JP4025416B2 - Vertical bolt support - Google Patents

Vertical bolt support Download PDFInfo

- Publication number

- JP4025416B2 JP4025416B2 JP09211298A JP9211298A JP4025416B2 JP 4025416 B2 JP4025416 B2 JP 4025416B2 JP 09211298 A JP09211298 A JP 09211298A JP 9211298 A JP9211298 A JP 9211298A JP 4025416 B2 JP4025416 B2 JP 4025416B2

- Authority

- JP

- Japan

- Prior art keywords

- vertical

- support

- vertical bolt

- bolt

- fitting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L3/00—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets

- F16L3/08—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing

- F16L3/10—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing divided, i.e. with two or more members engaging the pipe, cable or protective tubing

- F16L3/1091—Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets substantially surrounding the pipe, cable or protective tubing divided, i.e. with two or more members engaging the pipe, cable or protective tubing with two members, the two members being fixed to each other with fastening members on each side

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Supports For Pipes And Cables (AREA)

- Hooks, Suction Cups, And Attachment By Adhesive Means (AREA)

- Installation Of Indoor Wiring (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、例えばビルの如き建物の天井材を吊持する吊りボルトを利用して天井裏の空間に各種配管や電気配線を施す場合等、特に既設の垂直ボルトに係着して種々の物品を支持させるのに使用する垂直ボルト係着用支持具に関する。

【0002】

【従来技術とその課題】

ビル等の天井は、建物躯体の天井部の要所に、該天井部の構造や材質に応じて溶接、ボルト止め、コンクリート中への埋設、デッキプレートへの係嵌等の種々の手段によって吊元金具を取り付け、これら吊元金具に設けたねじ孔に吊りボルトを螺着し、この吊りボルトによって野縁や野縁受けを介して天井材を吊持する構造が一般的に採用されている。

【0003】

図14に、建物躯体の天井部(階上床)の下面がデッキプレートにて構成される場合の天井構造の一例を示す。このデッキプレート31は、凹陥部31aと凸条部31bとが交互に配置した波板状をなし、各凹陥部31aの両側面に溝部32,32が対向状に設けてある。そして、該凹陥部31aに、中央部を高く略へ字状に曲成した金属帯板からなる吊元金具40が両端を溝部32,32に係嵌して取り付けられ、この吊元金具40の中央部に固設したナット40aに、吊りボルト41が上部を螺挿して垂直状態に保持され、この吊りボルト41の下部に取り付けた吊りハンガー42にて野縁受け43が支持されると共に、該野縁受け43に嵌装したグリップ44…を介して野縁45が吊持され、この野縁45に天井材46が取り付けられている。

【0004】

なお、デッキプレート係嵌用の吊元金具40は、図では最も単純な形態のものを例示しているが、デッキプレート31の断面形状や負荷重量に応じて係合方式や形態の異なる極めて多種多様なものが用いられている。また、吊りハンガー42としても多種のものがある。

【0005】

ところで、上述のような吊りボルト41を用いる天井構造において、天井裏の空間を利用して、例えば水道管、排水管、ガス管、空調ダクト、電線管等の各種配管を行ったり、電気配線、電話等のケーブル、これら配線用のチャンネル材等の配設を行う場合、その配設仕様が予め判明している設計通りであれば、これら配管や配線に専用の支持部材を天井材取付け施工前に建物躯体の天井部の要所に適当な手段で独立に取り付けたり、天井材取付け施工途上の前記吊元金具40に吊りボルト41を保持させる段階で、この吊りボルト41の中間部位に前記吊りハンガー42と同様のものを野縁受け43の支持用とは別に上記配管や配線用として螺着させておくことができる。

【0006】

しかしながら、実際には、建築の進行に伴って様々な要因により上記配管や配線の仕様変更を必要とする場合が多々あり、また完工後のビル使用中においても、各種の機器や設備の新設、増設、設置場所の変更等により、新たな配管や配線を行ったり、配設替えを要することが少なくない。ところが、既述の吊りハンガー42やこれに類するものは、いずれも吊りボルト41に螺挿もしくは嵌装して取り付ける構造であるから、吊りボルト41に野縁受け43や野縁45を吊持させた以降の段階では、当該吊りボルト41の両端が塞がっているために装着できず、一旦吊持させていた野縁受け43や野縁45を取り外して装着することは膨大な労力と時間の無駄になるので到底不可能である。

【0007】

一方、両端が塞がった吊りボルト41に取付け可能な支持具としては、例えば図15に示すようなものがある。同図(A)の支持具50は、金属板をコ字枠状に曲成したもので、両側板部50b,50bに設けた切欠部51,51を吊りボルト41に係嵌し、その内側に通した長尺物品M(図ではチャンネル材)を、基板部50aに螺挿した蝶ねじ52によって吊りボルト41に押し付けて固定するようになされている。また同図(B)の支持具52は、硬質合成樹脂製であり、U字状枠部52aを吊りボルト41に圧嵌させ、該U字状枠部52aより側方へ張出する受け板部52b上に長尺物品M(図ではパイプ)を載せ、U字状枠部52aと受け板部52bの各長孔53に通した合成樹脂製の締結バンド54によって長尺物品Mを固定するようになされている。

【0008】

しかるに、これら支持具50,52では、吊りボルト41に対する係着強度に劣るために支持荷重の上限(安全荷重)が小さく、重量負荷が大きくなるとずれ落ちを生じることから、物品Mが軽量である場合にしか使用できないという難点があった。

【0009】

本発明は、上述の事情に鑑みて、天井材を吊持する吊りボルトを利用して天井裏の空間に各種配管や電気配線を施す場合等、特に既設の垂直ボルトに係着して種々の物品を支持させるのに使用する支持具として、両端が塞がった状態の垂直ボルトの任意位置に極めて簡単に取付けることができ、しかも非常に大きな係着強度が得られ、支持させる物品の重量や種類の制約が少ないものを提供することを目的としている。

【0010】

【課題を解決するための手段】

上記目的を達成するために、本発明の請求項1に係る垂直ボルト係着用支持具は、物品を支持させる支持金具と、この支持金具を垂直ボルトの任意位置に固定させる固定金具とからなり、支持金具は、垂直ボルトに側方から嵌合可能な横断面略U字形をなす嵌合枠部と、この嵌合枠部の下部より延設された物品取付部とを備えると共に、嵌合枠部の内周面に垂直ボルトの雄ねじに噛合し得る雌ねじ部が刻設され、固定金具は、縦壁部とその左右両側から当該縦壁部の一面側へ延設された一対の抱持片とで、支持金具の嵌合枠部に上方から外嵌し得る抱持枠を形成すると共に、両抱持片の間で垂直ボルトが側方から出入可能で且つ支持金具の嵌合枠部が側方から出入不能な間隔のボルト出入部が構成され、垂直ボルトの任意位置に雌ねじ部を噛合して嵌合させた支持金具の嵌合枠部に、それよりも上位で該垂直ボルトに嵌め込んだ固定金具を縦壁部が垂直ボルトに当接した形で上方から外嵌させることにより、支持金具が垂直ボルトに離脱及び上下動不能に係着されるように設定されてなる。

【0011】

上記構成の支持具によれば、支持金具の嵌合枠部を垂直ボルトの任意位置に側方から嵌合できると共に、固定金具も該垂直ボルトに側方から嵌め込むことができ、この固定金具の嵌合位置を上位として、下位に嵌合している支持金具の嵌合枠部に固定金具を上方から外嵌させることにより、該嵌合枠部は内周の雌ねじ部が垂直ボルトの雄ねじに噛合した状態で当該垂直ボルトから開離不能に押さえ込まれた形になるから、支持金具は垂直ボルトに離脱及び上下動不能に係着される。この場合、支持金具及び固定金具は、既述の吊りハンガーのように垂直ボルトの端部から挿嵌させる必要はないから、該垂直ボルトの両端が塞がっている状態であっても全く支障なく係着できる。しかも、支持金具は雌ねじ部の全体で垂直ボルトの雄ねじに噛合するから、係着強度が非常に大きく、物品取付部に支持させる物品の重量負荷が大きくてもずれ落ちることはない。

【0012】

請求項2の発明では、上記請求項1の垂直ボルト係着用支持具における固定金具は、縦壁部の内面上部に小凸部を有し、垂直ボルトに嵌合した支持金具の嵌合枠部に外嵌した際に、該小凸部と縦壁部の下縁とが垂直ボルトに直接に当接するように設定されてなるものとしている。この場合、固定金具は、抱持枠の内側上部が小凸部の突出分だけ内側下部よりも狭くなっているから、支持金具の嵌合枠部に対する外嵌位置が下がるほど当該嵌合枠部を強く締め付ける形になり、この嵌合枠部への外嵌に際して例えば適当な打圧具で軽く叩いて強制的に押し下げることにより、小凸部が垂直ボルトの雄ねじの谷間に噛み込んだ状態で垂直ボルトに強固に係着するから、取付け後の振動等による上方への変位が確実に防止される。

【0013】

しかして、上記請求項1又は2の垂直ボルト係着用支持具における固定金具は、請求項3の発明のように、平板状の縦壁部と両抱持片とで平面視略ワ字形又は略コ字形の抱持枠を形成したものや、請求項4の発明のように、平板状の縦壁部の上部より弧状に延出する一方の抱持片と、該縦壁部の下部より弧状に延出する他方の抱持片とを有すると共に、両抱持片の上下間にボルト出入部が構成されたものとすれば、金属板材の曲成によって容易に製作可能である。しかして、請求項4の固定金具は、横向き状態で該ボルト出入部に垂直ボルトを嵌入させた上で、縦向き状態に変えて該垂直ボルトに嵌装させる。

【0014】

また、上記請求項1〜4のいずれかの垂直ボルト係着用支持具において、請求項5の発明のように、固定金具が、縦壁部の上下縁の一方から外向きに張出した支持片を有してなる構成とすれば、支持金具に加えて固定金具にも支持片を利用して物品を支持させることができる。

【0015】

一方、上記請求項1〜5のいずれかの垂直ボルト係着用支持具において、請求項6の発明のように、支持金具の物品取付部が、物品を載置し得る受け形状を有してなるものとすれば、該物品取付部を利用して各種配管のパイプ、チャンネル材、ケーブル等の長尺物品の配設を容易に行える。

【0016】

また、上記請求項1〜6のいずれかの垂直ボルト係着用支持具において、請求項7の発明のように、支持金具の物品取付部に透孔及びねじ孔の一方又は両方が穿設されてなる構成とすれば、各種配管のパイプ、チャンネル材、ケーブル等の長尺物品を配設する際に、該長尺物品を固定するための種々の補助固定具を上記透孔やねじ孔を利用して取り付けることができる。

【0017】

更に、上記請求項1〜7のいずれかの垂直ボルト係着用支持具において、請求項8の発明のように、支持金具の物品取付部に垂直ボルトに係合する係止片が一体形成されてなるものとすれば、当該金具にかかる物品の荷重が偏っても、該係止片によって当該金具の傾きが防止される。

【0018】

【発明の実施の形態】

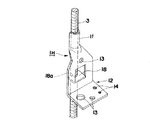

以下、本発明に係る垂直ボルト係着用支持具の実施例について、図面を参照して具体的に説明する。図1及び図2に示す第一実施例の垂直ボルト係着用支持具は、共に一枚の金属板より打ち抜き及び曲げ加工して得られる支持金具1Aと固定金具2Aとからなる。

【0019】

支持金具1Aは、垂直ボルト3に側方から嵌合可能な横断面略U字形をなす嵌合枠部11と、この嵌合枠部11の下部より延設された上向き開放コ字形の物品取付部12とを備え、嵌合枠部11の内周面に垂直ボルト3の雄ねじに噛合し得る雌ねじ部4が刻設され、また嵌合枠部11の略対向する内面上部に幅方向に長い係止用凸部12a,12bが背面からのプレスによって形成されている。しかして、嵌合枠部11は、図2(ロ)に示すように、垂直ボルト3に雌ねじ部4が噛合する状態で適嵌すると共に、当該嵌合枠部11の両側縁を結ぶ線よりも垂直ボルト3が僅かに外側へはみ出るように寸法設定されている。また物品取付部12は、嵌合枠部11が垂直ボルト3に嵌合した状態において、図2(イ)に示すように垂直ボルト3から離れた位置で垂下するように設定されている。

【0020】

一方、固定金具2Aは、平板状の縦壁部21と、その左右の一側から当該縦壁部21の一面側へ延設された短い円弧状の抱持片22と、同他側から同様に延設された長い円弧状の抱持片23とで、支持金具1Aの嵌合枠部11に外嵌し得る大きさの平面視略ワ字形の抱持枠を構成すると共に、両抱持片22,23の端縁間によって垂直ボルト3が出入可能で且つ支持金具1Aの嵌合枠部11が出入不能な間隔のボルト出入部5を形成しており、縦壁部21の内面上部に小凸部21aが背面からのプレスによって形成されている。

【0021】

上記構成の垂直ボルト係着用支持具は、図2(イ)〜(ハ)に示すように、支持金具1Aの嵌合枠部11を垂直ボルト3の任意位置に嵌合して内周の雌ねじ部3を該垂直ボルト3の雄ねじに噛合させると共に、この嵌合位置よりも上位に、固定金具2Aを該垂直ボルト3にボルト出入部5より内側へ嵌め込み、この固定金具2Aを下降させて支持金具1Aの嵌合枠部11に外嵌させることにより、該固定金具2Aの縦壁部21がその内面上部の小凸部21aと下縁21bとで垂直ボルト3に当接した形で、嵌合枠部11を当該垂直ボルト3から開離不能に押さえ込み、もって支持金具1Aが垂直ボルト3に離脱及び上下動不能に係着される。そして、この垂直ボルト3に係着された支持金具1Aの物品取付部12には、例えば図2(イ)に示すチャンネル材Tの如き角形の長尺物品を嵌め込んで支承させることができ、係止用凸部12a,12bが該物品の抜け止めとして機能する。

【0022】

この場合、支持金具1A及び固定金具2Aは、垂直ボルト3の両端が塞がっている状態であっても全く支障なく係着できるから、例えば既述のビル等の天井材の取付け施工(図14参照)において、建物躯体の天井部のデッキプレートに取り付けた吊元金具に上端部を螺着した吊りボルト(垂直ボルト)に対し、その下端部に野縁受けや野縁を吊持させた後の段階でも任意位置に係着でき、この係着した支持金具1Aの物品取付部12を利用して天井裏の空間に、例えば水道管、排水管、ガス管、空調ダクト、電線管等の各種配管を行ったり、電気配線、電話等のケーブル、これら配線用のチャンネル材等の配設を行うことができる。従って、既に前記野縁受けや野縁、更には天井材の取付けが終わった段階で上記配管や配線の仕様変更を必要としたり、また完工後のビル使用中における各種の機器や設備の新設、増設、設置場所の変更等により天井裏に新たな配管や配線等の施工や配設替えを要する場合に、既設の吊りボルトに支持金具1A及び固定金具2Aを係着して、これら配管や配線等の支承部を形成できる。無論、既に天井材を取付けている場合は、その一部を外して所要の配管や配線の施工を行える。

【0023】

しかして、固定金具2Aは、抱持枠の内側上部が小凸部6の突出分だけ内側下部よりも狭くなっており、支持金具1Aの嵌合枠部11に対する外嵌位置が下がるほど当該嵌合枠部を強く締め付ける形になるから、該嵌合枠部11に外嵌させる際、例えば適当な打圧具で軽く叩くようにして強制的に押し下げることにより、小凸部21aが垂直ボルト3の雄ねじの谷間に噛み込んだ状態で垂直ボルト3に強固に係着し、取付け後の振動等による上方への変位が確実に防止される。また、支持金具1Aは雌ねじ部4の全体で垂直ボルト3の雄ねじに噛合するから、係着強度が非常に大きく(例えば図15に示すような支持具に比較して安全荷重として数十倍)、物品取付部12に支持させる物品による重量負荷が大きい場合でもずれ落ちる懸念はない。

【0024】

図3は本発明に係る垂直ボルト係着用支持具の他の実施例における固定金具を示す。同図(イ)の第二実施例の固定金具2Bは、平板状の縦壁部21と、その左右両側から当該縦壁部21の一面側へ延設された一対の平板状の抱持片22,23とで、平面視略コ字形の抱持枠を構成すると共に、両抱持片22,23の内側に折り返し状に曲成された端縁部22a,23a間でボルト出入部5を形成している。同図(ロ)の第三実施例の固定金具2Cは、平板状の縦壁部21の上部より円弧状に延出する一方の抱持片22と、該縦壁部21の下部より円弧状に延出する他方の抱持片23とを有すると共に、両抱持片22,23の上下間にボルト出入部5が構成されている。同図(ハ)の第四実施例の固定金具2Dは前記第一実施例における固定金具2Aの縦壁部21の下縁に、また同図(ニ)の第五実施例の固定金具2Eは前記第一実施例における固定金具2Aの縦壁部21の下縁に、それぞれ係止孔24aを有する支持片24が外向きに張出するように一体形成されたものである。

【0025】

しかして、これら固定金具2B〜2Eにおいても、第一実施例の固定金具2Aと同様に、抱持枠として支持金具1(前記1Aと後述の他の実施例の支持金具1B〜1H等を含む総称としての符号)の嵌合枠部11に外嵌し得る大きさを備えると共に、ボルト出入部5は垂直ボルト3が出入り可能で前記嵌合枠部11を出入り不能とする間隔に設定され、且つ縦壁部21の内面上部に小凸部21aを設けてある。従って、これら固定金具2B〜2Eは、前記第一実施例の固定金具2Aと同様に、垂直ボルト3にボルト出入部5より嵌装し、当該垂直ボルト3に嵌合している支持金具1の嵌合枠部11に外嵌させることにより、該支持金具を垂直ボルト3に離脱及び上下動不能に係着固定できる。図4は、第二実施例の固定金具2Bにより、前記第一実施例で用いた支持金具1Aを垂直ボルト3に係着固定した状態を示す。

【0026】

ただし、第三実施例の固定金具2Cは、これを垂直ボルト3に嵌装する際、図5の仮想線で示すように横向き状態でボルト出入部5に該垂直ボルト3を嵌入させた上で、同図実線で示すように縦向き状態に変えることにより、該垂直ボルト3に嵌装させる。この嵌装後に支持金具1の嵌合枠部11に外嵌させる操作は前記第一実施例と同じである。なお、第四及び第五実施例の固定金具2D,2Eでは、例えば図13に示すように、支持片24の係止孔24aに係止したフックFや他の種々の吊り具を介し、電線L等の比較的軽量の物品を支承して配設するのに利用できる。

【0027】

一方、本発明の垂直ボルト係着用支持具における支持金具1としては、前記第一実施例で用いた支持金具1Aに限らず、図6〜図12に例示するように、物品取付部12の形状が種々異なるものを包含する。例えば、図6に示す第六実施例の支持金具1Bの物品取付部12は長尺物品がパイプP等の円筒状である場合に対応したU字形をなし、図7に示す第七実施例の支持金具1Cの物品取付部12は長尺物品が角筒Sやチャンネル材のような角形である場合の支承に適するL字形をなし、共に該物品取付部12の基部側と先端側に設けた透孔13,13を利用して、針金6や合成樹脂製の締結バンド7の如き補助固定具にて長尺物品を締着固定できるようになっている。また、図8に示す第八実施例の支持金具1Dでは、物品取付部12が上向き開放コ字形をなし、その上に水平配設する角形や円筒状の長尺物品を支承させて基部側と先端側の透孔13a,13bを利用して前記同様の補助固定具にて締着固定できると共に、先端側の透孔13bを利用して、例えば図の仮想線で示す電線管EPのような垂直方向に配設される2本の細径の管体やケーブル等を、W形の押さえ金具8aとボルト8b及び蝶ナット8cを介して外側で固定することも可能である。

【0028】

図9に示す第九実施例の支持金具1Eでは、平板状の物品取付部12に径大の透孔13と径小のねじ孔14が穿設されており、例えば、透孔13に金属帯板からなる一対の半円形クリップバンド9,9の鍔付き先端部9a,9aを嵌め込み、両クリップバンド9,9間にパイプ等の円筒形の長尺物品を挟んだ状態で孔付き尾端部9b,9bをビス25とナット26にて締め付けて固定したり、金属帯板からなる開環状のクリップバンド27に円筒形の長尺物品を通し、このクリップバンド27の孔付き両端部27a,27bに通したビス25をねじ孔14に螺挿して取り付けたり、更にはねじ孔14を利用して図8に示すようなW形の押さえ金具8aとボルト8bとで垂直方向に配設される2本の細径の管体やケーブル等を固定することもできる。

【0029】

図10に示す第十実施例の支持金具1Fでは、平板状の物品取付部12に、径の異なるねじ孔14a〜14cと、径大の透孔13、長孔14を設けており、ねじ孔14a〜14cを利用して前記図9に示すクリップバンド27を始めとする種々のねじ止め式補助固定具を支持荷重に応じてねじ径を選択して取付け、また透孔13を利用して前記図9に示す半円形クリップバンド9,9を始めとする種々の嵌め込み式補助固定具を取付け、更に長孔14を利用してねじ止め式や嵌め込み式の補助固定具を位置調整可能に取付ける等、多様な物品取付け形態が可能になるように設定されている。

【0030】

図11に示す第十一実施例の支持金具1Gでは、物品取付部12に、全体のL字形折曲による下段受け部16と、その垂直部の切り起こしによる上段受け部17との2段に形成され、基部と両受け部16,17の立ち上げ先端部に各々透孔13が設けてあり、両受け部16,17の一方又は両方で水平配設する長尺物品を支承し、それぞれ透孔13を利用して既述の針金や締結バンドにて締着固定できるようになっている。

【0031】

図12に示す第十二実施例の支持金具1Hでは、L字形をなす物品取付部12の垂直部に、半円弧状切欠部18aを有する係止片18が背面側へ切り起こし形成されると共に、同水平部に各々径の異なる複数個の透孔13やねじ孔14が設けてある。この場合、透孔13やねじ孔14を利用して前記同様の種々の補助固定具を介して各種物品を支持できるが、その支持位置によって当該支持金具1Hにかかる荷重が偏っても、垂直ボルト3に嵌合枠部11を嵌合させる際、図示のように係止片18の切欠部18aを当該垂直ボルト3に係嵌させることにより、荷重の偏りによる当該支持金具1Hの傾きを確実に防止できる。

【0032】

なお、本発明においては、支持金具1の物品取付部12について、上記の例示以外の様々な形態とすることができ、受け部形状とする場合でも例えば垂直部の面方向に沿う両側にL字形等の受け部を形成し、垂直ボルト3の両側を通って水平配設する二本の長尺物品を支承させることも可能であり、また透孔13やねじ孔14の形成位置や個数も種々設定できる。一方、固定金具2についても、例えばボルト出入部5を斜めに設定したり、第四及び第五実施例の固定金具2D,2Eにおける支持片24を縦壁部21の上縁側に延設したり、該支持片24をL字形やU字形とする等、例示した以外の種々の形態が可能である。更に、支持対象とする物品は、長尺のものに限らず、例えば電気配線の中継・分岐部とするアウトレットボックス等、配線や配管の途上に介在させる各種部材や機器を支持金具1の物品取付部12で固定するようにしてもよい。

【0033】

【発明の効果】

請求項1の発明によれば、ビル等の天井材を吊持する吊りボルトを利用して天井裏の空間に各種配管や電気配線を施す場合等、特に既設の垂直ボルトに係着して種々の物品を支持させるのに使用する垂直ボルト係着用支持具として、物品取付部を有する支持金具と、この支持金具を垂直ボルトの任意位置に固定させる固定金具とからなり、両金具を共に垂直ボルトに対して側方からの嵌合によって任意位置に極めて簡単に取付けることができ、しかも支持金具の雌ねじ部が垂直ボルトの雄ねじに噛合するために非常に大きな係着強度が得られ、支持させる物品の重量や種類の制約が少ないものが提供される。しかして、この支持具を用いれば、例えば上記の天井材の取付け施工において、建物躯体の天井部のデッキプレートに取り付けた吊元金具に上端部を螺着した吊りボルトに対し、その下端部に野縁受けや野縁を吊持させた後でも任意位置に係着できるから、これら吊持後の段階や天井材の取付けが終わった段階で上記配管や配線の仕様変更を必要としたり、また完工後のビル使用中における各種の機器や設備の新設、増設、設置場所の変更等により天井裏に新たな配管や配線等の施工や配設替えを要する場合でも、前記吊りボルトを支承部として利用することが可能となる。

【0034】

請求項2の発明によれば、上記の垂直ボルト係着用支持具において、固定金具が縦壁部の内面上部の小凸部と下縁とで垂直ボルトに当接し、小凸部が垂直ボルトの雄ねじの谷間に噛み込む形になるため、垂直ボルトに取付け後に振動等を受けても固定金具が上方へ変位することがなく、もって該変位による係着力の低下が確実に防止され、高い取付け信頼性が得られる。

【0035】

請求項3及び請求項4の発明によれば、上記の垂直ボルト係着用支持具において、特に固定金具が構成的に簡素であるために容易に製作可能となる。

【0036】

請求項5の発明によれば、上記の垂直ボルト係着用支持具において、固定金具に支持片を有するから、支持金具に加えて固定金具にも物品を支持させることができる。

【0037】

請求項6の発明によれば、上記の垂直ボルト係着用支持具において、支持金具の物品取付部が受け形状を有するため、該物品取付部を利用して各種配管のパイプ、チャンネル材、ケーブル等の長尺物品の配設を容易に行える。

【0038】

請求項7の発明によれば、上記の垂直ボルト係着用支持具において、支持金具の物品取付部に透孔及びねじ孔の一方又は両方が穿設されているから、各種配管のパイプ、チャンネル材、ケーブル等の長尺物品を配設する際に、該長尺物品を固定するための種々の補助固定具を上記透孔やねじ孔を利用して取り付けることができる。

【0039】

請求項8の発明によれば、上記の垂直ボルト係着用支持具において、支持金具の物品取付部に垂直ボルトに係合する係止片を有するから、当該金具にかかる物品の荷重が偏っても、当該金具の傾きが防止される。

【図面の簡単な説明】

【図1】 本発明に係る垂直ボルト係着用支持具の第一実施例を示し、(イ)は取付け前の垂直ボルトと支持金具及び固定金具を示す斜視図、(ロ)は同支持金具の背面図である。

【図2】 同第一実施例における垂直ボルト係着用支持具の取付け状態を示し、(ト)は側面図、(ロ)は(イ)のローロ線の断面矢視図、(ハ)は(ロ)のハーハ線の断面矢視図である。

【図3】 本発明の他の実施例に用いる固定金具を示し、(イ)は第二実施例の固定金具の斜視図、(ロ)は第三実施例の固定金具の斜視図、(ハ)は第四実施例の固定金具の斜視図、(ニ)は第五実施例の固定金具の斜視図である。

【図4】 同第二実施例の固定金具を用いた垂直ボルト係着用支持具の取付状態を示す横断平面図である。

【図5】 同第三実施例の固定金具を用いた垂直ボルト係着用支持具の取付操作を示す側面図である。

【図6】 同第六実施例に用いる支持金具の斜視図である。

【図7】 同第七実施例に用いる支持金具の斜視図である。

【図8】 同第八実施例に用いる支持金具と取付け用補助具を示す斜視図である。

【図9】 同第九実施例に用いる支持金具と取付け用補助具を示す斜視図である。

【図10】 同第十実施例に用いる支持金具の正面図である。

【図11】 同第十一実施例に用いる支持金具の斜視図である。

【図12】 同第十二実施例における支持金具の取付け状態を示す斜視図である。

【図13】 同第三及び第四実施例の固定金具を用いた垂直ボルト係着用支持具の取付状態を示す側面図である。

【図14】 ビル等の天井構造の一例を示す縦断側面図である。

【図15】 従来の支持具を吊りボルトに係着た状態を示し、(A)は第一例の斜視図、(B)は第二例の斜視図である。

【符号の説明】

1,1A〜1H 支持金具

11 嵌合枠部

12 物品取付部

13,13a,13b 透孔

14,14a〜14c ねじ孔

18 係止片

2,2A〜2E 固定金具

21 縦壁部

21a 小凸部

21b 下縁

22,23 抱持片

24 支持片

3 垂直ボルト

4 雌ねじ部

5 ボルト出入部

T チャンネル材(物品)

P パイプ(物品)

S 角筒(物品)[0001]

BACKGROUND OF THE INVENTION

The present invention relates to various articles particularly engaged with existing vertical bolts, such as when various pipes and electrical wiring are applied to the space behind the ceiling using suspension bolts that suspend ceiling materials of buildings such as buildings. The present invention relates to a vertical bolt engaging support used for supporting a skirt.

[0002]

[Prior art and its problems]

The ceiling of a building or the like is suspended at various points of the ceiling of the building frame by various means such as welding, bolting, embedding in concrete, or engaging with a deck plate according to the structure and material of the ceiling. A structure is generally adopted in which a main bracket is attached, a suspension bolt is screwed into a screw hole provided in the suspension bracket, and a ceiling material is suspended by the suspension bolt via a field edge or a field edge receiver. .

[0003]

FIG. 14 shows an example of the ceiling structure in the case where the lower surface of the ceiling (floor floor) of the building frame is constituted by a deck plate. The

[0004]

The

[0005]

By the way, in the ceiling structure using the

[0006]

However, in practice, there are many cases where it is necessary to change the specifications of the piping and wiring due to various factors as the building progresses, and new equipment and facilities are newly installed, even during use of the building after completion. It is often the case that new piping or wiring is required or relocation is required due to expansion, change of installation location, or the like. However, the above-described

[0007]

On the other hand, as a support that can be attached to the

[0008]

However, in these

[0009]

In view of the above-mentioned circumstances, the present invention uses various types of pipes and electrical wiring in the space behind the ceiling using a suspension bolt that suspends the ceiling material. As a support tool used to support an article, it can be attached very easily to an arbitrary position of a vertical bolt with both ends closed, and a very large fastening strength can be obtained, and the weight and type of the article to be supported. It aims to provide something with less restrictions.

[0010]

[Means for Solving the Problems]

In order to achieve the above object, a vertical bolt engaging support device according to claim 1 of the present invention comprises a support fitting for supporting an article and a fixing fitting for fixing the support fitting to an arbitrary position of the vertical bolt, The support bracket includes a fitting frame portion having a substantially U-shaped cross section that can be fitted to a vertical bolt from the side, and an article mounting portion extending from a lower portion of the fitting frame portion, and a fitting frame. A female threaded portion that can mesh with a male screw of a vertical bolt is formed on the inner peripheral surface of the vertical portion, and the fixing bracket is a pair of holding pieces that extend from the left and right sides of the vertical wall portion to one surface side of the vertical wall portion. and in, to form a holding frame which can fitted from above to the fitting frame portion of the support bracket, the vertical bolt between the two retaining pieces fitting frame portion and the support bracket can and out from the side bolt and out of and out non intervals from the side is formed, engage the female thread portion in an arbitrary position of the vertical bolt By fitting the fixing bracket fitted to the vertical bolt at a higher position to the fitting frame portion of the support fitting fitted in this manner, the vertical wall portion is externally fitted from the top in contact with the vertical bolt, The support metal fitting is set to be engaged with the vertical bolt so as not to be detached and vertically movable.

[0011]

According to the support having the above-described configuration, the fitting frame portion of the support fitting can be fitted to an arbitrary position of the vertical bolt from the side, and the fixing fitting can be fitted to the vertical bolt from the side. The fitting position of the fixing bracket is externally fitted to the fitting frame portion of the support fitting that is fitted in the lower position, so that the internal thread portion of the fitting frame portion is the male screw of the vertical bolt. In this state, the support metal fitting is engaged with the vertical bolt so that it cannot be separated and cannot be moved up and down. In this case, it is not necessary to insert the support bracket and the fixing bracket from the end of the vertical bolt as in the case of the hanging hanger described above, so even if both ends of the vertical bolt are closed, there is no problem. I can wear it. In addition, since the support fitting meshes with the male screw of the vertical bolt throughout the female screw portion, the engagement strength is very high, and even if the weight load of the article supported by the article mounting portion is large, it does not fall off.

[0012]

According to a second aspect of the present invention, the fixing bracket in the vertical bolt engaging support device according to the first aspect has a small convex portion on the inner surface of the vertical wall portion, and a fitting frame portion of the supporting bracket fitted to the vertical bolt. When it is externally fitted, the small convex portion and the lower edge of the vertical wall portion are set so as to come into direct contact with the vertical bolt. In this case, since the inner upper part of the holding frame is narrower than the inner lower part by the protrusion of the small convex part, the fitting frame part is lowered as the fitting position of the support metal part with respect to the fitting frame part is lowered. In the state where the small convex part is bitten in the valley of the male thread of the vertical bolt, for example, by lightly striking it with an appropriate striking tool and forcibly pushing it down when fitting to the fitting frame part Since it is firmly engaged with the vertical bolt, upward displacement due to vibration after mounting is reliably prevented.

[0013]

Thus, the fixing bracket in the vertical bolt engaging support device according to

[0014]

Further, in the vertical bolt engaging support device according to any one of claims 1 to 4, as in the invention of

[0015]

On the other hand, in the vertical bolt engaging support device according to any one of the first to fifth aspects, the article mounting portion of the support fitting has a receiving shape on which the article can be placed as in the invention of the sixth aspect. If so, it is possible to easily arrange long articles such as pipes, channel materials, and cables of various pipes by using the article attachment portion.

[0016]

Further, in the vertical bolt engaging support device according to any one of claims 1 to 6, as in the invention of

[0017]

Furthermore, in the vertical bolt engaging support device according to any one of claims 1 to 7, as in the invention of claim 8, a locking piece that engages with the vertical bolt is integrally formed on the article mounting portion of the support fitting. If it becomes, even if the load of the article concerning the metal fitting is biased, the locking piece prevents the metal fitting from being inclined.

[0018]

DETAILED DESCRIPTION OF THE INVENTION

Embodiments of the vertical bolt engaging support according to the present invention will be specifically described below with reference to the drawings. The vertical bolt engaging support of the first embodiment shown in FIGS. 1 and 2 is composed of a support fitting 1A and a fixing fitting 2A both obtained by punching and bending from a single metal plate.

[0019]

The support metal fitting 1A has a

[0020]

On the other hand, the fixing

[0021]

As shown in FIGS. 2 (A) to 2 (C), the vertical bolt engaging support device having the above-described configuration is configured such that the

[0022]

In this case, since the support metal 1A and the fixing

[0023]

Thus, in the fixing

[0024]

FIG. 3 shows a fixing bracket in another embodiment of the vertical bolt engagement support according to the present invention. The fixing metal fitting 2B of the second embodiment shown in FIG. 2A is a flat plate-like

[0025]

Thus, in the fixing brackets 2B to 2E, as in the case of the fixing

[0026]

However, when the fixing

[0027]

On the other hand, the support metal fitting 1 in the vertical bolt engagement support tool of the present invention is not limited to the support metal fitting 1A used in the first embodiment, and as illustrated in FIGS. Includes different ones. For example, the

[0028]

In the support fitting 1E of the ninth embodiment shown in FIG. 9, a large diameter through

[0029]

In the support fitting 1F of the tenth embodiment shown in FIG. 10, the flat

[0030]

In the support bracket 1G of the eleventh embodiment shown in FIG. 11, the

[0031]

In the support bracket 1H of the twelfth embodiment shown in FIG. 12, a locking

[0032]

In the present invention, the

[0033]

【The invention's effect】

According to the first aspect of the present invention, when various pipes and electrical wiring are applied to the space behind the ceiling using a suspension bolt that suspends a ceiling material of a building or the like, it is particularly engaged with an existing vertical bolt. As a support for attaching a vertical bolt used to support an article, a support bracket having an article mounting portion and a fixing bracket for fixing the support bracket to an arbitrary position of the vertical bolt. Can be attached to any position by fitting from the side, and the female threaded part of the support fitting meshes with the male thread of the vertical bolt, so that a very high engagement strength can be obtained and supported. With less weight and type restrictions. If this support is used, for example, in the above-described installation of the ceiling material, the lower end of the suspension bolt is attached to the suspension bracket that is attached to the deck plate of the ceiling of the building frame. Even after suspending the field ledge and the field rim, it can be engaged in any position, so it is necessary to change the piping and wiring specifications at the stage after suspending or after the ceiling material is installed. Even if new piping, wiring, etc. need to be installed or replaced on the back of the ceiling due to new installation, expansion, or change of installation location of various equipment and facilities during use of the building after completion, the above-mentioned suspension bolts can be used as support parts. It can be used.

[0034]

According to the second aspect of the present invention, in the above vertical bolt engagement support, the fixing bracket abuts the vertical bolt at the small convex portion and the lower edge of the inner surface of the vertical wall portion, and the small convex portion is the vertical bolt. Since it is in the form of being bitten between the valleys of male threads, even if it receives vibration after mounting on a vertical bolt, the fixing bracket will not be displaced upward, and the lowering of the engaging force due to the displacement is surely prevented, and high mounting reliability Sex is obtained.

[0035]

According to the third and fourth aspects of the present invention, in the above-described vertical bolt engagement support, the fixing bracket is particularly simple in structure, and thus can be easily manufactured.

[0036]

According to the fifth aspect of the present invention, in the above-described vertical bolt engagement support, since the fixing bracket has the support piece, the article can be supported by the fixing bracket in addition to the support bracket.

[0037]

According to the invention of

[0038]

According to the seventh aspect of the present invention, in the above vertical bolt engagement support, one or both of the through hole and the screw hole are formed in the article mounting portion of the support metal fitting. When arranging a long article such as a cable, various auxiliary fixtures for fixing the long article can be attached using the through holes and screw holes.

[0039]

According to the eighth aspect of the present invention, in the above-described vertical bolt engagement support tool, since the article mounting portion of the support metal fitting has the engaging piece that engages with the vertical bolt, even if the load of the article applied to the metal fitting is uneven. The inclination of the metal fitting is prevented.

[Brief description of the drawings]

1A and 1B show a first embodiment of a vertical bolt engaging support according to the present invention, in which FIG. 1A is a perspective view showing a vertical bolt, a support bracket and a fixing bracket before mounting, and FIG. It is a rear view.

FIG. 2 shows a mounting state of the vertical bolt engaging support in the first embodiment, wherein (G) is a side view, (B) is a cross-sectional view of the roll line of (A), and (C) is ( It is a cross-sectional view of the Haha line of (b).

3A and 3B show a fixing bracket used in another embodiment of the present invention, in which FIG. 3A is a perspective view of the fixing bracket of the second embodiment, FIG. 3B is a perspective view of the fixing bracket of the third embodiment, and FIG. ) Is a perspective view of the fixing bracket of the fourth embodiment, and (d) is a perspective view of the fixing bracket of the fifth embodiment.

FIG. 4 is a cross-sectional plan view showing a mounting state of a vertical bolt engaging support using the fixing bracket of the second embodiment.

FIG. 5 is a side view showing the mounting operation of the vertical bolt engaging support using the fixture of the third embodiment.

FIG. 6 is a perspective view of a support fitting used in the sixth embodiment.

FIG. 7 is a perspective view of a support fitting used in the seventh embodiment.

FIG. 8 is a perspective view showing a support fitting and a mounting aid used in the eighth embodiment.

FIG. 9 is a perspective view showing a support fitting and a mounting aid used in the ninth embodiment.

FIG. 10 is a front view of a support fitting used in the tenth embodiment.

FIG. 11 is a perspective view of a support fitting used in the eleventh embodiment.

FIG. 12 is a perspective view showing a mounting state of a support fitting in the twelfth embodiment.

FIG. 13 is a side view showing a mounting state of a vertical bolt engaging support using the fixing brackets of the third and fourth embodiments.

FIG. 14 is a longitudinal side view showing an example of a ceiling structure of a building or the like.

FIGS. 15A and 15B show a state in which a conventional support is attached to a suspension bolt. FIG. 15A is a perspective view of a first example, and FIG. 15B is a perspective view of a second example.

[Explanation of symbols]

1, 1A to

P pipe (goods)

S square tube (article)

Claims (8)

支持金具は、垂直ボルトに側方から嵌合可能な横断面略U字形をなす嵌合枠部と、この嵌合枠部の下部より延設された物品取付部とを備えると共に、嵌合枠部の内周面に垂直ボルトの雄ねじに噛合し得る雌ねじ部が刻設され、

固定金具は、縦壁部とその左右両側から当該縦壁部の一面側へ延設された一対の抱持片とで、支持金具の嵌合枠部に上方から外嵌し得る抱持枠を形成すると共に、両抱持片の間で垂直ボルトが側方から出入可能で且つ支持金具の嵌合枠部が側方から出入不能な間隔のボルト出入部が構成され、

垂直ボルトの任意位置に雌ねじ部を噛合して嵌合させた支持金具の嵌合枠部に、それよりも上位で該垂直ボルトに嵌め込んだ固定金具を縦壁部が垂直ボルトに当接した形で上方から外嵌させることにより、支持金具が垂直ボルトに離脱及び上下動不能に係着されるように設定されてなる垂直ボルト係着用支持具。It consists of a support bracket that supports the article and a fixing bracket that fixes the support bracket to an arbitrary position of the vertical bolt,

The support bracket includes a fitting frame portion having a substantially U-shaped cross section that can be fitted to a vertical bolt from the side, and an article mounting portion extending from a lower portion of the fitting frame portion, and a fitting frame. A female screw part that can mesh with a male screw of a vertical bolt is engraved on the inner peripheral surface of the part,

Fixing bracket is a vertical wall portion and a pair of retaining pieces extending from both left and right sides to one side of the vertical wall portion, the holding frame may be fitted from above to the fitting frame portion of the support bracket and forming, bolt and out of and out non spacing from the fitting frame portion side of and support fitting can and out vertical bolt from the side between the two retaining pieces is formed,

The vertical wall part is in contact with the vertical bolt on the fitting frame part of the support metal fitting that engages the female screw part at an arbitrary position of the vertical bolt, and the upper part is fitted to the vertical bolt. A vertical bolt engaging support tool which is set so that the support fitting is engaged with the vertical bolt so that it can be detached and cannot be moved up and down by being externally fitted from above .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP09211298A JP4025416B2 (en) | 1998-04-03 | 1998-04-03 | Vertical bolt support |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP09211298A JP4025416B2 (en) | 1998-04-03 | 1998-04-03 | Vertical bolt support |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPH11287012A JPH11287012A (en) | 1999-10-19 |

| JP4025416B2 true JP4025416B2 (en) | 2007-12-19 |

Family

ID=14045356

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP09211298A Expired - Lifetime JP4025416B2 (en) | 1998-04-03 | 1998-04-03 | Vertical bolt support |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4025416B2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3821724B2 (en) * | 2002-02-19 | 2006-09-13 | 株式会社ブレスト工業研究所 | Hanging bolt support for lip channel steel |

| JP2008144823A (en) * | 2006-12-08 | 2008-06-26 | Sekisui House Ltd | Sleeve holder |

| KR20080072203A (en) * | 2007-02-01 | 2008-08-06 | 복진홍 | Ceiling hanger |

| JP2009041338A (en) * | 2007-08-10 | 2009-02-26 | Sanyuu:Kk | Fixing device |

| CN102285427A (en) * | 2011-05-25 | 2011-12-21 | 江苏海陆科技股份有限公司 | Marine ceiling clamp hanger |

| JP5826021B2 (en) * | 2011-12-27 | 2015-12-02 | アロン化成株式会社 | Fixing member for header |

| JP6302434B2 (en) * | 2015-07-29 | 2018-03-28 | 因幡電機産業株式会社 | Supporting equipment for long objects, supporting method, and holding member used for these |

| JP6575427B2 (en) * | 2016-04-27 | 2019-09-18 | Jfeスチール株式会社 | Tight frame, folding roof construction method, and column installation method |

| WO2019218233A1 (en) * | 2018-05-16 | 2019-11-21 | 深圳市君盈建筑科技有限公司 | Construction method for house having water pipe separate from main structure |

| JP6964637B2 (en) * | 2019-10-01 | 2021-11-10 | 泉 加藤 | Bolt support unit |

-

1998

- 1998-04-03 JP JP09211298A patent/JP4025416B2/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JPH11287012A (en) | 1999-10-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6761341B2 (en) | Bar hanger and mounting clip assembly | |

| US6364266B1 (en) | Universal electrical wire hanger | |

| JP5588488B2 (en) | Fall prevention bracket | |

| US6254040B1 (en) | Mounting angle clamp for attaching additional structures to hanging rod | |

| JP4025416B2 (en) | Vertical bolt support | |

| US11619324B2 (en) | Structural fastener | |

| US5713157A (en) | Deck hanger | |

| US6464179B1 (en) | System and method for mounting pendant light fixtures | |

| US7967272B2 (en) | Industrial hangers for framing and method of fabricating the same | |

| US6477770B1 (en) | Cable supporting methods | |

| US11261897B2 (en) | Structural fastener | |

| US6417449B1 (en) | Modular holder for conduit and junction boxes | |

| JP4002665B2 (en) | Vertical bolt support | |

| JP5460072B2 (en) | Hanging bracket for square steel | |

| US7243891B2 (en) | Mounting bracket, and method therefor | |

| JP4166164B2 (en) | Support material | |

| US11784428B2 (en) | Structural fastener | |

| JPH0683047U (en) | Sprinkler attachment | |

| JP3360096B2 (en) | Wiring and piping material receiver | |

| JPH06346985A (en) | Hanger for channel material | |

| KR960009086Y1 (en) | Guide hanger for electric pipe | |

| JP3472785B2 (en) | Wiring and piping support and washers | |

| JP3019357U (en) | Box rack box fixing bracket | |

| JP3094111U (en) | Fixtures for hanging shelves | |

| AU2012201550B2 (en) | An anchoring device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050309 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20070403 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070509 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070530 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070912 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071005 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101012 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121012 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121012 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131012 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |