exhaust passage) through the exhaust communication passage, and also communicates with the intake system through the intake communication passage, and the gas in the exhaust communication passage is caused by the pressure difference between the exhaust pressure and the intake pressure. Exchange is facilitated. Further, the amount of exhaust gas flowing through the exhaust gas sensor increases with an increase in the pressure ratio between the exhaust pressure and the intake pressure, and when the pressure ratio reaches the critical ratio and reaches a critical state, the increase in the exhaust gas flow rate is limited. When the cross-sectional area is set as in the present invention, the outlet side of the exhaust gas sensor (the intake communication passage side) reaches a critical state earlier, and the increase in the exhaust gas flow rate is restricted at this point, and this point is used as a boundary. Exhaust pressure acts on the upstream side, and intake pressure acts on the downstream side. Therefore, exhaust pressure close to atmospheric pressure acts on the exhaust gas sensor, reducing the pressure-dependent influence of the exhaust gas sensor, and improving the exhaust air / fuel ratio determination accuracy .

According to a fourth aspect of the present invention, in a multi-cylinder internal combustion engine having a plurality of cylinders, an exhaust gas that is provided in an exhaust passage extending from an exhaust port of each cylinder and purifies exhaust gas, and that communicates at least two or more exhaust passages. An intake communication passage that communicates the communication passage, an exhaust gas sensor provided in the exhaust communication passage, an exhaust gas sensor and an intake system of the internal combustion engine, and promotes gas exchange in the exhaust communication passage by a pressure difference between the exhaust pressure and the intake pressure The sum of the effective cross-sectional area of the exhaust communication passage to the exhaust gas sensor is set smaller than the effective cross-section area of the intake communication passage to the exhaust gas sensor, and the effective connection of each exhaust communication path to the exhaust gas sensor The cross-sectional areas are set substantially equal to each other .

Therefore, the exhaust gas sensor communicates with the exhaust system (exhaust passage) through the exhaust communication passage, and also communicates with the intake system through the intake communication passage, and the gas in the exhaust communication passage is caused by the pressure difference between the exhaust pressure and the intake pressure. Exchange can be promoted. If it is not necessary to take measures against the pressure dependence of the exhaust gas sensor, the exhaust gas sensor inlet side (exhaust communication passage side) will reach a critical state earlier if it is configured as in the present invention. Although the increase in exhaust gas flow rate is limited, the effective cross-sectional area of each exhaust communication passage is substantially equal, so the amount of exhaust gas flowing into the exhaust gas sensor from each exhaust communication passage is not affected by fluctuations in exhaust pressure of each cylinder. It becomes equal, and the accurate determination of the exhaust air-fuel ratio that uniformly reflects the air-fuel ratio of each cylinder is realized .

請求項5の発明は、請求項3,4において、排ガスセンサの下流に、排ガスの冷却による体積変化により排気連通路内のガス交換を促進する冷却空間が形成され、冷却空間の排ガスの体積変化が排気連通路の容積と略同程度になるように、冷却空間の容積、排気連通路の容積、冷却空間における温度低下率の少なくとも一つ以上が設定されているものである。

従って、排ガスセンサを経て冷却空間内に導入された排ガスは温度低下により体積変化(体積縮小)し、この体積変化に伴って冷却空間より上流側の排ガスが冷却空間内に移送されると共に、排気連通路内の排ガスが排ガスセンサ側に移送され、結果として排気連通路内のガス交換が一層促進される。そして、冷却空間での排ガスの体積変化に伴って排気連通路内の排ガスのほぼ全量が吸気連通路や排気下流連通路側に移送されるため、排気連通路内のガス交換が効率的に促進される。

According to a fifth aspect of the present invention, in the third and fourth aspects, a cooling space is formed downstream of the exhaust gas sensor to promote gas exchange in the exhaust communication path due to a volume change due to cooling of the exhaust gas. so they become the volume substantially the same degree of the exhaust communication passages, the volume of the cooling space, the volume of the exhaust communication passages, a shall have at least one temperature decrease rate is set in the cooling space.

Therefore, the exhaust gas introduced into the cooling space through the exhaust gas sensor changes in volume (volume reduction) due to a temperature drop, and along with this volume change, the exhaust gas upstream from the cooling space is transferred into the cooling space and the exhaust gas is exhausted. The exhaust gas in the communication passage is transferred to the exhaust gas sensor side, and as a result, gas exchange in the exhaust communication passage is further promoted. As the exhaust gas volume changes in the cooling space, almost all of the exhaust gas in the exhaust communication passage is transferred to the intake communication passage and the exhaust downstream communication passage, so that the gas exchange in the exhaust communication passage is efficiently promoted. Is done.

請求項6の発明は、請求項3〜5において、各排気連通路が吸気連通路に対して略水平面上で所定角度毎に略等間隔で配置されているものである。

従って、吸気連通路に対して各排気連通路が略水平面上で所定角度毎に略等間隔で配置されているため、各排気連通路の排ガスは排ガスセンサを経て吸気連通路にほぼ同一条件で流入し、これにより排ガスセンサの全周が排ガスの空燃比検出に利用されて応答性が向上すると共に、特定気筒の空燃比の影響が強くなる或いは弱くなることが防止されて、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定が実現される。

A sixth aspect of the present invention is the method according to any one of the third to fifth aspects, wherein the exhaust communication passages are arranged at substantially equal intervals for each predetermined angle on a substantially horizontal plane with respect to the intake communication passage.

Therefore, since the exhaust communication passages are arranged at substantially equal intervals at predetermined angles on a substantially horizontal plane with respect to the intake communication passage, the exhaust gas in each exhaust communication passage passes through the exhaust gas sensor under substantially the same conditions as the intake communication passage. As a result, the entire circumference of the exhaust gas sensor is utilized for detecting the air-fuel ratio of the exhaust gas, and the responsiveness is improved, and the influence of the air-fuel ratio of the specific cylinder is prevented from becoming stronger or weaker. Accurate exhaust air-fuel ratio determination that uniformly reflects the fuel ratio is realized.

請求項7の発明は、請求項3〜6において、吸気連通路が、吸気連通路内を流通する排ガス量を調整可能な開閉バルブを備えているものである。

従って、燃焼悪化の虞がある運転領域で開閉バルブの開度を減少又は全閉すれば、吸気連通路を経て内燃機関の吸気系に還流される排ガス量が制限されて燃焼悪化が防止される。

According to a seventh aspect of the invention, according to claim 3-6, the intake communication passage is shall have an adjustable opening and closing valve and the amount of exhaust gas flowing through the intake communication passage.

Therefore, if the opening / closing valve opening is reduced or fully closed in the operating region where there is a possibility of deterioration of combustion, the amount of exhaust gas recirculated to the intake system of the internal combustion engine via the intake communication passage is limited, thereby preventing deterioration of combustion. .

請求項8の発明は、複数の気筒を有する多気筒内燃機関において、各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、少なくとも2つ以上の排気通路を連通する排気連通路と、排気連通路に設けられる排ガスセンサと、排ガスセンサと内燃機関の排気系の上記触媒より下流側とを連通し、排気系の上流側と下流側との圧力差により排気連通路内のガス交換を促進する排気下流連通路と、排気下流連通路に備えられ、排気下流連通路内を流通する排ガス量を調整可能な開閉バルブとを備えたものである。

従って、冷態始動時には、燃料増量による未燃ガスが排気下流連通路を経て触媒を迂回して排出される現象が生じるが、このときに開閉バルブの開度を減少又は全閉すれば、排気下流連通路内を流通する排ガス量が制限されて排ガス悪化が防止される。

請求項9の発明は、請求項8において、各排気連通路が排気下流連通路に対して略水平面上で所定角度毎に略等間隔で配置されているものである。

従って、排気下流連通路に対して各排気連通路が略水平面上で所定角度毎に略等間隔で配置されているため、各排気連通路の排ガスは排ガスセンサを経て排気下流連通路にほぼ同一条件で流入し、これにより排ガスセンサの全周が排ガスの空燃比検出に利用されて応答性が向上すると共に、特定気筒の空燃比の影響が強くなる或いは弱くなることが防止されて、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定が実現される。

According to an eighth aspect of the present invention, in a multi-cylinder internal combustion engine having a plurality of cylinders, an exhaust gas that is provided in an exhaust passage extending from an exhaust port of each cylinder and purifies exhaust gas, and communicates at least two exhaust passages. A communication passage, an exhaust gas sensor provided in the exhaust communication passage, and the exhaust gas sensor and the exhaust system of the internal combustion engine communicate with the downstream side of the catalyst, and a pressure difference between the upstream side and the downstream side of the exhaust system Are provided with an exhaust downstream communication passage that facilitates gas exchange, and an open / close valve that is provided in the exhaust downstream communication passage and that can adjust the amount of exhaust gas flowing in the exhaust downstream communication passage .

Therefore, at the time of cold start, a phenomenon occurs in which unburned gas due to the increase in fuel is exhausted by bypassing the catalyst through the exhaust downstream communication passage. At this time, if the opening / closing valve opening is reduced or fully closed, the exhaust gas The amount of exhaust gas flowing through the downstream communication passage is limited, and exhaust gas deterioration is prevented.

A ninth aspect of the present invention is that in the eighth aspect , the exhaust communication passages are arranged at substantially equal intervals at predetermined angles on a substantially horizontal plane with respect to the exhaust downstream communication passage.

Accordingly, the exhaust communication passages are arranged at substantially equal intervals at predetermined angles on a substantially horizontal plane with respect to the exhaust downstream communication passage, so that the exhaust gas in each exhaust communication passage is substantially the same as the exhaust downstream communication passage through the exhaust gas sensor. As a result, the entire circumference of the exhaust gas sensor is used for detecting the air-fuel ratio of the exhaust gas, thereby improving the response and preventing the influence of the air-fuel ratio of the specific cylinder from becoming stronger or weaker. This makes it possible to accurately determine the exhaust air-fuel ratio that uniformly reflects the air-fuel ratio.

以上説明したように請求項1,2の発明の多気筒内燃機関によれば、排ガスセンサの必要数を減少させて製造コストを低減できると共に、応答性の良い排気空燃比の判定を実現でき、しかも排ガスの放熱を抑制して排ガスセンサの不活性防止及び早期活性化を達成することができる。

請求項3の発明の多気筒内燃機関によれば、内燃機関の排圧と吸気圧との圧力差を利用して排気連通路内の排ガスのガス交換を促進できると共に、排ガスセンサに大気圧に近い排圧を作用させることにより、排ガスセンサが有する圧力依存の影響を軽減でき、もって排気空燃比の判定精度を向上させることができる。

As described above, according to the multi-cylinder internal combustion engine of the first and second aspects of the invention, the required number of exhaust gas sensors can be reduced to reduce the manufacturing cost, and the exhaust air / fuel ratio can be determined with good responsiveness . In addition, it is possible to suppress the heat release of the exhaust gas and to achieve inactivation prevention and early activation of the exhaust gas sensor .

According to the multi-cylinder internal combustion engine of the third aspect of the invention, gas exchange of the exhaust gas in the exhaust communication passage can be promoted by utilizing the pressure difference between the exhaust pressure and the intake pressure of the internal combustion engine, and the exhaust gas sensor is brought to atmospheric pressure. By applying a close exhaust pressure, it is possible to reduce the pressure-dependent influence of the exhaust gas sensor, and to improve the accuracy of determining the exhaust air / fuel ratio .

請求項4の発明の多気筒内燃機関によれば、内燃機関の排気系の上流と下流との圧力差を利用して排気連通路内の排ガスのガス交換を促進できると共に、各気筒の排圧変動の影響を受けず各排気連通路から排ガスセンサに流入する排ガス量を略等しくして、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現することができる。

請求項5の発明の多気筒内燃機関によれば、請求項3,4に加えて、冷却空間による排ガスの体積変化を利用して排気連通路内の排ガスのガス交換を促進できると共に、冷却空間の排ガスの体積変化が排気連通路の容積と略同程度であるため、排気連通路内のガス交換を効率的に促進することができる。

According to the multi-cylinder internal combustion engine of the fourth aspect of the invention, the gas exchange of the exhaust gas in the exhaust communication passage can be promoted using the pressure difference between the upstream and downstream of the exhaust system of the internal combustion engine, and the exhaust pressure of each cylinder The exhaust gas amount flowing into the exhaust gas sensor from each exhaust communication passage without being affected by fluctuations can be made substantially equal, and accurate exhaust air / fuel ratio determination can be realized that uniformly reflects the air / fuel ratio of each cylinder .

According to the multi-cylinder internal combustion engine of the fifth aspect of the present invention, in addition to the third and fourth aspects, the exchange of the exhaust gas in the exhaust communication passage can be promoted by utilizing the volume change of the exhaust gas by the cooling space, and the cooling space Since the volume change of the exhaust gas is substantially the same as the volume of the exhaust communication passage, gas exchange in the exhaust communication passage can be promoted efficiently .

請求項6の発明の多気筒内燃機関によれば、請求項3〜5に加えて、吸気連通路に対して各排気連通路を略水平面上で所定角度毎に略等間隔で配置することで、排ガスセンサの応答性を向上できると共に、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現することができる。

請求項7の発明の多気筒内燃機関によれば、請求項3〜6に加えて、燃焼悪化の虞がある運転領域では、吸気連通路を経て内燃機関の吸気系に還流される排ガス量を開閉バルブにより制限して燃焼悪化を防止することができる。

According to the multi-cylinder internal combustion engine of the sixth aspect of the invention, in addition to the third to fifth aspects , the exhaust communication passages are arranged at substantially equal intervals at predetermined angles on a substantially horizontal plane with respect to the intake communication passages. In addition to improving the responsiveness of the exhaust gas sensor, it is possible to realize accurate exhaust air / fuel ratio determination that uniformly reflects the air / fuel ratio of each cylinder.

According to the multi-cylinder internal combustion engine of the seventh aspect of the invention, in addition to the third to sixth aspects , in the operation region where there is a risk of deterioration of combustion, the amount of exhaust gas recirculated to the intake system of the internal combustion engine through the intake communication passage is reduced. Combustion deterioration can be prevented by limiting by an open / close valve .

請求項8の発明の多気筒内燃機関によれば、冷態始動時には、排気下流連通路内を流通する排ガス量を開閉バルブにより制限することにより、燃料増量による未燃ガスが触媒を迂回したときの排ガス悪化を防止することができる。

請求項9の発明の多気筒内燃機関によれば、請求項8に加えて、排気下流連通路に対して各排気連通路を略水平面上で所定角度毎に略等間隔で配置することで、排ガスセンサの応答性を向上できると共に、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現することができる。 According to the multi-cylinder internal combustion engine of the eighth aspect of the invention, at the time of cold start, the amount of exhaust gas flowing through the exhaust downstream communication passage is limited by the open / close valve, so that the unburned gas due to the increase in fuel bypasses the catalyst. It is possible to prevent the exhaust gas from deteriorating.

According to the multi-cylinder internal combustion engine of the ninth aspect of the invention, in addition to the eighth aspect , the exhaust communication passages are arranged at substantially equal intervals at predetermined angles on a substantially horizontal plane with respect to the exhaust downstream communication passage. The responsiveness of the exhaust gas sensor can be improved, and an accurate determination of the exhaust air / fuel ratio that uniformly reflects the air / fuel ratio of each cylinder can be realized .

[第1実施形態]

以下、本発明を具体化した多気筒内燃機関の第1実施形態を説明する。

図1は本実施形態の多気筒内燃機関を示す全体構成図であり、本実施形態の内燃機関は直列4気筒機関として構成され、図では機関本体の図示が省略されて排気系のみが示されている。内燃機関のシリンダヘッドの側面には排気マニホールド1(排気通路)の上流側フランジ2が周囲のボルト孔2aを利用して図示しないボルトにより連結され、上流側フランジ2には各気筒の排気ポート10と対応するようにブランチ3(排気ポート側排気通路)の上部がそれぞれ溶接されている。#1,#4気筒のブランチ3の下流側、#2,#3気筒のブランチの下流側はそれぞれ相互に合流して排気通路合流部4を形成し、両排気通路合流部4は下流側フランジ5に対して溶接されている。

[First Embodiment]

Hereinafter, a first embodiment of a multi-cylinder internal combustion engine embodying the present invention will be described.

FIG. 1 is an overall configuration diagram showing a multi-cylinder internal combustion engine of the present embodiment. The internal combustion engine of the present embodiment is configured as an in-line four-cylinder engine. In the figure, the illustration of the engine body is omitted and only the exhaust system is shown. ing. An

排気マニホールド1の下流側フランジ5には排気管6(排気通路)のフランジ7が図示しないボルトにより連結され、フランジ7に溶接された排気管6の上流側は二股状をなして排気マニホールド1の排気通路合流部4とそれぞ連通する一方、排気管6の下流側は排気通路合流部8で合流した後に触媒9に接続され、更に図示しない消音器を経て車両の後部まで延設されている。従って、内燃機関の運転時には、各排気ポート10から排出された排ガスが排気マニホールド1及び排気管6内で案内されながら順次合流し、その後に触媒9及び消音器を経て外部に排出される。

A

上記排気マニホールド1の各ブランチ3には、上流側フランジ2に対する溶接箇所の近傍にそれぞれパイプ状をなす排気連通路11の一端が接続され、各排気連通路11の他端は1点に集合してセンサ固定ベース12に対して接続されている。センサ固定ベース12には排ガスセンサ13が固定され、排ガスセンサ13と各排気連通路11とはセンサ固定ベース12の内部で相互に連通している。尚、排ガスセンサ13は、O2センサ、空燃比センサ、NOxセンサ等の如何なるセンサであってもよい。又、排気連通路11を排気マニホールド1ではなく図示しない排気ポートに接続するようにしてもよい。

Each

排ガスセンサ13は車両の搭載されたECU(電子制御ユニット)と電気的に接続され、排ガスセンサ13の出力がECUに入力される。ECUは排ガスセンサ13により判定された排気空燃比に基づいて内燃機関の空燃比制御、例えば空燃比フィードバック制御、燃焼限界制御等のように小さい空燃比変動が要求される空燃比制御を実行する。

各排気連通路11はそれぞれのブランチ3から上方に延び、略直角に屈曲形成されて#2−#3気筒間に位置するセンサ固定ベース12に向けて延設されており、排気連通路11の全体が排気マニホールド1の直上に位置している。このようなレイアウトのため、排気ポート10から排ガスセンサ13までの排ガス流路に沿った距離A1(排気連通路11の長さは気筒によって異なるが、長い側の#1又は#4気筒であっても)は必要最小限に短縮され、排気ポート10から触媒9の上流側入口までの距離A2に比較して格段に短くなっている。

The

Each

以上のように構成された本実施形態の多気筒内燃機関では、以下のようにして排ガスセンサ13による排気空燃比の判定が行われる。

内燃機関の運転時において、各排気ポート10からは#1−#3−#4−#2の点火順序に従って排ガスが排出されて排気マニホールド1のブランチ3内を流通する。ブランチ3内で排ガスの一部は排気連通路11内に取り込まれ、主としてガス拡散作用により排気連通路11を経て排ガスセンサ13まで到達することから、排ガスセンサ13は排気連通路11を経て供給される各気筒の排ガスの空燃比を順次検出することになる。ここで、上記のように排気ポート10から排ガスセンサ13までの距離A1が非常に短いため、排気ポートから排出された排ガスが排ガスセンサ13に到達するまでの輸送遅れは最小限に抑制され、例えば触媒9の上流側入口に排ガスセンサ13を取付けた一般的なレイアウトに比較して、非常に応答性の良い排気空燃比の判定を実現することができる。

In the multi-cylinder internal combustion engine of the present embodiment configured as described above, the exhaust air / fuel ratio is determined by the

During operation of the internal combustion engine, exhaust gas is discharged from each

結果として空燃比判定に基づいてECUにより実行される空燃比制御の応答性も向上するため、触媒9の排ガス種の破過を防止して浄化性能の悪化を未然に回避することができる。又、良好な応答性の空燃比制御により振幅の小さな高速自励変調を実現できることから、リッチ側への振幅増大による燃費悪化やリーン側への振幅増大による燃焼悪化を未然に防止できると共に、図2の特性図に示すように、空燃比の変調周期の短縮化に伴ってTHCとNOxとのクロスオーバポイント(COP)の浄化効率を向上することができる。

As a result, the responsiveness of the air-fuel ratio control executed by the ECU based on the air-fuel ratio determination is also improved. Therefore, it is possible to prevent the exhaust gas species from passing through the

一方、各気筒から排出される排ガスを排気連通路11を経て共通の排ガスセンサ13に導いて空燃比を検出しているため、例えば各気筒の排気ポート10に個別に排ガスセンサ13を設置した場合に比較して、排ガスセンサ13の必要数を減少でき、ひいては内燃機関の製造コストを低減することができる。

更に、図1から明らかなように、各排気連通路11は相互に直接的に連通することなく何れも排ガスセンサ13を介して接続されている。この構成によれば、排気連通路11内で生じている圧力脈動の一部が排ガスセンサ13により遮断されるため、各気筒の排気干渉を抑制して排気干渉による機関の出力低下を防止することができる。

On the other hand, since the exhaust gas discharged from each cylinder is guided to the common

Further, as is apparent from FIG. 1, the

ところで、上記のように高速自励変調ではCOPの浄化効率を向上できる一方、図2に示すように変調周期の短縮化により所謂ウインド幅が減少する傾向がある。よって、積極的に空燃比を変化させる制御を実施した場合、若しくは何らかの要因により空燃比が目標空燃比からずれた場合には、高速自励変調ではウインドを外れてしまう可能性が高くなる。そこで、所定期間毎にリーンスパイクを実行、或いは排ガスセンサ13による所定のリッチ判定後にリーンスパイクを実行して、触媒9に対するHCパージを行ってもよい。

By the way, while high-speed self-excited modulation can improve the COP purification efficiency as described above, the so-called window width tends to be reduced by shortening the modulation period as shown in FIG. Therefore, when the control for actively changing the air-fuel ratio is carried out, or when the air-fuel ratio deviates from the target air-fuel ratio due to some factor, there is a high possibility that the window will be out of the window in the high-speed self-excitation modulation. Therefore, the HC purge may be performed on the

又、空燃比がウインドを外れたときのHC排出を防止するために、排ガスセンサ13による空燃比判定に適切な遅れ時間を設定して故意に高速自励変調の周期を延長化してもよい。この場合でも、高速自励変調の周期は任意に設定可能であるため、HC排出を防止した上で可能な限り自励変調の周期を高めることができ、もって従来の自励変調より良好な空燃比判定の応答性を確保することができる。

In order to prevent HC emission when the air-fuel ratio deviates from the window, an appropriate delay time may be set for the air-fuel ratio determination by the

尚、本実施形態では各気筒の排気連通路11を一点に集合させて単一の排ガスセンサ13に接続したが、気筒数より少ない数の排ガスセンサ13を設けて、何れかの排ガスセンサ13に各気筒の排気連通路11を接続する構成であれば、排気連通路11のレイアウトや排ガスセンサ13の数は種々に変更可能である。よって、例えば3気筒分の排気連通路11を単一の排ガスセンサ13に接続したり、2気筒分の排気連通路11を単一の排ガスセンサ13に接続したりしてもよい。

In this embodiment, the

ところで、本実施形態では上記のように排気連通路11での排ガスの移送を主にガス拡散作用により行っているため、排気連通路11内で排ガスのガス交換が今一つ円滑に行われない傾向がある。そこで、以下に排気連通路11内のガス交換を促進するためのガス交換促進手段を追加した第2〜第5実施形態を説明する。尚、各実施形態の基本的な構成(距離A1,A2の設定等)は第1実施形態と同様であり、相違点は上記ガス交換を促進する構成にあるため、相違点を重点的に説明し、共通する構成の箇所は同一部材番号を付して重複する説明を省略する。

[第2実施形態]

図3は本実施形態の多気筒内燃機関の排気マニホールド1に対する排気連通路11の接続状態を示す断面図である。本実施形態ではガス交換の促進を目的として、排気連通路11の先端の流入部21(ガス交換促進手段)を排ガスが排気連通路11内に流入し易いように配置している。即ち、第1実施形態の排気連通路11が排気マニホールド1のブランチ3に対して単に直角に接続されているのに対して、本実施形態では、流入部21をヘッド側に接近させる方向に排気連通路11が傾斜して配置されると共に、流入部21をブランチ3内に突出させて排気ポート10内の排気弁22近傍に位置させている。

By the way, in this embodiment, since the transfer of the exhaust gas in the

[Second Embodiment]

FIG. 3 is a cross-sectional view showing a connection state of the

排気ポート10内の排気弁22近傍では、燃焼室23からの排ガスが図中に矢印で示す排ガス流線L1に沿って斜め上方に向けて排出されるが、この排ガス流線L1に対して、排気連通路11の流入部21に排ガスが流入されるときの流入線L2(換言すれば、流入部21の軸心)は鋭角の挟み角αを形成する。従って、燃焼室23から排気ポート10に排出された排ガスは、排出時の運動エネルギにより積極的に排気連通路11の流入部21に流入し、更に排気連通路11内を経て排ガスセンサ13に到達する。

In the vicinity of the

その結果、主にガス拡散作用により排ガスを移送する第1実施形態に比較すると、各気筒の排ガスは排気連通路11内を経て円滑に排ガスセンサ13まで移送されて、排気連通路11内の排ガスのガス交換が促進されるため、第1実施形態に比較して排ガスセンサ13による空燃比判定の応答性を一層向上させることができる。

尚、排気マニホールド1に対する排気連通路11の接続状態は上記実施形態に限ることはなく、例えば図4に示すように構成してもよい。この例では上記と同様に排気連通路11を傾斜させると共に、排気連通路11の流入部21を排気ポート10内の出口付近に開口させている。排気ポート10の出口では図中に矢印で示す排ガス流線L1に沿って排ガスが略水平に流通するが、この排ガス流線L1に対して流入部21への流入線L2は鋭角の挟み角αを形成するため、上記実施形態と同様の作用効果を得ることができる。

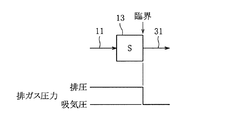

[第3実施形態]

図5は本実施形態の多気筒内燃機関の吸気連通路の接続状態を示す図である。本実施形態ではガス交換の促進を目的として、排ガスセンサ13を内燃機関の吸気系と接続して排ガスセンサ13の前後に圧力差を発生させている。即ち、第1実施形態の排ガスセンサ13には排気連通路11のみが接続されているのに対して、本実施形態では排気連通路11に加えて排ガスセンサ13に1本の吸気連通路31(ガス交換促進手段)の一端が接続され、吸気連通路31の他端は吸気マニホールド32に接続されている。従って、排ガスセンサ13は排気連通路11を介して排気マニホールド1の各気筒のブランチ3と連通する一方、吸気連通路31を介して吸気マニホールド32に対しても連通している。

As a result, the exhaust gas in each cylinder is smoothly transferred to the

The connection state of the

[Third Embodiment]

FIG. 5 is a view showing a connection state of the intake communication passage of the multi-cylinder internal combustion engine of the present embodiment. In the present embodiment, for the purpose of promoting gas exchange, the

そして、排気連通路11が接続されたブランチ3には排圧(正圧)が作用するのに対して、吸気連通路31が接続された吸気マニホールド32には吸気圧(負圧)が発生しているので、排ガスセンサ13の前後には圧力差が生じる。従って、排気連通路11内の排ガスは排ガスセンサ13を経て低圧側の吸気連通路31へと流通し、結果として各気筒の排ガスが排気連通路11内を経て円滑に排ガスセンサ13まで移送されるため、排気連通路11内の排ガスのガス交換を促進することができる。

Exhaust pressure (positive pressure) acts on the

ところで、排ガスの流通による閉塞防止のために吸気連通路31にはある程度の断面積を確保する必要があるため、結果的にガス交換の促進に要する量以上の排ガスが吸気連通路31を経て吸気マニホールド32側に還流される傾向がある。従って、EGR制御においてNOx低減のために燃焼限界付近までEGR量を増大させている場合には、吸気連通路31を経て還流される排ガスが燃焼悪化の要因となり得る。そこで、図5に破線で示すように吸気連通路31に開閉バルブ33を設けて、上記燃焼悪化の虞がある運転領域では開閉バルブ33の開度を減少又は全閉し、これにより吸気連通路31を経て吸気マニホールド32側に還流される排ガス量を制限して燃焼悪化の防止を図ってもよい。

[第4実施形態]

図6は本実施形態の多気筒内燃機関の排気下流連通路の接続状態を示す図である。本実施形態ではガス交換の促進を目的として、排ガスセンサ13を排気管6の触媒9の下流側と接続して排ガスセンサ13の前後に圧力差を発生させている。即ち、第3実施形態の吸気連通路31に代えて、排ガスセンサ13には1本の排気下流連通路41(ガス交換促進手段)の一端が接続され、排気下流連通路41は排気管6に沿って下流側に延設されて他端を触媒9の下流側に接続されている。

By the way, since it is necessary to secure a certain cross-sectional area in the

[Fourth Embodiment]

FIG. 6 is a view showing a connection state of the exhaust downstream communication passage of the multi-cylinder internal combustion engine of the present embodiment. In this embodiment, for the purpose of promoting gas exchange, the

そして、排気連通路11が接続された排気マニホールド1のブランチ3に比較して、排気下流連通路41が接続された触媒9の上流側では触媒9の絞り効果等により排圧が増大しているので、排ガスセンサ13の前後には圧力差が生じる。従って、排気連通路11内の排ガスは排ガスセンサ13を経て低圧側の排気下流連通路41へと流通し、結果として各気筒の排ガスが排気連通路11内を経て円滑に排ガスセンサ13まで移送されるため、排気連通路11内の排ガスのガス交換を促進することができる。

Then, compared with the

ところで、冷態始動時には、燃料増量による未燃ガスが排気下流連通路41を経て触媒9を迂回して排出される現象が生じる。そこで、図6に破線で示すように、排気下流連通路41に上記第3実施形態と同様の開閉バルブ42を設けて上記冷態始動時等に開閉バルブ42の開度を減少又は全閉し、排気下流連通路41内を流通する排ガス量を制限して未燃ガスの排出防止を図ってもよい。

By the way, at the time of cold start, a phenomenon occurs in which unburned gas due to an increase in fuel is exhausted by bypassing the

尚、排気下流連通路41の接続箇所は触媒9の下流側に限らず、触媒9の上流側であってもよい。この場合、排気管6に設けられた既存の絞り部の下流側、或いは圧力差を発生させるために新たに設けた絞り部の下流側に排気下流連通路41を接続すれば、上記触媒9と同様の絞り効果が得られてガス交換を促進することができる。

[第5実施形態]

図7は本実施形態の多気筒内燃機関の冷却空間の接続状態を示す図である。本実施形態ではガス交換の促進を目的として、第4実施形態で説明した排気下流連通路41に冷却空間51(ガス交換促進手段)を設けている。即ち、第4実施形態と同じく排ガスセンサ13と排気管6の触媒9の下流側とは排気下流連通路41により接続され、加えて本実施形態では排気下連通路41の中程に冷却空間51が設けられている。

The connection location of the exhaust

[Fifth Embodiment]

FIG. 7 is a view showing a connection state of the cooling space of the multi-cylinder internal combustion engine of the present embodiment. In this embodiment, for the purpose of promoting gas exchange, a cooling space 51 (gas exchange promoting means) is provided in the exhaust

従って、排ガスセンサ13を経た排ガスは排気下流連通路41内を経て冷却空間51内に導入されて温度低下により体積変化(体積縮小)し、この体積変化に伴って冷却空間51より上流側の排気下流連通路41内の排ガスが冷却空間51内に移送されると共に、排気連通路11内の排ガスが排ガスセンサ13を経て排気下流連通路41に移送され、結果として冷却空間51を備えない第4実施形態に比較して排気連通路11内の排ガスのガス交換を一層促進することができる。

Accordingly, the exhaust gas that has passed through the

ここで、冷却空間51により排気連通路11内のガス交換を効率的に促進させるには、冷却空間51での排ガスの体積変化に伴って排気連通路11内の排ガスのほぼ全量を排気下流連通路41側に移送することが望ましい。このためには、冷却空間51の排ガスの体積変化と排気連通路11の容積とが同程度となるように、冷却空間51の容積、或いは排気連通路11の容積、或いは冷却空間51における温度低下率の少なくとも一つ以上を設定すればよい。

Here, in order to efficiently promote the gas exchange in the

尚、上記のように排気下流連通路41に独立した冷却空間51を設けることなく、例えば排気下流連通路41自体、或いは排気下流連通路41の一部に、例えばフィンや冷却水配路等の冷却装置を設けて冷却空間51として機能させてもよい。

又、本実施形態では冷却空間51を排気下流連通路41に設けたが、第3実施形態で説明した吸気連通路31に冷却空間51を設けることもでき、この場合でも冷却空間51は上記と同様の作用効果を奏してガス交換を一層促進できる。

In addition, without providing the

In this embodiment, the cooling

以上でガス交換促進手段に関する第2〜第5実施形態の説明を終えるが、これらの実施形態以外にも種々の実施形態が考えられ、以下に順次説明する。

[第6実施形態]

本実施形態では、排気連通路11を排気マニホールド1の外部に設けた第1実施形態に対して排気連通路11を内蔵している点が相違している。図8は本実施形態の多気筒内燃機関のヘッド側スペーサ部材を示す正面図、図9は同じくマニ側スペーサ部材を示す正面図、図10は同じく各スペーサ部材の組付状態を示す断面図である。尚、以下の説明では、図10の左方に相当するシリンダヘッド側をヘッド側と称し、図10の右方に相当する排気マニホールド側とマニ側と称するものとし、図8,9は各スペーサ部材をヘッド側より見た状態を示している。

Although the description of the second to fifth embodiments relating to the gas exchange promoting means has been completed above, various embodiments other than these embodiments can be considered and will be sequentially described below.

[Sixth Embodiment]

The present embodiment is different from the first embodiment in which the

ヘッド側スペーサ部材61及びマニ側スペーサ部材62は排気マニホールド1の上流側フランジ2(図1に示す)と近似する形状の板状をなし、ヘッド側スペーサ部材61をヘッド側に、マニ側スペーサ部材62をマニ側に配置した状態で、シリンダヘッド63と排気マニホールド1の上流側フランジ2との間に介装されている。両スペーサ部材61,62は周囲に貫設されたボルト孔61a,62aを利用して排気マニホールド取付用のボルト64により共締めされて、排気マニホールド1と共にシリンダヘッド63に固定されており、両スペーサ部材61,62に貫設された4つのポート連通孔65を介して各排気ポート10(図1に示す)からの排ガスが排気マニホールド1側に流通する。

The head-

マニ側スペーサ部材62のマニ側の面には、#2気筒と#3気筒のポート連通孔65間の若干上方位置に円形状をなすセンサ固定ベース12が溶接され、センサ固定ベース12の中央には排ガスセンサ固定用のねじ孔67が形成されると共に、ねじ孔67と対応してマニ側スペーサ部材62には挿入孔68が貫設されている。マニ側スペーサ部材62の挿入孔68と対応してヘッド側スペーサ部材61のマニ側の面には屈曲路69の一端が開口し、屈曲路69は上方に向けて略直角に屈曲形成され、屈曲路69の他端はねじ孔70を介してヘッド側スペーサ部材61の上縁に開口している。

A circular

センサ固定ベース12のねじ孔67には排ガスセンサ13が螺合して固定され、排ガスセンサ13の検出部13aは挿入孔68内及び屈曲路69内に位置し、検出部13aの先端は屈曲路69内の水平部分のほぼ最奥部まで達している。一方、ヘッド側スペーサ部材61のねじ孔70には、上記した第3実施形態の吸気連通路31、或いは第4実施形態の排気下流連通路41の一端が接続され、これらの連通路31,41を介して内燃機関の吸気マニホールド32や排気管6の触媒9下流側と連通している。

The

マニ側スペーサ部材62のヘッド側の面には、各ポート連通孔65と挿入孔68とを接続する4本の直線状の溝71が形成され、図10に示すようにマニ側スペーサ部材62にヘッド側スペーサ部材61が重ねられた状態では各溝71がヘッド側スペーサ部材61により閉塞されて、各排気ポート10と排ガスセンサ13とを連通する第1実施形態の排気連通路11として機能する。

Four

そして、第1実施形態と同様に本実施形態でも、排気ポート10から排ガスセンサ13までの距離A1が必要最小限に短縮されて、排気ポート10から触媒9の上流側入口までの距離A2(図1に示す)に比較して格段に短いため、排気ポート10から排出された排ガスが排ガスセンサ13に到達するまでの輸送遅れを最小限に抑制して、極めて良好な応答性で排気空燃比を判定できると共に、各気筒の排ガスを共通の排ガスセンサ13により検出するため、内燃機関の製造コストを低減することができる。

In this embodiment as well as the first embodiment, the distance A1 from the

しかも、排気連通路11がスペーサ部材61,62内に形成され、且つ、スペーサ部材61,62がシリンダヘッド63と排気マニホールド1の上流側フランジ2との間に介装されているため、各排気連通路11内を流通する排ガスの放熱が抑制される。従って、高い温度を保ったまま排ガスを排ガスセンサ13に供給でき、排ガスセンサ13の不活性防止及び早期活性化を実現できるという別の利点も得られる。

In addition, since the

尚、このように排気連通路11内での排ガスの放熱を抑制する構成は上記に限ることはなく、例えば排気連通路11を排気マニホールド1の外部に設けた第1実施形態において、排気連通路11を2重管として構成したり排気連通路11を保温材により覆ったりしても排ガスの放熱が抑制されて、本実施形態と同様の作用効果を得ることができる。又、排ガスの放熱を抑制する代わりに、排ガスセンサ13をヒータ等により積極的に昇温することで不活性防止及び早期活性化を図ってもよい。

The configuration for suppressing the heat radiation of the exhaust gas in the

一方、ヘッド側スペーサ部材61及びマニ側スペーサ部材62は上記構成に限ることはなく種々に変更可能であり、以下に別例を説明する。

第6実施形態では、ヘッド側スペーサ部材61に屈曲路を形成して排ガスセンサ13を吸気連通路31や排気下流連通路41と接続したが、第1実施形態と同様に吸気連通路31や排気下流連通路41を省略してもよい。この場合には圧力差によるガス交換の促進は期待できないが、排ガスの放熱抑制の作用は上記第6実施形態と同様に得られる。

On the other hand, the head

In the sixth embodiment, a curved path is formed in the head

第6実施形態では、図10に示すように排ガスセンサ13の検出部13aの先端を屈曲路69内の水平部分のほぼ最奥部に位置させたが、例えば図11示すようにヘッド側スペーサ部材61の板厚を増大させて、排ガスセンサ13の検出部13aの先端が屈曲路69内の水平部分の中程に留まるように設定してもよい。この場合には図10とは排ガスセンサ13の検出部13aに対する排ガスの流通状態が異なるため、排ガスセンサ13の特性等を考慮して何れの配置にするかを選択すればよい。

In the sixth embodiment, as shown in FIG. 10, the tip of the

第6実施形態では、ヘッド側スペーサ部材61に形成した屈曲路69を介して排ガスセンサ13と吸気連通路31或いは排気下流連通路41とを連通させたが、排気連通路11と同様にマニ側スペーサ部材62に溝72を形成して屈曲路69の代替としてもよい。具体的には図12に示すようにマニ側スペーサ部材62に排ガスセンサ13の検出部13aから上方に延びる1本の溝72を形成し、この溝72をヘッド側スペーサ部材61により閉塞して通路73を形成し、通路73の上部を吸気連通路31或いは排気下流連通路41と接続すればよい。マニ側スペーサ部材62に対する溝72の加工は屈曲路69を形成するための加工に比較して格段に容易なため製造コストを低減でき、且つ、屈曲路69の廃止によりヘッド側スペーサ部材61の厚みを大幅に減少できるため、ひいては内燃機関の小型化に貢献できるという利点が得られる。

In the sixth embodiment, the

第6実施形態では、シリンダヘッド63及び排気マニホールド1とは別個の独立した部材としてヘッド側スペーサ部材61及びマニ側スペーサ部材62を製作し、これらのスペーサ部材61,62に排気連通路11や排ガスセンサ13を設けたが、両スペーサ部材61,62の何れか一方、又は双方をシリンダヘッド63や排気マニホールド1に一体化してもよい。図13はヘッド側スペーサ部材61をシリンダヘッド63に一体化し、マニ側スペーサ部材62を排気マニホールド1に一体化した例を示しており、排気マニホールド1の上流側フランジ2に溝71を形成して排ガスセンサ13を固定する一方、排ガスセンサ13の検出部13aと連通するようにシリンダヘッド63に屈曲路69を形成している。このように構成すれば両スペーサ部材61,62の厚み相当だけ内燃機関を小型化することができる。

In the sixth embodiment, the head

ところで、排ガスセンサ13での各排気連通路11のガス交換量が不均等なときには、センサ出力に対して特定気筒の空燃比の影響が強くなる或いは弱くなる等の問題を生じて、正確な排気空燃比の判定が期待できなくなる。そこで、以下に各排気連通路11内の排ガスのガス交換を均等化するための対策を実施した第7,8実施形態を説明する。

[第7実施形態]

図14は本実施形態の多気筒内燃機関のマニ側スペーサ部材を示す正面図である。本実施形態では、第6実施形態で述べた各排気連通路11の容積を略等しくすることでガス交換の均等化を図っており、その他の構成は第6実施形態と同様であるため、相違点を重点的に説明する。

By the way, when the amount of gas exchange in each

[Seventh Embodiment]

FIG. 14 is a front view showing a manifold side spacer member of the multi-cylinder internal combustion engine of the present embodiment. In the present embodiment, gas exchange is equalized by making the volumes of the

マニ側スペーサ部材62のヘッド側の面には第6実施形態と同様に4本の溝81,82が形成され、本実施形態では排ガスセンサ13から離間している#1,#4気筒の溝81に比較して、排ガスセンサ13に近接する#2,#3気筒の溝82は同一深さのまま幅広に形成され、より大きな断面積を有している。この設定により、全ての排気連通路11のポート連通孔65から挿入孔68まで容積が略等しくなっている。

Four

このように各排気連通路11の容積が略等しいため、内部を排ガスが流通する際の圧力脈動が等しく影響して均等にガス交換が行われ、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現できる。

尚、各排気連通路11の断面積を調整する手法としては、上記溝81,82の幅に代えて深さを相違させたり、或いは幅と深さとの両方を相違させてもよい。

As described above, since the volumes of the

As a method for adjusting the cross-sectional area of each

ここで、各排気連通路11の長さによっては内部で圧力脈動の共振が生じる場合があり、圧力脈動の共振は排ガス流量を変動させて排ガスセンサ13の出力を変動させてしまう。そこで、機関の常用回転域では圧力脈動の共振を発生しないように各排気連通路11の長さを設定することが望ましい。

[第8実施形態]

図15は本実施形態の多気筒内燃機関の吸気連通路或いは排気下流連通路に対する各排気連通路の配置状態を示す斜視図である。本実施形態では、吸気連通路31や排気下流連通路41に対して各排気連通路11を等間隔で配置しており、その他の構成は第1実施形態と同様であるため、相違点を重点的に説明する。

Here, depending on the length of each

[Eighth Embodiment]

FIG. 15 is a perspective view showing an arrangement state of each exhaust communication path with respect to the intake communication path or the exhaust downstream communication path of the multi-cylinder internal combustion engine of the present embodiment. In the present embodiment, the

排ガスセンサ13が取付けられたセンサ固定ベース12には4本の排気連通路11の一端が接続され、各排気連通路11はセンサ固定ベース12を中心として略水平面上で90°毎に等間隔で配置され、図示はしないが、各排気連通路11の他端は排気マニホールド1の各気筒のブランチ3に接続されている。センサ固定ベース12の下面には、上記した第3実施形態の吸気連通路31、或いは第4実施形態の排気下流連通路41の一端が接続され、これらの連通路31,41の他端は内燃機関の吸気マニホールド32や排気管6の触媒9下流側と接続されている。

One end of four

このような各連通路11,31,41の配置により、吸気連通路31や排気下流連通路41に対して各排気連通路11が略等間隔で位置することになり、各排気連通路11の排ガスは排ガスセンサ13を経て吸気連通路31や排気下流連通路41にほぼ同一条件で流入する。これにより、排ガスセンサ13の検出部13aの全周が空燃比検出に有効に利用されるため応答性が向上すると共に、特定気筒の空燃比の影響が強くなる或いは弱くなることが防止されて、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現できる。

With the arrangement of the

ところで、第3実施形態のように排ガスセンサ13に吸気連通路31を接続した場合、排ガスセンサ13を流れる排ガス量は排圧と吸気圧との圧力比の増加に応じて増大し、圧力比が臨界比に達して臨界状態となった時点で排ガスの流量増大は制限される。この現象を利用して排ガスセンサ13の出口或いは入口で臨界状態を発生させることで種々の利点が得られ、以下、それぞれの場合を第9,10実施形態として説明する。

[第9実施形態]

本実施形態では、排ガスセンサ13が有する圧力依存の影響を軽減する目的で、排ガスセンサ13の出口側で臨界状態が発生するように、各排気連通路11及び吸気連通路31の断面積が設定されている。即ち、排ガスセンサ13に対する吸気連通路31の接合有効断面積に比較して、排ガスセンサ13に対する各排気連通路11の接合有効断面積の総和が大きく設定されている。

By the way, when the

[Ninth Embodiment]

In the present embodiment, the cross-sectional areas of the

図16は本実施形態の多気筒内燃機関において排ガス圧力が臨界状態に達したときの排ガスセンサ13の前後の圧力分布を示す説明図である。上記した断面積の設定により、排ガスの流通時に排圧と吸気圧との圧力比が増加すると、排ガスセンサ13の入口側(排気連通路11側)より早期に排ガスセンサ13の出口側(吸気連通路31側)が臨界状態に達し、この箇所において排ガス流量の増大が制限される。

FIG. 16 is an explanatory diagram showing the pressure distribution before and after the

このときの排ガスの圧力は排ガスセンサ13の出口側を境界として上流側は排圧に、下流側は吸気圧になり、排ガスセンサ13には吸気圧に比較してより大気圧に近い排圧が作用する。一般に排ガスセンサ13は排ガス圧力に依存して検出特性を変動させる性質を有するが、より大気圧に近い排圧が作用することで圧力依存の影響を軽減できるため、排気空燃比の判定精度を向上させることができる。

[第10実施形態]

本実施形態は、上記第9実施形態の排ガスセンサ13の圧力依存への対策を実施する必要がない場合、例えば圧力依存の影響が小さい場合や圧力依存に対してガス圧力補正を実施する場合を想定したものであり、各排気連通路11から排ガスセンサ13に流入する排ガス量を均等にする目的で、第9実施形態とは逆に排ガスセンサ13の入口側で臨界状態が発生するように、各排気連通路11及び吸気連通路31の断面積が設定されている。即ち、排ガスセンサ13に対する吸気連通路31の接合有効断面積に比較して、各排気連通路11の接合有効断面積の総和が小さく設定されている。又、本実施形態では各排気連通路11の接合有効断面積が相互に均等に設定されている。

The exhaust gas pressure at this time is the exhaust pressure on the upstream side and the intake pressure on the downstream side with the outlet side of the

[Tenth embodiment]

In the present embodiment, when it is not necessary to implement measures against the pressure dependency of the

図17は本実施形態の多気筒内燃機関において排ガス圧力が臨界状態に達したときの排ガスセンサ13の前後の圧力分布を示す説明図である。上記した断面積の設定により、排ガスの流通時に排圧と吸気圧との圧力比が増加すると、排ガスセンサ13の出口側(吸気連通路31側)より早期に排ガスセンサ13の入口側(排気連通路11側)が臨界状態に達し、この箇所において排ガス流量の増大が制限される。

FIG. 17 is an explanatory diagram showing the pressure distribution before and after the

このように排ガスセンサ13の入口が臨界状態になり、且つ各排気連通路11の接合有効断面積が均等のため、各排気連通路11から排ガスセンサ13に流入する排ガス量が略等しくなり、各気筒の空燃比を均一に反映させた正確な排気空燃比の判定を実現できる。

以上で実施形態の説明を終えるが、本発明の態様はこの実施形態に限定されるものではない。例えば、上記実施形態では、直列4気筒の内燃機関として具体化したが、多気筒であれば気筒数や気筒配列はこれに限ることはなく任意に変更可能である。

In this way, the inlet of the

This is the end of the description of the embodiment, but the aspect of the present invention is not limited to this embodiment. For example, in the above-described embodiment, the invention is embodied as an in-line four-cylinder internal combustion engine. However, if the number of cylinders is large, the number of cylinders and the cylinder arrangement are not limited to this and can be arbitrarily changed.

又、上記各実施形態の構成を個別に実施する場合に限定されることはなく、各実施形態の構成を任意に組み合わせて実施可能であり、例えば排ガス流線L1に対して排気連通路11の流入部21を鋭角に配置した第2実施形態の構成と、排気下流連通路41に冷却空間51を設けた第5実施形態の構成を組み合わせてもよい。

又、吸気連通路31を吸気マニホールド32ではなく、EGR下流通路に接続するようにしてもよい。

Moreover, it is not limited to the case where the structure of each said embodiment is implemented separately, It can implement combining the structure of each embodiment arbitrarily, for example, is the

Further, the

又、ガス交換が促進できないような圧力差(例えば、吸気管負圧増大、上流排圧低減、下流排圧増大)となった場合は、空燃比判定を索止するようにしてもよい。

又、排ガスセンサ13の保護カバーに設けられた通気口と当該排ガスセンサ13に流入する排気連通路11の連通口との関係を各気筒で均等にすることが好ましい。排ガスセンサ13に流入する排ガス(検査ガス)の流速が速いと、当該通路口の投影面に当該通気口が多くある場合と少ない場合とで、排ガスセンサ13の検出部13aに到達する検査ガス量にバラツキが生じ空燃比の気筒間バラツキの影響を受け易くなる問題があるが、係る問題を低減することができる。

Further, when the pressure difference is such that gas exchange cannot be promoted (for example, intake pipe negative pressure increase, upstream exhaust pressure decrease, downstream exhaust pressure increase), the air-fuel ratio determination may be stopped.

Further, it is preferable that the relationship between the vent provided in the protective cover of the

又、排気連通路11、吸気連通路31.排気下流連通路41の通路断面積は、実施例に示すように各通路において均一である必要はなく、断面積が最小となる部分が通路の一部のみとなるようにしてもよい。各通路は排ガスが通過することから、デボジット付着等により通路断面積が変化し、例えぱ各排気連通路11の有効断面積が各気筒間で不均一となった場合には空燃比判定に気筒間バラツキが生じ問題があるが、デボジット等は通路内に均一に付着するわけではないため、最小断面積領域を一部分とすることで、最小断面積部にデポジット等が付着する確率を低減させることができる。

Further, the cross-sectional areas of the

これにより、各排気通路の有効断面積が各気簡間で不均一となる確率を低減し、もって空燃比検出の気筒間バラツキに伴う判定精度悪化を抑制することができる。

又、各排気連通路により導入された排ガスが排ガスセンサ13部の空間で混合され、当該混合された排ガスを排ガスセンサ13により判定するようにしてもよく、混含されずに各気筒の空燃比を個別に判定するようにしてもよい。

As a result, the probability that the effective cross-sectional area of each exhaust passage is non-uniform among the easy passages can be reduced, and deterioration in determination accuracy due to variation between cylinders in air-fuel ratio detection can be suppressed.

Further, the exhaust gas introduced through each exhaust communication passage may be mixed in the space of the

1 排気マニホールド(排気通路)

3 ブランチ(排気ポート側排気通路)

4,8 排気通路合流部

6 排気管(排気通路)

9 触媒

10 排気ポート

11 排気連通路

13 排ガスセンサ

21 流入部(ガス交換促進手段)

31 吸気連通路(ガス交換促進手段)

33,42 開閉バルブ

41 排気下流連通路(ガス交換促進手段)

51 冷却空間(ガス交換促進手段)

1 Exhaust manifold (exhaust passage)

3 Branch (exhaust port side exhaust passage)

4, 8

9

31 Intake communication passage (gas exchange promotion means)

33, 42 Open /

51 Cooling space (gas exchange promotion means)

Claims (9)

各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、

上記内燃機関のシリンダヘッドと上記排気通路とのフランジ接合箇所に内蔵され、少なくとも2つ以上の上記排気通路を連通する排気連通路と、

上記排気連通路に設けられる排ガスセンサとを備え、

上記排気ポートから上記排ガスセンサまでの距離を該排気ポートから上記触媒の上流側入口までの距離より短くしたことを特徴とする多気筒内燃機関。 In a multi-cylinder internal combustion engine having a plurality of cylinders,

A catalyst for purifying exhaust gas provided in an exhaust passage extending from the exhaust port of each cylinder;

An exhaust communication passage that is built in a flange joint between the cylinder head of the internal combustion engine and the exhaust passage, and communicates at least two of the exhaust passages;

An exhaust gas sensor provided in the exhaust communication path,

A multi-cylinder internal combustion engine characterized in that the distance from the exhaust port to the exhaust gas sensor is shorter than the distance from the exhaust port to the upstream inlet of the catalyst.

各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、A catalyst for purifying exhaust gas provided in an exhaust passage extending from the exhaust port of each cylinder;

少なくとも2つ以上の上記排気通路を連通する排気連通路と、An exhaust communication passage communicating at least two or more of the exhaust passages;

上記排気連通路に設けられる排ガスセンサと、An exhaust gas sensor provided in the exhaust communication path;

上記排ガスセンサと上記内燃機関の吸気系とを連通し、排圧と吸気圧との圧力差により上記排気連通路内のガス交換を促進する吸気連通路とを備え、An exhaust communication passage that communicates the exhaust gas sensor and the intake system of the internal combustion engine and promotes gas exchange in the exhaust communication passage by a pressure difference between the exhaust pressure and the intake pressure;

上記排ガスセンサに対する上記吸気連通路の接合有効断面積に比較して、該排ガスセンサに対する上記排気連通路の接合有効断面積の総和が大きく設定されていることを特徴とする多気筒内燃機関。A multi-cylinder internal combustion engine, wherein a sum of effective joint areas of the exhaust communication passages with respect to the exhaust gas sensor is set larger than a joint effective sectional area of the intake communication passages with respect to the exhaust gas sensor.

各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、

少なくとも2つ以上の上記排気通路を連通する排気連通路と、

上記排気連通路に設けられる排ガスセンサと、

上記排ガスセンサと上記内燃機関の吸気系とを連通し、排圧と吸気圧との圧力差により上記排気連通路内のガス交換を促進する吸気連通路とを備え、

上記排ガスセンサに対する上記吸気連通路の接合有効断面積に比較して、該排ガスセンサに対する上記排気連通路の接合有効断面積の総和が小さく設定されると共に、該排ガスセンサに対する各排気連通路の接合有効断面積が相互に略均等に設定されていることを特徴とする多気筒内燃機関。 In a multi-cylinder internal combustion engine having a plurality of cylinders,

A catalyst for purifying exhaust gas provided in an exhaust passage extending from the exhaust port of each cylinder;

An exhaust communication passage communicating at least two or more of the exhaust passages;

An exhaust gas sensor provided in the exhaust communication path;

And communicating the intake system of the exhaust gas sensor and the internal combustion engine, and an intake communication passage that promotes gas exchange in the exhaust communication passages due to the pressure difference between the exhaust pressure and the intake pressure,

The sum of the effective joint areas of the exhaust communication passages to the exhaust gas sensor is set smaller than the effective joint area of the intake communication passages to the exhaust gas sensor, and the connection of each exhaust communication passage to the exhaust gas sensor. A multi-cylinder internal combustion engine characterized in that effective cross-sectional areas are set substantially equally to each other.

上記冷却空間の排ガスの体積変化が上記排気連通路の容積と略同程度になるように、上記冷却空間の容積、上記排気連通路の容積、該冷却空間における温度低下率の少なくとも一つ以上が設定されていることを特徴とする請求項3又は4記載の多気筒内燃機関。 Downstream of the upper Sharing, ABS gas sensor, cooling space to promote gas exchange in the exhaust communication passage is formed by a volume change caused by cooling of exhaust gases,

At least one of the volume of the cooling space, the volume of the exhaust communication path, and the temperature decrease rate in the cooling space is set so that the volume change of the exhaust gas in the cooling space is approximately the same as the volume of the exhaust communication path. The multi-cylinder internal combustion engine according to claim 3 or 4, wherein the multi-cylinder internal combustion engine is set.

各気筒の排気ポートから延出する排気通路に設けられ排ガスを浄化する触媒と、

少なくとも2つ以上の上記排気通路を連通する排気連通路と、

上記排気連通路に設けられる排ガスセンサと、

上記排ガスセンサと上記内燃機関の排気系の上記触媒より下流側とを連通し、該排気系の上流側と下流側との圧力差により上記排気連通路内のガス交換を促進する排気下流連通路と、

上記排気下流連通路に備えられ、該排気下流連通路内を流通する排ガス量を調整可能な開閉バルブと

を備えたことを特徴とする多気筒内燃機関。 In a multi-cylinder internal combustion engine having a plurality of cylinders,

A catalyst for purifying exhaust gas provided in an exhaust passage extending from the exhaust port of each cylinder;

An exhaust communication passage communicating at least two or more of the exhaust passages;

An exhaust gas sensor provided in the exhaust communication path;

Communicates the downstream side of the catalyst in the exhaust system of the exhaust gas sensor and the internal combustion engine, the exhaust downstream communication passage to promote gas exchange in the exhaust communication passages due to the pressure difference between the upstream side and the downstream side of the exhaust system When,

An open / close valve provided in the exhaust downstream communication passage, and capable of adjusting an amount of exhaust gas flowing through the exhaust downstream communication passage;

A multi-cylinder internal combustion engine comprising:

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004198263A JP4257528B2 (en) | 2004-07-05 | 2004-07-05 | Multi-cylinder internal combustion engine |

| KR1020050053850A KR100675478B1 (en) | 2004-07-05 | 2005-06-22 | Multicylinder internal combustion engine |

| US11/171,368 US8015799B2 (en) | 2004-07-05 | 2005-07-01 | Multicylinder internal combustion engine |

| DE602005024082T DE602005024082D1 (en) | 2004-07-05 | 2005-07-04 | More piston internal combustion engine |

| EP05014493A EP1614872B1 (en) | 2004-07-05 | 2005-07-04 | Multicylinder internal combustion engine |

| CNB2005100833228A CN100478549C (en) | 2004-07-05 | 2005-07-05 | Multicylinder internal combustion engine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004198263A JP4257528B2 (en) | 2004-07-05 | 2004-07-05 | Multi-cylinder internal combustion engine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006017081A JP2006017081A (en) | 2006-01-19 |

| JP4257528B2 true JP4257528B2 (en) | 2009-04-22 |

Family

ID=34993351

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004198263A Expired - Fee Related JP4257528B2 (en) | 2004-07-05 | 2004-07-05 | Multi-cylinder internal combustion engine |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8015799B2 (en) |

| EP (1) | EP1614872B1 (en) |

| JP (1) | JP4257528B2 (en) |

| KR (1) | KR100675478B1 (en) |

| CN (1) | CN100478549C (en) |

| DE (1) | DE602005024082D1 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006052657A (en) * | 2004-08-10 | 2006-02-23 | Nissan Motor Co Ltd | Exhaust manifold |

| JP4885808B2 (en) * | 2007-08-01 | 2012-02-29 | 日本特殊陶業株式会社 | Internal combustion engine structure |

| JP5051043B2 (en) * | 2008-07-30 | 2012-10-17 | 日産自動車株式会社 | Engine exhaust system |

| JP4906891B2 (en) * | 2009-06-12 | 2012-03-28 | 本田技研工業株式会社 | Fuel cell |

| JP2011169311A (en) * | 2010-01-25 | 2011-09-01 | Toyota Motor Corp | Exhaust manifold |

| DE102010007877A1 (en) * | 2010-02-13 | 2011-08-18 | Bayerische Motoren Werke Aktiengesellschaft, 80809 | Exhaust manifold for an internal combustion engine |

| JP5517665B2 (en) | 2010-02-17 | 2014-06-11 | フタバ産業株式会社 | Exhaust system |

| JP5118231B2 (en) * | 2011-05-11 | 2013-01-16 | 日本特殊陶業株式会社 | Internal combustion engine structure |

| DE102011116360A1 (en) * | 2011-10-19 | 2013-04-25 | GM Global Technology Operations LLC (n. d. Gesetzen des Staates Delaware) | Exhaust system for an internal combustion engine, internal combustion engine and vehicle |

| US9157363B2 (en) * | 2012-08-21 | 2015-10-13 | Ford Global Technologies, Llc | Twin independent boosted I4 engine |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2145340A5 (en) * | 1971-07-08 | 1973-02-16 | Hinderks M V | |

| GB1569948A (en) | 1978-05-02 | 1980-06-25 | British Leyland Cars Ltd | Internal combustion engine havng air/fuel ratio control means |

| JPS5865562U (en) * | 1981-10-26 | 1983-05-04 | 日産自動車株式会社 | Dual manifold oxygen sensor mounting structure |

| JPS58106530U (en) * | 1982-01-12 | 1983-07-20 | 日産自動車株式会社 | Air-fuel ratio control device for multi-cylinder internal combustion engine |

| JPH055215Y2 (en) | 1986-10-28 | 1993-02-10 | ||

| JP2966554B2 (en) * | 1991-02-22 | 1999-10-25 | ヤマハ発動機株式会社 | O2 sensor arrangement structure for exhaust system for motorcycle |

| US5408215A (en) * | 1991-09-04 | 1995-04-18 | Ford Motor Company | Catalyst monitoring using a hydrocarbon sensor |

| US5450749A (en) * | 1993-08-25 | 1995-09-19 | Wci Outdoor Products, Inc. | Gas sampling method and dilution tunnel therefor |

| US5711148A (en) * | 1994-05-06 | 1998-01-27 | Sanshin Kogyo Kabushiki Kaisha | Sensor arrangement for engine control system |

| US6135100A (en) * | 1994-05-06 | 2000-10-24 | Sanshin Kogyo Kabushiki Kaisha | Sensor arrangement for engine control system |

| US5836155A (en) | 1994-05-06 | 1998-11-17 | Sanshin Kogyo Kabushiki Kaisha | Sensor arrangement for engine control system |

| DE4442573A1 (en) | 1994-11-30 | 1996-06-05 | Bischoff Erhardt Gmbh Co Kg | Flange connection |

| US5625156A (en) * | 1996-04-29 | 1997-04-29 | General Motors Corporation | Apparatus for sensing exhaust gas |

| JP3627881B2 (en) * | 1996-04-30 | 2005-03-09 | ヤマハマリン株式会社 | Fuel injection control device for internal combustion engine |

| US5953912A (en) * | 1996-09-10 | 1999-09-21 | Honda Giken Kobyo Kabushiki Kaisha | Exhaust manifold of a multi-cylinder internal combustion engine |

| JP3649306B2 (en) * | 1996-09-12 | 2005-05-18 | 本田技研工業株式会社 | Exhaust manifold for multi-cylinder internal combustion engines |

| JP3123474B2 (en) * | 1997-07-28 | 2001-01-09 | トヨタ自動車株式会社 | Exhaust gas purification device for internal combustion engine |

| JP3378474B2 (en) * | 1997-08-06 | 2003-02-17 | トヨタ自動車株式会社 | Exhaust manifold of internal combustion engine |

| JPH11182289A (en) * | 1997-12-18 | 1999-07-06 | Sanshin Ind Co Ltd | Control device for cylinder fuel injection type two-cycle engine |

| JPH11280458A (en) | 1998-03-31 | 1999-10-12 | Nissan Motor Co Ltd | Exhaust device for serial four-cylinder internal combustion engine |

| US5907109A (en) * | 1998-05-05 | 1999-05-25 | Tedeschi; Rinaldo R. | Vehicle emission sampling probe apparatus |

| JP2000054880A (en) * | 1998-08-05 | 2000-02-22 | Honda Motor Co Ltd | Intake a/f controller for outboard engine |

| EP1006272B1 (en) * | 1998-12-01 | 2007-04-11 | Honda Giken Kogyo Kabushiki Kaisha | Cylinder head structure in multi-cylinder engine |

| US6324838B1 (en) * | 1999-10-07 | 2001-12-04 | Metaldyne Tubular Products, Inc. | Flow deflector member for exhaust manifold |

| US6458267B2 (en) * | 2000-01-12 | 2002-10-01 | Bran + Luebbe Gmbh | Sample fluid filtering device |

| JP2001295684A (en) * | 2000-04-13 | 2001-10-26 | Sanshin Ind Co Ltd | Exhaust emission control method for cylinder injection engine |

| JP4387067B2 (en) * | 2001-03-30 | 2009-12-16 | カルソニックカンセイ株式会社 | Manufacturing method of branch pipe for exhaust manifold |

| US6539706B2 (en) * | 2001-06-19 | 2003-04-01 | Ford Global Technologies, Inc. | Method and system for preconditioning an emission control device for operation about stoichiometry |

| JP2003120381A (en) * | 2001-10-15 | 2003-04-23 | Nissan Motor Co Ltd | Air-fuel ratio controller of internal combustion engine |

| JP4394868B2 (en) * | 2002-07-30 | 2010-01-06 | 日産自動車株式会社 | Engine exhaust system |

| US6826902B2 (en) * | 2003-03-18 | 2004-12-07 | Ford Global Technologies, Llc | Method and apparatus for estimating oxygen storage capacity and stored NOx in a lean NOx trap (LNT) |

| US7089811B2 (en) * | 2004-01-28 | 2006-08-15 | Innovate! Technology, Inc. | System, apparatus, and method for guiding an exhaust gas |

-

2004

- 2004-07-05 JP JP2004198263A patent/JP4257528B2/en not_active Expired - Fee Related

-

2005

- 2005-06-22 KR KR1020050053850A patent/KR100675478B1/en active IP Right Grant

- 2005-07-01 US US11/171,368 patent/US8015799B2/en not_active Expired - Fee Related

- 2005-07-04 DE DE602005024082T patent/DE602005024082D1/en active Active

- 2005-07-04 EP EP05014493A patent/EP1614872B1/en not_active Ceased

- 2005-07-05 CN CNB2005100833228A patent/CN100478549C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US8015799B2 (en) | 2011-09-13 |

| EP1614872B1 (en) | 2010-10-13 |

| JP2006017081A (en) | 2006-01-19 |

| KR100675478B1 (en) | 2007-01-29 |

| KR20060049423A (en) | 2006-05-18 |

| US20060000204A1 (en) | 2006-01-05 |

| CN100478549C (en) | 2009-04-15 |

| CN1721665A (en) | 2006-01-18 |

| EP1614872A3 (en) | 2008-09-03 |

| EP1614872A2 (en) | 2006-01-11 |

| DE602005024082D1 (en) | 2010-11-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6962049B2 (en) | Exhaust manifold for four-cylinder engine | |

| JP4257528B2 (en) | Multi-cylinder internal combustion engine | |

| JP6217678B2 (en) | cylinder head | |

| US10626781B2 (en) | Exhaust device of engine | |

| JP2019138216A (en) | Exhaust emission control device for internal combustion engine | |

| JP2011080396A (en) | Egr device | |

| US7171805B2 (en) | Deflector style exhaust manifold | |

| US10550750B2 (en) | Exhaust device of engine | |

| US6609506B2 (en) | Exhaust gas recirculation system | |

| US9382829B2 (en) | Bypass exhaust pathway to allow gases to bypass the start catalyst of a vehicle | |

| US7832205B2 (en) | Deflector style exhaust manifold | |

| EP2184456B1 (en) | Exhaust gaz purification apparatus for an internal combustion engine | |

| JP4811117B2 (en) | Engine exhaust gas recirculation system | |

| JP2010121534A (en) | Control device for internal combustion engine | |

| JP4449816B2 (en) | EGR gas flow rate detection device and engine control method | |

| JP4345610B2 (en) | Exhaust gas recirculation device for internal combustion engine | |

| JP2006214275A (en) | Exhaust circulating device of internal combustion engine | |

| US10557443B2 (en) | Exhaust device of engine | |

| JP3584958B2 (en) | Exhaust purification system for multi-cylinder internal combustion engine | |

| KR101405177B1 (en) | Engine that exhaust manifold and cylinder head are integrally fomred | |

| JP3856207B2 (en) | Exhaust device for multi-cylinder internal combustion engine | |

| JP4583958B2 (en) | Secondary air supply device for multi-cylinder engine | |

| JP6819563B2 (en) | Internal combustion engine system | |

| JP4962418B2 (en) | Exhaust control device for internal combustion engine | |

| JP5051043B2 (en) | Engine exhaust system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060626 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080729 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080806 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081002 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090107 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090120 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 4257528 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120213 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120213 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130213 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140213 Year of fee payment: 5 |

|

| LAPS | Cancellation because of no payment of annual fees |